Abstract

Protected cultivation is a resource-efficient method of crop production, however, at the same time, it is resource intensive. An optimum rate and time of fertilizer application is required in order to maximize crop yield vis-à-vis resource use efficiency. However, these aspects are scarcely studied for tomato under low- and medium-tech greenhouses in Indian humid sub-tropics. In this regard, a two-year study was conducted to assess the effect of four NPK fertilization rates (i.e., 120, 100, 80, and 60% of the recommended dose of fertilizers, RDF) and three fertigation scheduling approaches—fertigation at different stages in different proportions of NPK, along with an additional treatment, i.e., farmers’ practice (soil-based application of recommended NPK) for tomatoes under a naturally ventilated polyhouse. The plant growth attributes, the tomato yield- and quality-related traits, the nutrient (NPK) accumulation by the plants, the water use efficiency (WUE), and economics were studied in response to different fertigation rates and scheduling approaches. These parameters were affected by both the rates of NPK fertilization and their time of application (scheduling) over the different growth stages. Among the different rates and time of fertigation, the recommended dose of fertilizer (100% RDF) (i.e., 300 kg N, 150 kg P2O5, and 150 kg K2O per ha and their scheduling as 15% N, 10% P2O5, and 10% K2O of RDF during 15–45 days after transplanting (P1); 40% N, 40% P2O5, and 40% K2O of RDF during 47–76 DAT (P2); 30% N, 40% P2O5, and 40% K2O of RDF during 77–107 DAT (P3); and 15% N, 10% P2O5, and 10% K2O of RDF during 108–138 DAT (P4)) was found to be the optimum for fruit yield, WUE, and economics of tomato under protected condition.

1. Introduction

The tomato (Solanum lycopersicum L.) is the most popular fruiting vegetable across the world. Its high nutritive value and attractive look mean that it is often considered as the “poor man’s orange” [1]. Its fruits possess handsome amounts of health-promoting nutrients, namely vitamin A, vitamin C, and a variety of minerals [2]. In addition, it also contains a considerable amount of lycopene—a powerful antioxidant that helps to reduce oxidative stress [3].

Tomatoes are cultivated both in open and protected conditions in greenhouses, requiring specialized growing practices. Contrary to open-field-grown tomatoes, the modified microclimate under the protected structure of a greenhouse, depending on the cladding materials and the environment control mechanisms, provides multiple benefits—several folds of yield increase, an extended growing season, better quality fruits, and a good market price [4,5,6]. In India, among the different types of greenhouse structures, naturally ventilated polyhouses (plastic greenhouse) are the most common. Unlike climate-controlled greenhouses, the microclimate of naturally ventilated polyhouses (NVP) is often influenced by the ambient environment [6], and, hence, the crop growth and yields [5].

At present, the ever-increasing population, rapid industrialization, the increasing urban population, and the impact of unpredictable rainfall have raised the competition for available water amongst agricultural operations and non-agricultural uses, thereby reducing the share of water for agriculture [7]. The requirement of water for agricultural activity will increase by 20% to meet the 70% increase in food production in order to feed 9.6 billion of world population by 2050 [8]. The application of water through a network of tubing, i.e., drip irrigation, is a highly efficient irrigation method, with a water application efficiency of 90%, thanks to the drip irrigation system, which enables the supply of fertilizers along with irrigation water (fertigation) as per the need of the crop and stage.

The principal factors that influence evapotranspiration or irrigation requirements are air temperature, thermal radiation, humidity, and wind speed. Since these weather parameters vary with time and space, the irrigation scheduling of different crops also varies with time and space in different agro-climatic regions [9]. The advent of water-soluble fertilizers has enabled us to supply nutrients more precisely and timely, along with the irrigation water through the drip method (fertigation). It has been established from research that split fertilizer application improves nutrient efficiency, favors better growth and development, increases the yield potential, and reduces the nutrient losses [10]. Fertigation scheduling (when and how much to apply) for a particular crop, including tomato, can also vary depending on the phenological stages, the soil, and environmental factors. Hence, in order to assure sustainable production, as well as realizing the high crop productivity of greenhouse-grown crops, proper and timely nutrient application synchronization with crop demand is essential for a particular region [11].

It is a matter of fact that the information related to the fertigation need of tomato under medium-tech greenhouse, i.e., the NVP available in other parts of the country or world, will not be applicable to a particular region. Therefore, a two-year study was undertaken to optimize the rate of fertilizers (major nutrients, NPK) and their scheduling with drip irrigation for tomato cultivation under NVP in order to achieve the full potential under protected conditions in the Indian humid sub-tropical regions of the north-western Himalayas.

2. Materials and Methods

2.1. Growth Conditions

The studies were undertaken at the Vegetable Research Center (VRC) of G.B.P.U.A.T., Pantnagar, India, in a naturally ventilated polyhouse (plastic greenhouse) of 500 m2 area from October to April 2020–2021 and 2021–2022. The polyhouse was 25 m in length, 20 m in width, with 6.5 m ridge height and 4 m gutter height, and it was covered with standard greenhouse plastic film (200µ thick, UV stabilized). The coordinates of VRC were 29° N and 79.3° E, having an elevation of 243.84 m MSL. The experimental area had a humid sub-tropical climate, where temperature ranged from 32 to 43 °C during summer (May–June) and 0 °C to 9 °C during winter (January). The average lower and upper ranges of temperature and relative humidity during the cropping period under the polyhouse were 18.6 °C and 28.7 °C, and 30.3% and 56.6%, respectively. The physical and chemical properties of the experimental area were analyzed before experimentation by collecting soil samples at 0 to 15 cm depth randomly, and a representative sample was prepared by mixing. The basic soil properties comprised the following: soil texture—sandy loam; field capacity—16.35%; soil organic carbon—0.75%; soil pH—7.30; and soil EC—0.2 dS/m. The available soil N, P, and K was 175.6, 38.15, and 178.09 kg/ha, respectively.

This study was carried out in randomized block design with two factors and one additional treatment. Of the two factors, the first one was the fertigation rates (F) (i.e., for nitrogen, phosphorus, and potassium, NPK), whereas the second one was the NPK scheduling through the drip system (S). Soil application of the recommended dose of NPK fertilizers (RDF), i.e., farmers’ practices, was kept as the control. The treatment details are presented in Table 1.

Table 1.

Treatment details—four fertigation levels (A) and three fertigation scheduling approaches (B) applied in tomato.

The tomato cv. Heemsona F1 seeds were grown in the same polyhouse that was used for experimentation in plastic pro/plug trays. Twenty-five-day-old seedlings at the 3–4 leaf stage were transplanted in the month of October at a spacing of 60 cm × 50 cm during both years of experimentation. The recommended dose of fertilizers (100% RDF), 300 kg N, 150 kg P2O5, and 150 kg of K2O per ha were applied. Fertigation was started 15 days after planting (DAT) and the fertilizer dose changed as per treatment scheduling. The water-soluble fertilizers (Ms. Indian Farmers Fertilizer Cooperative Ltd., Maharashtra, India) were used for fertigation. In farmers’ practice plots, commercial fertilizers—urea, single super phosphate, and murate of potash—were applied as per common practices. Drip laterals with turbulent-flow-type drippers, having a discharge exponent of 0.5 and discharge rate of 4 L per hours spaced at 50 cm intervals, were used for irrigation and fertigation. Water distribution uniformity was about 90%. Soil moisture was maintained between 22 and 30 kPa during the cropping period. One dripline per plant row was laid before tomato transplanting on the planting bed. The fertilizer solution containing the measured quantity of water-soluble fertilizers as per treatments was supplied through ventury with irrigation water.

Standard protocols were followed to record the data at various growth and development stages. The single stem of the tomato plants was retained, and all side shoots were removed at regular intervals. The main stem was supported with plastic thread that was supported with overhead trellis wire. Regular crop management activities, such as training, pruning, pinching, etc., were carried out. In the initial stage of plant establishment, carbendazim 50% WP and metalaxyl 8% + mancozeb 64 WP were applied at recommended doses to manage soilborne fungi, and co-formulation of Azoxystrobin 18.2 + Difenoconazole 11.4% was applied to control foliar fungal diseases. The neem-based formulation and imidacloprid 17.8% SL were applied as per the need to manage sucking insects.

2.2. Plant Growth Parameters

In each treatment, five plants were arbitrarily selected and tagged to determine the growth and yield parameters of tomato. The experiment was completed after 180 days and 186 days after planting during the first and second year of study, respectively. The plant height was measured from the base to the growing point, starting from 30 days after planting, at regular intervals to last harvest. During every pruning, the number of side branches or shoots plant−1, was removed, and their number was counted at 30, 60, 90, 120, 150, and 180 days after planting. Flower cluster and fruit number per plant were recorded from each tagged plant in each treatment and replication. The mean weight of fruit per plant was also calculated.

2.3. Fruit Yield Parameters

During each harvest, harvested fruit number and weight were measured for each selected plant across all of the treatments and replications, and yield and mean fruit weight were obtained by summing up harvests.

2.4. Fruit Quality Parameters

The total soluble solids of selected fruits from five tagged plants were measured with a hand refractometer. The ascorbic acid content of three randomly selected heads from tagged plants was determined using the “2,6-dichlorophenol-indophenol Visual Titration Method”, as proposed by Ranganna [12].

2.5. Nutrient Uptake by Plants

The micro-Kjeldhal method [13] was used to determine nitrogen content (%). Phosphorus content (%) was estimated as reported by Olsen et al. [14]. Potassium content (%) was estimated using a flame photometer in the triacid digest [15]. The nitrogen, phosphorus, and potassium uptake levels were calculated as shown below and the contents were presented as kg/ha.

2.6. Water Use Efficiency

The quantity of applied water in different treatments through the drip system (Table 2) was also worked out, as per Allen et al. [9].

where, V = Amount of water required by plant/day, Ep = PAN evaporation in mm, Kp = Pan coefficient, Kc = Crop coefficient at various different stages of growth, Sp = Spacing between plants, Sr = Row spacing, and Wp = Fraction of wetted soil area.

V = Kp × Ep × Kc × Sp × Sr × Wp

Table 2.

Irrigation water applied (mm) in the years 2020–2021 and 2021–2022 during the tomato growth period in naturally ventilated polyhouse.

The pH of the irrigation water was 7.0 and its electrical conductivity was 0.08 dS m−1. Water use efficiency (WUE) (kg ha−1 mm−1) was worked out by dividing total fruit yield by the water requirement of the crop (mm).

2.7. Economics

The cost of cultivation of tomato under NVP was worked out taking consideration of fixed cost and the cost of inputs separately for each treatment. The output, i.e., yield obtained separately for each treatment, was converted into gross return in Indian rupees (INR) based on the local market prices. The net return, or net income, was calculated by deducting the cost of cultivation from the gross income. The benefit–cost ratio (B:C) was also worked out by following formula:

2.8. Statistic

The data set was analyzed statistically using control vs. rest analysis methods, as proposed by Rangaswamy [16]. The least significant difference (p = 0.05) was worked out to signify differences amongst the treatments.

2.9. Technique for Order Preference by Similarity to Ideal Solutions (TOPSIS)

The multi-objective decision making and evaluation using TOPSIS was analyzed to find the best way of obtaining higher yield, better quality, water use efficiency, and economic superiority simultaneously using Deng et al. [17]. The calculation was performed in the following five steps:

- Creation of a matrix, called an “evaluation matrix”, consisting of m alternatives and n criteria as follows:where, Vij (i = 1, 2, …….., m and j = 1, 2, ……, n) represents the jth measurement (no. of flower clusters/plant, no. of fruits/plant, average weight of fruit, yield, and water use efficiency) from ith treatment. In this study, m = 13 and n = 5;

- Construction of normalized decision matrix: For attributes, comparisons comparable scales are needed, which are obtained by normalization. To calculate the normalized value of Zij, the vector normalization approach divides the rating of each attribute by its sum, as follows:where, Zij is the normalized Vij and Wj is the weight of the jth evaluated index. In this study, Wj was considered 1, as all evaluated parameters were treated equally;

- Estimation of the positive (Zmax, Z+) and negative (Zmin, Z−) ideal solutions;

- Computation of Euclidean distance (Vi+ and Vi−) with Z+ and Z−, as follows:

- Computation of the comprehensive benefit evaluation index (Ci) for all of the treatments, as follows:

3. Results

3.1. Plant Growth Parameters

The pooled data that were obtained during the two years of study (Table 3 and Table 4) indicate significant influence of the various levels of fertigation and scheduling approaches on the growth attributes of tomatoes that were grown under NVP. The plant height (324.01 cm) and the number of side shoots (22.31) recorded under treatment F1 (fertigation at 120% of NPK) were significantly higher than the other fertigation levels and were statistically similar to F2. Whereas significantly lower plant height (295.02) and side shoots (19.19) were recorded under the lowest rate of fertilizer application, i.e., F4 (fertigation at 60% of RDF). A significantly larger plant height of 320.62 cm at final harvesting was measured under scheduling S1, which was statistically similar to S3; similar trends were also observed for the side shoots. Almost similar trends were observed during the entire growth stages. The fertigation treatment registered a 10.13% higher plant height than the farmers’ practices.

Table 3.

Height of tomato plants as affected by fertigation levels and scheduling at different growth stages of tomato (2-years pooled data).

Table 4.

Number of primary branches per plant as affected by fertigation levels and scheduling at different growth stages of tomato (2-years pooled data).

3.2. Fruit Yield Parameters

The maximum number of fruits per plant was observed in F2 (66.6), and it does not show statistical variation from F1, whereas an apparently lower number of fruits was recorded in treatment F4 (57.8). A significantly higher number of fruits (64.9) per plant−1 was recorded under scheduling S1, statistically similar to S3. The number of fruits per plant−1 in the fertigation treatments (62.2) was significantly higher than the control (54.3) (Table 5). The data that were pooled for both of the years indicate significantly higher fruit weight (102.3 g) and yield (182.0 t ha−1) in the treatment of 100% of RDF (F2), with no statistical difference from 120% of RDF (F1) when comparing with 80% (171.3 t ha−1) or 60% (161.9 t ha−1) of RDF. The scheduling of the fertilizer also showed a significant influence on the fruit weight and yield of tomato. The highest average fruit weight of 100.3 g and yield of 180.4 t ha−1 was recorded in scheduling S1. The pooled data revealed that the fertigation treatments registered a 19.6% higher yield over the farmers’ practices (145.2 t ha−1), whereas 100% RDF registered a 12.42% higher yield over 60% of RDF.

Table 5.

Impact of fertigation doses and their scheduling on growth and yield attributing parameters in tomato (2-years pooled data).

3.3. Fruit Quality Parameters

It is evident from Table 6 that the content of the total soluble solid (TSS) of tomato fruits was influenced significantly through the variation in fertigation doses. Increasing the NPK dose through fertigation increased the TSS content in the tomato fruits. The maximum TSS content of 11.45 °B was registered in treatment F1, followed by F2 (10.51 °B). The TSS in the fertigation treatments (10.46 °Brix) was significantly higher than the control (8.52 °Brix) based on the pooled value. The ascorbic acid contents in fruits obtained with 120% (26.30 mg 100 mL−1) or 100% (25.25 mg 100 mL−1) of RDF were statistically similar; however, they were significantly better over 80% (25.03 mg 100 mL−1) or 60% (24.52 mg 100 mL−1) of RDF. The ascorbic acid content in the fertigation plots was 8.69% higher compared to the control plots. The influence of the scheduling of nutrient levels and the interaction of both were non-significant for both the ascorbic acid content and the TSS of tomato fruits.

Table 6.

Impact of fertigation dose and its application on fruit quality characteristics of tomato (2-years pooled data).

3.4. Uptake of Plant Nutrients

The uptake of nutrients by tomato plants that were grown under NVP was significantly affected through the variation in levels of fertigation doses and its delivery (Table 7). Increasing the dose of NPK through irrigation resulted in increased nitrogen absorption throughout the growth stages of the crops. Across the different phases of crop growth (vegetative, flowering, fruiting, and harvesting), the maximum application of NPK (120%) through drip irrigation (F1) recorded significantly higher nitrogen uptake by the plants from the soil, though it was statistically similar to F2 (100% of RDF). Whereas the minimum value was recorded in the plants that were receiving fertigation at 60% of RDF (131.0 kg ha−1). The scheduling of the fertigation levels, i.e., the application of nutrients at different growth stages, also had a significant impact on the nitrogen that was assimilated by the plants. The highest nitrogen uptake of 145.5 kg ha−1 was observed in treatment S1, while the minimum value of 138.5 kg ha−1 was recorded in plants under S2. Assessing the nitrogen uptake between the treatments of control and fertigation revealed a statistical difference. At final harvesting, the nitrogen uptake in the plants under the control was 133.4 kg ha−1, as compared to 142.9 kg ha−1 under the fertigation treatments (Table 7).

Table 7.

Uptake of nitrogen, phosphorus, and potassium in tomato plants at different stages of plant growth (2-years pool data).

Similarly, P and K uptake by tomato was also significantly affected by the fertigation levels and their scheduling (Table 7). The increasing levels of NPK in fertigation helped in increasing the amount of P and K absorption by the plants. Throughout the crop growth and development stages, 120% of RDF registered significantly higher K uptake by the plants, with no statistical difference from that of 100% of RDF (F2). Similarly, the K uptake of the plants was also significantly impacted by the scheduling of the fertigation levels. The pooled analysis of the data revealed a significantly higher P and K uptake in treatment S1 and statistically parity with S3, while the minimum value was recorded in the plants under S2. The control and fertigation treatments revealed that the K uptake by the plants differed significantly. At harvesting, the P and K uptake by the tomato plants in the fertigation treatment were 46.32% and 8.54% higher than the control, respectively, on the basis of the pooled data analysis (Table 7).

3.5. Water Use Efficiency (WUE)

The data depicted in Table 8 show that WUE was significantly varied through the fertigation levels and their scheduling, whereas their interactive effect was non-significant. The water consumption by tomato plants that were grown under NVP that are presented in Table 2 reveal that F2 recorded the maximum WUE (195.2 and 209.5 kg ha−1 mm−1), which was statistically at par with F1. The scheduling of nutrients also significantly affected WUE. The highest WUE was observed for scheduling S1, which was significantly higher than the others and was followed by S3. Significant variation was also noted for WUE amongst the control and the other fertigation levels. However, the lowest WUE of 144.3 kg ha−1 mm−1 and 153.6 kg ha−1 mm−1 was recorded in the control, as compared to 186.5 kg ha−1 mm−1 and 199.3 kg ha−1 mm−1 in the treatments that were subjected to fertigation during first and second year of studies, respectively.

Table 8.

Impact of fertigation levels and scheduling on water use efficiency in tomato plants.

3.6. Technique for the Order Preference by Similarity to an Ideal Solution (TOPSIS)

Multi-objective decision making and evaluation using TOPSIS was performed to obtain the optimal combination of fertigation rates and scheduling in tomato under NVP (Table 9). The results showed that the number of flower clusters and the number of fruits per plant, the average fruit weight, the fruit yield, and the water use efficiency were determined not only by the fertigation levels and their scheduling methods, but also by their interaction. In this study, the maximum number of flower clusters per plant, number of fruits per plant, average fruit weight, yield, and water use efficiency were achieved when F2 was applied through S1. The TOPSIS analysis identified the best alternative for the simultaneous optimization of the number of flower clusters and number of fruits per plant, average fruit weight, fruit yield, and water use efficiency. The results of TOPSIS showed that F2 in combination with S1 could simultaneously achieve higher yield-related traits along with maximum water use efficiency.

Table 9.

TOPSIS analysis of the number of flower clusters and number of fruits per plant, fruit yield, average fruit weight, and water use efficiency for different fertigation levels and scheduling methods for tomato plants under polyhouse condition.

3.7. Correlation Analysis

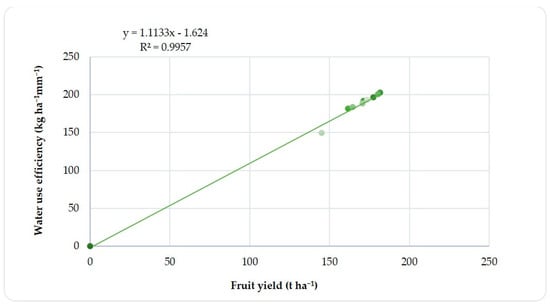

The plant height (PH) was strongly positively and significantly correlated with the number of flower clusters per plant (NFCP), the number of fruits per plant (NFP), the fruit yield (FY), and the water use efficiency (WUE). The results in Table 10 indicate that the number of side shoots per plant (NSS) was positively correlated with all of the other parameters studied here. The number of flower clusters per plant (NFCP) was strongly positively correlated with the plant height (cm), the number of fruits per plant (NFP), the average fruit weight (AFW), the fruit yield (FY), and the water use efficiency (WUE). The correlation analysis of the tomatoes revealed that the plant height (PH), the number of flower clusters per plant (NFCP), the number of fruits per plant (NFP), the average fruit weight (AFW), and the water use efficiency (WUE) were strongly positively and significantly associated with the fruit yield (FY). The ascorbic acid (AA) revealed a positive and significant correlation with the number of side shoots (NSS), the number of flower clusters (NFCP) and the number of fruits per plant, and the average fruit weight (AFW), whereas it shows a non-significant correlation with the plant height (PH) and the water use efficiency (WUE). Furthermore, a strong relationship between the fruit yield and WUE was evident over all the fertigation and scheduling treatments (Figure 1).

Table 10.

Simple correlation coefficient among growth, yield, and quality parameters.

Figure 1.

Relationship between fruit yield and water use efficiency of tomato during 2020–2021 and 2021–2022.

3.8. Economics

Among the different fertigation levels, the highest cost of cultivation was computed in the treatment receiving a fertigation dose of 120% of NPK (INR 65,173.0) and was gradually reduced to INR 63,251.5 with the reduction in fertigation to 60% of RDF (Table 11). The conventional approach of fertilization, along with surface irrigation, registered the cost of cultivation of INR 67,520.8. Out of the three scheduling approaches studied here, the highest cost of cultivation was recorded in S2 (INR 65,966.5) and the lowest was under scheduling S1 (INR 62,255.2). Among the fertigation levels, the highest gross return of INR 179,216.7, net return of INR 113,589.7, and B:C ratio of 2.76 was observed in treatment F2 (100% of RDF).

Table 11.

Effect of fertigation level and scheduling on the economics of tomato cultivation (2-years pooled data).

The higher cost of cultivation at the higher fertigation levels and scheduling S1 was attributed to the extra expenditure on water-soluble fertilizer, electricity, and extra resources on harvesting and packaging. The highest returns (gross and net), along with B:C ratio, at 100% of fertigation levels and scheduling S1 was attributed to the higher yield under the optimum nutrient supply, as required by the crop.

4. Discussion

4.1. Plant Growth and Fruit Yield

The fertigation rate and time of application through irrigation caused a significant effect on the tomato crop performance, but in different ways. The plant height was significantly influenced by the fertigation treatments. The plant height increased with the increase in fertilizer level from 60% to 120% RDF. A similar response of fertigation on cotton was reported by Kakade et al. [18]. The increase in plant height in the fertigation levels seemed to be due to the increase in fertilization, especially the nitrogen level, that was delivered though drip irrigation, as compared to the traditional method of fertilization. Since nitrogen takes part in cell elongation and cell division, plant growth is directly related to nitrogen availability. The increasing rate of nitrogen application has also promoted the growth of brinjal plants [19]. The higher vegetative growth of tomato under S1, as compared to other scheduling approaches, could be attributed to the timely availability of nutrients and as per the demand of the crop according to the different stages of growth, resulting in fulfilling the nutritional need of the crop, which leads to better photosynthesis expressed in terms of higher vegetative growth, as observed by Tanaskovik et al. [20] in tomato plants.

The fruit set in tomato is directly correlated to the temperature—both at higher- and lower-than-optimal temperatures (26/22 °C, day/night), the fruit set is affected, due to reduced pollen viability and germination because of reduced stigma receptivity [21]. However, the optimum temperatures of NVP can help us to achieve more efficient water and nutrient utilization, thereby resulting in enhanced tomato fruit yield [22]. The maximum number of fruits per plant with a higher mean fruit weight obtained in the optimized rate of fertigation resulted in a higher total fruit yield. Furthermore, it has been reported that the altered microclimate in protected structures shows a positive effect on the physiological processes of plants and a consequent effect on growth and yield, as reported in cucumbers by Khapte et al. [23]. Hence, the higher yield under drip fertigation was believed to be due to the frequent application of nutrients through the drip system, which probably helped to maintain higher plant nutrient uptake, as well as maintaining regular availability of nutrients to plants and avoiding the leaching of fertilizers applied with measured quantity. Fertilizers that are applied in a traditional way are usually not utilized efficiently. In contrast, in drip fertigation, the nutrients are delivered directly near to the root zone, where maximum root activity occurs, thus, high fertilizer use efficiency is achieved [24]. Hebbar et al. [25] recorded significantly higher tomato fruit yield (7.92 t/ha) with the application of a 100 per cent recommended dose of water-soluble fertilizer in comparison with a furrow-irrigated control (5.21 t ha−1). The highest yield of tomato under scheduling S1 in our study might be accredited to the upsurge in all of the yield-related attributes as a result of the balanced and timely application of nutrients (i.e., NPK) through the cultivation cycle, which perhaps improved the accessibility as well as the absorption of elements by the plants.

4.2. Fruit Quality Attributes

Microclimate parameters such as air temperature, relative humidity, and photosynthetically active radiation were in a quite favorable range in NVP, which resulted in an encouraging response, not only on plant growth, development, and yield, but also on fruit quality traits, as also reported earlier [26]. The quality traits such as the contents of dry matter and total soluble solids were also considerably higher in the fruits that were grown under NVP, where optimum growing conditions were available. Furthermore, some of the tomato fruit quality attributes (TSS, firmness, and color) were found to be favorably affected by a certain level of water deficit [26]. The ascorbic acid content, which was higher with the higher levels of fertigation, is thought to be ascribed to the increased synthesis and catalytic activity of certain (co)enzymes, due to higher absorption of nitrogen, which is instrumental in ascorbic acid synthesis. The results are in line with those that were reported by Sumati et al. [27] in cucumber and Jeeleni et al. [28] in broccoli.

4.3. Nutrient (NPK) Uptake

The higher uptake of NPK by plants with fertigation at 120% of RDF was possibly due to the higher amount of dry matter production. Moreover, a greater NPK absorption at a higher fertigation rate might be related to an augmented soil nutrient availability with an upper rate of application and a decline in losses via leaching and volatilization, which, finally, upsurges the elements that the plants uptake. These results tie well with those of Debbarma and Bhatt [29] on broccoli, who reported that, during harvest, N, P, and K uptake by broccoli plants under fertigation was considerably increased in comparison with soil fertilization in the two years of their study. Ughade et al. [30], in their two-year study, assessed the response of irrigation along with fertigation scheduling on tomatoes under a polyhouse and recorded significantly higher total N, P, and K uptake by the plants with 100% of RDF, as compared to rest of the fertigation levels. Higher mineral uptake under scheduling S1 might be attributed to a greater dry matter, which represents the outcome of the balanced and split fertilizer application throughout the cultivation period, as per crop necessity, which, finally, elicits plant growth and development. These outcomes are coherent with those stated by Shedeed et al. [31] in tomato plants. The relationships among the growth, the yield, and the quality parameters were analyzed, and the positive correlation was significant.

4.4. Water Use Eefficiency

Vankooten et al. [32] proclaimed that the water use efficiency in protected cultivation structures is very high, while it is affected by numerous aspects, comprising region, structures, the type of soil, the plant species, and the agronomic practices. Sagar et al. [33] compared the water demands under a polyhouse to that of open environments for growing tomatoes. In their study, the average water needs for tomato were 0.2149 and 0.2924 L per day per plant, respectively; demonstrating that the water that was supplied in the polyhouse was 30% less than that of the open environment. Saxena et al. [34] stated that decreasing the water amount via a drip system is supportive in increasing the WUE in different vegetable crops. The highest WUE in our study was under fertigation with 100% of RDF. This may be associated with the increased yields when 100% RDF was applied, which resulted in the higher WUE. Increasing the fertigation rate from 100 to 120% of RDF was not so active in the superior yield fraction. A similar finding was observed by Kashyap et al. [35] in broccoli and by Edossa and Emana [36] in green pepper. Likewise, Ankush et al. [37] also reported the peak WUE in tomato through fertigation using drip irrigation.

4.5. Economic Benefit

The economic benefits—gross return as well as net return and B:C ratio—were apparently higher with the application of 100% of RDF (F2) in the form of water-soluble fertilizers through drip irrigation in combination with fertigation scheduling S1, in comparison with other rates and times of fertilizer application. As compared to the traditional method of irrigation, drip irrigation and using optimum fertigation scheduling have been found to improve crop yields along with water use efficiency and economic benefits of tomato crop in the previous studies [34,37].

Furthermore, TOPSIS analysis was employed as a tool to find the optimum combination of irrigation and nutrient level by some researchers [38]. Similarly, by using this analysis, we found that the F2 fertigation level in combination with S1 scheduling could simultaneously provide a higher number of flower clusters and number of fruits per plant, average fruit weight, fruit yield, and water use efficiency.

5. Conclusions

From this study, we conclude that fertigation with 100% RDF (F2, 300:150:150 kg N, P2O5, and K2O per ha) in form of water-soluble fertilizes that are supplied through drip irrigation as per scheduling S1 (15%, 10%, and 10% of respective N, P2O5, and K2O of RDF between 15 and 45 DAT; 40%, 40%, and 40% of respective N, P2O5, and K2O of RDF between 47 and 76 DAT; 30%, 40%, and 40% of respective N, P2O5, and K2O of RDF between 77 and 107 DAT; and 15%, 10%, and 10% of respective N, P2O5, and K2O of RDF between 108 and 138 DAT) was the most optimum for obtaining the highest fruit yield, WUE, and economic benefit. The TOPSIS analysis also revealed that F1 and S2 combination was optimal for balancing the different yield-related traits and water use efficiency in tomato cultivation under a naturally ventilated polyhouse in the subtropical humid plains of India.

Author Contributions

Conceptualization, S.R. and L.B.; methodology, S.R., L.B., P.G. and P.K.S.; software, S.R. and P.K.S.; validation, S.R., L.B., P.K.S., S.K.M. and P.K.; formal analysis, S.R., P. and P.G.; investigation, S.R., P.G. and P.K.S.; resources, L.B., S.R. and S.K.M.; data curation, S.R., P.G. and P.K.; writing—original draft preparation, S.R., P. and S.K.M.; writing—review and editing, P.K., L.B., P.G. and L.S.; visualization, L.B. and P.K.S.; supervision, L.B. and S.K.M.; project administration, L.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data related to the research are reported in the paper. Any additional data may be acquired from the first corresponding author upon request.

Acknowledgments

The authors acknowledge the help and support of Dean, College of Agriculture and Precision Farming Development Center, GBPUAT, Pantnagar, for his academic and research support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Singh, N.P.; Bharadwaj, A.K.; Kumar, A.; Singh, K.M. Modern Technology on Vegetable Production; International Book Distribution Company: Lucknow, India, 2004; pp. 84–98. [Google Scholar]

- Doris, M.; Ehret, D.L.; Papandopoulos, A.P. Tomato (SolanIum lycopersicum) health component: From the seed to the consumer. Phytochem. Rev. 2008, 7, 231–250. [Google Scholar] [CrossRef]

- Bacalni, M.; Basaran, N.; Basaran, A. Lycopene: Is it Beneficial to Human Health as an Antioxidant? Turk. J. Pharm. Sci. 2017, 14, 311–318. [Google Scholar]

- Lin, M.; Srinivasan, R. Growing tomato under protected cultivation conditions: Overall effects on productivity, nutritional yield and pest incidences. Crops 2021, 1, 97–110. [Google Scholar]

- Khapte, P.S.; Kumar, P.; Saxena, A.; Singh, A. Performance evaluation and character association studies in arid region greenhouse tomato hybrids. Indian J. Hortic. 2018, 75, 457–462. [Google Scholar] [CrossRef]

- Kumar, P.; Khapte, P.; Saxena, A.; Singh, A.; Parwar, N. Intergeneric grafting for enhanced growth, yield and nutrient acquisition in greenhouse cucumber during winter. J. Environ. Biol. 2019, 40, 295–301. [Google Scholar] [CrossRef]

- Gariya, M.S.; Bhatt, L.; Uniyal, S.P.; Maurya, S.K. Optimization of planting geometry and water requirement through drip irrigation in sprouting broccoli. Res. Crops 2016, 17, 562–567. [Google Scholar] [CrossRef]

- FAO. High Level Expert Forum—Global Agriculture towards 2050. 2009. Available online: https://www.fao.org/ (accessed on 17 July 2022).

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop Evapotranspiration (Guidelines for Computing Crop Water Requirements); FAO Irrigation and Drainage Paper No. 56; Food and Agriculture Organization of the United Nation: Rome, Italy, 1998; p. 300. [Google Scholar]

- Debbarma, S.; Bhatt, L.; Singh, P.K.; Gautam, P.; Raghav, M.; Yadav, L.; Singh, A.K. Standardization of fertigation scheduling in broccoli (Brassica oleracea var italica). Indian J. Agric. Sci. 2021, 91, 1160–1164. [Google Scholar] [CrossRef]

- Savvas, D.; Ntatsi, G.; Barouchas, P.E. Soil conservation, soil fertility and plant nutrition management. In FAO Plant Production and Protection Paper: Good Agricultural Practices for Green House Vegetable Production in the South East European Countries; Food and Agriculture Organization of The United Nations: Rome, Italy, 2017; pp. 53–78. [Google Scholar]

- Ranganna, S. Manuals of Analysis of Fruits and Vegetable Products; Tata McGraw Hill Book Company: New Delhi, India, 1979; p. 1112. [Google Scholar]

- Subbiah, B.V.; Asija, G.L. A rapid procedure for estimation of available nitrogen in acid soils. Curr. Sci. 1956, 25, 259–260. [Google Scholar]

- Olsen, S.R.; Cole, C.V.; Dean, L.A. Estimation of available phosphorus in soil by extraction with sodium bicarbonate. In Methods of Soil Analysis: Part 2; Black, C.A., Ed.; American Society of Agronomy, Inc.: Madison, WI, USA, 1957; pp. 1044–1046. [Google Scholar]

- Pratt, P.F. Potassium. In Methods of Soil Analysis. Chemical and Biological Properties: Part 2; Black, C.A., Ed.; American Society of Agronomy: Madison, WI, USA, 1965; pp. 1023–1030. [Google Scholar]

- Rangaswamy, R. A Textbook of Agricultural Statistics; New Age International (P) Ltd.: New Delhi, India, 2015; p. 329. [Google Scholar]

- Deng, H.; Yeh, C.H.; Willis, R.J. Inter-company comparison using modified TOPSIS with objective weights. Comp. Operat. Res. 2000, 27, 963–973. [Google Scholar] [CrossRef]

- Kakade, S.; Bhale, V.; Deshmukh, J.; Wadatkar, S. Growth, Nutrient uptake and seed cotton yield as influenced by split application of nutrients through fertigation in Bt cotton. Int. J. Curr. Microbiol. App. Sci. 2017, 6, 2982–2990. [Google Scholar] [CrossRef]

- Sollapur, D.L.; Hiremath, S.M. Effects of planting geometry and fertilizer levels on growth and yield of hybrid brinjal. Int. J. Agric. Sci. 2017, 13, 97–100. [Google Scholar] [CrossRef]

- Tanaskovik, V.; Cukaliev, O.; Romic, D.; Ondrasek, G. The influence of drip fertigation on water use efficiency in tomato crop production. Agric. Conspec. Sci. 2011, 76, 57–63. [Google Scholar]

- Sato, S.; Peet, M.M.; Thomas, J.F. Physiological factors limit fruit set of tomato (Lycopersicin esculentum Mill.) under chronic, mild heat stress. Plant Cell Environ. 2000, 23, 719–726. [Google Scholar] [CrossRef]

- Khapte, P.S.; Kumar, P.; Singh, A.; Wakchaure, G.C.; Saxena, A.; Sabatino, L. Integrative Effect of Protective Structures and Irrigation Levels on Tomato Performance in Indian Hot-Arid Region. Plants 2022, 11, 2743. [Google Scholar] [CrossRef] [PubMed]

- Khapte, P.S.; Kumar, P.; Panwar, N.R.; Burman, U.; Rouphel, y.; Kumar, P. Combined influence of grafting and type of protected environment structure on agronomic and physiological traits of single and cluster bearing cucumber hybrids. Agronomy 2021, 11, 1604. [Google Scholar] [CrossRef]

- Adawadkar, M.; Deshmukh, M.; Wadatkar, S. Effect of drip fertigation with different fertilizer levels and traditional method of fertilizer application on growth and yield of brinjal. Int. J. Curr. Microbiol. App. Sci. 2019, 8, 2793–2800. [Google Scholar] [CrossRef]

- Hebbar, S.; Ramachandrappa, B.; Nanjappa, H.; Prabhakar, M. Studies on NPK drip fertigation in field grown tomato (Lycopersicon esculentum Mill.). Eur. J. Agron. 2004, 21, 117–127. [Google Scholar] [CrossRef]

- Nangare, D.D.; Singh, Y.; Kumar, P.S.; Minhas, P.S. Growth, fruit yield and quality of tomato (Lycopersicon esculentum Mill.) as affected by deficit irrigation regulated on phonological basis. Agric. Water Mang. 2016, 171, 73–79. [Google Scholar] [CrossRef]

- Sumathi, T.; Ponnuswami, V.; Thangamani, C.; Pugalendhi, L. Effect of shade and fertigation on quality of cucumber (Cucumis sativus L.). Plant Arch. 2011, 11, 275–279. [Google Scholar]

- Jeelani, J.; Katoch, K.K.; Sandal, S.K.; Gupta, R.K. Effect of Varying Drip Irrigation Levels and Different Methods of NPK Fertilizer Application on Soil Water Dynamics, Water use Efficiency and Yield of Broccoli (Brassica oleracea L. var. italica) in Wet Temperate Zone of Himachal Pradesh. Int. J. Pure Appl. Biosci. 2017, 5, 210–220. [Google Scholar] [CrossRef]

- Debbarma, S.; Bhatt, L. Nutrient uptake, soil nutrient status and water use efficiency as influenced by drip fertigation in broccoli (Brassica oleracea var. italica). J. Plant Nutr. 2022, 45, 674–685. [Google Scholar] [CrossRef]

- Ughade, S.R.; Tumbare, A.D.; Surve, U.S. Response of tomato to different fertigation levels and schedules under polyhouse. Int. J. Agric. Sci. 2016, 12, 76–80. [Google Scholar] [CrossRef]

- Sheeded, S.I.; Zaghloul, S.M.; Yaseen, A.A. Effect of method and rate of fertilizer application under drip irrigation on yield and nutrient uptake of tomato. Ozean J. App. Sci. 2009, 2, 139–147. [Google Scholar]

- Vankooten, O.; Heuvelink, E.; Stanghellini, C. New development in greenhouse technology can mitigate the water shortage problem in the 21st centuary. Acta Hortic. 2008, 767, 45–51. [Google Scholar] [CrossRef]

- Sagar, A.; Singh, P.K. Evaporation based micro irrigation scheduling of tomato crop under naturally ventilated polyhouse. Curr. J. Appl. Sci. Tech. 2019, 36, 1–7. [Google Scholar] [CrossRef]

- Saxena, A.; Kumar, P.; Goyal, R.K.; Patel, N.; Khapte, P.S. Assessment of Water Productivity of Different Cropping Systems under Drip Irrigation in Arid Region of Western India. Ann. Arid Zone 2016, 55, 101–105. [Google Scholar]

- Kasyap, S.; Phookan, D.B.; Baruah, P.; Bhuyan, P. Effect of drip irrigation and polythene mulch on yield, quality, water use efficiency and economics of broccoli production. Indian J. Hortic. 2009, 66, 323–325. [Google Scholar]

- Edossa, D.C.; Emana, T.G. Interaction effects of drip irrigation level and planting method on water use efficiency, irrigation uniformity and yield in green pepper (Capsicum annuum L.). Philipp. Agric. Sci. 2011, 94, 350–358. [Google Scholar]

- Ankush; Sharma, S.K. Yield, quality, nutrient and water use efficiency of tomato as affected by different fertigation rates through drip irrigation system. India J. Agric. Res. 2017, 51, 478–482. [Google Scholar]

- Rathore, V.S.; Nathawat, N.S.; Bhardwaj, S.; Yadav, B.M.; Kumar, M.; Santra, P.; Kumar, P.; Reagar, M.L.; Yadav, N.D.; Yadav, O.P. Optimization of deficit irrigation and nitrogen fertilizer management for peanut production in an arid region. Sci. Rep. 2021, 11, 5456. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).