Effects of Nitrogen Application Rate on Dry Matter Weight and Yield of Direct-Seeded Rice under Straw Return

Abstract

:1. Introduction

2. Materials and Methods

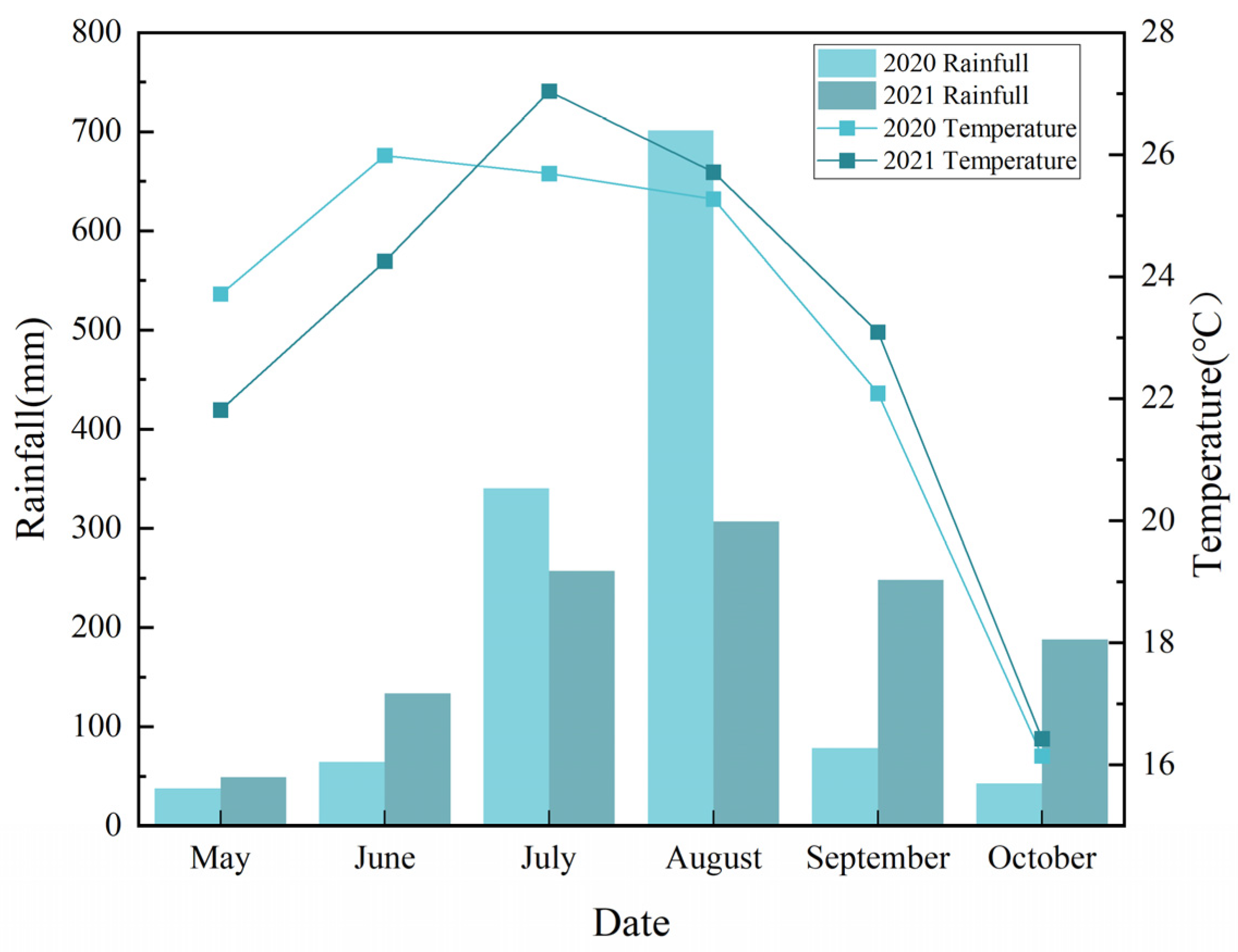

2.1. Experimental Design

2.2. Variables

2.2.1. Tillering Dynamics

2.2.2. Leaf Area Index (LAI)

2.2.3. Dry Matter

2.2.4. Yield

2.3. Statistical Analyses

3. Results

3.1. Effects of Straw Return and Nitrogen Application Rate on LAI

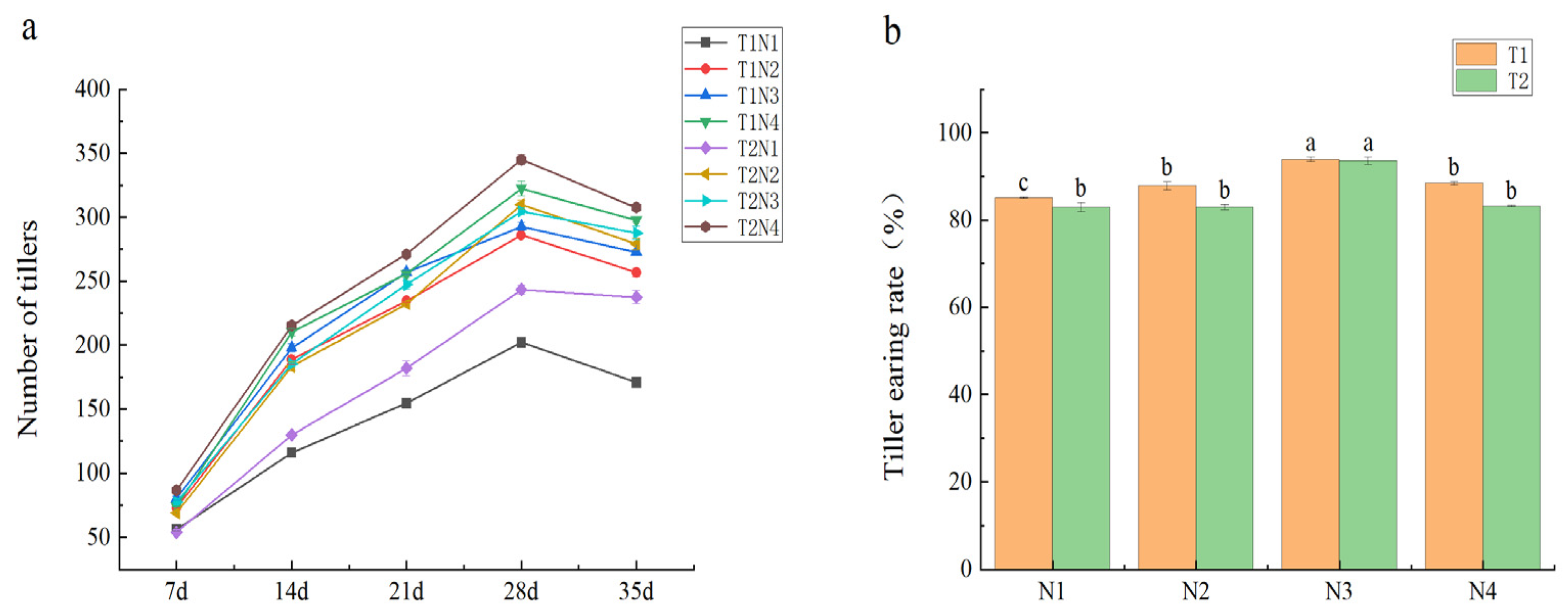

3.2. Effects of Straw Return and Nitrogen Application Rate on Tillering Dynamics

3.3. Effects of Straw Return and Nitrogen Application Rate on Dry Matter Accumulation

3.4. Effects of Straw Return and Nitrogen Application Rate on Yield

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, J.; Qiu, Y.; Zhang, X.; Zhou, Z.; Han, X.; Zhou, Y.; Qin, L.; Liu, K.; Li, S.; Wang, W. Increasing basal nitrogen fertilizer rate improves grain yield, quality and 2-acetyl-1-pyrroline in rice under wheat straw returning. Front. Plant Sci. 2023, 13, 1099751. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Sun, B.; Wu, S.; Feng, H.; Gao, M.; Zhang, B.; Liu, Y. After-effects of straw and straw-derived biochar application on crop growth, yield, and soil properties in wheat (Triticum aestivum L.)-maize (Zea mays L.) rotations: A four-year field experiment. Sci. Total Environ. 2021, 780, 146560. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Wu, J.-F.; Pan, X.-H.; Tan, X.-M.; Zeng, Y.-J.; Shi, Q.-H.; Liu, T.-J.; Zeng, Y.-H. Effects of long-term straw return on soil organic carbon fractions and enzyme activities in a double-cropped rice paddy in South China. J. Integr. Agric. 2021, 20, 236–247. [Google Scholar] [CrossRef]

- Wang, Q.X.; Li, M.L.; Chen, X.J.; Su, Y.; Yu, M.; Shen, A.L. Effects of nitrogen management on soil microbial community structure at different growth stages under straw returning in paddy soils. Ying Yong Sheng Tai Xue Bao 2020, 31, 935–944. [Google Scholar] [CrossRef] [PubMed]

- Jin, Z.; Shah, T.; Zhang, L.; Liu, H.; Peng, S.; Nie, L. Effect of straw returning on soil organic carbon in rice–wheat rotation system: A review. Food Energy Secur. 2020, 9, e200. [Google Scholar] [CrossRef]

- Zheng, W.; Shao, X.; Geng, Y.; Jin, F.; Sun, Q.; Liu, L.; Fan, H.; Guo, L. Effects of straw returning and nitrogen application on rice yield and nitrogen utilization. J. Irrig. Drain. 2019, 38, 8. [Google Scholar] [CrossRef]

- Guo, C.; Li, P.; Lu, J.; Ren, T.; Cong, R.; Li, X. Application of Controlled-Release Urea in Rice: Reducing Environmental Risk While Increasing Grain Yield and Improving Nitrogen Use Efficiency. Commun. Soil Sci. Plant Anal. 2016, 47, 1176–1183. [Google Scholar] [CrossRef]

- Timsina, J.; Panaullah, G.M.; Saleque, M.A.; Ishaque, M.; Pathan, A.B.M.B.U.; Quayyum, M.A.; Connor, D.J.; Saha, P.K.; Humphreys, E.; Meisner, C.A. Nutrient Uptake and Apparent Balances for Rice-Wheat Sequences. I. Nitrogen. J. Plant Nutr. 2006, 29, 137–155. [Google Scholar] [CrossRef]

- Bai, Z. Effects of Nitrogen Application on Nitrogen Metabolism of Rice and Nitrogen Use Efficiency in Paddy Field. Ph.D. Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2019. [Google Scholar]

- Gotoh, E.; Suetsugu, N.; Yamori, W.; Ishishita, K.; Kiyabu, R.; Fukuda, M.; Higa, T.; Shirouchi, B.; Wada, M. Chloroplast Accumulation Response Enhances Leaf Photosynthesis and Plant Biomass Production. Plant Physiol. 2018, 178, 1358–1369. [Google Scholar] [CrossRef]

- Liang, B.; Yang, X.; Murphy, D.V.; He, X.; Zhou, J. Fate of 15 N-labeled fertilizer in soils under dryland agriculture after 19 years of different fertilizations. Biol. Fertil. Soils 2013, 49, 977–986. [Google Scholar] [CrossRef]

- Network CAI. Available online: http://www.agri.cn/V20/ZX/nyyw/202007/t20200703_7444643.htm (accessed on 3 July 2023).

- Beckinghausen, A.; Odlare, M.; Thorin, E.; Schwede, S. From removal to recovery: An evaluation of nitrogen recovery techniques from wastewater. Appl. Energy 2020, 263, 114616. [Google Scholar] [CrossRef]

- Soon, Y.K.; Lupwayi, N.Z. Straw management in a cold semi-arid region: Impact on soil quality and crop productivity. Field Crops Res. 2012, 139, 39–46. [Google Scholar] [CrossRef]

- Grzyb, A.; Wolna-Maruwka, A.; Niewiadomska, A. The Significance of Microbial Transformation of Nitrogen Compounds in the Light of Integrated Crop Management. Agronomy 2021, 11, 1415. [Google Scholar] [CrossRef]

- Tian, G.; Zhou, Y.; Sun, B.; Zhang, R.; Zhou, X.; Guo, S. The mechanism of the effects of nitrogen and planting density on rice tillering dynamics. J. Plant Nutr. Fertil. 2018, 24, 896–904. [Google Scholar]

- Tao, H.; Lin, S. Comparison of punching weighing method, copy weighing method and length-width correction method for determination of rice leaf area. Plant Physiol. J. 2006, 42, 496–498. [Google Scholar]

- Mo, J. Brief introduction of rice leaf area index determination method. Guangxi Agric. Sci. 1978, 8, 22–23. [Google Scholar]

- Ye, W.; Xie, X.; Wang, K.; Li, Z. Effects of straw returning at different stages on growth and yield of rice. Chin. J. Rice Sci. 2008, 1, 65–70. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, L.; Cui, Y.; Hao, X.; Wang, B.; Tian, X.; Li, X.; Qin, Y. Effects of rotation mode and straw returning on rice yield, rice quality and soil fertility. Plant Nutr. Fert. Sci. 2021, 27, 1926–1937. [Google Scholar]

- Zhang, R.-P.; Huang, Z.; Ashen, R.; Zhou, N.-N.; Zhou, L.; Feng, T.-Y.; Zhang, K.-Y.; Liao, X.-H.; Aer, L.; Ma, P. Phosphorus Application during Rapeseed Season Combined with Straw Return Improves Crop Productivity and Soil Bacterial Diversity in Rape-Rice Rotation. Agronomy 2023, 13, 506. [Google Scholar] [CrossRef]

- Yang, F.; Dong, Y.; Xu, M.; Bao, Y. Effects of straw returning on the integrated soil fertility and crop yield in southern China. Chin. J. Appl. Ecol. 2012, 23, 3040–3044. [Google Scholar] [CrossRef]

- Yin, R.; Guo, C.; Sun, Y.; Wu, Y.; Yu, H.; Sun, Z.; Zhang, Q.; Wang, H.; Yang, Z.; Ma, J. Effects of rape straw returning and water and nitrogen management on population quality and yield of hybrid rice under rice-rape rotation. Chin. J. Rice Sci. 2019, 33, 257–268. [Google Scholar] [CrossRef]

- Su, W.; Feng, Y.; Xu, G.; Guan, Z.F.; Ou, D.; Zhang, J.; Wang, L. Effects of straw returning and nitrogen application rate on dry matter accumulation and yield of indica hybrid rice in karst area. Acta Agric. Nucl. Sin. 2019, 33, 1856–1864. [Google Scholar]

- Liu, J.; Fang, L.; Qiu, T.; Chen, J.; Wang, H.; Liu, M.; Yi, J.; Zhang, H.; Wang, C.; Sardans, J.; et al. Crop residue return achieves environmental mitigation and enhances grain yield: A global meta-analysis. Agron. Sustain. Dev. 2023, 43, 78. [Google Scholar] [CrossRef]

- Hu, Y.; Zhu, D.; Xing, Z.; Gong, J.; Zhang, H.; Dai, Q.; Huo, Z.; Xu, K.; Wei, H.; Guo, B. Effects of improved nitrogen application on rice yield and nitrogen uptake and utilization. Plant Nutr. Fert. Sci. 2015, 21, 12–22. [Google Scholar]

- Iqbal, A.; He, L.; Khan, A.; Wei, S.; Akhtar, K.; Ali, I.; Ullah, S.; Munsif, F.; Zhao, Q.; Jiang, L. Organic Manure Coupled with Inorganic Fertilizer: An Approach for the Sustainable Production of Rice by Improving Soil Properties and Nitrogen Use Efficiency. Agronomy 2019, 9, 651. [Google Scholar] [CrossRef]

- Yan, J.; Wang, W.; Li, B.; Li, Y.; Jiang, R.; Shen, M.; Wang, C.; Cui, B. Effects of chemical fertilizer reduction under straw returning on rice yield and nitrogen absorption and utilization in northern Jiangsu. China Soils Fert. 2021, 5, 74–82. [Google Scholar]

- Sheng-Gang, P.; Sheng-Qi, H.; Jing, Z.; Jing-Ping, W.; Cou-Gui, C.; Ming-Li, C.; Ming, Z.; Xiang-Ru, T. Effects of N Management on Yield and N Uptake of Rice in Central China. J. Integr. Agric. 2012, 11, 1993–2000. [Google Scholar]

- Shan, A.; Pan, J.; Kang, K.J.; Pan, M.; Wang, G.; Wang, M.; He, Z.; Yang, X. Effects of straw return with N fertilizer reduction on crop yield, plant diseases and pests and potential heavy metal risk in a Chinese rice paddy: A field study of 2 consecutive wheat-rice cycles. Environ. Pollut. 2021, 288, 117741. [Google Scholar] [CrossRef]

- Zheng, W. Effects of Straw Returning and Nitrogen Application on Growth and Yield of Rice. Master’s Thesis, Jilin Agricultural University, Jilin, China, 2021. [Google Scholar]

- Xie, F.; Han, X.; Yang, J.; Liu, X.; Zuo, R.; Wu, Z. Effects of different nitrogen treatments on nitrogen uptake and yield of rice. China. Soils Fert. 2010, 4, 24–26+45. [Google Scholar]

- Zhou, L.; Huang, Y.; Zhang, S.; Guo, Z.; Hong, R.; Wang, Y.; Xia, L.; Fu, L.; Li, Y.; Chen, Q. Effects of different nitrogen fertilizer regulation on tiller number and leaf area index of rice. Hubei Agric. Sci. 2020, 59, 33–37. [Google Scholar] [CrossRef]

- Xie, H.; Wu, K.; Iqbal, A.; Ali, I.; He, L.; Ullah, S.; Wei, S.; Zhao, Q.; Wu, X.; Huang, Q.; et al. Synthetic nitrogen coupled with seaweed extract and microbial inoculants improves rice (Oryza sativa L.) production under a dual cropping system. Ital. J. Agron. 2021, 16, 1800. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.; Su, Z. Effects of nitrogen application rate on yield components and dry matter accumulation of hybrid rice. J. Tianjin Agric. Coll. 2005, 1, 5–8+30. [Google Scholar]

- Cong, X.; Shi, F.; Ruan, X.; Luo, Y.; Ma, T.; Luo, Z. Effects of nitrogen fertilizer levels on nitrogen use efficiency, yield and quality of different rice genotypes. Chin. J. Appl. Ecol. 2017, 28, 1219–1226. [Google Scholar] [CrossRef]

| Year | Treatment | Maximum Tillering Stage | Full Heading Stage | Mature Stage | Dry Matter Accumulation After Full Heading | ||||

|---|---|---|---|---|---|---|---|---|---|

| Stem | Leaf | Stem and Leaf | Panicle | Stem and Leaf | Panicle | ||||

| 2020 | T1 | N1 | 891.07c | 626.44d | 5282.19d | 624.18c | 2946.08d | 4526.39d | 1566.10c |

| N2 | 1562.11b | 1346.98c | 8100.41c | 1420.88b | 3821.40c | 7847.33c | 2147.45b | ||

| N3 | 1926.29a | 1838.93b | 9274.91b | 1383.75b | 5200.84b | 8738.29b | 3280.47a | ||

| N4 | 2025.12a | 1887.52a | 10,433.16a | 1843.30a | 6255.46a | 9356.98a | 3335.98a | ||

| Mean | 1601.15 | 1424.97 | 8272.67 | 1318.03 | 4351.94 | 7617.25 | 2582.50 | ||

| T2 | N1 | 1057.33c | 860.86c | 6851.03d | 982.26d | 3470.56d | 5954.73c | 1592.00c | |

| N2 | 1576.85b | 1518.06b | 9273.27c | 1524.25c | 4825.92c | 8012.56b | 2040.95b | ||

| N3 | 1995.09a | 1856.40a | 10,668.85b | 1806.53b | 5775.23b | 9643.28a | 2943.13a | ||

| N4 | 1969.42a | 2039.31a | 10,901.99a | 1933.39a | 6144.14a | 9761.22a | 3069.98a | ||

| Mean | 1649.67 | 1568.66 | 9423.79 | 1561.61 | 5053.96 | 8342.95 | 2411.51 | ||

| 2021 | T1 | N1 | 1199.84c | 573.85d | 5112.75d | 507.23d | 3337.70d | 5199.29d | 2917.01d |

| N2 | 1306.31c | 713.08c | 6654.68c | 589.95c | 4856.95c | 6869.78c | 4482.09c | ||

| N3 | 1732.46a | 986.08b | 7450.18b | 700.52b | 5156.43b | 7922.69b | 4928.42b | ||

| N4 | 1815.45a | 1196.56a | 8953.78a | 933.66a | 6974.64a | 9399.67a | 6486.87a | ||

| Mean | 1513.52 | 867.39 | 7042.85 | 682.84 | 5081.43 | 7347.86 | 4703.60 | ||

| T2 | N1 | 945.40d | 512.97d | 6103.19d | 619.16c | 4327.60d | 6426.70d | 4031.94c | |

| N2 | 1135.95c | 636.09c | 7632.05c | 749.93b | 5465.30c | 8467.10c | 5550.42b | ||

| N3 | 1528.53b | 907.18b | 8477.73b | 815.18b | 6342.75b | 8627.08b | 5676.93b | ||

| N4 | 1574.67b | 1140.60a | 9711.30a | 958.50a | 7479.28a | 9507.78a | 6317.25a | ||

| Mean | 1296.14 | 1025.96 | 7981.07 | 785.69 | 5903.73 | 8257.17 | 5394.14 | ||

| F Value | Y | 386.97 ** | 964.59 ** | 21,634.69 ** | 5491.30 ** | 1307.79 ** | 42.79 ** | 14,693.69 ** | |

| T | 0.3 | 0.23 | 16,432.18 ** | 107.96 ** | 1032.01 ** | 2588.20 ** | 1175.44 ** | ||

| N | 386.72 ** | 622.19 ** | 8864.67 ** | 519.40 ** | 5450.63 ** | 5902.37 ** | 2264.68 ** | ||

| Y ×T | 20.94 * | 3.55 | 170.62 ** | 17.81 * | 62.26 ** | 32.64 ** | 3232.06 ** | ||

| Y × N | 29.75 ** | 92.63 ** | 295.19 ** | 138.74 ** | 80.31 ** | 185.34 ** | 222.01 ** | ||

| T × N | 7.42 ** | 3.81 * | 63.02 ** | 13.00 ** | 73.07 ** | 95.95 ** | 74.81 ** | ||

| Y × T × N | 10.86 ** | 12.04 ** | 23.88 ** | 9.70 ** | 43.89 ** | 86.24 ** | 39.03 ** | ||

| Year | Treatment | 1000-Grain Weight (g) | Grain Filling (%) | Panicles (×104·hm−2) | Spikelets per Panicle | Grain Yield (kg·hm−2) | |

|---|---|---|---|---|---|---|---|

| 2020 | T1 | N1 | 26.53a | 82.71c | 171.99d | 114.72d | 4329.61d |

| N2 | 26.50a | 88.28a | 251.35c | 149.06c | 8764.84c | ||

| N3 | 26.63a | 86.11b | 275.18b | 150.93b | 9520.63a | ||

| N4 | 26.56a | 80.04d | 285.39a | 156.17a | 9471.93b | ||

| Mean | 26.55 | 80.29 | 245.98 | 142.72 | 8021.75 | ||

| T2 | N1 | 26.59b | 82.77c | 197.17c | 125.40b | 5438.22d | |

| N2 | 26.81ab | 87.18b | 257.33b | 148.61a | 8936.52c | ||

| N3 | 26.80ab | 86.98b | 285.39a | 153.91a | 10,236.67b | ||

| N4 | 26.90a | 89.76a | 287.55a | 154.65a | 10,738.26a | ||

| Mean | 26.77 | 86.67 | 256.86 | 145.64 | 8837.42 | ||

| 2021 | T1 | N1 | 25.46b | 85.60a | 181.40c | 146.15c | 5776.07c |

| N2 | 26.01b | 88.35a | 218.55b | 152.62b | 7662.26b | ||

| N3 | 26.89a | 87.30a | 223.86b | 164.82a | 8661.46a | ||

| N4 | 26.06b | 85.91a | 232.44a | 165.62a | 8618.70a | ||

| Mean | 26.10 | 86.79 | 214.06 | 157.30 | 7678.98 | ||

| T2 | N1 | 25.50b | 86.19a | 181.51d | 156.17b | 6228.93d | |

| N2 | 27.00a | 87.83a | 227.80c | 156.92b | 8478.09c | ||

| N3 | 26.92a | 87.76a | 236.14b | 166.00a | 9260.87b | ||

| N4 | 27.07a | 88.14a | 247.52a | 166.08a | 9804.17a | ||

| Mean | 26.62 | 87.48 | 223.24 | 161.29 | 8443.01 | ||

| F Value | Y | 10.26 | 92.95 * | 1719.11 ** | 120.13 ** | 105.58 ** | |

| T | 39.45 ** | 36.84 ** | 113.62 ** | 15.21 * | 480.15 ** | ||

| N | 16.27 ** | 21.36 ** | 1075.23 ** | 246.20 ** | 2466.26 ** | ||

| Y × T | 6.48 | 11.16 * | 0.81 | 0.36 | 0.51 | ||

| Y × N | 15.30 ** | 3.40 * | 109.40 ** | 88.22 ** | 161.95 ** | ||

| T × N | 3.21 * | 20.38 ** | 1.44 | 11.13 ** | 17.48 ** | ||

| Y × T × N | 3.31 * | 8.46 ** | 16.67 ** | 1.7 | 11.77 ** | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, P.; Zhang, K.-Y.; Liao, X.-H.; Aer, L.-S.; Yang, E.-L.; Deng, J.; Zhou, L.; Zhang, R.-P. Effects of Nitrogen Application Rate on Dry Matter Weight and Yield of Direct-Seeded Rice under Straw Return. Agronomy 2023, 13, 3058. https://doi.org/10.3390/agronomy13123058

Ma P, Zhang K-Y, Liao X-H, Aer L-S, Yang E-L, Deng J, Zhou L, Zhang R-P. Effects of Nitrogen Application Rate on Dry Matter Weight and Yield of Direct-Seeded Rice under Straw Return. Agronomy. 2023; 13(12):3058. https://doi.org/10.3390/agronomy13123058

Chicago/Turabian StyleMa, Peng, Ke-Yuan Zhang, Xue-Huan Liao, Li-Se Aer, Er-Luo Yang, Jun Deng, Lin Zhou, and Rong-Ping Zhang. 2023. "Effects of Nitrogen Application Rate on Dry Matter Weight and Yield of Direct-Seeded Rice under Straw Return" Agronomy 13, no. 12: 3058. https://doi.org/10.3390/agronomy13123058

APA StyleMa, P., Zhang, K.-Y., Liao, X.-H., Aer, L.-S., Yang, E.-L., Deng, J., Zhou, L., & Zhang, R.-P. (2023). Effects of Nitrogen Application Rate on Dry Matter Weight and Yield of Direct-Seeded Rice under Straw Return. Agronomy, 13(12), 3058. https://doi.org/10.3390/agronomy13123058