Abstract

Open-canopy pesticide application technology is not affected by the canopy structure and can substantially increase droplet penetration and deposition in the middle and lower rice canopy. However, the optimal working position of the canopy opener is difficult to determine. The purpose of this study was to examine the characteristics of rice canopy disturbances under the action of a canopy opener, verify simulation results using high-speed photography tests, and identify the spraying effect of the optimal operating parameters of a canopy opener through spray tests. The mechanical characteristic parameters of the rice heading stage were determined through experiments, and the canopy-opening process was simulated based on the finite element method of explicit dynamics. The simulation results show that when the speed of the canopy opener is 1.2 m s−1 and the height is 0.6 m, the rice canopy is the most disturbed. The spray experiment results show that under this condition, the overall coverage rate of the rice canopy is relatively high, and the coverage rates of the upper, middle, and lower layers of rice are 92.18%, 66.43%, and 52.84%, respectively.

1. Introduction

Rice is a major cereal crop in China. Boom sprayers, which are typically applied with top spraying technology, are widely used in the control of plant diseases and insect pests during the mid-growth stage of rice [1]. Compared with traditional backpack and knapsack sprayers, boom sprayers provide advantages in terms of spray uniformity and efficiency [2]. However, top spraying technology has a fundamental problem: as the leaf density increases, the penetration of the spray to the leaves decreases [3,4], resulting in a decrease in spray uniformity [2]. This can reduce the effectiveness of disease and insect pest control in the lower part of the rice canopy to some extent, and then the targeted disease and insect pests can seriously impact rice yield [5,6].

To increase the amount of spray reaching the lower canopy, two methods are usually considered: using air-assisted sprayers or a canopy opener. Air-assisted sprayers can increase spray deposition [7] and coverage within the tree canopy compared with traditional boom sprayers [8] by increasing deposits in the lower canopy and on leaf undersides [9]. However, wind-powered sprayers are expensive, and the use of large fans requires additional power [10]. The wetland conditions in which rice is grown limit the possibility of using air-assisted boom sprayers. Due to the poor bearing capacity of wetlands, the plow layer traversed by the spraying machine with wind-spraying equipment is crushed [11], causing the wetland to sink and form many underground channels that are difficult to change.

Canopy openers are used to effectively open an internal space within the crop canopy [12], and they are not affected by the canopy characteristics [13]. Give droplets more opportunities to reach the middle and lower parts of the canopy, increasing droplet penetration in the crop canopy [14]. Canopy openers can increase the droplet deposition rate through the use of different nozzles by 8.6% to 18.0% [15]. The structure of canopy openers is simple and reliable [10,16], and they cause minimal mechanical damage to plants. These openers produce appropriate application effects and are more suitable for wide promotion and application.

The position of the canopy opener is difficult to determine. Applicator speed also affects the effectiveness of pesticide application [17,18]. If the canopy opener is positioned too high, the gaps created within the canopy are too small, and the droplets cannot easily enter the lower canopy layer. If the canopy opener is positioned too low, they damage the rice plants. Zhu et al. (2008) developed a mathematical model based on the physical characteristics of soybean plants to determine the optimal position of a canopy opener connected to a traditional spray boom [10,16]. Wu and Wei (2019) studied the rice-canopy-opening process through physical experiments and transient dynamic simulations, and they determined the optimal canopy opener position by studying the relationship between the canopy opener position and the maximum rice stem displacement [12].

Although transient methods can be used to study geometric and contact nonlinearities, another problem arises in the simulation process. Transient methods based on implicit solvers are performed considering static or quasistatic loading, small strain deformations, short periods, small displacements, and linear contact assumptions. If the material has uniform linearity and elasticity and undergoes minimal deformation, and if loads or constraints of the same magnitude or direction are continuously applied to the model, the implicit solver can be used to solve the problem. If complex contacts exist between models, an implicit solver cannot be used. Because the relationship between load (generalized force) and response (generalized displacement) becomes nonlinear, a nonlinear analysis must be performed to obtain actual results that reflect true behavior [19]. The rice-canopy-opening process is a typical dynamic contact process, which is characterized by a long duration (>1 s), low speed, large displacement, and complex contact. In this context, explicit solution methods are valuable tools for solving load situations, such as dynamic contact events [20,21,22,23]. The explicit dynamics method is essentially an incremental method for determining the dynamic response of a structure. It is most suitable for calculating events that occur within a few milliseconds or less, but it can perform calculations for events that last longer than a second, although long simulation run times are expected. Additionally, quasistatic analysis can be performed under complex and highly nonlinear deformation conditions, such as for large deformation and geometric nonlinearity, complex contact conditions, complex material behavior, and material damage and failure [24]. Additionally, as the model size increases, explicit solving methods require fewer system resources than implicit solving methods. Therefore, the analysis of rice canopy perturbation under the influence of a canopy-opening device can be considered a dynamic application covered by the explicit dynamic systems mentioned above.

Under the action of a canopy opener, the interactions within the rice canopy are more complex than the effect of the canopy opener disturbing the rice canopy. In this study, numerical simulation was used to analyze the influence of the main operating parameters of a canopy opener on the canopy-opening effect, and the optimal operating parameters of the canopy-opening sprayer were determined. The simulation results were verified through high-speed photography, and the spraying effect achieved when applied the optimal working parameters of the canopy opener was verified through spray tests. These results provide a design basis for the future development of spraying devices suitable for high-density crops in rice fields.

2. Materials and Methods

2.1. Rice Sample and Canopy Opener

The rice sample variety used in this study was “nanjing46”. Disease-free rice samples at the heading stage were collected from the experimental fields of Runguo Agriculture Co., Ltd., in Zhenjiang, Jiangsu province, China. The distance between rice rows is 18 cm and the distance between plants is 10 cm. The collected rice samples were used for measurements of the morphological structure and material parameters of the rice. To reduce the measurement errors caused by water loss in rice plants, all measurements were completed within 24 h of plant collection.

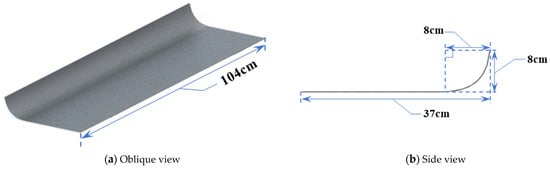

The 3D model and geometric parameters of the canopy opener are shown in Figure 1. The positional relationship between the canopy opener and nozzle is shown in Figure 2. The distance between the canopy opener and the spray boom can be adjusted vertically and horizontally (Figure 2c). Adjust the canopy opener to the inside of the canopy before spraying.

Figure 1.

Geometric model and morphological parameters of the canopy opener.

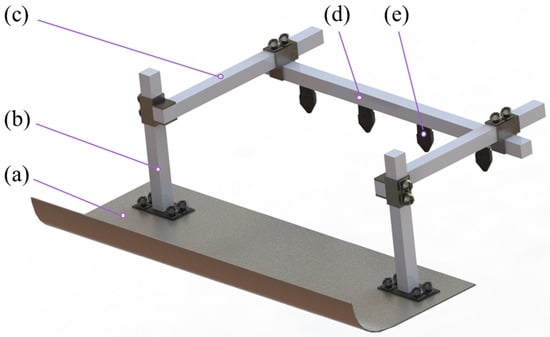

Figure 2.

Positional relationship between the canopy opener and nozzle. (a) The canopy opener; (b) adjusting the height between the canopy opener and spray boom; (c) adjusting the horizontal distance between the canopy opener and spray boom; (d) spray boom; (e) nozzle.

2.2. Parameters of Rice Materials

The sample included 300 rice plants, which were divided into three groups for measuring the morphological structural parameters and the density, elastic modulus, and Poisson’s ratio of the rice stems. The mechanical properties of the rice and canopy opener are shown in Table 1.

Table 1.

Mechanical properties of the rice and canopy opener used in the simulation.

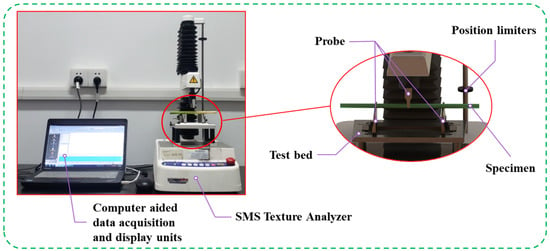

The parameters of 100 rice plants were measured, including plant height, leaf number, leaf area, leaf width, stem length, stem diameter, and stem wall thickness. To simplify the rice structure, the stem and leaves were mainly considered. A digital scale with an accuracy of 0.01 g was used to weigh the rice, and the average volume of the rice was determined using the water displacement method [25]. Then, the average density of the rice was calculated (Table 1). The elastic modulus of the stems of 100 rice plants was determined using a three-point bending test (Figure 3) with an SMS texture analyzer [26] (TA.XT Express Connect, Texture Technologies Company, Hamilton, MA, USA).

Figure 3.

Measurement of elastic modulus.

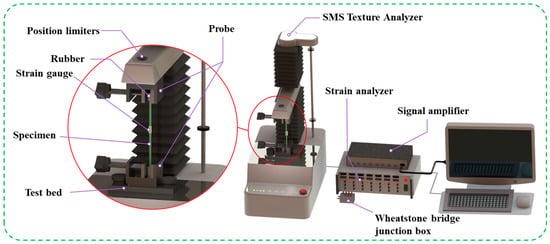

Measuring Poisson’s ratio of rice stems using tensile test and electrical measurement method. Tensile tests were conducted on the rice stem samples using an SMS texture analyzer. Use electrical measurement method to measure the transverse strain of rice straw and further calculate Poisson’s ratio [27]. For the experiment, 100 straight rice stem samples were selected, and the ends of the stems were polished smooth with sandpaper. The rice samples were wrapped in soft elastic rubber. The rice stem samples were wrapped with soft elastic rubber at both ends to reduce damage to the samples caused by the fixture (Figure 4). Used strain glue to attach the strain gauge to the measuring point in the middle of the rice stem samples. The strain gauge parameters used in this experiment are listed in Table 2. To ensure the freshness of the rice, all testing was completed within 24 h.

Figure 4.

Measurement of Poisson’s ratio in rice.

Table 2.

Parameters of strain gauge.

2.3. High-Speed Photography Experimental Design

A high-speed camera system (i-speed716, ix camera Company, Woburn, MA, USA) was used to track the movement trajectory of the rice stems under the effect of the canopy-opening device in a real scenario (Figure 5) to evaluate the effectiveness of the simulation results. The entire high-speed camera system included (1) a high-speed camera (i-speed TR) with a maximum frame rate of 10,000 fps and a monitor manufactured (Olympus BX51, Olympus Co., Tokyo, Japan); (2) a photography light with a power of 1000 W and a white halogen lamp with a power of 1000 W; and (3) a micro lens (AT-X PO D 100 mm F 2.8 Macro, Kenko Tokina Co, Ltd., Tokyo, Japan). The 3D coordinate motion trajectory of the rice plants was extracted using ProAnalyst V1.5.6.8 (Xcitex Company, Woburn, MA, USA). After completing the HSP experiment, the HSP memory card data were exported, and the dedicated postprocessing software Analyst was used to process the data. ProAnalyst is an omnidirectional automatic tracking and data analysis software package. Automatic tracking included two tracking methods: along the timeline and a directional map. ProAnalyst software was used to perform fast Fourier transform, filtering, and further analysis of the synchronized data.

Figure 5.

High-speed photography (HSP) experiment.

2.4. Finite Element Simulation Model

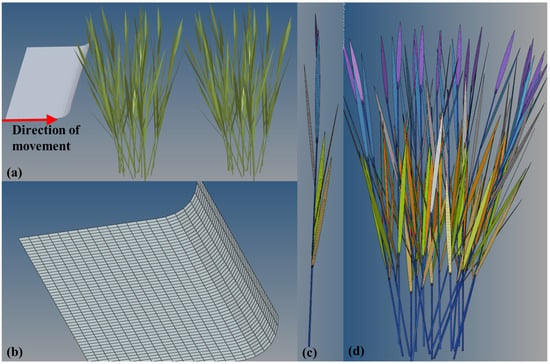

A three-dimensional model of the rice canopy during the opening process was created using SolidWorks 2019 software (Dassault Systems SolidWorks Corporation, Waltham, MA, USA). To simulate the actual field conditions as closely as possible, 2 clusters of 40 rice plants in total were included in the model. A random rotation angle was assigned to each rice plant to simulate the spatial position of the rice stems and leaves in the canopy (Figure 6a).

Figure 6.

Model of rice-canopy-opening process: (a) 3D model of rice-canopy-opening process; (b) mesh division of canopy opener; (c) mesh division of single plant rice; (d) mesh division of a cluster of rice.

To determine the driving velocity and height range of the canopy opener, the driving velocity was set based on the working velocity range of the applicator (0~2 m s−1). The initial position of the canopy opener was set to 0.1 m on the rice stem, the rice stem was horizontally pushed at a speed of 1 m s−1, and the damage to the rice stem was recorded. After the recording was completed, the placement position of the canopy opener was raised by 0.1 m. The test results showed that when the position of the canopy opener was lower than 0.5 m, the rice plants were easily damaged, as shown in Figure 7. Therefore, the height range of the canopy opener from the ground was determined by measuring the average height of the rice plants. Finally, in the field experiments and simulations, three different heights (0.5, 0.6, and 0.7 m) and three different velocities (0.8, 1.2, and 1.6 m s−1) of the canopy opener were considered.

Figure 7.

When the canopy opener was too low, the rice was bent.

To numerically simulate the rice-canopy-opening process, HyperMesh software (Altair Engineering, Troy, MI, USA)was used for preprocessing. In the software, the properties of the rice plants were set as non-rigid bodies, while the properties of the canopy opener was set as rigid bodies. The contact process is set to automatic general contact. Subsequently, the LS-DYNA software(LSTC, Livermore, CA, USA) was used to numerically simulate the rice canopy-opening process based on explicit solver. Because the display dynamic module in LS-DYNA software can be used to analyze complex contact and large dynamic deformation, it was used for simulating the rice-canopy-opening process. During the numerical simulation, in order to obtain more accurate results, a smaller time step was set. For the boundary conditions, the bottom of the rice stems was set to be relatively fixed, and the canopy opener was defined to only translate along the positive X axis direction with a fixed speed without attenuation.

I In the HyperMesh software, the element type was set as the rice plant material attribute using MATL3 (Figure 6c). The rice plants were assumed to be nonlinear viscoelastic tissue; however, in previous crop studies, many scholars have simplified it as linear elastic tissue [28,29]. The MATL20 element type was chosen to model the canopy opener, which had an elastic modulus of 193,000 MPa and a density of 7750 kg m−3 (Table 1).

To consider the nonrigid characteristics of rice plants, shell elements were used to model the rice plant in HyperMesh, considering the thickness of the rice leaves during model creation. A mixed mesh of triangular and quadrilateral elements of 0.001 mm was used. The final rice model consisted of 240,663 nodes and 226,240 units. To model the opening device, shell elements were also used, with different thicknesses assigned to different parts of the model. A mesh consisting of 1229 nodes and 1092 elements was generated using 0.02 mm quadrilateral elements.

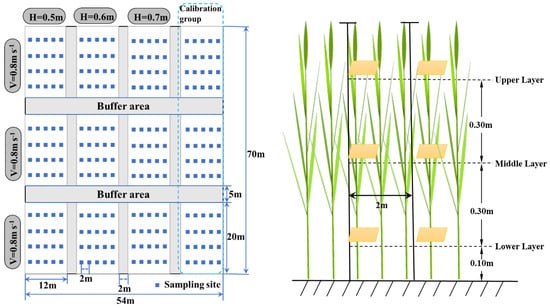

2.5. Spray Droplet Test

The droplet spraying test was conducted at Runguo Farm, Jiangsu province, China. The spraying test was conducted under windless or weak wind conditions (wind speed < 1.5 m s−1). The spraying platform was a SWAN3WP-500 boom sprayer produced by Swan Group Co., Ltd. (Changzhou City, Jiangsu Province, China). A hydraulic system was placed in front of the sprayer to control the height of the canopy opener (Figure 8). The total length of the canopy opener was 12 m. The height of the canopy opener from the ground could be adjusted from 0.5 to 1.43 m.

Figure 8.

Boom spray equipped with canopy opener.

Water-sensitive paper (WSP, 25 × 75 mm2) was used as the sampling material to capture liquid droplets. The sampling points were placed as shown in Figure 9, with each point sampled three times. Samples were collected after the droplets had completely dried. The WSP was carefully removed using clean tweezers, and it was marked and analyzed with DepositScan V1.2 image processing software [30]. In the field experiment, 720 sediment measurements were conducted, consisting of 12 experiments, 20 collection points, and 3 different collection points. The WSP model number was 20301-1N. A Lenovo M7605D scanner (Lenovo, Beijing, China) was used to scan the water-sensitive paper at 600 dpi.

Figure 9.

Spray test design and location of water-sensitive paper.

The working parameters of the pesticide applicator are shown in Table 3. Conditions A to I were used for the canopy opener, whereas conditions K, L, and M were not used for the device.

Table 3.

Applicator working parameter settings.

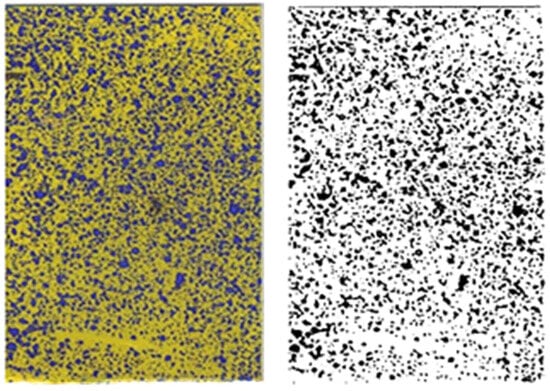

The spray coverage (%) was used to evaluate the effect of the spray. The droplet coverage is expressed using the ratio of the droplet pixel number on the water-sensitive paper to the pixel number of the analyzed area [31], which was calculated using Equation (1):

where represents the droplet deposition rate; and denote the number of pixels in the width and height of the analyzed area, respectively; and represents the value of the pixel at the relative coordinates of in the binary images of the analyzed area. If the pixel was black, then = 1; otherwise, = 0. Figure 10 shows the original image and conversion results of the WSP.

Figure 10.

Grayscale image and normal water-sensitive paper image.

3. Results and Discussion

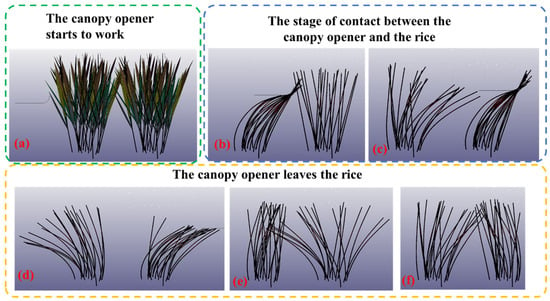

LS-Prepost V4.0 software was used to visualize the simulation results and output a video of the entire crown opening process. Six frames were extracted from the video of the canopy-opening process as examples, as shown in Figure 11. Due to the occlusion of rice leaves, the leaves are hidden in Figure 11b–f.

Figure 11.

The process of the action of the canopy opener on the rice canopy. (a) The canopy opener starts to work, (b–d) contact between the canopy opener and rice, and (e,f) canopy opener leaves the rice.

Figure 11 illustrates the process of the canopy opener leaving the rice cluster after opening the rice canopy layer. Before the canopy opener contacts the rice cluster, no gap exists between the two clusters of rice (Figure 11a). As the canopy opener begins to contact the rice, the rice stems bend forward in the direction of the canopy opener (Figure 11b). When the canopy opener completely leaves the first cluster of rice, the rice stems rebound and oscillate in the direction opposite to the movement of the canopy opener (Figure 11d).

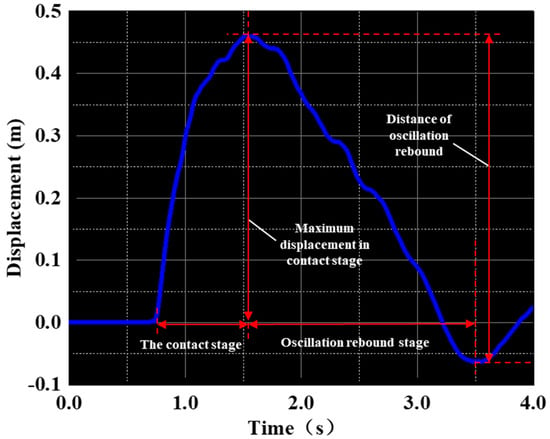

To evaluate the effectiveness of the canopy opener, the canopy-opening process was divided into two stages: the stage of contact between the canopy opener and the rice plant, and the stage of rice plant oscillation after the canopy opener has left (Figure 11). A fixed monitoring point was set at the top of each rice stem, and the displacement data of all monitoring points were recorded throughout the canopy-opening process. When the canopy opener began to contact the rice stem, the rice stem bent (Figure 12).

Figure 12.

Schematic diagram of the characteristics of the canopy-opening process.

Table 4 presents the mean maximum displacements of the rice stems during the contact and oscillation stages at three different velocities (0.8, 1.2, and 1.6 m s−1) and heights (0.5, 0.6, and 0.7 m) of the canopy opener, as well as the predicted maximum displacement during the oscillation stage, the determined value, and the prediction error.

Table 4.

Results of rice canopy opening.

According to Table 4, at the same driving velocity, the maximum displacement of the rice stems during the contact and oscillation stages is higher at a canopy opener height of 0.5 m than at other heights. This is because the canopy opener acts on the middle part of the rice stem at this height, allowing for more contact and increasing the degree of rice stem bending, resulting in larger displacement. When the canopy opener is at a height of 0.7 m, it acts on the upper part of the rice stem, creating a shorter contact time and a smaller degree of bending due to the increased height, resulting in a lower maximum displacement during the contact stage than at other heights. As the height of the canopy opener increases, the degree of bending of the rice stem decreases, resulting in a decrease in displacement during the contact stage with increasing canopy opener height.

However, during the oscillation stage, the maximum displacement of the rice stem is achieved when the canopy opener is at a height of 0.6 m. The minimum displacement occurs when the canopy opener height is 0.7 m. This indicates the existence of a critical canopy opener height during the oscillation stage, where the maximum displacement of the rice stem occurs. Increasing or decreasing the canopy opener height from this critical value results in a decrease in the maximum rice stem displacement during the oscillation stage.

The impact of different driving velocities of the canopy opener on the maximum displacement of rice stem varies at different stages and at the same height. During the contact stage, the driving velocity of the canopy opener weakly influences the displacement, so the displacement during the oscillation stage is mainly influenced by the canopy opener height.

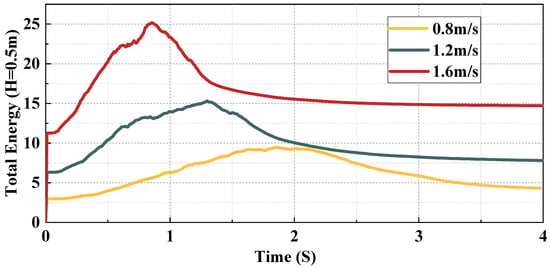

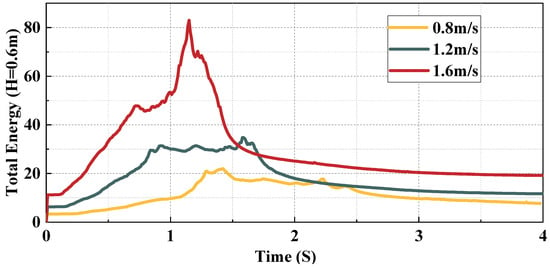

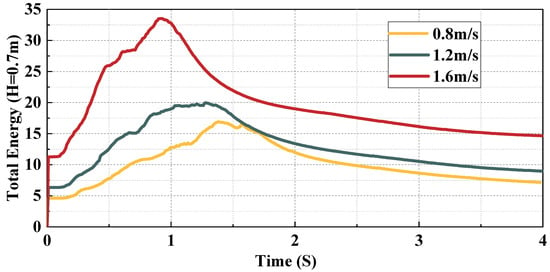

During the oscillation stage, the maximum rice stem displacement was reached at canopy opener heights of 0.5 m and 0.6 m with a driving speed of 1.2 m s−1, which did not increase with increasing driving speed. The order of the rice stem displacement was 1.2 m s−1 > 1.6 m s−1 > 0.8 m s−1. Figure 13, Figure 14 and Figure 15 show the change in total energy of the canopy-opening process simulation model under different conditions. The total energy increases first and then decreases over time because the total energy increases when the canopy opener interacts with the rice stems and then starts to decrease when the canopy opener leaves the rice stems.

Figure 13.

Change in modeled total energy over time for different driving velocities (H = 0.5 m).

Figure 14.

Change in modeled total energy over time under different driving velocities (H = 0.6 m).

Figure 15.

Change in modeled total energy over time for different driving velocities (H = 0.7 m).

Under the same height, the total energy increases with an increase in the velocity of the canopy opener, and the higher the velocity, the greater the total energy. The maximum energy was reached at a height of 0.6 m and a velocity of 1.6 m s−1. After reaching the maximum energy, the interaction between the rice stem and leaves rapidly reduces the energy, which explains why the maximum displacement of the rice stem during the oscillation stage was greater at a velocity of 1.2 m s−1 than at a velocity of 1.6 m s−1. At a height of 0.7 m, the maximum displacement of the stem increases with an increase in velocity, and it reaches the maximum at a velocity of 1.6 m s−1. It is evident that a decrease in the velocity of the canopy opener reduces the impact energy.

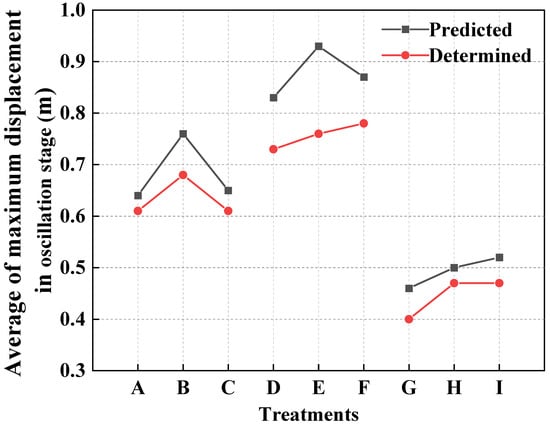

Comparison of the maximum displacement of the rice stem during the oscillation stage predicted by the HSP experiment and the finite element model (Figure 16) and the errors are shown in Table 3; the minimum and maximum errors in predicting the maximum displacement during the oscillation stage are 4.69% and 18.28%, respectively. The field environment is more complex, and it is difficult for the spraying machine to maintain a stable velocity and height in the paddy field, which increases the error. The correlation coefficient between these two sets of data is approximately 0.9642, indicating good correlation between the modeling and measurement.

Figure 16.

Average maximum displacement of rice stems during oscillation stage. A~I correspond to the treatments in Table 4.

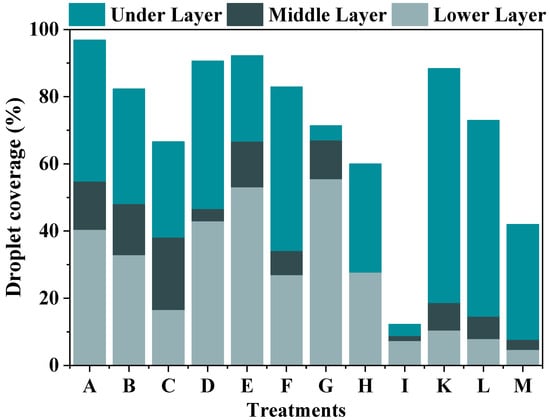

Table 5 shows the spray coverage on the upper, middle, and lower layers of rice plants for different canopy opener heights and driving velocities.

Table 5.

Effects of different treatment conditions on droplet coverage.

The data in Table 5 and Figure 17 show that the droplet coverage rate in each treatment followed the pattern of top > middle > bottom. For treatments A, B, and C at a height of 0.5 m, the droplet coverage rate of the upper, middle, and lower rice plant layers decreases with increasing velocity. Among them, the droplet coverage rate of the upper rice layer under treatment A is the highest, reaching 96.89%, but the droplet coverage rate of the lower layer is not ideal. At a height of 0.6 m, the droplet coverage rate of all layers of the rice is relatively high under treatment E at a velocity of 1.2 m s−1, with droplet coverage rates of the upper, middle, and lower layers of 92.18%, 66.43%, and 52.84%, respectively, which is high coverage overall. For treatments G, H, and I, at a height of 0.7 m, the droplet coverage rate of the upper, middle, and lower layers follows the same trend as in treatments A, B, and C. Among them, the droplet coverage rate of the middle and lower layers of the rice under treatment G is the highest, reaching 66.79% and 55.29%, respectively, but the droplet coverage rate of the upper layer of the rice is not ideal. Compared with treatments K, L and M, the droplet coverage rates of the upper, middle, and lower layers of the rice in treatments A~F are higher at the same velocity. Under treatments A~F, the droplet coverage rate of the upper layer of the rice is the highest, being at most 97.48% higher and at least 2.52% higher; the droplet coverage rate increases more for the middle and lower rice layers. Among them, the droplet coverage rate of the middle rice layer of the rice increases at most by 407.35% and increases in the least by 151.73%. The droplet coverage rate of the lower rice layer increases at most by 583.57% and at least by 267.42%.

Figure 17.

Droplet deposition rate of each layer of rice under different treatments. A~M correspond to the treatments in Table 5.

4. Conclusions

This study focused on the application of a dynamic finite element model in the process of rice canopy opening. The material properties of rice at the heading stage were measured. High-speed photography experiments were conducted to determine the rice-canopy-opening effect using different opening devices at different speeds and heights, and modeling was conducted. The values predicted using LS-DYNA software and the minimum and maximum errors of the maximum displacement generated during the oscillation stage of the rice-canopy-opening process were 4.69% and 18.28%, respectively. The simulation results showed that the speed of the opening device did not affect the displacement during the contact stage, but changes in height substantially changed the maximum displacement of the rice stem during the contact stage. During the oscillation stage, the interaction between the height and speed of the canopy opener strongly impacted the maximum displacement. A critical velocity value was identified, which increased the total energy of the model but also intensified the interaction between the rice stem and leaves, resulting in a rapid decay in energy and a decrease in the rice stem displacement during the oscillation stage. The results of the spray test showed that the use of the canopy opener considerably improved the penetration of droplets, providing a feasible method for the prevention of rice pests and diseases in the mid-to-late stages of rice growth.

Author Contributions

Conceptualization, X.W.; Writing—original draft, L.J.; Writing—review & editing, Q.S. and F.W. All authors contributed to the writing and editing of the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Key and General Projects in Jiangsu Province (BE2020327), National Natural Science Foundation of China (51575244), Jiangsu key R and D plan (BE2019318).

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to follow-up research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gong, Y.; Yu, L.; Zhang, X.; Wang, G.; Chen, W.; Chen, X. Application of Self-propelled Boom Sprayers for Control of Rice Insects and Diseases. Agric. Sci. Technol. 2016, 17, 1667. [Google Scholar]

- Xu, D.J.; Xu, G.C.; Xu, L.; Wang, C.B.; Hu, S.N.; Gu, Z.Y.; Baijing, Q.I. Effects of spray parameters on pesticide utilization efficiency and droplet deposition distribution in paddy field of self-propelled boom sprayer. Chin. J. Pestic. Sci. 2020, 22, 324–332. [Google Scholar]

- Gu, J.; Zhu, H.; Ding, W.; Wang, X. Characterization of air profiles impeded by plant canopies for a variable-rate air-assisted sprayer. Trans. ASABE 2014, 57, 1307–1315. [Google Scholar]

- Liu, X.; Liu, X.; Li, Y.; Yuan, J.; Li, H. Predicting spray deposit distribution within a cotton plant canopy based on canopy stratification porosity and Gaussian process models. Biosyst. Eng. 2021, 204, 1–14. [Google Scholar] [CrossRef]

- Skamnioti, P.; Gurr, S.J. Against the grain: Safeguarding rice from rice blast disease. Trends Biotechnol. 2009, 27, 141–150. [Google Scholar] [CrossRef]

- Heong, K.L.; Cheng, J.; Escalada, M.M. Rice Planthoppers; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Van De Zande, J.C.; Michielsen, J.M.; Stallinga, H.; Porskamp, H.A.; Holterman, H.J.; Huijsmans, J.F. Spray Distribution when Spraying Potatoes with a Conventional or an Air-Assisted Field Boom Sprayer (p. 1). In Proceedings of the 2002 ASAE Annual Meeting, Chicago, IL, USA, 28 July–31 July 2002; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2002. [Google Scholar]

- Sumner, H.R.; Herzog, G.A. Assessing the effectiveness of air-assisted and hydraulic sprayers in cotton via leaf bioassay. J. Cotton Sci. 2000, 4, 79–83. [Google Scholar]

- Ade, G.; Rondelli, V. Performance of an air-assisted boom sprayer in the control of Colorado beetle infestation in potato crops. Biosyst. Eng. 2007, 97, 181–187. [Google Scholar] [CrossRef]

- Zhu, H.; Brazee, R.D.; Fox, R.D.; Derksen, R.C.; Ozkan, H.E. Development of a canopy opener to improve spray deposition and coverage inside soybean canopies: Part 1. Mathematical models to assist opener development. Trans. ASABE 2008, 51, 1905–1912. [Google Scholar] [CrossRef]

- Wang, C.; He, X.; Liu, Y.; Song, J.; Zeng, A. The small single-and multi-rotor unmanned aircraft vehicles chemical application techniques and control for rice fields in China. Asp. Appl. Biol. 2016, 132, 73–81. [Google Scholar]

- Wu, S.; Wei, X. Mechanical interaction between a canopy opener and rice stalks based on the transient dynamic analysis. Biosyst. Eng. 2019, 178, 256–263. [Google Scholar] [CrossRef]

- Prado, E.P.; Dal Pogetto, M.H.F.D.; De Cerqueira, D.T.; Raetano, C.G.; Costa, S.Í.D.A. Construction and practical application of a canopy opener device. Eng. Agric. 2016, 36, 1126–1135. [Google Scholar] [CrossRef][Green Version]

- Wang, S.L.; Li, X.; Lei, X.H.; Gu, Y.; Herbst, A.; Bonds, J.; Lv, X.L. Influences of canopy-pushing plate on droplet drift and deposition characteristics of boom sprayer. Plant Prot. 2021, 47, 68–73. [Google Scholar]

- Womac, A.R.; Ozkan, E.; Zhu, H.; Kochendorfer, J.; Jeon, H. Status of spray penetration and deposition in dense fieldcrop canopies. J. ASABE 2022, 65, 1107–1117. [Google Scholar] [CrossRef]

- Zhu, H.; Derksen, R.C.; Ozkan, H.E.; Reding, M.E.; Krause, C.R. Development of a canopy opener to improve spray deposition and coverage inside soybean canopies: Part 2: Opener design with field experiments. Trans. ASABE 2008, 51, 1913–1922. [Google Scholar] [CrossRef]

- Acharya, P.; Burgers, T.; Nguyen, K.D. Ai-enabled droplet detection and tracking for agricultural spraying systems. Comput. Electron. Agric. 2022, 202, 107325. [Google Scholar] [CrossRef]

- Acharya, P.; Burgers, T.; Nguyen, K.D. A deep-learning framework for spray pattern segmentation and estimation in agricultural spraying systems. Sci. Rep. 2023, 13, 7545. [Google Scholar] [CrossRef] [PubMed]

- Wakabayashi, N.; Ona, M.; Suzuki, T.; Igarashi, Y. Nonlinear finite element analyses: Advances and challenges in dental applications. J. Dent. 2008, 36, 463–471. [Google Scholar] [CrossRef]

- Lee, H.H. Finite Element Simulations with ANSYS Workbench 18; SDC Publications: Mission, KS, USA, 2018. [Google Scholar]

- Wu, S.R.; Gu, L. Introduction to the Explicit Finite Element Method for Nonlinear Transient Dynamics; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- ANSYS. Release Notes: Explicit Dynamics Analysis; ANSYS Documentation; ANSYS: Canonsburg, PA, USA, 2015. [Google Scholar]

- Celik, H.K. Determination of bruise susceptibility of pears (Ankara variety) to impact load by means of FEM-based explicit dynamics simulation. Postharvest Biol. Technol. 2017, 128, 83–97. [Google Scholar] [CrossRef]

- Liu, W.C.; Liu, Z.D.; Huang, C.; Lu, M.H.; Liu, J.; Yang, Q.P. Statistics and analysis of crop yield losses caused by main diseases and insect pests in recent 10 years. Plant Prot. 2016, 42, 1–9. [Google Scholar]

- Mohsenin, N.N. Physical Properties of Plant and Animal Materials: Structure, Physical Characteristics, and Mechanical Properties; Department of Agricultural Engineering, Pennsylvania State University: State College, PA, USA, 1986. [Google Scholar]

- Crook, M.J.; Ennos, A.R. Stem and root characteristics associated with lodging resistance in four winter wheat cultivars. J. Agric. Sci. 1994, 123, 167–174. [Google Scholar] [CrossRef]

- Wang, Z.; Xie, W.; Wang, Z.; Cao, Y. Strain method for synchronous dynamic measurement of elastic, shear modulus and Poisson’s ratio of wood and wood composites. Constr. Build. Mater. 2018, 182, 608–619. [Google Scholar] [CrossRef]

- Hernández, L.F.; Bellés, P.M. A 3-D finite element analysis of the sunflower (Helianthus annuus L.) fruit. Biomechanical approach for the improvement of its hullability. J. Food Eng. 2007, 78, 861–869. [Google Scholar] [CrossRef]

- Yousefi, S.; Farsi, H.; Kheiralipour, K. Drop test of pear fruit: Experimental measurement and finite element modelling. Biosyst. Eng. 2016, 147, 17–25. [Google Scholar] [CrossRef]

- Zhu, H.; Salyani, M.; Fox, R.D. A portable scanning system for evaluation of spray deposit distribution. Comput. Electron. Agric. 2011, 76, 38–43. [Google Scholar] [CrossRef]

- Cunha, M.; Carvalho, C.; Marcal, A.R.S. Assessing the ability of image processing software to analyse spray quality on water-sensitive papers used as artificial targets. Biosyst. Eng. 2012, 111, 11–23. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).