Anti-Drift Technology Progress of Plant Protection Applied to Orchards: A Review

Abstract

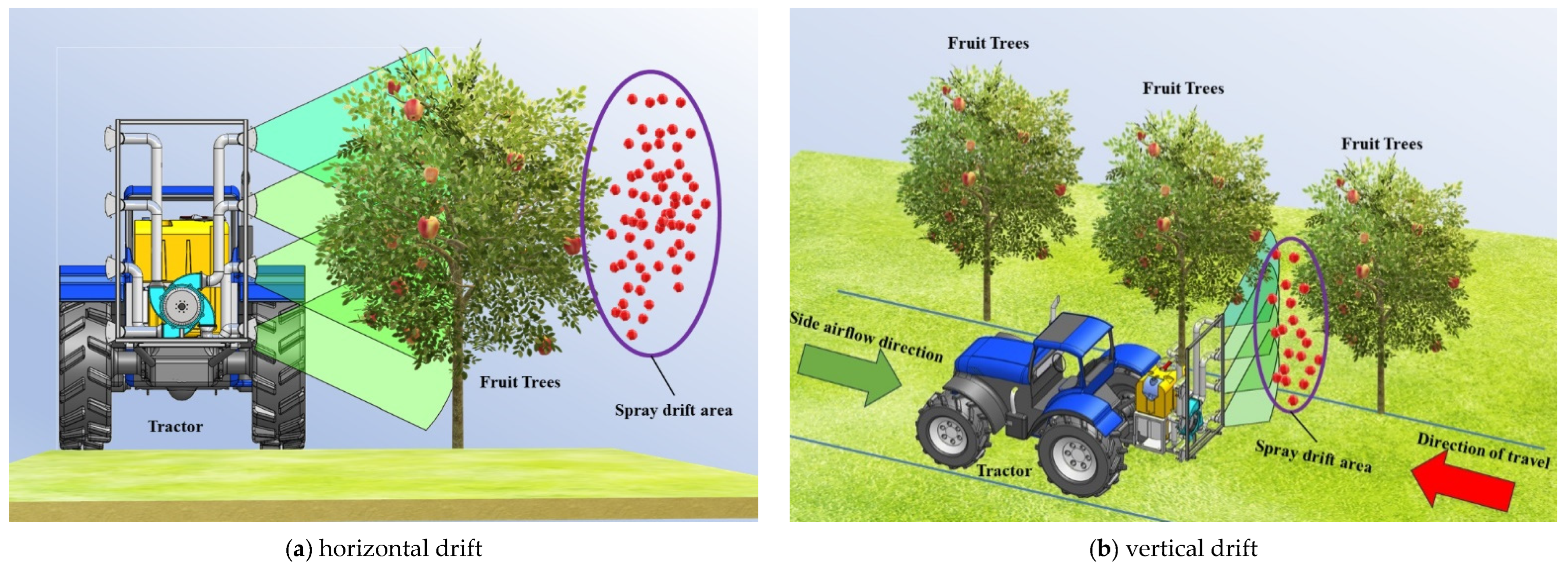

:1. Introduction

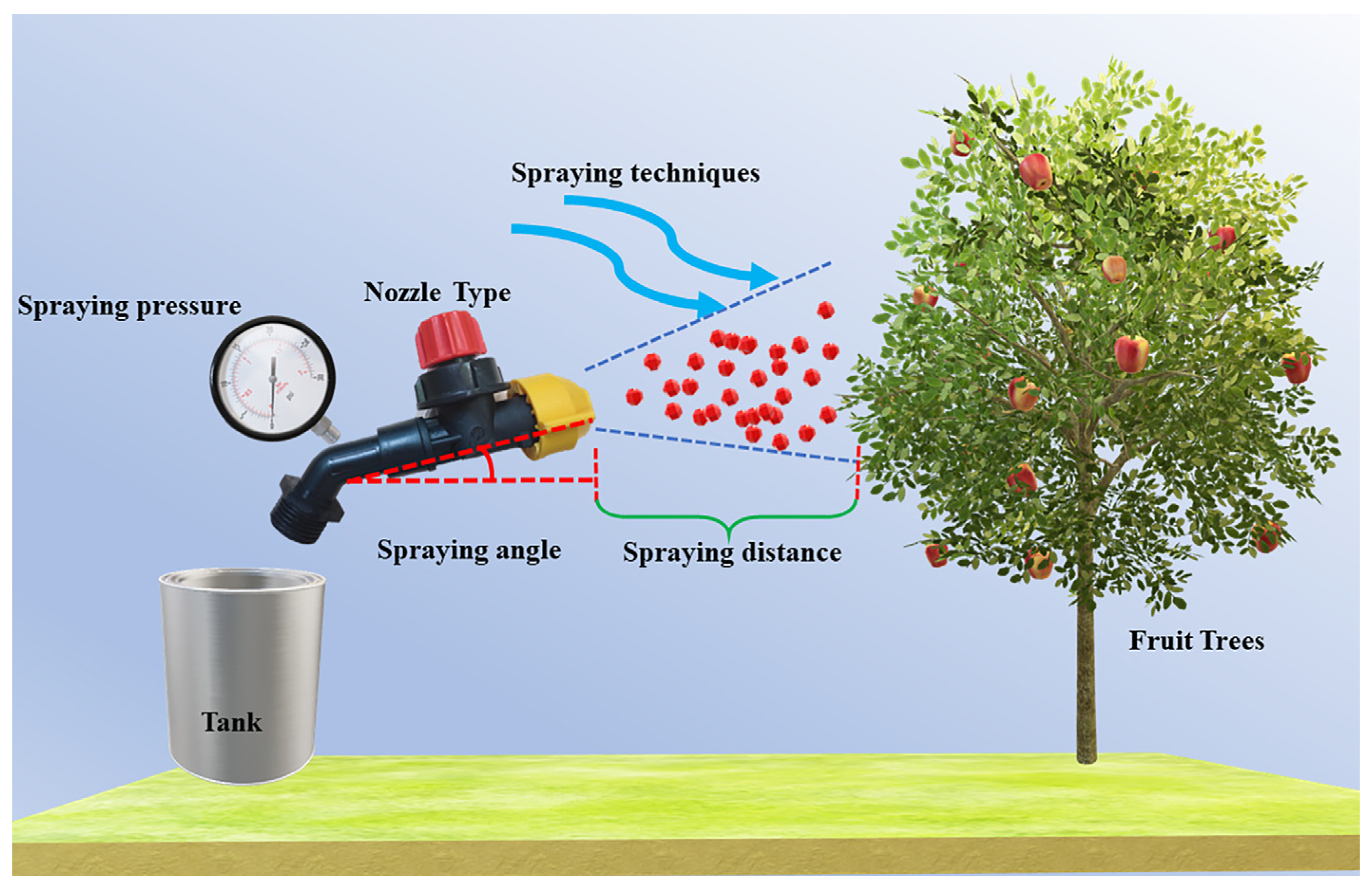

2. Progress of Research on Anti-Drift Nozzle Research

3. Progress of Research on Anti-Drift Technology of Plant Protection Machinery

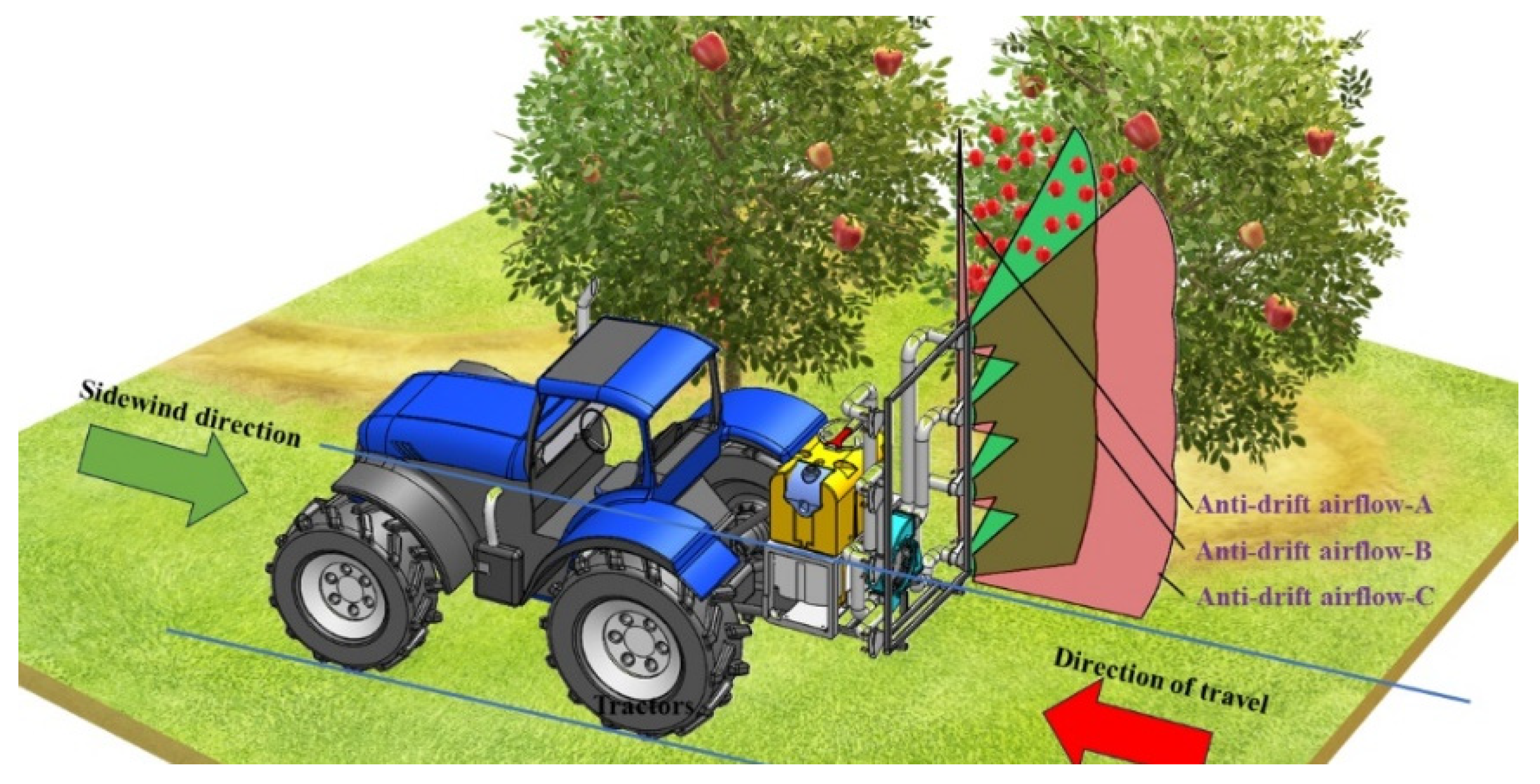

3.1. Air-Assisted Spraying Technology

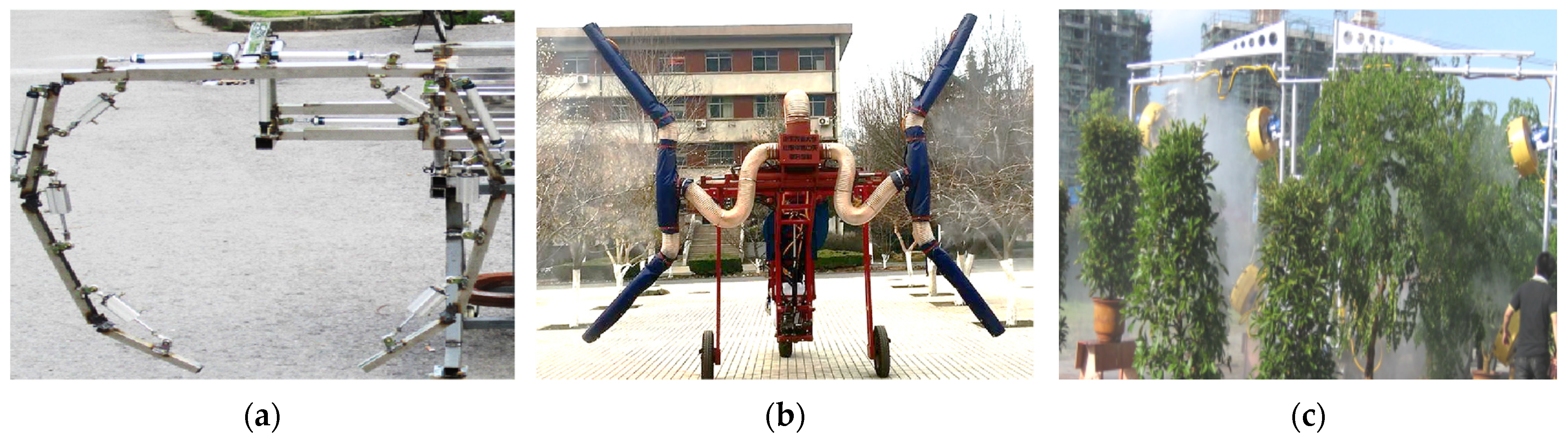

3.2. Recycling Spraying Technology

3.3. Profiling Spraying Technology

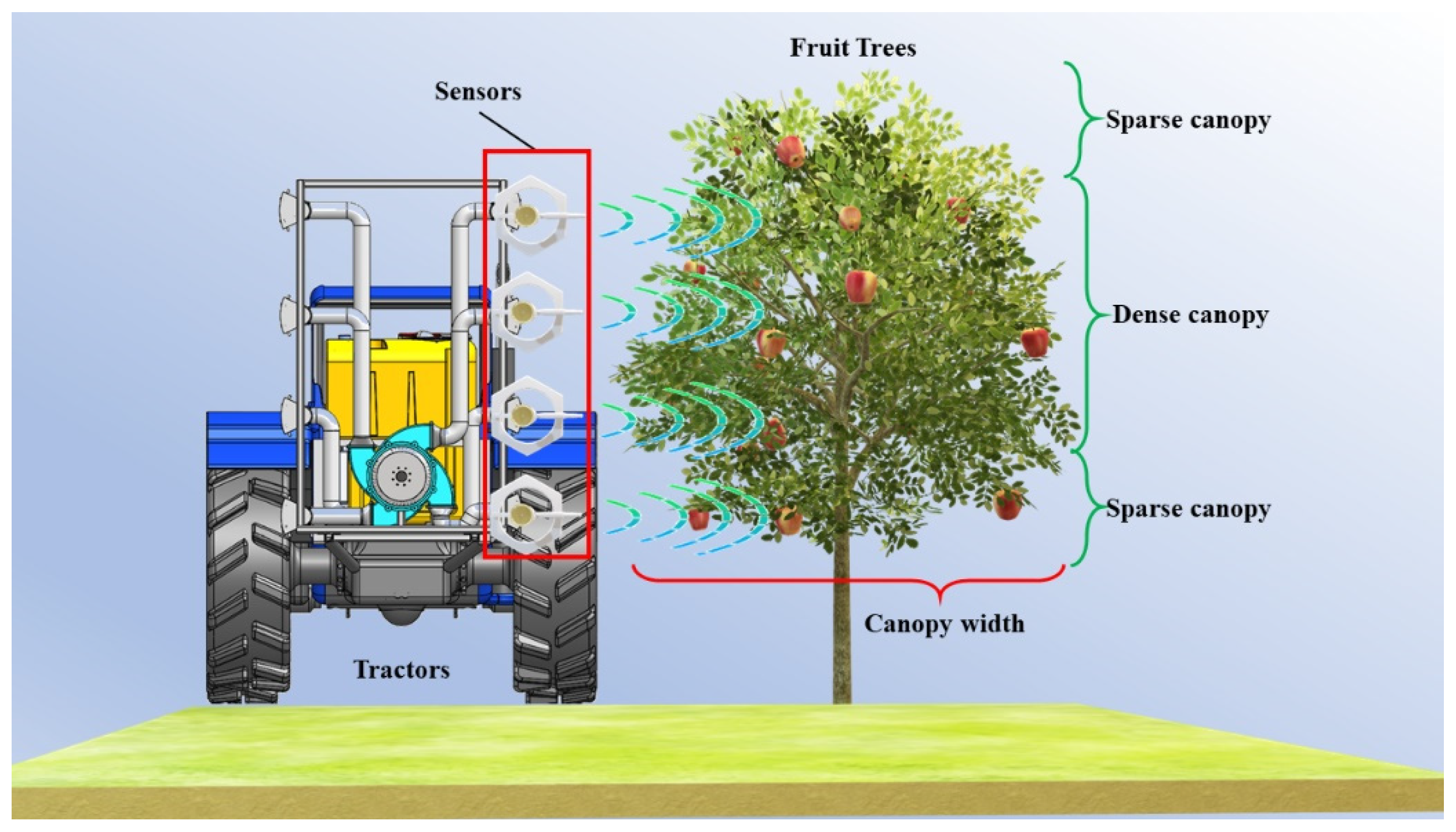

3.4. Target Variable Spraying Technology

3.5. Plant Protection UAVs

4. Summary and Future Scope

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, X.K. Research Progress on plant protection machinery and application technology in China. J. Pestic. Sci. 2019, 21, 921–930. [Google Scholar] [CrossRef]

- Liu, X.M.; Liu, X.H.; Cui, H.Y.; Yuan, J. Progress and prospects of crop canopy droplet deposition. J. Agric. Mach. 2021, 52, 1–20. [Google Scholar] [CrossRef]

- Palleja, T.; Landers, A.J. Electro-Leaf, A biomimicry system to estimate in-canopy airflow in fruit crops. Comput. Electron. Agric. 2016, 127, 606–614. [Google Scholar] [CrossRef]

- Tudi, M.; Daniel Ruan, H.; Wang, L.; Lyu, J.; Sadler, R.; Connell, D.; Chu, C.; Phung, D.T. Agricultural development, pesticide application and its impact on the environment. Int. J. Environ. Res. Public Health 2021, 18, 1112. [Google Scholar] [CrossRef]

- Privitera, S.; Manetto, G.; Pascuzzi, S.; Pessina, D.; Cerruto, E. Drop size measurement techniques for agricultural sprays: A state-of-the-art review. Agronomy 2023, 13, 678. [Google Scholar] [CrossRef]

- Damalas, C.A.; Eleftherohorinos, I.G. Pesticide exposure, safety issues, and risk assessment indicators. Int. J. Environ. Res. Public Health 2011, 8, 1402–1419. [Google Scholar] [CrossRef]

- Yarpuz-Bozdogan, N. The importance of personal protective equipment in pesticide applications in agriculture. Curr. Opin. Environ. Sci. Health 2018, 4, 1–4. [Google Scholar] [CrossRef]

- Hong, S.; Park, J.; Jeong, H.; Lee, S.; Choi, L.; Zhao, L.; Zhu, H. Fluid Dynamic approaches for prediction of spray drift from ground pesticide Applications: A Review. Agronomy 2021, 11, 1182. [Google Scholar] [CrossRef]

- Ru, Y.; Zhu, C.; Bao, R. Spray drift model of droplets and analysis of influencing factors based on wind tunnel. Trans. Chin. Soc. Agric. Mach. 2014, 45, 66–72. [Google Scholar]

- Wang, X.N.; Qi, P.; Yu, C.W.; He, X.K. Advances in the study of drift loss by atomization deposition of pesticide droplets. J. Pestic. Sci. 2022, 24, 1065–1079. [Google Scholar] [CrossRef]

- Pascuzzi, S. The Effects of the forward speed and air volume of an air-assisted sprayer on spray deposition in Tendone trained Vineyards. J. Agric. Eng. 2013, 44, 18. [Google Scholar] [CrossRef]

- Dai, S.; Ou, M.; Du, W.; Yang, X.; Dong, X.; Jiang, L.; Zhang, T.; Ding, S.; Jia, W. Effects of sprayer speed, spray distance, and nozzle arrangement angle on low-flow air-assisted spray deposition. Front. Plant Sci. 2023, 14, 1184244. [Google Scholar] [CrossRef] [PubMed]

- Lv, X.N.; Fu, X.M.; Song, J.L.; He, X.K. Influence of spraying technology parameters on droplet drift characteristics. J. Agric. Mach. 2011, 42, 59–63. [Google Scholar]

- Wang, J.; Liang, Q.; Zeng, T.; Zhang, X.; Fu, W.; Lan, Y. Drift potential characteristics of a flat fan nozzle: A numerical and experimental study. Appl. Sci. 2022, 12, 6092. [Google Scholar] [CrossRef]

- Zhai, C.Y.; Zhao, C.J.; Wang, N.; Long, J.; Wang, X.; Weckler, P.; Zhang, H. Research progress on precision control method of wind-fed spray in orchards. J. Agric. Eng. 2018, 34, 1–15. [Google Scholar]

- Zheng, J.J.; Xu, Y.L. Progress and prospects of research on environmentally friendly pesticide spraying machinery. J. Agric. Mach. 2021, 52, 1–16. [Google Scholar]

- Liang, Z.; Fan, G.Q.; Wang, G.M.; Ding, H.; Zhang, X.H. Modeling of wind-stressed droplet deposition distribution based on bimodal distribution. J. Agric. Mach. 2020, 51, 28–37. [Google Scholar]

- Mercier, T. Direct dermal and inhalation exposure of bystanders and residents during vine foliar application using sprayer equipment fitted with an anti-drift device: A comparison between measured exposure levels and existing exposure models. Anti-drift device: A comparison between measured exposure levels and existing exposure models. J. Consum. Prot. Food Saf. 2020, 15, 219–227. [Google Scholar]

- Fan, G.J.; Niu, C.Q.; Zhang, Z.M.; Wang, D.W.; Mao, W.H.; Jiang, H.H. Design and test of V-shaped anti-drift spraying device for orchards with multi-airflow synergy. J. Agric. Mach. 2022, 53, 138–147. [Google Scholar]

- Fan, G.; Wang, S.; Bai, P.; Wang, D.; Shi, W.; Niu, C. Research on droplets deposition characteristics of anti-drift spray device with multi-airflow synergy based on CFD Simulation. Appl. Sci. 2022, 12, 7082. [Google Scholar] [CrossRef]

- Zhang, J.; Song, J.L.; He, X.K.; Zeng, A.J.; Liu, Y.J. Anti-drift performance test of Π-type recirculating sprayer. J. Agric. Mach. 2012, 43, 37–39+125. [Google Scholar]

- Niu, M.M.; Fang, H.M.; Qiao, L.; Zhu, S.C.; Zhu, Z.B.; Peng, Q.J. Design and test of a tunnel-type recirculating sprayer for highland clearance. Chin. J. Agric. Mech. Chem. 2019, 40, 41–48. [Google Scholar] [CrossRef]

- Zhou, L.F.; Zhang, L.; Xue, X.Y.; Qin, W.C.; Chen, C.; Zhou, Q.Q. Experimental distribution of droplet deposition in orchard space in dual air-fed electrostatic spraying. Jiangsu Agric. Sci. 2019. [Google Scholar] [CrossRef]

- Osterman, A.; Godeša, T.; Hočevar, M.; Širok, B.; Stopar, M. Real-time positioning algorithm for variable-geometry air-assisted orchard sprayer. Comput. Electron. Agric. 2013, 98, 175–182. [Google Scholar] [CrossRef]

- Wei, Z.; Xue, X.; Salcedo, R.; Zhang, Z.; Gil, E.; Sun, Y.; Li, Q.; Shen, J.; He, Q.; Dou, Q.; et al. Key technologies for an orchard variable-rate sprayer: Current Status and Future Prospects. Agronomy 2022, 13, 59. [Google Scholar] [CrossRef]

- Liu, Q.; Shan, C.; Zhang, H.; Song, C.; Lan, Y. Evaluation of liquid atomization and spray drift reduction of hydraulic nozzles with four spray Adjuvant Solutions. Agriculture 2023, 13, 236. [Google Scholar] [CrossRef]

- McGinty, J.A.; Morgan, G.D.; Dotray, P.A.; Baumann, P.A. Herbicide formulation, spray nozzle design, and operating pressure affects the droplet size spectra of agricultural sprays. J. Exp. Agric. Int. 2019, 38, 1–7. [Google Scholar] [CrossRef]

- Zhang, F.J.; Feng, S.H.; Chen, L.P.; Zhang, R.R.; Li, L.L. A wind tunnel test study on the potential drift characteristics of same-size shaped nozzles. Agric. Mech. Res. 2021, 43, 157–164. [Google Scholar] [CrossRef]

- Li, X.P.; Zhang, R.R.; Tang, Q.; Li, L.L.; Ding, C.C.; Chen, L.P. Experimental study on the spatial distribution of spray nozzle atomizedss droplet size and velocity. Agric. Mech. Res. 2024, 46, 159–167. [Google Scholar] [CrossRef]

- Miranda-Fuentes, A.; Marucco, P.; González-Sánchez, E.J.; Gil, E.; Grella, M.; Balsari, P. Developing strategies to reduce spray drift in pneumatic spraying in Vineyards: Assessment of the parameters affecting droplet size in pneumatic spraying. Sci. Total Environ. 2018, 616–617, 805–815. [Google Scholar] [CrossRef]

- Nuyttens, D.; Baetens, K.; De Schampheleire, M.; Sonck, B. Effect of nozzle type, size and pressure on spray droplet characteristics. Biosyst. Eng. 2007, 97, 333–345. [Google Scholar] [CrossRef]

- Miranda-Fuentes, A.; Rodríguez-Lizana, A.; Cuenca, A.; González-Sánchez, E.J.; Blanco-Roldán, G.L.; Gil-Ribes, J.A. Improving plant protection product applications in traditional and intensive olive orchards through the development of new prototype air-assisted sprayers. Crop Prot. 2017, 94, 44–58. [Google Scholar] [CrossRef]

- Langkamp-Wedde, T.; Rautmann, D.; Von Hörsten, D.; Niemann, J.-U.; Wegener, J.K. Possibilities to reduce drift by 75 percent in biocidal applications of insecticides with cannon sprayers. Environ. Sci. Eur. 2023, 35, 23. [Google Scholar] [CrossRef]

- Li, C.; Zhang, X.H.; Jiang, J.H.; Hu, Y.Y. The development and test of vineyard riser air-delivered sprayer. J. Agric. Eng. 2013, 29, 71–78. [Google Scholar]

- Lu, X.; Campos, J.; Salas, B.; Fabregas, F.X.; Zhu, H.; Gil, E. Advanced spraying systems to improve pesticide saving and reduce spray drift for appleorchards. Precis. Agric. 2023, 24, 1526–1546. [Google Scholar] [CrossRef]

- Qiu, W.; Miao, J.J.; Li, X.L.; Li, H.; Lv, X.L.; Ding, W.M. Design and test of a multi-channel directional air-fed fogging device for orchards. J. Nanjing Agric. Univ. 2020, 43, 547–555. [Google Scholar]

- Li, J.P.; Bian, Y.L.; Yang, X.; Wang, P.F.; Li, X.H.; Xue, C.L. Optimization and test of operating parameters of multi-fan air sprayer in orchard. J. Jilin Univ. (Eng. Ed.) 2022, 52, 2474–2485. [Google Scholar] [CrossRef]

- Ranta, O.; Marian, O.; Muntean, M.V.; Molnar, A.; Ghețe, A.B.; Crișan, V.; Stănilă, S.; Rittner, T. Quality analysis of some spray parameters when performing treatments in vineyards in order to reduce environment pollution. Some spray parameters when performing treatments in vineyards in order to reduce environment pollution. Sustainability 2021, 13, 7780. [Google Scholar] [CrossRef]

- Delele, M.A.; Jaeken, P.; Debaer, C.; Baetens, K.; Endalew, A.M.; Ramon, H.; Nicolaï, B.M.; Verboven, P. CFD Prototyping of an air-assisted orchard sprayer aimed at drift reduction. Comput. Electron. Agric. 2007, 55, 16–27. [Google Scholar] [CrossRef]

- Delele, M.A.; De Moor, A.; Sonck, B.; Ramon, H.; Nicolaï, B.M.; Verboven, P. Modelling and validation of the air flow generated by a cross flow air Sprayer as Affected by Travel Speed and Fan Speed. Biosyst. Eng. 2005, 92, 165–174. [Google Scholar] [CrossRef]

- Balsari, P.; Grella, M.; Marucco, P.; Matta, F.; Miranda-Fuentes, A. Assessing the influence of air speed and liquid flow rate on the droplet size and homogeneity in pneumatic spraying: Air speed and liquid flow rate influence on droplets in pneumatic spraying. Pest Manag. Sci. 2019, 75, 366–379. [Google Scholar] [CrossRef] [PubMed]

- Zhou, R.Q.; Zhang, H.C.; Zhou, H.P.; Zheng, J.J.; Hu, H.C. Influence of interaction effects among spraying parameters on pesticide droplet drift. J. Irrig. Drain. Mach. Eng. 2019, 37, 612–617+638. [Google Scholar]

- Michael, C.; Gil, E.; Gallart, M.; Stavrinides, M.C. Influence of spray technology and application tate on leaf deposit and ground losses in mountain viticulture. Agriculture 2020, 10, 615. [Google Scholar] [CrossRef]

- Fox, R.D.; Derksen, R.C.; Zhu, H.; Brazee, R.D.; Svensson, S.A. A History of air-blast sprayer development and future prospects. Trans. ASABE 2008, 51, 405–410. [Google Scholar] [CrossRef]

- MUNCKHOF Manufactures Deflector-Type Air-Assisted Sprayers. [EB/OL]. Available online: https://www.agriexpo.cn/prod/munckhof/product-184798-82698.html (accessed on 2 October 2020).

- HARDI Manufactures Axial Air-Assisted Sprayer [EB/OL]. Available online: https://www.agriexpo.cn/prod/hardi/product-169215-13149.html (accessed on 2 October 2020).

- HARDI Manufactures Cannon Type Air-Assisted Sprayer [EB/OL]. Available online: https://hardi-international.com/sprayers/mistblowers/zenit-orchard/cannon#nav (accessed on 2 October 2020).

- ASIA TECH Manufactures Self-Propelled Air-Assisted Sprayer [EB/OL]. Available online: https://www.agriexpo.cn/prod/asia-technology-co-ltd/product-180444-55544.html (accessed on 2 October 2020).

- Gil, Y.; Sinfort, C.; Brunet, Y.; Polveche, V.; Bonicelli, B. Atmospheric loss of pesticides above an artificial vineyard during air-assisted spraying. Atmos. Environ. 2007, 41, 2945–2957. [Google Scholar] [CrossRef]

- Doruchowski, G.; Holownicki, R. Environmentally friendly spray techniques for tree crops. Crop Prot. 2000, 19, 617–622. [Google Scholar] [CrossRef]

- Song, J.L.; He, X.K.; Zhang, J.; Liu, Y.J.; Zeng, A.J. “Π” cycle sprayer design. J. Agric. Mach. 2012, 43, 31–36. [Google Scholar]

- Ade, G.; Molari, G.; Rondelli, V. Vineyard evaluation of a recycling tuunel sprayer. Trans. ASAE 2005, 48, 2105–2112. [Google Scholar] [CrossRef]

- Ade, G.; Molari, G.; Rondelli, V. Recycling tunnel sprayer for pesticide dose adjustment to the crop environment. Trans. ASABE 2007, 50, 409–413. [Google Scholar] [CrossRef]

- Jamar, L.; Mostade, O.; Huyghebaert, B.; Pigeon, O.; Lateur, M. Comparative performance of recycling tunnel and conventional sprayers using standard and drift-mitigating nozzles in dwarf apple orchards. Crop Prot. 2010, 29, 561–566. [Google Scholar] [CrossRef]

- Porras Soriano, A.; Porras-Soriano, M.L.; Porras Piedra, A.; Soriano Martín, M.L. Comparison of the pesticide coverage achieved in a trellised vineyard by a prototype tunnel sprayer, a hydraulic sprayer, an air-assisted sprayer and a pneumatic sprayer. Span. J. Agric. Res. 2005, 3, 175. [Google Scholar] [CrossRef]

- Pergher, G.; Zucchiatti, N. Influence of canopy development in the vineyard on spray deposition from a tunnel sprayer. J. Agric. Eng. 2018, 49, 164–173. [Google Scholar] [CrossRef]

- Qiu, W.; Sun, H.; Sun, Y.H.; Liao, Y.Y.; Zhou, L.F.; Wen, Z.J. Design and testing of a circular flow recirculating air sprayer for low orchards. J. Agric. Eng. 2021, 37, 18–25. [Google Scholar]

- Nestor Recycling Sprayer [EB/OL]. Available online: https://www.agriexpo.cn/prod/weremczuk-fmr-sp-z-o-o/product-170611-17417.html (accessed on 2 October 2020).

- Gong, S.J.; Song, J.L. Tunnel recycling Sprayer Development Study. Beijing Agric. 2007, 14, 55–58. [Google Scholar]

- Yu, B. Research on Multi-Joint Tree Profile Sprayer and Its Key Components; Nanjing Forestry University: Nanjing, China, 2014. [Google Scholar]

- Zhang, T. Development and Experimental Study of Three-in-One Multi-Function Sprayer; Shandong Agricultural University: Shandong, China, 2016. [Google Scholar]

- Zhou, L.F.; Fu, X.M.; Ding, W.M.; Ding, S.M.; Chen, J.; Chen, Z.J. Design and test of a combined disc-type orchard air sprayer. J. Agric. Eng. 2015, 31, 64–71. [Google Scholar]

- Li, L.L.; He, X.K.; Song, J.L.; Liu, Y.; Wang, Z.c.; Li, J.Y.; Jia, X.M.; Liu, Z.H. Comparison of the performance of profiling variable spraying and conventional wind spraying in orchards. Trans. Chin. Soc. Agric. Eng. 2017, 33, 56–63. [Google Scholar]

- Li, L.L.; He, X.K.; Song, J.L.; Wang, X.N.; Jia, X.M.; Liu, Z.H. Design and test of variable spray-based automatic profiling sprayer for orchards. J. Agric. Eng. 2017, 33, 70–76. [Google Scholar]

- Song, Y.; Sun, H.; Li, M.; Zhang, Q. Technology application of smart Spray in agriculture: A Review. Intell. Autom. Soft Comput. 2015, 21, 319–333. [Google Scholar] [CrossRef]

- Chen, Z.H.; Chen, J.Z.; Song, H.R.; Song, D.Z. Development and testing of a hanging flexible target spraying device for orchards. J. Agric. Eng. 2022, 38, 11–20. [Google Scholar]

- Wang, Y.X.; Kang, F.; Li, W.B. Current status and trend of precision target application technology for forest trees. Guangdong Agric. Sci. 2013, 40, 83–87. [Google Scholar] [CrossRef]

- Gu, C.; Wang, X.; Wang, X.; Yang, F.; Zhai, C. Research progress on variable-rate spraying technology in orchards. Appl. Eng. Agric. 2020, 36, 927–942. [Google Scholar] [CrossRef]

- Cross, J.V.; Walklate, P.J.; Murray, R.A.; Richardson, G.M. Spray Deposits and losses in different sized apple trees from an axial fan orchard sprayer: 2. Effects of spray quality. Crop Prot. 2001, 20, 333–343. [Google Scholar] [CrossRef]

- Koc, C.; Duran, H.; Gerdan Koc, D. Orchard sprayer design for precision pesticide application. Erwerbs-Obstbau 2023, 65, 1819–1828. [Google Scholar] [CrossRef]

- Salcedo, R.; Pons, P.; Llop, J.; Zaragoza, T.; Campos, J.; Ortega, P.; Gallart, M.; Gil, E. Dynamic evaluation of airflow stream generated by a reverse system of an axial fan sprayer using 3D-ultrasonic anemometers. Effect of canopy structure. Comput. Electron. Agric. 2019, 163, 104851. [Google Scholar] [CrossRef]

- Xu, L.Y.; Zhang, H.T.; Zhang, H.F.; Xu, Y.Y.; Xu, M.M.; Jiang, X.S. Development and test of automatic target spray control system for orchard sprayer Trans. Chin. Soc. Agric. Eng. 2014, 22, 1–9. [Google Scholar]

- Chen, Y.; Zhu, H.; Ozkan, H.E.; Derksen, R.C.; Krause, C.R. Spray drift and off-target loss reductions with a precision air-assisted sprayer. Trans. ASABE 2013, 56, 1273–1281. [Google Scholar]

- Chen, Y.; Ozkan, H.E.; Zhu, H.; Derksen, R.C.; Krause, C.R. Spray deposition inside tree canopies from a newly developed variable-rate air-assisted sprayer. Trans. ASABE 2013, 56, 1263–1272. [Google Scholar]

- Jichen, C.; Xiu, W.; Jian, S.; Songlin, W.; Shuo, Y.; Chunjiang, Z. Development of real-time laser-scanning system to detect tree canopy characteristics for variable-rate pesticide application. Int. J. Agric. Biol. Eng. 2017, 10, 155–163. [Google Scholar] [CrossRef]

- Xiongkui, H.; Aijun, Z.; Yajia, L.; Jianli, S. Precision orchard sprayer based on automatically infrared target detecting and electrostatic spraying techniques. Int. J. Agric. Biol. Eng. 2011, 4, 35–40. [Google Scholar]

- Gonzalez, R.; Pawlowski, A.; Rodriguez, C.; Guzman, J.L.; Sanchez-Hermosilla, J. Design and implementation of an automatic pressure-control system for a mobile sprayer for greenhouse applications. Span. J. Agric. Res. 2012, 10, 939–949. [Google Scholar] [CrossRef]

- Giles, D.K.; Delwiche, M.J.; Dodd, R.B. Sprayer Control by sensing orchard crop characteristics: Orchard architecture and spray liquid savings. J. Agric. Eng. Res. 1989, 43, 271–289. [Google Scholar] [CrossRef]

- Landers, A.J. Developments towards an automatic precision sprayer for fruit crop canopies. In Proceedings of the ASABE Annual International Meeting, Pittsburg, PA, USA, 20–23 June 2010; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2010; p. 1. [Google Scholar]

- Balsari, P.; Doruchowski, G.; Marucco, P.; Tamagnone, M.; Vande Zande, J.; Wenneker, M. A system for adjusting the spray application to the target characteristics. Agric. Eng. Int. CIGR J. 2008, 10. [Google Scholar]

- Bayat, A.; İtmeç, M.; Özlüoymak, Ö.B. Development and assessment of a novel servo-controlled spraying system for real time adjustment of the orientation angle of the nozzles of a boom sprayer. Pest Manag. Sci. 2023, 79, 4439–4450. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.W.; Zhao, L.; Zhu, H. CFD simulation of airflow inside tree canopies discharged from air-assisted sprayers. Comput. Electron. Agric. 2018, 149, 121–132. [Google Scholar] [CrossRef]

- Doruchowski, G.; Swiechowski, W.; Godyn, A.; Holownicki, R. Automatically controlled sprayer to implement spray drift reducing application strategies in orchards. J. Fruit Ornam. Plant Res 2011, 19, 175–182. [Google Scholar]

- Gu, C.; Zhai, C.; Wang, X.; Wang, S. CMPC: An innovative lidar-based method to estimate tree canopy meshing-profile volumes for orchard target-oriented spray. Sensors 2021, 21, 4252. [Google Scholar] [CrossRef]

- Gu, C.; Zou, W.; Wang, X.; Chen, L.; Zhai, C. Wind loss model for the thick canopies of orchard trees based on accurate variable spraying. Front. Plant Sci. 2022, 13, 1010540. [Google Scholar] [CrossRef]

- Li, Q.; Xue, Y. Total Leaf Area Estimation based on the total grid area measured using mobile laser scanning. Comput. Electron. Agric. 2023, 204, 107503. [Google Scholar] [CrossRef]

- Hołownicki, R.; Doruchowski, G.; Świechowski, W.; Godyń, A.; Konopacki, P.J. Variable air assistance system for orchard sprayers; concept, design and preliminary testing. Biosyst. Eng. 2017, 163, 134–149. [Google Scholar] [CrossRef]

- Dou, H.; Zhai, C.; Chen, L.; Wang, X.; Zou, W. Comparison of orchard target-oriented spraying systems using photoelectric or ultrasonic sensors. Agriculture 2021, 11, 753. [Google Scholar] [CrossRef]

- Gil, E.; Llorens, J.; Llop, J.; Fàbregas, X.; Escolà, A.; Rosell-Polo, J.R. Variable rate sprayer Part 2-Vineyard prototype: Design, implementation, and validation. Comput. Electron. Agric. 2013, 95, 136–150. [Google Scholar] [CrossRef]

- Yang, F.B.; Xue, X.T.; Zhang, L.; Sun, Z. Numerical simulation and experimental verification on downwash air flow of six-rotor agricultural unmanned aerial vehicle in hover. Int. J. Agric. Biol. Eng. 2017, 10, 41–53. [Google Scholar]

- Hou, C.J.; Tang, Y.; Luo, S.M.; Lin, J.T.; He, Y.; Zhuang, J.J.; Huang, W.F. Optimization of control parameters of droplet density in citrus trees using UAVs and the Taguchi method. Int. J. Agric. Biol. Eng. 2019, 12, 1–9. [Google Scholar] [CrossRef]

- Zhou, Q.Q.; Xue, X.Y.; Qin, W.C.; Chen, C.; Zhou, L.F. Optimization and test for structural parameters of UAV spraying rotary cup atomizer. Int. J. Agric. Biol. Eng. 2017, 10, 78–86. [Google Scholar]

- Kah, M.; Hofmann, T. Nanopesticide research: Current trends and future priorities. Environ. Int. 2014, 63, 224–235. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, N.; Rajput, V.D.; Mandzhieva, S.; Minkina, T.; Saharan, B.S.; Duhan, J.S. Advances in biopolymeric nanopesticides: A new eco-friendly/eco-protective perspective in precision agriculture. Nanomaterials 2022, 12, 3964. [Google Scholar] [CrossRef]

- Yan, S.; Gu, N.; Peng, M.; Jiang, Q.; Liu, E.; Li, Z.; Dong, M. A preparation method of nano-pesticide improves the selective toxicity toward natural enemies. Nanomaterials 2022, 12, 2419. [Google Scholar] [CrossRef]

- Hou, R.; Li, C.; Tan, Y.; Wang, Y.; Huang, S.; Zhao, C.; Zhang, Z. Eco-friendly O-carboxymethyl chitosan base chlorfenapyr nanopesticide for effective pest control and reduced toxicity to honey bees. Int. J. Biol. Macromol. 2023, 224, 972–983. [Google Scholar] [CrossRef]

- Wang, G.; Xu, X.; Cheng, Q.; Hu, J.; Xu, X.; Zhang, Y.; Su, C. Preparation of sustainable release mesoporous silica nano-pesticide for control of Monochamus alternatus. Sustain. Mater. Technol. 2023, 35, e00538. [Google Scholar] [CrossRef]

- Vasseghian, Y.; Arunkumar, P.; Joo, S.W.; Gnanasekaran, L.; Kamyab, H.; Rajendran, S.; Klemeš, J.J. Metal-organic framework-enabled pesticides are an emerging tool for sustainable cleaner production and environmental hazard reduction. J. Clean. Prod. 2022, 373, 133966. [Google Scholar] [CrossRef]

- Gao, Y.; Li, D.; Li, D.; Xu, P.; Mao, K.; Zhang, Y.; He, S. Efficacy of an adhesive nanopesticide on insect pests of rice in field trials. J. Asia-Pac. Entomol. 2020, 23, 1222–1227. [Google Scholar] [CrossRef]

- Guo, S.; Yao, W.; Xu, T.; Ma, H.; Sun, M.J.; Chen, C.L.; Lan, Y.B. Assessing the application of spot spray in Nanguo pear orchards: Effect of nozzle type, spray volume rate and adjuvant. Pest Manag. Sci. 2022, 78, 3564–3575. [Google Scholar] [CrossRef] [PubMed]

- Van Zyl, S.A.; Brink, J.-C.; Calitz, F.J.; Fourie, P.H. Effects of adjuvants on deposition efficiency of fenhexamid sprays applied to chardonnay grapevine foliage. Crop Prot. 2010, 29, 843–852. [Google Scholar] [CrossRef]

- İtmeç, M.; Bayat, A.; Bolat, A.; Toraman, M.C.; Soysal, A. Assessment of Spray Drift with Various Adjuvants in a Wind Tunnel. Agronomy 2022, 12, 2377. [Google Scholar] [CrossRef]

- Oliveira, R.B.D.; Antuniassi, U.R.; Mota, A.A.B.; Chechetto, R.G. Potential of Adjuvants to Reduce Drift in Agricultural Spraying. Eng. Agríc. 2013, 33, 986–992. [Google Scholar] [CrossRef]

- Hołownicki, R.; Doruchowski, G.; Świechowski, W.; Konopacki, P.; Godyń, A. Effect of Nozzle Type and Adjuvants on Spray Coverage on Apple Leaves. Agronomy 2021, 11, 1790. [Google Scholar] [CrossRef]

- Milanowski, M.; Subr, A.; Parafiniuk, S.; Różańska-Boczula, M. The Effect of Adjuvant Concentration on Changes of Spray Characteristics and Spraying Parameters for Selected Types of Nozzles. Agric. Eng. 2022, 26, 119–132. [Google Scholar] [CrossRef]

- Yang, W.; Jia, W.; Ou, M.; Zhong, W.; Jiang, L.; Wang, X. Effect of Physical Properties of an Emulsion Pesticide on the Atomisation Process and the Spatial Distribution of Droplet Size. Agriculture 2022, 12, 949. [Google Scholar] [CrossRef]

- He, Y.; Wu, J.J.; Fang, H.; Zheng, Q.S.; Xiao, S.F.; Cen, H.Y. Research on deposition effect of droplets based on plant protection unmanned aerial vehicle: A review. J. Zhejiang Univ. (Agric. Life Sci. Ed.) 2018, 44, 392–398+515. [Google Scholar]

- Zhang, J.; Zhang, C.; Chen, Q.; Zhou, H.P.; Yang, F.B.; Ru, Y. Effect of Ambient Wind Speed on Downwash Airflow and Droplet Deposition for Six-rotor UAV Trans. Chin. Soc. Agric. Mach. 2022, 53, 74–81. [Google Scholar]

- Chen, S.D.; Zhan, Y.L.; Lan, Y.B.; Yan, Y.B.; Xian, S.C.; Chen, W.R.; Chen, L.J. Influence of crosswind on droplet drift of flat-fan nozzle in aviation plant protection UAV J. South China Agric. Univ. 2021, 42, 89–98. [Google Scholar]

- Wang, J.; Lan, Y.B.; Yao, W.X.; Chen, P.C.; Lin, J.L.; Yan, Y.B. Effects of Working Height of Single-rotor Unmanned Aerial Vehicle on Drift and Droplets Deposition Distribution of Areca Tree. J. Fruit Trees 2016, 33, 34–42. [Google Scholar]

- Lv, M.; Xiao, S.P.; Tang, Y.; He, Y. Influence of UAV flight speed on droplet deposition characteristics with the application of infrared thermal imaging. Int. J. Agric. Biol. Eng. 2019, 12, 10–17. [Google Scholar] [CrossRef]

- Richardson, B.; Rolando, C.A.; Kimbe, O. Quantifying spray deposition from a UAV configured for spot spray applications to individual plants. Trans. ASABE 2020, 63, 1049–1058. [Google Scholar] [CrossRef]

- Liu, Y.; Li, L.L.; Liu, Y.J.; He, X.K.; Song, L.J.; Zeng, A.J.; Wang, Z.C. Assessment of spray deposition and losses in an apple orchard with an unmanned agricultural aircraft system in China. Trans. ASABE 2020, 63, 619–627. [Google Scholar] [CrossRef]

- Wang, S.; Li, X.; Zeng, A.; Song, J.; Xu, T.; Lv, X.; He, X. Effects of adjuvants on spraying characteristics and control efficacy in unmanned aerial application. Agriculture 2022, 12, 138. [Google Scholar] [CrossRef]

- Cornelis, W.; Gabriels, D.; Spanoghe, P. Effects on pesticide spray drift of the physicochemical properties of the spray liquid. Precis. Agric. 2008, 10, 409–420. [Google Scholar]

- Fornasiero, D.; Mori, N.; Tirello, P.; Pozzebon, A.; Duso, C.; Tescari, E.; Bradascio, R.; Otto, S. Effect of spray drift reduction techniques on pests and predatory mites in orchards and vineyards. Crop Prot. 2017, 98, 283–292. [Google Scholar] [CrossRef]

- Kooij, S.; Sijs, R.; Denn, M.M.; Villermaux, E.; Bonn, D. What determines the drop size in sprays? Phys. Rev. X 2018, 8, 031019. [Google Scholar] [CrossRef]

- Chu, X. Experimental Study on the Spraying Performance of a Conical Airflow Assist Device; Heilongjiang Bayi Agricultural Reclamation University: Daqing, China, 2020. [Google Scholar]

- Liu, C.X.; Hu, J.; Chu, X.; Li, Y.F.; Sun, S.Y.; Zhang, W. Optimization of flow channel and anti-drift characteristics of conical wind-field type anti-drift spray device. J. Agric. Eng. 2021, 37, 11–20. [Google Scholar]

- Hu, J.; Liu, C.X.; Chu, X.; Li, Y.F.; Sun, S.Y.; Zhang, W. Characterization of droplet deposition in a conical wind-field-type anti-drift device. Trans. Chin. Soc. Agric. Eng. 2020, 51, 142–149+174. [Google Scholar]

- Appah, S.; Wang, P.; Ou, M.; Gong, C.; Jia, W. Review of electrostatic system parameters, charged droplets characteristics and substrate impact behavior from pesticides spraying. Int. J. Agric. Biol. Eng. 2019, 12, 1–9. [Google Scholar] [CrossRef]

- Patel, M.K. Technological improvements in electrostatic spraying and its impact to agriculture during the last decade and future research perspectives—A review. Eng. Agric. Environ. Food 2016, 9, 92–100. [Google Scholar] [CrossRef]

- Gan, Y.H.; Zheng, X.H.; Jiang, Z.W.; Luo, Y.L.; Zhou, Y. Effect of ring electrode structure on spray pattern and charging effect. J. Agric. Mach. 2019, 50, 387–393. [Google Scholar]

- He, Y.; Zhao, B.; Yu, Y. Effect, Comparison and analysis of pesticide electrostatic spraying and traditional spraying. Bulg. Chem. Commun. 2016, 48, 340–344. [Google Scholar]

- Salcedo, R.; Sánchez, E.; Zhu, H.; Fàbregas, X.; García-Ruiz, F.; Gil, E. Evaluation of an electrostatic spray charge system implemented in three conventional orchard sprayers used on a commercial apple trees plantation. Crop Prot. 2023, 167, 106212. [Google Scholar] [CrossRef]

| Nozzle Type | Branding | Model Number | Specificities | Related Research |

|---|---|---|---|---|

| Anti-drift nozzle | TeeJet (Wheaton, Illinois, United States) | AIXR11003 | Large droplet size, good anti-drift effect | Liu [26] McGinty [27] Zhang [28] |

| Anti-drift nozzle | Lechler(Metzingen, Germany) | DG11003 | Small droplet size, general anti-drift effect | McGinty [27] |

| Micro-drift nozzle | Hardi (Denmark) | MD 11003 | Large droplet size, good anti-drift effect | Zhang [28] |

| Anti-drift nozzle | Lechler(Metzingen, Germany) | AD12003 | Medium droplet size, good anti-drift effect | Li [29] |

| Hollow cone nozzle | TeeJet (Wheaton, Illinois, United States) | TXVK-4 | Very small droplet size, poor anti-drift effect | Liu [26] |

| Detection Technology | Measuring Principle | Specificities |

|---|---|---|

| Ultrasonic sensing method [71] | Judge the existence and position of the target according to the ultrasonic propagation speed and the round-trip flight time between the launching point and the launching target, and then calculate the spraying distance. | Measurement accuracy of 10 mm and cost effective, but the response time is longer, achieving a distance of not less than 30 cm [72]. |

| Laser sensing method [73] | Judge the existence and position of the target by laser irradiation or scanning a measurement area, obtain the distance and relative angle between the target point and the sensor, and process and model these distance point cloud data to determine the position and shape of the target. | Measurement accuracy of 10 mm and recognition spacing of 2 cm can be used to obtain 3D images of the canopy, but the price is high and the working environment is more demanding [74]. It is not suitable for use in foggy or humid environments. |

| Machine vision method [75] | Use a binocular digital camera to obtain the image of the tree crown and the parameter information such as the volume of the tree crown through the image-processing algorithm. | Can be used to obtain 3D images of the canopy but has high ambient light requirements and is not suitable for measuring thicker canopies. |

| Infrared sensing method [76] | Use an infrared photoelectric detector to emit and receive reflected infrared rays to the crop, determine the target position, and then transmit signals to the control system to control the corresponding spray nozzle spraying operation. | Cost effective and fast response speed, but the detection distance is close and the ambient light requirements are high. |

| Control System | Principle | Effect |

|---|---|---|

| Spray volume control system [77] | Spray volume regulation through pressure flow regulation, variable nozzle flow regulation, PWM flow regulation, and other technologies. | Effective, flow detection error within 0.05 L/min range. |

| Airflow rate control system [73] | Adjusting the fan speed to change the spray air velocity, thus realizing the spray airflow rate adjustment. | Owing to the long response time and difficulty in controlling the airflow distribution of high-speed fans to adjust to changes in canopy structure, current research has mainly focused on changing the form of the airflow path to match the airflow distribution with a specific canopy. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Li, J.; Yu, S.; Wang, P.; Liu, H.; Yang, X. Anti-Drift Technology Progress of Plant Protection Applied to Orchards: A Review. Agronomy 2023, 13, 2679. https://doi.org/10.3390/agronomy13112679

Li S, Li J, Yu S, Wang P, Liu H, Yang X. Anti-Drift Technology Progress of Plant Protection Applied to Orchards: A Review. Agronomy. 2023; 13(11):2679. https://doi.org/10.3390/agronomy13112679

Chicago/Turabian StyleLi, Shaobo, Jianping Li, Shaomeng Yu, Pengfei Wang, Hongjie Liu, and Xin Yang. 2023. "Anti-Drift Technology Progress of Plant Protection Applied to Orchards: A Review" Agronomy 13, no. 11: 2679. https://doi.org/10.3390/agronomy13112679

APA StyleLi, S., Li, J., Yu, S., Wang, P., Liu, H., & Yang, X. (2023). Anti-Drift Technology Progress of Plant Protection Applied to Orchards: A Review. Agronomy, 13(11), 2679. https://doi.org/10.3390/agronomy13112679