Quantifying Nutrient and Economic Consequences of Residue Loss from Harvest Weed Seed Control

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Harvest Index of Soybean

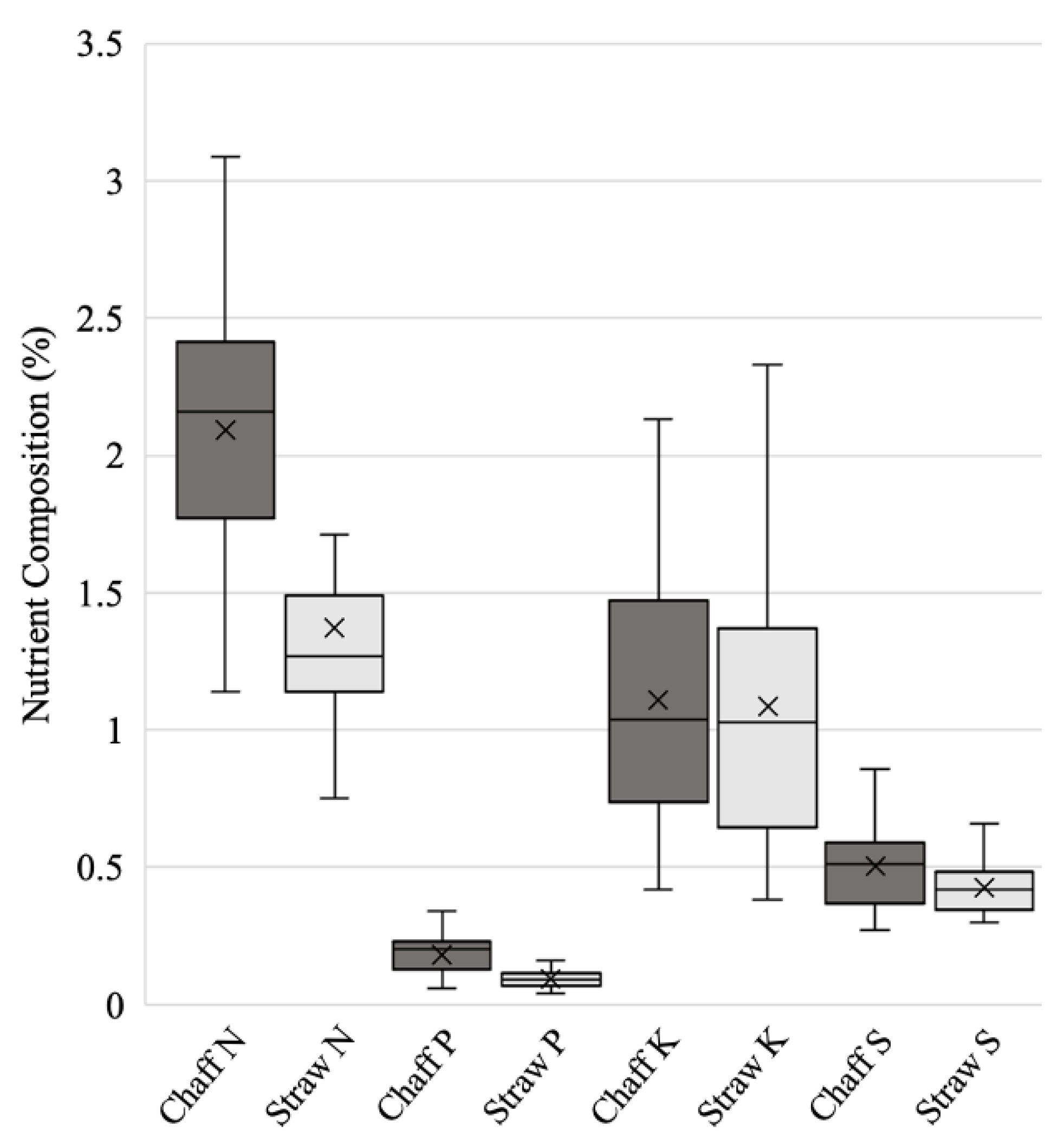

3.2. Nutrient Composition of Harvest Residues

3.3. Nutrient Cost of HWSC in Soybean Production

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Harker, K.N.; O’Donovan, J.T. Recent Weed Control, Weed Management, and Integrated Weed Management. Weed Technol. 2013, 27, 1–11. [Google Scholar] [CrossRef]

- Heap, I. Global Perspective of Herbicide-Resistant Weeds. Pest Manag. Sci. 2014, 70, 1306–1315. [Google Scholar] [CrossRef] [PubMed]

- Heap, I. The International Survey of Herbicide Resistant Weeds. Available online: http://www.weedscience.org/Home.aspx (accessed on 7 July 2022).

- Stubler, H.; Strek, H. Invited Plenary Presentation: Weed Control at the Crossroads—Which Innovations Are on the Horizon? In Proceedings of the 7th International Weed Science Congress, Prague, Czech Republic, 19–25 June 2016; pp. 8–12. [Google Scholar]

- Walsh, M.J.; Broster, J.C.; Schwartz-Lazaro, L.M.; Norsworthy, J.K.; Davis, A.S.; Tidemann, B.D.; Beckie, H.J.; Lyon, D.J.; Soni, N.; Neve, P.; et al. Opportunities and Challenges for Harvest Weed Seed Control in Global Cropping Systems. Pest Manag. Sci. 2018, 74, 2235–2245. [Google Scholar] [CrossRef]

- Duke, S.O. Perspectives on Transgenic, Herbicide-Resistant Crops in the United States Almost 20 Years after Production. Pest Manag. Sci. 2015, 71, 652–657. [Google Scholar] [CrossRef]

- Evans, J.A.; Tranel, P.J.; Hager, A.G.; Schutte, B.; Wu, C.; Chatham, L.A.; Davis, A.S. Managing the Evolution of Herbicide Resistance. Pest Manag. Sci. 2016, 72, 74–80. [Google Scholar] [CrossRef]

- Peterson, M.A.; Collavo, A.; Ovejero, R.; Shivrain, V.; Walsh, M.J. The Challenge of Herbicide Resistance around the World: A Current Summary. Pest Manag. Sci. 2018, 74, 2246–2259. [Google Scholar] [CrossRef]

- Sosnoskie, L.M.; Culpepper, A.S. Glyphosate-Resistant Palmer Amaranth (Amaranthus Palmeri) Increases Herbicide Use, Tillage, and Hand-Weeding in Georgia Cotton. Weed Sci. 2014, 62, 393–402. [Google Scholar] [CrossRef]

- Norsworthy, J.K.; Ward, S.M.; Shaw, D.R.; Llewellyn, R.S.; Nichols, R.L.; Webster, T.M.; Bradley, K.W.; Frisvold, G.; Powles, S.B.; Burgos, N.R.; et al. Reducing the Risks of Herbicide Resistance: Best Management Practices and Recommendations. Weed Sci. 2012, 60, 31–62. [Google Scholar] [CrossRef]

- Kumar, V.; Singh, S.; Chhokar, R.S.; Malik, R.K.; Brainard, D.C.; Ladha, J.K. Weed Management Strategies to Reduce Herbicide Use in Zero-till Rice–Wheat Cropping Systems of the Indo-Gangetic Plains. Weed Technol. 2013, 27, 241–254. [Google Scholar] [CrossRef]

- Walsh, M.; Ouzman, J.; Newman, P.; Powles, S.; Llewellyn, R. High Levels of Adoption Indicate That Harvest Weed Seed Control Is Now an Established Weed Control Practice in Australian Cropping. Weed Technol. 2017, 31, 341–347. [Google Scholar] [CrossRef]

- Shergill, L.S.; Schwartz-Lazaro, L.M.; Leon, R.; Ackroyd, V.J.; Flessner, M.L.; Bagavathiannan, M.; Everman, W.; Norsworthy, J.K.; VanGessel, M.J.; Mirsky, S.B. Current Outlook and Future Research Needs for Harvest Weed Seed Control in North American Cropping Systems. Pest Manag. Sci. 2020, 76, 3887–3895. [Google Scholar] [CrossRef] [PubMed]

- Glasner, C.; Vieregge, C.; Robert, J.; Fenselau, J.; Bitarafan, Z.; Andreasen, C. Evaluation of New Harvesting Methods to Reduce Weeds on Arable Fields and Collect a New Feedstock. Energies 2019, 12, 1688. [Google Scholar] [CrossRef]

- Walsh, M.; Newman, P.; Powles, S. Targeting Weed Seeds In-Crop: A New Weed Control Paradigm for Global Agriculture. Weed Technol. 2013, 27, 431–436. [Google Scholar] [CrossRef]

- Walsh, M.J.; Powles, S.B. Management Strategies for Herbicide-Resistant Weed Populations in Australian Dryland Crop Production Systems. Weed Technol. 2007, 21, 332–338. [Google Scholar] [CrossRef]

- Somerville, G.J.; Powles, S.B.; Walsh, M.J.; Renton, M. Modeling the Impact of Harvest Weed Seed Control on Herbicide-Resistance Evolution. Weed Sci. 2018, 66, 395–403. [Google Scholar] [CrossRef]

- Walsh, M.J.; Powles, S.B. High Seed Retention at Maturity of Annual Weeds Infesting Crop Fields Highlights the Potential for Harvest Weed Seed Control. Weed Technol. 2014, 28, 486–493. [Google Scholar] [CrossRef]

- Flessner, M.L.; Mirsky, S.B.; Schwartz-Lazaro, L.M.; Bagavathiannan, M.V.; VanGessel, M.J.; Shergill, L.S.; Ackroyd, V.J.; Rubione, C.G. From Spreader to Predator: Killing Weed Seeds with the Combine. Crop. Soils 2021, 54, 40–45. [Google Scholar] [CrossRef]

- Walsh, M. Development of Harvest Weed Seed Control (HWSC) in Australian Cropping Systems. Outlooks Pest Manag. 2018, 29, 114–119. [Google Scholar] [CrossRef]

- Lyon, D.J.; Walsh, M.J.; Barroso, J.; Campbell, J.M.; Hulting, A.G. Harvest Weed Seed Control: Applications for the PNW Wheat Production Systems; Washington State University Extension: Pullman, WA, USA, 2019. [Google Scholar]

- Aase, J.K.; Siddoway, F.H. Spring Wheat Yield Estimates from Spectral Reflectance Measurements. IEEE Trans. Geosci. Remote Sens. 1981, GE-19, 78–84. [Google Scholar] [CrossRef]

- Stumborg, M.; Townley-Smith, L. Agriculture Biomass Resources in Canada. In Proceedings of the American Society of Agricultural and Biological Engineers Annual Meeting, ASABE, Ottawa, ON, Canada, 1–4 August 2004. [Google Scholar]

- Suardi, A.; Stefanoni, W.; Alfano, V.; Bergonzoli, S.; Pari, L. Equipping a Combine Harvester with Turbine Technology Increases the Recovery of Residual Biomass from Cereal Crops via the Collection of Chaff. Energies 2020, 13, 1572. [Google Scholar] [CrossRef] [Green Version]

- McCartney, D.H.; Block, H.C.; Dubeski, P.L.; Ohama, A.J. Review: The Composition and Availability of Straw and Chaff from Small Grain Cereals for Beef Cattle in Western Canada. Can. J. Anim. Sci. 2006, 86, 443–455. [Google Scholar] [CrossRef]

- Broster, J.; Rayner, A.; Ruttledge, A.; Walsh, M. Impact of Stripper Fronts and Chaff Lining on Harvest Weed Seed Control. In Proceedings of the 2018 West Wyalong GRDC Grains Research Update, West Wyalong, Australia, 25 July 2018; pp. 55–61. [Google Scholar]

- Broster, J.C.; Walsh, M.J. Nutrient Removal and Movement as a Result of Different HWSC Practices. In Proceedings of the 20th Agronomy Australia Conference, Toowoomba, Australia, 18–22 September 2022; pp. 3–6. [Google Scholar]

- Zhang, H.; Turner, N.C.; Poole, M.L. Increasing the Harvest Index of Wheat in the High Rainfall Zones of Southern Australia. Field Crops Res. 2012, 129, 111–123. [Google Scholar] [CrossRef]

- Kernan, J.A.; Coxworth, E.C.; Crowle, W.L.; Spurr, D.T. The Nutritional Value of Crop Residue Components from Several Wheat Cultivars Grown at Different Fertilizer Levels. Anim. Feed Sci. Technol. 1984, 11, 301–311. [Google Scholar] [CrossRef]

- Bergonzoli, S.; Suardi, A.; Rezaie, N.; Alfano, V.; Pari, L. An Innovative System for Maize Cob and Wheat Chaff Harvesting: Simultaneous Grain and Residues Collection. Energies 2020, 13, 1265. [Google Scholar] [CrossRef]

- Coronado, D.L.L.; Alejo, J. Wheat Plant Composition: Varietal Differences in Physical Composition, Chemical Composition and in Vitro Digestibility of Various Plant Parts. M.S. Thesis, The University of Arizona, Tucson, AZ, USA, 1979. [Google Scholar]

- Coxworth, E.; Kernan, J.; Knipfel, J.; Thorlacius, O.; Crowle, L. Crop Residues and Forages in Western Canada; Potential for Feed Use Either with or without Chemical or Physical Processing. Agric. Environ. 1981, 6, 245–256. [Google Scholar] [CrossRef]

- Ruttledge, A.; Widderick, M.; Walsh, M.; Broster, J.; Bell, K.; Rayner, A.; Jalaludin, A.; Cooray, O.; Heuke, L.; Robilliard, S.; et al. The Efficacy of Chaff Lining and Chaff Tramlining in Controlling Problem Weeds; GRDC: Barton, Australian, 2018. [Google Scholar]

- Stumborg, M.A.; Townley-Smith, L. Assessment of Cereal Chaff as a Biomass Resource for Ethanol and Other Uses. In Proceedings of the Ethanol Research and Development Workshop, Natural Resources Canada Green Plan Program, Ottawa, ON, Canada, 17–18 March 1997; pp. 9–15. [Google Scholar]

- Stumborg, M.; Townley-Smith, L.; Coxworth, E. Sustainability and Economic Issues for Cereal Crop Residue Export. Can. J. Plant Sci. 1996, 76, 669–673. [Google Scholar] [CrossRef]

- Broster, J.C.; Walsh, M.J.; Chambers, A.J. Harvest Weed Seed Control: The Influence of Harvester Set up and Speed on Efficacy in South-Eastern Australia Wheat Crops; Narromine GRDC Grains Research Update; GRDC: Narromine, Australian, 2016; pp. 26–45. [Google Scholar]

- White, L.M.; Bergman, J.W. Chaff Feed Quality of Winter Wheat, Spring Wheat, Barley, and Oat Cultivars. Agronomy 1985, 77, 269–274. [Google Scholar] [CrossRef]

- Schapaugh, W.T.; Wilcox, J.R. Relationships between Harvest Indices and Other Plant Characteristics in Soybean. Crop Sci. 1980, 20, 529–533. [Google Scholar] [CrossRef]

- Spaeth, S.C.; Randall, H.C.; Sinclair, T.R.; Vendeland, J.S. Stability of Soybean Harvest Index. Agron. J. 1984, 76, 482–486. [Google Scholar] [CrossRef]

- Green, J.K.; Norsworthy, J.K.; Walsh, M.J. Distribution of Common Cocklebur and Palmer Amaranth Seed Exiting the Combine for Harvest Weed Seed Control in Soybean. Crop Forage Turfgrass Manag. 2020, 6, 1–6. [Google Scholar] [CrossRef]

- Schwartz-Lazaro, L.M.; Norsworthy, J.K.; Walsh, M.J.; Bagavathiannan, M.V. Efficacy of the Integrated Harrington Seed Destructor on Weeds of Soybean and Rice Production Systems in the Southern United States. Crop Sci. 2017, 57, 2812–2818. [Google Scholar] [CrossRef]

- Scagnozzi, A.; Saviozzi, A.; Levi-Minzi, R.; Riffaldi, R. Nutrient Release from Decomposing Crop Residues in Soil: A Laboratory Experiment. Am. J. Altern. Agric. 1997, 12, 10–13. [Google Scholar] [CrossRef]

- Isaac, R.A.; Johnson, W.C. Elemental Analysis of Plant Tissue by Plasma Emission Spectroscopy: Collaborative Study. J. Assoc. Off. Anal. Chem. 1985, 3, 499–505. [Google Scholar] [CrossRef]

- Quinn, R. DTN Retail Fertilizer Trends; AgFax: Burnsville, MN, USA, 2022. [Google Scholar]

- North Carolina Production Cost Report (Weekly) (RA_GR210); United States Department of Agriculture: Raleigh, NC, USA, 2021.

- Schultz, J.E.; French, R.J. Mineral Content of Herbage and Grain of Halberd Wheat in South Australia. Aust. J. Exp. Agric. 1976, 16, 887–892. [Google Scholar] [CrossRef]

- Hocking, P.J. Dry-Matter Production, Mineral Nutrient Concentrations, and Nutrient Distribution and Redistribution in Irrigated Spring Wheat. J. Plant Nutr. 1994, 17, 1289–1308. [Google Scholar] [CrossRef]

- Burnside, O.; Wilson, R.; Wicks, G.; Roeth, F.; Moomaw, R. Weed Seed Decline and Buildup in Soils under Various Corn Management Systems across Nebraska. Agron. J. 1986, 78, 451–454. [Google Scholar] [CrossRef]

- Korres, N.E. Agronomic Weed Control: A Trustworthy Approach for Sustainable Weed Management. Non-Chem. Weed Control 2018, 97–114. [Google Scholar] [CrossRef]

- Manson, J. Harvest Weed Seed Control for the Southern High Rainfall Zone; Grains Research and Development Corporation: Barton, Australian, 2019. [Google Scholar]

- Newman, P. Tools and Tips Setting Up for Chaff Lining; Grains Research and Development Corporation: Barton, Australian, 2019. [Google Scholar]

- Orson, J.H. The Cost to the Farmer of Herbicide Resistance. Weed Technol. 1999, 13, 607–611. [Google Scholar] [CrossRef]

- Llewellyn, R.; Ronning, D.; Ouzman, J.; Walker, S.; Mayfield, A.; Clarke, M. Impact of Weeds on Australian Grain Production: The Cost of Weeds to Australian Grain Growers and the Adoption of Weed Management and Tillage Practices; CSIRO: Canberra, Australia, 2016. [Google Scholar]

- Vaiknoras, K. Costs and Returns Associated with Soybean Production, 2012–2020; 2021. Available online: https://www.ers.usda.gov/data-products/chart-gallery/gallery/chart-detail/?chartId=101716 (accessed on 20 August 2022).

- Flower, K.; Dang, Y.; Ward, P. Advances in Crop Residue Management. In Proceedings of the Australian Agriculture in 2020: From Conservation to Automation, Agronomy Australia and Charles Sturt University, Wagga Wagga, Australia, 27 August 2019; pp. 137–149. [Google Scholar]

- Kirkegaard, J.; Swan, T.; Hunt, J.; Vadakattu, G.; Kelly, J. The Effects of Stubble on Nitrogen Tie-up and Supply. In Proceedings of the Grains Research Update: Strategic Steps-Enduring Profit, Grains Research and Development Corporation, Corowa, Australia, 27 February 2018; pp. 57–65. [Google Scholar]

- Scott, B.J.; Eberbach, P.L.; Evans, J.; Wade, L.J. Stubble Retention in Cropping Systems in Southern Australia: Benefits and Challenges; Industry and Investment NSW: Wagga Wagga, Australia, 2010; p. 105.

- Riar, D.S.; Norsworthy, J.K.; Steckel, L.E.; Stephenson, D.O.; Eubank, T.W.; Scott, R.C. Assessment of Weed Management Practices and Problem Weeds in the Midsouth United States—Soybean: A Consultant’s Perspective. Weed Technol. 2013, 27, 612–622. [Google Scholar] [CrossRef]

| Chaff of Total | Straw of Total | Grain of Total | Chaff of Grain Yield | Location | Combine Type | Reference |

|---|---|---|---|---|---|---|

| ---------------- % ---------------- | ||||||

| 19 | 44 | 38 | 33 | Southern New South Wales, Australia | Combine type unspecified | [27] |

| 15 | 47 | 39 | 38 | Kojonup, Western Australia | Hand threshing | [28] |

| 12 | 38 | 50 | 24 | Saskatoon, Canada | Hand threshing | [29] |

| 9.6 | 46 | 44 | 22 | Revello, Northern Italy | Axial Flow (CASE IH 7088) | [30] |

| 33 | 67 | - | - | Northwest Mexico | Laboratory threshing unit | [31] |

| 22 | - | 78 | 28 | Pannecè, France | Hand threshing | [24] |

| 26–37 | 63–74 | - | Saskatoon, Canada | Hand threshing | [32] | |

| - | - | - | 30 | Narrabri and Toowoomba, Australia | - | [33] |

| - | - | - | 17 | Swift Current, Saskatchewan | Combine type unspecified | [34] |

| - | - | - | 25 | Swift Current, Saskatchewan | Rotary | [35] |

| 20–30 | 70–80 | - | New South Wales, Australia | - | [5,36] | |

| Soybean Fraction | Total Aboveground Biomass | Aboveground Biomass Excluding Seed | Relationship to Seed Yield |

|---|---|---|---|

| -------- % SE -------- | |||

| Chaff | 7.25 0.37 | 17.55 1.21 | 13.39 0.76 |

| Straw | 36.05 1.20 | 82.45 1.21 | 68.45 3.62 |

| Seed | 56.70 1.20 | ---------- | ---------- |

| Harvest Residue | Mg | Ca | B | Zn | Mn | Fe | Cu |

|---|---|---|---|---|---|---|---|

| ---------- % --------- | ------------------------------- ppm ------------------------------- | ||||||

| Chaff | 0.51 ± 0.02 | 1.19 ± 0.06 | 28.25 ± 1.04 | 30.36 ± 2.08 | 55.23 ± 3.77 | 236.43 ± 34.87 | 12.70 ± 1.10 |

| Straw | 0.42 ± 0.01 | 0.89 ± 0.03 | 24.53 ± 0.91 | 15.98 ± 1.50 | 29.14 ± 1.52 | 46.56 ± 2.79 | 12.75 ± 1.23 |

| Nutrient | Fertilizer—Price | Chaff Value | Straw Value |

|---|---|---|---|

| USD ton−1 | ----- USD ha−1 ----- | ||

| N | Urea—403.02 | 0.91 | 3.05 |

| P | MAP—528.37 | 0.18 | 0.47 |

| K | Potash—387.01 | 0.43 | 2.15 |

| S | Ammonium sulfate—414.69 | 0.06 | 0.21 |

| Total Value | 1.58 | 5.88 | |

| HWSC System | Chaff Outcome | Straw Outcome | Cost to Replace Nutrients |

|---|---|---|---|

| USD ha−1 | |||

| No_HWSC (conventional harvest) | Spread_evenly behind combine | Spread_evenly behind combine | 0 |

| Seed_Impact Mills | Spread_evenly behind combine | Spread_evenly behind combine | 0 |

| Narrow Windrow Burning | Concentrated + Burned | Concentrated + Burned | 7.46 |

| Bale Direct | Removed | Removed | 7.46 |

| Chaff Carts | Removed | Spread_evenly behind combine | 1.58 |

| Chaff Lining/Tramlining | Concentrated | Spread_evenly behind combine | 1.58 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spoth, M.P.; Schwartz-Lazaro, L.M.; LaBiche, G.L.; Thomason, W.E.; Bamber, K.W.; Flessner, M.L. Quantifying Nutrient and Economic Consequences of Residue Loss from Harvest Weed Seed Control. Agronomy 2022, 12, 2028. https://doi.org/10.3390/agronomy12092028

Spoth MP, Schwartz-Lazaro LM, LaBiche GL, Thomason WE, Bamber KW, Flessner ML. Quantifying Nutrient and Economic Consequences of Residue Loss from Harvest Weed Seed Control. Agronomy. 2022; 12(9):2028. https://doi.org/10.3390/agronomy12092028

Chicago/Turabian StyleSpoth, Matthew P., Lauren M. Schwartz-Lazaro, Gabrielle L. LaBiche, Wade E. Thomason, Kevin W. Bamber, and Michael L. Flessner. 2022. "Quantifying Nutrient and Economic Consequences of Residue Loss from Harvest Weed Seed Control" Agronomy 12, no. 9: 2028. https://doi.org/10.3390/agronomy12092028

APA StyleSpoth, M. P., Schwartz-Lazaro, L. M., LaBiche, G. L., Thomason, W. E., Bamber, K. W., & Flessner, M. L. (2022). Quantifying Nutrient and Economic Consequences of Residue Loss from Harvest Weed Seed Control. Agronomy, 12(9), 2028. https://doi.org/10.3390/agronomy12092028