Evaluation of Agricultural Residues as Organic Green Energy Source Based on Seabuckthorn, Blackberry, and Straw Blends

Abstract

:1. Introduction

2. Material and Methods

2.1. Sampling and Sample Preparation for Biomass and Finished Product Testing

2.2. Methodologies Used for Biomass Characterisation

| Parameters | Class | ||||||

|---|---|---|---|---|---|---|---|

| Unit | ENplusA1 | ENplusA2 | En-B | I1 | I2 | I3 | |

| For Commercial and Residential Applications | For Industrial Use | ||||||

| Moisture, M | % in mass, as received, wet basis | M10 ≤ 10 | M10 ≤ 10 | ||||

| Ash, Ad | % in mass dry | A0.7 ≤ 0.7 | A1.2 ≤ 1.2 | A2.0 ≤ 2.0 | A1.0 ≤ 1.0 | A1.5 ≤ 1.5 | A3.0 ≤ 3.0 |

| Net calorific value, q p, net, m = 10% | MJ/kg or kWh/kg, as received | ≥16.5 or ≥4.6 | ≥16.5 or ≥4.6 | ||||

| Mechanical durability, DU | % in mass as received | DU97.5 ≥ 97.5 (DU98.0 ≥ 98.0 for D06) | DU97.5 ≥ 97.5 | DU96.5 ≥ 96.5 | 97.5 ≤ DU ≤ 99.0 | 97.0 ≤ DU ≤ 99.0 | 96.5 ≤ DU ≤ 99.0 |

| Fines, F (<3.15 mm) | % in mass, as received | F1.0 ≤ 1.0 | F4.0 ≤ 4.0 | F5.0 ≤ 5.0 | F6.0 ≤ 6.0 | ||

| Bulk density, BD | kg/m3, as received | 600 ≤ BD ≤ 750 | BD600 ≥ 600 | ||||

- Determination of lignin content by the Klason–Komarov method using a 72% H2SO4 solution (ISO/DIS 21.436 Paste-determination of lignin content—acid hydrolysis method) (L, %);

- Detection of hemicellulose content by rapid acid hydrolysis method using 4% H2SO4 solution in one step at 121 °C for 1 h (HC, %); [9];

3. Results

3.1. Experimental Plan for Optimizing the Constitution of the Studied Blends and the Results Obtained

| Sample No. | Influencing Factors | Response Factors | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Coded Coordinates | Natural Coordinates, % | qp,net,d. | Qp,net,M = 10% | A | F | DU | BD, (kg/m3) | L | Ce | HC | ||||

| x1 | x2 | X1 | X2 | Straw | MJ/kg | (w-%) | % | |||||||

| 1 | −1 | 0 | 0 | 15 | 85 | 17.25 | 15.29 | 4.68 | 2.67 | 97.843 | 548.8 | 21.27 | 45.19 | 33.54 |

| 2 | −1 | 1 | 0 | 30 | 70 | 17.39 | 15.41 | 4.15 | 2.24 | 97.485 | 547.6 | 22.10 | 45.43 | 32.47 |

| 3 | 1 | 1 | 70 | 30 | 0 | 18.41 | 16.76 | 1.21 | 0.2 | 97.497 | 597.2 | 32.25 | 44.98 | 22.77 |

| 4 | −1 | −1 | 0 | 0 | 100 | 17.14 | 15.18 | 5.20 | 3.11 | 94.664 | 567.6 | 20.44 | 44.95 | 34.61 |

| 5 | 0 | 1 | 35 | 30 | 35 | 18.14 | 16.09 | 2.68 | 1.22 | 92.428 | 560 | 27.18 | 45.21 | 27.62 |

| 6 | 0 | 0 | 35 | 15 | 50 | 18.01 | 15.97 | 3.21 | 1.66 | 98.555 | 616.8 | 26.35 | 44.96 | 28.69 |

| 7 | 1 | 0 | 70 | 15 | 15 | 18.81 | 16.65 | 1.74 | 0.63 | 99.064 | 610 | 31.43 | 44.73 | 23.84 |

| 8 | 0 | −1 | 35 | 0 | 65 | 17.89 | 15.86 | 3.73 | 2.09 | 99.203 | 618.4 | 25.52 | 44.72 | 29.76 |

| 9 | 1 | −1 | 70 | 0 | 30 | 18.65 | 16.54 | 2.26 | 0.46 | 98.097 | 612 | 30.60 | 44.49 | 24.91 |

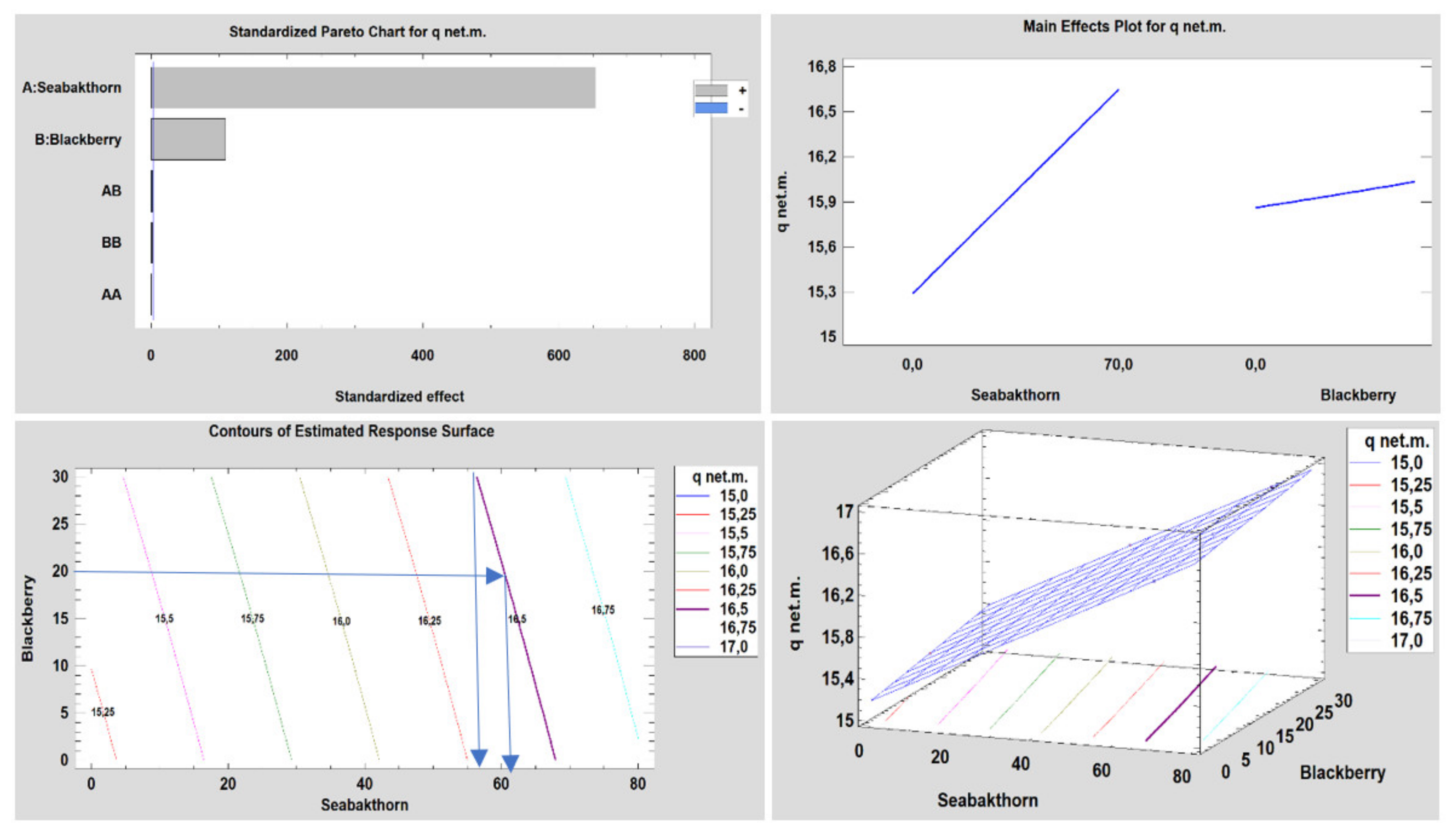

3.2. Results Regarding the Net Calorific Value at Humidity of 10% (qp,net,M = 10%) Depending on the Percentage of Raw Material Constituents (Seabuckthorn Biomass + Blackberry + Straw)

3.3. Dependence of the Ash Content on the Percentage of the Raw Material Constituents

3.4. Dependence of the Content of Fine Fraction according to the Percentage of the Constituents of the Raw Material

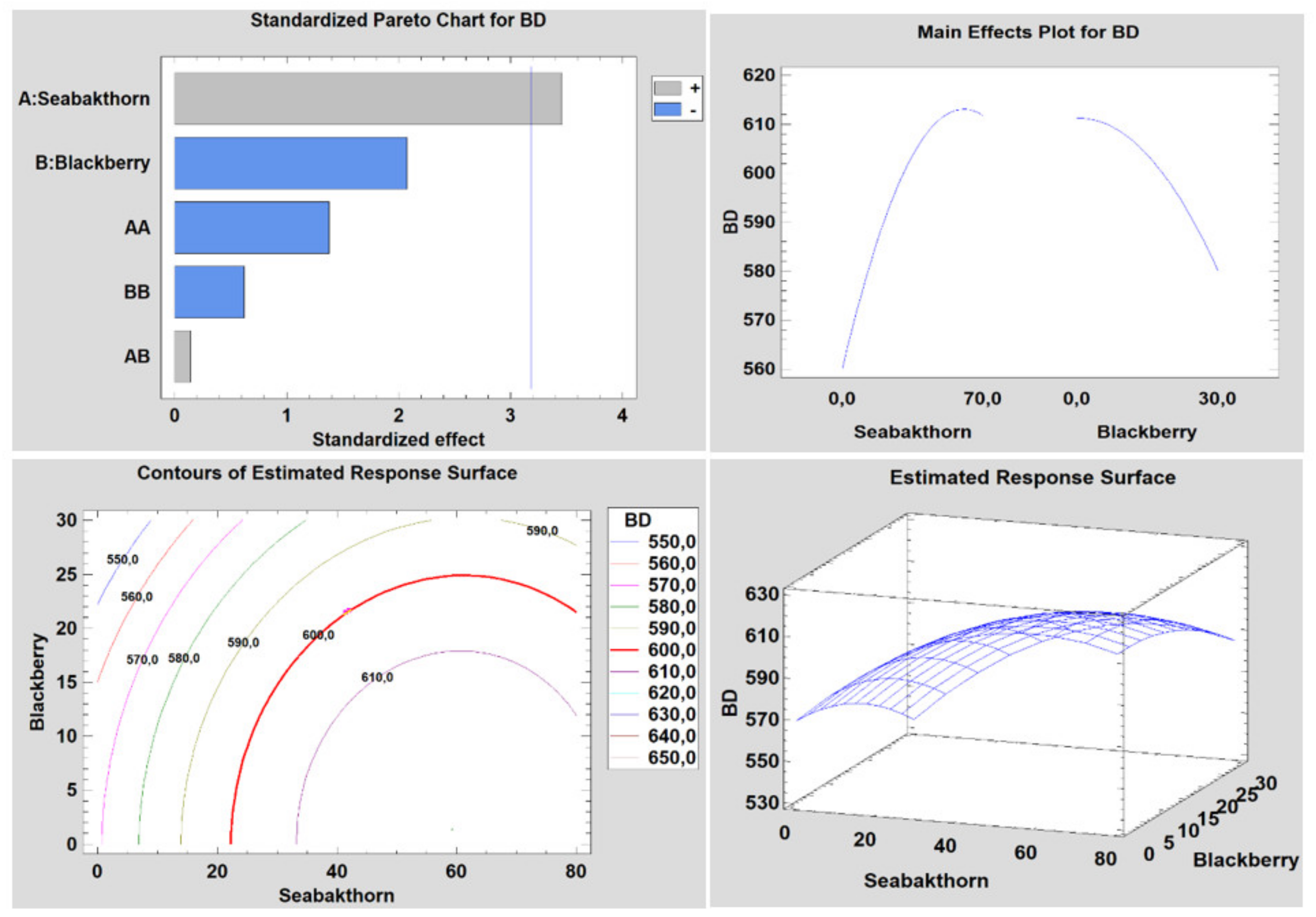

3.5. Dependence of the Bulk Density of the Pellets according to the Percentage of the Constituents of the Raw Material

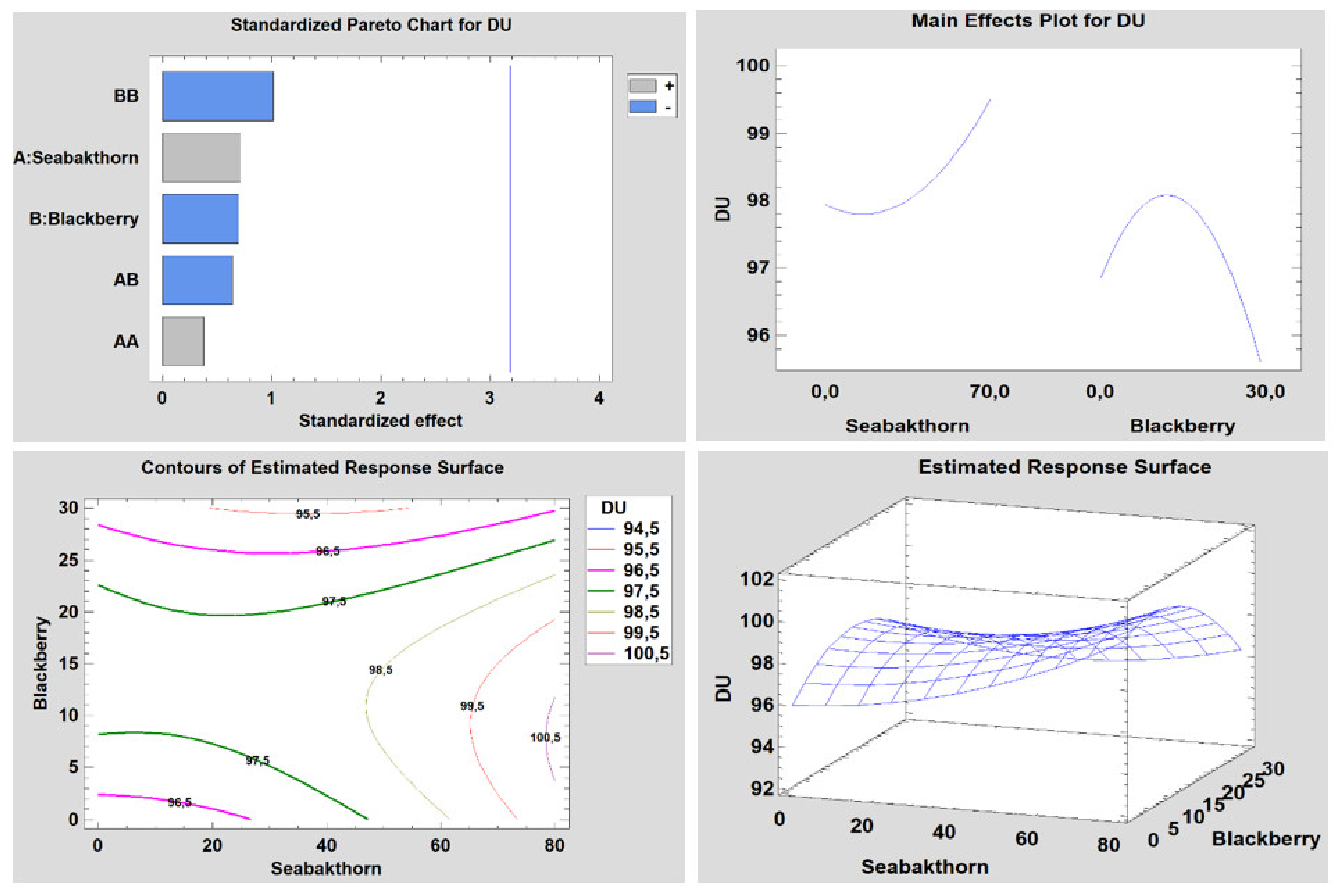

3.6. Dependence of the Mechanical Durability of the Pellets according to the Percentage of the Constituents of the Raw Material

4. Discussions

4.1. Use of Seabuckthorn, Blackberry, and Wheat Straw Plant Residues as Raw Material for Pellet Production

- -

- Lignin percentages vary in a relatively wide range from 20.44% (mixture 4) to 32.25% (sample 7), increasing with the biomass content of seabuckthorn.

- -

- The hemicellulose content of the wood and non-wood waste analyzed ranged from 22.77% (mixture 3) to 34.61% (mixture 4) being higher the higher the biomass content of wheat straw.

- -

- The cellulose content varies within very narrow limits between biomass mixtures of different origins.

4.2. The Influence of the Composition of the Biomass Mixture on the Calorific Value of the Pellets

4.3. Ash Content Resulting from the Burning of Pellets Produced from the Studied Biomass Mixtures

4.4. Influence of the Composition of the Biomass Mixture on the Fine Fraction Content of the Pellets

4.5. Influence of Biomass Mixture Composition on Pellet Bulk Density

4.6. Influence of Biomass Mixture Composition on Mechanical Durability of Pellets

5. Conclusions

- At least 75% seabuckthorn biomass, the rest wheat straw;

- At least 70% seabuckthorn biomass + (10–20)% blackberry biomass, the rest straw.

- At most 20% blackberry biomass, the rest seabuckthorn biomass.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alakangas, E. Biomass and Agricultural Residues for Energy Generation. In Fuel Flexible Energy Generation; Elsevier: Amsterdam, The Netherlands, 2016; pp. 59–96. ISBN 978-1-78242-378-2. [Google Scholar]

- Toklu, E. Biomass Energy Potential and Utilization in Turkey. Renew. Energy 2017, 107, 235–244. [Google Scholar] [CrossRef]

- Paiano, A.; Lagioia, G. Energy Potential from Residual Biomass towards Meeting the EU Renewable Energy and Climate Targets. The Italian Case. Energy Policy 2016, 91, 161–173. [Google Scholar] [CrossRef]

- Scarlat, N.; Blujdea, V.; Dallemand, J.-F. Assessment of the Availability of Agricultural and Forest Residues for Bioenergy Production in Romania. Biomass Bioenergy 2011, 35, 1995–2005. [Google Scholar] [CrossRef]

- Marian, G. Agroforestry Biomass Management for Energy Purposes; Universitatea Agrară de Stat din Moldova: Chișinău, Moldova, 2014; ISBN 978-9975-4021-4-9. [Google Scholar]

- Gudîma, A. Evaluation of the Use of Agricultural Residues for Energy Purposes. Case Study for Soroca District, Republic of Moldova. Meridian Ing. 2017, 1, 26–29. [Google Scholar]

- Pavlenco, A. Quality of Solid Biofuels Produced from Agricultural Residues. Summary Article. Știința Agric. 2018, 2, 128–140. [Google Scholar]

- Marian, G.; Ianuș, G.; Istrate, B.; Gudîma, A.; Nazar, B.; Pavlenco, A.; Banari, A.; Daraduda, N. Quality of Pellets Produced from Agricultural Wood Residues Specific to the Prut River Basin. Bull. Agrar. Sci. Black Sea Coast 2021, 109, 84–93. [Google Scholar] [CrossRef]

- Ciolacu, F.; Ianuș, G.; Marian, G.; Munteanu, C.; Paleu, V.; Nazar, B.; Istrate, B.; Gudîma, A.; Daraduda, N. A Qualitative Assessment of the Specific Woody Biomass of Fruit Trees. Forests 2022, 13, 405. [Google Scholar] [CrossRef]

- Ţenu, I.; Roman, C.; Senila, L.; Roşca, R.; Cârlescu, P.; Băetu, M.; Arsenoaia, V.; Dumitrachi, E.P.; Corduneanu, O.-R. Valorization of Vine Tendrils Resulted from Pruning as Densified Solid Biomass Fuel (Briquettes). Processes 2021, 9, 1409. [Google Scholar] [CrossRef]

- EN ISO 17225-2:2021; Solid Biofuels—Fuel Specifications and Classes—Part 2: Graded Wood Pellets (ISO 17225-2:2021). International Organization for Standardization: Geneva, Switzerland, 2021.

- Pavlenco, A.; Marian, G.; Gudîma, A. Quality of the Energy Potential of Agricultural Residues: Case Study for the Northern Development Region, Republic of Moldova. Știința Agric. 2018, 2, 141–148. [Google Scholar]

- Karkania, V.; Fanara, E.; Zabaniotou, A. Review of sustainable biomass pellets production—A study for agricultural residues pellets’ market in Greece. Renew. Sustain. Energy Rev. 2012, 16, 1426–1436. [Google Scholar] [CrossRef]

- Jamradloedluk, J.; Lertsatitthanakorn, C. Influences of Mixing Ratios and Binder Types on Properties of Biomass Pellets. Energy Procedia 2017, 138, 1147–1152. [Google Scholar] [CrossRef]

- Papandrea, S.F.; Cataldo, M.F.; Palma, A.; Gallucci, F.; Zimbalatti, G.; Proto, A.R. Pelletization of Compost from Different Mixtures with the Addition of Exhausted Extinguishing Powders. Agronomy 2021, 11, 1357. [Google Scholar] [CrossRef]

- Kovacs, E.; Hoaghia, M.-A.; Senila, L.; Scurtu, D.A.; Varaticeanu, C.; Roman, C.; Dumitras, D.E. Life Cycle Assessment of Biofuels Production Processes in Viticulture in the Context of Circular Economy. Agronomy 2022, 12, 1320. [Google Scholar] [CrossRef]

- Kizuka, R.; Ishii, K.; Sato, M.; Fujiyama, A. Characteristics of wood pellets mixed with torrefied rice straw as a biomass fuel. Int. J. Energy Environ. Eng. 2019, 10, 357–365. [Google Scholar] [CrossRef]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and utilization of fuel pellets from biomass: A review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- Lisowski, A.; Matkowski, P.; Dąbrowska, M.; Piątek, M.; Świętochowski, A.; Klonowski, J.; Mieszkalski, L.; Reshetiuk, V. Particle Size Distribution and Physicochemical Properties of Pellets Made of Straw, Hay, and Their Blends. Waste Biomass Valor. 2020, 11, 63–75. [Google Scholar] [CrossRef]

- El-Sayed, S.A.; Elsaid Mohamed, M.K. Mechanical Properties and Characteristics of Wheat Straw and Pellets. Energy Environ. 2018, 29, 1224–1246. [Google Scholar] [CrossRef]

- Pavlenco, A. Improving the Quality of Densified Solid Biofuels in Line with Renewable Energy Development Policies. Ph.D. Thesis, State Agrarian University of Moldova, Chișinău, Moldova, 2018. [Google Scholar]

- Marian, G.; Banari, A.; Gudîma, A.; Daraduda, N.; Pavlenco, A. Characterisation of Residues from the White Currant Production Chain. Știința Agric. 2020, 2, 91–96. [Google Scholar]

- EN ISO 18135:2017; Solid Biofuels—Sampling (ISO 18135:2017). International Organization for Standardization: Geneva, Switzerland, 2017.

- EN ISO 14780:2017; Solid Biofuels—Sample Preparation (ISO 14780:2017). International Organization for Standardization: Geneva, Switzerland, 2017.

- EN ISO 18134-3:2015; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 3: Moisture in General Analysis Sample (ISO 18134-3:2015). International Organization for Standardization: Geneva, Switzerland, 2015.

- EN ISO 18123:2017; Solid Biofuels—Determination of the Content of Volatile Matter (ISO 18123:2015). International Organization for Standardization: Geneva, Switzerland, 2017.

- EN ISO 18125:2017; Solid Biofuels—Determination of Calorific Value (ISO 18125:2017). International Organization for Standardization: Geneva, Switzerland, 2017; p. 68, ISBN: 978-0-580-89326-1.

- Cimpoieș, G.; Popa, S. White Seabuckthorn; Universitatea Agrară de Stat din Moldova: Chișinău, Moldova, 2018; ISBN 978-9975-56-601-8. [Google Scholar]

- Sava, P. Research Oriented to the Development of Baciferous Crops. Academus 2015, 2, 111–116. [Google Scholar]

- Balan, V.; Sava, P.; Calalb, T.; Ciorchină, N.; Cumpănici, A.; Dodică, D.; Roșca, I.; Todiraș, V.; Zbancă, A. Cropping of Fruit Bushes and Strawberry; Universitatea Agrară de Stat din Moldova: Chișinău, Moldova, 2017; p. 434. [Google Scholar]

- Marian, G.; Banari, A.; Nazar, B.; Daraduda, N.; Pavlenco, A. Prospects on the Capitalization of Seabuckthorn Residues for Energy Purposes. Lucr. Științifice UASM 2022, 56, 297–301. [Google Scholar]

- Niedziółka, I.; Szpryngiel, M.; Kachel-Jakubowska, M.; Kraszkiewicz, A.; Zawiślak, K.; Sobczak, P.; Nadulski, R. Assessment of the Energetic and Mechanical Properties of Pellets Produced from Agricultural Biomass. Renew. Energy 2015, 76, 312–317. [Google Scholar] [CrossRef]

- Miranda, T.; Montero, I.; Sepúlveda, F.; Arranz, J.; Rojas, C.; Nogales, S. A Review of Pellets from Different Sources. Materials 2015, 8, 1413–1427. [Google Scholar] [CrossRef] [PubMed]

- Lu, D.; Tabil, L.G.; Wang, D.; Wang, G.; Emami, S. Experimental Trials to Make Wheat Straw Pellets with Wood Residue and Binders. Biomass Bioenergy 2014, 69, 287–296. [Google Scholar] [CrossRef]

- Larsson, S.H.; Samuelsson, R. Prediction of ISO 17831-1:2015 Mechanical Biofuel Pellet Durability from Single Pellet Characterization. Fuel Proces. Technol. 2017, 163, 8–15. [Google Scholar] [CrossRef]

- Kaliyan, N.; Vance Morey, R. Factors Affecting Strength and Durability of Densified Biomass Products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Marian, G. Solid Biofuels: Production and Properties; Bons Ofices: Chișinău, Moldova, 2016; ISBN 978-9975-87-166-2. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marian, G.; Ianuș, G.; Istrate, B.; Banari, A.; Nazar, B.; Munteanu, C.; Măluțan, T.; Gudîma, A.; Ciolacu, F.; Daraduda, N.; et al. Evaluation of Agricultural Residues as Organic Green Energy Source Based on Seabuckthorn, Blackberry, and Straw Blends. Agronomy 2022, 12, 2018. https://doi.org/10.3390/agronomy12092018

Marian G, Ianuș G, Istrate B, Banari A, Nazar B, Munteanu C, Măluțan T, Gudîma A, Ciolacu F, Daraduda N, et al. Evaluation of Agricultural Residues as Organic Green Energy Source Based on Seabuckthorn, Blackberry, and Straw Blends. Agronomy. 2022; 12(9):2018. https://doi.org/10.3390/agronomy12092018

Chicago/Turabian StyleMarian, Grigore, Gelu Ianuș, Bogdan Istrate, Alexandru Banari, Boris Nazar, Corneliu Munteanu, Teodor Măluțan, Andrei Gudîma, Florin Ciolacu, Nicolae Daraduda, and et al. 2022. "Evaluation of Agricultural Residues as Organic Green Energy Source Based on Seabuckthorn, Blackberry, and Straw Blends" Agronomy 12, no. 9: 2018. https://doi.org/10.3390/agronomy12092018

APA StyleMarian, G., Ianuș, G., Istrate, B., Banari, A., Nazar, B., Munteanu, C., Măluțan, T., Gudîma, A., Ciolacu, F., Daraduda, N., & Paleu, V. (2022). Evaluation of Agricultural Residues as Organic Green Energy Source Based on Seabuckthorn, Blackberry, and Straw Blends. Agronomy, 12(9), 2018. https://doi.org/10.3390/agronomy12092018