Abstract

With the intensified greenhouse effect, high temperature has gradually become an adverse factor in growth of rice. Transplanting (TP) and direct seeding (DS) are two common rice planting modes. At present, the response of rice quality to high temperature under different planting modes and at different growth stages have not yet to be identified. Therefore, in our study, high-quality japonica rice Nanjing 9108 (NJ9108) and Nanjing 46 (NJ46) were cultivated through TP and DS under the setting of normal temperature (NT), moderate heating (2 °C higher than NT, MT) and extreme high temperature (5 °C higher than NT, HT) at early heading stage (EH, 0–14 d after heading) and middle heading stage (MH, 15–28 d after heading) respectively. The results showed that better resistance to high temperature was achieved with TP. The head rice rate, gel consistency and amylose content of rice decreased with the increase of temperature, while chalkiness degree, setback viscosity, average particle size, crystallinity and gelatinization temperature were opposite. Compared with high temperature at MH, the effect of EH on rice quality was more significant. In terms of varieties, the resistance to high temperature was stronger for NJ46 relative to NJ9108, mainly because NJ46 has a longer growth period and can avoid the stress of high temperature at heading stage. Above all, our results suggest that NJ46 could have better resistance with a longer growth period through TP under background of climate warming.

1. Introduction

Due to the intensification of human activities, the global temperature has risen by 0.74 °C in the last century, and it is expected to rise by 1.5 °C in 2050 [1]. At the same time, the frequent occurrence and increased duration of extreme weather have made high temperature a main catastrophic factor in rice production [2]. Rice is a staple food crop for more than 50% of the world’s population [3], and suffers high probability and risks of high temperature during its temperature sensitive period. Since starch is an important ingredient of rice, the study on how to maintain the quality of rice and its starch under high temperature is of great significance to agricultural development [4,5]. Concerning the effect of cultivation measures on rice quality, Bian et al. [6] found that the milled rice and head rice rates under transplanting was significantly higher than those under direct seeding. Compared with transplanting, the length to width ratio of rice increased significantly, while the rate, size, and degree of chalkiness were significantly decreased under direct seeding conditions.

There have been many research reports available for the effect of high temperature on rice quality. Through research on high temperature at different periods of heading and filling stage, Zhang et al. [7] found that the influence of high temperature on rice quality was the greatest during 8–14 d and the smallest during 18–22 d after heading. Yang et al. [8] suggested that post-anthesis warming increased peak viscosity, breakdown value, and pasting temperature but decreased the setback viscosity. Other studies had shown that higher temperature during grain filling stage was not conducive to the accumulation of grain starch, resulting in poor appearance quality processing quality of japonica rice [9,10,11], and increased the average grain size, surface area and volume of starch grains [12]. Research also showed that high temperature at maturity stage increased starch crystallinity [13]. Besides, high temperature at heading stage increased starch gelatinization temperature [14]. A previous study showed that the effect of high temperature on amylose content also varies with genotype, which was related to the amylose content in rice. Under high temperature conditions at night, rice varieties with lower amylose content could have decreased amylose content, while rice varieties with higher amylose content had the opposite effect [15]. However, Kwak et al. [16] believed that high temperature during grain-filling period reduces amylose content.

With the enhancement of greenhouse effect and global warming, the growth and development of rice has been seriously affected. In general, the quality of rice was greatly affected by temperature at heading stage and filling stage, and many previous studies focused on filling stage. Therefore, we simulated two widely used mechanized planting modes (TP and DS) in the early and middle heading stage, selected varieties with different growth stages (NJ9108 and NJ46), and set three temperature treatments (NT, MT and HT), to study the effects of high temperature on rice quality. The purpose of this study was to elucidate the most sensitive period of rice quality to high temperature and the effect of high temperature on rice quality by simulating short-term high temperature. Aiming to further reveal the response of rice quality to high temperature under different planting modes, and selecting rice planting modes and varieties to cope with climate change, so as to realize rice stress tolerance cultivation.

2. Materials and Methods

2.1. Experimental Location

The experiment was conducted in the experimental potted field of College of Agriculture, Yangzhou University (119.42° E, 32.39° N), Yangzhou City, Jiangsu Province from 2017 to 2018, a place which belongs to subtropical monsoon climate. Temperature treatment were carried out in the artificial intelligence climate laboratory of Agriculture College, Yangzhou University.

2.2. Test Materials and Treatment Methods

Two japonica varieties with high yield and good quality were selected in this experiment: Nanjing 9108 (NJ9108) and Nanjing 46 (NJ46). The whole growth period of NJ9108 is about 150 days, which is suitable for extensive planting in central Jiangsu. The whole growth period of NJ46 is about 165 days, which is suitable for extensive planting in southern Jiangsu. Standard mechanized transplanting (TP) and direct seeding (DS) were adopted. DS was carried out on 15 June, set three holes in each pot in a triangular shape for sowing, 5 to 6 seeds per hole. After the seedlings grew two leaves and one terminal bud, they were re-arranged to three seedlings per hole. TP was carried out on 27 May, and the rice seeds were evenly planted in the rice tray (58 cm × 28 cm × 2.5 cm) to raise rice seedlings. On 15 June, the seeds were transplanted into the pot (25 cm in diameter, 30 cm in height). Strong seedlings with similar sizes were selected when transplanting. Three holes were triangularly arranged in each pot, and planted with three seedlings. The pot was filled with sieve soil (soil was loam, and irrigated with water before transplanting). The soil pH was 6.03, the organic matter was 25.5 g·kg−1, the available nitrogen was 120.60 mg·kg−1, the available phosphorus was 59.0 mg·kg−1 and the available potassium was 68.8 mg·kg−1. Before TP, 2 g urea and 0.5 g potassium dihydrogen phosphate (KH2PO4) were applied as the base fertilizer in each pot. After 7 d of TP, 0.5 g urea was applied per pot. At panicle differentiation stage 0.6 g urea was applied per pot.

In the early and middle stages of heading, 20 potted plants with the same tiller number and heading quantity in each hole were selected for each treatment and transferred to the artificial climate chamber with normal temperature (NT), moderate heating (MT) and extreme high temperature (HT). The NT setting in the artificial climate chamber refer to the average temperature for the same period of the calendar year released by the China Meteorological Administration, MT increased 2 °C than NT, HT increased 5 °C than NT (Table 1). The artificial climate simulated the change rule of nature. The temperature was automatically adjusted to the set temperature every 3 h through setting, with a control accuracy was ± 0.5 °C, and the photoperiod was from 6:00 a.m. to 7:00 p.m. The constant humidity was set at 70%. The duration of temperature treatment for rice in each treatment was 14 days in the early and middle heading stage. After 14 days of treatment, they were moved outdoors for further growth until maturity.

Table 1.

Temperature of artificial intelligence climate laboratory.

2.3. Measuring Items and Methods

2.3.1. Rice Quality Determination

Processing Quality

The grain were air-dried at 35 °C (moisture content 14%) and stored for 3 months. Rough rice was processed to brown rice with Japan’s big house type II and milled rice was obtained by milling brown rice with SDJ-100 machine. The determination of brown rice rate and head rice rate was based on the National Standard of the People’ s Republic of China “GB/T 17891-1999 High Quality Rice”. The milled rice rate was determined according to the standard “NY122-86 high quality edible rice” issued by the Ministry of Agriculture. Brown rice rate, milled rice rate and head rice rate were expressed as percentage of total grain weight.

Appearance Quality

Appearance quality were measured by rice grain appearance quality scanning machine (MRS-9600TFU2L, Shanghai Zhongjing Technology Co., LTD., Shanghai, China). Measure the total length of ten random grains of brown rice and calculate the average length, measure the width in the same way. The length-width ratio was determined by dividing the length by the width. The proportion of chalky grains to measured grains was the chalky rice rate. The chalkiness degree was expressed as the percentage of chalkiness in the total area.

Cooking and Eating Quality

The gel consistency was measured by weights and measures. The nitrogen content was determined by Kjeldahl determination and multiplied by conversion factor 5.95 to obtain the protein content. The content of amylose was determined by triiodide colorimetry.

Rice Viscosity

Rice viscosity was determined with a Rapid Viscosity Analyzer (RVA) manufactured by Newport Scientific Instruments, Australia. The data were further analyzed by Thermal Cycle for Windows (TCW). The curves were analyzed by operating procedure provided by the American Grain Chemical Association (AACC).

2.3.2. Determination of Starch Quality in Rice

Purification of Starch

After grinding, rice grains were ground into homogenate by adding appropriate amount of water. Then the filtrate was filtered and collected with 400 purpose filter screen. The collected filtrate was transferred into the centrifuge tube, balanced by an electronic balance, and centrifuged for 10 min to discard the supernatant and keep the precipitation. 2% (w/v) SDS were added to the precipitation and shaken for 30 min, and the supernatant was discarded to retain the precipitation. The precipitation was centrifuged 3 times with distilled water and 2 times with anhydrous ethanol (centrifugation to remove supernatant). The separated precipitation was put into an oven at 40 °C and dried for 2 days. Finally, the precipitation was filtered with a 100-mesh filter for drying and preservation.

Starch Morphology and Structure

Added a small amount of starch into absolute ethanol, dropped it on the cover glass, stuck the starch on the aluminum alloy stage with double-sided tape after drying, and sprayed gold (SCD 500 Sputter, Bal-Tec, Pfaffikon, Switzerland). Make observation with an environmental scanning electron microscope (XL30-ESEM, Philips, Amsterdam, The Netherlands).

Starch Granularity

The starch particle size distribution was measured with a laser light scattering particle size analyzer (Mastersizer 2000, Malvern Company, Malvern, UK). The starch samples were immersed in anhydrous ethanol and stirred at a speed of 2000 RPM.

Starch Crystal Structure

D8 Advance polycrystalline X-ray diffractometer (Bruker AXS Company, Karlsruhe, Germany) was used for analysis. The starch granules were placed in a closed container containing saturated NaCl solution and absorbed water for a week. The crystallinity of the samples was calculated by dividing the crystalline area by the sum of the crystalline and amorphous areas [17].

Starch Gelatinization Temperature

The gelatinization temperature was measured using a differential scanning calorimetry (DSC) technique (DSC200F3) of German Dairy Company, and the curve was analyzed with supporting software. DSC could accurately measure the initial temperature, peak temperature, final temperature and enthalpy value of japonica rice starch [18,19].

2.3.3. Data Processing and Analysis

The two years’ experiments were carried out in the same artificial climate chamber, and the temperature and humidity characteristic values were consistent. As the results of the two years showed the same trend, so the data of 2018 were mainly used in this paper. The experimental data were processed by Microsoft Excel 2016, Origin 2018 and SPSS 20.0 software were used to analyze data and draw charts. The comparison among treatments were done by one-way ANOVA and the Duncan method was chosen as post-hoc test. The statistical results were reported as mean value and confirmed with LSD (least significant difference) test.

3. Results

3.1. Analysis of Variance between Treatment Effects

The characteristic values of rice quality and starch quality were significantly or extremely significantly different among variety, planting mode and temperature treatment (Table 2). There were significant differences among the characteristic values (except the milled rice rate) due to the processing stage. The interaction effect during the year has no significant effect on each eigenvalue, indicating that variety, planting mode, processing stage and temperature treatment had little difference on quality among years. As the main characteristic values were not significantly different between years, the data of 2018 were mainly used in this paper.

Table 2.

Analysis of variance (F-value) for rice quality and starch quality among year, variety, planting mode, processing stage and temperature treatment.

3.2. Effects of High Temperature on Processing Quality of Japonica Rice in Early and Middle Heading Stage under Different Planting Modes

As shown in Table 3, the processing quality was poorer due to high temperature. At EH, under TP, HT reduced the head rice rate of NJ9108 by 8.59%, while NJ46 decreased by 3.8%; under DS, NJ9108 dropped by 6.21%, while NJ46 didn’t drop significantly. At MH, the decline of characteristic values was obviously less significant, and even not significant.

Table 3.

Effects of high temperature on processing quality of japonica rice in early and middle heading stage under transplanting and direct seeding.

Under the same growth period and planting mode, the characteristic value all showed NJ46 > NJ9108; all characteristic values of NJ9108 were TP < DS, while that of NJ46 showed TP > DS (the ratio was not shown). Under the same planting modes, the characteristic values of NJ9108 showed MH > EH, NJ46 had no significant difference. The results showed that high temperature at EH had great influence on the processing quality, NJ46 had better processing quality. Better resistance to temperature was achieved under transplanting conditions.

3.3. Effects of High Temperature on Appearance Quality of Japonica Rice in Early and Middle Heading Stage under Different Planting Modes

High temperature decreased the length to width ratio of japonica rice, while increased the chalky rice rate, chalkiness size and chalkiness degree (Table 4). At EH, under TP, HT increased the chalky rice rate, chalkiness size and chalkiness degree of NJ9108 by 14.7%, 14.52% and 151.59%, respectively; NJ46 increased by 95.79%, 103.63% and 354.77% respectively. In case of DS, HT increased the chalky rice rate, chalkiness size and chalkiness degree of NJ9108 by 7.97%, 8.4% and 84.6%, respectively; NJ46 increased by 134.19%, 135.09% and 244%, respectively. At MH, under TP, HT increased the chalkiness degree of NJ9108 by 28.64%; NJ46 increased by 190.09%. In case of DS, the increase was 16.20% for NJ9108 and 155.56% for NJ46.

Table 4.

Effects of high temperature on appearance quality of japonica rice in early and middle heading stage under transplanting and direct seeding.

Under the same growth period and planting mode, with the increase of temperature the chalky rice rate, chalkiness size and chalkiness degree showed NJ9108 > NJ46, but the change amplitude of NJ46 was significantly greater than that of NJ9108, and the length to width ratio showed NJ9108 < NJ46. The characteristic values of NJ9108 were TP < DS, while the ratio of NJ46 was opposite (ratio was not shown). Under high temperature, the length to width ratio showed EH < MH, and other characteristic values showed EH > MH, and the difference was more obvious for NJ46 between EH and MH. In conclusion, EH has a great influence on appearance quality. NJ9108 and TP conditions showed good resistance to high temperature.

3.4. Effects of High Temperature on Cooking and Eating Quality of Japonica Rice in Early and Middle Heading Stage under Different Planting Modes

The gel consistency and amylose content of japonica rice decreased and the protein content increased under high temperature (Table 5). At EH, under TP, HT reduced the gel consistency and amylose content of NJ9108 by 15.76% and 18.48%, increased protein content by 43.14%; and in NJ46 decreased the gel consistency and amylose content by 23.76% and 7.14%, increased protein content by 27.97%. In this way, under DS, the gel consistency and amylose content decreased by 24.71% and 14.51% respectively, the protein content increased by 46.76% for NJ9108; and the decrease of gel consistency and amylose content was 24.02% and 22.94% respectively, the protein content increased by 28.13% for NJ46. At MH, the variation range of characteristic values was obviously smaller.

Table 5.

Effects of high temperature on cooking and eating quality of japonica rice in early and middle heading stage under transplanting and direct seeding.

Under the same growth period and planting mode, the influence of high temperature on gel consistency showed NJ46 > NJ9108, but the protein content was opposite. Under TP, the amylose content showed NJ9108 > NJ46, but the result was opposite under DS. During the same period, the gel consistency of NJ9108 showed TP < DS, while protein content and amylose content showed TP > DS. The gel consistency and protein content of NJ46 showed TP > DS, but the amylose content was opposite (the ratio was not shown). The gel consistency and amylose content were lower at EH than at MH, but the protein content was opposite. The results indicated that high temperature at EH had a great effect on the cooking and eating quality. The influence of high temperature was greater on NJ9108 than NJ46, and DS conditions showed good resistance to high temperature.

3.5. Effects of High Temperature on RVA of Japonica Rice in Early and Middle Heading Stage under Different Planting Modes

The effect of high temperature on RVA of japonica rice at EH and MH was shown in Table 6. With the increase of temperature, the setback viscosity and pasting temperature showed an upward trend, while other characteristic values showed a downward trend. At EH, under TP, HT reduced the peak viscosity and hot paste viscosity of NJ9108 by 64.10% and 81.75% respectively, and reduced by 9.82% and 20.15% for NJ46, respectively. In case of DS, NJ9108 decreased by 75.06% and 88.34%, and NJ46 decreased by 17.65% and 30.28%, respectively. The range of characteristic values at MH was not as obvious as that at EH.

Table 6.

Effects of high temperature on RVA of japonica rice in early and middle heading stage under transplanting and direct seeding.

In the same period and planting mode, the influence of high temperature on the viscosity and breakdown values of NJ46 were significantly higher than those on NJ9108, and the change range of NJ9108 was more obvious. Under HT, the characteristic values at EH showed TP > DS, while the result was opposite at MH (the ratio was not shown). Except the pasting temperature and setback viscosity, the characteristic values of RVA at EH were lower than that at MH. This indicated that the effect of high temperature at EH was more obvious than that at MH, and the effect of high temperature on NJ9108 was greater than that on NJ46 and TP showed better resistance to high temperature.

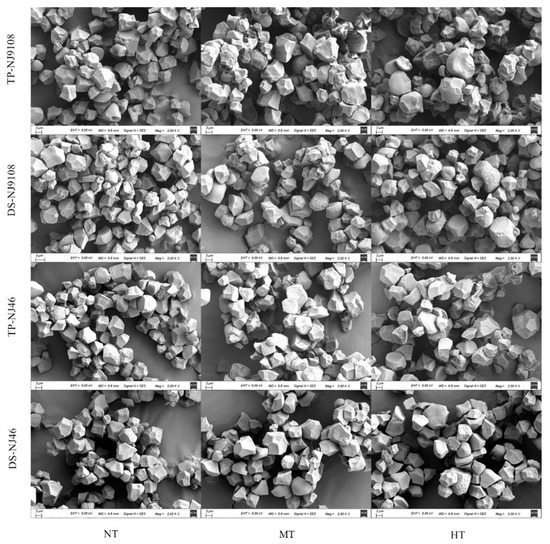

3.6. Effects of High Temperature on Starch Morphological Structure of Japonica Rice in Early and Middle Heading Stage under Different Planting Modes

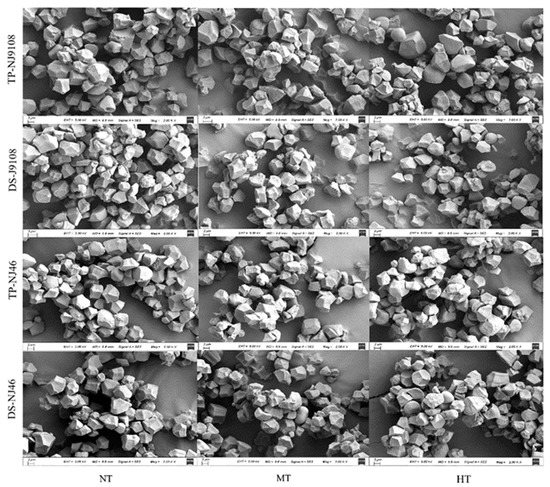

As shown in Figure 1, at EH, the diameter of starch granules of different cultivars gradually increased with the increase of temperature and the proportion of large granules also increased continuously. The polyhedral starch granules and densely packed granular structure were observed under NT and MT, whereas smooth and loose starch granules were observed under HT. The change trend at MH was similar to that at EH, while the large starch granules were less than those at EH (Figure 2).

Figure 1.

Effects of high temperature on starch morphological structure of japonica rice in early heading stage under transplanting and direct seeding (2000×).

Figure 2.

Effects of high temperature on starch morphological structure of japonica rice in middle heading stage under transplanting and direct seeding (2000×).

Under the condition of high temperature at different stages, compared with NJ46, NJ9108 had more large starch granules, the rice under TP had more large starch granules than it under DS. In conclusion, under DS the rice had a better starch morphological structure, and NJ46 had a good resistance to high temperature.

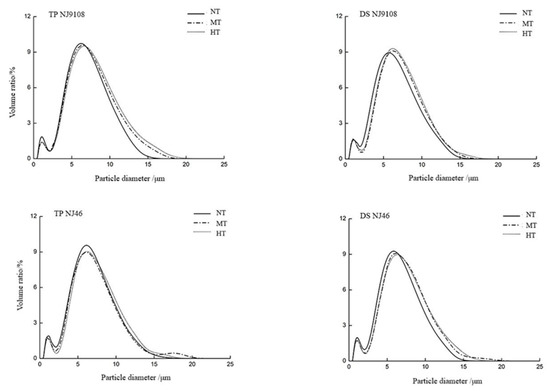

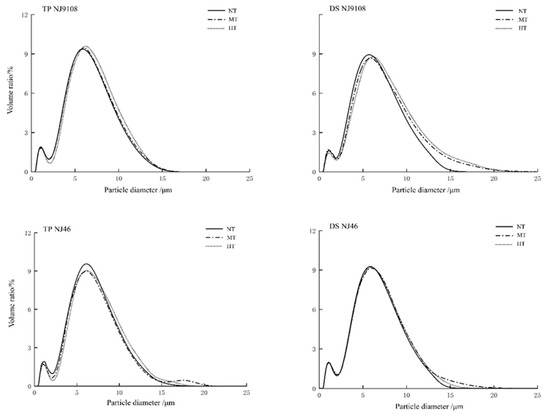

3.7. Effects of High Temperature on Starch Granularity of Japonica Rice in Early and Middle Heading Stage under Different Planting Modes

At EH, the average particle size of starch granules was the largest under HT, and the difference was significant difference compared with NT (Table 7). The proportion of starch granules with diameters less than 2 μm and 2–7 μm showed NT > MT > HT. Compared with NT, under TP, MT and HT increased the proportion of starch granules with diameter larger than 7 μm in NJ9108 by 13.4% and 19.3% respectively, and by 22.1% and 26.8% in NJ46. Under DS, the proportion of starch granules with diameter larger than 7μm in NJ9108 increased by 42.2% and 40.5%, while NJ46 increased by 26.5% and 27.7%, respectively. At MH, the variation range of each parameter was less significant and even not significant. It can also be seen from the grain size distribution (Figure 3 and Figure 4) that the proportion of starch granules with diameter larger than 7 μm at EH showed a trend of right-shift compared with NT under high temperature, but the shift is not significant at MH.

Table 7.

Effects of high temperature on starch granularity of japonica rice in early and middle heading stage under transplanting and direct seeding.

Figure 3.

Effects of high temperature on starch particle size distribution of japonica rice in early heading stage under transplanting and direct seeding.

Figure 4.

Effects of high temperature on starch particle size distribution of japonica rice in middle heading stage under transplanting and direct seeding.

Under the condition of the same period and planting mode, the average particle size showed NJ9108 > NJ46, and the volume distribution of NJ9108 and NJ46 showed no obvious rule. At the same period, the starch granules with diameters larger than 7 μm of NJ46 showed TP > DS, while the other characteristic values were opposite. The value of NJ9108 showed no obvious regularity (the ratio was not shown). Under the same variety and planting mode, the ratio of average particle size and the starch granules with diameter larger than 7 μm showed EH > MH, and other characteristic values were opposite. This indicated that EH had a great influence on starch granularity. NJ46 and TP had a good resistance to high temperature.

3.8. Effects of High Temperature on Starch Crystal Structure of Japonica Rice in Early and Middle Heading Stage under Different Planting Modes

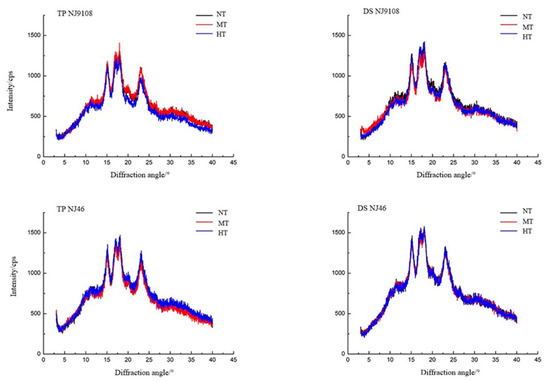

The XRD patterns of the two cultivar showed a typical “A” diffraction characteristic under different planting modes and temperature treatment (Figure 5). At EH, compared with the NT, HT reduced the intensity of the peak of NJ9108 at 2θ 15°, 2θ 17°, 2θ 18° and 2θ 23° under TP, while under MT the peak intensity was somehow recovered. For NJ46, the intensity of peak increased or flat under high temperature. Under the conditions of DS, the change of peak intensity at all diffraction angles was not obvious. At MH (Figure 6), compared with the NT, HT had no significant effect on the peak intensity under TP. Under DS, the starch peak intensity of NJ9108 increased or remained the same under high temperature, while that of NJ46 increased significantly.

Figure 5.

Effects of high temperature on starch crystal structure of japonica rice in early heading stage under transplanting and direct seeding.

Figure 6.

Effects of high temperature on starch crystal structure of japonica rice in middle heading stage under transplanting and direct seeding.

As can be seen from Figure 7, the starch crystallinity was the largest under HT at EH and MH, and the crystallinity is relatively small with little difference between MT and NT. The crystallinity of starch at MH was higher than that at EH. In conclusion, the effect of EH on starch crystal structure was greater than that of MH. As far as planting mode is concerned, better resistance to high temperature is achieved with TP.

Figure 7.

Effects of high temperature on starch crystallinity of japonica rice in early and middle heading stage under transplanting and direct seeding. Different letters in the same stage, in the same variety and in the same planting modes were significantly different at the level of 0.05.

3.9. Effects of High Temperature on DSC of Japonica Rice in Early and Middle Heading Stage under Different Planting Modes

Except the peak index, other characteristic values were shown as HT > MT > NT (Table 8). At EH, compared with NT, HT increased the enthalpy value, initial temperature and finial temperature of NJ9108 under TP by 16.33%, 11.61% and 11.34%, respectively; and increased by 10.02%, 3.06% and 5.23% in NJ46, respectively. Under DS, the finial temperature of NJ9108 increased by 9.10%; and in NJ46 increased by 9.13%. At MH, the changes of characteristic values were consistent with those at EH. Compared with NT, HT increased the final temperature of NJ9108 by 6.53% under DS; NJ46 increased by 11.56%. The characteristic values under TP did not increase as much as DS.

Table 8.

Effects of high temperature on DSC of japonica rice in early and middle heading stage under transplanting and direct seeding.

Under the condition of the same period and planting mode, the characteristic values of DSC were as follows: NJ9108 > NJ46; Under HT, the peak index of NJ9108 showed EH < MH, and the other characteristic values were opposite. Under TP, the gelatinization range and peak index of NJ46 showed EH > MH, while the other characteristic values were opposite; under DS, all the other characteristic values were EH < MH (except gelatinization range). In conclusion, the effect of high temperature on starch DSC at EH was greater than that at MH. The selection of TP and the variety NJ46 with long growth period showed better resistance to high temperature.

3.10. Correlation Analysis between Temperature and Quality

It could be seen from Table 9 that processing quality, gel consistency, amylose content, peak viscosity, hot paste viscosity are significantly or extremely significantly negatively correlated with all temperature indexes. The other quality indexes were positively correlated with temperature. It showed that there is significant correlation between temperature and quality.

Table 9.

Correlation analysis between temperature and quality.

4. Discussion

4.1. Effects of High Temperature on Quality of Japonica Rice

In this experiment, under MT and HT, the head rice rate, gel consistency and amylose content of NJ9108 and NJ46 decreased, while the chalkiness degree, setback viscosity and pasting temperature increased, and HT had a greater impact on rice quality. This is mainly because high temperature will affect the accumulation of grain nutrients, resulting in less full grains, and the higher the temperature, the greater the impact on rice quality. The conclusions of this study were reached after different degrees of temperature stress at the early and middle heading stage. Some researchers also reached the conclusion by temperature stress at other stages (mainly the grain filling stage). Li et al. [20] conducted daytime high temperature (DHT) and nighttime high temperature (NHT) treatments at grain filling period, and found that the head rice rate decreased, but compared with DHT, NHT exerted less effect on head rice rate. Chen et al. [21] and Zhang et al. [22] found that the chalky rice rate and chalkiness degree increased with the increase of temperature and duration at the grain filling stage. This is mainly due to the high temperature triggers nonuniform filling and impairment of starch biosynthesis, resulting in irregular and smaller starch granules and deposition of loosely packed starch granules, thus increasing chalky kernel formation [23]. Zhong et al. [24] used four cultivars with different amylose content and found that high temperature reduced or kept gel consistency of varieties with higher amylose content, but increased gel consistency of varieties with lower amylose content. Our study was consistent with Yang et al. [25] and Dou et al. [26] who suggested that amylose content decreased with the increase of temperature, this suggested that lower activity of amylose synthesis may be involved in chalk formation [27]. Liang et al. [28] believed that the protein content of rice increased under high temperature in the grain filling stage. The above research result and the conclusions herein revealed the tendency of rice quality deterioration caused by temperature stress in different periods. Different scholars had different opinions on the influence of temperature on rice RVA characteristic values: Wu et al. [29] choose a special japonica type: Peng-Lai rice, and found that high temperature decreased the peak viscosity and breakdown values, while the consistence viscosity increased; Taira [30] held totally opposite opinions. In this experiment, it was found that the viscosity, breakdown value, recovery value and peak time all showed a downward trend with the increase of temperature, while the setback viscosity and pasting temperature gradually increased. In contrast, Peng-Lai rice is a variety in Taiwan with good temperature tolerance. In this study NJ9108 and NJ46 were greatly affected by temperature, and the downward trend of each quality characteristic values of NJ9018 was greater than that of NJ46. Therefore, there are different conclusions on the impact of temperature on RVA characteristic values.

Shi et al. [23] studied the morphology of starch grains under high temperature in a greenhouse with natural lighting, the results showed that under high temperature, the interspace between starch grains was large, which was consistent with the conclusions of Cao et al. [31]. Yang et al. [32] conducted an increasing temperature experiment with four indica rice varieties as test materials under double cropping rice cultivation, and found that increasing temperature increased the average diameter of starch by 6.9%. Lin et al. [33] and Tang et al. [34] found that starch granule size and average starch particle size increased under high temperature. Zhang et al. [35] carried out temperature treatment at grain filling stage, and found that the crystallinity of starch was relatively high at high temperature. In this study, it was found that starch grains were more in the EH than in the MH, and more in NJ9108 than in NJ46. The proportion of starch grains with a diameter larger than 7 μm increased with the increase of temperature. The characteristic values of DSC (except the peak index) show HT > MT > NT, and the conclusion is consistent with previous studies [36,37].

In this study, two varieties of rice exhibited the same trend of quality changes under high temperature, and the influence of high temperature at EH was greater than that at MH. NJ46 has better resistance to high temperature than NJ9108, this is mainly because NJ9108 has a short growth period, and its high temperature sensitive period happens to be in the period of high temperature. While NJ46 has a longer growth period, its high temperature sensitive period can avoid the most serious period of heat damage, although it is still persecuted by high temperature, the influence degree is less than that of NJ9108.

4.2. Response of Planting Modes to Climate Change

The response of planting modes to climate change includes selection of heat resistant varieties [38], preservation of soil moisture, use of late maturing varieties and pretreatment of rice seedlings. The Rice Production and Physiology Research Group in China National Rice Research Institute evaluated the heat tolerance of 116 rice varieties which were dominant planted in the middle and lower reaches of the Yangtze River region, and the results indicated that indica-japonica hybrid rice demonstrated better heat resistance compared to indica and japonica rice [39]. However, some scholars believed that indica rice varieties had higher heat resistance than japonica rice [40,41]. Krishnan et al. [42] found that additions of crop residues and manure to arable soils will improve the soil water holding capacities and enhance the adaptability of rice to extreme weather. Oh-e et al. [43] found that in the plain area of Okayama Prefecture, some farmers mainly cultivated the late maturing cultivar such as Hinohikari and Akebono. The rice headed in August or early September, and were harvested in late or mid-October, thus avoiding the influence of high temperature at the high temperature sensitive period. Uchida et al. [44] found that pretreating rice seedlings with low levels (<10 mm) of H2O2 or NO resulted in more survived green leafy tissue under heat stress compared with the untreated control seedlings.

This experiment simulated the two most common planting modes in the middle and lower reaches of the Yangtze River: TP and DS. Temperature treatment conducted at EH and MH respectively. It was found that transplanting achieved better resistance to temperature rise, indicating that transplanting is an effective cultivation mode to cope with climate change in the future. The growth stage of NJ46 is about 14 d later than that of NJ9108, and its initial heading stage is 10–14 d later correspondingly. Therefore, as the treatment period goes on, the damage of high temperature decreases, so NJ46 has better heat resistance than NJ9108. The frequent occurrence of extreme climate in the future will have a serious impact on rice in China, with significant spatial differences. If appropriate planting modes and other coping strategies can be selected, the adverse effects of extreme climate on rice can be partially eliminated.

5. Conclusions

In this study, the sensitive stage of rice quality was in early heading stage, and the effect of high temperature on rice quality in early heading stage was more obvious than that in middle heading stage. Under high temperature, the brown rice rate, milled rice rate, head rice rate, gel consistency and amylose content were decreased, the chalkiness degree, protein content, the setback value and the pasting temperature of RVA characteristic values were increased, and the viscosity and breakdown value were decreased. In terms of starch quality, high temperature increased the proportion of large starch, average starch particle size, crystallinity and gelatinization temperature. From the perspective of climate change measures, NJ46 with a long growth period combined with TP show good resistance to high temperature. In conclusion, our results would help promote rice production and decline the negative effects of climate warming through optimizing combination of appropriate planting modes and varieties.

Author Contributions

L.H. led the project and designed this research strategy; Q.Z., X.H. (Xiao Han) and M.Z. carried out the field work; Q.Z. and X.H. (Xiao Han) performed laboratory experiments; Q.Z. was responsible for data processing and manuscript writing; L.H., X.H. (Xiaomin Huang) and M.J. revised the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key R&D Program of China Under Grant, projects number 2017YFD0300102. Modern Agricultural Development Projects of Jiangsu Province, projects number 2019-SJ-039-08-11.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are openly available from Yangzhou University.

Acknowledgments

We thank the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD) for sponsoring our research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Siddik, M.A.; Zhang, J.; Chen, J.; Qian, H.Y.; Jiang, Y.; Raheem, A.K.; Deng, A.X.; Song, Z.W.; Zheng, C.Y.; Zhang, W.J. Responses of indica rice yield and quality to extreme high and low temperatures during the reproductive period. Eur. J. Agron. 2019, 28, 30–38. [Google Scholar] [CrossRef]

- Song, X.Y.; Du, Y.X.; Song, X.N.; Zhao, Q.Z. Effects of high night temperature during grain filling on formation of physicochemical properties for japonica rice. J. Cereal Sci. 2015, 66, 74–80. [Google Scholar] [CrossRef]

- Xiong, D.L.; Ling, X.X.; Huang, J.L.; Peng, S.B. Meta-analysis and dose-response analysis of high temperature effects on rice yield and quality. Environ. Exp. Bot. 2017, 141, 1–9. [Google Scholar] [CrossRef]

- Kong, X.L.; Zhu, P.; Sui, Z.Q.; Bao, J.S. Physicochemical properties of starches from diverse rice cultivars varying in apparent amylose content and gelatinisation temperature combinations. Food Chem. 2015, 172, 433–440. [Google Scholar] [CrossRef] [PubMed]

- Jin, Z.X.; Qian, C.R.; Yang, J.; Liu, H.Y.; Jin, X.Y. Effect of temperature at grain filling stage on activities of key enzymes related to starch synthesis and grain quality of rice. Rice Sci. 2005, 12, 261–266. [Google Scholar]

- Bian, J.L.; Xu, F.F.; Han, C.; Qiu, S.; Ge, J.L.; Xu, J.; Zhang, H.C.; Wei, H.Y. Effects of planting methods on yield and quality of different types of japonica rice in northern Jiangsu plain, China. J. Integr. Agric. 2018, 17, 2624–2635. [Google Scholar] [CrossRef]

- Zhang, G.L.; Zhang, S.T.; Wang, L.; Xiao, Y.H.; Tang, W.B.; Chen, G.H.; Chen, L.Y. Effects of high temperature at different times during the heading and filling periods on rice quality. Sci. Agric. Sin. 2013, 46, 2869–2879, (In Chinese with English Abstract). [Google Scholar]

- Yang, T.T.; Xiong, R.Y.; Tan, X.M.; Huang, S.; Pan, X.H.; Guo, L.; Zeng, Y.J.; Zhang, J.; Zeng, Y.H. The impacts of post-anthesis warming on grain yield and quality of double-cropping high-quality indica rice in Jiangxi Province, China. Eur. J. Agron. 2022, 139, 126551. [Google Scholar] [CrossRef]

- Song, X.Y.; Du, Y.X.; Song, X.N.; Zhao, Q.Z. Effect of high night temperature during grain filling on amyloplast development and grain quality in japonica rice. Cereal Chem. 2013, 90, 114–119. [Google Scholar] [CrossRef]

- Shi, W.J.; Yin, X.Y.; Struik, P.C.; Xie, F.M.; Schmidt, R.C.; Jagadish, K.S.V. Grain yield and quality responses of tropical hybrid rice to high night-time temperature. Field Crops Res. 2015, 190, 18–25. [Google Scholar] [CrossRef]

- Yao, D.P.; Wu, J.; Luo, Q.H.; Li, J.W.; Zhuang, W.; Xiao, G.; Deng, Q.Y.; Lei, D.Y.; Bai, B. Influence of high natural field temperature during grain filling stage on the morphological structure and physicochemical properties of rice (Oryza sativa L.) starch. Food Chem. 2020, 310, 125817. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.C.; Zhao, Q.; Zhou, L.J.; Cao, Z.Z.; Shi, C.H.; Cheng, F.M. Influence of environmental temperature during grain filling period on granule size distribution of rice starch and its relation to gelatinization properties. J. Cereal Sci. 2017, 76, 42–55. [Google Scholar] [CrossRef]

- Chun, A.; Lee, H.-J.; Hamaker, B.R.; Janaswamy, S. Effects of ripening temperature on starch structure and gelatinization, pasting, and cooking properties in rice (Oryza sativa). J. Agric. Food Chem. 2015, 63, 3085–3093. [Google Scholar] [CrossRef] [PubMed]

- Kato, K.; Suzukic, Y.; Hosakac, Y.; Takahashia, R.; Kodamaa, I.; Satoa, K.; Kawamotoa, T.; Kumamarub, T.; Fujita, N. Effect of high temperature on starch biosynthetic enzymes and starch structure in japonica rice cultivar ‘Akitakomachi’ (Oryza sativa L.) endosperm and palatability of cooked rice. J. Cereal Sci. 2019, 87, 209–214. [Google Scholar] [CrossRef]

- Shi, W.J.; Muthurajan, R.; Rahman, H.; Selvam, J.; Peng, S.B.; Zou, Y.B.; Jagadish, K.S.V. Source–sink dynamics and proteomic reprogramming under elevated night temperature and their impact on rice yield and grain quality. N. Phytol. 2013, 197, 825–837. [Google Scholar] [CrossRef] [PubMed]

- Kwak, J.; Lee, J.S.; Won, Y.J.; Park, H.M.; Kwak, K.S.; Kim, M.J.; Lee, C.K.; Kim, S.L.; Yoon, M.R. Effects of ripening temperature on starch structure and storage protein characteristics of early maturing rice varieties during grain filling. Korean J. Crop Sci. 2018, 63, 77–85, (In Korean with English Abstract). [Google Scholar]

- Srisang, N.; Varanyanond, W.; Soponronnarit, S.; Prachayawarakorn, S. Effects of heating media and operating conditions on drying kinetics and quality of germinated brown rice. J. Food Eng. 2011, 107, 385–392. [Google Scholar] [CrossRef]

- Fan, X.L.; Li, Y.Q.; Zhang, C.Q.; Li, E.P.; Chen, Z.Z.; Li, Q.F.; Zhang, Z.W.; Zhu, Y.; Sun, X.S.; Liu, Q.Q. Effects of high temperature on the fine structure of starch during the grain-filling stages in rice: Mathematical modeling and integrated enzymatic analysis. J. Sci. Food Agric. 2019, 99, 2865–2873. [Google Scholar] [CrossRef]

- Li, Y.F.; Teng, F.; Shi, F.; Wang, L.; Chen, Z.X. Effects of high-temperature air fluidization (HTAF) on eating quality, digestibility, and antioxidant activity of black rice(Oryza sativa L.). Starch-Stärke 2017, 69, 1600274. [Google Scholar] [CrossRef]

- Li, H.X.; Chen, Z.; Hu, M.X.; Wang, Z.M.; Hua, H.; Yin, C.X.; Zeng, H.L. Different effects of night versus day high temperature on rice quality and accumulation profiling of rice grain proteins during grain filling. Plant Cell Rep. 2011, 30, 1641–1659. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.L.; Tang, L.; Shi, P.H.; Yang, B.H.; Sun, T.; Cao, W.X.; Zhu, Y. Effects of short-term high temperature on grain quality and starch granules of rice (Oryza sativa L.) at post-anthesis stage. Protoplasma 2016, 254, 935–943. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.L.; Liao, B.; Li, B.; Cai, Z.H. The effect of high temperature after anthesis on rice quality and starch granule structure of endosperm. Meteorol. Environ. Res. 2016, 7, 72–75. [Google Scholar]

- Shi, W.J.; Yin, X.Y.; Struik, C.P.; Solis, C.; Xie, F.M.; Schmidt, C.R.; Huang, M.; Zou, Y.B.; Ye, C.R.; Jagadish, S.V.K. High day- and night-time temperatures affect grain growth dynamics in contrasting rice genotypes. J. Exp. Bot. 2017, 68, 5233–5245. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhong, L.J.; Cheng, F.M.; Wen, X.; Sun, Z.X.; Zhang, G.P. The deterioration of eating and cooking quality caused by high temperature during grain filling in early-season indica rice cultivars. J. Agron. Crop Sci. 2005, 191, 218–225. [Google Scholar] [CrossRef]

- Yang, J.; Chen, X.R.; Zhu, C.L.; Peng, X.S.; He, X.P.; Fu, J.R.; Bian, J.M.; Hu, L.F.; Ouyang, L.J.; He, H.H. Effects of high temperature on yield, quality and physiological components of early rice. Pak. J. Agric. Sci. 2018, 55, 13–22. [Google Scholar] [CrossRef]

- Dou, Z.; Tang, S.; Li, G.H.; Liu, Z.H.; Ding, C.Q.; Chen, L.; Wang, S.H.; Ding, Y.F. Application of nitrogen fertilizer at heading stage improves rice quality under elevated temperature during grain-filling stage. Crop Sci. 2017, 57, 2183–2192. [Google Scholar] [CrossRef] [Green Version]

- Ishimaru, T.; Parween, S.; Saito, Y.; Shigemitsu, T.; Yamakawa, H.; Nakazono, M.; Masumura, T.; Nishizawa, K.N.; Kondo, M.; Sreenivasulu, N. Laser microdissection-based tissue-specific transcriptome analysis reveals a novel regulatory network of genes involved in heat-induced grain chalk in rice endosperm. Plant Cell Physiol. 2019, 60, 626–642. [Google Scholar] [CrossRef]

- Liang, C.G.; Chen, L.P.; Wang, Y.; Liu, J.; Xu, G.L.; Li, T. High temperature at grain-filling stage affects nitrogen metabolism enzyme activities in grains and grain nutritional quality in rice. Rice Sci. 2011, 18, 210–216. [Google Scholar] [CrossRef]

- Wu, Y.C.; Chang, S.J.; Lur, H.S. Effects of field high temperature on grain yield and quality of a subtropical type japonica rice—Pon-Lai rice. Plant Prod. Sci. 2016, 19, 145–153. [Google Scholar] [CrossRef]

- Taira, T. Relation between mean air temperature during ripening period of rice and amylographic characteristics or cooking quality. Jpn. J. Crop Sci. 1999, 68, 45–47, (In Japanese with English Abstract). [Google Scholar] [CrossRef] [Green Version]

- Cao, Z.Z.; Pan, G.; Wang, F.B.; Wei, K.S.; Li, Z.W.; Shi, C.H.; Geng, W.; Cheng, F.M. Effect of high temperature on the expressions of genes encoding starch synthesis enzymes in developing rice endosperms. J. Integr. Agric. 2015, 14, 642–659. [Google Scholar] [CrossRef]

- Yang, T.T.; Tan, X.M.; Shan, H.; Pan, X.H.; Shi, Q.H.; Zeng, Y.J.; Zhang, J.; Zeng, Y.H. Effects of experimental warming on physicochemical properties of indica rice starch in a double rice cropping system. Food Chem. 2020, 310, 125981. [Google Scholar] [CrossRef] [PubMed]

- Lin, G.Q.; Yang, Y.; Chen, X.Y.; Yu, X.R.; Wu, Y.F.; Xiong, F. Effects of high temperature during two growth stages on caryopsis development and physicochemical properties of starch in rice. Int. J. Biol. Macromol. 2020, 145, 301–310. [Google Scholar] [CrossRef] [PubMed]

- Tang, S.; Zhang, H.X.; Liu, W.Z.; Dou, Z.; Zhou, Q.Y.; Chen, W.Z.; Wang, S.H.; Ding, Y.F. Nitrogen fertilizer at heading stage effectively compensates for the deterioration of rice quality by affecting the starch-related properties under elevated temperatures. Food Chem. 2019, 277, 455–462. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.Q.; Zhou, L.H.; Zhu, Z.B.; Lu, H.W.; Zhou, X.Z.; Qian, Y.T.; Li, Q.F.; Lu, Y.; Gu, M.H.; Liu, Q.Q. Characterization of grain quality and starch fine structure of two japonica rice (Oryza sativa) cultivars with good sensory properties at different temperatures during the filling stage. J. Agric. Food Chem. 2016, 64, 4048–4057. [Google Scholar] [CrossRef]

- Hu, Y.J.; Li, L.; Tian, J.Y.; Zhang, C.X.; Wang, J.; Yu, E.W.; Xiang, Z.P.; Guo, B.W.; Wei, H.Y.; Huo, Z.Y.; et al. Effects of dynamic low temperature during the grain filling stage on starch morphological structure, physicochemical properties, and eating quality of soft japonica rice. Cereal Chem. 2020, 97, 540–550. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, N.; Tetlow, I.J.; Nawaz, S.; Iqbal, A.; Mubin, M.; Rehman, M.S.N.; Butt, A.; Lightfoot, D.A.; Maekawa, M. Effect of high temperature on grain filling period, yield, amylose content and activMTy of starch biosynthesis enzymes in endosperm of basmati rice. J. Sci. Food Agric. 2015, 95, 2237–2243. [Google Scholar] [CrossRef]

- Xu, Y.F.; Chu, C.C.; Yao, S.G. The impact of high-temperature stress on rice: Challenges and solutions. Crop. J. 2021, 9, 963–976. [Google Scholar] [CrossRef]

- Wang, Y.L.; Wang, L.; Zhou, J.X.; Hu, S.B.; Chen, H.Z.; Xiang, J.; Zhang, Y.K.; Zeng, Y.J.; Shi, Q.H.; Zhu, D.F.; et al. Research progress on heat stress of rice at flowering stage. Rice Sci. 2019, 26, 1–10. [Google Scholar] [CrossRef]

- Matsui, T.; Kobayasi, K.; Kagata, H.; Horie, T. Correlation between viability of pollination and length of basal dehiscence of the theca in rice under a hot-and-humid condition. Plant Prod. Sci. 2005, 8, 109–114. [Google Scholar] [CrossRef]

- Matsui, T.; Omasa, K.; Horie, T. The difference in sterility due to high temperatures during the flowering period among japonica-rice varieties. Plant Prod. Sci. 2001, 4, 90–93. [Google Scholar] [CrossRef]

- Krishnan, P.; Ramakrishnan, B.; Reddy, K.R.; Reddy, V.R. High temperature effects on rice growth, yield, and grain quality. Adv. Agron. 2011, 111, 87–206. [Google Scholar]

- Oh-e, I.; Saitoh, K.; Kuroda, T. Effects of high temperature on growth, yield and dry-matter production of rice grown in the paddy field. Plant Prod. Sci. 2007, 10, 412–422. [Google Scholar] [CrossRef]

- Uchida, A.; Jagendorf, A.T.; Hibino, T.; Takabe, T.; Takabe, T. Effects of hydrogen peroxide and nitricoxide on both salt and heat stress tolerance in rice. Plant Sci. 2002, 163, 515–523. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).