One-Time Nitrogen Fertilizer Application Using Controlled-Release Urea Ensured the Yield, Nitrogen Use Efficiencies, and Profits of Winter Wheat

Abstract

:1. Introduction

2. Materials and Methods

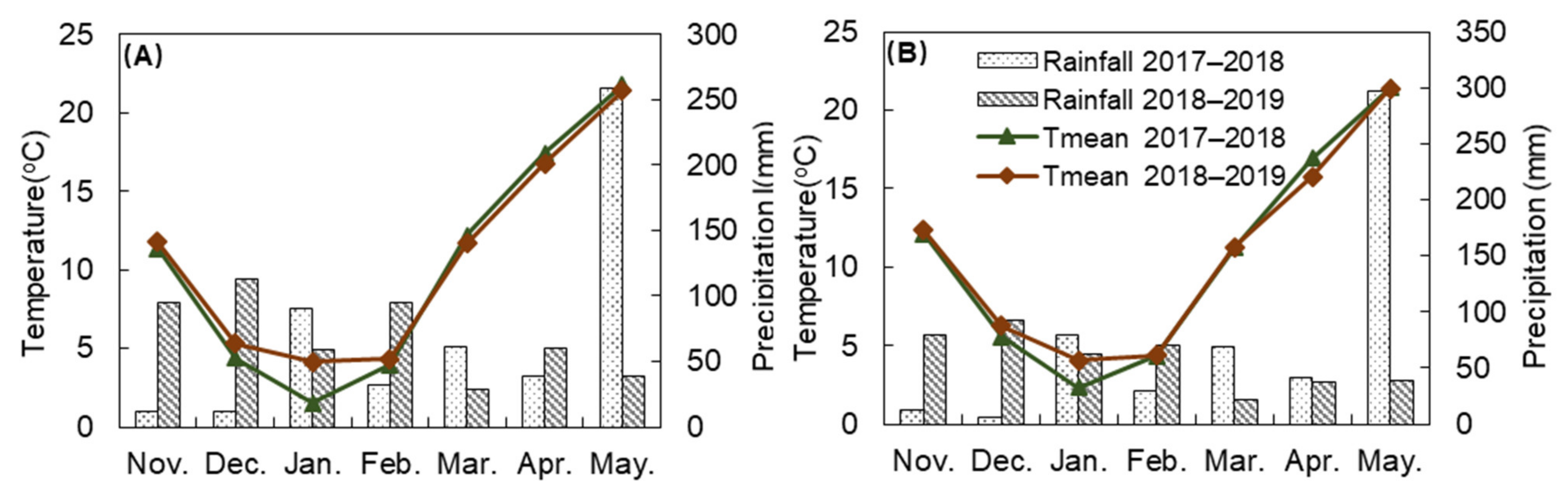

2.1. Experimental Sites and Materials

2.2. Experimental Design

2.3. Samplings and Measurements

2.3.1. Measurement of the N Content and Release Characteristics of CRU

2.3.2. Soil Inorganic N Content

2.3.3. Grain Yield Determination

2.3.4. Nitrogen Accumulation

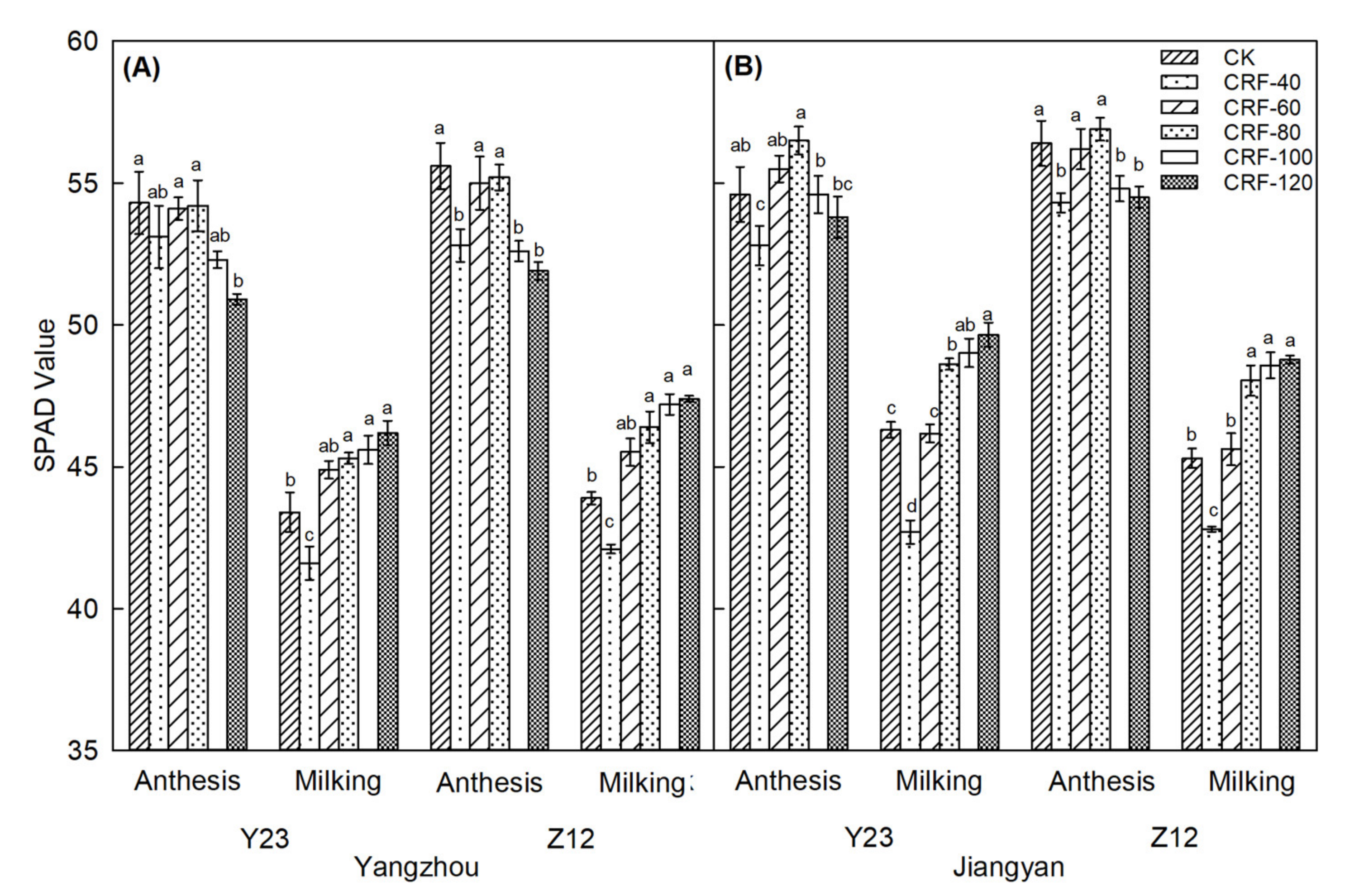

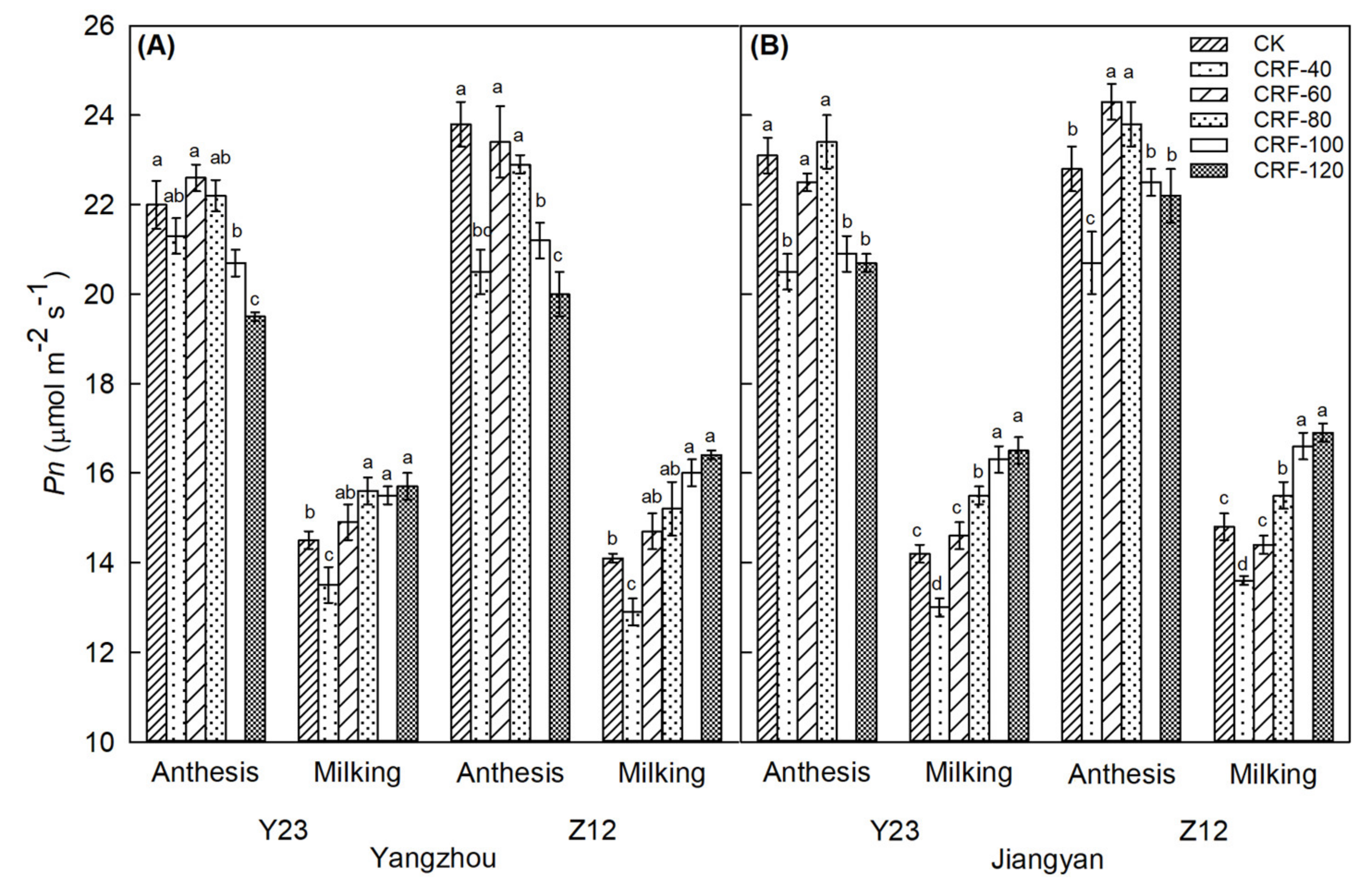

2.3.5. Analysis of Relative Chlorophyll Content and Net Photosynthetic Rate

2.4. Statistical Analysis

2.5. Economic Evaluation

3. Results

3.1. N Release Behavior of CRU and the Response of Soil Inorganic N Content

3.2. Shoot Biomass and N Accumulation in Wheat

3.3. Wheat Post-Anthesis Photosynthetic Characteristics

3.4. Grain Yield and Its Components

3.5. Nitrogen Use Efficiency and the Benefit-Cost Analysis

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, X.; Cui, Z.; Fan, M.; Vitousek, P.; Zhao, M.; Ma, W.; Wang, Z.; Zhang, W.; Yan, X.; Yang, J.; et al. Producing More Grain with Lower Environmental Costs. Nature 2014, 514, 486–489. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J. China’s Success in Increasing per Capita Food Production. J. Exp. Bot. 2011, 62, 3707–3711. [Google Scholar] [CrossRef] [PubMed]

- FAO. FAOSTAT Database; Food and Agriculture Organization of the United Nations: Rome, Italy, 2021. [Google Scholar]

- Peng, S.; Buresh, R.J.; Huang, J.; Zhong, X.; Zou, Y.; Yang, J.; Wang, G.; Liu, Y.; Hu, R.; Tang, Q.; et al. Improving Nitrogen Fertilization in Rice by Sitespecific N Management. A Review. Agron. Sustain. Dev. 2010, 30, 649–656. [Google Scholar] [CrossRef]

- Zhou, Z.; Shen, Y.; Du, C.; Zhou, J.; Qin, Y.; Wu, Y. Economic and Soil Environmental Benefits of Using Controlled-release Bulk Blending Urea in the North China Plain. Land Degrad. Dev. 2017, 28, 2370–2379. [Google Scholar] [CrossRef]

- Zhang, F.; Cui, Z.; Fan, M.; Zhang, W.; Chen, X.; Jiang, R. Integrated Soil–Crop System Management: Reducing Environmental Risk While Increasing Crop Productivity and Improving Nutrient Use Efficiency in China. J. Environ. Qual. 2011, 40, 1051–1057. [Google Scholar] [CrossRef]

- Xu, H.C.; Dai, X.L.; Chu, J.P.; Wang, Y.C.; Yin, L.J.; Ma, X.; Dong, S.; He, M.R. Integrated Management Strategy for Improving the Grain Yield and Nitrogen-Use Efficiency of Winter Wheat. J. Integr. Agric. 2018, 17, 315–327. [Google Scholar] [CrossRef]

- Jin, S.; Yue, G.; Feng, L.; Han, Y.; Yu, X.; Zhang, Z. Preparation and Properties of a Coated Slow-Release and Water-Retention Biuret Phosphoramide Fertilizer with Superabsorbent. J. Agric. Food Chem. 2011, 59, 322–327. [Google Scholar] [CrossRef]

- Azeem, B.; KuShaari, K.; Man, Z.B.; Basit, A.; Thanh, T.H. Review on Materials & Methods to Produce Controlled Release Coated Urea Fertilizer. J. Control. Release 2014, 181, 11–21. [Google Scholar]

- Naz, M.Y.; Sulaiman, S.A. Slow Release Coating Remedy for Nitrogen Loss from Conventional Urea: A Review. J. Control. Release 2016, 225, 109–120. [Google Scholar] [CrossRef]

- Han, Y.; Fan, Y.; Yang, P.; Wang, X.; Wang, Y.; Tian, J.; Xu, L.; Wang, C. Net Anthropogenic Nitrogen Inputs (NANI) Index Application in Mainland China. Geoderma 2014, 213, 87–94. [Google Scholar] [CrossRef]

- Tian, X.; Li, C.; Zhang, M.; Li, T.; Lu, Y.; Liu, L. Controlled Release Urea Improved Crop Yields and Mitigated Nitrate Leaching under Cotton-Garlic Intercropping System in a 4-Year Field Trial. Soil Tillage Res. 2018, 175, 158–167. [Google Scholar] [CrossRef]

- Ma, Q.; Wang, M.; Zheng, G.; Yao, Y.; Tao, R.; Zhu, M.; Ding, J.; Li, C.; Guo, W.; Zhu, X. Twice-Split Application of Controlled-Release Nitrogen Fertilizer Met the Nitrogen Demand of Winter Wheat. Field Crop. Res. 2021, 267, 108163. [Google Scholar] [CrossRef]

- Li, G.; Cheng, G.; Lu, W.; Lu, D. Differences of Yield and Nitrogen Use Efficiency under Different Applications of Slow Release Fertilizer in Spring Maize. J. Integr. Agric. 2021, 20, 554–564. [Google Scholar] [CrossRef]

- Ke, J.; Xing, X.; Li, G.; Ding, Y.; Dou, F.; Wang, S.; Liu, Z.; Tang, S.; Ding, C.; Chen, L. Effects of Different Controlled-Release Nitrogen Fertilisers on Ammonia Volatilisation, Nitrogen Use Efficiency and Yield of Blanket-Seedling Machine-Transplanted Rice. Field Crop. Res. 2017, 205, 147–156. [Google Scholar] [CrossRef]

- Yang, Y.C.; Zhang, M.; Zheng, L.; Cheng, D.D.; Liu, M.; Geng, Y.Q. Controlled Release Urea Improved Nitrogen Use Efficiency, Yield, and Quality of Wheat. Agron. J. 2011, 103, 479–485. [Google Scholar] [CrossRef]

- Shaviv, A. Advances in Controlled-Release Fertilizers. Adv. Agron. 2001, 71, 1–49. [Google Scholar]

- Alijani, K.; Bahrani, M.J.; Kazemeini, S.A. Short-Term Responses of Soil and Wheat Yield to Tillage, Corn Residue Management and Nitrogen Fertilization. Soil Tillage Res. 2012, 124, 78–82. [Google Scholar] [CrossRef]

- Geng, J.; Sun, Y.; Zhang, M.; Li, C.; Yang, Y.; Liu, Z.; Li, S. Long-Term Effects of Controlled Release Urea Application on Crop Yields and Soil Fertility under Rice-Oilseed Rape Rotation System. Field Crop. Res. 2015, 184, 65–73. [Google Scholar] [CrossRef]

- Wei, H.Y.; Chen, Z.F.; Xing, Z.P.; Lei, Z.; Liu, Q.Y.; Zhang, Z.Z.; Jiang, Y.; Hu, Y.J.; Zhu, J.Y.; Cui, P.Y.; et al. Effects of Slow or Controlled Release Fertilizer Types and Fertilization Modes on Yield and Quality of Rice. J. Integr. Agric. 2018, 17, 2222–2234. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, F.; Liu, Y.; Yang, J.; Zhen, X.; Li, X.; Li, Y.; Zhao, J.; Li, J.; Qian, B.; et al. Timing and Splitting of Nitrogen Fertilizer Supply to Increase Crop Yield and Efficiency of Nitrogen Utilization in a Wheat–Peanut Relay Intercropping System in China. Crop J. 2019, 7, 101–112. [Google Scholar] [CrossRef]

- Irfan, S.A.; Razali, R.; KuShaari, K.Z.; Mansor, N.; Azeem, B.; Ford Versypt, A.N. A Review of Mathematical Modeling and Simulation of Controlled-Release Fertilizers. J. Control. Release 2018, 271, 45–54. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, X.; Yang, Y.; Cheng, D.; Chen, B.; Liu, Y.; Tang, Y.; Ma, J. Yield and Economic Profit Synergism of Controlled Release Urea and Fulvic Acid in Rice–Wheat Rotation System. J. Plant Nutr. Fertil. 2019, 12, 2122–2132. [Google Scholar]

- Carson, L.C.; Ozores-Hampton, M. Factors Affecting Nutrient Availability, Placement, Rate, and Application Timing of Controlled-Release Fertilizers for Florida Vegetable Production Using Seepage Irrigation. HortTechnology 2013, 23, 553–562. [Google Scholar] [CrossRef] [Green Version]

- Salman, O.A.; Hovakeemian, G.; Khraishi, N. Polyethylene-Coated Urea. 2. Urea Release As Affected by Coating Material, Soil Type, and Temperature. Ind. Eng. Chem. Res. 1989, 28, 633–638. [Google Scholar] [CrossRef]

- Ji, Y.; Liu, G.; Ma, J.; Xu, H.; Yagi, K. Effect of Controlled-Release Fertilizer on Nitrous Oxide Emission from a Winter Wheat Field. Nutr. Cycl. Agroecosyst. 2012, 94, 111–122. [Google Scholar] [CrossRef]

- Hawkesford, M.J. Reducing the Reliance on Nitrogen Fertilizer for Wheat Production. J. Cereal Sci. 2014, 59, 276–283. [Google Scholar] [CrossRef] [Green Version]

- Zheng, W.; Liu, Z.; Zhang, M.; Shi, Y.; Zhu, Q.; Sun, Y.; Zhou, H.; Li, C.; Yang, Y.; Geng, J. Improving Crop Yields, Nitrogen Use Efficiencies, and Profits by Using Mixtures of Coated Controlled-Released and Uncoated Urea in a Wheat-Maize System. Field Crop. Res. 2017, 205, 106–115. [Google Scholar] [CrossRef]

- Liu, G.; Wan, L.B.; Zhang, M.; Cao, Y.P.; Xu, Q.M.; Chen, H.K.; Yang, Y. State Standard of the People’s Republic of China-Slow Release Fertilizer (GB/T23348-2009). In General Administration of Quality Supervision, Inspection; China Standard Press: Beijing, China, 2009; pp. 2–5. [Google Scholar]

- Bremner, J.M. Determination of Nitrogen in Soil by the Kjeldahl Method. J. Agric. Sci. 1960, 55, 11–33. [Google Scholar] [CrossRef]

- Douglas, L.A.; Riazi, A.; Smith, C.J. A Semi-Micro Method for Determining Total Nitrogen in Soils and Plant Material Containing Nitrite and Nitrate. Soil Sci. Soc. Am. J. 1980, 44, 431–433. [Google Scholar] [CrossRef]

- Zhu, L.; Xiao, Q.; Shen, Y.; Li, S. Effects of Biochar and Maize Straw on the Short-Term Carbon and Nitrogen Dynamics in a Cultivated Silty Loam in China. Environ. Sci. Pollut. Res. 2017, 24, 1019–1029. [Google Scholar] [CrossRef]

- Zhang, M.M.; Dong, B.D.; Qiao, Y.Z.; Shi, C.H.; Yang, H.; Wang, Y.K.; Liu, M.Y. Yield and Water Use Responses of Winter Wheat to Irrigation and Nitrogen Application in the North China Plain. J. Integr. Agric. 2018, 17, 1194–1206. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Wang, J.; Wang, Z.; Li, W.; Wang, C.; Yan, S.; Li, H.; Zhang, A.; Tang, Z.; Wei, M. Optimized Nitrogen Fertilizer Application Mode Increased Culms Lignin Accumulation and Lodging Resistance in Culms of Winter Wheat. Field Crop. Res. 2018, 228, 31–38. [Google Scholar] [CrossRef]

- Ju, J.; Cai, Y.; Zuo, W.; Hai-Tao, Z.; Yang, H.; Mao, W.; Yu-Hua, S.; Ke, F. Effects of Nitrogen Management on Soil Nitrogen Content and Rice Grain Yield in Double Cropping Rice Production Area with Continuous Full Amount of Straw Returning. Commun. Soil Sci. Plant Anal. 2019, 50, 2655–2668. [Google Scholar] [CrossRef]

- Shi, Y.; Yu, Z.; Wang, D.; Li, Y.; Wang, X. Effects of Nitrogen Rate and Ratio of Base Fertilizer and Topdressing on Uptake, Translocation of Nitrogen and Yield in Wheat. Front. Agric. China 2007, 1, 142–148. [Google Scholar] [CrossRef]

- Bai, J.; Li, Y.; Zhang, J.; Xu, F.; Bo, Q.; Wang, Z.; Li, Z.; Li, S.; Shen, Y.; Yue, S. Straw Returning and One-Time Application of a Mixture of Controlled Release and Solid Granular Urea to Reduce Carbon Footprint of Plastic Film Mulching Spring Maize. J. Clean. Prod. 2021, 280, 124478. [Google Scholar] [CrossRef]

- Miao, X.; Xing, X.; Ding, Y.; Ke, J.; Liu, Z.; Tang, S.; Ding, C.; Wang, S.; Li, G. Yield and Nitrogen Uptake of Bowl-Seedling Machine-Transplanted Rice with Slow-Release Nitrogen Fertilizer. Agron. J. 2016, 108, 313–320. [Google Scholar] [CrossRef] [Green Version]

- Sempeho, S.I.; Kim, H.T.; Mubofu, E.; Hilonga, A. Meticulous Overview on the Controlled Release Fertilizers. Adv. Chem. 2014, 2014, 363071. [Google Scholar] [CrossRef]

- Nelson, K.A.; Scharf, P.C.; Bundy, L.G.; Tracy, P. Agricultural Management of Enhanced-efficiency Fertilizers in the North-central United States. Crop Manag. 2008, 7, 1–12. [Google Scholar] [CrossRef]

- Grant, C.A.; Wu, R.; Selles, F.; Harker, K.N.; Clayton, G.W.; Bittman, S.; Zebarth, B.J.; Lupwayi, N.Z. Crop Yield and Nitrogen Concentration with Controlled Release Urea and Split Applications of Nitrogen as Compared to Non-Coated Urea Applied at Seeding. Field Crop. Res. 2012, 127, 170–180. [Google Scholar] [CrossRef]

- Yang, X.; Geng, J.; Li, C.; Zhang, M.; Tian, X. Cumulative Release Characteristics of Controlled-Release Nitrogen and Potassium Fertilizers and Their Effects on Soil Fertility, and Cotton Growth. Sci. Rep. 2016, 6, 39030. [Google Scholar] [CrossRef] [Green Version]

- Liang, W.; Zhang, Z.; Wen, X.; Liao, Y.; Liu, Y. Effect of Non-Structural Carbohydrate Accumulation in the Stem Pre-Anthesis on Grain Filling of Wheat Inferior Grain. Field Crop. Res. 2017, 211, 66–76. [Google Scholar] [CrossRef]

- Farmaha, B.S.; Sims, A.L. Yield and Protein Response of Wheat Cultivars to Polymer-coated Urea and Urea. Agron. J. 2013, 105, 229–236. [Google Scholar] [CrossRef]

- Liu, R.; Wang, J.; Shi, J.; Chen, Y.; Sun, C.; Zhang, P.; Shen, Z. Runoff Characteristics and Nutrient Loss Mechanism from Plain Farmland under Simulated Rainfall Conditions. Sci. Total Environ. 2014, 468–469, 1069–1077. [Google Scholar] [CrossRef]

- Ercoli, L.; Lulli, L.; Mariotti, M.; Masoni, A.; Arduini, I. Post-Anthesis Dry Matter and Nitrogen Dynamics in Durum Wheat as Affected by Nitrogen Supply and Soil Water Availability. Eur. J. Agron. 2008, 28, 138–147. [Google Scholar] [CrossRef]

- Zheng, W.; Zhang, M.; Liu, Z.; Zhou, H.; Lu, H.; Zhang, W.; Yang, Y.; Li, C.; Chen, B. Combining Controlled-Release Urea and Normal Urea to Improve the Nitrogen Use Efficiency and Yield under Wheat-Maize Double Cropping System. Field Crop. Res. 2016, 197, 52–62. [Google Scholar] [CrossRef]

- Guo, J.; Wang, Y.; Blaylock, A.D.; Chen, X. Mixture of Controlled Release and Normal Urea to Optimize Nitrogen Management for High-Yielding (>15 Mg Ha−1) Maize. Field Crop. Res. 2017, 204, 23–30. [Google Scholar] [CrossRef]

| Experimental Sites | Soil Texture | FAO Soil Taxonomy | pH | Total N | SOM | Olsen-P | Available K |

|---|---|---|---|---|---|---|---|

| g kg−1 | g kg−1 | mg kg−1 | mg kg−1 | ||||

| Yangzhou | Sandy loam | Eutric fluvisols | 6.10 | 1.40 | 15.23 | 52.17 | 141.46 |

| Jiangyan | Clay | Cumulic anthrosols | 6.72 | 1.96 | 31.72 | 62.54 | 165.26 |

| Fertilization Treatment | N Application Level | N Fertilizer Application Method | N Source Type | Release Longevities of CRU |

|---|---|---|---|---|

| CK | 225 kg ha−1 | four-split application | CU | - |

| CRF-40 | one-time basal application | 40% CU + 60% CRU | 40 days | |

| CRF-60 | 60 days | |||

| CRF-80 | 80 days | |||

| CRF-100 | 100 days | |||

| CRF-120 | 120 days | |||

| N0 | 0 kg ha−1 | - | - | - |

| Cultivar | Fertilization | 2017–2018 | 2018–2019 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Jointing (kg·ha−1) | Anthesis (kg·ha−1) | Maturity (kg·ha−1) | DM after Anthesis (kg·ha−1) | Jointing (kg·ha−1) | Anthesis (kg·ha−1) | Maturity (kg·ha−1) | DM after Anthesis (kg·ha−1) | ||

| Yangzhou | |||||||||

| Y23 | CK | 6171.73 a | 11,394.59 a | 18,237.22 a | 6842.63 a | 6931.93 a | 12,798.12 a | 20,482.46 a | 7684.35 a |

| CRF-40 | 6151.78 a | 10,952.72 ab | 15,738.98 c | 4786.26 d | 6909.83 a | 12,734.78 a | 19,237.83 ab | 6503.05 bc | |

| CRF-60 | 6135.32 a | 11,329.17 a | 18,258.02 a | 6928.85 a | 6899.90 a | 12,741.01 a | 20,533.34 a | 7792.32 a | |

| CRF-80 | 5895.34 ab | 10,835.39 b | 17,049.90 b | 6214.51 b | 6783.08 ab | 12,680.98 a | 19,955.84 ab | 7274.86 b | |

| CRF-100 | 5776.75 b | 10,312.03 c | 15,518.55 c | 5206.52 c | 6363.33 b | 12,192.34 b | 18,366.04 b | 6173.70 c | |

| CRF-120 | 5745.14 b | 10,182.54 c | 15,261.59 c | 5079.05 c | 5922.85 c | 11,930.53 b | 17,916.67 c | 5986.14 c | |

| Z12 | CK | 6281.47 a | 11,759.37 a | 18,897.10 a | 7137.73 a | 7094.20 a | 13,011.59 a | 20,909.39 a | 7897.80 a |

| CRF-40 | 6251.08 a | 11,322.49 ab | 17,020.56 bc | 5698.07 c | 7061.65 a | 12,394.13 b | 19,288.29 ab | 6894.16 b | |

| CRF-60 | 6253.96 a | 11,602.02 a | 18,716.86 a | 7114.84 a | 7025.99 ab | 13,034.25 a | 21,027.39 a | 7993.14 a | |

| CRF-80 | 5992.73 b | 11,406.63 ab | 17,947.67 b | 6541.05 b | 6501.51 b | 12,692.75 ab | 19,971.32 ab | 7278.57 ab | |

| CRF-100 | 5845.52 b | 10,769.47 b | 16,577.47 c | 5808.00 c | 6181.04 bc | 12,025.94 bc | 18,477.25 b | 6451.31 bc | |

| CRF-120 | 5794.63 b | 10,417.14 c | 16,004.41 c | 5587.27 d | 6029.10 c | 11,664.66 c | 17,886.70 c | 6222.04 c | |

| Jiangyan | |||||||||

| Y23 | CK | 6795.55 ab | 12,370.46 a | 19,697.41 a | 7326.95 a | 7218.14 a | 13,139.74 a | 20,922.33 a | 7782.59 ab |

| CRF-40 | 7010.39 a | 12,022.55 a | 18,805.59 b | 6783.04 b | 7260.53 a | 12,451.53 b | 19,476.59 b | 7025.06 c | |

| CRF-60 | 6886.65 a | 12,250.40 a | 19,458.77 a | 7208.37 a | 7224.28 a | 13,040.35 a | 20,713.55 a | 7673.19 ab | |

| CRF-80 | 6820.57 a | 12,173.35 a | 19,567.27 a | 7393.92 a | 7088.26 ab | 13,033.29 a | 20,949.53 a | 7916.24 a | |

| CRF-100 | 6660.54 b | 11,332.74 b | 17,775.97 c | 6443.24 b | 6787.45 b | 12,286.54 b | 19,272.06 bc | 6985.52 c | |

| CRF-120 | 6496.32 b | 11,663.22 b | 17,676.30 c | 6013.08 c | 6708.44 b | 12,232.36 b | 18,538.86 c | 6306.50 d | |

| Z12 | CK | 6727.08 a | 12,156.89 a | 19,359.19 a | 7202.30 ab | 7285.31 a | 13,165.69 a | 20,965.65 a | 7799.96 a |

| CRF-40 | 6728.51 a | 11,469.12 b | 17,837.43 b | 6368.31 c | 7307.40 a | 12,839.43 b | 19,970.84 b | 7131.42 b | |

| CRF-60 | 6741.50 a | 12,310.57 a | 19,295.73 a | 6985.16 ab | 7288.23 a | 13,092.73 a | 20,859.52 a | 7766.79 a | |

| CRF-80 | 6631.47 a | 12,206.34 a | 19,818.08 a | 7611.74 a | 6915.44 ab | 13,067.26 a | 20,915.92 a | 7848.65 a | |

| CRF-100 | 6313.46 b | 11,089.51 b | 17,568.49 b | 6478.98 c | 6482.22 b | 12,343.87 b | 19,363.66 b | 7019.79 b | |

| CRF-120 | 6176.55 c | 10,359.10 c | 15,760.24 c | 5401.14 d | 6183.46 c | 12,115.78 b | 19,107.80 c | 6992.02 b | |

| Cultivar | Fertilization | 2017–2018 | 2018–2019 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Grain Yield (kg·ha−1) | Spikes (×104 ha−1) | Grains per Spike | TGW (g) | Grain Yield (kg·ha−1) | Spikes (×104 ha−1) | Grains per Spike | TGW (g) | ||

| Yangzhou | |||||||||

| Y23 | CK | 7600.00 a | 443.84 a | 43.0 a | 41.22 b | 8536.13 a | 451.19 a | 45.9 a | 43.64 b |

| CRF-40 | 6076.89 c | 410.18 b | 41.6 b | 40.84 b | 7935.00 b | 432.47 ab | 42.9 bc | 43.66 b | |

| CRF-60 | 7632.96 a | 439.60 a | 44.1 a | 41.64 b | 8584.18 a | 455.42 a | 44.9 ab | 44.05 b | |

| CRF-80 | 7442.24 ab | 437.90 a | 38.8 b | 41.44 b | 8242.50 ab | 446.51 a | 43.3 bc | 44.88 ab | |

| CRF-100 | 6329.80 c | 411.37 b | 37.1 c | 41.96 b | 7491.25 c | 417.62 bc | 42.4 c | 45.56 a | |

| CRF-120 | 6081.92 c | 385.65 c | 37.5 c | 43.69 a | 7140.00 d | 404.66 c | 42.8 bc | 45.72 a | |

| Z12 | CK | 7880.43 a | 427.73 ab | 39.2 a | 53.56 ab | 8719.59 a | 472.34 a | 38.7 ab | 52.05 bc |

| CRF-40 | 6985.13 c | 412.85 ab | 34.9 c | 52.88 ab | 7646.25 b | 440.37 ab | 36.5 c | 51.31 c | |

| CRF-60 | 7868.92 a | 438.84 a | 41.2 a | 51.04 c | 8840.31 a | 470.92 a | 39.2 a | 52.57 b | |

| CRF-80 | 7257.84 b | 408.40 b | 38.5 ab | 51.13 c | 8076.18 b | 440.37 ab | 37.0 bc | 52.49 b | |

| CRF-100 | 6705.32 c | 406.17 b | 35.6 bc | 52.06 bc | 7473.75 c | 406.58 b | 36.3 c | 54.24 ab | |

| CRF-120 | 6440.30 d | 393.95 b | 34.3 c | 54.37 a | 7197.75 d | 399.32 b | 36.0 c | 55.57 a | |

| Jiangyan | |||||||||

| Y23 | CK | 8144.50 a | 439.42 ab | 39.9 ab | 44.53 bc | 8650.98 a | 432.06 a | 46.8 a | 44.65 c |

| CRF-40 | 7690.71 b | 430.34 b | 37.5 bc | 42.91 d | 7965.12 b | 429.13 a | 43.9 bc | 45.07 c | |

| CRF-60 | 7937.62 ab | 431.51 b | 41.4 a | 43.99 c | 8449.47 a | 440.10 a | 44.5 bc | 45.34 bc | |

| CRF-80 | 8166.44 a | 445.88 a | 42.7 a | 43.79 c | 8743.33 a | 444.69 a | 46.0 ab | 45.37 bc | |

| CRF-100 | 7293.77 c | 402.82 c | 33.6 d | 44.95 b | 7907.64 b | 396.54 b | 44.3 bc | 45.95 b | |

| CRF-120 | 7100.17 c | 399.62 c | 36.5 cd | 45.84 a | 7446.64 c | 385.67 b | 42.9 c | 46.90 a | |

| Z12 | CK | 8116.48 ab | 479.82 ab | 35.6 a | 52.38 b | 8790.00 a | 500.03 a | 39.3 a | 52.91 b |

| CRF-40 | 7203.11 c | 468.82 b | 34.1 ab | 52.54 b | 8063.72 c | 488.16 a | 36.4 c | 52.92 b | |

| CRF-60 | 7931.76 b | 481.41 a | 34.0 ab | 52.69 b | 8575.02 b | 509.88 a | 37.8 b | 52.96 b | |

| CRF-80 | 8344.70 a | 489.07 a | 35.0 a | 52.22 b | 8718.97 a | 516.96 a | 38.8 ab | 53.43 b | |

| CRF-100 | 7130.57 c | 454.77 c | 32.3 bc | 53.08 b | 8234.13 c | 448.35 b | 34.9 d | 53.75 b | |

| CRF-120 | 6202.95 d | 435.37 d | 31.5 c | 54.12 a | 8030.00 c | 412.00 c | 33.5 e | 55.60 a | |

| Cultivar | Fertilization | Yangzhou | Jiangyan | ||

|---|---|---|---|---|---|

| Average Yield (kg·ha−1) | % Change Relative to CK | Average Yield (kg·ha−1) | % Change Relative to CK | ||

| Y23 | CK | 8068.1 | - | 8397.7 | - |

| CRF-40 | 7005.9 | −13.2 | 7827.9 | −6.8 | |

| CRF-60 | 8108.6 | 0.5 | 8193.5 | −2.4 | |

| CRF-80 | 7842.4 | −2.8 | 8454.9 | 0.7 | |

| CRF-100 | 6910.5 | −14.3 | 7600.7 | −9.5 | |

| CRF-120 | 6611.0 | −18.1 | 7273.4 | −13.4 | |

| Z12 | CK | 8300.0 | - | 8453.2 | - |

| CRF-40 | 7315.7 | −11.9 | 7633.4 | −9.7 | |

| CRF-60 | 8354.6 | 0.7 | 8253.4 | −2.4 | |

| CRF-80 | 7667.0 | −7.6 | 8531.8 | 0.9 | |

| CRF-100 | 7089.5 | −14.6 | 7682.4 | −9.1 | |

| CRF-120 | 6819.0 | −17.8 | 7116.5 | −15.8 | |

| Cultivar | Fertilization | Yangzhou | Jiangyan | ||||

|---|---|---|---|---|---|---|---|

| PFPN (kg kg−1) | AEN (kg kg−1) | AREN (%) | PFPN (kg kg−1) | AEN (kg kg−1) | AREN (%) | ||

| Y23 | CK | 35.86 a | 19.62 a | 49.23 b | 37.32 a | 20.67 a | 51.33 b |

| CRF-40 | 31.14 c | 14.90 c | 30.56 de | 34.79 c | 18.14 c | 40.10 c | |

| CRF-60 | 36.04 a | 19.80 a | 54.33 a | 36.42 b | 19.77 b | 49.97 b | |

| CRF-80 | 34.85 b | 18.61 b | 41.05 c | 37.58 a | 20.93 a | 56.32 a | |

| CRF-100 | 30.71 d | 14.47 c | 31.66 d | 33.78 cd | 17.13 d | 36.73 c | |

| CRF-120 | 29.38 d | 13.14 d | 29.83 e | 32.33 d | 15.68 e | 21.98 d | |

| Z12 | CK | 36.89 a | 20.40 a | 50.86 b | 37.57 a | 20.64 a | 51.43 b |

| CRF-40 | 32.51 c | 16.02 c | 27.48 d | 33.93 c | 17.00 c | 37.31 c | |

| CRF-60 | 37.13 a | 20.64 a | 56.05 a | 36.68 b | 19.75 b | 52.02 b | |

| CRF-80 | 34.08 b | 17.58 b | 39.40 c | 37.92 a | 20.99 a | 57.63 a | |

| CRF-100 | 31.51 d | 15.02 d | 23.87 e | 34.14 c | 17.21 c | 34.95 c | |

| CRF-120 | 30.31 d | 13.81 e | 18.48 f | 31.63 d | 14.70 d | 27.92 d | |

| Site | Fertilization | Total Input | Fertilizer Cost | Fertilization Labor Cost | Other Cost | Net Income | % Change Relative to CK |

|---|---|---|---|---|---|---|---|

| (CNY ha−1) | |||||||

| Yangzhou | CK | 8649.7 | 2289.7 | 600 | 5760 | 9355.2 a | |

| CRF-40 | 8530.9 | 2561.9 | 150 | 5760 | 7281.9 c | −22.2% | |

| CRF-60 | 8530.9 | 2561.9 | 150 | 5760 | 9637.6 a | 3.0% | |

| CRF-80 | 8530.9 | 2561.9 | 150 | 5760 | 8588.4 b | −8.2% | |

| CRF-100 | 8530.9 | 2561.9 | 150 | 5760 | 6928.1 c | −25.9% | |

| CRF-120 | 8530.9 | 2561.9 | 150 | 5760 | 6301.1 d | −32.6% | |

| Jiangyan | CK | 8649.7 | 2289.7 | 600 | 5760 | 9886.3 a | |

| CRF-40 | 8530.9 | 2561.9 | 150 | 5760 | 8535.5 b | −13.7% | |

| CRF-60 | 8530.9 | 2561.9 | 150 | 5760 | 9619.7 a | −2.7% | |

| CRF-80 | 8530.9 | 2561.9 | 150 | 5760 | 10,213.5 a | 3.3% | |

| CRF-100 | 8530.9 | 2561.9 | 150 | 5760 | 8339.5 b | −15.6% | |

| CRF-120 | 8530.9 | 2561.9 | 150 | 5760 | 7357.0 c | −25.6% | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, P.; Chen, Z.; Ning, Q.; Wei, H.; Zhang, H.; Lu, H.; Gao, H.; Zhang, H. One-Time Nitrogen Fertilizer Application Using Controlled-Release Urea Ensured the Yield, Nitrogen Use Efficiencies, and Profits of Winter Wheat. Agronomy 2022, 12, 1792. https://doi.org/10.3390/agronomy12081792

Cui P, Chen Z, Ning Q, Wei H, Zhang H, Lu H, Gao H, Zhang H. One-Time Nitrogen Fertilizer Application Using Controlled-Release Urea Ensured the Yield, Nitrogen Use Efficiencies, and Profits of Winter Wheat. Agronomy. 2022; 12(8):1792. https://doi.org/10.3390/agronomy12081792

Chicago/Turabian StyleCui, Peiyuan, Zhixuan Chen, Qianqian Ning, Haiyan Wei, Haipeng Zhang, Hao Lu, Hui Gao, and Hongcheng Zhang. 2022. "One-Time Nitrogen Fertilizer Application Using Controlled-Release Urea Ensured the Yield, Nitrogen Use Efficiencies, and Profits of Winter Wheat" Agronomy 12, no. 8: 1792. https://doi.org/10.3390/agronomy12081792

APA StyleCui, P., Chen, Z., Ning, Q., Wei, H., Zhang, H., Lu, H., Gao, H., & Zhang, H. (2022). One-Time Nitrogen Fertilizer Application Using Controlled-Release Urea Ensured the Yield, Nitrogen Use Efficiencies, and Profits of Winter Wheat. Agronomy, 12(8), 1792. https://doi.org/10.3390/agronomy12081792