Mechanical Pruning of ‘Clemenules’ Mandarins in Spain: Yield Effects and Economic Analysis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Site and Vegetal Material

2.2. Experimental Design

2.3. Pruning Machines

2.4. Assessments

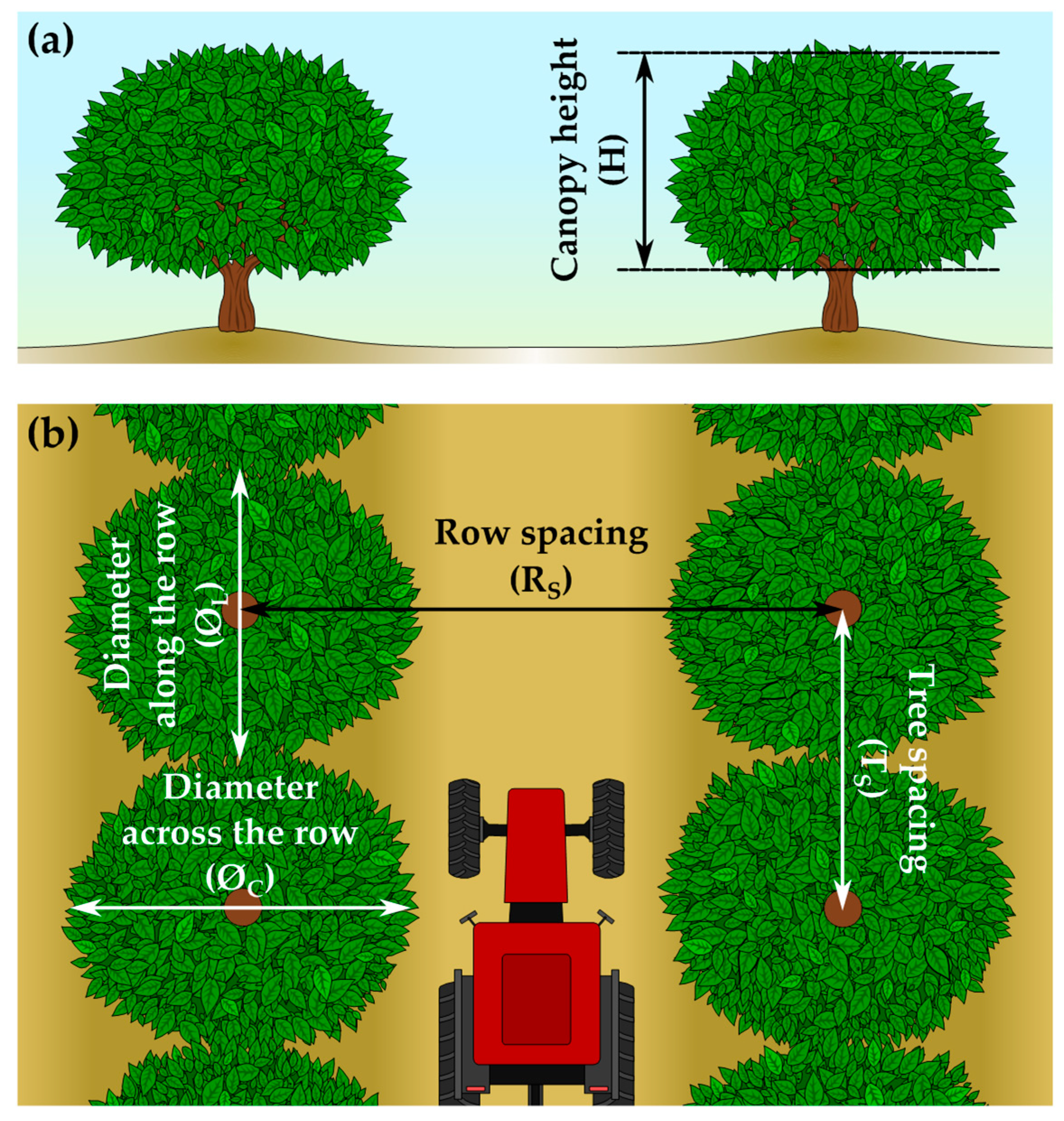

2.4.1. Characterization of Pruned Biomass and Trees

- -

- The length (cm) and the diameter (mm) of the branch in the cutting area were measured in a minimum of 100 branches for the topping, hedging, and manual follow-up cuttings, and in a minimum of 50 branches for the manual cutting. For this, the branches were chosen from pruning strategies in which there was no annual alternation between manual and mechanical pruning.

- -

- The quantity of fresh biomass removed with each pruning strategy was measured (kg∙tree−1). For this, all the pruned branches in each type of cutting of the evaluation tree were weighed using a digital dynamometer (Advanced Force Gauge 500 N, Mecmesin Ltd., England, UK). Afterwards, the total fresh biomass of each sample tree was calculated by adding the weights obtained in the different types of cuts included in each strategy.

- -

- The moisture content (%) of the fresh biomass was measured in the laboratory, based on the thermogravimetric analysis method, for the first year of the trial. For this, five random samples of fresh pruned biomass of each type of cutting (topping, hedging, manual follow-up, and manual pruning) were selected. Each sample was divided into leaves and wood, and dried in an oven (Dry-Big 2003741, J.P. Selecta S.A., Abrera, Barcelona, Spain) at 65 °C for the time necessary to reach a constant weight. In this way, the moisture content (%) in the biomass of leaves and wood, respectively, was calculated with Equation (2):

2.4.2. Pruning Effect on Citrus Production: Yield and Fruit Size

2.4.3. Pruning Working Capacity and Costs

2.4.4. Economic Profit

2.5. Statistical Methods

3. Results

3.1. Characterization of Pruned Biomass and Canopy Dimensions

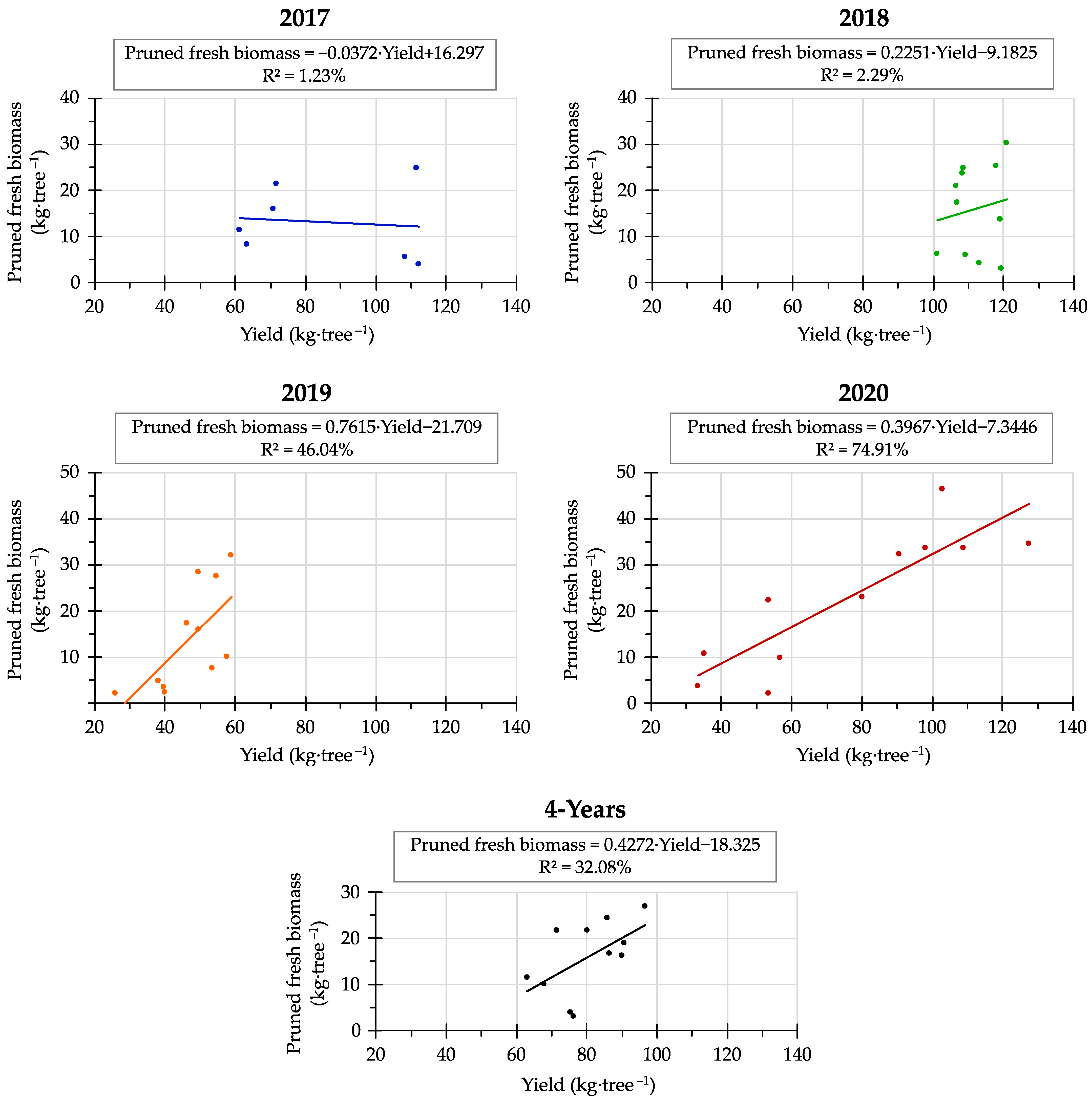

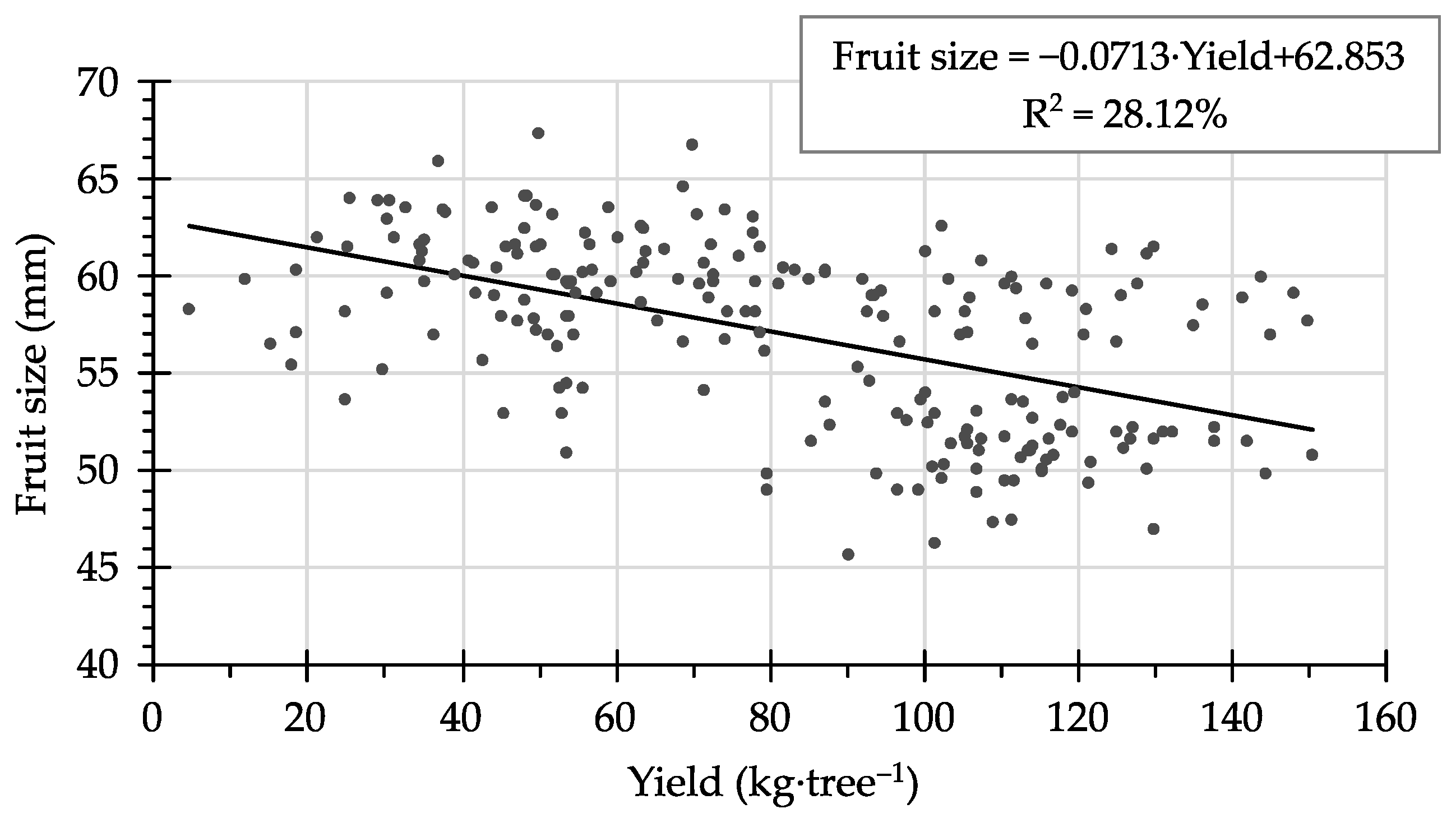

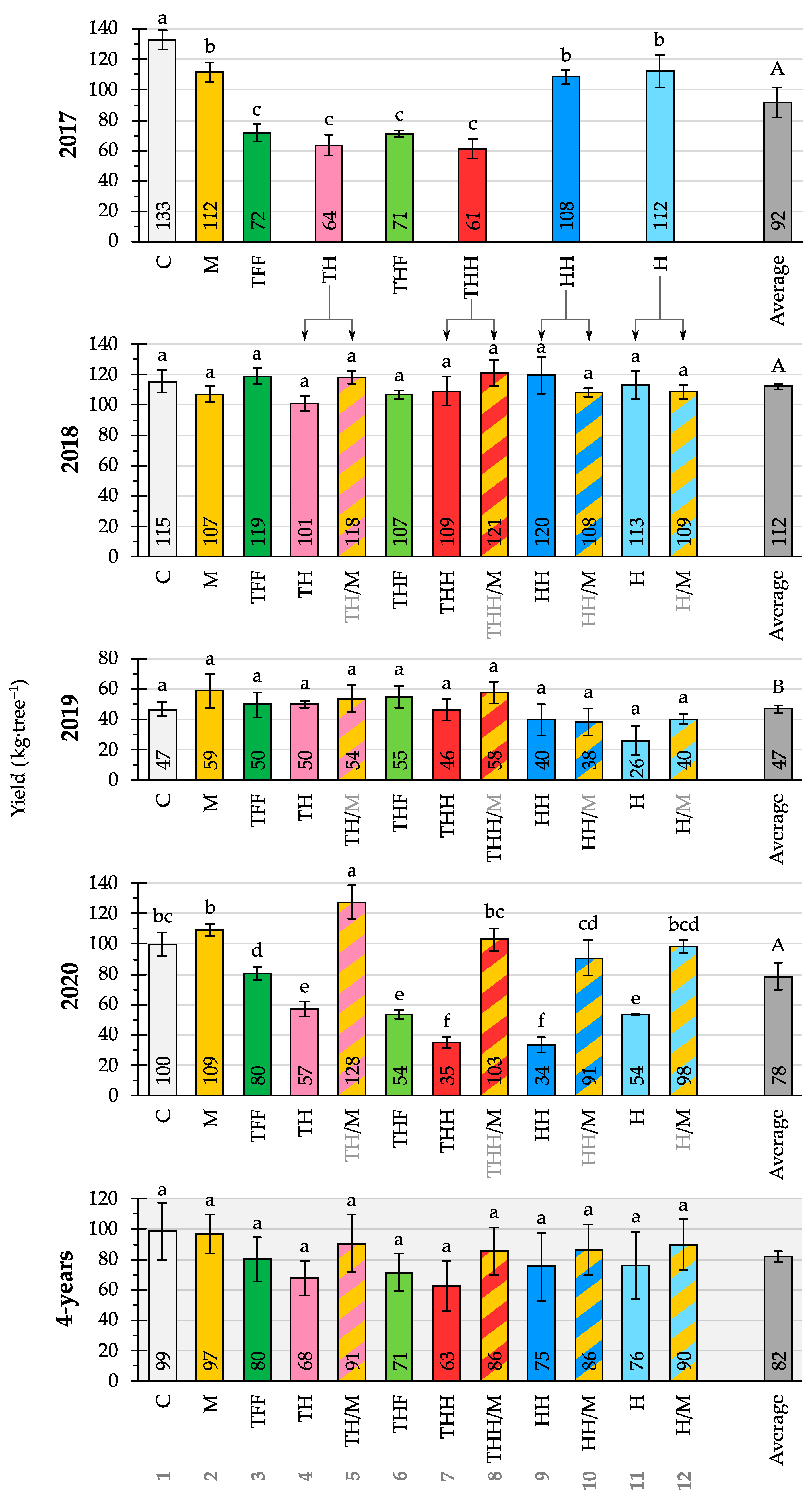

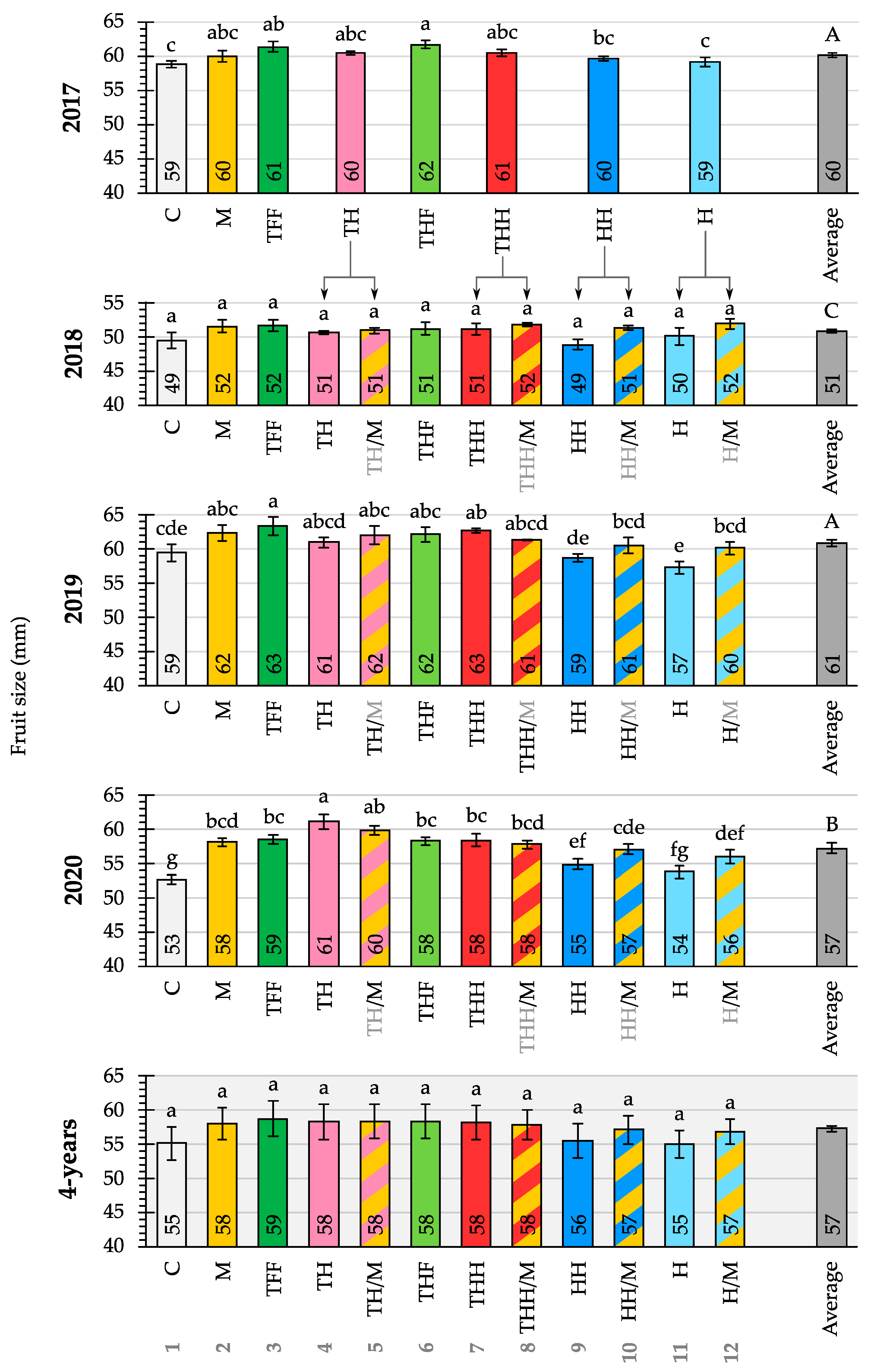

3.2. Pruning Effect on Citrus Production: Yield and Fruit Size

3.3. Pruning Working Capacity and Costs

3.4. Economic Profit

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- FAOSTAT. 2021. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 5 July 2021).

- Fernández-Zamudio, M.A. La citricultura valenciana, la evolución de sus costes de producción e insumos que los determinan. Levante Agrícola 2021, 455, 57–62. (In Spanish) [Google Scholar]

- Junta de Andalucía, Consejería de Agricultura, Ganadería, Pesca y Desarrollo Sostenible. Observatorio de Precios y Mercados—Cítricos. Available online: https://www.juntadeandalucia.es/agriculturaypesca/observatorio/servlet/FrontController?action=Static&subsector=21&url=subsector.jsp (accessed on 10 February 2022). (In Spanish).

- Juste, F.; Martín, B.; Fabado, F.; Moltó, E. Estudio sobre la reducción de los costes de producción de cítricos mediante la mecanización de las prácticas de cultivo. Comunitat Valencia. Agrar. 2000, 12, 23–29. (In Spanish) [Google Scholar]

- Soro, R. Panorama actual citrícola. Phytoma 2019, 307, 16–17. (In Spanish) [Google Scholar]

- Caballero, P.; de-Miguel, M.D.; Fernández-Zamudio, M.A. Análisis de los costes de producción de cítricos y posibles actuaciones empresariales. Vida Rural 2011, 328, 52–57. (In Spanish) [Google Scholar]

- Chueca, P.; Castro García, S.; Martin-Gorriz, B.; Torregrosa, A.; Mateu, G.; González-González, M.G.; Garcerá, C. La mecanización de los tratamientos fitosanitarios, la poda y la recolección: Presente y futuro. In Una Hoja de Ruta Para la Citricultura Española; García, J.M., Moltó, E., Eds.; Fundación Cajamar: Almería, Spain, 2020; pp. 177–190. (In Spanish) [Google Scholar]

- Caballero, P.; Carmona, B.; Fernández-Zamudio, M.A. Opciones en la reducción de los costes de producción y sus efectos en la competitividad y en la rentabilidad de los agrios. Levante Agrícola 2010, 403, 376–386. (In Spanish) [Google Scholar]

- Mateu, G.; Caballero, P.; Torregrosa, A.; Segura, B.; Juste, F.; Chueca, P. Análisis de la influencia de las operaciones de cultivo sobre los costes de producción en la citricultura de la Comunidad Valenciana. Levante Agrícola Rev. Int. Cítricos 2018, 440, 60–64. (In Spanish) [Google Scholar]

- Martin-Gorriz, B.; Martínez-Barba, C.; Torregrosa, A. Lemon trees response to different long-term mechanical and manual pruning practices. Sci. Hortic. 2021, 275, 109700. [Google Scholar] [CrossRef]

- Chueca, P.; Mateu, G.; Garcerá, C.; Fonte, A.; Ortiz, C.; Torregrosa, A. Yield and Economic Results of Different Mechanical Pruning Strategies on “Navel Foyos” Oranges in the Mediterranean Area. Agriculture 2021, 11, 82. [Google Scholar] [CrossRef]

- Intrigliolo, F.; Roccuzzo, G. Modern trends of citrus pruning in Italy. Adv. Hort. Sci. 2011, 25, 187–192. [Google Scholar]

- Bevington, K.B.; Bacon, P.E. Effect of hedging on the productivity of Valencia orange trees. Am. J. Expt. Agric. Anim. Husb. 1978, 18, 591–596. [Google Scholar] [CrossRef]

- Agustí, M.; Martínez-Fuentes, A.; Reig, C.; Iglesias, D.J.; Primo-Millo, E.; Mesejo, C. Alleviation of alternate bearing in Citrus by means of mechanical pruning. In Proceedings of the International Symposium on Flowering, Fruit Set and Alternate Bearing, Palermo, Italy, 19–23 June 2017. [Google Scholar]

- Monselise, S.P.; Goldschmidt, E.E. Alternate bearing in fruit trees. Am. Soc. Hortic. Sci. 1982, 4, 128–173. [Google Scholar]

- Mesejo, C.; Martínez-Fuentes, A.; Reig, C.; Balasch, S.; Primo-Millo, E.; Agustí, A. Mechanical pruning attenuates alternate bearing in ‘Nadorcott’ mandarin. Sci. Hortic. 2020, 261, 108993. [Google Scholar] [CrossRef]

- Fallahi, E.; Kilby, M. Rootstock and pruning influence on yield and fruit quality of ‘Lisbon’ lemon. Fruit Var. J. 1997, 51, 242–246. [Google Scholar]

- Vashisth, T.; Zekri, M.; Alferez, F. 2021–2022 Florida Citrus Production Guide: Canopy Management: Chapter 19, CMG16/HS1303, Rev. 4/2021. EDIS 2021, 4. Available online: https://edis.ifas.ufl.edu/pdf/HS/HS1303/HS1303-Dxj7z1csni.pdf (accessed on 18 February 2022). [CrossRef]

- Morales, P.; Davies, F.S.; Littell, R.C. Pruning and skirting affect canopy microclimate, yield and fruit quality of “Orlando” tangelo. HortScience 2000, 35, 30–35. [Google Scholar] [CrossRef]

- Phillips, P.A.; O’Connell, N.V.; Menge, J.A. Citrus skirt pruning—A management technique for Phytophthora brown rot. Calif. Agric. 1990, 44, 6–7. [Google Scholar] [CrossRef]

- Krajewski, A.; Pittaway, T. Manipulation of citrus flowering and fruiting by pruning. In Proceedings of the International Citrus Congresses, Orlando, FL, USA, 3–7 December 2000; Volume 1, pp. 357–360. [Google Scholar]

- Martin-Gorriz, B.; Porras Castillo, I.; Torregrosa, A. Effect of mechanical pruning on the yield and quality of ‘Fortune’ mandarins. Span. J. Agric. Res. 2014, 12, 952–959. [Google Scholar] [CrossRef]

- Tucker, D.P.H.; Wheaton, T.A.; Muraro, R.P. Citrus Tree Pruning Principles and Practices. UF Coop Ext. Ser.; Fact Sheet HS-144. 1994, p. 9. Available online: http://ufdcimages.uflib.ufl.edu/IR/00/00/46/22/00001/CH02700.PDF (accessed on 18 February 2022).

- Zekri, M. Mechanical Pruning of Citrus Trees. UF Coop Ext. Ser. HS1267. 2018. Available online: https://edis.ifas.ufl.edu/publication/HS1267 (accessed on 18 February 2022).

- Prosser, D. Hedging practices in Florida citrus groves. Calif. Citrogr. 1955, 40, 292. [Google Scholar]

- Moore, P.W.; Nauer, E. Mechanical hedging in California orchards. Calif. Citrogr. 1955, 40, 399. [Google Scholar]

- Moore, P.W. Mechanical pruning for citrus. Calif. Agric. 1958, 11, 7–13. [Google Scholar]

- Ortiz-Cañavate, J. Mechanical pruning of citrus. An. Inst. Nac. Investig. Agrar. Tecnol. Agrar. 1979, 5, 155–167. (In Spanish) [Google Scholar]

- Zaragoza, S.; Alonso, E. Citrus pruning in Spain. Proc. Int. Soc. Citric. 1981, 1, 172–175. [Google Scholar]

- Raciti, G.; Spina, P.; Scuderi, A.; Intrigliolo, F. Three years of mechanical pruning of citrus in Italy. Proc. Intl. Soc. Citricult. 1981, 1, 175–180. [Google Scholar]

- Spina, P.; Giuffrida, A.; Melita, E. Comparative trials of citrus mechanical and aided pruning. In Proceedings of the International Society of Citriculture 1, 1984, International Citrus Congress, Sao Paulo, Brazil, 15–20 July 1984; pp. 106–109. [Google Scholar]

- Wheaton, T.A.; Whitney, J.D.; Castle, W.S.; Tucker, D.P.H. Crosshedging, tree removal, and topping affect fruit yield and quality of citrus hedge rows. Proc. Intl. Soc. Citricult. 1984, 1, 109–114. [Google Scholar]

- Kallsen, C.E. Topping and manual pruning effects on the production of commercially valuable fruit in a midseason Navel Orange variety. HorTecnology 2005, 15, 335–341. [Google Scholar] [CrossRef]

- Mendonça, V.; Ramos, J.D.; Neto, S.E.A.; Rufini, J.C.M. Production of ‘Poncan’ tangerine tree after pruning recovery. Cienc. Agrotecnol. 2008, 32, 103–109. [Google Scholar] [CrossRef] [Green Version]

- Yildirim, B.; Yesiloglu, T.; Incesu, M.; Kamiloglu, M.; Ozguven, F.; Tuzcu, O.; Kaçar, Y.A. The effects of mechanical pruning on fruit yield and quality in ‘Star Ruby’ grapefruit. J. Food Agric. Environ. 2010, 8, 834–838. [Google Scholar]

- Velázquez, B.; Fernández, E. The influence of mechanical pruning in cost reduction, production of fruit, and biomass waste in citrus orchards. Appl. Eng. Agric. 2010, 26, 531–540. [Google Scholar] [CrossRef]

- Agustí, M.; Zaragoza, S.; Bleiholder, H.; Buhr, L.; Hack, H.; Klose, R.; Stauß, R. Codificación BBCH de los Estadios Fenológicos del Desarrollo de los Agrios (Gén. Citrus). Ficha Técnica. Serie Citricultura Nº 6. Generalitat Valenciana. Conselleria d’Agricultura, Peixca i Alimentació. 1995. Available online: https://agroambient.gva.es/documents/163228750/167772287/Codificaci%C3%B3n+BBCH+de+los+estadios+fenol%C3%B3gicos+del+desarrollo+de+los+agrios/127b4d39-2bcc-4206-9537-247e049f7649 (accessed on 27 January 2021). (In Spanish).

- Cubero, S.; Moltó, E.; Gutiérrez, A.; Aleixos, N.; García-Navarrete, O.L.; Juste, F.; Blasco, J. Real-time inspection of fruit on a mobile harvesting platform in field conditions using computer vision. Prog. Agric. Eng. Sci. 2010, 6, 1–16. [Google Scholar]

- Cubero, S.; Aleixos, N.; Albert, F.; Torregrosa, A.; Ortiz, C.; García-Navarrete, O.; Blasco, J. Optimised computer vision system for automatic pre-grading of citrus fruit in the field using a mobile platform. Precis. Agric. 2014, 15, 80–94. [Google Scholar] [CrossRef] [Green Version]

- Cámara de Valencia. Lonja de Cítricos. Información de la Mesa de Precios de Cítricos del Consulado de la Lonja de Valencia. 2021. Available online: http://www.precioscitricos.com/indexp.asp (accessed on 4 August 2021). (In Spanish).

- Velázquez-Martí, B.; Fernández-González, E.; López-Cortés, I.; Callejón-Ferre, A. Prediction and evaluation of biomass obtained from citrus trees pruning. J. Food Agric. Environ. 2013, 11, 1485–1494. [Google Scholar]

- Zaragoza, S.; Alonso, E. La poda mecanizada de los agrios en España. An. Inst. Nac. Investig. Agrar. Ser. Prod. Veg. 1980, 12, 157–180. (In Spanish) [Google Scholar]

- Agustí, M.; Mesejo, C.; Reig, C. Citricultura, 3rd ed.; Ediciones Mundi-Prensa: Madrid, Spain, 2020. (In Spanish) [Google Scholar]

- Ahmad, S.; Chatha, Z.A.; Nasir, M.A.; Aziz, A.; Virk, N.A.; Khan, A.R. Effect of pruning on the yield and quality of Kinnow fruit. J. Agric. Soc. Sci. 2006, 2, 51–53. [Google Scholar]

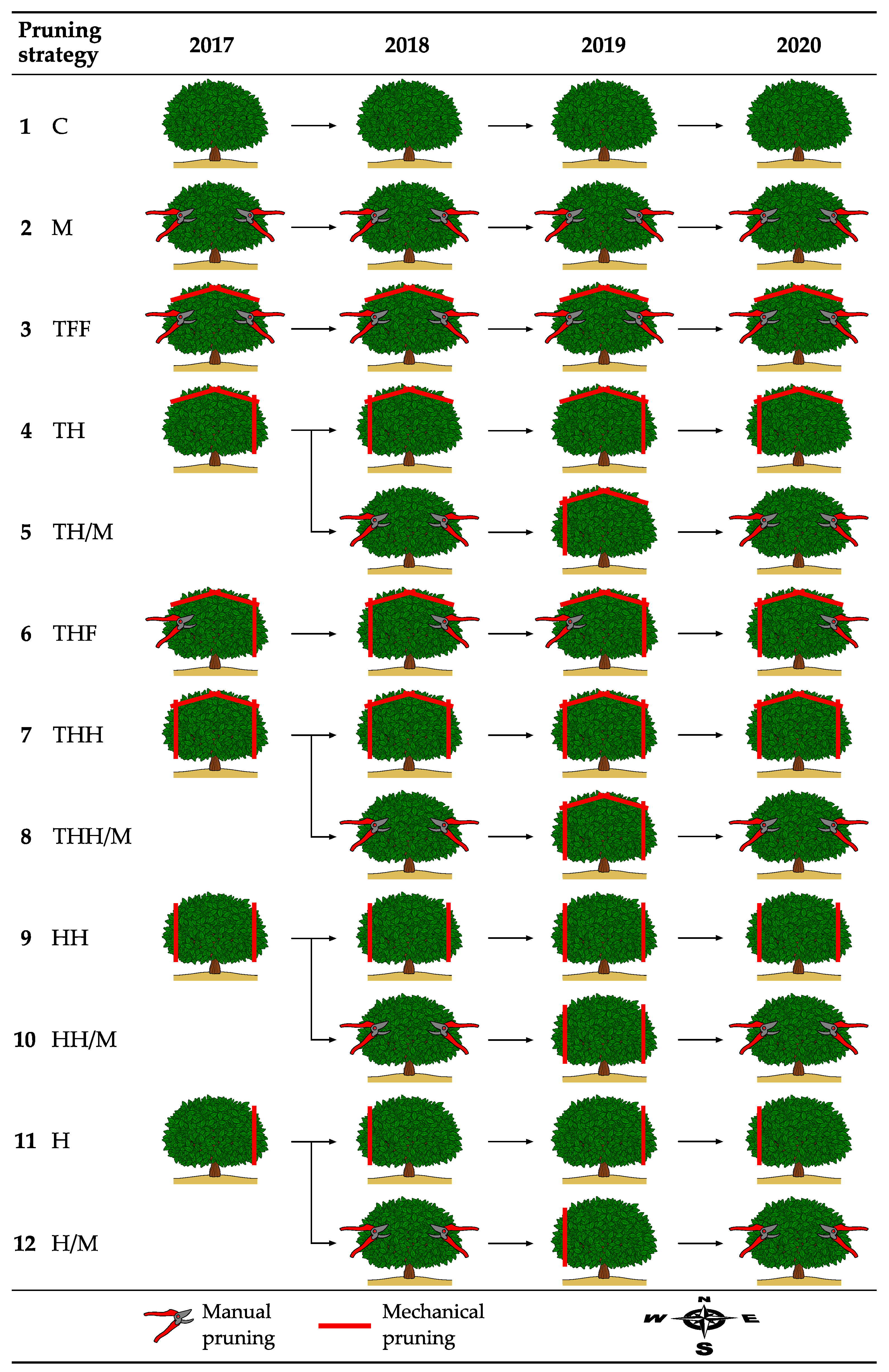

| Pruning Strategy | Definition | |

|---|---|---|

| № | Nomenclature 1 | |

| 1 | C | Control (no pruning). |

| 2 | M | Manual pruning. |

| 3 | TFF | Topping and manual follow-up pruning of a complete tree. |

| 4 | TH | Topping and one-sided hedging, alternating annually between sides (East/West). |

| 5 | TH/M | Alternating annually between TH and M. |

| 6 | THF | TH plus manual follow-up pruning of the nonhedged side. |

| 7 | THH | Topping and two-sided hedging. |

| 8 | THH/M | Alternating annually between THH and M. |

| 9 | HH | Two-sided hedging. |

| 10 | HH/M | Alternating annually between HH and M. |

| 11 | H | One-sided hedging, alternating annually between sides (East/West). |

| 12 | H/M | Alternating annually between H and M. |

| Year | Measurement | Pruning | BBCH Stage | |

|---|---|---|---|---|

| 2017 | 20 March | 20 March | 55–56 | Flowers developing: flowers visible and flower petals elongating. |

| 2018 | 26 February | 5–7 March | 11–15 | Leaves developing: first leaves visible but without reaching the final size. |

| 2019 | 26 March | 27–29 March | 51–59 | Flowers developing: buds swell and burst, flowers visible and flower petals elongating, sepals open and flowers have closed petals and elongated ball shapes. |

| 2020 | 6 March | 9–11 March | 51–59 | Flowers developing: buds swell and burst, flowers visible and flower petals elongating, sepals open and flowers have closed petals and elongated ball shapes. |

| Year | Harvesting Date | Mandarins Price Date | Mandarins Price (€∙kg−1) |

|---|---|---|---|

| 2017 | 1 December | 4 December | 0.294 |

| 2018 | 8 November | 12 November | 0.235 |

| 2019 | 27–28 November | 2 December | 0.388 |

| 2020 | 10–11 November | 16 November | 0.282 |

| Year | Pruning Strategy | H (m) | ØC (m) | ØL (m) | Canopy Volume (m3∙tree−1) | |

|---|---|---|---|---|---|---|

| 2017 | 1 | C | 2.67 (0.19) | 4.47 (0.24) | 3.03 (0.38) | 18.49 (0.93) bc |

| 2 | M | 2.65 (0.10) | 4.80 (0.17) | 3.27 (0.26) | 21.58 (0.79) ab | |

| 3 | TFF | 2.60 (0.10) | 4.73 (0.09) | 3.73 (0.19) | 24.23 (2.63) a | |

| 4 | TH | 2.53 (0.06) | 4.50 (0.21) | 3.97 (0.17) | 23.69 (1.67) a | |

| 5 | TH/M | |||||

| 6 | THF | 2.57 (0.14) | 4.37 (0.18) | 3.13 (0.09) | 18.41 (1.48) bc | |

| 7 | THH | 2.37 (0.06) | 4.37 (0.13) | 3.33 (0.03) | 18.01 (0.38) bc | |

| 8 | THH/M | |||||

| 9 | HH | 2.37 (0.09) | 4.33 (0.20) | 2.97 (0.32) | 15.90 (1.90) c | |

| 10 | HH/M | |||||

| 11 | H | 2.52 (0.02) | 4.53 (0.23) | 3.00 (0.06) | 17.95 (1.23) bc | |

| 12 | H/M | |||||

| 2018 | 1 | C | 3.39 (0.13) | 4.68 (0.30) | 2.88 (0.18) | 24.49 (3.63) a |

| 2 | M | 3.25 (0.15) | 4.40 (0.11) | 2.88 (0.18) | 21.76 (2.58) a | |

| 3 | TFF | 3.33 (0.04) | 4.74 (0.13) | 3.00 (0.24) | 25.00 (2.74) a | |

| 4 | TH | 3.44 (0.08) | 4.76 (0.14) | 2.80 (0.18) | 24.09 (1.99) a | |

| 5 | TH/M | |||||

| 6 | THF | 3.38 (0.07) | 4.48 (0.25) | 2.90 (0.07) | 23.06 (2.05) a | |

| 7 | THH | 3.43 (0.15) | 4.42 (0.15) | 3.06 (0.12) | 24.41 (2.00) a | |

| 8 | THH/M | |||||

| 9 | HH | 3.36 (0.13) | 4.58 (0.16) | 3.12 (0.09) | 25.18 (1.74) a | |

| 10 | HH/M | |||||

| 11 | H | 3.32 (0.05) | 4.64 (0.13) | 2.96 (0.11) | 23.94 (1.43) a | |

| 12 | H/M | |||||

| 2019 | 1 | C | 3.14 (0.19) | 4.77 (0.11) | 3.05 (0.19) | 24.19 (3.09) a |

| 2 | M | 2.59 (0.03) | 4.77 (0.03) | 2.85 (0.15) | 18.43 (1.05) a | |

| 3 | TFF | 2.76 (0.10) | 4.67 (0.21) | 2.97 (0.18) | 19.88 (0.28) a | |

| 4 | TH | 2.95 (0.24) | 4.60 (0.06) | 2.88 (0.25) | 20.29 (1.28) a | |

| 5 | TH/M | 2.66 (0.12) | 4.70 (0.12) | 3.07 (0.33) | 19.88 (0.98) a | |

| 6 | THF | 3.04 (0.05) | 4.27 (0.09) | 2.92 (0.17) | 19.78 (1.01) a | |

| 7 | THH | 3.26 (0.17) | 4.38 (0.07) | 2.90 (0.06) | 21.77 (1.84) a | |

| 8 | THH/M | 2.93 (0.04) | 4.70 (0.13) | 2.53 (0.24) | 18.20 (1.23) a | |

| 9 | HH | 3.03 (0.16) | 4.38 (0.03) | 2.53 (0.02) | 17.63 (1.02) a | |

| 10 | HH/M | 2.65 (0.16) | 4.60 (0.22) | 3.05 (0.06) | 19.32 (0.26) a | |

| 11 | H | 3.26 (0.13) | 4.57 (0.17) | 3.05 (0.13) | 23.75 (1.26) a | |

| 12 | H/M | 2.89 (0.14) | 4.77 (0.02) | 3.25 (0.28) | 23.49 (2.48) a | |

| 2020 | 1 | C | 3.12 (0.15) | 4.87 (0.10) | 3.12 (0.10) | 24.99 (2.19) a |

| 2 | M | 2.91 (0.08) | 4.64 (0.10) | 3.19 (0.11) | 22.44 (0.59) a | |

| 3 | TFF | 2.73 (0.05) | 4.56 (0.14) | 3.14 (0.07) | 20.46 (0.71) a | |

| 4 | TH | 2.96 (0.05) | 4.60 (0.11) | 2.94 (0.17) | 20.99 (1.47) a | |

| 5 | TH/M | 2.77 (0.11) | 4.62 (0.07) | 3.12 (0.15) | 20.91 (1.52) a | |

| 6 | THF | 2.87 (0.05) | 4.36 (0.13) | 3.18 (0.20) | 20.77 (1.06) a | |

| 7 | THH | 3.09 (0.04) | 4.30 (0.06) | 3.22 (0.18) | 22.44 (1.44) a | |

| 8 | THH/M | 2.87 (0.05) | 4.38 (0.06) | 3.40 (0.19) | 22.31 (0.87) a | |

| 9 | HH | 3.33 (0.08) | 4.34 (0.09) | 3.10 (0.16) | 23.34 (0.65) a | |

| 10 | HH/M | 3.08 (0.03) | 4.32 (0.08) | 3.02 (0.16) | 21.04 (1.22) a | |

| 11 | H | 3.30 (0.06) | 4.54 (0.15) | 3.20 (0.24) | 25.14 (2.13) a | |

| 12 | H/M | 3.13 (0.08) | 4.50 (0.17) | 3.22 (0.12) | 23.68 (0.96) a | |

| Year | Type of Cutting | Øbranches (mm) | Lbranches (cm) |

|---|---|---|---|

| 2017 | Hedging | 8.90 (0.30) b | 56.43 (1.54) d |

| Topping | 9.51 (0.45) b | 62.37 (2.48) c | |

| Manual follow-up | 16.47 (0.62) a | 104.44 (2.53) b | |

| Manual | 17.63 (0.80) a | 121.30 (3.88) a | |

| 2018 | Hedging | 6.87 (0.26) b | 45.92 (0.98) c |

| Topping | 5.77 (0.24) c | 63.20 (1.77) b | |

| Manual follow-up | 20.12 (0.82) a | 125.50 (3.25) a | |

| Manual | 17.86 (0.99) a | 140.90 (5.09) a | |

| 2019 | Hedging | 5.58 (0.26) c | 35.55 (1.61) c |

| Topping | 7.77 (0.25) b | 82.12 (2.64) b | |

| Manual follow-up | 21.77 (0.79) a | 110.71 (3.29) a | |

| Manual | 21.62 (1.21) a | 132.14 (7.29) a | |

| 2020 | Hedging | 5.78 (0.20) b | 37.00 (1.36) d |

| Topping | 5.92 (0.16) b | 48.90 (1.40) c | |

| Manual follow-up | 21.86 (1.00) a | 111.11 (3.51) b | |

| Manual | 23.15 (1.67) a | 141.00 (6.01) a | |

| 4-years | Hedging | 6.78 (0.76) b | 43.72 (4.81) d |

| Topping | 7.24 (0.88) b | 64.15 (6.83) c | |

| Manual follow-up | 20.06 (1.26) a | 112.94 (4.46) b | |

| Manual | 20.06 (1.38) a | 133.84 (4.67) a |

| Pruning Strategy | Pruned Fresh Biomass (kg∙tree−1) | |||||

|---|---|---|---|---|---|---|

| 2017 | 2018 | 2019 | 2020 | 4-Years | ||

| 1 | C | – | – | – | – | – |

| 2 | M | 24.83 (0.94) a | 17.29 (0.51) cd | 32.06 (1.44) a | 33.66 (4.28) b | 26.96 (3.75) a |

| 3 | TFF | 21.53 (1.44) a | 13.80 (1.91) d | 28.49 (4.95) a | 23.07 (2.21) c | 21.72 (3.03) a |

| 4 | TH | 8.26 (0.73) cd | 6.39 (0.30) e | 16.01 (0.82) b | 9.84 (1.26) de | 10.13 (2.09) bc |

| 5 | TH/M | 25.38 (0.70) ab | 7.59 (0.41) cd | 34.56 (0.95) b | 18.95 (6.64) abc | |

| 6 | THF | 16.13 (2.47) b | 20.92 (4.44) bc | 27.64 (3.11) a | 22.48 (1.08) c | 21.79 (2.37) a |

| 7 | THH | 11.48 (1.99) c | 6.13 (0.71) e | 17.40 (1.10) b | 10.91 (0.90) d | 11.48 (2.31) b |

| 8 | THH/M | 30.21 (3.16) a | 10.17 (0.59) c | 46.30 (2.23) a | 24.54 (8.58) abc | |

| 9 | HH | 5.62 (0.68) d | 3.10 (0.92) e | 3.64 (0.58) ef | 3.85 (0.74) ef | 4.05 (0.55) c |

| 10 | HH/M | 23.75 (1.41) b | 5.04 (0.94) de | 32.33 (1.93) b | 16.68 (6.79) abc | |

| 11 | H | 3.92 (0.89) d | 4.35 (1.16) e | 2.25 (0.43) ef | 2.19 (0.21) f | 3.18 (0.56) c |

| 12 | H/M | 24.83 (3.09) ab | 2.46 (0.68) ef | 33.80 (4.20) b | 16.25 (7.77) abc | |

| Type of Cutting | Fresh Leaf Biomass (%) | Fresh Wood Biomass (%) | Leaf Biomass Moisture (%) | Wood Biomass Moisture (%) |

|---|---|---|---|---|

| Hedging | 47.98 (2.54) a | 52.02 (2.54) a | 57.74 (1.19) c | 59.29 (0.94) a |

| Topping | 59.45 (2.25) a | 40.55 (2.25) a | 59.52 (0.58) bc | 55.89 (1.99) a |

| Manual follow-up | 59.66 (2.04) a | 40.34 (2.04) a | 70.84 (1.95) a | 34.46 (0.70) b |

| Manual | 58.78 (5.55) a | 41.22 (5.55) a | 64.04 (2.72) b | 30.82 (2.29) b |

| GLOBAL | 56.47 (1.93) | 43.53 (1.93) | 63.04 (1.42) | 45.12 (2.99) |

| Pruning Strategy | Productive Time (min∙tree−1∙operator−1) | TWC (tree∙h−1∙operator−1) | Work Performance (h∙operator∙ha−1) | Pruning Cost (€∙ha−1) | |

|---|---|---|---|---|---|

| 1 | C | – | – | – | – |

| 2 | M | 5.48 | 10.94 | 50.82 | 401.52 |

| 3 | TFF | 5.69 | 10.55 | 52.68 | 474.02 |

| 4 | TH | 0.28 | 214.15 | 2.60 | 101.26 |

| 5 | TH/M | 2.88 | 112.54 | 4.94 | 251.39 |

| 6 | THF | 3.02 | 19.85 | 28.01 | 302.02 |

| 7 | THH | 0.36 | 166.79 | 3.33 | 130.01 |

| 8 | THH/M | 2.92 | 88.86 | 6.26 | 265.76 |

| 9 | HH | 0.16 | 377.11 | 1.47 | 57.50 |

| 10 | HH/M | 2.82 | 194.02 | 2.87 | 229.51 |

| 11 | H | 0.08 | 754.21 | 0.74 | 28.75 |

| 12 | H/M | 2.78 | 382.58 | 1.45 | 215.13 |

| Pruning Strategy | Net Value + k (€∙ha−1) | ||||||

|---|---|---|---|---|---|---|---|

| 2017 | 2018 | 2019 | 2020 | 4-years → | |||

| 1 | C | 19,771–23,666 | 13,148–17,030 | 8237–11,885 | 13,295–17,982 | 10,948–20,305 |  |

| 2 | M | 15,801–19,900 | 12,208–14,938 | 7737–16,824 | 15,463–17,921 | 12,545–17,653 | |

| 3 | TFF | 9423–13,061 | 13,723–16,463 | 6862–13,592 | 10,824–13,416 | 10,116–14,225 | |

| 4 | TH | 8103–12,461 | 11,837–14,413 | 9661–11,587 | 7257–10,343 | 8948–12,467 | |

| 5 | TH/M | 13,934–16,085 | 7717–15,165 | 16,140–23,091 | 9972–18,202 | ||

| 6 | THF | 10,531–12,086 | 12,915–14,323 | 8433–14,548 | 7255–8948 | 8900–13,359 | |

| 7 | THH | 7838–11,921 | 11,604–16,656 | 6772–12,939 | 4248–6490 | 6303–13,314 | |

| 8 | THH/M | 13,203–17,606 | 9256–15,420 | 13,527–17,923 | 10,628–16,046 | ||

| 9 | HH | 16,172–19,181 | 12,515–18,618 | 4090–12,898 | 3575–6819 | 5985–17,482 | |

| 10 | HH/M | 13,032–14,451 | 4404–11,946 | 10,250–17,354 | 9517–17,180 | ||

| 11 | H | 14,902–21,785 | 12,351–17,148 | 1484–9636 | 8215–8550 | 6041–17,477 | |

| 12 | H/M | 12,645–14,950 | 7267–10,000 | 13,672–16,334 | 9996–17,893 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fonte, A.; Torregrosa, A.; Garcerá, C.; Mateu, G.; Chueca, P. Mechanical Pruning of ‘Clemenules’ Mandarins in Spain: Yield Effects and Economic Analysis. Agronomy 2022, 12, 761. https://doi.org/10.3390/agronomy12040761

Fonte A, Torregrosa A, Garcerá C, Mateu G, Chueca P. Mechanical Pruning of ‘Clemenules’ Mandarins in Spain: Yield Effects and Economic Analysis. Agronomy. 2022; 12(4):761. https://doi.org/10.3390/agronomy12040761

Chicago/Turabian StyleFonte, Alberto, Antonio Torregrosa, Cruz Garcerá, Guillermo Mateu, and Patricia Chueca. 2022. "Mechanical Pruning of ‘Clemenules’ Mandarins in Spain: Yield Effects and Economic Analysis" Agronomy 12, no. 4: 761. https://doi.org/10.3390/agronomy12040761

APA StyleFonte, A., Torregrosa, A., Garcerá, C., Mateu, G., & Chueca, P. (2022). Mechanical Pruning of ‘Clemenules’ Mandarins in Spain: Yield Effects and Economic Analysis. Agronomy, 12(4), 761. https://doi.org/10.3390/agronomy12040761