Optimization Design of Pot Slot Structure of Tea De-enzyming and Carding Machine

Abstract

:1. Introduction

2. Materials and Methods

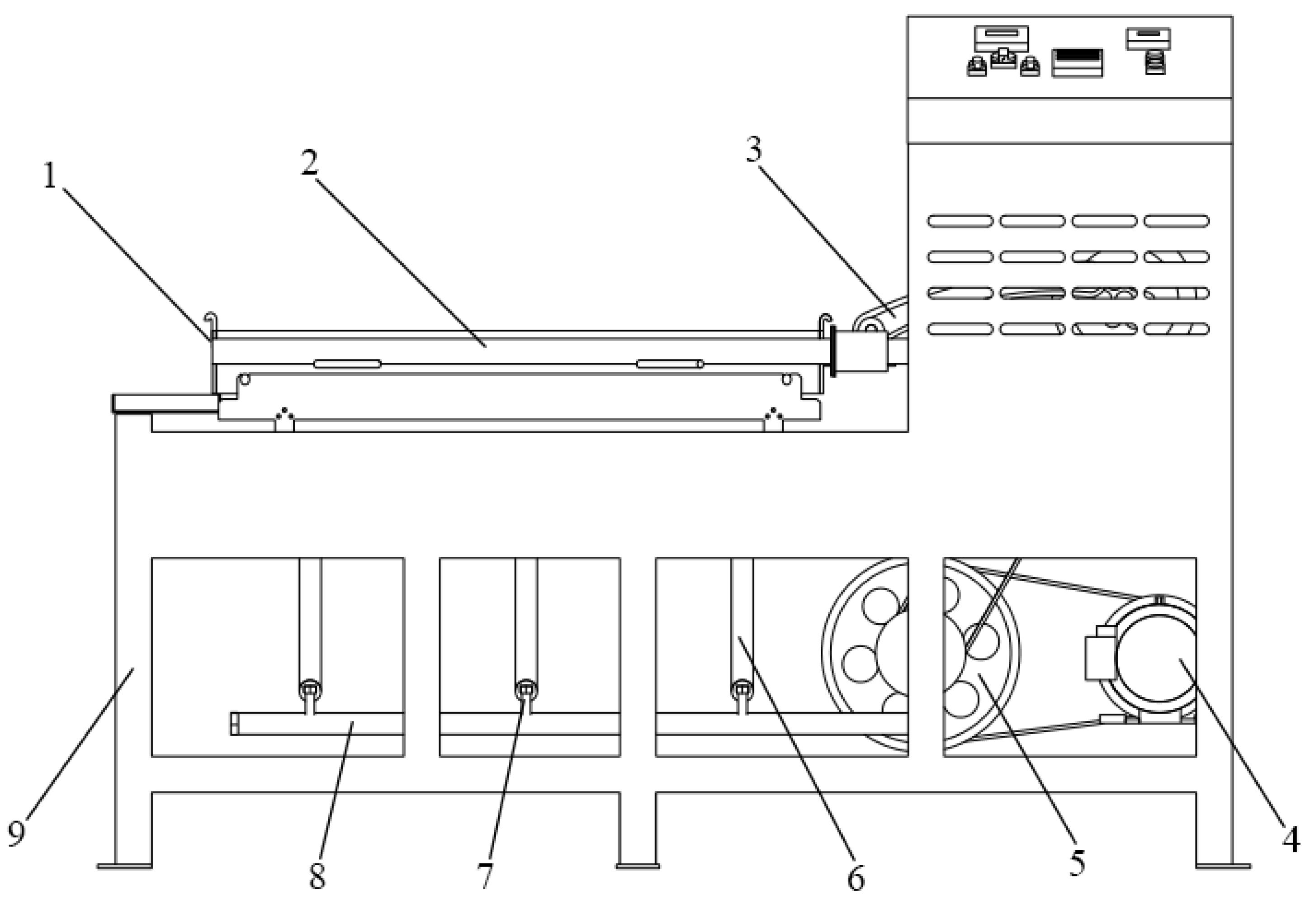

2.1. Structure and Working Principle

2.2. Measuring Principle

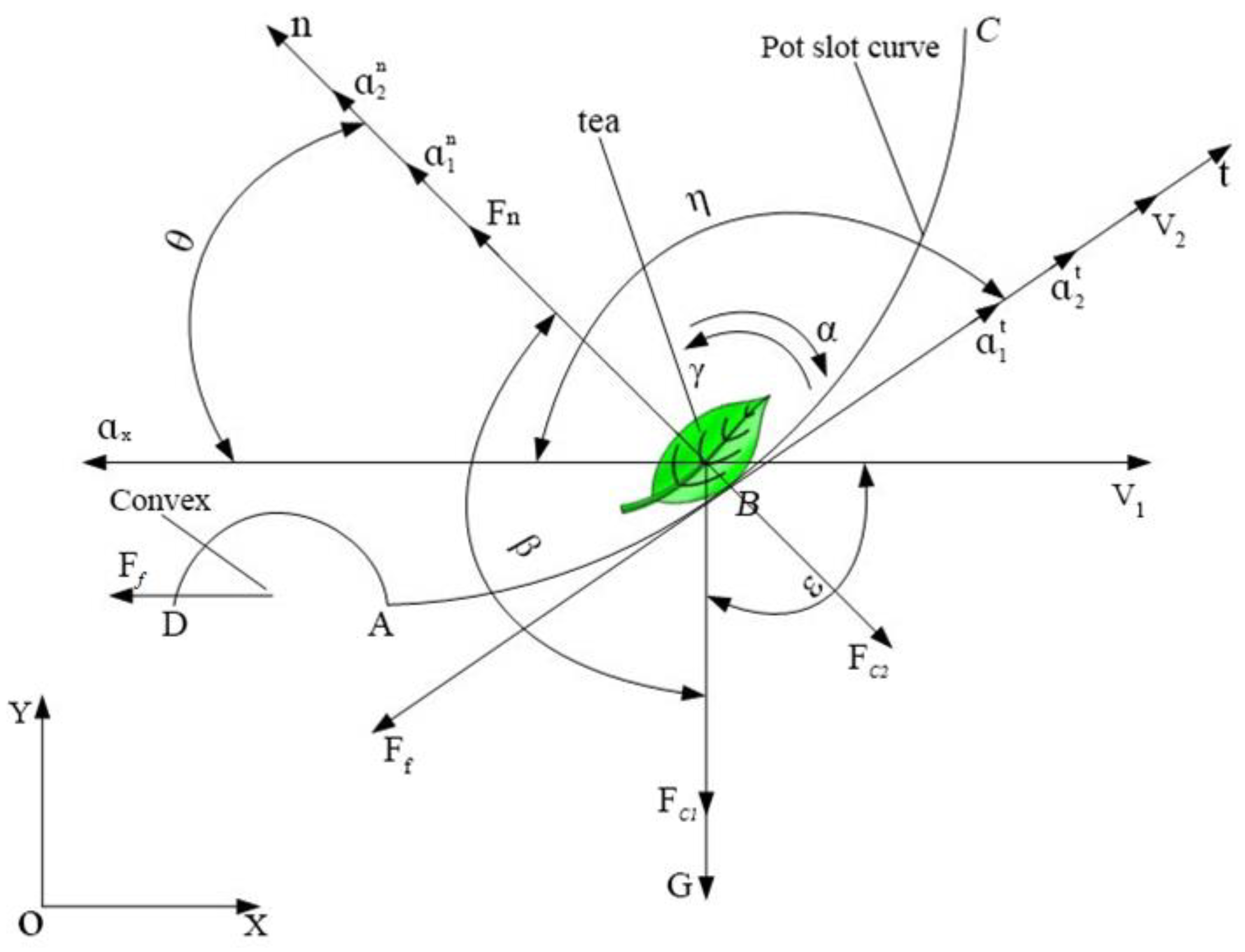

2.2.1. Force Analysis of Tea in Pot

- FN—support force of the tea particle on the wall of the pot slot, N;

- Ff—kinetic friction between the mass point and the inner wall of the pot slot, N;

- G—gravitational force of the tea particle (m represents the mass, g represents the gravitational acceleration, and G = mg), N;

- Fc1—Coriolis force of the mass point under the action of V1, N;

- Fc2—Coriolis force of the mass point caused by V2, N;

- β—angle between the gravitational force G and the normal vector n, (°);

- ε—angle between the gravitational force G and the tangential vector t, (°);

- —normal component of the absolute acceleration of the mass point in the direction of the inner surface of the pot slot, mm;

- —tangential vector of the absolute acceleration of the mass point in the direction of the inner surface of the pot slot, mm;

- μ—coefficient of friction of the tea particle on the wall of the pot slot, mm.

- γ—angular velocity of the tea particles, rad/s;

- V1—speed of reciprocating motion of the pot slot during operation, mm/s;

- V2—relative velocity of a mass point moving against the inner wall of a pot slot, mm/s;

- ac1—Coriolis acceleration of Fc1, mm/s2;

- ac2—Coriolis acceleration of Fc2, mm/s2.

- Ff—resistance of the convex strip to the tea particles during the reciprocating movement of the pot slot, N;

- —tangential vector of acceleration of particles along the inner wall of the pot slot, mm.

- ax—the acceleration during reciprocating motion of the pot slot, mm/s2;

- η—the acceleration a1 and the angle of the tangential vector t for the motion of the pot slot, (°);

- θ—the angle between the acceleration a1 and the normal vector n of the motion of the pot slot, (°).

- —the normal component of the acceleration of a mass point in the direction of movement with respect to the inner surface of the pot slot, mm;

- —the tangential vector quantity of acceleration of a mass point in the direction of movement with respect to the inner surface of the pot slot, mm.

- a1x—the component of the relative tangential acceleration of tea particles moving along the inner wall of the pot slot on the X-axis, mm;

- a1y—the component of the relative tangential acceleration of the tea particles moving along the inner wall of the pot slot on the Y-axis, mm;

- v2x—the component of the relative average velocity v2 of tea particles moving along the inner wall of the pot slot on the X-axis, mm;

- v2y—the component of the relative average velocity v2 of tea particles moving along the inner wall of the pot slot on the Y-axis, mm.

- xB’—the component on the X-axis of the mass point B as it reciprocates motion and forth on the relative coordinate system of the pot slot, mm;

- yB’—the component on the Y-axis of the mass point B as it reciprocates motion and forth on the relative coordinate system of the pot slot, mm;

- ∆t—the amount of change per unit of time in the reciprocating motion of the tea particles in the pot slot.

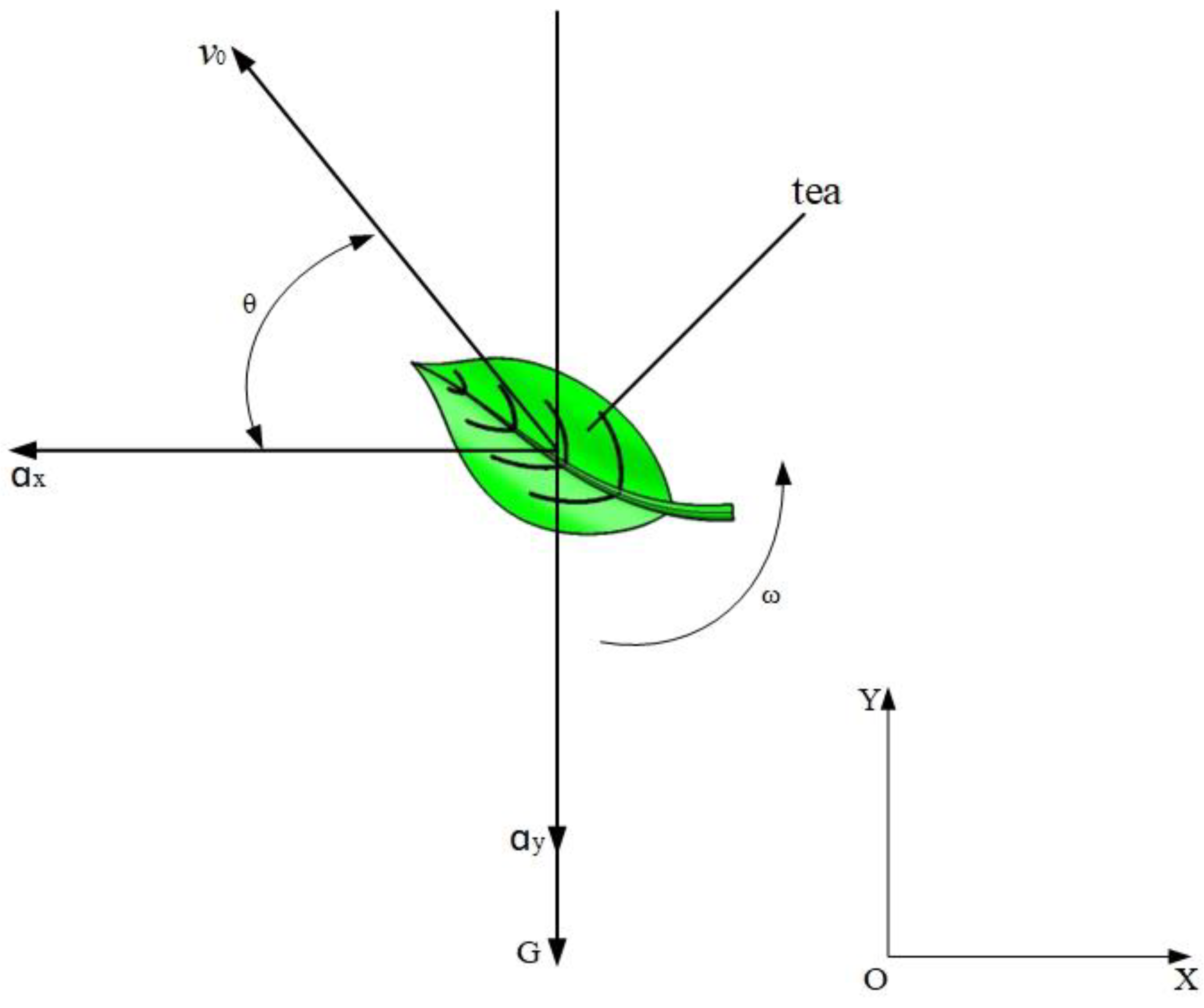

2.2.2. Force Analysis of Tea Leaves in Throwing Motion

- x—the component of the tea particle mass point on the X-axis, mm;

- y—the component of the tea particle mass point on the Y-axis, mm;

- v0—initial velocity of the tea particle when it leaves the pot slot for the throwing movement, mm/s;

- g—gravitational acceleration, mm/s2;

- t—the movement time of the tea particles, s;

- θ—the angle between the direction of the initial velocity of the center of mass of the tea particles and the direction of the X-axis, (°).

- v0x´—the component of the velocity 𝑣0´ of the center of mass of the tea particle in the X-axis direction at the next moment, mm;

- v0y´—the component of the velocity 𝑣0´ of the center of mass of the tea particle in the direction of the Y-axis at the next moment, mm.

- x’—the component of the coordinates of the center of mass of the tea particles on the X-axis at the next moment, mm;

- y’—the component of the coordinates of the center of mass of the tea particles on the Y-axis at the next moment, mm.

2.2.3. Force Analysis of the Collision Motion of Tea Leaves

- dt—instantaneous speed, mm/s;

- Fn—the impulse of the wall of the pot slot in the normal direction against the tea particles, N;

- Ft—friction in the tangential direction, N.

- e—coefficient restitution of tea particles against the wall of the pot slot during the collision;

- Vnr—normal rebound velocity of the mass center of tea particles, mm/s.

- Vtr—the velocity of the center of mass of the tea particles in the horizontal direction during collisional contact between the tea particles and the wall of the pot slot, mm/s;

- Vti—the initial velocity of the mass point A in the horizontal direction, mm/s.

2.2.4. Force Analysis of the Interaction between Particles

- Fn—the normal collision force, N;

- δn—the embedding quantity; the shape variable representing the object at the point of collision, δn > 0, n is a constant related to the material and geometric characteristics of the colliding object;

- k—the coefficient of elasticity; k = (4/3)ER1/2, R is the comprehensive radius of curvature, mm.

- E—synthesizes Young’s modulus;

- E1, E2—Young’s modulus of the colliding object;

- v1, v2—Poisson’s ratio of the colliding object.

- R1—the radius of curvature of the colliding object, mm;

- δn1—the normal overlap quantity, mm.

- e—the coefficient of recovery;

- v3n—the normal component of the relative velocity, mm/s;

- m1—the equivalent mass, kg;

- Sn1—the normal stiffness, N/mm.

- St2—the tangential stiffness, N/m;

- δt2—the tangential overlap, m.

- v3t—the tangential component of the relative velocity, m/s.

3. Simulation Test

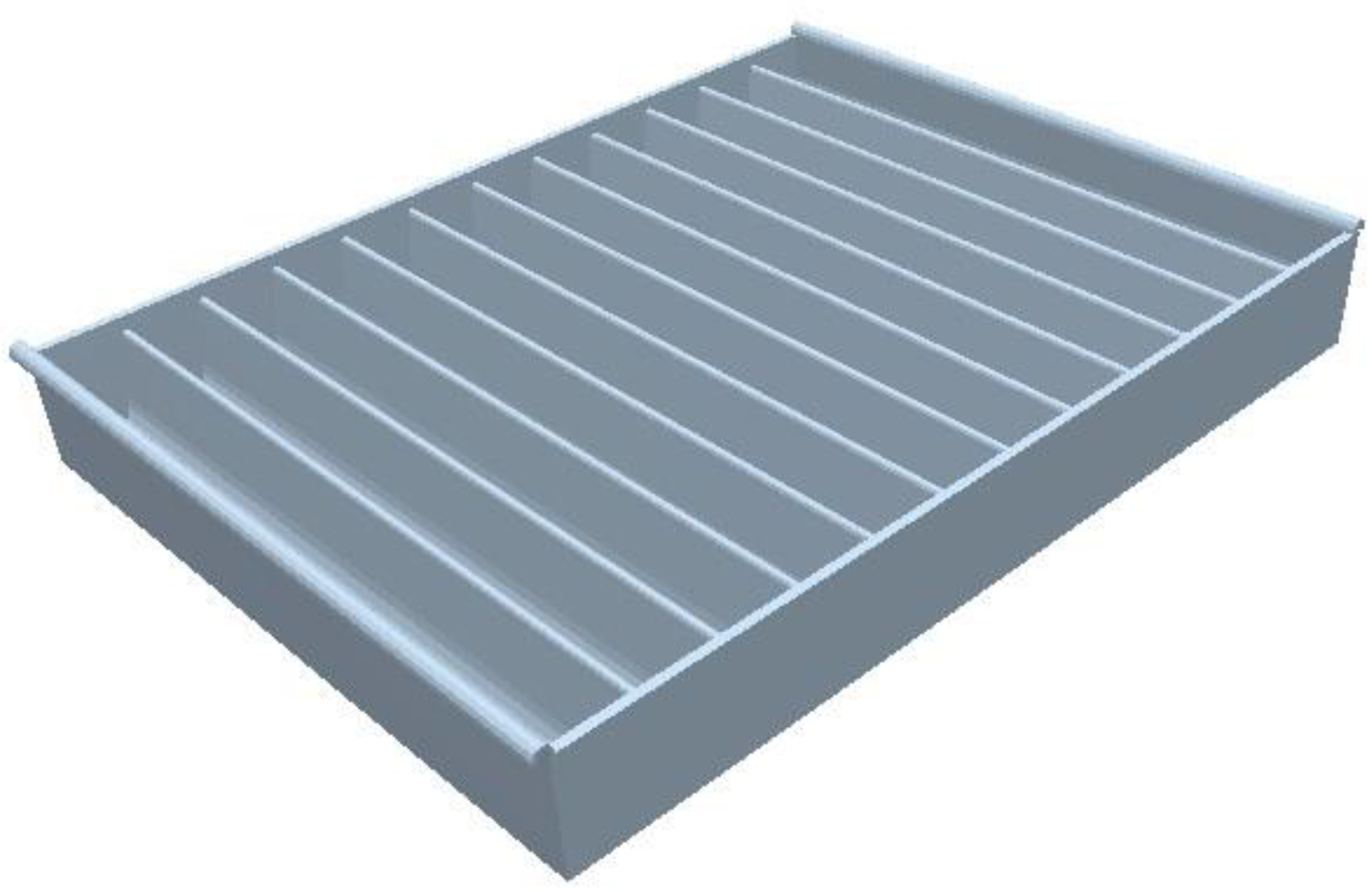

3.1. Modeling of the De-enzyming and Carding Machine

3.2. Tea Particle Modelling and Simulation Parameter Setting

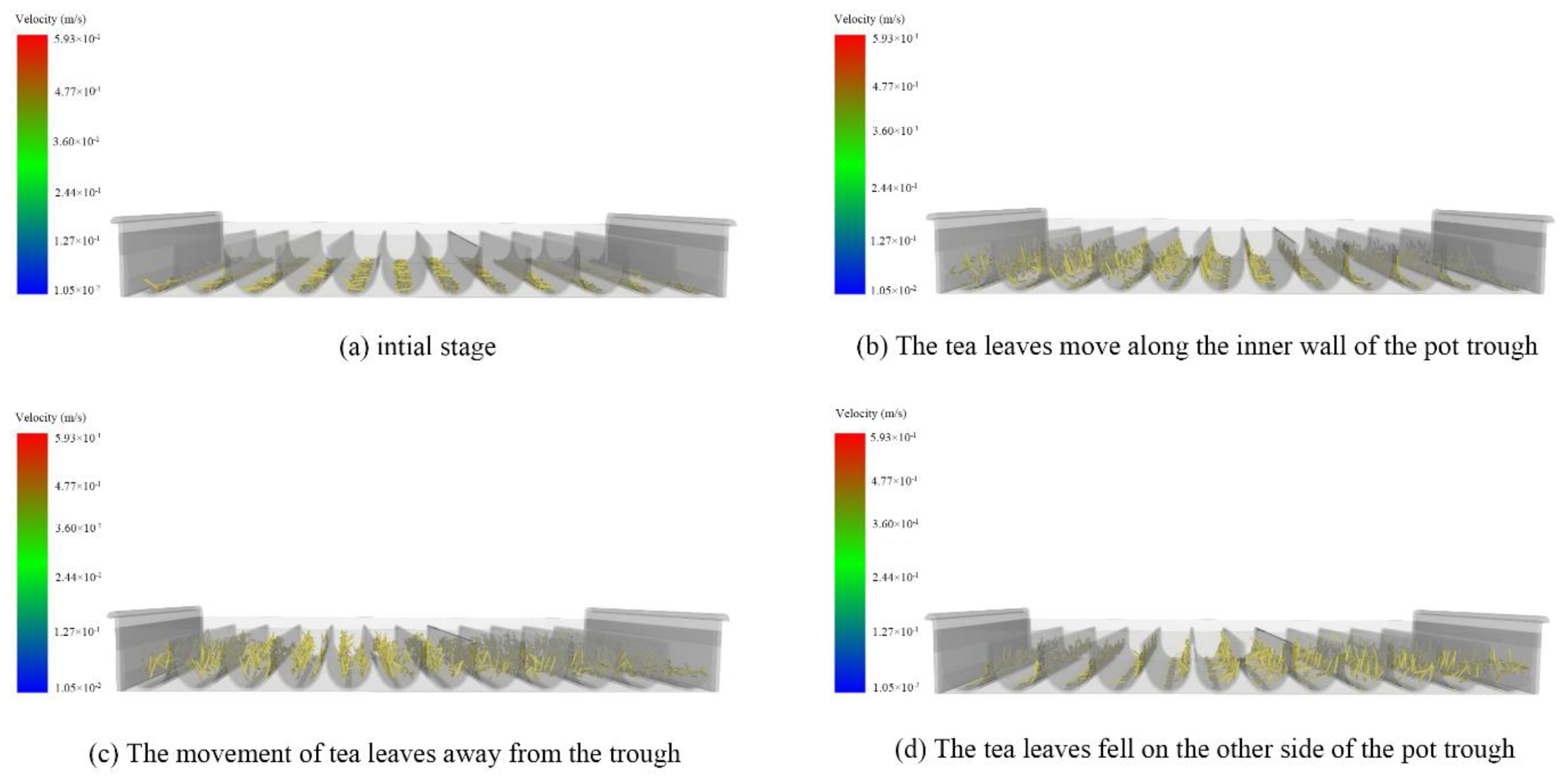

3.3. Motion Simulation Process

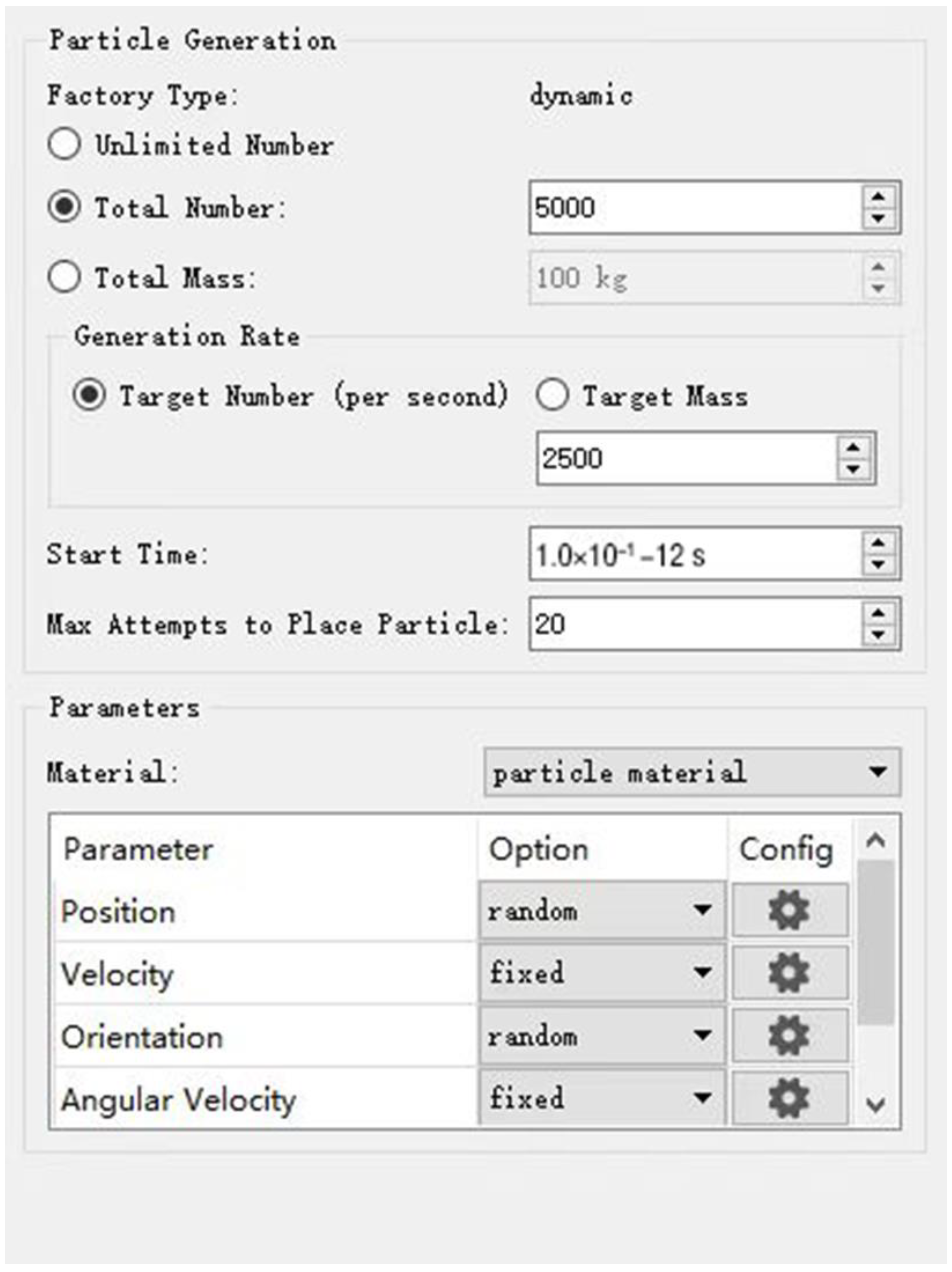

3.3.1. Creating a Particle Factory

3.3.2. Set Simulation Time and Grid Size

4. Analysis of Simulation Results

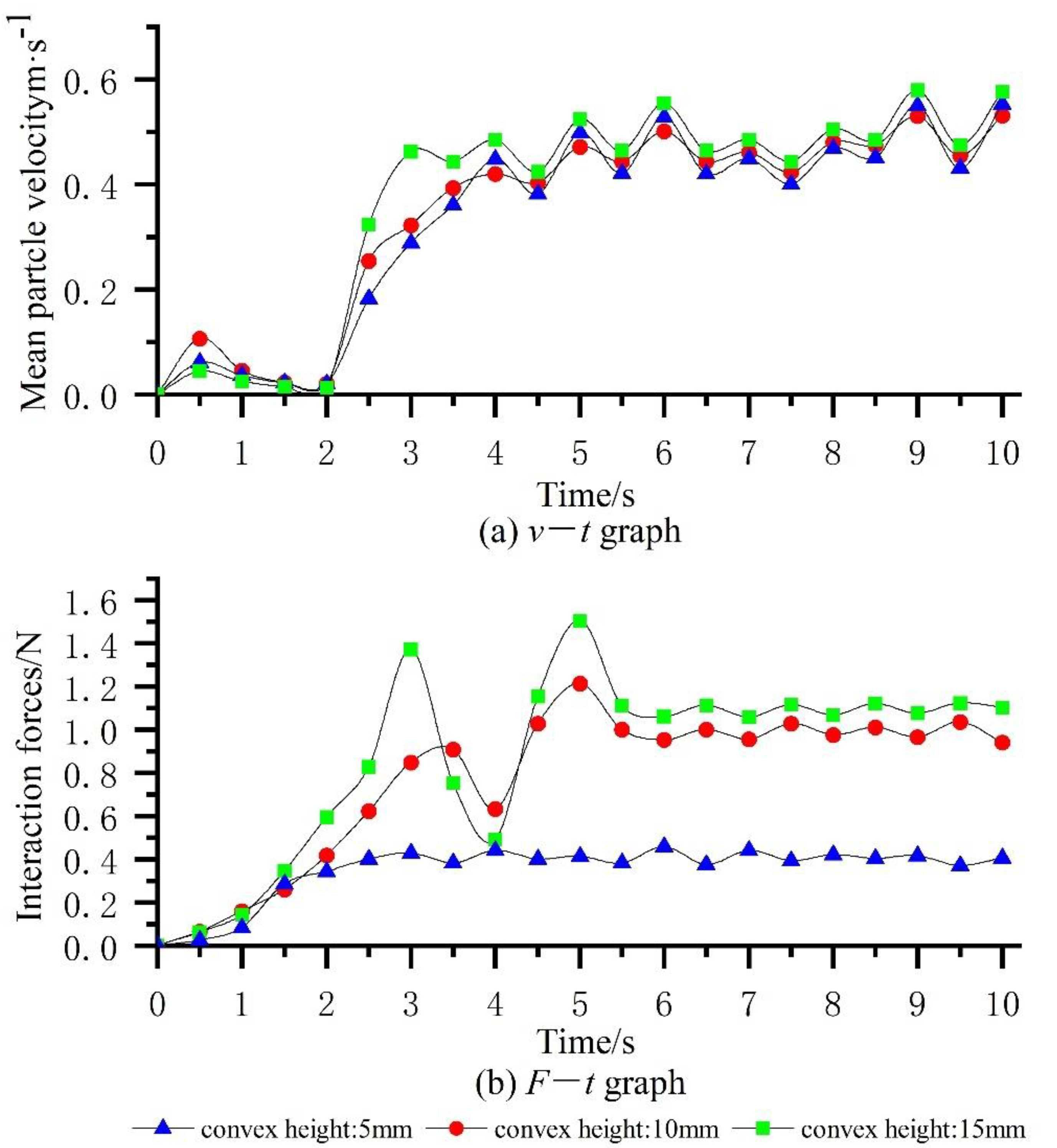

4.1. Influence of Different Convex Bar Heights on the Effect of Tea De-enzyming and Carding

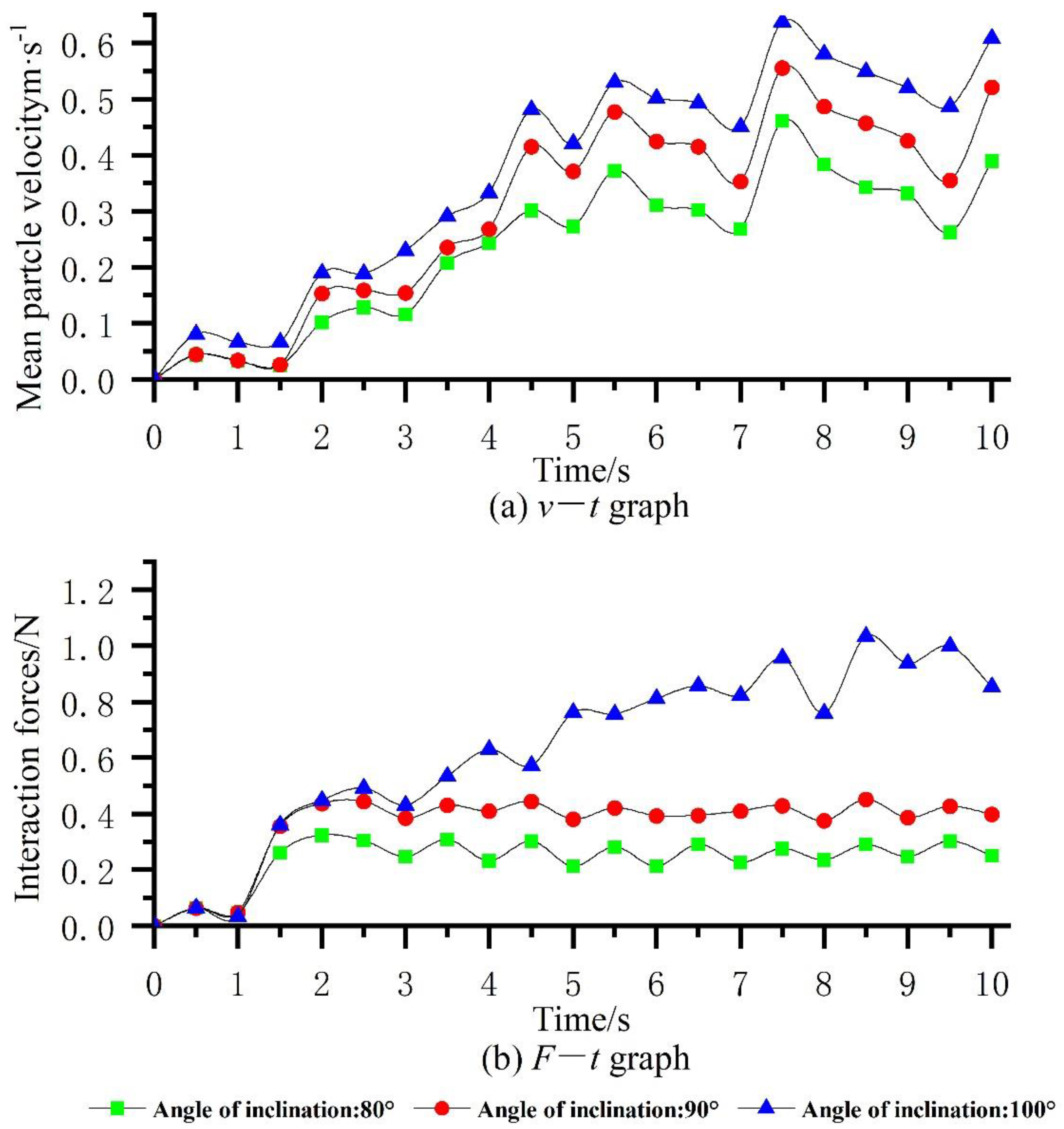

4.2. Influence of Different Pot Slot Inclination Angles on the Effect of Tea De-enzyming and Carding

4.3. Influence of Different Numbers of Slots on the Effect of Tea De-enzyming and Carding

5. Results Analysis and Test

5.1. Experimental Design

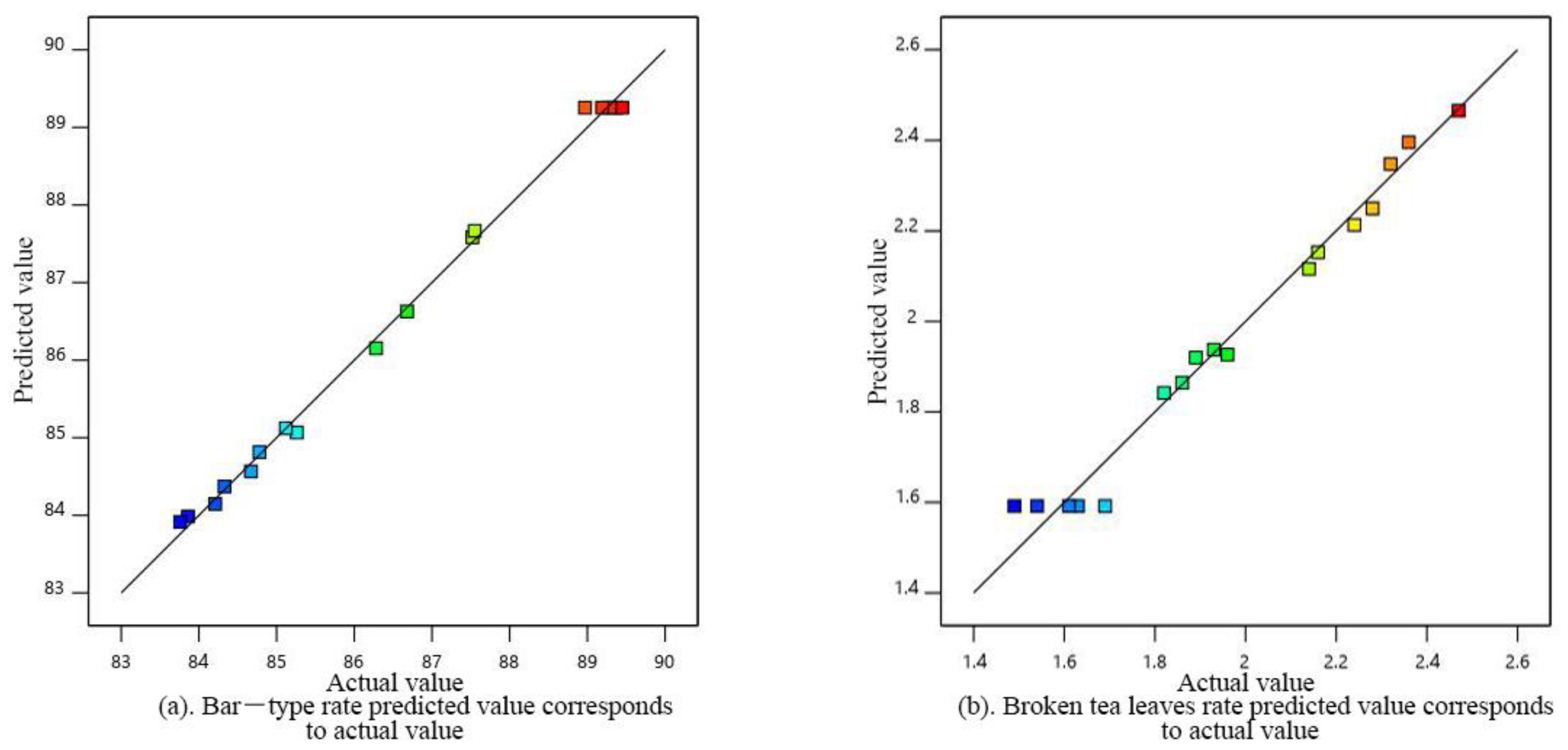

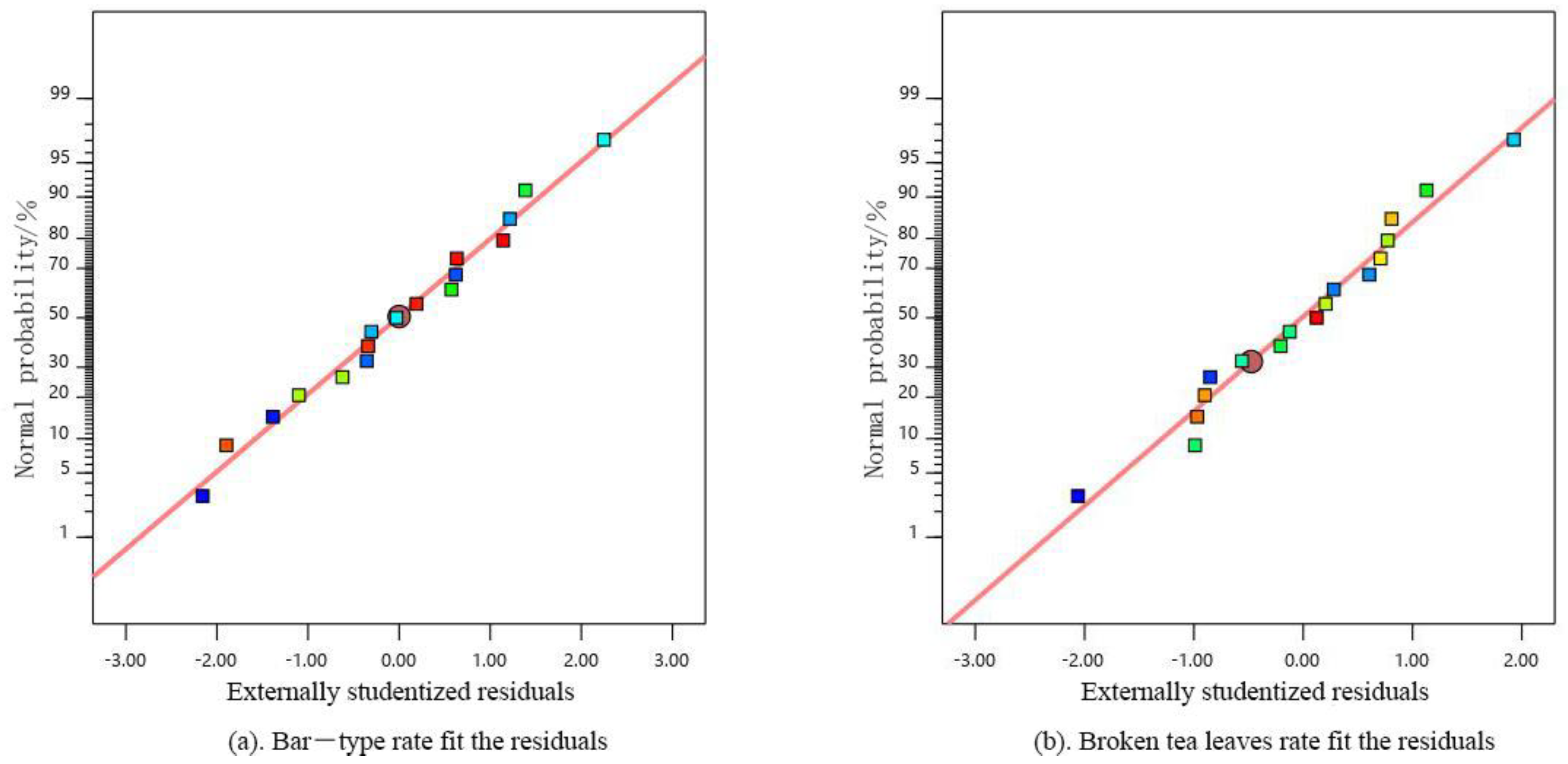

5.2. Test Results and Analysis of Variance

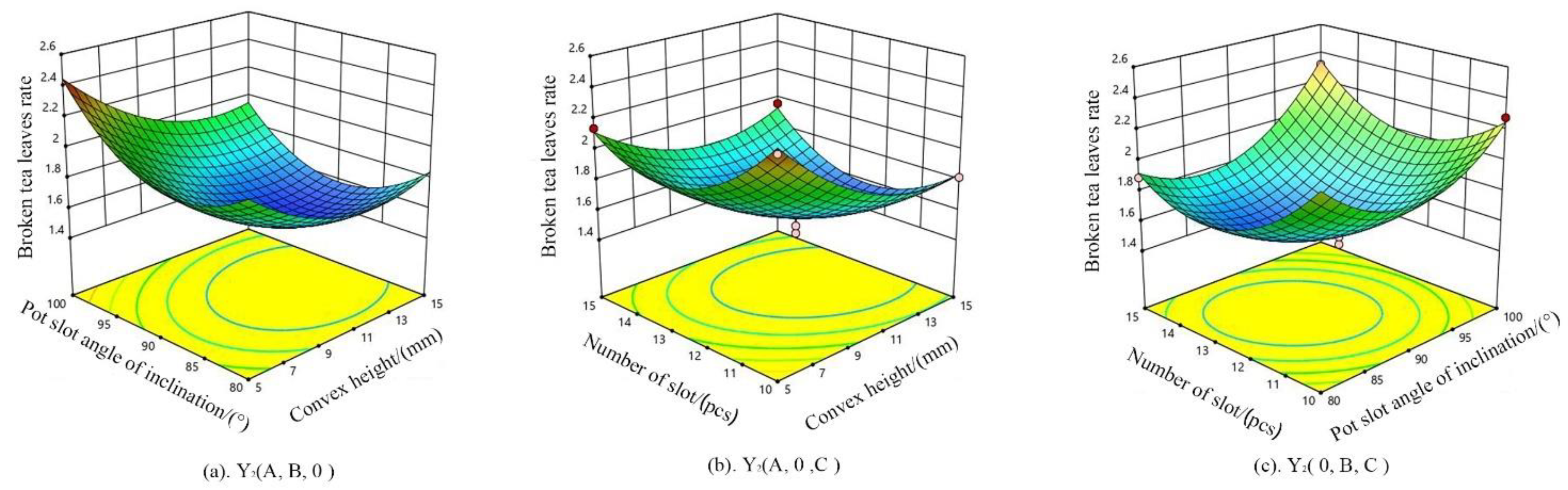

5.3. Response Surface Analysis

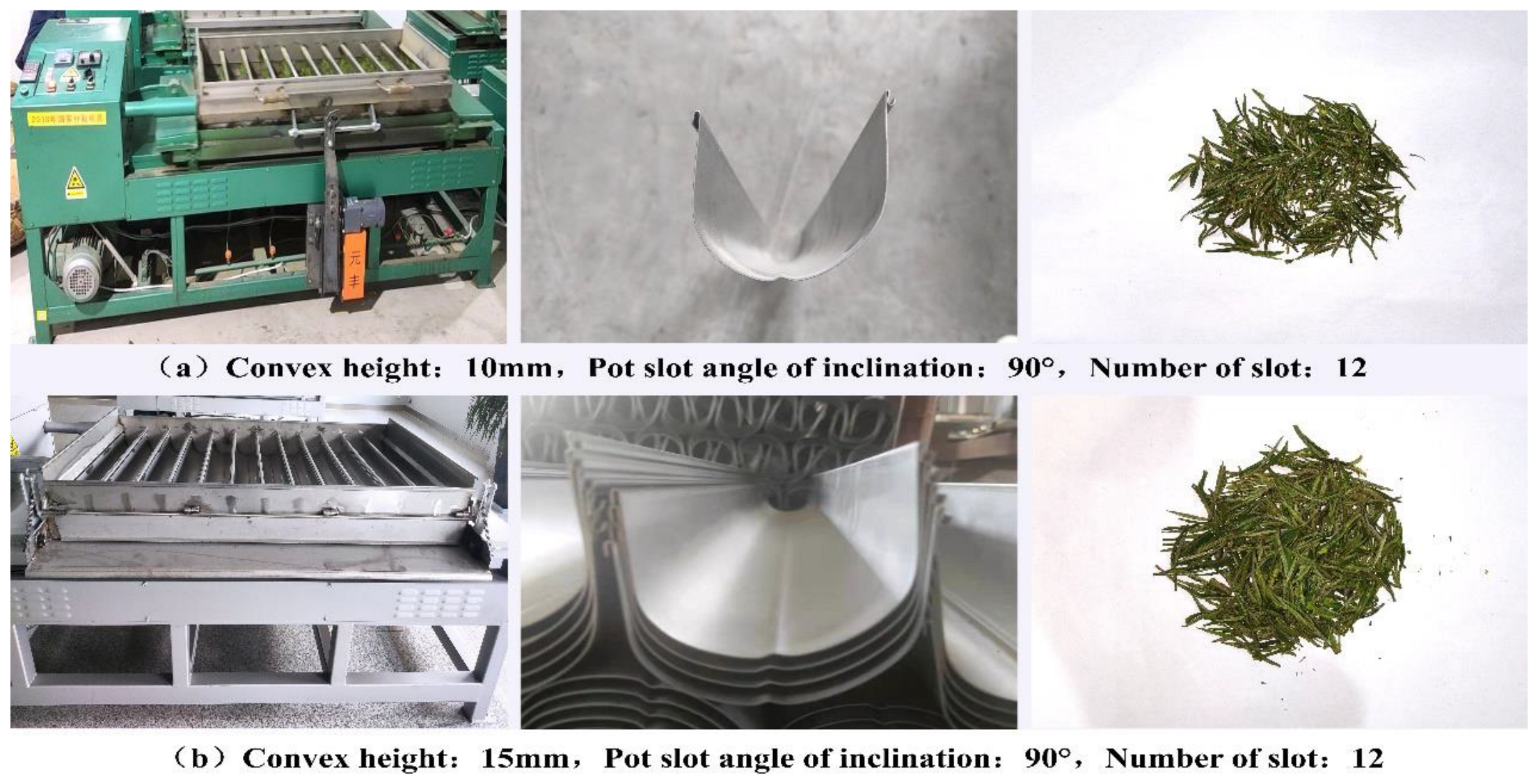

5.4. Conclusion Verification

6. Conclusions

- (1)

- This study optimized and improved the pot slot structure of a tea de-enzyming and carding machine to improve the bar-type rate and reduce the rate of broken tea in the de-enzyming and carding machine by optimizing the height of the convex bar, the sloped angle of the slots and the number of the slots. Simulation modelling of tea particles was conducted using EDEM software. The working process for pot slots and pots was simulated with different convex bar heights, pot slot inclination angles, and numbers of slots, and the average speed and interaction force curves of tea particles were obtained. To further confirm the feasibility of the parameter optimization results, we carried out the scheme design according to the quadratic regression orthogonal combination rotation test. The results show that the sizes of the bar-type rate and the broken tea rate were affected by the parameters in the following order: convex bar heights > pot slot inclination angles > number of slots. Data were analyzed using Design-Expert software. The optimal combination of operating parameters obtained from the response surface optimization results is as follows: height of the convex bar, 10 mm; inclination angle of pot slot, 90°; and number of slots, 12. At this time, the bar-type rate was 89.45%, and the rate of broken tea was 1.63%. The validation test yielded 88.63% bar-type rate, and the rate of broken tea was 1.65%. The results of the verification test are basically consistent with the results of parameter optimization.

- (2)

- In this paper, the geometric model of the de-enzyming and carding machine prototype was generated using UG software, and the tea particle simulation model constructed using EDEM software can accurately analyze the movement of tea in the pot slot. The results can provide a theoretical reference for the design of subsequent tea de-enzyming and carding machines and similar tea machine equipment.

- (3)

- Considering that the existing tea de-enzyming and carding equipment has been standardized, this paper takes the 6CSL-800 tea de-enzyming and carding machine as the research object. The effect of thermal deformation of the pots and uneven temperatures in the front and back of the pots caused by different heating methods on the efficiency of de-enzyming and carding was not considered. Further optimizations and improvements can be made in the subsequent design process to address these issues.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, S.; Li, D. Analysis on the causes of tea export fluctuation between China and the United States—CMS model based on modification. J. Sci. Tea 2021, 41, 876–888. [Google Scholar] [CrossRef]

- Zhang, M.; Tang, X.; Fan, Q.; Li, W.; Wang, J. Progress and prospect of Chinese tea machinery research. J. China Tea Process. 2021, 4, 5–9. [Google Scholar] [CrossRef]

- Cheng, F.; Yi, W.; Tuo, H.; Wang, P.; Lu, Y. Research current situation and development trend of tea carding machinery. J. Chin. Agric. Mech. 2019, 40, 69–74. [Google Scholar] [CrossRef]

- Yan, J.; Hu, D.; Liu, Q.; Yu, L.; Niu, S. Research progress and development trend of tea stripping technology and machinery. J. Chin. Agric. Mech. 2022, 43, 75–83. [Google Scholar] [CrossRef]

- Su, Z.; Xu, W.; Su, Y.; Wu, Z.; Gui, J.; Zhu, S.; Jiang, S. A kind of tea cutting pot and tea cutting machine. P. Zhejiang CN206333281U, 18 July 2017. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?FileName=CN206333281U&DbName=SCPD2017 (accessed on 10 October 2022).

- Wu, J. A kind of pot and groove structure for de-enzyming and carding machine. P. Anhui Province CN208480543U, 12 February 2019. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?FileName=CN208480543U&DbName=SCPD2019 (accessed on 10 October 2022).

- Huang, J.; Li, J.; Zhu, Y.; Dai, H.; Xu, W. A kind of multi-groove pot for continuous cutting machine. P. Zhejiang Province CN210275751U, 10 April 2020. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?FileName=CN210275751U&DbName=SCPD2020 (accessed on 10 October 2022).

- Qin, J.; Xiao, M. Application of different heat sources in tea processing machinery. J. Agric. Mach. Qual. Superv. 2020, 5, 14–16. [Google Scholar]

- Dai, H.; Ye, Y.; Cheng, M.; Cao, J. Structure design and test of electromagnetic heat strip machine. J. Green Sci. Technol. 2018, 14, 253–254. [Google Scholar] [CrossRef]

- Jin, X. Tea Leaf Mechanics; China Agriculture Press: Beijing, China, 2018. [Google Scholar]

- Zhang, S.; Zhang, X.; Zhao, Z.; Zhong, J.; Qiao, X.; Zhou, J. Mechanism research of tea carding process and processing equipment parameters optimization. J. Mech. Electr. Eng. 2016, 33, 1302–1308. [Google Scholar]

- Liu, X.; Cheng, J.; Liang, J. Hybrid collision modeling method and its experimental verification. J. Mech. Eng. 2022, 58, 116–123. [Google Scholar]

- Cleary, P.W.; Sawley, M.L. DEM modelling of industrial granular flows: 3D case studies and the effect of particle shape on hopper discharge. J. Appl. Math. Model. 2010, 26, 89–111. [Google Scholar] [CrossRef]

- Ren, C. Research on Forming Ability Evaluation Index of Spherical Tea Processing Equipment. D. Zhejiang University of Technology. 2018. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?FileName=1019829177.nh&DbName=CMFD2019 (accessed on 10 October 2022).

- Dun, G.; Chen, H.; Feng, Y.; Yang, J.; Li, A.; Zha, S. Parameter optimization and test of key parts of fertilizer allocation device based on EDEM software. J. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2016, 32, 36–42. [Google Scholar]

- Di Renzo, A.; Di Maio, F. An improved integral non-linear model for the contact of particles in distinct element simulations. J. Chem. Eng. Sci. 2005, 60, 1303–1312. [Google Scholar] [CrossRef]

- Li, W.; Song, Y.; Li, B. Simulation test of double pan roasting machine based on EDEM. J. Food Mach. 2019, 35, 90–95. [Google Scholar] [CrossRef]

- Tang, H.; Xu, C.; Wang, Z.; Wang, Q.; Wang, J. Optimized Design, Monitoring System Development and Experiment for a LongBelt Finger-Clip Precision Corn Seed Metering Device. Front. Plant Sci. 2022, 13, 814747. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Li, W.; Bai, X.; Huang, J. Parameter Optimization and Experimental Study of Tea Twisting Machine Based on EDEM. J. Tea Sci. 2020, 40, 375–385. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, Q.; Ye, W. Optimization design of roller screen based on EDEM software numerical simulation. J. Chin. J. Environ. Eng. 2016, 10, 5197–5202. [Google Scholar]

- Li, B. Parameter Optimization and Experimental Research of Tea Cylinder Fixation Machine Based on EDEM. J. China Tea Process. 2021, 3, 24–33. [Google Scholar] [CrossRef]

- Swain, G.; Singh, S.; Sonwani, R.K.; Singh, R.S.; Jaiswal, R.P.; Rai, B.N. Removal of Acid Orange 7 dye in a packed bed bioreactor: Process optimization using response surface methodology and kinetic study. J. Bioresour. Technol. Rep. 2021, 13, 100620. [Google Scholar] [CrossRef]

- Zou, S.; Su, G.; Shao, Y. Simulation optimization and experiment of separation device for ramie stalks based on discrete element method. J. Chin. Agric. Mech. 2017, 38, 60–67. [Google Scholar] [CrossRef]

- Jing, A.N.; Longtao, Z.H.O.U.; Yue, J.I.A.; Yang, X.U.; Yangfei, M.A.; Lei, S.U.N. Process optimization of demulsification and centrifugal dewatering of oily sludge in Xinjiang oilfield. J. Chin. J. Environ. Eng. 2021, 15, 2721–2729. [Google Scholar]

- Nie, X.; Bi, Y.; Shen, L.; Wang, P.; Yan, J.; Peng, Y. Prediction of SCR performance of diesel engine based on response surface methodology. J. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2021, 37, 64–72. [Google Scholar]

- Tang, H.; Xu, C.; Qi, X.; Wang, Z.; Wang, J.; Zhou, W.; Wang, Q.; Wang, J. Study on Periodic Pulsation Characteristics of Corn Grain in a Grain Cylinder during the Unloading Stage. Foods 2021, 10, 2314. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Wu, X.; Lin, S.; Zheng, X.; Shen, H.; Wei, X.; Lv, E. Parameter optimization on convective heat transfer of cold plate for cold storage temperature control box based on multi-parameter coupling. J. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2021, 37, 228–235. [Google Scholar]

- Wang, J.; Shen, L.; Yang, Y.; Bi, Y.; Wan, M. Optimizing calibration of design points for non-road high pressure common rail diesel engine base on response surface methodology. J. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2017, 33, 31–39. [Google Scholar]

- Tang, H.; Xu, C.; Xu, W.; Xu, Y.; Xiang, Y.; Wang, J. Method of straw ditchburied returning, development of supporting machine and analysis of influencing factors. Front. Plant Sci. 2022, 13, 967838. [Google Scholar] [CrossRef] [PubMed]

| Name | Working Parameter |

|---|---|

| Pot slot length (mm) | 1000 |

| Pot slot width (mm) | 600 |

| Motor speed (rpm) | 90–220 |

| Power of motor (kW) | 0.55 |

| Output (kg/h) | 20 |

| Form of energy | Gas |

| Dimension (mm) | 2450 × 1100 × 950 |

| Materials | Parameters | Values |

|---|---|---|

| Tea particle | Poisson’s ratio | 0.4 |

| Density/(kg·m−3) | 562.4 | |

| Shear modulus/Pa | 1 × 107 | |

| 316 stainless steel | Poisson’s ratio | 0.3 |

| Density/(kg·m−3) | 78.00 | |

| Shear modulus/Pa | 7 × 107 | |

| Particle-particle | Coefficient of restitution | 0.37 |

| Coefficient of static friction | 0.8 | |

| Coefficient of rolling friction | 0.05 | |

| Particle-316 stainless steel | Coefficient of restitution | 0.4 |

| Coefficient of static friction | 0.65 | |

| Coefficient of rolling friction | 0.02 |

| Code | Convex Height | Pot Slot Angle of Inclination | Number of Slots |

|---|---|---|---|

| −1 | 5 | 80 | 10 |

| 0 | 10 | 90 | 12 |

| 1 | 15 | 100 | 15 |

| Test Number | Test Influencing Factors | Evaluation Index | |||

|---|---|---|---|---|---|

| Convex Height/(mm) | Pot Slot Angle of Inclination/(°) | Number of Slots/(pcs) | Bar-Type Rate/% | Broken Tea Leaves Rate/% | |

| 1 | 10 | 100 | 10 | 85.26 | 2.28 |

| 2 | 15 | 100 | 12 | 87.52 | 1.93 |

| 3 | 10 | 90 | 12 | 89.45 | 1.63 |

| 4 | 5 | 90 | 15 | 84.67 | 2.14 |

| 5 | 10 | 90 | 12 | 89.29 | 1.54 |

| 6 | 15 | 80 | 12 | 86.28 | 1.86 |

| 7 | 10 | 90 | 12 | 89.19 | 1.61 |

| 8 | 10 | 90 | 12 | 89.37 | 1.49 |

| 9 | 10 | 100 | 15 | 85.12 | 2.32 |

| 10 | 10 | 90 | 12 | 88.97 | 1.69 |

| 11 | 5 | 90 | 10 | 84.33 | 2.36 |

| 12 | 15 | 90 | 15 | 86.68 | 1.96 |

| 13 | 5 | 100 | 12 | 83.86 | 2.47 |

| 14 | 5 | 80 | 12 | 84.21 | 2.16 |

| 15 | 10 | 80 | 15 | 83.76 | 1.89 |

| 16 | 10 | 80 | 10 | 84.78 | 2.24 |

| 17 | 15 | 90 | 10 | 87.55 | 1.82 |

| Evaluation Index | Source | Sum of Squares | df | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|---|

| Bar-type rate Y1 | Model | 74.19 | 9 | 8.24 | 214.43 | <0.0001 |

| A | 14.07 | 1 | 14.07 | 365.98 | <0.0001 | |

| B | 1.04 | 1 | 1.04 | 27.21 | 0.0012 | |

| C | 0.35 | 1 | 0.35 | 9.28 | 0.0187 | |

| AB | 0.63 | 1 | 0.63 | 16.44 | 0.0048 | |

| AC | 0.38 | 1 | 0.38 | 10.12 | 0.0155 | |

| BC | 0.23 | 1 | 0.23 | 6.06 | 0.0433 | |

| A2 | 7.72 | 1 | 7.72 | 200.94 | <0.0001 | |

| B2 | 24.90 | 1 | 24.90 | 647.79 | <0.0001 | |

| C2 | 17.32 | 1 | 17.32 | 450.67 | <0.0001 | |

| Residual | 0.26 | 7 | 0.03 | |||

| Lack of fit | 0.13 | 3 | 0.04 | 1.27 | 0.3980 | |

| Pure error | 0.14 | 4 | 0.03 | |||

| Cor Total | 74.46 | 16 | ||||

| Broken tea leaves rate Y2 | Model | 1.50 | 9 | 0.17 | 37.37 | <0.0001 |

| A | 0.27 | 1 | 0.27 | 60.45 | 0.0001 | |

| B | 0.10 | 1 | 0.11 | 23.55 | 0.0018 | |

| C | 0.01 | 1 | 0.02 | 4.24 | 0.0785 | |

| AB | 0.01 | 1 | 0.01 | 3.21 | 0.1163 | |

| AC | 0.03 | 1 | 0.03 | 7.56 | 0.0285 | |

| BC | 0.03 | 1 | 0.04 | 8.70 | 0.0214 | |

| A2 | 0.16 | 1 | 0.17 | 37.65 | 0.0005 | |

| B2 | 0.41 | 1 | 0.41 | 91.83 | <0.0001 | |

| C2 | 0.34 | 1 | 0.34 | 76.00 | <0.0001 | |

| Residual | 0.03 | 7 | 0.004 | |||

| Lack of fit | 0.01 | 3 | 0.002 | 0.38 | 0.78 | |

| Pure error | 0.02 | 4 | 0.01 | |||

| Cor Total | 1.54 | 16 | 0.17 |

| Evaluation Index | Parameters | Values |

|---|---|---|

| Bar-type rate Y1 | Coefficient of determination, R2 | 0.9964 |

| Adjusted coefficient of determination, | 0.9917 | |

| Standard deviation, Std. Dev. | 0.1961 | |

| Coefficient of variation, CV | 35.51 | |

| Broken tea leaf rate Y2 | Coefficient of determination, R2 | 0.9796 |

| Adjusted coefficient of determination, | 0.9534 | |

| Standard deviation, Std. Dev. | 0.0670 | |

| Coefficient of variation, CV | 3.41 |

| Evaluation Index | Test Number | A | B | C | Predictive Value | Actual Value | Relative Error |

|---|---|---|---|---|---|---|---|

| Y1 | 1 | 10 | 90 | 12 | 89.45 | 88.19 | 1.43 |

| 2 | 10 | 90 | 12 | 89.45 | 90.37 | 1.02 | |

| 3 | 10 | 90 | 12 | 89.45 | 87.33 | 2.43 | |

| 4 | 15 | 90 | 12 | 87.55 | 86.28 | 1.47 | |

| 5 | 15 | 90 | 12 | 87.55 | 85.89 | 1.93 | |

| 6 | 15 | 90 | 12 | 87.55 | 86.43 | 1.30 | |

| Y2 | 1 | 10 | 90 | 12 | 1.63 | 1.66 | 1.81 |

| 2 | 10 | 90 | 12 | 1.63 | 1.69 | 3.56 | |

| 3 | 10 | 90 | 12 | 1.63 | 1.61 | 1.24 | |

| 4 | 15 | 90 | 12 | 1.82 | 1.86 | 2.15 | |

| 5 | 15 | 90 | 12 | 1.82 | 1.77 | 2.82 | |

| 6 | 15 | 90 | 12 | 1.82 | 1.89 | 3.71 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bi, H.; Jia, P.; Qin, K.; Yu, L.; Cao, C.; Bai, Y. Optimization Design of Pot Slot Structure of Tea De-enzyming and Carding Machine. Agronomy 2022, 12, 2937. https://doi.org/10.3390/agronomy12122937

Bi H, Jia P, Qin K, Yu L, Cao C, Bai Y. Optimization Design of Pot Slot Structure of Tea De-enzyming and Carding Machine. Agronomy. 2022; 12(12):2937. https://doi.org/10.3390/agronomy12122937

Chicago/Turabian StyleBi, Haijun, Pengcheng Jia, Kuan Qin, Lei Yu, Chengmao Cao, and Yuxuan Bai. 2022. "Optimization Design of Pot Slot Structure of Tea De-enzyming and Carding Machine" Agronomy 12, no. 12: 2937. https://doi.org/10.3390/agronomy12122937

APA StyleBi, H., Jia, P., Qin, K., Yu, L., Cao, C., & Bai, Y. (2022). Optimization Design of Pot Slot Structure of Tea De-enzyming and Carding Machine. Agronomy, 12(12), 2937. https://doi.org/10.3390/agronomy12122937