Abstract

Lighting is a major component of energy consumption in controlled environment agriculture (CEA) operations. Skyscraper farms (multilevel production in buildings with transparent glazing) have been proposed as alternatives to greenhouse or plant factories (opaque warehouses) to increase space-use efficiency while accessing some natural light. However, there are no previous models on natural light availability and distribution in skyscraper farms. This study employed climate-based daylight modeling software and the Typical Meteorological Year (TMY) dataset to investigate the effects of building geometry and context shading on the availability and spatial distribution of natural light in skyscraper farms in Los Angeles (LA) and New York City (NYC). Electric energy consumption for supplemental lighting in 20-storey skyscraper farms to reach a daily light integral target was calculated using simulation results. Natural lighting in our baseline skyscraper farms without surrounding buildings provides 13% and 15% of the light required to meet a target of 17 mol·m−2·day−1. More elongated buildings may meet up to 27% of the lighting requirements with natural light. However, shading from surrounding buildings can reduce available natural light considerably; in the worst case, natural light only supplies 5% of the lighting requirements. Overall, skyscraper farms require between 4 to 11 times more input for lighting than greenhouses per crop canopy area in the same location. We conclude that the accessibility of natural light in skyscraper farms in dense urban settings provides little advantage over plant factories.

1. Introduction and Literature Review

The growing global population has raised concerns over meeting food demand within a context of decreasing availability of agricultural land. This has sparked interest in alternatives to traditional agricultural production and supply chains. It is predicted that by 2050, two out of three people will live in an urban setting, totaling 2.5 billion new urban dwellers among a global population of 9.5 billion people [1]. To provide high-nutrient-density food for an increasingly urban population, controlled environment agriculture (CEA) is a frequently discussed strategy due to its high space-use efficiency and ability to be located near consumers, and the reliability of weather independent production [2].

CEA operations control several environmental variables with varying levels of sophistication to improve the conditions for growing plants in an enclosed area. Greenhouses and high-tunnels are common forms of CEA operations that are used to grow year-round or extend the growing season, respectively, while utilizing natural light. The transparent glazing materials used in the construction of greenhouses are generally not good thermal insulators and can result in high heating loads in cold environments. Plant factories are a more recently established plant production typology but have gained popularity for the tight control on growing conditions, high space-use efficiency, and ability to be located near city centers [3]. With completely opaque construction, plant factories must provide 100% of crop lighting requirements with electric fixtures. Zeidler et al. produced a design and analysis of an economically feasible multilevel plant factory with sole source lighting, i.e., 100% artificial lighting for crop growth [4]. There have been several studies examining the relative energy intensity of greenhouses vs. plant factories that found energy requirements to provide sufficient lighting present the largest energy consuming end-use for plant factories [5,6,7]. Skyscraper farms have been proposed as alternatives to greenhouses and plant factories in an attempt to increase space-use efficiency while accessing some natural light as well as offsetting the environmental cost of transporting food into urban area [8,9]. However, the quantities of light necessary for plant production are generally much higher than the light requirements of typical offices in skyscraper buildings. For example, according to the National Renewable Energy Laboratory lighting guidelines and ASHRAE standards, office buildings should maintain light levels between 300 and 600 lux over work-spaces [10]. For reference, the light levels needed to grow lettuce would require an equivalent of between 10,000 and 18,000 lux depending on the photoperiod, and control strategy. Rather than using lux, plant lighting is typically discussed in terms of photosynthetic photon flux density (PPFD) in units of µmol·s−1·m−2, which is the rate at which photons within the photosynthetically active radiation (PAR) band (400–700 nm) reach a unit area. The daily light integral (DLI) is the cumulative daily PAR in units of mol·m−2·day−1.

Calculating natural light availability and supplementary lighting requirements for plant production is an important step in determining the practical operational costs and financial feasibility of indoor farm operations. Architects, engineers, and building scientists have pioneered natural light modeling and simulation techniques through software development and visualization [9]. Articles involving natural light modeling typically focus on architectural design considerations including impacts of natural light on humans, light impacts on building energy performance, and aesthetics [11]. Researchers in these fields have developed performance metrics such as “daylit area” [12] and “daylight autonomy” to inform and improve building design with quantitative data. Dogan et al. investigated urban daylight availability in residential buildings in a variety of urban contexts [13], however, architectural studies do not typically consider agricultural productivity and model DLI. Metrics used for architectural considerations such as number of lighting hours and depth of light penetration, are not tailor fit for agricultural considerations because the quantity of light (i.e., DLI) is central to plant production [14].

Light simulation has been used in agricultural research in recent years to estimate interception of light at the canopy for tomatoes [15] and mangos [16] grown in greenhouses. Saito et al. used light simulation to improve the efficiency of utilization for the lighting system in a plant factory [17]. Wang used climate-based analysis to characterize PAR availability for large-scale agricultural greenhouses [18]. Similarly, others have developed techniques to understand the spatial lighting distribution in greenhouses to aid design and operation [19,20]. Benis et al. developed a simulation-based workflow to model urban building-integrated agriculture with access to natural light, which included a light-simulation step [21]; however their work focused on rooftop greenhouses. Various other studies have considered the viability of urban agriculture focusing on economics, workforce, and reduction in transportation [22,23,24]; however the lighting conditions in skyscraper farms have not received much in depth analysis.

A more recent study by Palliwal et al. evaluated the farming potential in urban residential buildings via 3D city models by employing climate-based daylight modeling software and simulating lighting conditions in various open spaces in the buildings, including facades [25]. The study analyzed the level of PAR on different facades of the building for a set of weather conditions, including cloudy, partly cloudy, and sunny days. They also compared their simulations with measured results, showing good agreement and demonstrating the value of 3D city modeling combined with light simulation [25]. Their study simulated lighting conditions over short periods of time (~1 day) using characteristic days to understand the variation in light availability in Singapore.

Proponents of skyscraper farms usually assume that natural light can be used to offset much of the electric lighting costs, however, there is a lack of data to support this idea [8]. While there is existing information on the lighting energy use of plant factories vs. greenhouses [6,7], there is a research gap in the availability and spatial distribution of natural light in skyscraper buildings intended for CEA production and the energy requirements to provide supplemental lighting in these structures. In this study, we aimed to generate quantitative information to investigate the potential value of natural light for crop production in skyscraper farms.

This manuscript details two parametric studies conducted to answer the question ‘how much advantage comes from introducing transparent glazing to multilevel indoor production facilities?’ Climate-based daylight modeling was employed to first examine the availability of useful natural light in a variety of basic skyscraper farm building geometries, and second, to study how in an urban context, shading from other structures further reduces natural light availability. In contrast to the study by Palliwal et al. [25], this work uses a full year of solar radiation data to characterize the spatiotemporal availability of PAR within the interior of skyscraper farms in an urban context, and uses simulation results to make conclusions about the annual energy requirements to supplement lighting for these structures. The quantities of light for each scenario are reported in units relevant for agricultural production.

2. Materials and Methods

2.1. Overview

Annual lighting simulations were run on model skyscraper farms to quantify the amount of light reaching each level of the buildings using DAYSIM [26], which is a daylight modeling software built upon the Radiance optical simulation engine [27]. Architectural drafting software Rhinoceros 6.0 [28] was used to generate building geometry, and the Diva-for-Rhino plug-in [29] was used to generate simulation parameters and produce hourly simulations with DAYSIM. Radiance, DAYSIM, and Diva-for-Rhino are industry-trusted software packages for light simulation that are commonly used to understand the spatial variability and availability of natural and electric lighting within the interior of multi-level buildings and throughout urban cityscapes [25,26,29]. The workflow for this study had five main steps: generate scene geometry, specify simulation parameters, conduct lighting simulations, analyze results, and calculate energy consumption.

2.2. Model Descriptions

This investigation was segmented into two parts, referred to as skyscraper farm in a field (SIF) and skyscraper farm in a city (SIC). The SIF scenarios were designed to examine the quantities of natural light available in a skyscraper farm without any shading cast by neighboring buildings, which is considered here as the best-case scenario. The SIC scenarios were a set of theoretical urban settings, modeled to produce a range of natural lighting conditions available to skyscraper farms in an urban context.

2.2.1. Skyscraper Farm in a Field

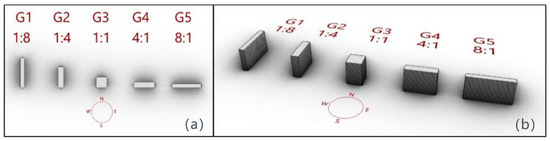

Five simplified skyscraper geometries were considered for two U.S. locations—New York City (NYC) and Los Angeles (LA). All buildings were designed to have one acre of rectangular area footprint (i.e., 43,560 ft2 or 4046 m2), but with contrasting north-face vs. east-face length ratios (Figure 1). Each level of the building was discretized into grids of 2 m × 2 m squares, with light levels recorded in the center point of each grid hourly throughout the year. All skyscraper buildings had 20 floors with 5 m inter-floor height. The walls of the skyscrapers were defined as a transparent glazing material with 70% transmittance of incident light (i.e., Glazing_Tvis70) embedded in the Diva material library. To compare the light availability of skyscraper farms to a greenhouse of the same area and overall transmittance of 70%, we generated a single-floor 5-m-tall rectangular box greenhouse model.

Figure 1.

(a) Top-view and (b) perspective view of skyscraper farm geometries G1–G5 with corresponding side ratios. All buildings had 20 floors with 5 m inter-floor height.

2.2.2. Skyscraper Farm in a City

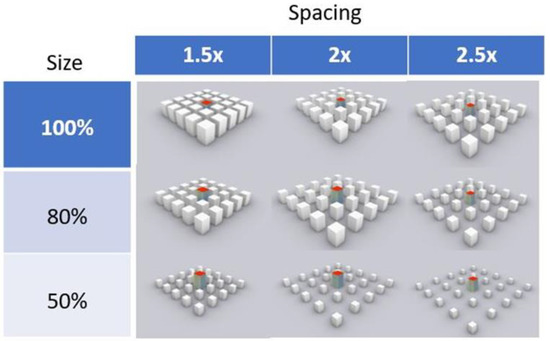

Nine urban scenarios were considered for two U.S. locations—New York City (NYC), and Los Angeles (LA). All modeled farms in the “skyscraper farm in a city” (SIC) scenarios were located in the center of an urban environment ranging in size and density of surrounding buildings. The farms modeled in the SIC scenarios had the same dimensions as Geometry 3 (G3) in the ‘SIF’ section above i.e., a square area footprint. Each level of the building was discretized into grids of 2 m × 2 m squares, with light levels recorded in the center point of each grid hourly throughout the year. Nine conceptual urban settings were modeled varying the size and proximity of the surrounding rectangular buildings. The size and spacing of neighboring buildings in each urban setting was defined relative to the size of the target skyscraper farm; the variety of size and spacing levels is depicted below. The spacing between neighboring buildings was parameterized by the width of the building—the notation “2.5 × spacing” signifies that the distance between the farm and the nearest building (center-to-center) was 2.5 times the width of the farm (Figure 2). The sizing of neighboring buildings in each scenario was parameterized by the length scale of the farm, meaning the notation ‘80%’ means that the height and width of neighboring buildings were 80% of the height and width of the farm, i.e., 80 m high, 50.9 m wide. Detailed parameters and notations of each urban scenario are described in Table 1.

Figure 2.

Nine conceptual urban settings were modeled varying the size and proximity of the surrounding rectangular buildings.

Table 1.

Details of neighboring structures in nine urban scenarios for Skyscraper Farm in a City (SIC).

2.3. Calculation of Natural Light Availability

To model the useful natural light reaching each level of the skyscraper farms, we employed solar radiation (RAD) data for each location from the Typical Meteorological Year (TMY3) dataset, which was produced by the United States National Renewable Energy Laboratory [30]. The TMY dataset provides typical hourly weather conditions for a given location using ‘characteristic months’ from historical datasets between 1976 and 2005, thus preserving the natural variability of the original data. However, only a portion of the light spectrum has direct effects on plant growth [31], i.e., the photosynthetically active radiation (PAR) between 400 and 700 nm. The quantity of PAR reaching the earth at a given moment and location depends upon many factors including atmospheric composition the solar angle of incidence and weather conditions. However, PAR can be approximated from total radiation from a conversion constant calculated using the formula below [32].

where PAR is the photosynthetically active radiation (mol·m−2); RAD is solar radiation (Wh·m−2) from the TMY3 datasets; C1 is the statistical coefficient, 2.0699 (mol·MJ−1); C2 is a conversion constant, 3600 (J·Wh−1); and C3 is a conversion constant, 106 (J·MJ−1).

PAR = RAD × C1 × C2 × C3−1

We then calculated the daily light integral (DLI) of PAR as the accumulated amount of photosynthetically active radiation over a 24 h period, because crop yields have been shown to increase proportionally to DLI [33]. The lighting calculations for the skyscraper farms in this study were based on the assumption that the facility would maintain a target DLI of 17 mol·m−2·day−1. This amount of light was found to be optimal for growing head lettuce (Lactuca sativa L.) at ambient CO2 levels by driving fast growth without inducing the physiological disorder of inner leaf tipburn [34].

The required supplemental lighting at each grid-point for each day was calculated as the difference between DLI available each day and the target DLI of 17 mol·m−2·day−1. The supplemental lighting for a particular day and location is 0 if the DLI on that day is greater than the target. The calculation for supplemental lighting assumes perfect knowledge of future light availability. In practice, the stochastic nature of weather patterns does not allow for completely accurate prediction of future available natural light. However, this assumption is useful because it does provide a best-case scenario or a lower bound for the lighting energy consumption to meet the DLI target.

2.4. Calculation of Energy Consumption

PAR efficacy of a lighting fixture is simply the ratio between the number of PAR photons output from a lamp (µmol) per unit of electrical energy input (J). The PAR efficacy of lighting fixtures can vary depending on the arrangement and choice of LEDs and manufacturing tolerances, and whether a fixture is actively or passively cooled [35,36]. Published literature on horticulture lighting technologies has shown PAR efficacies of horticultural lighting fixtures between 1.2 and 2.0 µmol·J−1 [37], though recent advances in LED lighting have generated more efficacious fixtures with some lighting manufacturers listing efficacies as high as 3.6 µmol·J−1 [38]. Recent publications provide detail on the physical limits of lighting efficacy and find that the limiting efficacy for red and white fixtures is 3.4 µmol·J−1, and for blue and red fixtures is 4.1 µmol·J−1 [36]. LEDs are also projected to play a large role in the future of horticulture lighting due to advances in efficacy and other favorable properties such as dimmability, and spectral tuning [39]. For the present study, an efficacy of 2.0 µmol·J−1 was used for calculations; an analysis using higher and lower PAR efficacies is shown in Section 3.2. The energy consumption to provide supplemental lighting was calculated from the following equation.

where, AEU is annual energy usage of lighting system (kWh), Lij is supplemental lighting on day “i” for grid-point “j” (µmol·m−2), n is the number of grid-points, ϵ is PAR efficacy of fixture (2.0 µmol·J−1), A is the area of each grid-point (m2), and C4 is a conversion constant (3.6 × 106 J·kWh−1). Skyscraper farm lighting energy requirements were compared to energy requirements for a 20-acre plant factory (PF) with one growing layer, calculated by the method described above assuming zero available natural light (Table 2).

AEU = ∑∑ Lij × A × C4−1 × ϵ−1

Table 2.

Result summary for five 20-storey (20-acre) skyscraper farms and a 20-acre greenhouse in NYC and LA. PF: plant factory.

3. Results and Discussion

3.1. Skyscraper Farm in a Field

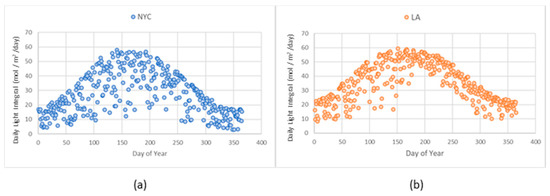

In terms of photosynthetic light provided by the sun, the mean DLI values on each level of the skyscraper farms in the SIF scenarios were significantly below the target level of 17 mol·m−2·day−1 (Table 1). However, it is important to note that mean DLI does not directly reflect lighting requirements because any light over the DLI target will influence the mean value but is not considered ‘useful’ for offsetting supplemental lighting. For example, the mean DLI in a GH in NYC is greater than the DLI target of 17 mol·m−2·day−1, though there is still a requirement for supplemental lighting to meet lighting targets periodically throughout the year (i.e., in summer there is too much light, triggering shading, in winter there is not enough light, so supplemental light must be added). As shown in Figure 3, the two locations, NYC and LA, received similar maximum DLIs at around 60 mol·m−2·day−1 on some of the sunniest days of the year (Figure 2), however, the specific weather conditions of each location affected the distribution of useful natural light throughout the year. Though LA is generally sunnier than NYC, both locations would require supplemental lighting to consistently meet a modest DLI target.

Figure 3.

Daily light integral (mol·m−2·day−1) in (a) New York City and (b) Los Angeles.

The results show the stark difference between the lighting energy intensity of grow operations with access to natural light and those without. The five skyscraper farm geometries for each of the two locations all requires 4 to 11 times more supplemental lighting than the greenhouses located in the same regions (Table 1). Comparing the different building configurations, the more elongated buildings which had greater perimeter area (such as 8:1 and 1:8) required slightly less supplemental light than the squarer building configurations, although, overall, the skyscraper farms required much more energy input for lighting than greenhouses in the same location, and between 13 and 27% less lighting than a plant factory (Table 2). It is also important to note, that despite G1 requiring the least amount of supplemental lighting for plant production, this orientation was found to be suboptimal when considering heating ventilation and cooling (HVAC) energy demands [25]. Building G5 required more supplemental lighting than G1, however the orientation of G5 was found to be optimal in [25] when only considering HVAC energy use by minimizing solar gains during summer and maximizing them during wintertime.

The amount of lighting energy consumption for each structure depended on the lighting target, the PAR efficacy, and the total daylight available to offset electric lighting energy requirements. Results showed that to meet a DLI of 17 mol·m−2·day−1 with a 2.0 µmol·J−1 PAR efficacy, a single-layer plant factory would consume 862 kWh·m−2·year−1. Similarly, Harbick and Albright, found a single layer plant factory required 1014 kWh·m−2·year−1 of electric lighting assuming a lower PAR efficacy of about 1.7 µmol·J−1 [6]. Graamans et al. calculated plant factory lighting energy consumption around 1,128 kWh·m−2·year−1 with a DLI of 28.8 mol·day−1 indicating a higher assumed PAR efficacy of 2.59 µmol·J−1 [6]. In comparison, Benis, et al. calculated that an urban farm with no daylight access (plant factory) would require 232 kWh·m−2·year−1 [21] of electric lighting energy to meet a DLI target of 20 mol·day−1, however, achieving this would require an unrealistically high PAR efficacy of 8.74 µmol·J−1 that is beyond physical limitations [36]. Discrepancy among studies is partly due to the variation in modeling assumptions and reported units, reflecting the need to clearly report PAR efficacy in CEA simulation research and horticultural lighting-product labels [40]. LA has more ambient sunlight than NYC which yielded a lower energy requirement for all geometries including the base-line greenhouse. Comparing greenhouses, the lighting energy consumption for a greenhouse located in Los Angeles was calculated to be 71 kWh·m−2·year−1. This result is comparable with the results of Harbick and Albright, finding that a greenhouse located in Phoenix, AZ would require 82 kWh·m−2·year−1 with a lower lighting efficacy, while not assuming “perfect knowledge” of future solar conditions [7].

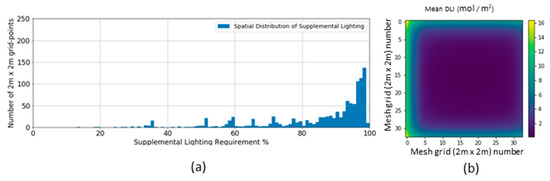

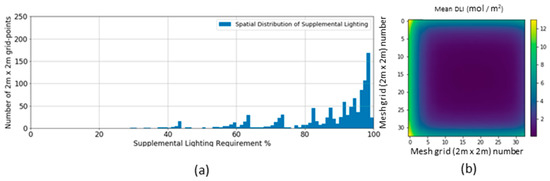

Spatially, the building perimeter (especially the south and west face) receive an appreciable amount of sunlight whereas the interior of the building (and north face) receive negligible ambient light (Figure 4 and Figure 5). The overall spatial distribution pattern was similar between LA and NYC; however, the LA skyscraper farm received slightly more natural light as compared to NYC (Figure 4 and Figure 5).

Figure 4.

(a) Distribution of supplemental lighting requirements at 19th level of Geometry 3 in Los Angeles and (b) map of mean DLI of natural light throughout building interior.

Figure 5.

(a) Distribution of supplemental lighting requirements at 19th-level of Geometry 3 in New York and (b) map of mean DLI of natural light throughout building interior.

Intuitively it seems that crops grown in a building with transparent glazing would have adequate access to natural light, however the model shows that the quantities of light available throughout the space are not significant enough to offset electric lighting due to shading from higher floors across the primary growing area. The perimeter zones of the building may require as little as 20% supplemental light, however, the majority of the space requires more than 80% supplemental lighting throughout the year as shown by the right-skewed distribution of Figure 4 and Figure 5a. The DLI received on the façade of high-rise buildings in Singapore was modeled in [25], with the façade on the upper floors receiving 15 mol·m−2 on sunny days. Similarly, Figure 4 and Figure 5b reveal the ‘hottest’ zones were located nearest the façade on the south side, each of which received between 12 and 13 and 14 and 16 mol·m−2 for NY and LA, respectively, however the light levels diminished rapidly with distance from the windows. As the availability of PAR within the interior of a skyscraper building was not modeled in previous literature, we compare our results to studies involving simulation of natural lighting conditions of high-rise buildings for human use. For instance, investigations of daylight access of high-rise office buildings in Hong Kong [41] agree with lighting patterns shown in Figure 4 and Figure 5b, where the daylight factor was observed to dwindle exponentially with distance from the windows [41]. Light-shelves, and light-pipes are possible design options to address the lack of daylight reaching deep into the building floor-area, [42,43]. Although these solutions prove sufficient for human lighting levels, they serve only to redirect light and are consequently less consequential in addressing the large DLI deficit for plant production in skyscraper farms. Using the perimeter space of skyscrapers for plant production while the inner space is used for offices may be a more realistic implementation of skyscraper farms than one that is wholly used for plant production. Though it was not the focus of this research, the height between floors in the skyscraper farm affects the availability of natural light. An inter-floor height of 5 m is relatively spacious for skyscrapers, although more space between floors would allow more natural light. Through additional simulations, it was found that floor heights between 2 and 10 m share the same trend and this range accounts for typical construction story heights. All other building geometries modeled share the right-skewed supplemental lighting load distribution with some variation due to the larger perimeter; they are not shown here to avoid redundancy. This trend holds for skyscraper farms in an urban context; however, the available natural light is further reduced by surrounding buildings, and lower floors receive considerably less natural light.

3.2. Skyscraper Farm in a City

A skyscraper farm sited in the city (i.e., various configurations of neighboring buildings) received overall less ambient light than a field-sited skyscraper (Table 2 vs. Table 3). Natural light in a skyscraper sited in a city varied from 0.70 to 2.51 mol·m−2·day−1 with the greatest light availability in the configuration where neighboring buildings were spaced further away. (Table 3).

Table 3.

Natural light availability for nine urban settings in terms of mean DLI (mol·m−2·day−1). Note that the DLI is averaged over the 20-acre production area.

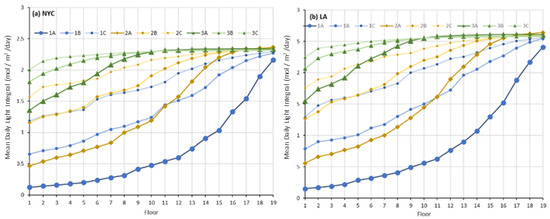

The nine SIC scenarios for each of the two locations all required significant amounts of supplemental lighting and, intuitively, the average DLI in denser urban settings is lower than the SIF scenario for the same geometry (G3). Natural light availability drops significantly in the lower levels of skyscraper farms in urban settings due to shade cast by surrounding buildings (Figure 6). The results shown in Figure 6 agree with the trends found in [25] where the DLI at the lower floors of the building drops dramatically; the lower floors of the high-rise building modeled in [25] receive as little as 0.7 mol·m−2 due to shade from surrounding buildings. However, in [25] the DLI being measured was the façade of the building rather than the average lighting throughout the interior. Li et al. investigated the lighting energy use of high-rise buildings that use daylighting controls to quantify the energy implications of shading effects from nearby buildings [44]. Similarly, they found that light entering the lower floors is highly dependent on the angle between the top of surrounding buildings and the floor of interest [44]. An architectural investigation published in 2017 shows how the daylight factor diminishes toward the lower floors of high-rise buildings in a similar style to the data for high density urban scenarios (1A, 1B, and 2A) in Figure 6a,b.

Figure 6.

Mean daily light integral (DLI) (mol·m−2·day−1) for each level of a skyscraper farm in NYC (a) and LA (b) under different urban scenarios. Details of urban scenarios are described in Table 2.

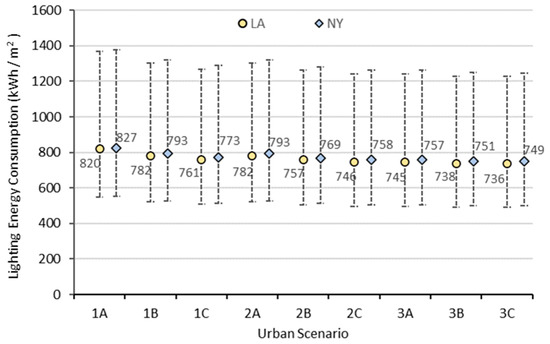

Both LA and NYC required similar amounts of supplemental lighting energy in each urban scenario due to the amount of self-shading (Figure 7). The total energy required to supply light in each urban setting was relatively constant (Figure 7). The constancy of the energy consumption is because the absolute quantity of daylight available in the growing space in both locations was low relative to the amount required for plant production, 17 mol·m−2·day−1 (LA: <3.0 mol·m−2·day−1 and NYC: <2.5 mol·m−2·day−1). The lighting energy use required in the denser urban scenarios (1A 1B, 1C, 2A) tend to converge toward the value found for the plant factory in Section 3.1 (862 kWh·m−2), whereas energy use in sparser urban scenarios (2C, 3A, 3B, 3C) tend toward the value found in the SIF scenario, Geometry 3 of Section 3.1 (NYC: 747 kWh·m−2 and LA: 734 kWh·m−2). Error bars shown in Figure 7 represent the lighting energy consumption in each scenario for a set of PAR efficacies (1.2, 2.0, and 3.0 µmol·J−1). Using a conservative value for PAR efficacy of 1.2 µmol·J−1, the lighting energy intensity could reach as high as 1378 kWh·m−2 in scenario 1A, while using a higher value for PAR efficacy yields lighting energy intensity as low as 492 kWh·m−2 in scenario 3C. It should be noted that the lower value for PAR efficacy (1.2 µmol·J−1) was chosen because it is a common value for high-pressure sodium, and some LED fixtures based on published literature [37]. The higher value for PAR efficacy (3.0 µmol·J−1) was taken to be a reasonable value based on more recent LED fixture efficacy data and expected future efficacies [37,38]. The large difference in annual energy consumption between operations using the lower efficacy fixtures and higher efficacy fixtures illustrates the importance of improving PAR efficacy for energy and cost savings.

Figure 7.

Annual lighting energy use index (kWh·m−2) of nine urban settings (described in Table 3) for New York (NY) and Los Angeles (LA). The error bars represent the lighting energy consumption for different assumptions using PAR efficacy of 3 µmol·J−1 (lower bar) and 1.2 µmol·J−1 (upper bar).

4. Conclusions

To the best of our knowledge, this study represents the first scientific investigation of natural light availability (and resulting requirements for supplemental lighting) in skyscraper farms. This manuscript presents the results of two parametric studies—first, lighting simulations were run featuring five simple skyscraper farm geometries in two locations to understand the lighting energy implications of growing plants in skyscraper farms in the best-case scenario and second, the natural light availability of skyscraper farms in urban settings was studied by generating a set of theoretical cityscapes and running natural light simulations. Natural lighting in skyscraper farms in NYC and LA without surrounding buildings provides 13% and 11% of the light required to meet a target of 17 mol·m−2·day−1. Comparing the different building configurations, the more elongated buildings which have greater perimeter area require less supplemental light than the squarer building configurations, where up to 27% of the lighting requirements may come from natural light, although shading from surrounding buildings can reduce the natural light available considerably; in the worst case, natural light only supplies 5% of the lighting requirements given a dense urban context. Despite having transparent exterior surfaces, to meet crop requirements, skyscraper farms require 4 to 11 times the lighting energy of traditional greenhouses for the locations considered. The transparent glazing seems to offer benefit for crop production but introducing transparent glazing into multilevel production facilities will have interactive effects on heating, ventilation, and cooling systems and energy demand that are yet to be determined. For skyscraper farms, building shape, orientation, and urban context have a significant effect on the lighting energy usage. Quantifying the natural light resource in skyscraper farms removes some uncertainty around the energetic requirements of such structures and provides reference material for future investigations involving indoor agriculture with some access to natural light.

Research gaps remaining include quantifying the lifelong environmental impacts of skyscraper farms for food production using a life-cycle assessment and techno-economic analysis that considers the embedded energy in construction materials and equipment. Another avenue of research could involve investigating methods for improving the use of natural light in skyscraper farms (or building-integrated agriculture in general); this task would benefit from parsing the PAR available in different sections of the building for different time-periods. Additionally, it would be useful to characterize synergies between food production in skyscrapers and traditional high-rise office buildings or residential buildings. This study offers quantitative information on the availability of natural light for use in food production in skyscraper farms considering a variety of building geometry and urban context scenarios for two U.S. locations, and also calculates the energy requirements to supplement lighting to these structures assuming three different lighting efficacies.

Author Contributions

M.E., conceptualization, methodology, investigation, software, and writing—original draft preparation; T.S., writing—review and editing; K.H., conceptualization and writing—review and editing; N.M., conceptualization, supervision, writing—review and editing, and funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

Funding for this project is provided by the National Science Foundation under award number 1739163.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- UN. World Urbanization Prospects: The 2018 Revision; UN: New York, NY, USA, 2019; ISBN 978-92-1-148319-2. [Google Scholar]

- Gómez, C.; Currey, C.J.; Dickson, R.W.; Kim, H.-J.; Hernández, R.; Sabeh, N.C.; Raudales, R.E.; Brumfield, R.G.; Laury-Shaw, A.; Wilke, A.K.; et al. Controlled Environment Food Production for Urban Agriculture. HortScience 2019, 54, 1448–1458. [Google Scholar] [CrossRef]

- Kozai, T.; Niu, G. Plant Factory—An Indoor Vertical Farming System for Efficient Quality Food Production, 1st ed.; Academic Press: Cambridge, MA, USA, 2016; ISBN 978-0-12-801775-3. [Google Scholar]

- Zeidler, C.; Schubert, D.; Vrakking, V. Vertical Farm 2.0: Designing an Economically Feasible Vertical Farm—A Combined European Endeavor for Sustainable Urban Agriculture. Ph.D. Thesis, Association for Vertical Farming, Munich, Germany, 2017. [Google Scholar]

- Graamans, L.; Baeza, E.; van den Dobbelsteen, A.; Tsafaras, I.; Stanghellini, C. Plant Factories versus Greenhouses: Comparison of Resource Use Efficiency. Agric. Syst. 2018, 160, 31–43. [Google Scholar] [CrossRef]

- Harbick, K.; Albright, L.D. Comparison of Energy Consumption: Greenhouses and Plant Factories. Acta Hortic. 2016, 285–292. [Google Scholar] [CrossRef] [Green Version]

- Despommier, D. Farming up the City: The Rise of Urban Vertical Farms. Trends Biotechnol. 2013, 31, 388–389. [Google Scholar] [CrossRef]

- Despommier, D. The Vertical Farm: Controlled Environment Agriculture Carried out in Tall Buildings Would Create Greater Food Safety and Security for Large Urban Populations. J. Verbrauch. Lebensm. 2011, 6, 233–236. [Google Scholar] [CrossRef]

- NREL Lighting System Assessment Guidelines 2011. Available online: https://www.nrel.gov/docs/fy11osti/50125.pdf (accessed on 23 March 2021).

- Edmonds, I. Daylighting High-Density Residential Buildings with Light Redirecting Panels. Light. Res. Technol. 2005, 37, 73–84. [Google Scholar] [CrossRef]

- Dogan, T.; Park, Y. A Critical Review of Daylighting Metrics for Residential Architecture and a New Metric for Cold and Temperate Climates. Light. Res. Technol. 2019, 51, 206–230. [Google Scholar] [CrossRef]

- Dogan, T.; Reinhart, C.; Michalatos, P. Urban Daylight Simulation Calculating the Daylit Area of Urban Designs. Proc. SimBuild 2012, 5, 613–620. [Google Scholar]

- Brechner, M.; Both, A.J.; Staff, C.E.A. Hydroponic Lettuce Handbook. Cornell Control. Environ. Agric. 1996, 834, 504–509. [Google Scholar]

- Ohashi, Y.; Torii, T.; Ishigami, Y.; Goto, E. Estimation of the Light Interception of a Cultivated Tomato Crop Canopy under Different Furrow Distances in a Greenhouse Using the Ray Tracing. J. Agric. Meteorol. 2020, 76, 188–193. [Google Scholar] [CrossRef]

- Jung, D.; Lee, J.; Kang, W.; Hwang, I.; Son, J. Estimation of Whole Plant Photosynthetic Rate of Irwin Mango under Artificial and Natural Lights Using a Three-Dimensional Plant Model and Ray-Tracing. Int. J. Mol. Sci. 2018, 19, 152. [Google Scholar] [CrossRef] [Green Version]

- Saito, K.; Ishigami, Y.; Goto, E. Evaluation of the Light Environment of a Plant Factory with Artificial Light by Using an Optical Simulation. Agronomy 2020, 10, 1663. [Google Scholar] [CrossRef]

- Wang, C.; Du, J.; Liu, Y.; Chow, D. A Climate-Based Analysis of Photosynthetically Active Radiation Availability in Large-Scale Greenhouses across China. J. Clean. Prod. 2021, 127901. [Google Scholar] [CrossRef]

- Ashdown, I. Climate-Based Annual Daylight Modelling for Greenhouses with Supplemental Electric Lighting. In Proceedings of the International Symposium on Advanced Technologies and Management for Innovative Greenhouses: GreenSys2019, Angers, France, 16–21 June 2019. [Google Scholar]

- Buck-Sorlin, G.H.; Hemmerling, R.; Vos, J.; de Visser, P.H.B. Modelling of Spatial Light Distribution in the Greenhouse: Description of the Model. In Proceedings of the 2009 Third International Symposium on Plant Growth Modeling, Simulation, Visualization and Applications, Beijing, China, 9–13 November 2009; pp. 79–86. [Google Scholar]

- Benis, K.; Reinhart, C.; Ferrão, P. Development of a Simulation-Based Decision Support Workflow for the Implementation of Building-Integrated Agriculture (BIA) in Urban Contexts. J. Clean. Prod. 2017, 147, 589–602. [Google Scholar] [CrossRef]

- Avgoustaki, D.D.; Xydis, G. How Energy Innovation in Indoor Vertical Farming Can Improve Food Security, Sustainability, and Food Safety? Adv. Food Secur. Sustain. 2020, 5, 1–51. [Google Scholar] [CrossRef]

- Al-Kodmany, K. The Vertical Farm: A Review of Developments and Implications for the Vertical City. Buildings 2018, 8, 24. [Google Scholar] [CrossRef] [Green Version]

- Beacham, A.M.; Vickers, L.H.; Monaghan, J.M. Vertical Farming: A Summary of Approaches to Growing Skywards. J. Hortic. Sci. Biotechnol. 2019, 94, 277–283. [Google Scholar] [CrossRef]

- Palliwal, A.; Song, S.; Tan, H.T.W.; Biljecki, F. 3D City Models for Urban Farming Site Identification in Buildings. Comput. Environ. Urban Syst. 2021, 86, 101584. [Google Scholar] [CrossRef]

- Reinhart, C.F.; Walkenhorst, O. Validation of Dynamic RADIANCE-Based Daylight Simulations for a Test Office with External Blinds. Energy Build. 2001, 33, 683–697. [Google Scholar] [CrossRef]

- Ward Larson, G.; Shakespeare, R. Rendering with Radiance: The Art and Science of Lighting Visualization; Morgan Kaufman Publishers, Inc.: San Francisco, CA, USA, 1998. [Google Scholar]

- McNeel Rhinoceros 6.0. Available online: www.rhino3d.com (accessed on 16 December 2019).

- Jakubiec, J.A.; Reinhart, C.F. DIVA 2.0: Integrating Daylight and Thermal Simulations Using Rhinoceros 3D, Daysim and EnergyPlus. In Proceedings of the 12th Conference of International Building Performance Simulation Association, Sydney, Australia, 14–16 November 2011; Volume 20, pp. 2202–2209. [Google Scholar]

- Wilcox, S.; Marion, W. Users Manual for Tmy3 Data Sets (Revised); National Renewable Energy Lab (NREL): Golden, CO, USA, 2008. [Google Scholar]

- McCree, K.J. The Action Spectrum, Absorptance and Quantum Yield of Photosynthesis in Crop Plants. Agric. Meteorol. 1971, 9, 191–216. [Google Scholar] [CrossRef]

- Ting, K.C.; Giacomelli, G.A. Giacomelli Availability of Solar Photosynthetically Active Radiation. Trans. ASAE 1987, 30, 1453–1457. [Google Scholar] [CrossRef]

- Dorais, M. The Use of Supplemental Lighting for Vegetable Crop Production: Light Intensity, Crop Response, Nutrition, Crop Management, Cultural Practices. In Proceedings of the Canadian Greenhouse Conference, Jordan Station, ON, Canada, 9 October 2003. [Google Scholar]

- Both, A.-J. Dynamic Simulation of Supplemental Lightingfor Greenhouse Hydroponic Lettuce Production. Ph.D Thesis, Cornell University, Ithaca, NY, USA, 1995. [Google Scholar]

- Both, A.J.; Shelford, T. Plant Production in Controlled Environments; Virginia Tech Publishing: Blacksburg, VA, USA, 2020. [Google Scholar]

- Kusuma, P.; Pattison, P.M.; Bugbee, B. From Physics to Fixtures to Food: Current and Potential LED Efficacy. Hortic. Res. 2020, 7, 56. [Google Scholar] [CrossRef] [Green Version]

- Wallace, C.; Both, A.J. Evaluating Operating Characteristics of Light Sources for Horticultural Applications. Acta Hortic. 2016, 435–444. [Google Scholar] [CrossRef]

- DLC Horticultural Lighting Database. 2021. Available online: https://qpl.designlights.org/horticulture (accessed on 21 March 2021).

- Pattison, P.; Tsao, J.; Krames, M. Light-Emitting Diode Technology Status and Directions: Opportunities for Horticultural Lighting. Acta Hortic. 2016, 1134, 413–426. [Google Scholar] [CrossRef] [Green Version]

- Both, A.-J.; Bugbee, B.; Kubota, C.; Lopez, R.G.; Mitchell, C.; Runkle, E.S.; Wallace, C. Proposed Product Label for Electric Lamps Used in the Plant Sciences. HortTechnology 2017, 27, 544–549. [Google Scholar] [CrossRef] [Green Version]

- Li, D.H.W.; Tsang, E.K.W. An Analysis of Daylighting Performance for Office Buildings in Hong Kong. Build. Environ. 2008, 43, 1446–1458. [Google Scholar] [CrossRef]

- Dogan, T.; Stec, P. Prototyping a Façade-Mounted, Dynamic, Dual-Axis Daylight Redirection System. Light. Res. Technol. 2018, 50, 583–595. [Google Scholar] [CrossRef]

- Srisamranrungruang, T.; Hiyama, K. Possibilities of Using Light Pipes to Buildings. IOP Conf. Ser. Earth Environ. Sci. 2019, 294, 012064. [Google Scholar] [CrossRef]

- Li, D.H.W.; Wong, S.L. Daylighting and Energy Implications Due to Shading Effects from Nearby Buildings. Appl. Energy 2007, 84, 1199–1209. [Google Scholar] [CrossRef]

- Brebbia, C.A.; Zubir, S.S.; Hassan, A.S. Sustainable Development and Planning VIII; WIT Press: Billerica, MA, USA, 2017; ISBN 978-1-78466-153-3. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).