The Potential of Digestate and the Liquid Fraction of Digestate as Chemical Fertiliser Substitutes under the RENURE Criteria

Abstract

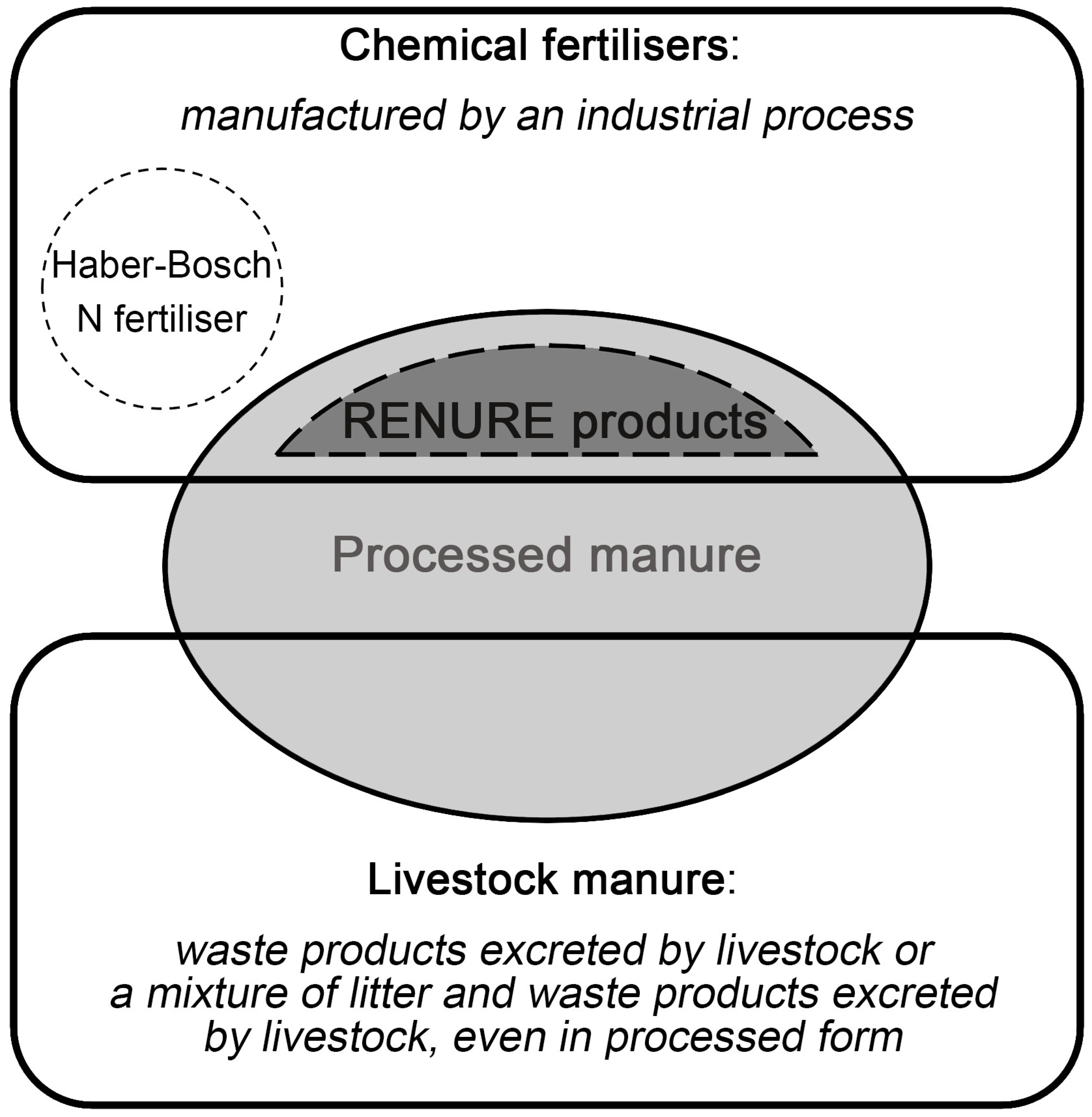

:1. Introduction

2. Materials and Methods

2.1. Digestate Databases

2.1.1. Database A

2.1.2. Database B

Literature Review

Sampling and Analysis Campaign

Data Collection from Stakeholders

2.2. Data Uniformization

2.2.1. Unit Conversions

2.2.2. TOC/OM Ratio

2.2.3. Mineral Nitrogen Content

2.2.4. Decimal Places

3. Results

3.1. Database B

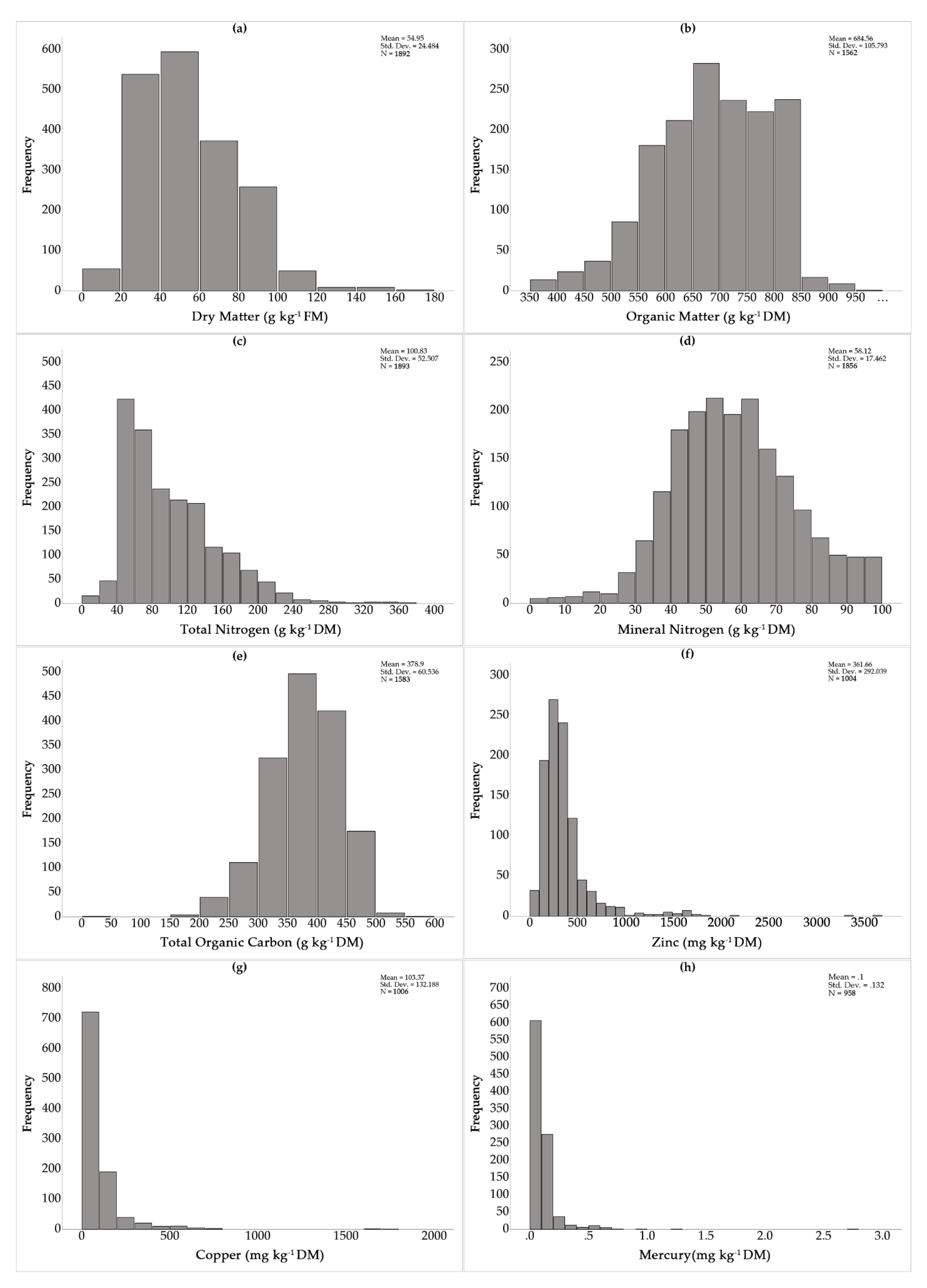

3.2. Database A

3.3. Database C

4. Discussion

4.1. Broad Range of Digestate and Feedstock Characteristics

4.2. Gross Estimation of Nutrients and Carbon Potential from Digestate

4.3. Compliance with ≤300 mg Cu kg−1 DM and ≤800 mg Zn kg−1 DM Criteria

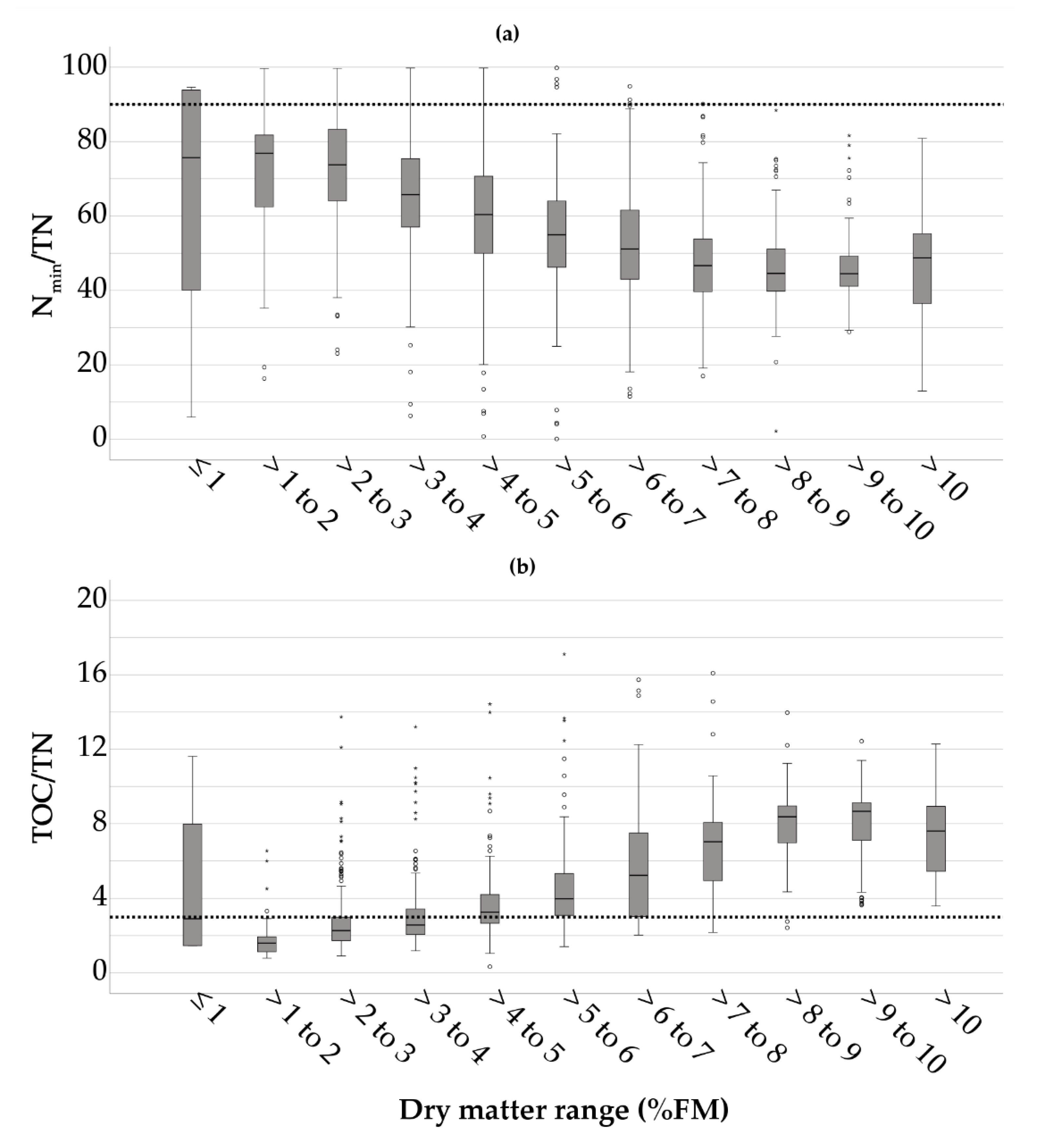

4.4. Compliance with Nmin/TN ≥ 90% or TOC/TN ≤ 3 RENURE Criteria

4.5. Dry Matter Content of RENURE Compliant Digestates

4.6. Identified LF Cases and Associated Separation Technologies

4.7. RENURE Compliance of the Targeted LF in the Database

4.8. Best Management Practices: Reaping Optimal Benefits and Minimising Environmental Risks

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Parameter | Unit | Mean ± Stdev | Median | n |

|---|---|---|---|---|

| DM | g kg−1 FM | 55.96 ± 31.57 | 51 | 153 |

| OM | g kg−1 DM | 661.13 ± 83.37 | 684 | 47 |

| TOC | g kg−1 DM | 353.79 ± 66.21 | 369 | 68 |

| pH | - | 8.14 ± 0.49 | 8.2 | 87 |

| TN | g kg−1 DM | 85.48 ± 47.59 | 75.81 | 153 |

| Nmin (NH4-N) | g kg−1 DM | 56.97 ± 39.03 | 459.6 | 137 |

| K2O | g kg−1 DM | 57.98 ± 33.17 | 48.65 | 56 |

| P2O5 | g kg−1 DM | 37.72 ± 27.53 | 29.5 | 107 |

| Zn | mg kg−1 DM | 863.83 ± 1039 | 440 | 22 |

| Cu | mg kg−1 DM | 312.39 ± 469.08 | 137.55 | 22 |

| Parameter | Unit | Mean ± Stdev | Median | n |

|---|---|---|---|---|

| DM | g kg−1 FM | 76.38 ± 29.04 | 82.15 | 14 |

| OM | g kg−1 DM | 628.66 ± 128.11 | 644.95 | 14 |

| TOC | g kg−1 DM | 267.75 ± 46.90 | 273.6 | 12 |

| pH | - | 8.09 ± 0.80 | 8.35 | 14 |

| TN | g kg−1 DM | 99.89 ± 40.31 | 85.6 | 14 |

| Nmin (NH4-N) | g kg−1 DM | 62.10 ± 31.75 | 50.4 | 14 |

| K2O | g kg−1 DM | 76.70 ± 54.53 | 69.1 | 6 |

| P2O5 | g kg−1 DM | 42.93 ± 16.84 | 43.95 | 6 |

| Zn | mg kg−1 DM | 648.25 ± 342.32 | 649.5 | 4 |

| Cu | mg kg−1 DM | 170.17 ± 168.26 | 76.5 | 6 |

| Hg | mg kg−1 DM | 0.67 ± 0.88 | 0.67 | 2 |

| Parameter | Unit | Mean ± Stdev | Median | n |

|---|---|---|---|---|

| DM | g kg−1 FM | 55.44 ± 37.42 | 50.9 | 22 |

| OM | g kg−1 DM | 645.32 ± 93.79 | 658.59 | 16 |

| TOC | g kg−1 DM | 332.91 ± 127.57 | 307.02 | 6 |

| pH | - | 8.02 ± 0.38 | 8.01 | 19 |

| TN | g kg−1 DM | 114.61 ± 69.42 | 98.5 | 11 |

| Nmin (NH4-N) | g kg−1 DM | 79.14 ± 45.83 | 45.83 | 18 |

| K2O | g kg−1 DM | 61.27 ± 29.35 | 55.42 | 9 |

| P2O5 | g kg−1 DM | 45.81 ± 36.73 | 32.2 | 13 |

| Zn | mg kg−1 DM | 562.31 ± 460.83 | 423.55 | 11 |

| Cu | mg kg−1 DM | 107.39 ± 62.15 | 90 | 11 |

| Hg | mg kg−1 DM | 4.00 × 10−2 ± 4.50 × 10−2 | 3.00 × 10−2 | 6 |

References

- Amon, B.; Amon, T.; Boxberger, J.; Alt, C. Emissions of NH3, N2O and CH4 from Dairy Cows Housed in a Farmyard Manure Tying Stall (Housing, Manure Storage, Manure Spreading). Nutr. Cycl. Agroecosyst. 2001, 60, 103–113. [Google Scholar] [CrossRef]

- Petersen, S.O.; Sommer, S.G.; Béline, F.; Burton, C.; Dach, J.; Dourmad, J.Y.; Leip, A.; Misselbrook, T.; Nicholson, F.; Poulsen, H.D.; et al. Recycling of Livestock Manure in a Whole-Farm Perspective. Livest. Sci. 2007, 112, 180–191. [Google Scholar] [CrossRef]

- Eurostat. Agri-Environmental Indicator—Greenhouse Gas Emissions—Statistics Explained. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Archive:Agri-environmental_indicator_-_greenhouse_gas_emissions (accessed on 17 May 2021).

- Bouwman, L.; Goldewijk, K.K.; Van Der Hoek, K.W.; Beusen, A.H.W.; Van Vuuren, D.P.; Willems, J.; Rufino, M.C.; Stehfest, E. Erratum: Exploring Global Changes in Nitrogen and Phosphorus Cycles in Agriculture Induced by Livestock Production over the 1900–2050 Period. Proc. Natl. Acad. Sci. USA 2013, 110, 21196. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Svanbäck, A.; McCrackin, M.L.; Swaney, D.P.; Linefur, H.; Gustafsson, B.G.; Howarth, R.W.; Humborg, C. Reducing Agricultural Nutrient Surpluses in a Large Catchment—Links to Livestock Density. Sci. Total Environ. 2019, 648, 1549–1559. [Google Scholar] [CrossRef]

- European Commission. Report from the Commission to the Council and the European Parliament on the Implementation of Council Directive 91/676/EEC; European Commission: Brussels, Belgium, 2018; p. 14. [Google Scholar]

- Koornneef, J.; Van Breevoort, P.; Noothout, P.; Hendriks, C.; Luning, L.; Camps, A. Global Potential for Biomethane Production with Carbon Capture, Transport and Storage up to 2050. Energy Procedia 2013, 37, 6043–6052. [Google Scholar] [CrossRef] [Green Version]

- Brear, M.J.; Baldick, R.; Cronshaw, I.; Olofsson, M. Sector Coupling: Supporting Decarbonisation of the Global Energy System. Electr. J. 2020, 33, 106832. [Google Scholar] [CrossRef]

- Gustafsson, M.; Svensson, N. Cleaner Heavy Transports—Environmental and Economic Analysis of Liquefied Natural Gas and Biomethane. J. Clean. Prod. 2021, 278, 123535. [Google Scholar] [CrossRef]

- Holm-Nielsen, J.B.; Al Seadi, T.; Oleskowicz-Popiel, P. The Future of Anaerobic Digestion and Biogas Utilization. Bioresour. Technol. 2009, 100, 5478–5484. [Google Scholar] [CrossRef]

- Burg, V.; Bowman, G.; Haubensak, M.; Baier, U.; Thees, O. Valorization of an Untapped Resource: Energy and Greenhouse Gas Emissions Benefits of Converting Manure to Biogas through Anaerobic Digestion. Resour. Conserv. Recycl. 2018, 136, 53–62. [Google Scholar] [CrossRef]

- Huygens, D.; Orveillon, G.; Lugato, E.; Tavazzi, S. Technical Proposals for the Safe Use of Processed Manure above the Threshold Established for Nitrate Vulnerable Zones by the Nitrates Directive (91/676/EEC); EUR 30363 EN; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar] [CrossRef]

- Hijbeek, R.H.F.M.; Whitmore, B.A.P.; ten Berge, H.F.M.; Whitmore, A.P.; Barkusky, D.; Schröder, J.J.; van Ittersum, M.K. Nitrogen Fertiliser Replacement Values for Organic Amendments Appear to Increase with N Application Rates. Nutr. Cycl. Agroecosyst. 2018, 110, 105–115. [Google Scholar] [CrossRef] [Green Version]

- Sigurnjak, I.; Vaneeckhaute, C.; Michels, E.; Ryckaert, B.; Ghekiere, G.; Tack, F.M.G.; Meers, E. Fertilizer Performance of Liquid Fraction of Digestate as Synthetic Nitrogen Substitute in Silage Maize Cultivation for Three Consecutive Years. Sci. Total Environ. 2017, 599–600, 1885–1894. [Google Scholar] [CrossRef]

- Möller, K.; Müller, T. Effects of Anaerobic Digestion on Digestate Nutrient Availability and Crop Growth: A Review. Eng. Life Sci. 2012, 12, 242–257. [Google Scholar] [CrossRef]

- Monlau, F.; Sambusiti, C.; Ficara, E.; Aboulkas, A.; Barakat, A.; Carrère, H. New Opportunities for Agricultural Digestate Valorization: Current Situation and Perspectives. Energy Environ. Sci. 2015, 8, 2600–2621. [Google Scholar] [CrossRef]

- Nkoa, R. Agricultural Benefits and Environmental Risks of Soil Fertilization with Anaerobic Digestates: A Review. Agron. Sustain. Dev. 2014, 34, 473–492. [Google Scholar] [CrossRef] [Green Version]

- Vaneeckhaute, C.; Lebuf, V.; Michels, E.; Belia, E.; Vanrolleghem, P.A.; Tack, F.M.G.; Meers, E. Nutrient Recovery from Digestate: Systematic Technology Review and Product Classification. Waste Biomass Valorizat. 2017, 8, 21–40. [Google Scholar] [CrossRef] [Green Version]

- Hjorth, M.; Christensen, K.V.; Christensen, M.L.; Sommer, S.G. Solid-Liquid Separation of Animal Slurry in Theory and Practice. Sustain. Agric. 2009, 2, 953–986. [Google Scholar] [CrossRef]

- Romero-Güiza, M.S.; Mata-Alvarez, J.; María, J.; Rivera, C. Nutrient Recovery Technologies for Anaerobic Digestion Systems: An Overview Tecnologías de Recuperación de Nutrientes Para Los Sistemas de Digestión Anaeróbica: Revisión Tecnologias de Recuperação de Nutrientes Para Os Sistemas de Digestão Anaeróbia: R. Bucaramanga 2015, 29, 7–26. [Google Scholar]

- Pognani, M.; D’Imporzano, G.; Scaglia, B.; Adani, F. Substituting Energy Crops with Organic Fraction of Municipal Solid Waste for Biogas Production at Farm Level: A Full-Scale Plant Study. Process Biochem. 2009, 44, 817–821. [Google Scholar] [CrossRef]

- Cristina, G.; Camelin, E.; Pugliese, M.; Tommasi, T.; Fino, D. Evaluation of Anaerobic Digestates from Sewage Sludge as a Potential Solution for Improvement of Soil Fertility. Waste Manag. 2019, 99, 122–134. [Google Scholar] [CrossRef]

- Tambone, F.; Orzi, V.; Zilio, M.; Adani, F. Measuring the Organic Amendment Properties of the Liquid Fraction of Digestate. Waste Manag. 2019, 88, 21–27. [Google Scholar] [CrossRef]

- Voća, N.; Krička, T.; Ćosić, T.; Rupić, V.; Jukić, Ž.; Kalambura, S. Digested Residue as a Fertilizer after the Mesophilic Process of Anaerobic Digestion. Plant Soil Environ. 2005, 51, 262–266. [Google Scholar] [CrossRef] [Green Version]

- Tambone, F.; Genevini, P.; D’Imporzano, G.; Adani, F. Assessing Amendment Properties of Digestate by Studying the Organic Matter Composition and the Degree of Biological Stability during the Anaerobic Digestion of the Organic Fraction of MSW. Bioresour. Technol. 2009, 100, 3140–3142. [Google Scholar] [CrossRef]

- De la Fuente, C.; Alburquerque, J.A.; Clemente, R.; Bernal, M.P. Soil C and N Mineralisation and Agricultural Value of the Products of an Anaerobic Digestion System. Biol. Fertil. Soils 2013, 49, 313–322. [Google Scholar] [CrossRef]

- Ernst, G.; Müller, A.; Göhler, H.; Emmerling, C. C and N Turnover of Fermented Residues from Biogas Plants in Soil in the Presence of Three Different Earthworm Species (Lumbricus terrestris, Aporrectodea longa, Aporrectodea caliginosa). Soil Biol. Biochem. 2008, 40, 1413–1420. [Google Scholar] [CrossRef]

- Alburquerque, J.A.; de la Fuente, C.; Bernal, M.P. Chemical Properties of Anaerobic Digestates Affecting C and N Dynamics in Amended Soils. Agric. Ecosyst. Environ. 2012, 160, 15–22. [Google Scholar] [CrossRef]

- Orzi, V.; Cadena, E.; Dimporzano, G.; Artola, A.; Davoli, E.; Crivelli, M.; Adani, F. Potential Odour Emission Measurement in Organic Fraction of Municipal Solid Waste during Anaerobic Digestion: Relationship with Process and Biological Stability Parameters. Bioresour. Technol. 2010, 101, 7330–7337. [Google Scholar] [CrossRef] [PubMed]

- Tambone, F.; Scaglia, B.; D’Imporzano, G.; Schievano, A.; Orzi, V.; Salati, S.; Adani, F. Assessing Amendment and Fertilizing Properties of Digestates from Anaerobic Digestion through a Comparative Study with Digested Sludge and Compost. Chemosphere 2010, 81, 577–583. [Google Scholar] [CrossRef]

- Vaneeckhaute, C.; Meers, E.; Michels, E.; Christiaens, P.; Tack, F.M.G. Fate of Macronutrients in Water Treatment of Digestate Using Vibrating Reversed Osmosis. Water. Air. Soil Pollut. 2012, 223, 1593–1603. [Google Scholar] [CrossRef] [Green Version]

- Sigurnjak, I.; Michels, E.; Crappé, S.; Buysens, S.; Tack, F.M.G.; Meers, E. Utilization of Derivatives from Nutrient Recovery Processes as Alternatives for Fossil-Based Mineral Fertilizers in Commercial Greenhouse Production of Lactuca Sativa L. Sci. Hortic. Amst. 2016, 198, 267–276. [Google Scholar] [CrossRef]

- Sigurnjak, I.; De Waele, J.; Michels, E.; Tack, F.M.; Meers, E.; De Neve, S. Nitrogen Release and Mineralization Potential of Derivatives from Nutrient Recovery Processes as Substitutes for Fossil Fuel-Based Nitrogen Fertilizers. Soil Use Manag. 2017, 33, 437–446. [Google Scholar] [CrossRef]

- Sigurnjak, I.; Michels, E.; Crappé, S.; Buysens, S.; Biswas, J.K.; Tack, F.M.G.; Neve, S.D.; Meers, E. Does Acidification Increase the Nitrogen Fertilizer Replacement Value of Bio-Based Fertilizers? J. Plant Nutr. Soil Sci. 2017, 180, 800–810. [Google Scholar] [CrossRef]

- Vaneeckhaute, C.; Meers, E.; Michels, E.; Buysse, J.; Tack, F.M.G. Ecological and Economic Benefits of the Application of Bio-Based Mineral Fertilizers in Modern Agriculture. Biomass Bioenergy 2013, 49, 239–248. [Google Scholar] [CrossRef] [Green Version]

- Vaneeckhaute, C.; Meers, E.; Michels, E.; Ghekiere, G.; Accoe, F.; Tack, F.M.G. Closing the Nutrient Cycle by Using Bio-Digestion Waste Derivatives as Synthetic Fertilizer Substitutes: A Field Experiment. Biomass Bioenergy 2013, 55, 175–189. [Google Scholar] [CrossRef] [Green Version]

- Vaneeckhaute, C.; Janda, J.; Vanrolleghem, P.A.; Tack, F.M.G.; Meers, E. Phosphorus Use Efficiency of Bio-Based Fertilizers: Bioavailability and Fractionation. Pedosphere 2016, 26, 310–325. [Google Scholar] [CrossRef] [Green Version]

- Chantigny, M.H.; Pelster, D.E.; Perron, M.-H.; Rochette, P.; Angers, D.A.; Parent, L.-É.; Massé, D.; Ziadi, N. Nitrous Oxide Emissions from Clayey Soils Amended with Paper Sludges and Biosolids of Separated Pig Slurry. J. Environ. Qual. 2013, 42, 30–39. [Google Scholar] [CrossRef] [PubMed]

- De Boer, H.C. Co-Digestion of Animal Slurry Can Increase Short-Term Nitrogen Recovery by Crops. J. Environ. Qual. 2008, 37, 1968–1973. [Google Scholar] [CrossRef]

- Abubaker, J.; Cederlund, H.; Arthurson, V.; Pell, M. Bacterial Community Structure and Microbial Activity in Different Soils Amended with Biogas Residues and Cattle Slurry. Appl. Soil Ecol. 2013, 72, 171–180. [Google Scholar] [CrossRef]

- Alburquerque, J.A.; de la Fuente, C.; Campoy, M.; Carrasco, L.; Nájera, I.; Baixauli, C.; Caravaca, F.; Roldán, A.; Cegarra, J.; Bernal, M.P. Agricultural Use of Digestate for Horticultural Crop Production and Improvement of Soil Properties. Eur. J. Agron. 2012, 43, 119–128. [Google Scholar] [CrossRef]

- Velthof, G.L.; Rietra, R.P.J.J. Nitrogen Use Efficiency and Gaseous Nitrogen Losses from the Concentrated Liquid Fraction of Pig Slurries. Int. J. Agron. 2019, 2019. [Google Scholar] [CrossRef]

- Barłóg, P.; Hlisnikovský, L.; Kunzová, E. Effect of Digestate on Soil Organic Carbon and Plant-Available Nutrient Content Compared to Cattle Slurry and Mineral Fertilization. Agronomy 2020, 10, 379. [Google Scholar] [CrossRef] [Green Version]

- Baral, K.R.; Labouriau, R.; Olesen, J.E.; Petersen, S.O. Nitrous Oxide Emissions and Nitrogen Use Efficiency of Manure and Digestates Applied to Spring Barley. Agric. Ecosyst. Environ. 2017, 239, 188–198. [Google Scholar] [CrossRef]

- Müller-Stöver, D.S.; Sun, G.; Kroff, P.; Thomsen, S.T.; Hauggaard-Nielsen, H. Anaerobic Co-Digestion of Perennials: Methane Potential and Digestate Nitrogen Fertilizer Value. J. Plant Nutr. Soil Sci. 2016, 179, 696–704. [Google Scholar] [CrossRef]

- Fouda, S.; Von Tucher, S.; Lichti, F.; Schmidhalter, U. Nitrogen Availability of Various Biogas Residues Applied to Ryegrass. J. Plant Nutr. Soil Sci. 2013, 176, 572–584. [Google Scholar] [CrossRef]

- Cavalli, D.; Cabassi, G.; Borrelli, L.; Fuccella, R.; Degano, L.; Bechini, L.; Marino, P. Nitrogen Fertiliser Value of Digested Dairy Cow Slurry, Its Liquid and Solid Fractions, and of Dairy Cow Slurry. Ital. J. Agron. 2014, 9, 71–78. [Google Scholar] [CrossRef]

- Bhogal, A.; Nicholson, F.A.; Rollett, A.; Taylor, M.; Litterick, A.; Whittingham, M.J.; Williams, J.R. Improvements in the Quality of Agricultural Soils Following Organic Material Additions Depend on Both the Quantity and Quality of the Materials Applied. Front. Sustain. Food Syst. 2018, 2, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Crolla, A.; Kinsley, C.; Pattey, E. Land Application of Digestate. Biogas Handb. Sci. Prod. Appl. 2013, 302–325. [Google Scholar] [CrossRef]

- Gagnon, B.; Ziadi, N.; Chantigny, M.H.; Bélanger, G.; Massé, D.I. Biosolids from Treated Swine Manure and Papermill Residues Affect Corn Fertilizer Value. Agron. J. 2012, 104, 483–492. [Google Scholar] [CrossRef]

- Riva, C.; Orzi, V.; Carozzi, M.; Acutis, M.; Boccasile, G.; Lonati, S.; Tambone, F.; D’Imporzano, G.; Adani, F. Short-Term Experiments in Using Digestate Products as Substitutes for Mineral (N) Fertilizer: Agronomic Performance, Odours, and Ammonia Emission Impacts. Sci. Total Environ. 2016, 547, 206–214. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Rodríguez, A.R.; Carswell, A.M.; Shaw, R.; Hunt, J.; Saunders, K.; Cotton, J.; Chadwick, D.R.; Jones, D.L.; Misselbrook, T.H. Advanced Processing of Food Waste Based Digestate for Mitigating Nitrogen Losses in a Winter Wheat Crop. Front. Sustain. Food Syst. 2018, 2, 1–14. [Google Scholar] [CrossRef]

- Tambone, F.; Adani, F. Nitrogen Mineralization from Digestate in Comparison to Sewage Sludge, Compost and Urea in a Laboratory Incubated Soil Experiment. Z. Pflanzenernahr. Bodenkd. 2017, 180, 355–365. [Google Scholar] [CrossRef] [Green Version]

- Tambone, F.; Orzi, V.; D’Imporzano, G.; Adani, F. Solid and Liquid Fractionation of Digestate: Mass Balance, Chemical Characterization, and Agronomic and Environmental Value. Bioresour. Technol. 2017, 243, 1251–1256. [Google Scholar] [CrossRef] [PubMed]

- Thomas, B.W.; Li, X.; Nelson, V.; Hao, X. Anaerobically Digested Cattle Manure Supplied More Nitrogen with Less Phosphorus Accumulation than Undigested Manure. Agron. J. 2017, 109, 836–844. [Google Scholar] [CrossRef] [Green Version]

- Šimon, T.; Kunzová, E.; Friedlová, M. The Effect of Digestate, Cattle Slurry and Mineral Fertilization on the Winter Wheat Yield and Soil Quality Parameters. Plant Soil Environ. 2015, 62, 522–527. [Google Scholar] [CrossRef] [Green Version]

- Walsh, J.J.; Jones, D.L.; Chadwick, D.R.; Williams, A.P. Repeated Application of Anaerobic Digestate, Undigested Cattle Slurry and Inorganic Fertilizer N: Impacts on Pasture Yield and Quality. Grass Forage Sci. 2018, 73, 758–763. [Google Scholar] [CrossRef]

- Walsh, J.J.; Jones, D.L.; Edwards-Jones, G.; Williams, A.P. Replacing Inorganic Fertilizer with Anaerobic Digestate May Maintain Agricultural Productivity at Less Environmental Cost. J. Plant Nutr. Soil Sci. 2012, 175, 840–845. [Google Scholar] [CrossRef]

- Bauer, A.; Mayr, H.; Hopfner-Sixt, K.; Amon, T. Detailed Monitoring of Two Biogas Plants and Mechanical Solid-Liquid Separation of Fermentation Residues. J. Biotechnol. 2009, 142, 56–63. [Google Scholar] [CrossRef]

- Risberg, K.; Cederlund, H.; Pell, M.; Arthurson, V.; Schnürer, A. Comparative Characterization of Digestate versus Pig Slurry and Cow Manure—Chemical Composition and Effects on Soil Microbial Activity. Waste Manag. 2017, 61, 529–538. [Google Scholar] [CrossRef] [PubMed]

- Cavalli, D.; Corti, M.; Baronchelli, D.; Bechini, L.; Marino Gallina, P. CO2 Emissions and Mineral Nitrogen Dynamics Following Application to Soil of Undigested Liquid Cattle Manure and Digestates. Geoderma 2017, 308, 26–35. [Google Scholar] [CrossRef]

- Xu, Y.; Yu, W.; Ma, Q.; Zhou, H. Accumulation of Copper and Zinc in Soil and Plant within Ten-Year Application of Different Pig Manure Rates. Plant Soil Environ. 2013, 59, 492–499. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Luo, W.; Jia, J.; Kong, P.; Tong, X.; Lu, Y.; Xie, L.; Ma, F.; Giesy, J.P. Effects of Pig Manure Containing Copper and Zinc on Microbial Community Assessed via Phospholipids in Soils. Environ. Monit. Assess. 2014, 186, 5297–5306. [Google Scholar] [CrossRef]

- Foged, H.L.; Flotats, X.; Blasi, A.B.; Palatsi, J.; Magri, A.; Schelde, K.M. Inventory of Manure Processing Activities in Europe; Technical Report No. I to the European Commission, Directorate-General Environment, Manure Processing Activities in Europe; European Commission: Brussels, Belgium, 2011; p. 138. [Google Scholar]

- Scarlat, N.; Fahl, F.; Dallemand, J.F.; Monforti, F.; Motola, V. A Spatial Analysis of Biogas Potential from Manure in Europe. Renew. Sustain. Energy Rev. 2018, 94, 915–930. [Google Scholar] [CrossRef]

- Meyer, A.K.P.; Ehimen, E.A.; Holm-Nielsen, J.B. Future European Biogas: Animal Manure, Straw and Grass Potentials for a Sustainable European Biogas Production. Biomass Bioenergy 2018, 111, 154–164. [Google Scholar] [CrossRef]

- Corden, C.; Bougas, K.; Cunningham, E.; Tyrer, D.; Kreißig, J.; Zetti, E.; Gamero, E.; Wildey, R.; Crookes, M. Digestate and Compost as Fertilisers: Risk Assessment and Risk Management Options; Wood Environment & Infrastructure Solutions UK Ltd.: Cheshire, UK, 2019. [Google Scholar]

- Metson, G.S.; Feiz, R.; Quttineh, N.-H.; Tonderski, K. Optimizing Transport to Maximize Nutrient Recycling and Green Energy Recovery. Resour. Conserv. Recycl. 2021, X, 100049. [Google Scholar] [CrossRef]

- Eurostat. Consumption of Inorganic Fertilizers, AEI_FM_USEFERT. Available online: https://ec.europa.eu/eurostat/databrowser/view/aei_fm_usefert/default/table?lang=en (accessed on 17 May 2021).

- Zilio, M.; Pigoli, A.; Rizzi, B.; Geromel, G.; Meers, E.; Schoumans, O.; Giordano, A.; Adani, F. Measuring Ammonia and Odours Emissions during Full Field Digestate Use in Agriculture. Sci. Total Environ. 2021, 782, 146882. [Google Scholar] [CrossRef] [PubMed]

- Möller, K. Effects of Anaerobic Digestion on Soil Carbon and Nitrogen Turnover, N Emissions, and Soil Biological Activity. A Review. Agron. Sustain. Dev. 2015, 35, 1021–1041. [Google Scholar] [CrossRef]

- Sager, M. Trace and Nutrient Elements in Manure, Dung and Compost Samples in Austria. Soil Biol. Biochem. 2007, 39, 1383–1390. [Google Scholar] [CrossRef]

- Brown, P.H.; Cakmak, I.; Zhang, Q. Form and Function of Zinc Plants. Zinc Soils Plants 1993, 93–106. [Google Scholar] [CrossRef]

- Nordlander, B.; Krantz, M.; Hohmann, S. Hog1-Mediated Metabolic Adjustments Following Hyperosmotic Shock in the Yeast. Current 2008, 20. [Google Scholar] [CrossRef]

- Tsachidou, B.; Scheuren, M.; Gennen, J.; Debbaut, V.; Toussaint, B.; Hissler, C.; George, I.; Delfosse, P. Biogas Residues in Substitution for Chemical Fertilizers: A Comparative Study on a Grassland in the Walloon Region. Sci. Total Environ. 2019, 666, 212–225. [Google Scholar] [CrossRef]

- Insam, H.; Gómez-Brandón, M.; Ascher, J. Manure-Based Biogas Fermentation Residues—Friend or Foe of Soil Fertility? Soil Biol. Biochem. 2015, 84, 1–14. [Google Scholar] [CrossRef]

- Barbosa, D.B.P.; Nabel, M.; Jablonowski, N.D. Biogas-Digestate as Nutrient Source for Biomass Production of Sida Hermaphrodita, Zea Mays L. and Medicago Sativa L. Energy Procedia 2014, 59, 120–126. [Google Scholar] [CrossRef] [Green Version]

- Gunnarsson, A.; Bengtsson, F.; Caspersen, S. Use Efficiency of Nitrogen from Biodigested Plant Material by Ryegrass. J. Plant Nutr. Soil Sci. 2010, 173, 113–119. [Google Scholar] [CrossRef]

- Nicholson, F.A.; Bhogal, A.; Rollett, A.; Taylor, M.; Williams, J.R. Precision Application Techniques Reduce Ammonia Emissions Following Food-Based Digestate Applications to Grassland. Nutr. Cycl. Agroecosyst. 2018, 110, 151–159. [Google Scholar] [CrossRef]

- Nicoletto, C.; Costa, L.D.; Sambo, P.; Zanin, G. Distillery Anaerobic Digestion Residues as Fertilizers for Field Vegetable Crops: Performance and Efficiency in Mid-Term Successions. Agronomy 2019, 9, 463. [Google Scholar] [CrossRef] [Green Version]

- Riau, V.; Burgos, L.; Camps, F.; Domingo, F.; Torrellas, M.; Antón, A.; Bonmatí, A. Closing Nutrient Loops in a Maize Rotation. Catch Crops to Reduce Nutrient Leaching and Increase Biogas Production by Anaerobic Co-Digestion with Dairy Manure. Waste Manag. 2021, 126, 719–727. [Google Scholar] [CrossRef] [PubMed]

- Valentinuzzi, F.; Cavani, L.; Porfido, C.; Terzano, R.; Pii, Y.; Cesco, S.; Marzadori, C.; Mimmo, T. The Fertilising Potential of Manure-Based Biogas Fermentation Residues: Pelleted vs. Liquid Digestate. Heliyon 2020, 6. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Task 2.11 Study on the Behaviour of Digestate in Agricultural Soils: “Providing Support in Relation to the Implementation of the Nitrates Directive (91/676/EEC)”; European Commission: Brussels, Belgium, 2014; pp. 1–28, No. 07. [Google Scholar]

- Wang, L.L.; Li, W.Z.; Wang, Z.J.; Wang, Z.W.; Sui, C.; Li, Y. Effects of Digestate Application Depth on Soil Nitrogen Volatilization and Vertical Distribution. Int. J. Agric. Biol. Eng. 2016, 9, 101–107. [Google Scholar] [CrossRef]

- Verdi, L.; Mancini, M.; Ljubojevic, M.; Orlandini, S.; Marta, A.D. Greenhouse Gas and Ammonia Emissions from Soil: The Effect of Organic Matter and Fertilisation Method. Ital. J. Agron. 2018, 13, 260–266. [Google Scholar] [CrossRef] [Green Version]

- Badagliacca, G.; Petrovičovà, B.; Pathan, S.I.; Roccotelli, A.; Romeo, M.; Monti, M.; Gelsomino, A. Use of Solid Anaerobic Digestate and No-Tillage Practice for Restoring the Fertility Status of Two Mediterranean Orchard Soils with Contrasting Properties. Agric. Ecosyst. Environ. 2020, 300. [Google Scholar] [CrossRef]

| (Left) Database A | (Right) Database B | ||||||

|---|---|---|---|---|---|---|---|

| Parameter | Unit | Mean ± Stdev | Median | n | Mean ± Stdev | Median | n |

| pH | - | 7.9 ± 0.3 | 7.9 | 1808 | 8.2 ± 0.4 | 8.2 | 119 |

| DM | g kg−1 FM | 57 ± 26 | 53 | 2100 | 56 ± 28 | 52 | 184 |

| OM | g kg−1 DM | 699 ± 106 | 707 | 1831 | 652 ± 94 | 676 | 77 |

| TOC | g kg−1 DM | 388 ± 59 | 393 | 1831 | 340 ± 75 | 352 | 86 |

| TN | g kg−1 DM | 102 ± 53 | 89 | 1758 | 88 ± 49 | 79 | 178 |

| Nmin (NH4-N) | g kg−1 DM | 60 ± 43 | 46 | 1945 | 59 ± 40 | 46 | 166 |

| K2O | g kg−1 DM | 55 ± 29 | 52 | 1447 | 60 ± 35 | 55 | 71 |

| P2O5 | g kg−1 DM | 35 ± 17 | 33 | 1452 | 40 ± 28 | 31 | 126 |

| Zn | mg kg−1 DM | 347 ± 239 | 299 | 1019 | 751 ± 848 | 425 | 37 |

| Cu | mg kg−1 DM | 97 ± 108 | 70 | 1020 | 233 ± 368 | 103 | 39 |

| Hg | mg kg−1 DM | 11 × 10−2 ± 13 × 10−2 | 7 × 10−2 | 994 | 15 × 10−2 ± 38 × 10−2 | 5 × 10−2 | 11 |

| Nmin/TN | % | 58 ± 18 | 57 | 1729 | 61 ± 14 | 62 | 160 |

| TOC/TN | - | 4.8 ± 2.8 | 3.9 | 1518 | 6.5 ± 9.1 | 4 | 86 |

| (Left) Database C | (Right) Database C: Compliance with TOC/TN ≤ 3 or Nmin/TN ≥ 90% | ||||||

|---|---|---|---|---|---|---|---|

| Parameter | Unit | Mean ± Stdev | Median | n | Mean ± Stdev | Median | n |

| pH | - | 8.0 ± 0.3 | 8 | 1905 | 8.0 ± 0.3 | 8.1 | 519 |

| DM | g kg−1 FM | 57 ± 26 | 53 | 2265 | 38 ± 14 | 35 | 606 |

| OM | g kg−1 DM | 697 ± 106 | 705 | 1887 | 612 ± 86 | 621 | 575 |

| TOC | g kg−1 DM | 386 ± 61 | 391 | 1896 | 338 ± 51 | 342 | 587 |

| TN | g kg−1 DM | 100 ± 53 | 87 | 1913 | 158 ± 45 | 151 | 606 |

| Nmin (NH4-N) | g kg−1 DM | 60 ± 43 | 45 | 2087 | 108 ± 37 | 108 | 590 |

| K2O | g kg−1 DM | 56 ± 29 | 52 | 1495 | 54 ± 27 | 50 | 578 |

| P2O5 | g kg−1 DM | 35 ± 18 | 33 | 1555 | 41 ± 16 | 40 | 588 |

| Zn | mg kg−1 DM | 361 ± 294 | 300 | 1035 | 353 ± 224 | 296 | 487 |

| Cu | mg kg−1 DM | 102 ± 131 | 71 | 1038 | 87 ± 81 | 60 | 487 |

| Hg | mg kg−1 DM | 10.2 × 10−2 ± 13.2 × 10−2 | 7 × 10−2 | 984 | 10.5 × 10−2 ± 15.6 × 10−2 | 7 × 10−2 | 481 |

| Nmin/TN | % | 58 ± 17 | 57 | 1856 | 70 ± 17 | 68 | 590 |

| TOC/TN | - | 4.9 ± 3.5 | 3.9 | 1583 | 2.3 ± 0.9 | 2.3 | 587 |

| Parameter | 180 Mt FM y−1 Digestate | ||

|---|---|---|---|

| kt y−1 Equivalent | |||

| 10th Percentile | Median | 90th Percentile | |

| DM | 5040 | 9540 | 16,506 |

| OM | 2787 | 6726 | 13,551 |

| TOC | 1547 | 3730 | 7527 |

| TN | 247 | 830 | 2856 |

| Nmin (NH4-N) | 86 | 429 | 2096 |

| K2O | 111 | 496 | 1519 |

| P2O5 | 81 | 315 | 924 |

| ≤300 mg Cu kg−1 DM | ≤800 mg Zn kg−1 DM | Nmin/TN ≥ 90% | TOC/TN ≤ 3 | Nmin/TN ≥ 90% or TOC/TN ≤ 3 | |

|---|---|---|---|---|---|

| Compliance (cases) | 986/1038 | 980/1035 | 96/1856 | 574/1583 | 606/1893 |

| Compliance (%) | 95 | 95 | 5 | 36 | 32 |

| Separation Technology | |||||||

|---|---|---|---|---|---|---|---|

| Renure Criterion | Compliance | Reverse Osmosis | Screw Press | Decanter | Centrifuge | Belt Press | Unspecified |

| Nmin/TN | Cases | 2/4 | 0/30 | 0/3 | 0/4 | 0/3 | 0/5 |

| (%) | 50 | 0 | 0 | 0 | 0 | 0 | |

| TOC/TN | Cases | - | 4/13 | 1/3 | 3/4 | 0/2 | 2/4 |

| (%) | - | 31 | 33 | 75 | 0 | 50 | |

| (Left) DM Range: 14 to 66 g kg−1 FM | (Right) DM Range: 1.5 to 44 g kg−1 FM | |||||

|---|---|---|---|---|---|---|

| Nmin/TN ≥ 90% | TOC/TN ≤ 3 | Nmin/TN ≥ 90% or TOC/TN ≤ 3 | Nmin/TN ≥ 90% | TOC/TN ≤ 3 | Nmin/TN ≥ 90% or TOC/TN ≤ 3 | |

| Compliance (cases) | 90/1291 | 548/1087 | 575/1324 | 76/745 | 424/658 | 444/770 |

| Compliance (%) | 7 | 52 | 43 | 10 | 64 | 58 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reuland, G.; Sigurnjak, I.; Dekker, H.; Michels, E.; Meers, E. The Potential of Digestate and the Liquid Fraction of Digestate as Chemical Fertiliser Substitutes under the RENURE Criteria. Agronomy 2021, 11, 1374. https://doi.org/10.3390/agronomy11071374

Reuland G, Sigurnjak I, Dekker H, Michels E, Meers E. The Potential of Digestate and the Liquid Fraction of Digestate as Chemical Fertiliser Substitutes under the RENURE Criteria. Agronomy. 2021; 11(7):1374. https://doi.org/10.3390/agronomy11071374

Chicago/Turabian StyleReuland, Gregory, Ivona Sigurnjak, Harmen Dekker, Evi Michels, and Erik Meers. 2021. "The Potential of Digestate and the Liquid Fraction of Digestate as Chemical Fertiliser Substitutes under the RENURE Criteria" Agronomy 11, no. 7: 1374. https://doi.org/10.3390/agronomy11071374

APA StyleReuland, G., Sigurnjak, I., Dekker, H., Michels, E., & Meers, E. (2021). The Potential of Digestate and the Liquid Fraction of Digestate as Chemical Fertiliser Substitutes under the RENURE Criteria. Agronomy, 11(7), 1374. https://doi.org/10.3390/agronomy11071374