Utilization of Quasi-Zenith Satellite System for Navigation of a Robot Combine Harvester

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Platform

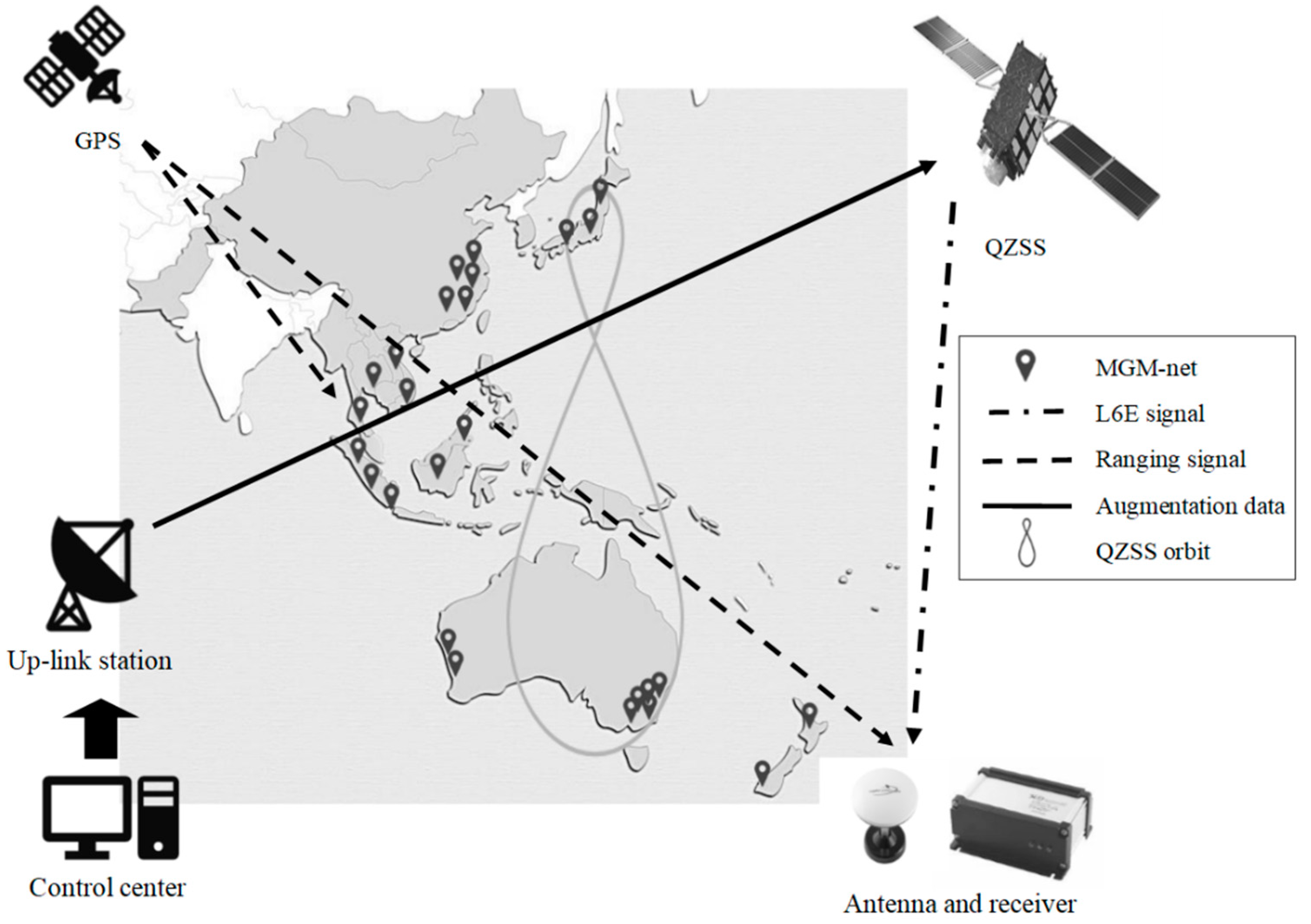

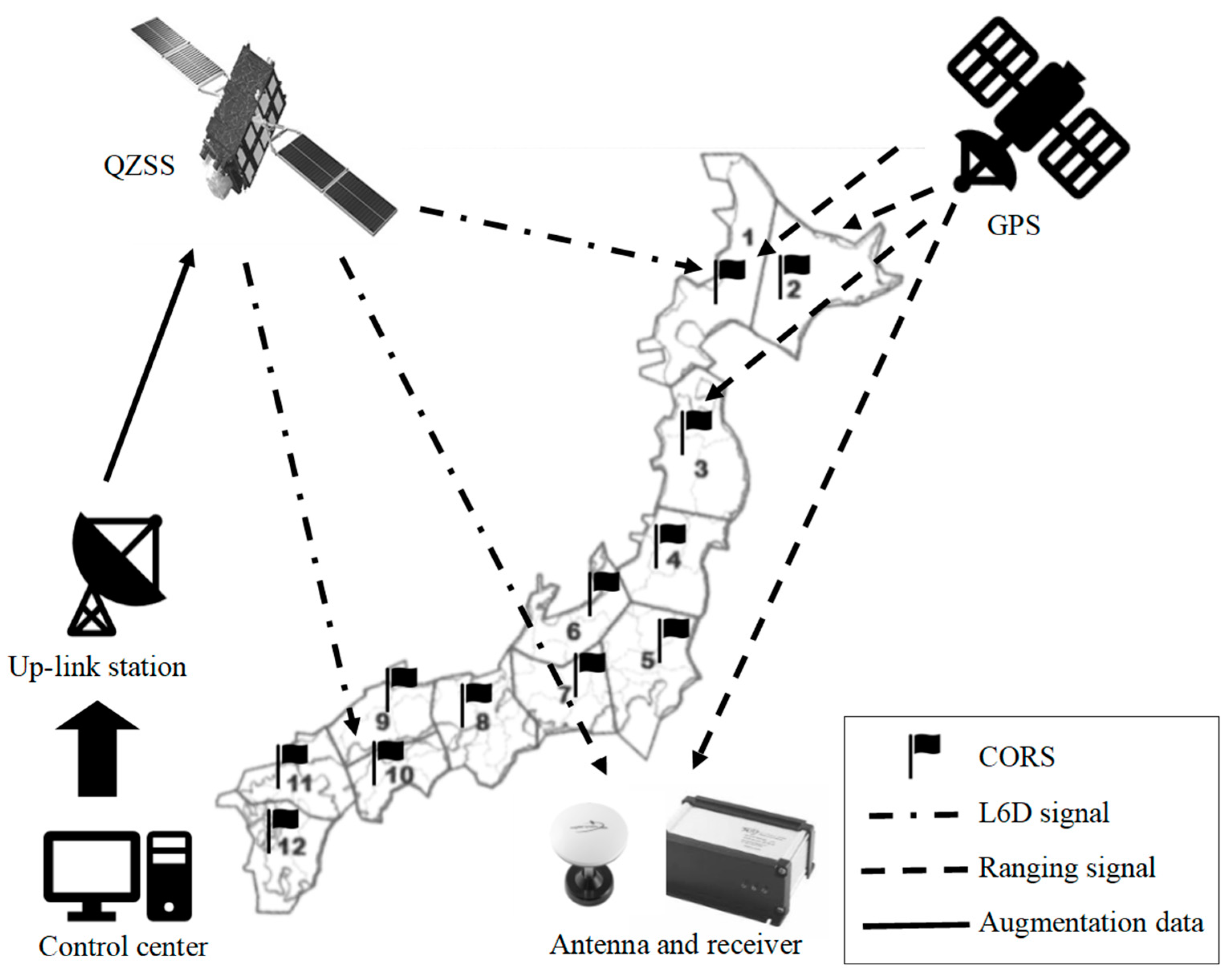

2.2. Positioning Augmentation Systems

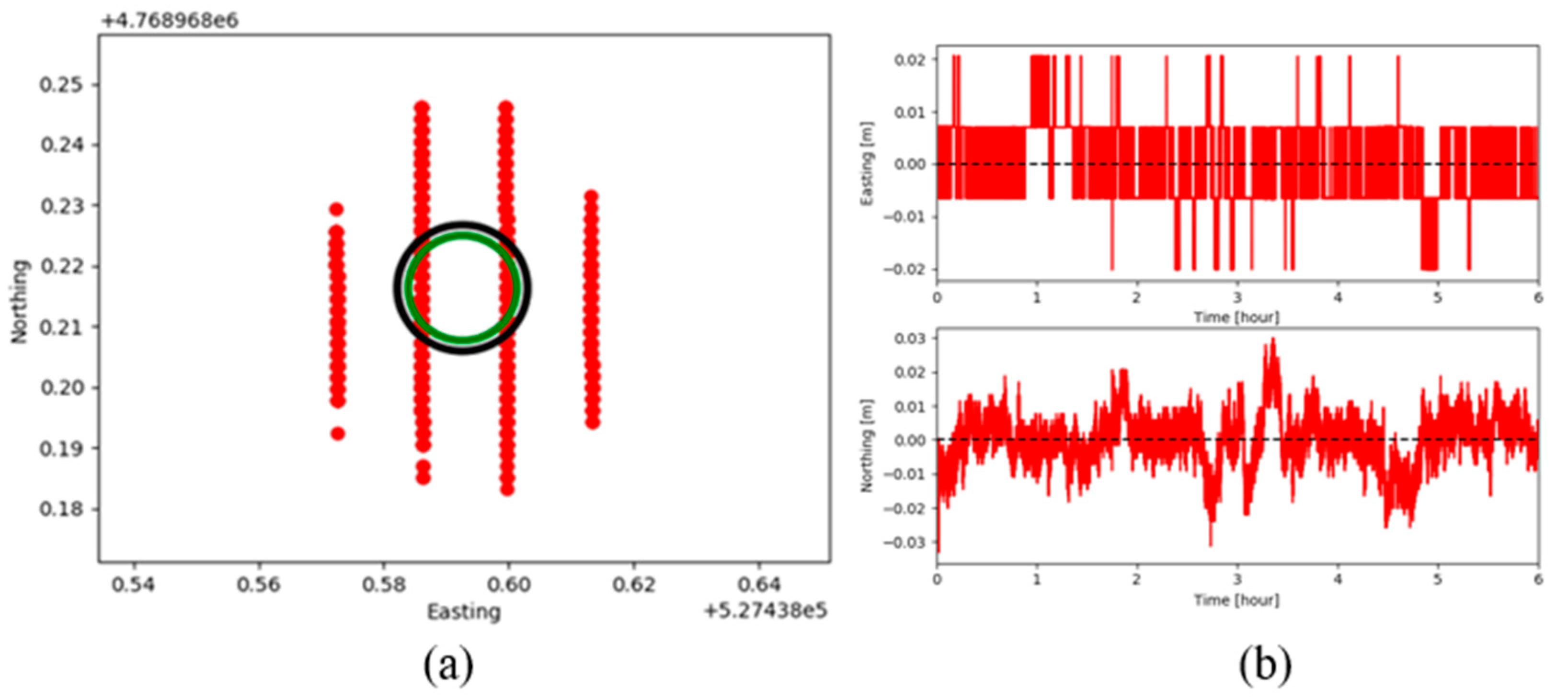

2.3. Static Experiment

2.4. Performance Evaluation of Robot Combine Harvester

3. Results

3.1. Static Experiment

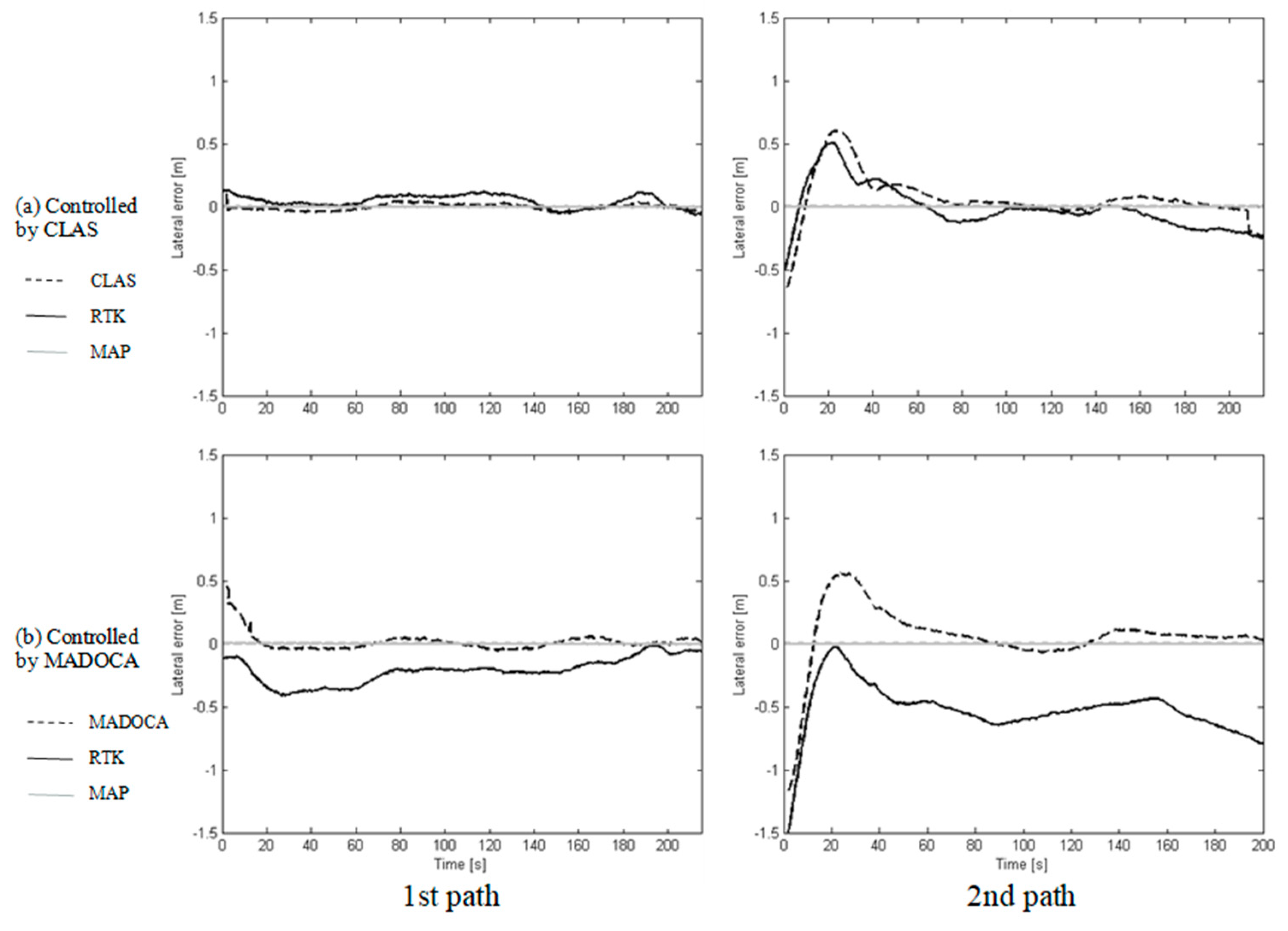

3.2. Performance Evaluation of Robot Combine Harvester

4. Discussion

4.1. Static Experiment

4.2. Performance Evaluation of Robot Combine Harvester

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z. Development of a Robot Combine Harvester Based on GNSS. Ph.D. Thesis, Hokkaido University, Hokkaido, Japan, 25 March 2014. [Google Scholar]

- Iida, M.; Ikemura, Y.; Suguri, M.; Masuda, R. Cut-edge and stubble detection for auto-steering system of combine harvester using machine vision. IFAC 2010, 43, 145–150. [Google Scholar] [CrossRef]

- Teng, Z.; Noguchi, N.; Liangliang, Y.; Ishii, K.; Jun, C. Development of uncut crop edge detection system based on laser rangefinder for combine harvester. Int. J. Agric. Biol. Eng. 2016, 9, 21–28. [Google Scholar]

- Wang, H.; Noguchi, N. Navigation of a robot tractor using the centimeter level augmentation information via Quasi-Zenith Satellite System. EAEF 2019, 12, 414–419. [Google Scholar] [CrossRef]

- Castleden, N.; Hu, G.R.; Abbey, D.A.; Weihing, D.; Øvstedal, O.; Earls, C.J.; Featherstone, W.E. First results from virtual reference station (VRS) and precise point positioning (PPP) GPS research at the western Austranlian Center for Geodesy. J. Glob. Position. Syst. 2004, 3, 79–84. [Google Scholar] [CrossRef]

- Fotopoulos, G.; Cannon, M.E. An overview of multi-reference station method for cm-level positioning. GPS Solut. 2001, 4, 1–10. [Google Scholar] [CrossRef]

- Lachapelle, G.; Alves, P.; Fortes, L.P.; Cannon, M.E.; Townsen, B. DGPS RTK positioning using a reference network. In Proceedings of the 13th International Technical Meeting of the Satellite Division of the Institute of Navigation (ION GPS 2000), Salt Lake City, UT, USA, 19–22 September 2000; pp. 1165–1171. [Google Scholar]

- Choy, S.; Harima, K.; Li, Y.; Choudhury, M.; Rizos, C.; Wakabayashi, Y.; Kogure, S. GPS precise point positioning with the Japanese Quasi-Zenith Satellite System LEX augmentation corrections. J. Navig. 2015, 68, 769–783. [Google Scholar] [CrossRef]

- Zumberge, J.F.; Helfin, M.B.; Jefferson, D.C.; Watkins, M.M.; Webb, F.H. Precise point positioning for the efficient and robust analysis of GPS data from large netswork. J. Geophys. Res. Solid Earth 1997, 102, 5005–5017. [Google Scholar] [CrossRef]

- Choy, S.; Bisnath, S.; Rizos, C. Uncovering common misconceptions in GNSS Precise Point Positioning and its future prospect. Gps Solut. 2017, 21, 13–22. [Google Scholar] [CrossRef]

- Yanmar Combine Harvester Steering System Full Time Drive System. Available online: https://www.yanmar.com/global/about/technology/technical_review/2015/0401_2.html (accessed on 25 March 2020).

- Inaba, N.; Matsumoto, A.; Hase, H.; Kogure, S.; Sawabe, M.; Terada, K. Design concept of quasi zenith satellite system. Acta Astrnautica 2009, 65, 1068–1075. [Google Scholar] [CrossRef]

- Kobayashi, K. QZSS PPP Service. Available online: https://home.csis.u-tokyo.ac.jp/~dinesh/GNSS_Train_files/202001/LectureNotes/Kobayashi/2020AIT_MADOCACLAS.pdf (accessed on 27 March 2020).

- Zhang, S.; Du, S.; Li, W.; Wang, G. Evaluation of the GPS Precise Orbit and Clock Corrections from MADOCA Real-Time Products. Sensors 2019, 19, 2580. [Google Scholar] [CrossRef] [PubMed]

- Saito, M.; Sato, Y.; Miya, M.; Shima, M.; Omura, Y.; Takiguchi, J.; Asari, K. Centimeter-class augmentation system utilizing quasi-zenith satellite. In Proceedings of the 24th International Technical Meeting of The Satellite Division of the Institute of Navigation (ION GNSS 2011), Portland, Oregon, 20–23 September 2011; pp. 1243–1253. [Google Scholar]

- Wübbena, G.; Schmitz, M.; Bagge, A. PPP-RTK: Precise point positioning using state-space representation in RTK networks. In Proceedings of the ION GNSS, Long Beach, CA, USA, 13–16 September 2005; pp. 13–16. [Google Scholar]

- Seigo, F.; Masakazu, M.; Junichi, T. Establish of Centimeter-class Augmentation System utilizing Quasi-Zenith Satellite System utilizating Quasi-Zenith Satellite System. Syst. Contr. Inf. 2015, 59, 126–131. [Google Scholar]

- Miya, M.; Fujita, S.; Sato, Y.; Ota, K.; Hirokawa, R.; Takiguchi, J. Centimeter level augmentation service (CLAS) in Japanese quasi-zenith satellite system, its user interface, detailed design, and plan. In Proceedings of the 29th International Technical Meeting of the Satellite Division of the Institute of Navigation (ION GNSS + 2016), Portland, Oregon, 12–16 September 2016; pp. 2864–2869. [Google Scholar]

- Petrovski, I.G.; Tsuiji, T. Digital Satellite Navigation and Geophysics: A Practical Guide with GNSS Signal Simulator and Receiver Laboratory. Camb. Univ. Press 2012. [Google Scholar] [CrossRef]

- Drosos, V.K.; Malesios, C.; Soutsas, K.P. Planimetry reliability with GPS. In Proceedings of the 44th International Symposium on Forestly Mechanisation, Graz, Austria, 9–13 October 2011. [Google Scholar]

- Rodriduez-Pérez, J.R.; Alvarez, M.F.; Sanz, E.; Gavela, A. Comparison of GPS Receiver Accuracy and Precision in Forest Environment. Practical recommendation regarding methods and receiver selection. In Proceedings of the 23rd FIG Conference, Munich, Germany, 8–13 October 2006. [Google Scholar]

- Fan, P.; Li, W.; Cui, X.; Lu, M. Precise and Robust RTK-GNSS Positioning in Urban Environments with Dual-Antenna Configuration. Sensors 2019, 19, 3586. [Google Scholar] [CrossRef] [PubMed]

| Length (mm) | 6150 |

| Width (mm) | 2350 |

| Height (mm) | 2760 |

| Engine output (kW) | 80.9 |

| Crawler size (mm) | 500 × 1780 |

| Speed (m/s) | Low: 0–1.0 Medium: 0–2.0 High: 0–2.81 |

| Test Number | RTK (Real-Time Kinematic) (2019/06/25) | MADOCA (2019/07/08) | CLAS (2020/01/16) | |||

|---|---|---|---|---|---|---|

| Act. Time (s) | React. Time (s) | Act. Time (s) | React. Time (s) | Act. Time (s) | React. Time (s) | |

| 1 | 13.9 | 13.4 | 31.5 | 43.7 | 127.1 | - |

| 2 | 15.1 | 12.5 | 30.2 | 42.8 | 128.4 | - |

| 3 | 13.7 | 12.3 | 29.5 | 43.7 | 128.5 | - |

| 4 | 14.3 | 13.2 | 29.2 | 43.3 | 129.1 | - |

| 5 | 14.2 | 12.7 | 30.8 | 43.9 | 128.3 | - |

| 6 | 14.7 | 12.8 | 31.1 | 42.4 | 127.6 | - |

| 7 | 14.1 | 13.1 | 30.7 | 43.1 | 128.3 | - |

| 8 | 14.0 | 12.4 | 30.5 | 44.2 | 128.6 | - |

| 9 | 13.8 | 12.9 | 30.1 | 42.7 | 127.3 | - |

| 10 | 14.6 | 13.5 | 29.7 | 43.5 | 128.1 | - |

| Min. | 13.7 | 12.3 | 29.2 | 42.4 | 127.1 | - |

| Max. | 15.1 | 13.5 | 31.5 | 44.2 | 129.1 | - |

| Average | 14.2 | 12.9 | 30.3 | 43.3 | 128.1 | - |

| S.D. | 0.44 | 0.42 | 0.73 | 0.58 | 0.62 | - |

| Positioning Augmentation System | 2DRMS (m) | CEP (m) | No. of Satellites | N-S Offset (m) | E-W Offset (m) | RMS Error (m) |

|---|---|---|---|---|---|---|

| RTK | 0.010 | 0.008 | 14.6 | Ref. | Ref. | Ref. |

| MADOCA | 0.107 | 0.089 | 12.7 | -0.427 | 0.326 | 0.54 |

| CLAS | 0.041 | 0.034 | 11.0 | -0.447 | 0.352 | 0.57 |

| Positioning Augmentation System | RMSE of Lateral Deviation (m) | |||

|---|---|---|---|---|

| 1st Run at 10:00 | 2nd Run at 12:00 | 3rd Run at 14:00 | 4th Run at 16:00 | |

| RTK | 0.04 | 0.03 | 0.04 | 0.03 |

| MADOCA | 0.32 | 0.18 | 0.06 | 0.07 |

| CLAS | 0.06 | 0.05 | 0.04 | 0.05 |

| Positioning Augmentation System | RMSE of Lateral Deviation from 1st Path (m) | RMSE of Lateral Deviation from 2nd Path (m) | ||||||

|---|---|---|---|---|---|---|---|---|

| 10:00 | 12:00 | 14:00 | 16:00 | 10:00 | 12:00 | 14:00 | 16:00 | |

| CLAS | 0.03 | 0.03 | 0.03 | 0.03 | 0.26 | 0.21 | 0.31 | 0.27 |

| RTK | 0.07 | 0.11 | 0.11 | 0.09 | 0.22 | 0.19 | 0.28 | 0.23 |

| Positioning Augmentation System | RMSE of Lateral Deviation from 1st Path (m) | RMSE of Lateral Deviation from 2nd Path (m) | ||||||

|---|---|---|---|---|---|---|---|---|

| 10:00 | 12:00 | 14:00 | 16:00 | 10:00 | 12:00 | 14:00 | 16:00 | |

| MADOCA | 0.11 | 0.04 | 0.07 | 0.08 | 0.36 | 0.69 | 0.63 | 0.67 |

| RTK | 0.23 | 0.09 | 0.08 | 0.09 | 0.58 | 0.66 | 0.58 | 0.66 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Udompant, K.; Ospina, R.; Kim, Y.-J.; Noguchi, N. Utilization of Quasi-Zenith Satellite System for Navigation of a Robot Combine Harvester. Agronomy 2021, 11, 483. https://doi.org/10.3390/agronomy11030483

Udompant K, Ospina R, Kim Y-J, Noguchi N. Utilization of Quasi-Zenith Satellite System for Navigation of a Robot Combine Harvester. Agronomy. 2021; 11(3):483. https://doi.org/10.3390/agronomy11030483

Chicago/Turabian StyleUdompant, Kannapat, Ricardo Ospina, Yong-Joo Kim, and Noboru Noguchi. 2021. "Utilization of Quasi-Zenith Satellite System for Navigation of a Robot Combine Harvester" Agronomy 11, no. 3: 483. https://doi.org/10.3390/agronomy11030483

APA StyleUdompant, K., Ospina, R., Kim, Y.-J., & Noguchi, N. (2021). Utilization of Quasi-Zenith Satellite System for Navigation of a Robot Combine Harvester. Agronomy, 11(3), 483. https://doi.org/10.3390/agronomy11030483