Impacts of Effects of Deficit Irrigation Strategy on Water Use Efficiency and Yield in Cotton under Different Irrigation Systems

Abstract

1. Introduction

2. Materials and Methods

2.1. APSIM Cotton Modelling

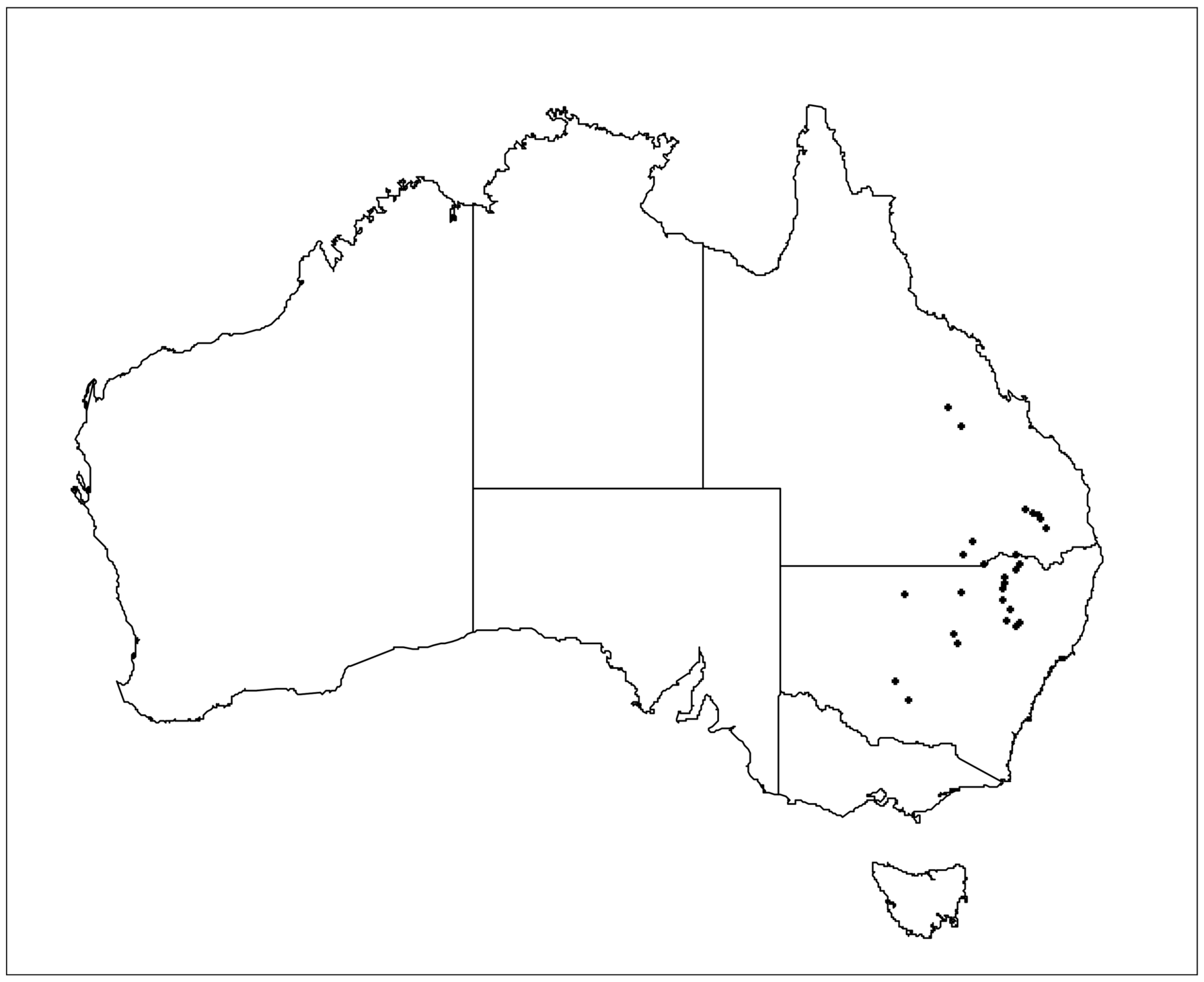

2.2. Validation Data

2.3. Statistical Analysis of Validation Simulation Results

2.4. Simulation of Deficit Irrigation (DI) Practices

2.5. Calculation of Water Use Efficiency, Marginal Water Use Efficiency and Statistical Analysis of Simulations Outputs

3. Results

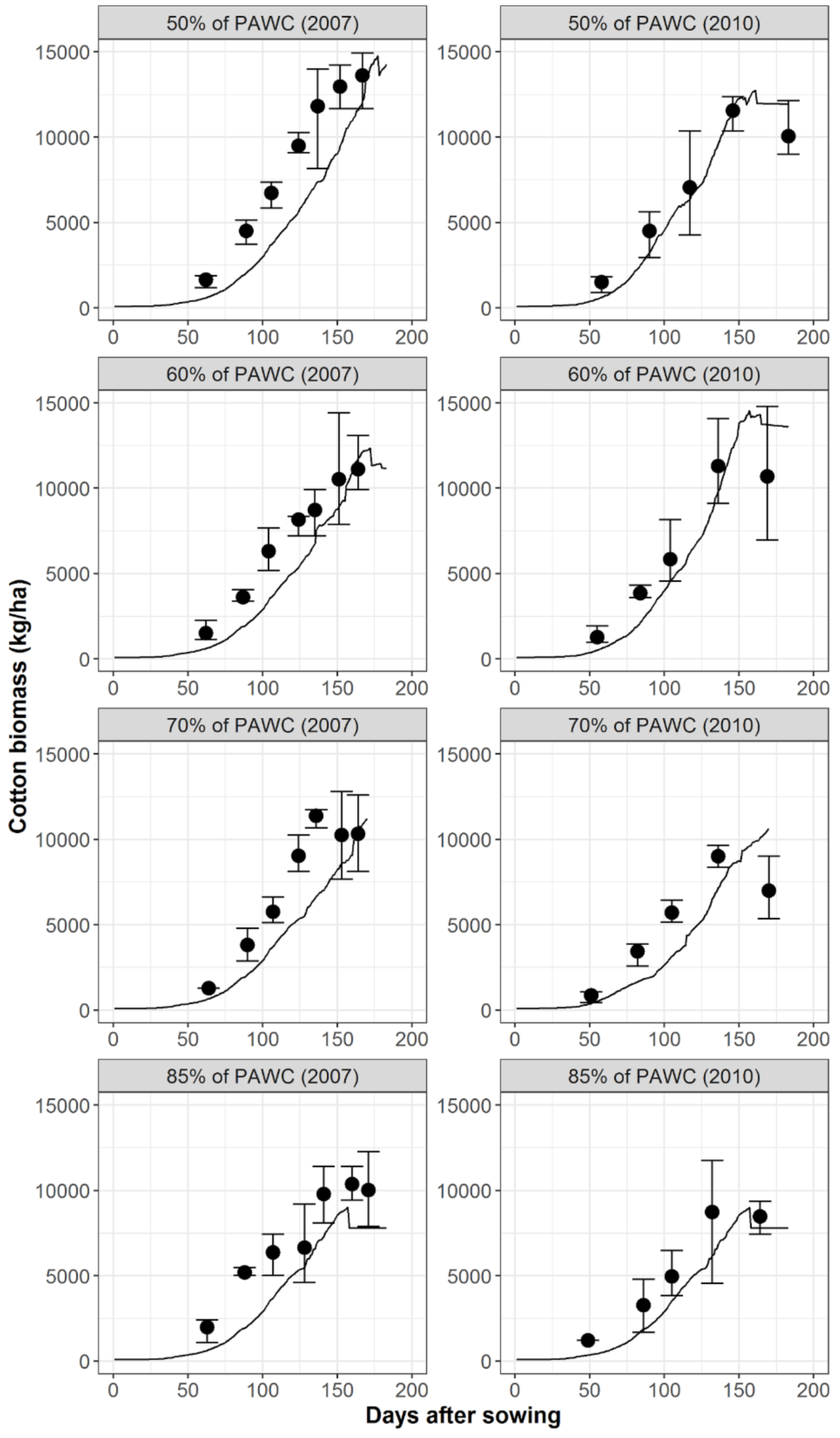

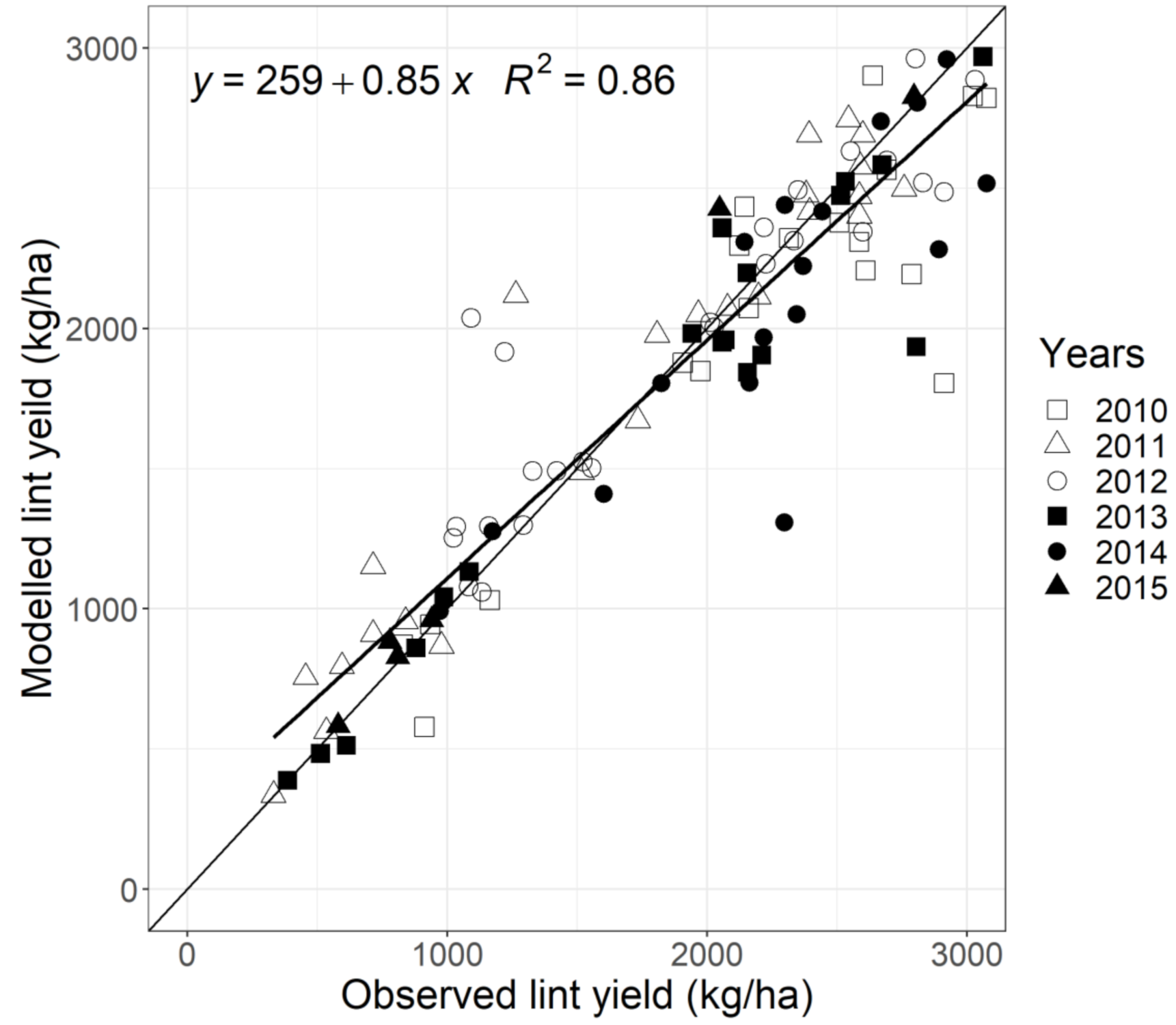

3.1. Model Validation

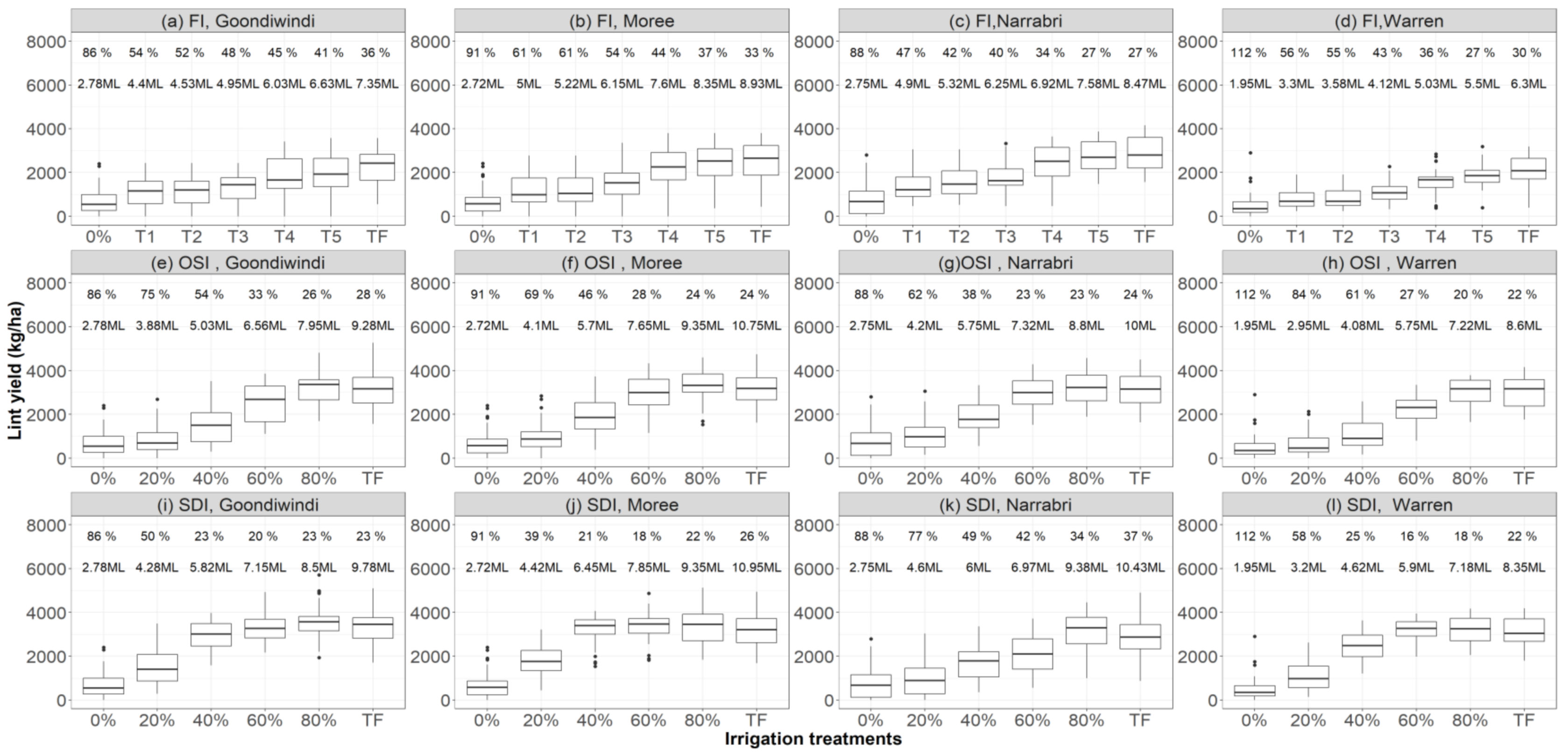

3.2. The Effects of Deficit Irrigation Practices on Lint Yield

3.3. The Effects of Deficit Irrigation Practices on Water Use Efficiency

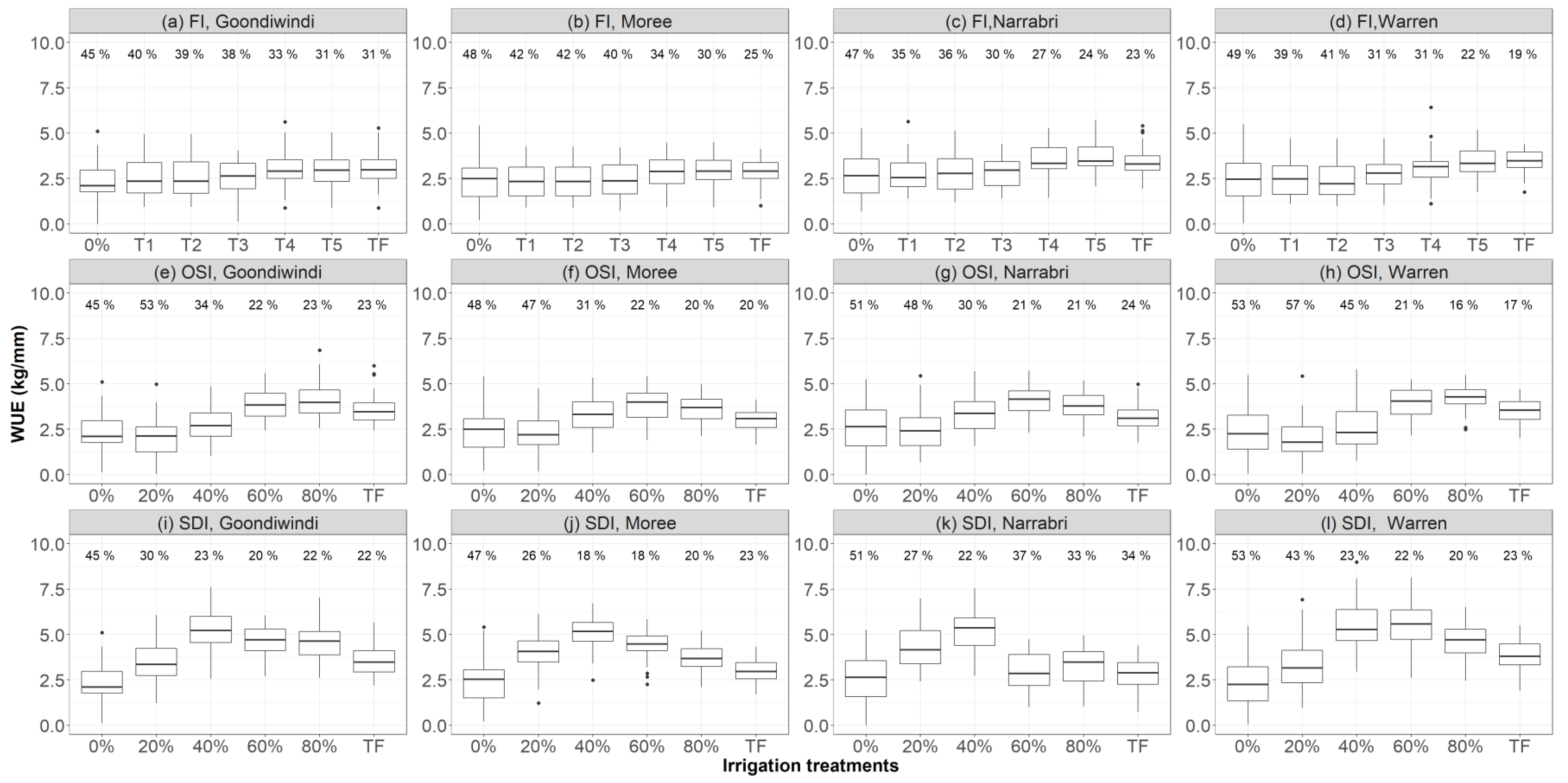

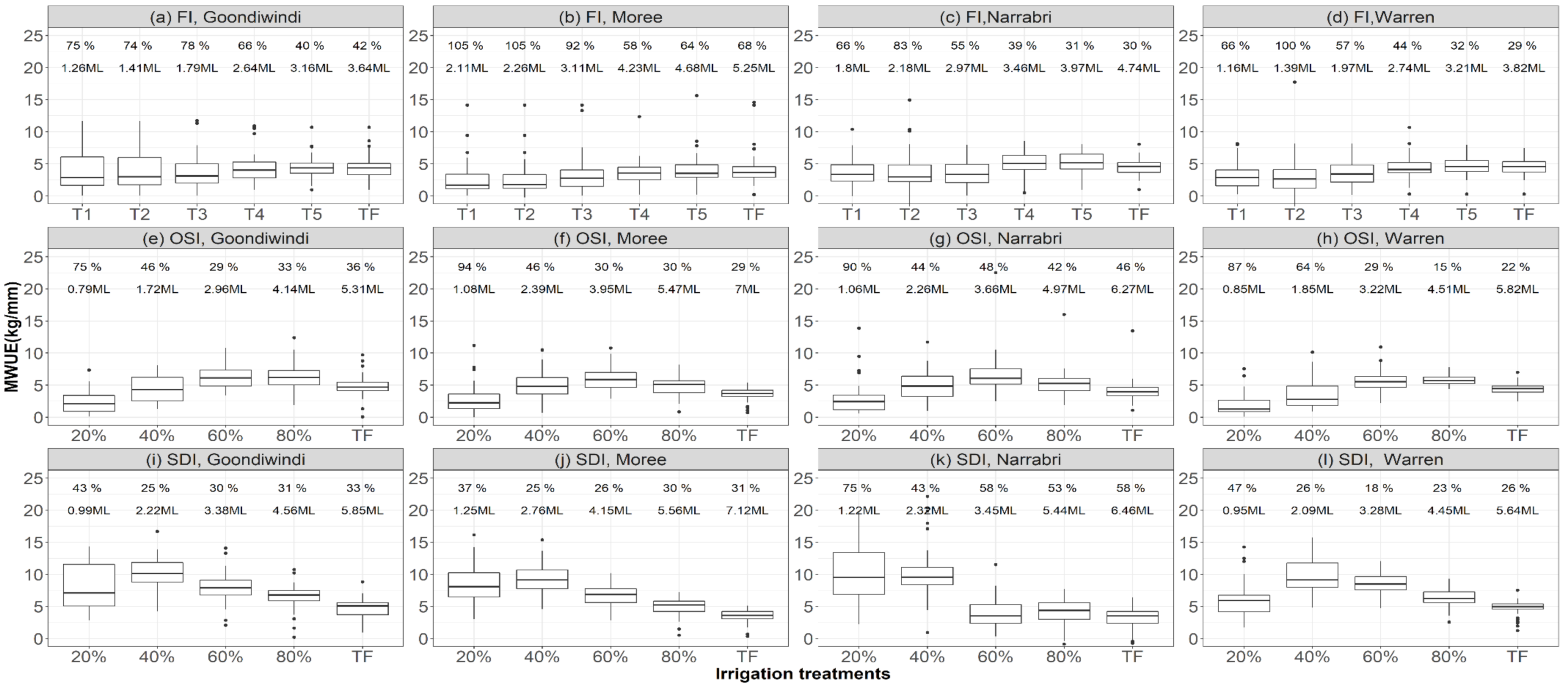

3.4. The Effects of Deficit Irrigation Practices on Marginal Water Use Efficiency

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cammarano, D.; Payero, J.; Basso, B.B.; Wilkens, P.; Grace, P. Agronomic and economic evaluation of irrigation strategies on cotton lint yield in Australia. Crop. Pasture Sci. 2012, 63, 647–655. [Google Scholar] [CrossRef]

- Stiller, W.N.; Wilson, I. Australian Cotton Germplasm Resources. In World Cotton Germplasm Resources; IntechOpen: London, UK, 2014; pp. 1–34. [Google Scholar]

- Azad, M.; Ancev, T. Economics of salinity effects from irrigated cotton: An efficiency analysis. Water Econ. Policy 2016, 2, 24. [Google Scholar] [CrossRef]

- Roth, G.; Harris, G.; Gillies, M.; Montgomery, J.; Wigginton, D. Water-use efficiency and productivity trends in Australian irrigated cotton: A review. Crop. Pasture Sci. 2013, 64, 1033–1048. [Google Scholar] [CrossRef]

- Seidl, C.; Wheeler, S.A.; Zuo, A. High turbidity: Water valuation and accounting in the Murray-Darling Basin. Agric. Water Manag. 2020, 230, 105929. [Google Scholar] [CrossRef]

- Wheeler, S.A.; Xu, Y.; Zuo, A. Modelling the climate, water and socio-economic drivers of farmer exit in the Murray-Darling Basin. Clim. Chang. 2019, 158, 551–574. [Google Scholar] [CrossRef]

- Perry, C.; Barnes, E.; Munk, D.; Fisher, K.; Bauer, P. Cotton Irrigation Management for Humid Regions; Cotton Incorporated: Cary, NC, USA, 2012. [Google Scholar]

- Qureshi, M.E.; Whitten, S.; Franklin, B. Impacts of climate variability on the irrigation sector in the southern Murray-Darling Basin, Australia. Water Resour. Econ. 2013, 4, 52–68. [Google Scholar] [CrossRef]

- Kodur, S.; Robinson, J.B. Modelling deep drainage rates of irrigation strategies under cropping sequence in subhumid, subtropical australia. Irrig. Drain. 2013, 63, 365–372. [Google Scholar] [CrossRef]

- An-Vo, D.-A.; Mushtaq, S.; Reardon-Smith, K.; Kouadio, L.; Attard, S.; Cobon, D.; Stone, R. Value of seasonal forecasting for sugarcane farm irrigation planning. Eur. J. Agron. 2019, 104, 37–48. [Google Scholar] [CrossRef]

- Qureshi, M.; Whitten, S. Regional impact of climate variability and adaptation options in the southern Murray–Darling Basin, Australia. Water Resour. Econ. 2014, 5, 67–84. [Google Scholar] [CrossRef]

- Brouwer, C.; Prins, K.; Kay, M.; Heibloem, M. Irrigation water management: Irrigation methods. Train. Man. 1988, 9, 5–7. [Google Scholar]

- Foley, J.P.; Raine, S.R. Overhead irrigation in the Australian cotton industry. Aust. Cottongrower 2002, 23, 40–44. [Google Scholar]

- Koech, R.K.; Smith, R.J.; Gillies, M. A real-time optimisation system for automation of furrow irrigation. Irrig. Sci. 2014, 32, 319–327. [Google Scholar] [CrossRef]

- Uddin, M.J.; Smith, R.J.; Gillies, M.H.; Moller, P.; Robson, D. Smart Automated Furrow Irrigation of Cotton. J. Irrig. Drain. Eng. 2018, 144, 04018005. [Google Scholar] [CrossRef]

- Darouich, H.; Pedras, C.G.; Gonçalves, J.M.; Pereira, L.S. Drip vs. surface irrigation: A comparison focussing on water saving and economic returns using multicriteria analysis applied to cotton. Biosyst. Eng. 2014, 122, 74–90. [Google Scholar] [CrossRef]

- Lowien, Z.; Gall, L. Grower Led Irrigation System Comparison in the Gwydir Valley. In CRDC1606 Technical Research Report; Gwydir Valley Irrigators Association Inc.: Moree, Australia, 2016. [Google Scholar]

- Dağdelen, N.; Başal, H.; Yılmaz, E.; Gürbüz, T.; Akçay, S. Different drip irrigation regimes affect cotton yield, water use efficiency and fiber quality in western Turkey. Agric. Water Manag. 2009, 96, 111–120. [Google Scholar] [CrossRef]

- Chai, Q.; Gan, Y.; Zhao, C.; Xu, H.-L.; Waskom, R.M.; Niu, Y.; Siddique, K.H.M. Regulated deficit irrigation for crop production under drought stress. A review. Agron. Sustain. Dev. 2016, 36, 1–21. [Google Scholar] [CrossRef]

- Capra, A.; Consoli, S.; Scicolone, B. Deficit irrigation: Theory and practice. Agric. Irrig. Res. Prog. 2008, 53–82. [Google Scholar]

- Mangalassery, S.; Rejani, R.; Singh, V.; Adiga, J.D.; Kalaivanan, D.; Rupa, T.R.; Philip, P.S. Impact of different irrigation regimes under varied planting density on growth, yield and economic return of cashew (Anacardium occidentale L.). Irrig. Sci. 2019, 37, 483–494. [Google Scholar] [CrossRef]

- Wen, Y. Spatial Variation of Soil Moisture and its Effect on Lint Yield in a Deficit Irrigated Cotton Field. bioRxiv 2017, 109025. [Google Scholar]

- Zhang, D.; Luo, Z.; Liu, S.; Li, W.; Tang, W.; Dong, H. Effects of deficit irrigation and plant density on the growth, yield and fiber quality of irrigated cotton. Field Crop. Res. 2016, 197, 1–9. [Google Scholar] [CrossRef]

- Kirda, C.; Moutonnet, P.; Hera, C.; Nielsen, D. Deficit Irrigation Practices. In Water Reports; FAO: Rome, Italy, 2002. [Google Scholar]

- Suleiman, A.A.; Soler, C.M.T.; Hoogenboom, G. Evaluation of FAO-56 crop coefficient procedures for deficit irrigation management of cotton in a humid climate. Agric. Water Manag. 2007, 91, 33–42. [Google Scholar] [CrossRef]

- Williams, A.; Mushtaq, S.; Kouadio, L.; Power, B.; Marcussen, T.; McRae, D.; Cockfield, G. An investigation of farm-scale adaptation options for cotton production in the face of future climate change and water allocation policies in southern Queensland, Australia. Agric. Water Manag. 2018, 196, 124–132. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, Y.; Han, S.; Macadam, I.; Liu, D.L. Prediction of cotton yield and water demand under climate change and future adaptation measures. Agric. Water Manag. 2014, 144, 42–53. [Google Scholar] [CrossRef]

- Holzworth, D.P.; Huth, N.I.; Devoil, P.G.; Zurcher, E.J.; Herrmann, N.I.; McLean, G.; Chenu, K.; Van Oosterom, E.J.; Snow, V.; Murphy, C.; et al. APSIM—Evolution towards a new generation of agricultural systems simulation. Environ. Model. Softw. 2014, 62, 327–350. [Google Scholar] [CrossRef]

- Meier, E.A.; Lilley, J.M.; Kirkegaard, J.; Whish, J.; McBeath, T.M. Management practices that maximise gross margins in Australian canola (Brassica napus L.). Field Crop. Res. 2020, 252, 107803. [Google Scholar] [CrossRef]

- Carberry, P.S.; Hochman, Z.; Hunt, J.R.; Dalgliesh, N.P.; McCown, R.; Whish, J.P.M.; Robertson, M.; Foale, M.A.; Poulton, P.L.; Van Rees, H. Re-inventing model-based decision support with Australian dryland farmers. 3. Relevance of APSIM to commercial crops. Crop. Pasture Sci. 2009, 60, 1044–1056. [Google Scholar] [CrossRef]

- Liu, K.; Harrison, M.T.; Hunt, J.; Angessa, T.T.; Meinke, H.; Li, C.; Tian, X.; Zhou, M. Identifying optimal sowing and flowering periods for barley in Australia: A modelling approach. Agric. For. Meteorol. 2020, 282, 107871. [Google Scholar] [CrossRef]

- Hearn, A. OZCOT: A simulation model for cotton crop management. Agric. Syst. 1994, 44, 257–299. [Google Scholar] [CrossRef]

- CSD. Cotton Seed Distributors, Variety Trial Results (2009–2015). 2017. Available online: http://www.csd.net.au/resources (accessed on 5 November 2017).

- SILO. SILO Climate Data. 2017. Available online: https://legacy.longpaddock.qld.gov.au/silo/ (accessed on 15 November 2020).

- Tedeschi, L.O. Assessment of the adequacy of mathematical models. Agric. Syst. 2006, 89, 225–247. [Google Scholar] [CrossRef]

- Willmott, C.; Matsuura, K. Advantages of the mean absolute error (MAE) over the root mean square error (RMSE) in assessing average model performance. Clim. Res. 2005, 30, 79–82. [Google Scholar] [CrossRef]

- DAF. Cotton Production Growing Cotton: Varieties, Planting and Irrigation. 2018. Available online: https://www.daf.qld.gov.au/business-priorities/plants/field-crops-and-pastures/broadacre-field-crops/cotton/growing (accessed on 13 June 2018).

- Nguyen, L.T.T.; Osanai, Y.; Anderson, I.C.; Bange, M.P.; Braunack, M.; Tissue, D.T.; Singh, B.K. Impacts of waterlogging on soil nitrification and ammonia-oxidizing communities in farming system. Plant Soil 2018, 426, 299–311. [Google Scholar] [CrossRef]

- Luo, Q.; Bange, M.; Braunack, M.; Johnston, D. Effectiveness of agronomic practices in dealing with climate change impacts in the Australian cotton industry—A simulation study. Agric. Syst. 2016, 147, 1–9. [Google Scholar] [CrossRef]

- Luo, Q.; Bange, M.; Johnston, D.; Braunack, M. Cotton production in a changing climate. In Building Productive, Diverse and Sustainable Landscapes, Proceedings of the17th Australian Agronomy Conference, Hobart, Australia, 20–24 September 2015; Australian Society of Agronomy Inc.: Hobart, Australia, 2015. [Google Scholar]

- Conaty, W.C.; Johnston, D.B.; Thompson, A.J.; Liu, S.; Stiller, W.N.; Constable, G. Use of a managed stress environment in breeding cotton for a variable rainfall environment. Field Crop. Res. 2018, 221, 265–276. [Google Scholar] [CrossRef]

- CSD. Cotton & Wheat Gross Margin Analysis; Cotton Seed Distributiors: Wee Waa, Australia, 2008. [Google Scholar]

- Hulugalle, N.R.; McCorkell, B.; Heimoana, V.F.; Finlay, L.A. Soil properties under cotton-corn rotations in Australian cotton farms. J. Cotton Sci. 2016, 20, 294–298. [Google Scholar]

- Jeffrey, S.J.; Carter, J.O.; Moodie, K.B.; Beswick, A.R. Using spatial interpolation to construct a comprehensive archive of Australian climate data. Environ. Model. Softw. 2001, 16, 309–330. [Google Scholar] [CrossRef]

- Dalgliesh, N.; Wockner, G.; Peake, A. Delivering soil water information to growers and consultants. In Proceedings of the 13th Australian Agronomy Conference, Perth, WA, Australia, 10–14 September 2006. [Google Scholar]

- Bhattarai, S.P.; Midmore, D.J.; Pendergast, L. Yield, water-use efficiencies and root distribution of soybean, chickpea and pumpkin under different subsurface drip irrigation depths and oxygation treatments in vertisols. Irrig. Sci. 2008, 26, 439–450. [Google Scholar] [CrossRef]

- Abdi, H.; Salkind, N. Coefficient of Variation. Encycl. Res. Des. 2012, 1, 169–171. [Google Scholar] [CrossRef]

- Kaman, H.; Çetin, M.; Kirda, C. Soil salinity in a drip and furrow irrigated cotton field under influence of different deficit irrigation techniques. J. Adnan Menderes Univ. Agric. Fac. 2008, 6, 243–253. [Google Scholar]

- Geerts, S.; Raes, D. Deficit irrigation as an on-farm strategy to maximize crop water productivity in dry areas. Agric. Water Manag. 2009, 96, 1275–1284. [Google Scholar] [CrossRef]

- Fereres, E.; Soriano, M.A. Deficit irrigation for reducing agricultural water use. J. Exp. Bot. 2007, 58, 147–159. [Google Scholar] [CrossRef]

- Evans, R.G.; Sadler, E.J. Methods and technologies to improve efficiency of water use. Water Resour. Res. 2008, 44. [Google Scholar] [CrossRef]

- Sampathkumar, T.; Pandian, B.; Rangaswamy, M.; Manickasundaram, P.; Jeyakumar, P. Influence of deficit irrigation on growth, yield and yield parameters of cotton–maize cropping sequence. Agric. Water Manag. 2013, 130, 90–102. [Google Scholar] [CrossRef]

| Treatments at: | Total Irrigation Water Applied | Number of Irrigation Applications |

|---|---|---|

| 50% of PAWC | 228 mm | 6 |

| 60% of PAWC | 83 mm | 3 |

| 70% of PAWC | 82 mm | 2 |

| 85% of PAWC | 0 mm (no irrigated) | 0 |

| Locations | Lat./Long. | APSIM Soil Number | Soil Type | DUL | DLL | PAWC | Average Annual Rainfall | Total Annual Evaporation | Maximum and Minimum Mean Monthly Temperatures (°C) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | |||||||||

| Goondiwindi (QLD) | −28.54° S/150.3 E | 219 | Clay vertisol | 481 | 280 | 253 | 614 | 2054 | 32 | 32 | 31 | 27 | 21 | 19 | 19 | 21 | 25 | 28 | 31 | 33 |

| 20 | 21 | 18 | 14 | 10 | 6 | 5 | 6 | 9 | 14 | 17 | 19 | |||||||||

| Moree (NSW) | −29.48° S/149.83° E | 870 | Clay vertisol | 562 | 316 | 372 | 594 | 2178 | 30 | 21 | 31 | 27 | 22 | 19 | 18 | 19 | 24 | 26 | 31 | 33 |

| 20 | 20 | 17 | 11 | 9 | 6 | 5 | 5 | 9 | 12 | 16 | 19 | |||||||||

| Narrabri (NSW) | −30.34° S/149.75° E | 125 | Clay vertisol | 628 | 350 | 279 | 652 | 2005 | 31 | 22 | 19 | 18 | 23 | 19 | 16 | 20 | 24 | 27 | 31 | 32 |

| 19 | 12 | 6 | 12 | 8 | 6 | 4 | 18 | 8 | 12 | 16 | 17 | |||||||||

| Warren (NSW) | −31.78° S/147.76° E | 705 | Medium clay vertisol | 454 | 257 | 234 | 487 | 2038 | 30 | 33 | 30 | 26 | 21 | 17 | 16 | 18 | 22 | 26 | 30 | 32 |

| 17 | 19 | 16 | 12 | 8 | 5 | 4 | 4 | 7 | 11 | 15 | 17 | |||||||||

| Code | FI Treatments | Code | OSI and SDI Treatments |

|---|---|---|---|

| TF | Full irrigation treatment | TF | Full irrigation treatment |

| T1 | Irrigated 1 out of 4 TF irrigation events | 20% | Irrigated 20% of TF application |

| T2 | Irrigated 1 out of 3 TF irrigation events | 40% | Irrigated 40% of TF application |

| T3 | Irrigated 1 out of 2 TF irrigation events | 60% | Irrigated 60% of TF application |

| T4 | Irrigated 2 out of 3 TF irrigation events | 80% | Irrigated 80% of TF application |

| T5 | Irrigated 3 out of 4 TF irrigation events | ||

| 0% | Dryland | 0% | Dryland |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shukr, H.H.; Pembleton, K.G.; Zull, A.F.; Cockfield, G.J. Impacts of Effects of Deficit Irrigation Strategy on Water Use Efficiency and Yield in Cotton under Different Irrigation Systems. Agronomy 2021, 11, 231. https://doi.org/10.3390/agronomy11020231

Shukr HH, Pembleton KG, Zull AF, Cockfield GJ. Impacts of Effects of Deficit Irrigation Strategy on Water Use Efficiency and Yield in Cotton under Different Irrigation Systems. Agronomy. 2021; 11(2):231. https://doi.org/10.3390/agronomy11020231

Chicago/Turabian StyleShukr, Hanan H., Keith G. Pembleton, Andrew F. Zull, and Geoff J. Cockfield. 2021. "Impacts of Effects of Deficit Irrigation Strategy on Water Use Efficiency and Yield in Cotton under Different Irrigation Systems" Agronomy 11, no. 2: 231. https://doi.org/10.3390/agronomy11020231

APA StyleShukr, H. H., Pembleton, K. G., Zull, A. F., & Cockfield, G. J. (2021). Impacts of Effects of Deficit Irrigation Strategy on Water Use Efficiency and Yield in Cotton under Different Irrigation Systems. Agronomy, 11(2), 231. https://doi.org/10.3390/agronomy11020231