Strategies for Improved Yield and Water Use Efficiency of Lettuce (Lactuca sativa L.) through Simplified Soilless Cultivation under Semi-Arid Climate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Location

2.2. Experimental Design

- Experiment 1 (NE-Brazil): The trial considered a curly green lettuce (cv Isabela). Conventional on-soil cultivation and SSC system were compared. Plants were transplanted on 24 June 2009 and were harvested when reaching full maturity, which occurred at 40 and 31 days after transplanting (DAT) for traditional on-soil cultivation and in the SSC system, respectively. The experimental design was a strip block design with two treatments and three replicates.

- Experiment 2 (CDZ-Myanmar): The experiment was carried out with a curly green lettuce (cv Green wave). Conventional on-soil cultivation and SSC systems were compared. Plants were transplanted on 28 December 2018. Harvest occurred at 31 DAT in both systems. The experimental design was a completely randomized block design with two treatments and three replicates.

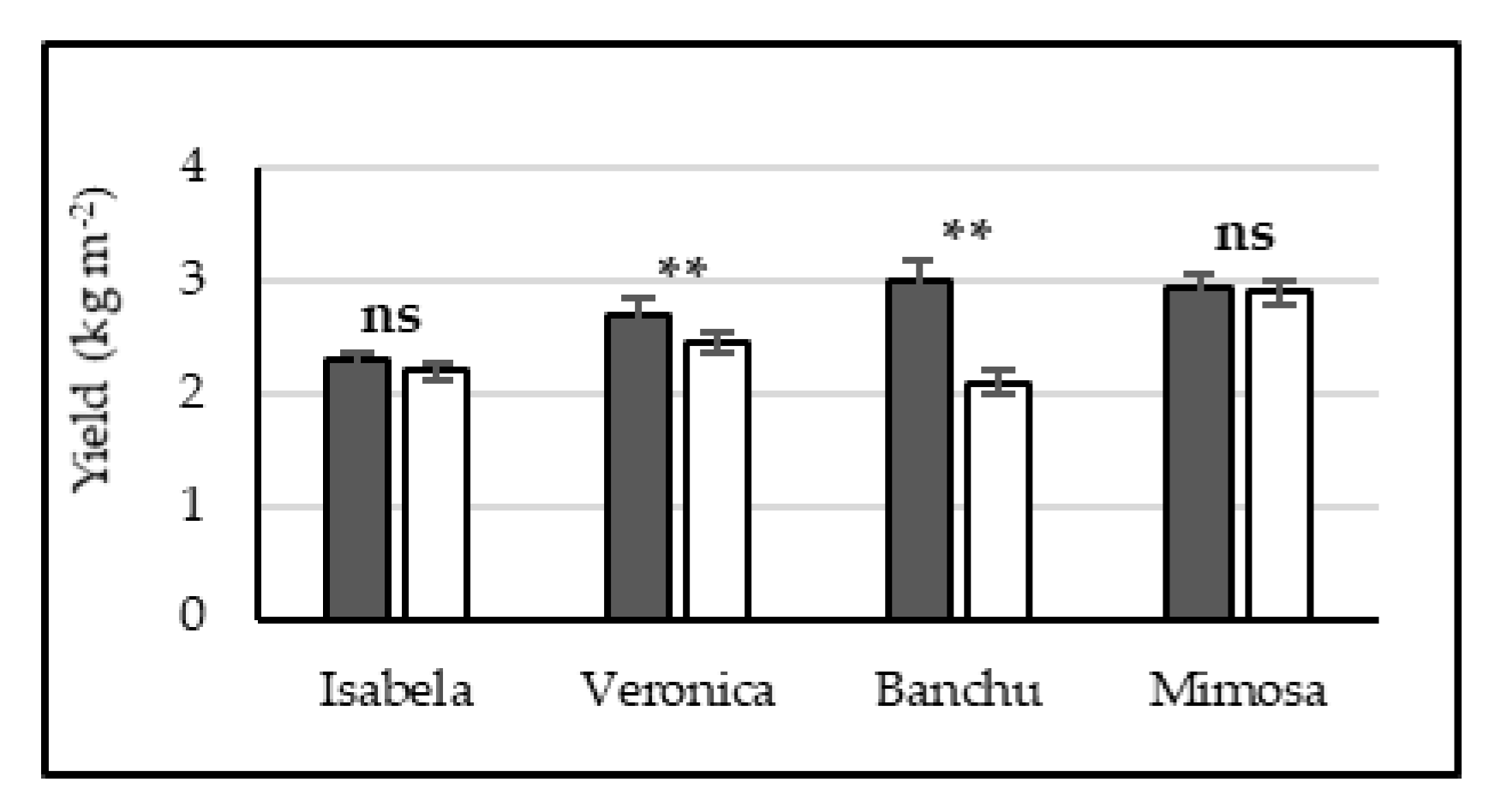

- Experiment 3 (NE-Brazil): Three green curly lettuce cultivars, namely cv Isabela, Veronica and Mimosa verde, and one red curly cultivar, namely cv Banchu Red Fire, were tested on their adaptability to the SSC system. The four cultivars were factorially combined with two different garden/plant row orientation (east and west exposure). Plants were transplanted on 18 July 2009. Harvest occurred at 31 DAT. The experimental design was a completely randomized block design with eight treatments and three replicates.

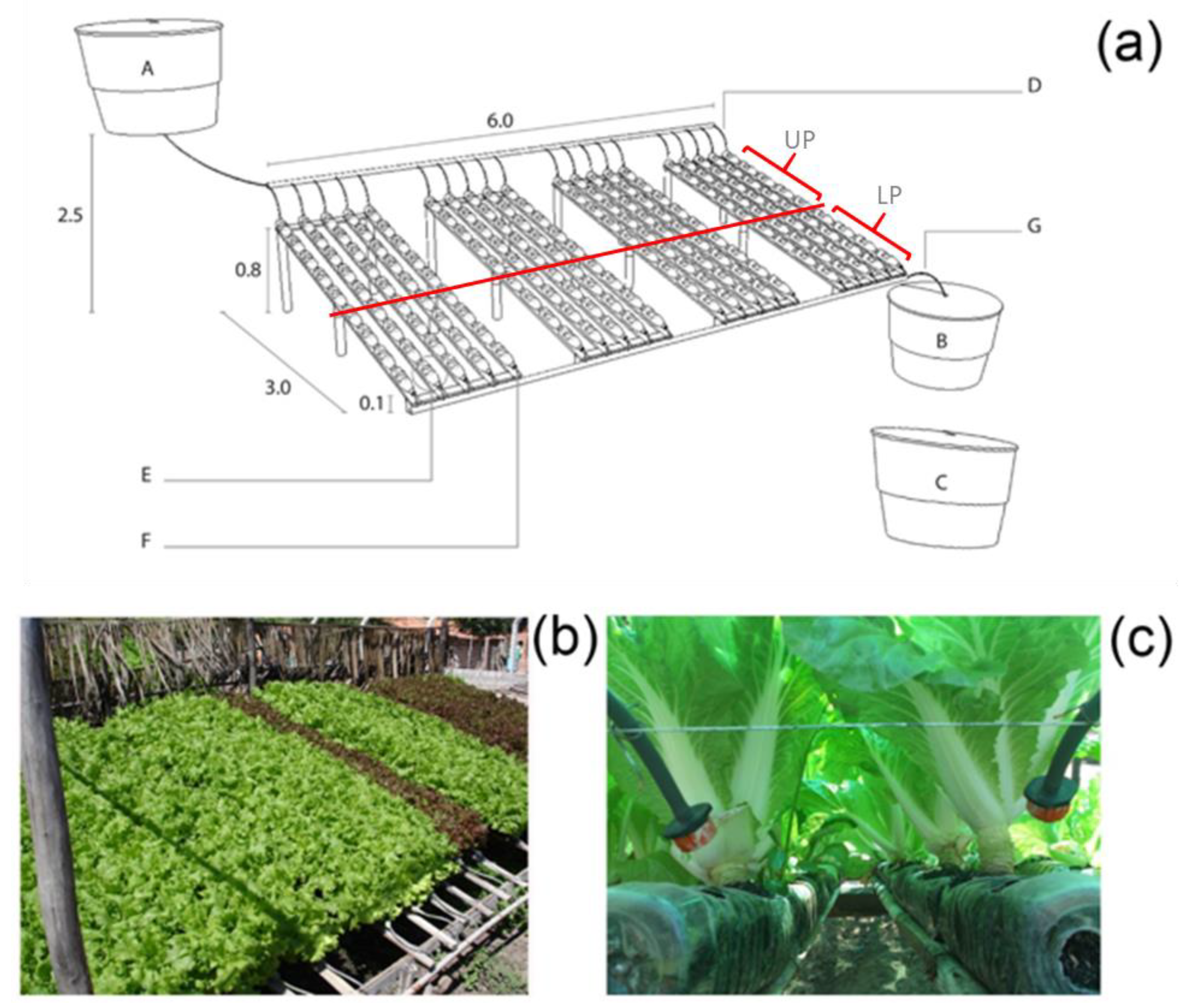

- Experiment 4 (CDZ-Myanmar): The experiment was carried out on two curly green lettuce cultivars, namely cv Green wave and Rapido 344. Plants were tested for their adaptability to SSC, and two different concentrations of nutrient solution salinity, characterized by an electrical conductivity (EC) of 1.2 dS m−1 (NS1.2) and E.C. 1.8 dS m−1 (NS1.8), were used. Moreover, the effect of plant growing position (upper position, UP vs lower position, LP) within the garden was evaluated. UP refers to the plant growing in the upper part of the SSC that receives the nutrient solution directly from the nutrient solution tank. LP refers to the plants growing in the lower part of the system, which get the nutrient solution drained from the upper part of the SSC system (Figure 1). Plants were transplanted on 19 February 2019 and were harvest at 31 DAT. The experimental design was a randomized block design with eight treatments and three replicates.

2.3. Simplified Soilless Cultivation System

2.4. Traditional on-Soil Cultivation

2.5. Irrigation Management

2.6. Plant Measurements

2.7. Statistical Analysis

3. Results

3.1. Climate during the Experiments.

3.2. Experiment 1—NE-Brazil

3.3. Experiment 2—CDZ-Myanmar

3.4. Experiment 3—NE-Brazil

3.5. Experiment 4—CDZ-Myanmar

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Eileen, E.B. Impact of Climate Change and Local Adaptation Strategies of Various Socio-economic Groups in Isabela, Northern Philliphines. Clim. Issue 2009, 22, RN15. [Google Scholar]

- Bisbis, M.B.N.; Gruda, M. Blanke 2018: Potential impacts of climate change on vegetable production and product quality—A review. J. Clean. Prod. 2018, 170, 1602–1620. [Google Scholar] [CrossRef]

- Gruda, N.; Bisbis, M.B.; Tanny, J. Impacts of protected vegetable cultivation on climate change and adaptation strategies for cleaner production—A review. J. Clean. Prod. 2019, 225, 324–339. [Google Scholar] [CrossRef]

- Audu, E.B. Gas Flaring: A Catalyst to Global Warming in Nigeria. Int. J. Sci. Technol. 2013, 3, 6–10. [Google Scholar]

- Gruda, N.; Bisbis, M.B.; Tanny, J. Influence of climate change on protected cultivation: Impacts and sustainable adaptation strategies—A review. J. Clean. Prod. 2019, 225, 481–495. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). Climate Change: Impacts, Adaptation and Vulnerability. In Exit Epa Disclaimer Contribution of Working Group II for the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Dowuona Nii Nortey, M.; Kwaghe, P.V.; Abdulsalam, B.; Aliyu, H.S.; Dahiru, B. Review of Farm Level Adaptation Strategies to Climate Change in Africa. Greener J. Agron. For. Hortic. 2014, 2, 038–043. [Google Scholar]

- Barbieri, A.F.; Domingues, E.; Queiroz, B.L.; Ruiz, R.M.; Rigotti, J.I.; Carvalho, J.A.; Resende, M.F. Climate change and population migration in Brazil’s Northeast: Scenarios for 2025–2050. Popul. Environ. 2010, 31, 344–370. [Google Scholar] [CrossRef]

- Orsini, F.; Kahane, R.; Nono-Womdim, R.; Gianquinto, G. Urban agriculture in the developing world: A review. Agron. Sustain. Dev. 2013, 33, 695–720. [Google Scholar] [CrossRef] [Green Version]

- Souza, E.D.; Carneiro, M.A.C.; Paulino, H.B.; Silva, C.A. Frações do carbono orgânico, biomassa e atividade microbiana em um Latossolo Vermelho sob cerrado submetido a diferentes sistemas de manejos e usos do solo. Acta Sci. Agron. 2006, 28, 323–329. [Google Scholar] [CrossRef]

- Cho, A.; Tun Oo, A.; Speelman, S. Assessment of household food security through crop diversification in Natmauk township, Magway Region, Myanmar. In Proceedings of the Tropentag 2016: Solidarity in a Competing World: Fair Use of Resource, Vienna, Austria, 18–21 September 2016; pp. 1–5. [Google Scholar]

- Pavelic, P.; Sellamuttu, S.S.; Johnston, R.; McCartney, M.; Sotoukee, T.; Balasubramanya, S.; Latt, K. Integrated Assessment of Groundwater Use for Improving Livelihoods in the Dry Zone of Myanmar; International Water Management Institute (IWMI): Colombo, Sri Lanka, 2015; Volume 164. [Google Scholar]

- Aoki, Y. A Problem of Climate Change as Seen by a Pharmaceutical Researcher. J. Health Sci. 2009, 55, 857–859. [Google Scholar] [CrossRef] [Green Version]

- Gianquinto, G.; Orsini, F.; Michelon, N.; da Silva, D.F.; De Faria, F.D. Improving yield of vegetables by using soilless micro-garden technologies in peri-urban area of north-east Brazil. Acta Hortic. 2007, 747, 57–65. [Google Scholar] [CrossRef]

- Savvas, D.; Gruda, N. Application of soilless culture technologies in the modern greenhouse industry—A review. Eur. J. Hortic. Sci. 2018, 83, 280–293. [Google Scholar] [CrossRef]

- Orsini, F.; Morbello, M.; Fecondini, M.; Gianquinto, G. Hydroponic gardens: Undertaking malnutrition and poverty through vegetable production in the suburbs of Lima, Peru. Acta Hortic. 2010, 881, 173. [Google Scholar] [CrossRef]

- Izquierdo, J. Simplified hydroponics: A tool for food security in Latin America and the Caribbean. Acta Hortic. 2007, 742, 67–74. [Google Scholar] [CrossRef]

- Gianquinto, G.; Michelon, N.; Orsini, F. Idroponia in un’area povera del nord est del Brasile. In Un Esempio di Cooperazione Decentrata: Simplified Soilless Cultivation in a Marginal Area of North-East Brazil: An Example of Decentralised Cooperation; Franceschetti, G., CLEUP. Regione Veneto-FAO, Eds.; Agricoltura e Ruralità nei Paesi ad Economia Povera: Padova, Italy, 2006; pp. 95–106. [Google Scholar]

- Rodríguez-Delfín, A.; Hoyos, M.; Chang, M. Soluciones Nutritivas en Hidroponía: Formulación y Preparación; Centro de Investigación de Hidroponía y Nutrición Mineral, Universidad Nacional Agraria La Molina: Lima, Peru, 2001; p. 100. [Google Scholar]

- Trajkovic, S. Hargreaves versus Penman-Monteith under humid conditions. J. Irrig. Drain. Eng. 2007, 133, 38–42. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A.; Blair, N. Solar Engineering of Thermal Processes, Photovoltaics and Wind, 5th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Baum, M.C.; Michael, D.D.; Grady, L.M. Analysis of residential irrigation distribution uniformity. J. Irrig. Drain. Eng. 2005, 131, 336–341. [Google Scholar] [CrossRef]

- Barbosa, G.L.; Gadelha, F.D.A.; Kublik, N.; Proctor, A.; Reichelm, L.; Weissinger, E.; Halden, R.U. Comparison of Land, Water, and Energy Requirements of Lettuce Grown Using Hydroponic vs. Conventional Agricultural Methods. Int. J. Environ. Res. Public Health 2015, 12, 6879–6891. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.; Carey, E.E. Summer production of lettuce, and microclimate in high tunnel and open field plots in Kansas. HortTechnology 2009, 19, 113–119. [Google Scholar] [CrossRef] [Green Version]

- Falah, M.A.F.; Wajima, T.; Yasutake, D.; Sago, Y.; Kitano, M. Responses of root uptake to high temperature of tomato plants (Lycopersicon esculentum Mill.) in soil-less culture. J. Agric. Sci. Technol. 2010, 6, 543–558. [Google Scholar]

- Silber, A.; Xu, G.; Levkovitch, I.; Soriano, S.; Bilu, A.; Wallach, R. High fertigation frequency: The effects on uptake of nutrients, water and plant growth. Plant Soil. 2003, 253, 467–477. [Google Scholar] [CrossRef]

- Sanchez, S.V. Avaliação de Alface Crespa Produzidas em Hidropônia Tipo NFT em Dois Ambientes Protegidos em Ribeirão Preto (SP); Paulista State University, College of Agricultural and Veterinary Science: Sao Paulo, Brazil, 2007; Available online: http://depositorio.unesp.br/handle/11449/96944 (accessed on 12 August 2020).

- Gruda, N.S. Increasing Sustainability of Growing Media Constituents and Stand-Alone Substrates in Soilless Culture Systems. Agronomy 2019, 9, 298. [Google Scholar] [CrossRef] [Green Version]

- Bradley, P.; Marulanda, C. Simplified hydroponics to reduce global hunger. Acta Hortic. 2000, 554, 289–296. [Google Scholar] [CrossRef]

- Wheeler, R.M.; Sager, J.C.; Berry, W.L.; Mackowiak, C.L.; Stutte, G.W.; Yorio, N.C.; Ruffe, L.M. Nutrient, acid and water budgets of hydroponically grown crops. Acta Hortic. 1997, 481, 655–662. [Google Scholar] [CrossRef]

- Michelon, N.; Pennisi, G.; Myint, N.O.; Orsini, F.; Gianquinto, G. Strategies for Improved Water Use Efficiency (WUE) of Field-Grown Lettuce (Lactuca sativa L.) under a Semi-Arid Climate. Agronomy 2020, 10, 668. [Google Scholar] [CrossRef]

- Martínez-Alvarez, V.; Soto-García, M.; Maestre-Valero, J.F. Hydroponic system and desalinated seawater as an alternative farm-productive proposal in water scarcity areas: Energy and greenhouse gas emissions analysis of lettuce production in southeast Spain. J. Clean. Prod. 2018, 172, 1298–1310. [Google Scholar] [CrossRef]

- Wheeler, T.R.; Hadley, P.; Morison, J.I.L.; Ellis, H. Effects of temperature on the growth of lettuce (Lactuca sativa L.) and the implications of assessing the impacts of potential climate changes. Eur. J. Agron. 1993, 2, 305–311. [Google Scholar] [CrossRef]

- Ehret, D.L.; Edwards, D.; Helmer, T.; Lin, W.; Jones, G.; Dorais, M.; Papadopoulos, A.P. Effects of oxygen-enriched nutrient solution on greenhouse cucumber and pepper production. Sci. Hortic. 2010, 125, 602–607. [Google Scholar] [CrossRef]

- Thompson, H.C.; Langhans, R.W.; Both, A.J.; Albright, L.D. Shoot and root temperature effects on lettuce growth in a floating hydroponic system. J. Am. Soc. Hortic. Sci. 1998, 123, 361–364. [Google Scholar] [CrossRef] [Green Version]

- Trejo-Téllez, L.I.; Gómez-Merino, F.C. Nutrient solutions for hydroponic systems. In Hydroponics-A Standard Methodology for Plant Biological Researches; Martinez-Mate, M.A., Martin-Gorriz, B., Eds.; InTechOpen: Rijeka, Croatia, 2012; pp. 1–22. [Google Scholar]

- Fecondini, M.; Damasio De Faria, A.C.; Michelon, N.; Mezzetti, M.; Orsini, F.; Gianquinto, G. Learning the value of gardening: Results from an experience of community based simplified hydroponics in north-east Brazil. Acta Hort. 2010, 881, 111–116. [Google Scholar] [CrossRef]

- Fecondini, M.; Casati, M.; Dimech, M.; Michelon, N.; Orsini, F.; Gianquinto, G. Improved cultivation of lettuce with a low cost soilless system in indigent areas of northeast brazil. Acta Hort. 2009, 807, 501–507. [Google Scholar] [CrossRef]

- Orsini, F.; Michelon, N.; Scocozza, F.; Gianquinto, G. Farmers-To-Consumers Pipeline: An Associative Example of Sustainable Soil-Less Horticulture in Urban And Peri-Urban Areas. Acta Hort. 2009, 809, 209–220. [Google Scholar] [CrossRef]

| Exp. | N (mmol L−1) | P (mmol L−1) | K (mmol L−1) | S (mmol L−1) | Ca (mmol L−1) | Mg (mmol L−1) | |

|---|---|---|---|---|---|---|---|

| NE-Brazil | |||||||

| Water | 1, 3 | 1.2 | nd | 0.6 | nd | 0.4 | 0.2 |

| NS1.6 | 1, 3 | 11.7 | 0.7 | 3.4 | 2.6 | 3.1 | 1.7 |

| CDZ-Myanmar | |||||||

| Water | 2, 4 | nd | nd | 0.05 | nd | 0.2 | 0.06 |

| NS1.2 | 2, 4 | 6.4 | 2.9 | 2.3 | 3.7 | 1.0 | 0.05 |

| NS1.8 | 4 | 8.6 | 3.4 | 3.1 | 3.1 | 1.3 | 0.07 |

| Exp. | Fe (µmol L−1) | Mn (µmol L−1) | Cu (µmol L−1) | Zn (µmol L−1) | B (µmol L−1) | Mo (µmol L−1) | |

|---|---|---|---|---|---|---|---|

| NE-Brazil | |||||||

| Water | 1, 3 | nd | 0. 5 | nd | 0.4 | 2.0 | nd |

| NS1.6 | 1, 3 | 26.9 | 12.4 | 1.6 | 4.6 | 21.5 | 0.5 |

| CDZ-Myanmar | |||||||

| Water | 2, 4 | 0.005 | 0.005 | nd | nd | nd | nd |

| NS1.2 | 2, 4 | 10.7 | 0.5 | 0.3 | 0.1 | nd | 0.01 |

| NS1.8 | 4 | 14.3 | 0.7 | 0.4 | 0.13 | nd | 0.02 |

| OM 1 (%) | pH | EC 2 (dS m−1) | Available | Exchangeable | CEC 3 (cmol (+) kg−1) | ||||

|---|---|---|---|---|---|---|---|---|---|

| N | P | K | Ca | Mg | Na | ||||

| NE-Brazil (Exp. 1) | |||||||||

| 1.01 | 5.1 | nd | nd | 9.0 | 35.2 | 1.4 | 0.1 | 9.2 | 4.51 |

| CDZ-Myanmar (Exp. 2) | |||||||||

| 0.38 | 6.2 | 0.11 | 54 | 10.9 | 25 | 3.04 | 0.2 | 34.8 | nd |

| Average Air Temperature (°C) | RH 1 (%) | DLI 2 (mol m−2 d−1) | Wind Speed (m s−1) | GDD 3 (°C) | ||

|---|---|---|---|---|---|---|

| max | min | max | min | |||

| NE-Brazil (Exp. 1) | ||||||

| 33.0 | 19.8 | 97 | 57 | 24.3 | 0.9 | 920 */698 ** |

| CDZ-Myanmar (Exp. 2) | ||||||

| 31.5 | 16.7 | 73 | 48 | 17.0 | 1.0 | 662 |

| NE-Brazil (Exp. 3) | ||||||

| 34.0 | 19.8 | 97 | 55 | 24.7 | 1.0 | 710 |

| CDZ-Myanmar (Exp. 4) | ||||||

| 35.6 | 19.5 | 59 | 30 | 20.9 | 1.9 | 731 |

| Yield (kg m−2) | Leaf Number (n plant−1) | gs (mmol m−2 s−1) | WUE (g L−1) | |

|---|---|---|---|---|

| EC of nutrient solution (EC) | *** | *** | *** | *** |

| Cultivar (Cv) | ** | *** | *** | * |

| Position (P) | *** | ns | *** | *** |

| EC × Cv | * | ** | ** | * |

| EC × P | *** | * | ** | *** |

| Cv × P | ns | ns | ns | ns |

| EC × Cv × P | ** | ns | * | ** |

| EC | Cultivar | Yield | gs | WUE | |||

|---|---|---|---|---|---|---|---|

| (dS m−1) | (kg m−2) | (mmol m−2 s−1) | (g L−1 H2O) | ||||

| UP | LP | UP | LP | UP | LP | ||

| 1.2 | Thai | 2.88 (a) | 1.18 (bc) | 212 (a) | 118 (b) | 38.4 (a) | 15.7 (bc) |

| 1.2 | Rapido 344 | 1.79 (b) | 1.14 (c) | 100 (b) | 44 (de) | 24.0 (b) | 15.2 (bc) |

| 1.8 | Thai | 0.71(c) | 0.65 (c) | 121 (b) | 91 (bc) | 10.57 (c) | 9.71 (c) |

| 1.8 | Rapido 344 | 0.82 (c) | 0.57 (c) | 78 (c) | 35 (e) | 12.3 (c) | 8.54 (c) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michelon, N.; Pennisi, G.; Myint, N.O.; Dall’Olio, G.; Batista, L.P.; Salviano, A.A.C.; Gruda, N.S.; Orsini, F.; Gianquinto, G. Strategies for Improved Yield and Water Use Efficiency of Lettuce (Lactuca sativa L.) through Simplified Soilless Cultivation under Semi-Arid Climate. Agronomy 2020, 10, 1379. https://doi.org/10.3390/agronomy10091379

Michelon N, Pennisi G, Myint NO, Dall’Olio G, Batista LP, Salviano AAC, Gruda NS, Orsini F, Gianquinto G. Strategies for Improved Yield and Water Use Efficiency of Lettuce (Lactuca sativa L.) through Simplified Soilless Cultivation under Semi-Arid Climate. Agronomy. 2020; 10(9):1379. https://doi.org/10.3390/agronomy10091379

Chicago/Turabian StyleMichelon, Nicola, Giuseppina Pennisi, Nang Ohn Myint, Giacomo Dall’Olio, Lucrecia Pacheco Batista, Adeodato Ari Cavalcante Salviano, Nazim S. Gruda, Francesco Orsini, and Giorgio Gianquinto. 2020. "Strategies for Improved Yield and Water Use Efficiency of Lettuce (Lactuca sativa L.) through Simplified Soilless Cultivation under Semi-Arid Climate" Agronomy 10, no. 9: 1379. https://doi.org/10.3390/agronomy10091379

APA StyleMichelon, N., Pennisi, G., Myint, N. O., Dall’Olio, G., Batista, L. P., Salviano, A. A. C., Gruda, N. S., Orsini, F., & Gianquinto, G. (2020). Strategies for Improved Yield and Water Use Efficiency of Lettuce (Lactuca sativa L.) through Simplified Soilless Cultivation under Semi-Arid Climate. Agronomy, 10(9), 1379. https://doi.org/10.3390/agronomy10091379