Simulated Biomass, Climate Change Impacts, and Nitrogen Management to Achieve Switchgrass Biofuel Production at Diverse Sites in U.S.

Abstract

1. Introduction

2. Materials and Methods

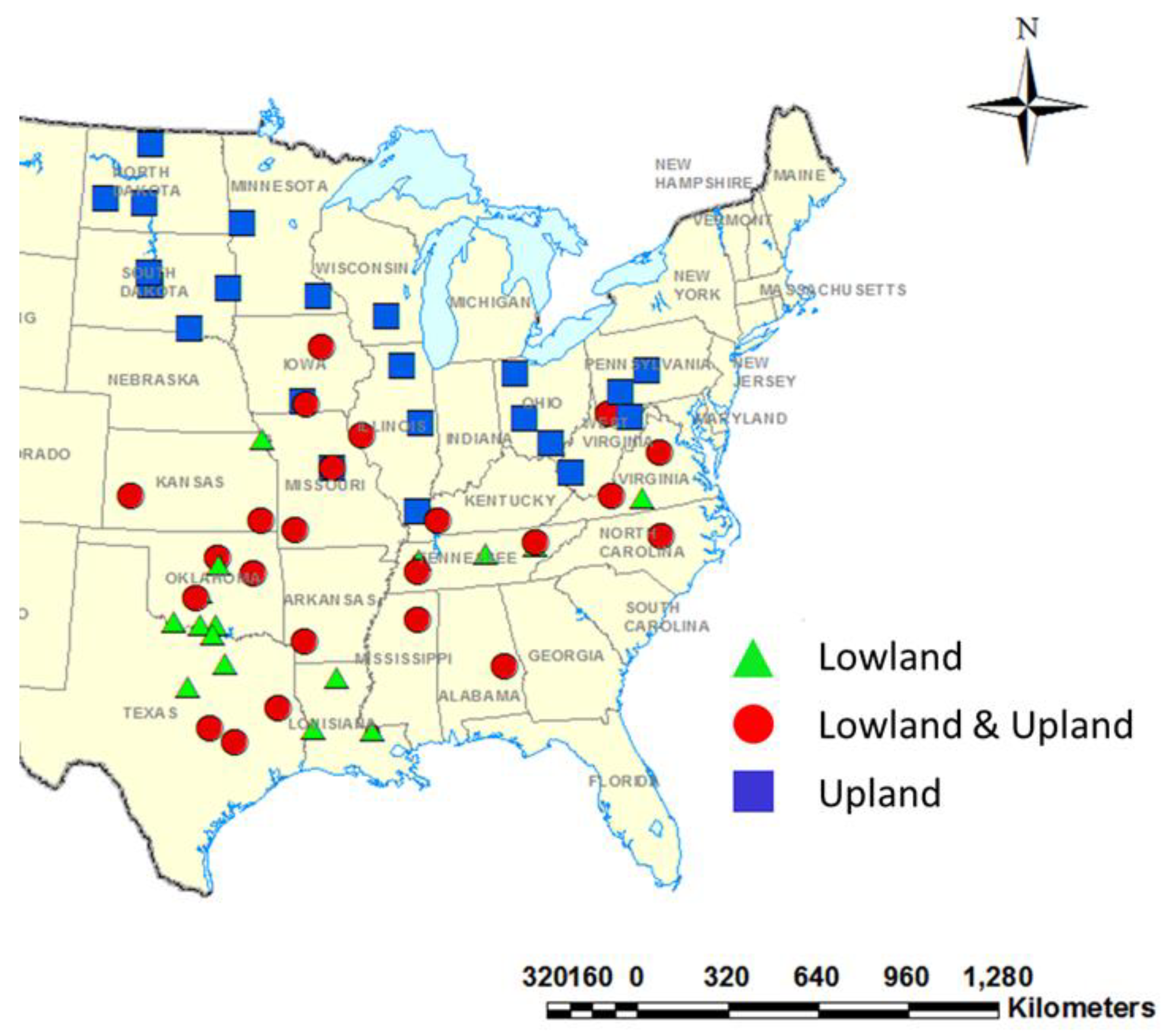

2.1. Data Collection

2.2. Analysis of Factors Determining Switchgrass Yield

2.3. ALMANAC Model Simulation of Development

2.4. Climate Change Projection

3. Results and Discussion

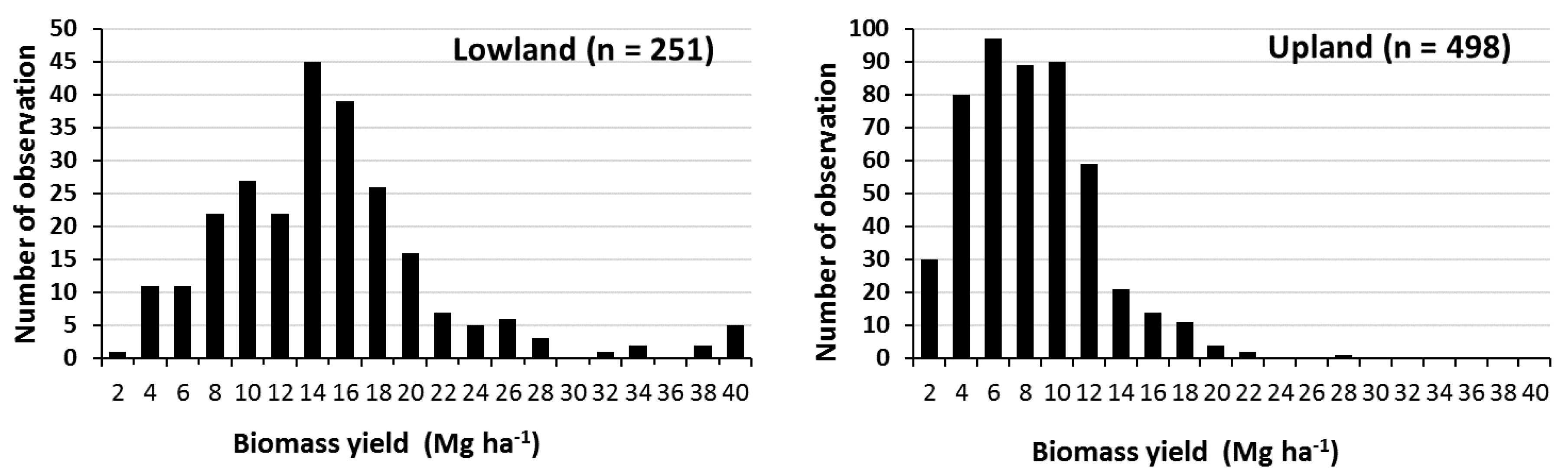

3.1. Switchgrass Yield Analysis

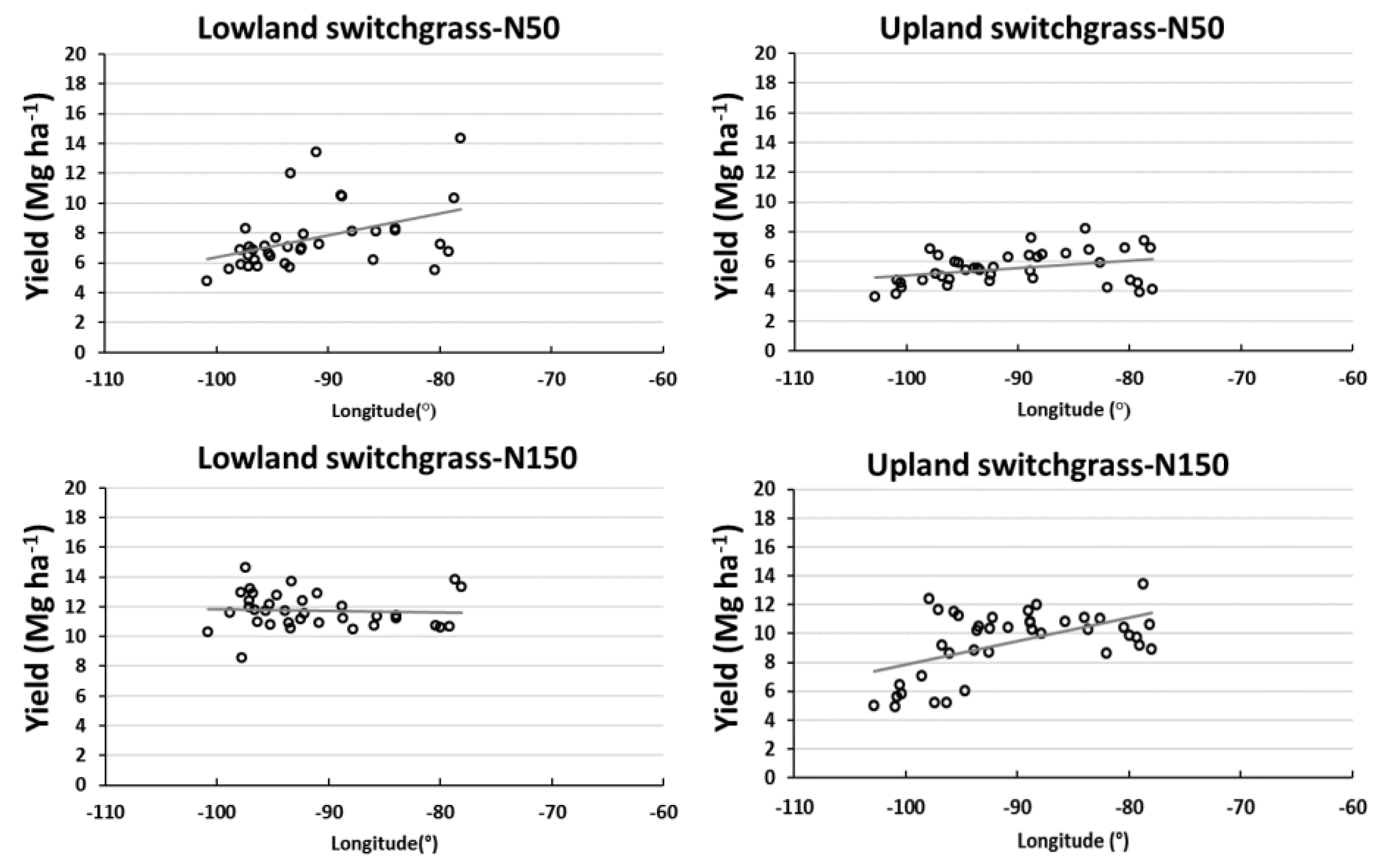

3.2. Analysis of Factors Influencing Yield Variability of Lowland and Upland Ecotypes

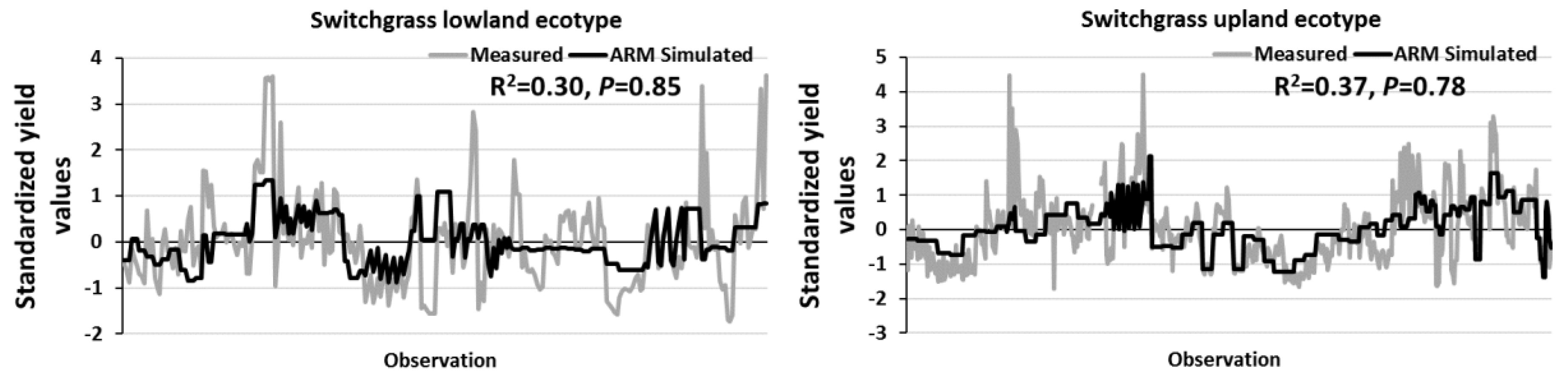

3.3. ALMANAC Evaluation

3.4. Switchgrass Yields in the Reference Period

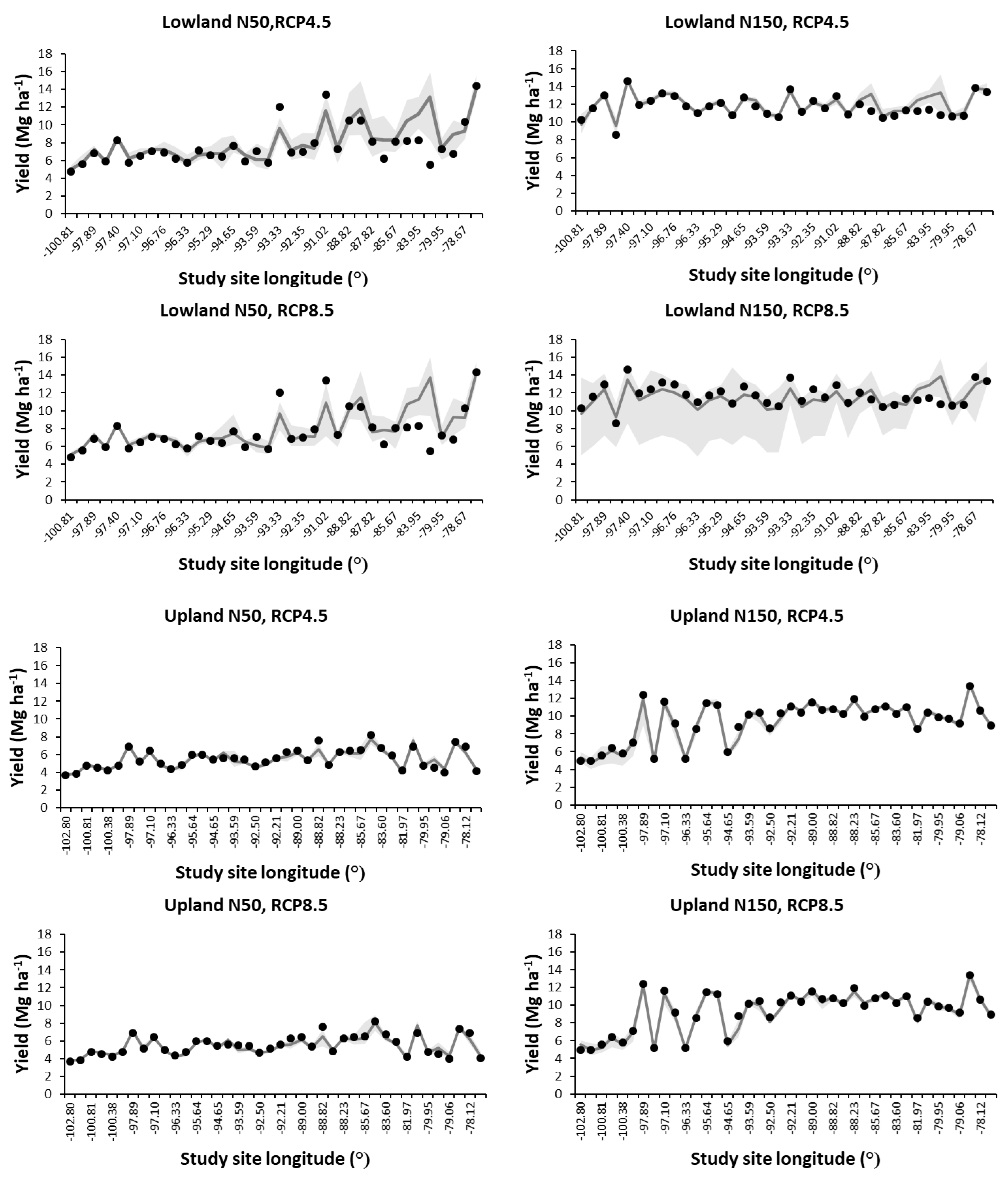

3.5. Switchgrass Yields in the Future Climate

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- EIA, Monthly Energy Review. U.S. Energy Information Admistration; EIA: Washington, DC, USA, 2017.

- Gomiero, T. Are Biofuels an Effective and Viable Energy Strategy for Industrialized Societies? A Reason. Overv. Potentials Limits 2015, 7, 8491–8521. [Google Scholar]

- Owusu, P.A.; Asumadu-Sarkodie, S. A review of renewable energy sources, sustainability issues and climate change mitigation. Cogent Eng. 2016, 3, 1167990. [Google Scholar] [CrossRef]

- Worldwatch. Biofuels for Transportation; Worldwatch Institute: Washington, DC, USA, 2006. [Google Scholar]

- EPA. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2015; U.S. Envrionmental Protection Agency: Washington, DC, USA, 2017.

- GPO. Public Law 110-140: The Energy Independence and Security Act of 2007 (EISA); U.S. Government Printing Office: Washington, DC, USA, 2007.

- EIA. Almost All U.S. Gasoline is Blended with 10% Ethanol; U.S. Energy Information Admistration: Washington, DC, USA, 2016.

- Foley, J. It’s Time to Rethink America’s Corn System. Scientific American. Available online: https://www.scientificamerican.com/article/time-to-rethink-corn/ (accessed on 24 January 2018).

- Duffield, J.A.; Xiarchos, I. Effects of policy on ethanol industry growth. In U.S. Ethanol: An Examination of Policy, Production, Use, Distribution, and Market Interactions; Duffield, J.A., Johansson, R., Meyer, S., Eds.; USDA: Washington, DC, USA, 2015. [Google Scholar]

- Statista. Global Biofuel Production by Select Country 2016; Statista: New York, NY, USA, 2018. [Google Scholar]

- Siciliano, J. Corn Ethanol Faces Its Limits under EPA Fuel Mandate; Washington Examiner: Washington, DC, USA, 2017. [Google Scholar]

- Prentice, C.; Renshaw, J.; Shepardson, D.U.S. Proposes Cutting Total Biofuels Requirements in 2018; 2017. REUTERS. Available online: https://www.reuters.com/article/us-usa-biofuels/u-s-proposes-cutting-total-biofuels-requirements-in-2018-idUSKBN19Q27M (accessed on 25 January 2018).

- Youngs, H.; Somerville, C. Development of feedstocks for cellulosic biofuels. F1000 Boil. Rep. 2012, 4, 10. [Google Scholar] [CrossRef] [PubMed]

- Sanderson, M.; Adler, P.; Boateng, A.; Casler, M.D.; Sarath, G. Switchgrass as a biofuels feedstock in the USA. Can. J. Plant Sci. 2006, 86, 1315–1325. [Google Scholar] [CrossRef]

- Mitchell, R.; Vogel, K.P.; Sarath, G. Managing and enhancing switchgrass as a bioenergy feedstock. Biorefining 2008, 2, 530–539. [Google Scholar] [CrossRef]

- Mehmood, M.; Rashid, U.; Nawaz, M.; Ali, S.; Hussain, A.; Gull, M. Biomass production for bioenergy using marginal lands. Sustain. Prod. Consum. 2017, 9, 3–21. [Google Scholar] [CrossRef]

- Quinn, L.D.; Straker, K.C.; Guo, J.; Kim, S.; Thapa, S.; Kling, G.; Lee, D.K.; Voigt, T.B. Stress-Tolerant Feedstocks for Sustainable Bioenergy Production on Marginal Land. BioEnergy Res. 2015, 8, 1081–1100. [Google Scholar] [CrossRef]

- Antizar-Ladislao, B.; Turrion-Gomez, J.L. Second-generation biofuels and local bioenergy systems. Biofuels, Bioprod. Biorefining 2008, 2, 455–469. [Google Scholar] [CrossRef]

- EIA. Monthly Biodiesel Production Report; U.S. Energy Information Admistration: Washington, DC, USA, 2017.

- Lynd, L.R.; Liang, X.; Biddy, M.J.; Allee, A.; Cai, H.; Foust, T.; Himmel, M.E.; Laser, M.S.; Wang, M.; Wyman, C.E. Cellulosic ethanol: Status and innovation. Curr. Opin. Biotechnol. 2017, 45, 202–211. [Google Scholar] [CrossRef]

- Brechbill, S.C.; Tyner, W.E. The Economics of Biomass Collection, Transportation, and Supply to Indiana Cellulosic and Electric Utility Facilities; Purdue University Press: Purdue, IN, USA, 2008. [Google Scholar]

- Lin, T.; Rodríguez, L.F.; Davis, S.; Khanna, M.; Shastri, Y.; Grift, T.; Long, S.; Ting, K.C. Biomass feedstock preprocessing and long-distance transportation logistics. GCB Bioenergy 2016, 8, 160–170. [Google Scholar] [CrossRef]

- TCS. Federal Subsidies for Corn Ethanol and Other Corn-Based Biofuels; Taxpayers for Common Sense: Mumbai, India, 2018. [Google Scholar]

- EPA. Final Renewable Fuel Standards for 2017, and the Biomass-Based Diesel Volume for 2018; U.S. Environmental Protection Agency: Washington, DC, USA, 2018.

- Brown, T.R. Why the cellulosic biofuels mandate fell short: A markets and policy perspective. Biofuels Bioprod. Biorefining 2019, 13, 889–898. [Google Scholar] [CrossRef]

- Meyer, S.; Thompson, W. How Do Biofuel Use Mandates Cause Uncertainty? United States Environmental Protection Agency Cellulosic Waiver Options. Appl. Econ. Perspect. Policy 2012, 34, 570–586. [Google Scholar] [CrossRef]

- Reichmann, L.; Collins, H.; Jin, V.; Johnson, M.-V.; Kiniry, J.; Mitchell, R.; Polley, H.; Fay, P. Inter-Annual Precipitation Variability Decreases Switchgrass Productivity from Arid to Mesic Environments. BioEnergy Res. 2018, 11, 614–622. [Google Scholar] [CrossRef]

- Lee, J.; Pedroso, G.; Linquist, B.A.; Putnam, D.; van Kessel, C.; Six, J. Simulating switchgrass biomass production across ecoregions using the DAYCENT model. GCB Bioenergy 2012, 4, 521–533. [Google Scholar] [CrossRef]

- Behrman, K.D.; Keitt, T.H.; Kiniry, J.R. Modeling Differential Growth in Switchgrass Cultivars across the Central and Southern Great Plains. BioEnergy Res. 2014, 7, 1165–1173. [Google Scholar] [CrossRef]

- Smith, P.; Clark, H.; Dong, H.; Elsiddig, E.A.; Haberl, H.; Harper, R.; House, J.; Jafari, M.; Masera, O.; Mbow, C.; et al. Agriculture, forestry and other land use (AFOLU). In Climate Change 2014: Mitigation of Climate Change. In Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Edenhofer, O.R.P.-M., Sokona, Y., Farahani, E., Kadner, S.S.K., Adler, A., Baum, I., Brunner, S., Eickemeier, P., Eds.; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Graves, R.A.; Pearson, S.M.; Turner, M.G. Landscape patterns of bioenergy in a changing climate: Implications for crop allocation and land-use competition. Ecol. Appl. 2016, 26, 515–529. [Google Scholar] [CrossRef]

- Liu, L.; Basso, B. Spatial evaluation of switchgrass productivity under historical and future climate scenarios in Michigan. GCB Bioenergy 2017, 9, 1320–1332. [Google Scholar] [CrossRef]

- Smith, P.; Smith, J.U.; Powlson, D.S.; Mcgill, W.B.; Arah, J.R.M.; Chertov, O.G.; Coleman, K.; Franko, U.; Frolking, S.; Jenkinson, D.S.; et al. A comparison of the performance of nine soil organic matter models using datasets from seven long-term experiments. Geoderma 1997, 81, 153–225. [Google Scholar] [CrossRef]

- Williams, J.R.; Arnold, J.G.; Kiniry, J.R.; Gassman, P.W.; Green, C.H. History of model development at Temple, Texas. Hydrol. Sci. J. 2008, 53, 948–960. [Google Scholar] [CrossRef]

- Meki, M.N.; Snider, J.L.; Kiniry, J.R.; Raper, R.L.; Rocateli, A.C. Energy sorghum biomass harvest thresholds and tillage effects on soil organic carbon and bulk density. Ind. Crops Products 2013, 43, 172–182. [Google Scholar] [CrossRef]

- Kiniry, J.R.; Cassida, K.A.; Hussey, M.A.; Muir, J.P.; Ocumpaugh, W.R.; Read, J.C.; Reed, R.L.; Sanderson, M.A.; Venuto, B.C.; Williams, J.R. Switchgrass simulation by the ALMANAC model at diverse sites in the southern US. Biomass Bioenergy 2005, 29, 419–425. [Google Scholar] [CrossRef]

- Kim, S.; Kiniry, J.R.; Williams, A.S.; Meki, N.; Gaston, L.; Brakie, M.; Shadow, A.; Fritschi, F.B.; Wu, Y. Adaptation of C4 Bioenergy Crop Species to Various Environments within the Southern Great Plains of USA. Sustainability 2017, 9, 89. [Google Scholar] [CrossRef]

- McMillan, C. The role of ecotypic variation in the distribution of the central grassland of North America. Ecol. Monogr. 1959, 29, 285–308. [Google Scholar] [CrossRef]

- Zhang, Y.; Zalapa, J.E.; Jakubowski, A.R.; Price, D.L.; Acharya, A.; Wei, Y.; Brummer, E.C.; Kaeppler, S.M.; Casler, M.D. Post-glacial evolution of Panicum virgatum: Centers of diversity and gene pools revealed by SSR markers and cpDNA sequences. Genetica 2011, 139, 933–948. [Google Scholar] [CrossRef]

- Milano, E.; Lowry, D.; Juenger, T. The Genetic Basis of Upland/Lowland Ecotype Divergence in Switchgrass (Panicum virgatum). G3 (Bethesda Md.) 2016, 6, 3561–3570. [Google Scholar] [CrossRef][Green Version]

- Cassida, K.; Kirkpatrick, T.L.; Robbins, R.T.; Muir, J.; Venuto, B.C.; Hussey, M.A. Plant-parasitic nematodes associated with switchgrass (Panicum virgatum L.) grown for biofuel in the South Central United States. Nematropica 2005, 35, 1–10. [Google Scholar]

- Parrish, D.; Samson, R. Establishing and Managing Switchgrass as an Energy Crop. In Forage and Grazinglands; Plant Management Network: St. Paul, MI, USA, 2008. [Google Scholar]

- NOAA. Climate Data Online Search; National Oceanic and Atmospheric Administration: Silver Spring, MA, USA, 2012.

- NRCS-USDA. Web Soil Survey; U.S. Department of Agriculture, Natrual Resources Conservation Service: Washington, DC, USA, 2018.

- Kandel, T.P.; Wu, Y.; Kakani, V.G. Growth and Yield Responses of Switchgrass Ecotypes to Temperature. Am. J. Plant Sci. 2013, 4, 8. [Google Scholar] [CrossRef][Green Version]

- Hui, D.; Yu, C.-L.; Deng, Q.; Dzantor, E.K.; Zhou, S.; Dennis, S.; Sauve, R.; Johnson, T.L.; Fay, P.A.; Shen, W.; et al. Effects of precipitation changes on switchgrass photosynthesis, growth, and biomass: A mesocosm experiment. PLoS ONE 2018, 13, e0192555. [Google Scholar] [CrossRef]

- McGowan, A.R.; Min, D.-H.; Williams, J.R.; Rice, C.W. Impact of Nitrogen Application Rate on Switchgrass Yield, Production Costs, and Nitrous Oxide Emissions. J. Environ. Qual. 2018, 47, 228–237. [Google Scholar] [CrossRef]

- de Koff, J.; Tyler, D. Improving Switchgrass Yields for Bioenergy Production. Coop Ext Fac. Res. 2012, 40, 1–5. [Google Scholar]

- Kim, S.; Kim, S.; Kiniry, J.R. Two-phase simulation-based location-allocation optimization of biomass storage distribution. Simul. Model. Pract. Theory 2018, 86, 155–168. [Google Scholar] [CrossRef]

- Rogers, S.; Girolami, M. A First Course in Machine Learning; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Grassini, P.; van Bussel, L.G.J.; Wart, J.V.; Wolf, J.; Classens, L.; Yang, H.; Boogaard, H.; de Groot, H.; van Ittersum, M.K.; Cassman, K.G. How good is good enough? Data requirements for reliable crop yield simulations and yield-gap analysis. Field Crops Res. 2015, 177, 49–63. [Google Scholar] [CrossRef]

- Jung, J.Y.; Lal, R. Impacts of nitrogen fertilization on biomass production of switchgrass (Panicum Virgatum L.) and changes in soil organic carbon in Ohio. Geoderma 2011, 166, 145–152. [Google Scholar] [CrossRef]

- Propheter, J.L.; Staggenborg, S.A.; Wu, X.; Wang, D. Performance of Annual and Perennial Biofuel Crops: Yield during the First Two Years. Agron. J. 2010, 102, 806–814. [Google Scholar] [CrossRef]

- Kering, M.K.; Biermacher, J.T.; Butler, T.J.; Mosali, J.; Guretzky, J.A. Biomass Yield and Nutrient Responses of Switchgrass to Phosphorus Application. BioEnergy Res. 2012, 5, 71–78. [Google Scholar] [CrossRef]

- Casler, M.D. Ecotypic Variation among Switchgrass Populations from the Northern USA This research was funded in part by Specific Cooperative Agreement 58-5440-7-123 between the USDA-ARS and the University of Wisconsin-Madison, which was a component of the U.S. Department of Energy, Oak Ridge National Laboratory and USDA-ARS Interagency Agreement under contract DE-A105-900R21954. Crop Sci. 2005, 45, 388–398. [Google Scholar]

- Cortese, L.M.; Honig, J.; Miller, C.; Bonos, S.A. Genetic Diversity of Twelve Switchgrass Populations Using Molecular and Morphological Markers. BioEnergy Res. 2010, 3, 262–271. [Google Scholar] [CrossRef]

- Kiniry, J.R.; Lynd, L.; Greene, N.; Johson, M.-V.V.; Casler, M.; Laser, M.S. Biofuels and Water Use: Comparison of Maize and Switchgrass and General Perspectives. In New Research on Biofuels; Wright, J.H., Evans, D.A., Eds.; Nova Science Publisher, Inc.: Hapac, NY, USA, 2008. [Google Scholar]

- Madakadze, I.C.; Coulman, B.E.; McElroy, A.R.; Stewart, K.A.; Smith, D.L. Evaluation of selected warm-season grasses for biomass production in areas with a short growing season. Bioresour. Technol. 1998, 65, 1–12. [Google Scholar] [CrossRef]

- Heaton, E.A.; Dohleman, F.G.; Long, S.P. Meeting US biofuel goals with less land: The potential of Miscanthus. Glob. Chang. Biol. 2008, 14, 2000–2014. [Google Scholar] [CrossRef]

- Kiniry, J.R.; Sanderson, M.A.; Williams, J.R.; Tischler, C.R.; Hussey, M.A.; Ocumpaugh, W.R.; Read, J.C.; Van Esbroeck, G.; Reed, R.L. Simulating Alamo Switchgrass with the ALMANAC Model. Agron. J. 1996, 88, 602–606. [Google Scholar] [CrossRef]

- Kiniry, J.; Johnson, M.-V.; Mitchell, R.; Vogel, K.; Kaiser, J.; Bruckerhoff, S.; Cordsiemon, R. Switchgrass Leaf Area Index and Light Extinction Coefficients. Agron. J. 2011, 103, 119. [Google Scholar] [CrossRef]

- Kiniry, J.R.; Anderson, L.C.; Johnson, M.-V.V.; Behrman, K.D.; Brakie, M.; Burner, D.; Cordsiemon, R.L.; Fay, P.A.; Fritschi, F.B.; Houx, J.H.; et al. Perennial Biomass Grasses and the Mason–Dixon Line: Comparative Productivity across Latitudes in the Southern Great Plains. BioEnergy Res. 2013, 6, 276–291. [Google Scholar] [CrossRef]

- Tubeileh, A.; Rennie, T.; Kerr, A.; Saita, A.; Patanè, C. Biomass Production by Warm-Season Grasses as Affected by Nitrogen Application in Ontario. Agron. J. 2014, 106, 416–422. [Google Scholar] [CrossRef]

- Gent, P.R.; Danabasoglu, G.; Donner, L.J.; Holland, M.M.; Hunke, E.C.; Jayne, S.R.; Lawrence, D.M.; Neale, R.B.; Rasch, P.J.; Vertenstein, M.; et al. The Community Climate System Model Version 4. J. Clim. 2011, 24, 4973–4991. [Google Scholar] [CrossRef]

- Meehl, G.A.; Washington, W.M.; Arblaster, J.M.; Hu, A.; Teng, H.; Kay, J.E.; Gettelman, A.; Lawrence, D.M.; Sanderson, B.M.; Strand, W.G. Climate Change Projections in CESM1(CAM5) Compared to CCSM4. J. Clim. 2013, 26, 6287–6308. [Google Scholar] [CrossRef]

- Fogli, P.G.; Manzini, E.; Vichi, M.; Alessandri, A.; Patara, L.; Gualdi, S.; Scoccimarro, E.; Masina, S.; Navarra, A. INGV-CMCC Carbon (ICC): A carbon cycle Earth system model. SSRN Electron. J. 2009. [Google Scholar] [CrossRef]

- Dunne, J.P.; John, J.G.; Shevliakova, E.; Stouffer, R.J.; Krasting, J.P.; Malyshev, S.L.; Milly, P.C.D.; Sentman, L.T.; Adcroft, A.J.; Cooke, W.; et al. GFDL’s ESM2 Global Coupled Climate–Carbon Earth System Models. Part II: Carbon System Formulation and Baseline Simulation Characteristics. J. Clim. 2013, 26, 2247–2267. [Google Scholar] [CrossRef]

- Baek, H.-J.; Lee, J.; Lee, H.-S.; Hyun, Y.-K.; Cho, C.; Kwon, W.-T.; Marzin, C.; Gan, S.-Y.; Kim, M.-J.; Choi, D.-H.; et al. Climate change in the 21st century simulated by HadGEM2-AO under representative concentration pathways. Asia-Pacific J. Atmos. Sci. 2013, 49, 603–618. [Google Scholar] [CrossRef]

- Watanabe, M.; Suzuki, T.; O’ishi, R.; Komuro, Y.; Watanabe, S.; Emori, S.; Takemura, T.; Chikira, M.; Ogura, T.; Sekiguchi, M.; et al. Improved Climate Simulation by MIROC5: Mean States, Variability, and Climate Sensitivity. J. Clim. 2010, 23, 6312–6335. [Google Scholar] [CrossRef]

- Giorgetta, M.A.; Jungclaus, J.; Reick, C.H.; Legutke, S.; Bader, J.; Böttinger, M.; Brovkin, V.; Crueger, T.; Esch, M.; Fieg, K.; et al. Climate and carbon cycle changes from 1850 to 2100 in MPI-ESM simulations for the Coupled Model Intercomparison Project phase 5. J. Adv. Model. Earth Syst. 2013, 5, 572–597. [Google Scholar] [CrossRef]

- Kitoh, A.; Noda, A.; Nikaidou, Y.; Ose, T.; Tokioka, T. AMIP Simulations of the MRl GCM. Papers Meteorol. Geophys. 1995, 45, 121–148. [Google Scholar] [CrossRef]

- Cho, J.; Ko, G.; Kim, K.; Oh, C. Climate Change Impacts on Agricultural Drought with Consideration of Uncertainty in CMIP5 Scenarios. Irrig. Drain. 2016, 65, 7–15. [Google Scholar] [CrossRef]

- Li, Y.; Miao, R.; Khanna, M. Effects of Ethanol Plant Proximity and Crop Prices on Land-Use Change in the United States. Am. J. Agric. Econ. 2018, 101, 467–491. [Google Scholar] [CrossRef]

- Sladden, S.E.; Bransby, D.I.; Aiken, G.E. Biomass yield, composition and production costs for eight switchgrass varieties in Alabama. Biomass Bioenergy 1991, 1, 119–122. [Google Scholar] [CrossRef]

- Kiniry, J.R.; Tischler, C.R.; Van Esbroech, G.A. Radiation use efficiency and leaf CO2 exchange for diverse C4 grasses. Biomass Bioenergy 1999, 17, 95–112. [Google Scholar] [CrossRef]

- Marra, M.; Keene, T.; Skousen, J.; Griggs, T. Switchgrass Yield on Reclaimed Surface Mines for Bioenergy Production. J. Environ. Qual. 2013, 42, 696–703. [Google Scholar] [CrossRef]

- Casler, M.D.; Vogel, K.; Taliaferro, C.M.; Ehlke, N.; Berdahl, J.D.; Brummer, C.; Kallenbach, R.L.; West, C.P.; Mitchell, R. Latitudinal and Longitudinal Adaptation of Switchgrass Populations. Crop Sci. 2007, 47. [Google Scholar] [CrossRef]

- Sanderson, M.; Read, J.; Reed, R. Harvest Management of Switchgrass for Biomass Feedstock and Forage Production. Agron. J. AGRON J. 1999, 91, 5–10. [Google Scholar] [CrossRef]

- Casler, M.; Boe, A.R. Cultivar × Environment Interactions in Switchgrass. Crop Science CROP SCI 2003, 43, 2226–2233. [Google Scholar] [CrossRef]

- Davis, E.B.; Jager, H.J.; West, T.O.; Perlack, R.D.; Brandt, C.C.; Wullschleger, S.D.; Baskaran, L.M.; Wilkerson, E.G.; Downing, M.E.; Gunderson, C.A. Exploring Potential U.S. Switchgrass Production for Lignocellulosic Ethanol; US Department Energy Publication: Washington, DC, USA, 2008; Volume 16, pp. 1–45.

- Abdullahi, A.A.; Aliero, B.L.; Aliero, A.A.; Zuru, A.A. Effects of Irrigation Regime, Organic and Inorganic Mineral Source on Growth and Yield Components of Switchgrass (Panicum virgatum L.) in Upland and Lowland Conditions in Sokoto, Nigeria. Pak. J. Biol. Sci. PJBS 2013, 16, 51–58. [Google Scholar]

- Sanderson, M.; Reed, R. Switchgrass Growth and Development: Water, Nitrogen, and Plant Density Effects. J. Range Manag. 2000, 53, 221–227. [Google Scholar] [CrossRef]

- Fike, J.H.; Pease, J.W.; Owens, V.N.; Farris, R.L.; Hansen, J.L.; Heaton, E.A.; Hong, C.O.; Mayton, H.S.; Mitchell, R.B.; Viands, D.R. Switchgrass nitrogen response and estimated production costs on diverse sites. GCB 2017, 9, 1526–1542. [Google Scholar] [CrossRef]

- Moriasi, D.; Arnold, J.; Van Liew, M.; Bingner, R.; Harmel, R.D.; Veith, T. Model Evaluation Guidelines for Systematic Quantification of Accuracy in Watershed Simulations. Transactions of the ASABE 2007, 50, 885–900. [Google Scholar] [CrossRef]

| Model Name | Modeling Center (or Group) | Reference |

|---|---|---|

| CCSM4 | Climate and Global Dynamics Laboratory | Gent et al. [64] |

| CESM1-CAM5 | National Center for Atmospheric Research | Meehl et al. [65] |

| CMCC-CMS | Centro Euro-Mediterraneo per I Cambiamenti Climatici | Fogli et al. [66] |

| GFDL-ESM2G | Princeton University Forrestal Campus | Dunne et al. [67] |

| HADGEM2-AO | Korean National Institute of Metrological Research | Baek et al. [68] |

| MIROC5 | Atmosphere and Ocean Research Institute (The University of Tokyo), National Institute for Environmental Studies, and Japan Agency for Marine-Earth Science and Technology | Watanabe et al. [69] |

| MPI-ESM-LR | Max Planck Institute for Meteorology | Giogetta et al. [70] |

| MRI-CGM3 | Meteorological Research Institute | Kitoh et al. [71] |

| Switchgrass | Fertilizer Rate | Measured | Simulated | |

|---|---|---|---|---|

| Site | Ecotype | N kg ha−1 | Yield (Mg ha−1) | Yield (Mg ha−1) |

| Northwest, OHa | Upland | 0 | 10.45 | 10.38 |

| 50 | 11.95 | 11.8 | ||

| 100 | 13.45 | 12.04 | ||

| 200 | 14.45 | 12.05 | ||

| Jackson, OHa | Upland | 0 | 7.2 | 8.02 |

| 50 | 11.05 | 9.22 | ||

| 100 | 11.25 | 14.22 | ||

| 200 | 11.7 | 15.97 | ||

| Western, OHa | Upland | 0 | 12.8 | 8.92 |

| 50 | 15.3 | 12.79 | ||

| 100 | 15.95 | 13.38 | ||

| 200 | 22.5 | 13.47 | ||

| Troy, KSb | Lowland | 0 | 6.65 | 6.58 |

| Manhattan, KSb | ||||

| Ardmore, OKc | Lowland | 0 | 6.47 | 6.27 |

| 135 | 12.97 | 13.61 | ||

| Waurika, OKc | Lowland | 0 | 9.57 | 8.57 |

| 135 | 12.67 | 9.67 |

| Calibration | Validation | |||

|---|---|---|---|---|

| Upland | Lowland | Upland | Lowland | |

| Measured yield (Mg ha−1) | 13.17 | 9.66 | 7.48 | 14.63 |

| Simulated yield (Mg ha−1) | 11.86 | 8.94 | 7.26 | 13.89 |

| R2 | 0.21 | 0.82 | 0.65 | 0.65 |

| RMSE (Mg ha−1) | 3.52 | 1.45 | 2.36 | 3.74 |

| RSR | 0.97 | 0.51 | 0.61 | 0.62 |

| NSE | 0.05 | 0.73 | 0.62 | 0.62 |

| PBIAS (%) | 9.9 | 7.5 | −2.8 | −5.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Kim, S.; Cho, J.; Park, S.; Jarrín Perez, F.X.; Kiniry, J.R. Simulated Biomass, Climate Change Impacts, and Nitrogen Management to Achieve Switchgrass Biofuel Production at Diverse Sites in U.S. Agronomy 2020, 10, 503. https://doi.org/10.3390/agronomy10040503

Kim S, Kim S, Cho J, Park S, Jarrín Perez FX, Kiniry JR. Simulated Biomass, Climate Change Impacts, and Nitrogen Management to Achieve Switchgrass Biofuel Production at Diverse Sites in U.S. Agronomy. 2020; 10(4):503. https://doi.org/10.3390/agronomy10040503

Chicago/Turabian StyleKim, Sumin, Sojung Kim, Jaepil Cho, Seonggyu Park, Fernando Xavier Jarrín Perez, and James R. Kiniry. 2020. "Simulated Biomass, Climate Change Impacts, and Nitrogen Management to Achieve Switchgrass Biofuel Production at Diverse Sites in U.S." Agronomy 10, no. 4: 503. https://doi.org/10.3390/agronomy10040503

APA StyleKim, S., Kim, S., Cho, J., Park, S., Jarrín Perez, F. X., & Kiniry, J. R. (2020). Simulated Biomass, Climate Change Impacts, and Nitrogen Management to Achieve Switchgrass Biofuel Production at Diverse Sites in U.S. Agronomy, 10(4), 503. https://doi.org/10.3390/agronomy10040503