Evaluating the Suitability of a Combine Harvester Equipped with the Sunflower Header to Harvest Cardoon Seeds: A Case Study in Central Italy

Abstract

1. Introduction

2. Materials and Methods

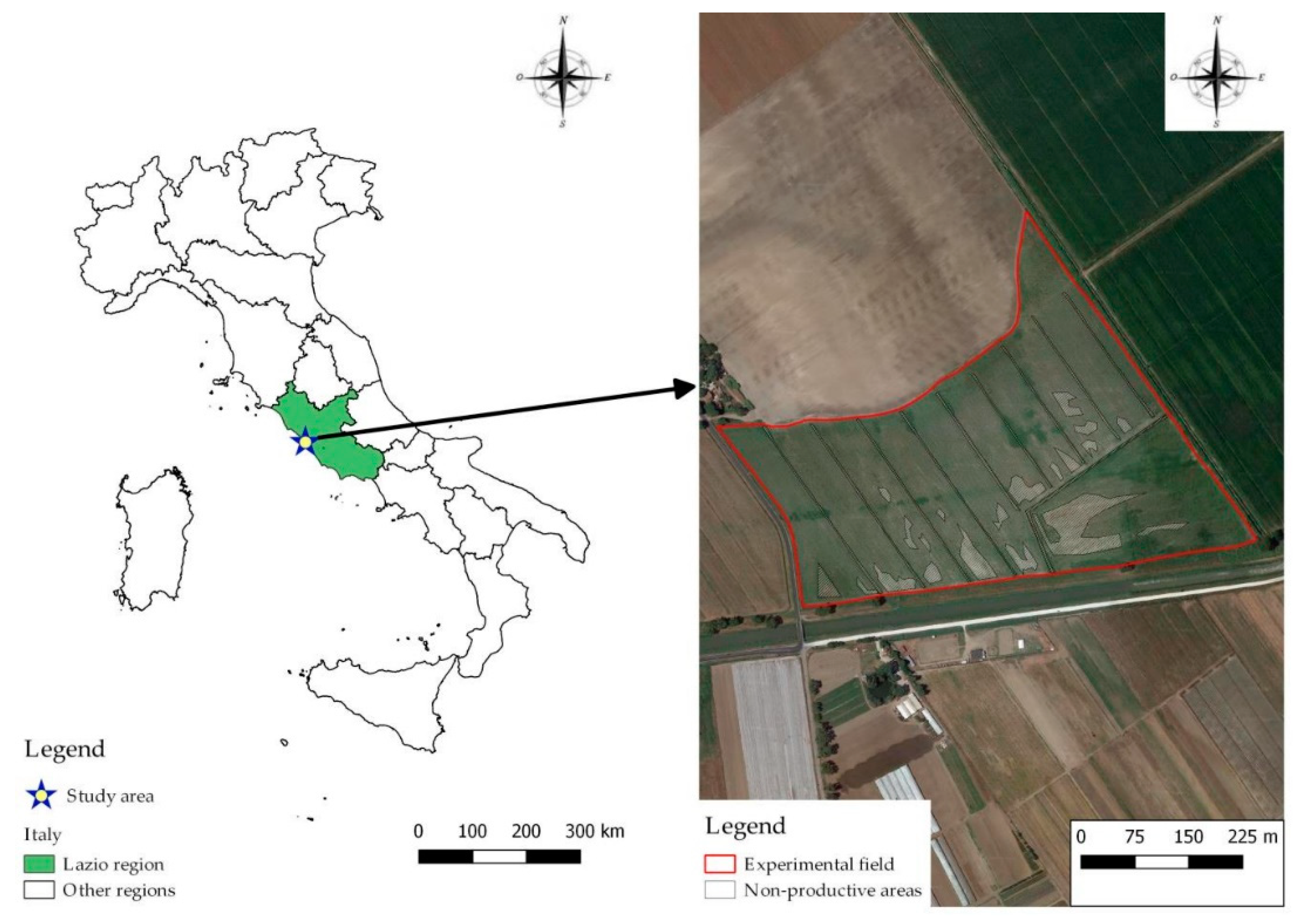

2.1. Study Area

2.2. Pre-Harvest Tests

2.3. Combine Harvester

2.4. Evaluation of the Harvesting Performance

- TFC: Working speed × cutting bar width;

- EFC: Harvested surface/working times (effective working time + maneuvers time, avoidable delay time + unavoidable delay time + accessory time);

- MC: Harvested seeds/working times (effective working time + maneuvers time, avoidable delay time + unavoidable delay time + accessory time).

2.5. Estimation of Harvesting Costs

2.6. Seed Loss Evaluation

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| EFC | Effective Field Capacity (ha h−1) |

| FE | Field Efficiency (%) |

| HASL | Harvesting seed loss (kg ha−1), i.e., overall loss of seeds due to harvesting |

| HESL | Header seed loss (kg ha−1), i.e., loss due to the impact of the header on the standing plants |

| MC | Material Capacity (Mg FM h−1) |

| PSY | Potential seed yield (Mg FM ha−1) |

| TFC | Theoretical Field Capacity (ha h−1) |

| TSL | Tarpaulin seed loss (kg ha−1), i.e., seed loss due to the threshing system of the combine harvester |

References

- Samarappuli, D.; Zanetti, F.; Berzuini, S.; Berti, M.T. Crambe (Crambe abyssinica Hochst): A Non-Food Oilseed Crop with Great Potential: A Review. Agronomy 2020, 10, 1380. [Google Scholar] [CrossRef]

- Zandi Atashbar, N.; Labadie, N.; Prins, C. Modelling and optimisation of biomass supply chains: A review. Int. J. Prod. Res. 2018, 56, 3482–3506. [Google Scholar] [CrossRef]

- Righini, D.; Zanetti, F.; Monti, A. The bio-based economy can serve as the springboard for camelina and crambe to quit the limbo. OCL 2016, 23, D504. [Google Scholar] [CrossRef]

- Gelfand, I.; Sahajpal, R.; Zhang, X.; Izaurralde, R.C.; Gross, K.L.; Robertson, G.P. Sustainable bioenergy production from marginal lands in the US Midwest. Nature 2013, 493, 514–517. [Google Scholar] [CrossRef]

- Von Cossel, M.; Lewandowski, I.; Elbersen, B.; Staritsky, I.; Van Eupen, M.; Iqbal, Y.; Mantel, S.; Scordia, D.; Testa, G.; Cosentino, S.L.; et al. Marginal Agricultural Land Low-Input Systems for Biomass Production. Energies 2019, 12, 3123. [Google Scholar] [CrossRef]

- D’Avino, L.; Di Bene, C.; Farina, R.; Razza, F. Introduction of Cardoon (Cynara cardunculus L.) in a Rainfed Rotation to Improve Soil Organic Carbon Stock in Marginal Lands. Agronomy 2020, 10, 946. [Google Scholar] [CrossRef]

- Toscano, V.; Sollima, L.; Genovese, C.; Melilli, M.G.; Raccuia, S.A. Pilot plant system for biodiesel and pellet production from cardoon: Technical and economic feasibility. Acta Hortic. 2016, 1147, 429–442. [Google Scholar] [CrossRef]

- Scordia, D.; Cosentino, S. Perennial Energy Grasses: Resilient Crops in a Changing European Agriculture. Agriculture 2019, 9, 169. [Google Scholar] [CrossRef]

- Vasilakoglou, I.; Dhima, K. Potential of two cardoon varieties to produce biomass and oil under reduced irrigation and weed control inputs. Biomass Bioenergy 2014, 63, 177–186. [Google Scholar] [CrossRef]

- Mauro, R.P.; Sortino, O.; Pesce, G.R.; Agnello, M.; Lombardo, S.; Pandino, G.; Mauromicale, G. Exploitability of cultivated and wild cardoon as long-term, low-input energy crops. Ital. J. Agron. 2015, 10, 44–46. [Google Scholar] [CrossRef]

- Velez, Z.; Campinho, M.A.; Guerra, Â.R.; García, L.; Ramos, P.; Guerreiro, O.; Felício, L.; Schmitt, F.; Duarte, M. Biological characterization of Cynara cardunculus L. Methanolic extracts: Antioxidant, anti-proliferative, anti-migratory and anti-angiogenic activities. Agriculture 2012, 2, 472–492. [Google Scholar] [CrossRef]

- Pappalardo, H.D.; Toscano, V.; Puglia, G.D.; Genovese, C.; Raccuia, S.A. Cynara cardunculus L. as a Multipurpose Crop for Plant Secondary Metabolites Production in Marginal Stressed Lands. Front. Plant Sci. 2020, 11, 240. [Google Scholar] [CrossRef]

- Gominho, J.; Curt, M.D.; Lourenço, A.; Fernández, J.; Pereira, H. Cynara cardunculus L. as a biomass and multi-purpose crop: A review of 30 years of research. Biomass Bioenergy 2018, 109, 257–275. [Google Scholar] [CrossRef]

- Raccuia, S.A.; Gallo, G.; Melilli, M.G. Effect of plant density on biomass and grain yields in Cynara cardunculus var. altilis cultivated in Sicily. Acta Hortic. 2012, 942, 303–308. [Google Scholar] [CrossRef]

- Fernández, J.; Manzanares, P. Cynara cardunculus L., a new crop for oil, paper pulp and energy. In Proceedings of the 5th European Conference on Biomass for Energy and Industry, Lisbon, Portugal, 9–13 October 1989; Elsevier Applied Science: London, UK, 1990; pp. 1184–1189. [Google Scholar]

- Sengo, I.; Gominho, J.; D’Orey, L.; Martins, M.; D’Almeida-Duarte, E.; Pereira, H.; Ferreira-Dias, S. Response surface modeling and optimization of biodiesel production from Cynara cardunculus oil. Eur. J. Lipid Sci. Technol. 2010, 112, 310–320. [Google Scholar] [CrossRef]

- Alexandre, A.; Dias, A.M.A.; Seabra, I.J.; Portugal, A.; De Sousa, H.C.; Braga, M.E.M. Biodiesel obtained from supercritical carbon dioxide oil of Cynara cardunculus L. J. Supercrit. Fluids 2012, 68, 52–63. [Google Scholar] [CrossRef]

- Raccuia, S.A.; Piscioneri, I.; Sharma, N.; Melilli, M.G. Genetic variability in Cynara cardunculus L. domestic and wild types for grain oil production and fatty acids composition. Biomass Bioenergy 2011, 35, 3167–3173. [Google Scholar] [CrossRef]

- Grammelis, P.; Malliopoulou, A.; Basinas, P.; Danalatos, N.G. Cultivation and characterization of Cynara cardunculus for solid biofuels production in the Mediterranean region. Int. J. Mol. Sci. 2008, 9, 1241–1258. [Google Scholar] [CrossRef]

- Francaviglia, R.; Bruno, A.; Falcucci, M.; Farina, R.; Renzi, G.; Russo, D.E.; Sepe, L.; Neri, U. Yields and quality of Cynara cardunculus L. wild and cultivated cardoon genotypes. A case study from a marginal land in Central Italy. Eur. J. Agron. 2016, 72, 10–19. [Google Scholar] [CrossRef]

- Gominho, J.; Lourenço, A.; Curt, M.; Fernández, J.; Pereira, H. Characterization of hairs and pappi from Cynara cardunculus capitula and their suitability for paper production. Ind. Crops Prod. 2009, 29, 116–125. [Google Scholar] [CrossRef]

- Fernández, J.; Curt, M.D.; Aguado, P.L. Industrial applications of Cynara cardunculus L. for energy and other uses. Ind. Crops Prod. 2006, 24, 222–229. [Google Scholar] [CrossRef]

- Angelini, L.G.; Ceccarini, L.; Nassi o Di Nasso, N.; Bonari, E. Long-term evaluation of biomass production and quality of two cardoon (Cynara cardunculus L.) cultivars for energy use. Biomass Bioenergy 2009, 33, 810–816. [Google Scholar] [CrossRef]

- Lourenço, A.; Neiva, D.M.; Gominho, J.; Curt, M.D.; Fernández, J.; Marques, A.V.; Pereira, H. Biomass production of four Cynara cardunculus clones and lignin composition analysis. Biomass Bioenergy 2015, 76, 86–95. [Google Scholar] [CrossRef]

- Fernández, J.; Hidalgo, M.; Del Monte, J.P.; Curt, M.D. Aprovechamiento del cardo (Cynara cardunculus L.) para la producción de biomasa lignocelulósica, aceite y forraje verde. Itea. Prod. Veg. 1996, 17, 40–56. [Google Scholar]

- Pari, L.; Latterini, F.; Stefanoni, W. Herbaceous Oil Crops, a Review on Mechanical Harvesting State of the Art. Agriculture 2020, 10, 309. [Google Scholar] [CrossRef]

- Fernandez, J.; Pari, L.; García Müller, M.; Marquez, L.; Fedrizzi, M.; Curt, M.D. Strategies for the mechanical harvesting of Cynara. In Proceedings of the 15th European Biomass Conference & Exhibition, Berlin, Germany, 7–11 May 2007. [Google Scholar]

- Pari, L.; Fedrizzi, M.; Gallucci, F. Cynara cardunculus exploitation for energy applications: Development of a combine head for thesing and concurrent residues collecting and utilization. In Proceedings of the 16th European Biomass Conference & Exhibition, Valencia, Spain, 2–6 June 2008. [Google Scholar]

- Pari, L.; Sissot, F.; Giannini, E. European Union Research Project Biocard: Mechanization Activities Results. In Proceedings of the Technology and Management to Increase the Efficiency in Sustainable Agricultural Systems, Rosario, Argentina, 1–4 September 2009. [Google Scholar]

- Pari, L.; Alfano, V.; Acampora, A.; Del Giudice, A.; Scarfone, A.; Sanzone, E. Harvesting and Separation of Different Plant Fractions in Cynara cardunculus L. In Perennial Biomass Crops for a Resource-Constrained World; Barth, S., Murphy-Bokern, D., Kalinina, O., Taylor, G., Jones, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 261–271. ISBN 978-3-319-44529-8. [Google Scholar]

- Pari, L.; Del Giudice, A.; Pochi, D.; Gallucci, F.; Santangelo, E. An innovative flexible head for the harvesting of cardoon (Cynara cardunculus L.) in stony lands. Ind. Crops Prod. 2016, 94, 471–479. [Google Scholar] [CrossRef]

- Pari, L.; Alfano, V.; Mattei, P.; Santangelo, E. Pappi of cardoon (Cynara cardunculus L.): The use of wetting during the harvesting aimed at recovering for the biorefinery. Ind. Crops Prod. 2017, 108, 722–728. [Google Scholar] [CrossRef]

- Zaffrani Sunflower Harvesting Kit. Available online: http://www.zaffrani.it/it/accessori_kit_adattamentoi_testata/ (accessed on 3 December 2020).

- Reith, S.; Frisch, J.; Winkler, B. Revision of the working time classification to optimize work processes in modern agriculture. Chem. Eng. Trans. 2017, 58, 121–126. [Google Scholar] [CrossRef]

- NSAI ISO 18134-2:2017 Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 2: Total Moisture—Simplified Method. Available online: https://www.iso.org/standard/71536.html (accessed on 6 July 2020).

- ISO 17828:2015 ISO 17828:2015 Solid Biofuels—Determination of Bulk Density. Available online: https://www.iso.org/obp/ui/#iso:std:iso:17828:ed-1:v1:en (accessed on 23 July 2020).

- Assirelli, A.; Pignedoli, S. Costo di esercizio delle macchine agricole. Cent. Ric. Prod. Anim. 2005, 5, 1–10. [Google Scholar]

- Suardi, A.; Stefanoni, W.; Bergonzoli, S.; Latterini, F.; Jonsson, N.; Pari, L. Comparison between Two Strategies for the Collection of Wheat Residue after Mechanical Harvesting: Performance and Cost Analysis. Sustainability 2020, 12, 4936. [Google Scholar] [CrossRef]

- Banca d’Italia Banca d’Italia Lending Rate. Available online: https://www.bancaditalia.it/ (accessed on 11 July 2020).

- American Society of Agricultural Engineers. American Society of Agricultural Engineers ASAE Standard D497.4: Agriculture Machinery Management Data; American Society of Agricultural Engineers: St. Joseph, MI, USA, 2003; pp. 373–380. [Google Scholar]

- Stefanoni, W.; Latterini, F.; Ruiz, J.P.; Bergonzoli, S.; Attolico, C.; Pari, L. Mechanical Harvesting of Camelina: Work Productivity, Costs and Seed Loss Evaluation. Energies 2020, 13, 5329. [Google Scholar] [CrossRef]

- Gherbin, P.; Monteleone, M.; Tarantino, E. Five year evaluation on cardoon (Cynara cardunculus L. var. altilis) biomass production in a Mediterranean environment. Ital. J. Agron. 2001, 5, 11–19. [Google Scholar]

- Bolohan, C.; Marin, D.I.; Mihalache, M.; Ilie, L.; Oprea, A.C. Research on Cynara cardunculus L. species under the conditions of southeastern Romania area. Sci. Pap. Ser. A Agron. 2013, 56, 429–432. [Google Scholar]

- Ierna, A.; Mauro, R.P.; Mauromicale, G. Biomass, grain and energy yield in Cynara cardunculus L. as affected by fertilization, genotype and harvest time. Biomass Bioenergy 2012, 36, 404–410. [Google Scholar] [CrossRef]

- Santhi, C.; Srinivasan, R.; Arnold, J.G.; Williams, J.R. A modeling approach to evaluate the impacts of water quality management plans implemented in a watershed in Texas. Environ. Model. Softw. 2006, 21, 1141–1157. [Google Scholar] [CrossRef]

- Curt, M.D.; Sánchez, G.; Fernández, J. The potential of Cynara cardunculus L. for seed oil production in a perennial cultivation system. Biomass Bioenergy 2002, 23, 33–46. [Google Scholar] [CrossRef]

- Raccuia, S.A.; Melilli, M.G. Biomass and grain oil yields in Cynara cardunculus L. genotypes grown in a Mediterranean environment. Field Crops Res. 2007, 101, 187–197. [Google Scholar] [CrossRef]

- Gominho, J.; Lourenço, A.; Palma, P.; Lourenço, M.E.; Curt, M.D.; Fernández, J.; Pereira, H. Large scale cultivation of Cynara cardunculus L. for biomass production—A case study. Ind. Crops Prod. 2011, 33, 1–6. [Google Scholar] [CrossRef]

- Archontoulis, S.V.; Danalatos, N.G.; Struik, P.C.; Vos, J.; Yin, X. Agronomy of Cynara cardunclulus growing on an aquic soil in central Greece. In Proceedings of the International Conference on Agricultural Engineering, Crete, Greece, 23–25 June 2008. [Google Scholar]

- Suardi, A.; Stefanoni, W.; Alfano, V.; Bergonzoli, S.; Pari, L. Equipping a Combine Harvester with Turbine Technology Increases the Recovery of Residual Biomass from Cereal Crops via the Collection of Chaff. Energies 2020, 13, 1572. [Google Scholar] [CrossRef]

- Suardi, A.; Saia, S.; Stefanoni, W.; Gunnarsson, C.; Sundberg, M.; Pari, L. Admixing Chaff with Straw Increased the Residues Collected without Compromising Machinery Efficiencies. Energies 2020, 13, 1766. [Google Scholar] [CrossRef]

- Semerci, A.; Kaya, Y. The Components of Production Cost in Sunflower and its Relationships with Input Prices. Int. Rev. Appl. Econ. 2010, 5, 139–146. [Google Scholar]

- Semerci, A. Cost analysis of oily sunflower production: The case of Tekirdag province, Turkey. Custos e Agronegocio 2019, 15, 167–191. [Google Scholar]

- Asoodar, A.M.; Izadinia, Y.; Desbiolles, J. Benefits of harvester front extension in reducing canola harvest losses. Int. Agric. Eng. J. 2012, 21, 32–37. [Google Scholar]

- Pari, L.; Assirelli, A.; Suardi, A.; Civitarese, V.; Del Giudice, A.; Costa, C.; Santangelo, E. The harvest of oilseed rape (Brassica napus L.): The effective yield losses at on-farm scale in the Italian area. Biomass Bioenergy 2012, 46, 453–458. [Google Scholar] [CrossRef]

- Reginato, P. Colheita Mecanizada de Sementes de Crambe (Crambe abyssinica L.) no Cerrado sul Mato Grossense. Ph.D. Thesis, Universidade Federal da Grande Dourados, Dourados, Brazil, 2014. [Google Scholar]

- Chaplygin, M.; Bespalova, O.; Podzorova, M. Results of tests of devices for sunflower harvesting in economic conditions. E3S Web Conf. 2019, 126, 1–7. [Google Scholar] [CrossRef]

- Startsev, A.S.; Demin, E.E.; Danilin, A.V.; Vasilyev, O.A.; Terentyev, A.G. Results of the production test of sunflower harvesting attachment with an auger reel. IOP Conf. Ser. Earth Environ. Sci. 2020, 433. [Google Scholar] [CrossRef]

- Shaforostov, V.D.; Makarov, S.S. The header for a breeding plot combine for sunflower harvesting. Acta Technol. Agric. 2019, 22, 60–63. [Google Scholar] [CrossRef]

- Gil, M.; Arauzo, I.; Teruel, E.; Bartolomé, C. Milling and handling Cynara cardunculus L. for use as solid biofuel: Experimental tests. Biomass Bioenergy 2012, 41, 145–156. [Google Scholar] [CrossRef]

- Encinar, J.M.; Gonzalez, J.F.; Rodriguez, J.J.; Tejedor, A. Biodiesel fuels from vegetable oils: Transesterification of Cynara cardunculus L. oils with ethanol. Energy Fuels 2002, 16, 443–450. [Google Scholar] [CrossRef]

- Encinar, J.M.; Gonzalez, J.F.; Gonzalez, J. Fixed-bed pyrolysis of Cynara cardunculus L. Product yields and compositions. Fuel Process. Technol. 2000, 68, 209–222. [Google Scholar] [CrossRef]

- Ballesteros, M.; Negro, M.J.; Manzanares, P.; Ballesteros, I.; Sáez, F.; Oliva, J.M. Fractionation of Cynara cardunculus (cardoon) biomass by dilute-acid pretreatment. In Applied Biochemistry and Biotecnology; Springer: Berlin/Heidelberg, Germany, 2007; pp. 239–252. [Google Scholar]

- Kalamaras, S.D.; Kotsopoulos, T.A. Anaerobic co-digestion of cattle manure and alternative crops for the substitution of maize in South Europe. Bioresour. Technol. 2014, 172, 68–75. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Measure Unit | Value | |

|---|---|---|---|

| Machine | Power | kW | 176 |

| Financial costs | Investment | € | 250,000 |

| Service life | yr | 10 | |

| Service life | h | 3000 | |

| Resale | % | 19.00 | |

| Resale | € | 47,500.00 | |

| Depreciation | € | 202,500.00 | |

| Annual usage | h yr−1 | 312 | |

| Interest rate | % | 3.00 | |

| Fixed costs | Ownership costs | € yr−1 | 20,250.00 |

| Interests | € yr−1 | 4462.50 | |

| Machine shelter | m2 | 22.08 | |

| Value of the shelter | € m−2 | 100.00 | |

| Value of the shelter | € yr−1 | 44.16 | |

| Insurance | € yr−1 | 625.00 | |

| Variable costs | Repair factor | % | 40 |

| Repairs and maintenance | € h−1 | 34.67 | |

| Fuel cost | € l−1 | 0.57 | |

| Fuel consumption | l h−1 | 25.00 | |

| Fuel cost | € h−1 | 14.25 | |

| Lubricant cost | € l−1 | 3.03 | |

| Lubricant consumption | l h−1 | 0.32 | |

| Lubricant cost | € h−1 | 0.97 | |

| Worker salary | € h−1 | 11.50 |

| Parameter | Measure Unit | Average | St. Dev. |

|---|---|---|---|

| Plants per hectare | N ha−1 | 22,667 | 1685 |

| Plants height | cm | 147 | 111 |

| Capitula per plant | N | 7.4 | 4.2 |

| Height of the lower capitulum | cm | 126 | 13 |

| Seeds content per capitulum | g FM | 6.7 | 0.7 |

| 1000-seeds weight | g FM | 37.17 | 1.20 |

| Bulk density of collected seed | Mg m−3 FM | 0.644 | 0.014 |

| Aerial biomass | Mg ha−1 FM | 6.25 | 2.86 |

| Potential seed yield (PSY) | Mg ha−1 FM | 1.11 | 0.14 |

| Potential seed yield (PSY) | Mg ha−1 DM | 1.05 | 0.13 |

| Harvest index (HI) | - | 0.20 | 0.07 |

| Seeds moisture | % | 5.82% | 0.03% |

| Leaves moisture | % | 14.08% | 1.67% |

| Stalk moisture | % | 44.00% | 15.90% |

| Parameter | Measure Unit | Average | St. Dev. |

|---|---|---|---|

| Working speed | km h−1 | 4.92 | 0.87 |

| Theoretical Field Capacity (TFC) | ha h−1 | 2.36 | 0.42 |

| Effective Field Capacity (EFC) | ha h−1 | 2.05 | 0.33 |

| Field Efficiency (FE) | % | 87.24% | 4.13% |

| Material Capacity (MC) | Mg h−1 | 1.82 | 0.30 |

| Parameter | Measure Unit | Value |

|---|---|---|

| Costs per unit of time | € h−1 | 142.74 |

| Cost per unit of surface | € ha−1 | 69.52 |

| Costs per unit of seed yield | € Mg−1 FM | 86.15 |

| Parameter | Measure Unit | Average | St. Dev. |

|---|---|---|---|

| Header seed loss (HESL) | kg ha−1 | 28.72 | 17.13 |

| Header seed loss (HESL) | % | 2.58% | 1.54% |

| Threshing system seed loss (TSL) | kg ha−1 | 6.44 | 3.20 |

| Threshing system seed loss (TSL) | % | 0.58% | 0.29% |

| Harvesting seed loss (HASL) | kg ha−1 | 35.16 | - |

| Harvesting seed loss (HASL) | % | 3.16% | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Latterini, F.; Stefanoni, W.; Sebastiano, S.; Baldi, G.M.; Pari, L. Evaluating the Suitability of a Combine Harvester Equipped with the Sunflower Header to Harvest Cardoon Seeds: A Case Study in Central Italy. Agronomy 2020, 10, 1981. https://doi.org/10.3390/agronomy10121981

Latterini F, Stefanoni W, Sebastiano S, Baldi GM, Pari L. Evaluating the Suitability of a Combine Harvester Equipped with the Sunflower Header to Harvest Cardoon Seeds: A Case Study in Central Italy. Agronomy. 2020; 10(12):1981. https://doi.org/10.3390/agronomy10121981

Chicago/Turabian StyleLatterini, Francesco, Walter Stefanoni, Simone Sebastiano, Gian Maria Baldi, and Luigi Pari. 2020. "Evaluating the Suitability of a Combine Harvester Equipped with the Sunflower Header to Harvest Cardoon Seeds: A Case Study in Central Italy" Agronomy 10, no. 12: 1981. https://doi.org/10.3390/agronomy10121981

APA StyleLatterini, F., Stefanoni, W., Sebastiano, S., Baldi, G. M., & Pari, L. (2020). Evaluating the Suitability of a Combine Harvester Equipped with the Sunflower Header to Harvest Cardoon Seeds: A Case Study in Central Italy. Agronomy, 10(12), 1981. https://doi.org/10.3390/agronomy10121981