1. Introduction

Organic farming has greatly expanded across the world in recent decades as a potential answer to the environmental challenge that agriculture poses. Organic farming aims to produce in a way that limits synthetic pesticides and maximizes natural equilibrium. All products are specially labelled and benefit from consumer recognition. However, some studies have shown that organic agriculture may generate lower yields [

1,

2] than conventional farming and suffers higher yield variability from one year to another [

3]. Although yields are only part of a set of benefits delivered by cropping systems, high yields are central to sustainable farmer income.

Vineyard cropping systems use substantial amounts of synthetic pesticides [

4]. In France, vineyard cropping systems accounted for 14.4% of the pesticides used for only 3.3% of total area [

5]. The average number of treatments is 20.1 per season for a Treatment Frequency Index (TFI) of 15.3 [

6]. These high figures are due to vineyards being extremely sensitive to attacks from pests and diseases such as powdery and downy mildew [

7,

8]. If not controlled, powdery and downy mildew expose winegrowers to a risk of low to null harvest [

9]. In light of this environmental context and rising consumer demand, organic vineyard areas have increased since 2000. In France in 2018, organic vineyards represented 11.9% of the total vineyard area [

10].

Converting a vineyard system to organic farming involves discontinuing the use of herbicides for weed control and chemicals for bud pruning, replacing mineral fertilizers with organic fertilizers and stopping the use of synthetic pesticides for pest and disease control (Council Regulation (EC) No. 834/2007). For weed control and bud pruning, no other products can be substituted. Winegrowers must use mechanical or manual alternatives, which are more time consuming [

11] and some interventions may have to be delayed. Such alternatives can result in high water and nitrogen competition between vines and weeds [

12] if mechanical weeding is not optimal and weeds are not controlled. Water or nitrogen stresses are essential limiting factors of yield that constrain the number of inflorescences and the number of berries at the sensitive period [

13]. Delayed bud pruning can result in poor vine canopy management, which can then lead to a degraded microclimate around clusters and higher disease severity [

9]. For pest and disease control, alternative products based on copper, sulfur or biocontrol exist. However, it can be complicated to implement a pest and disease management strategy based on copper and sulfur: Although switching products can be considered a substitution, significant adjustments are required [

11] in most vineyards. Winegrowers must increase their intervention frequency due to the non-systemic characteristics of copper and sulfur products as well as their high sensitivity to leaching. Finally, the many changes implemented when converting to organic farming are more time consuming and often have a sharp learning curve, with winegrowers using a trial-and-error approach [

11]. There is a real risk that winegrowers will make errors during the conversion process. Errors in the phytosanitary strategy can lead to higher annual disease prevalence and a decrease in the number of healthy berries [

14].

Winegrowers face a real risk of yield loss when converting to organic farming related to changes in practices. The risk of lower yields can be an obstacle to the development of organic farming and partly explains the stagnation in the number of conversions in the past three years in France. Organic farming productivity is therefore a crucial issue that some authors have investigated [

1,

2]. The meta-analysis by Seufert et al. [

2] showed that yields were lower in organic farming than in conventional farming, but that the differences were “highly contextual depending on system and site characteristics, (…). Under certain conditions—that is, with good management practices (…), particular crop types (…)—organic systems can thus nearly match conventional yields”. Data on vineyard cropping systems are sparse in general. Perennial crops, including vineyards, showed an organic-conventional yield ratio of around 0.9 [

2]. To our knowledge, no scientific research has been carried out on the conversion period for vineyard systems. Only advisory services showed yield trajectories at local scale.

In this paper, we analyze grapevine yield dynamics during the three-year conversion to organic farming. We also analyze the principal yield components and have put forward hypotheses to explain the dynamics observed.

2. Materials and Methods

2.1. Grapevine Yield Elaboration Process

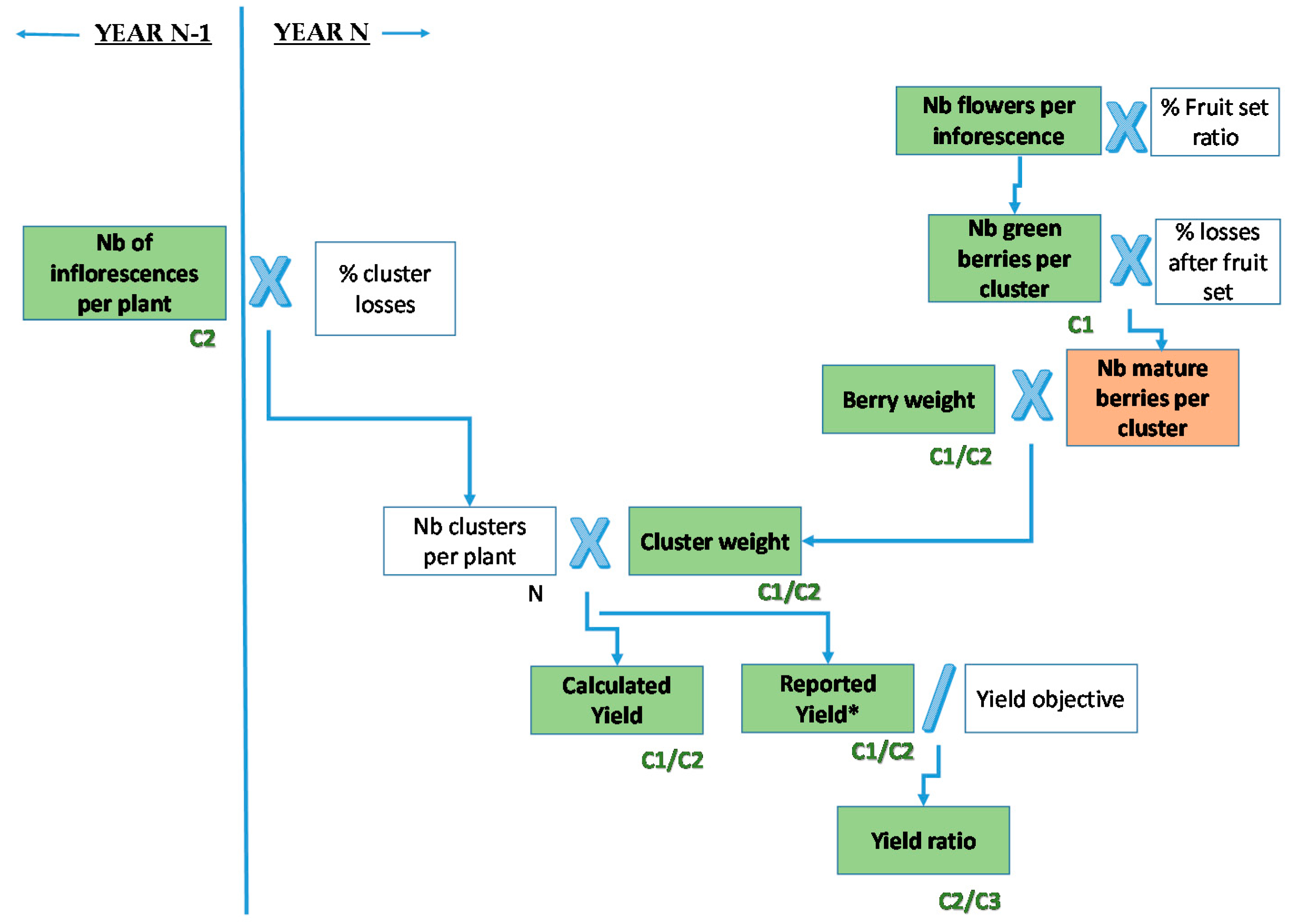

Every growing season, the grapevine yield from a given vineyard is the result of various short- and long-term processes. Long-term processes are responsible for the elaboration of yield potential on the plot. Long-term processes begin at vine planting and include initial conditions (e.g., density, planting operations). They continue throughout the lifespan of the vines with pedoclimatic conditions, maintenance practices (e.g., trellising and pruning) and soil management (e.g., mechanical weeding). They result in a given state of the plot, with vine density being potentially lower than the initial starting point and a vine state allowing for potential growth development and grape production for the year of study (n).

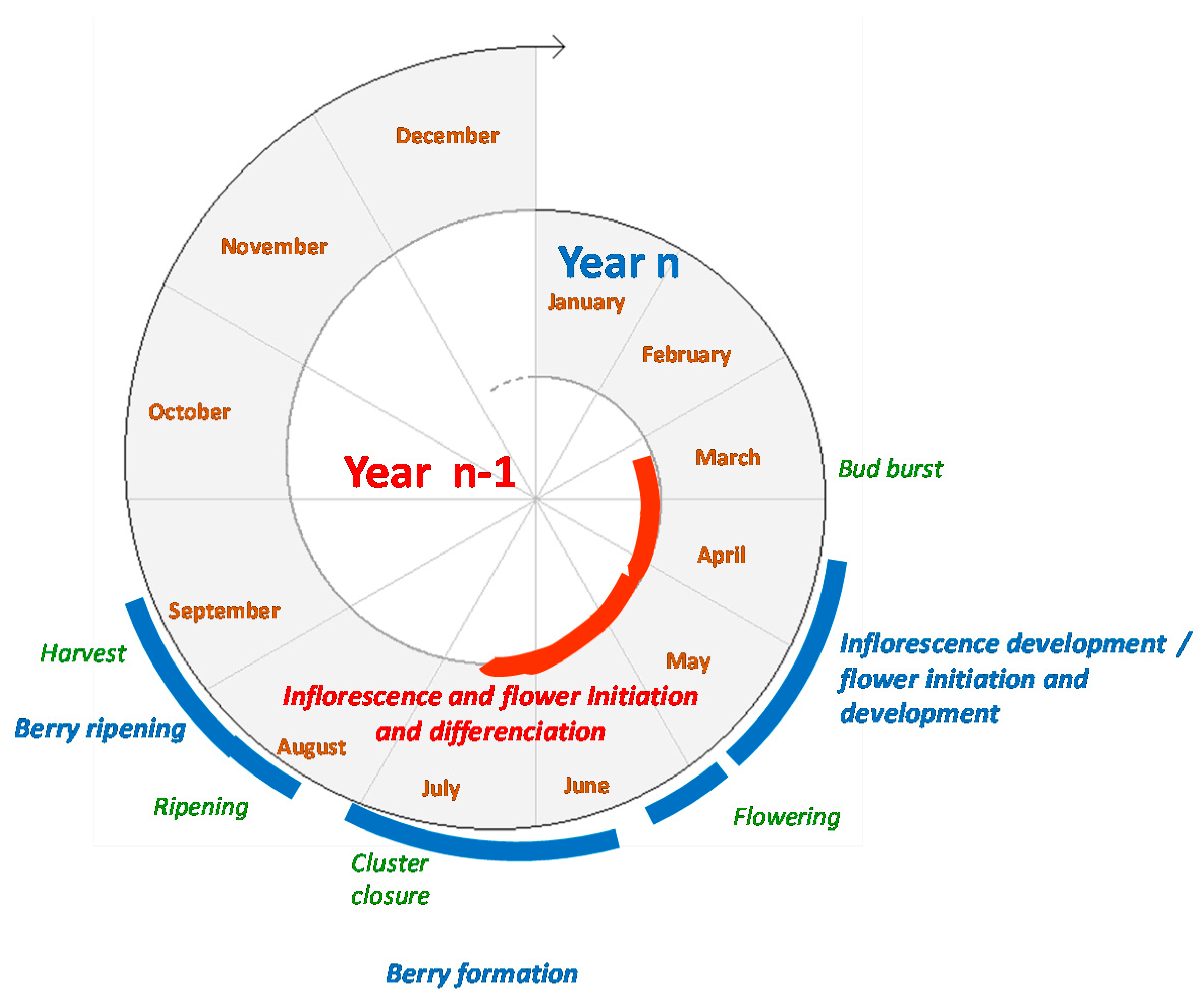

Short-term processes include the initiation and development of clusters and flowers and the formation, filling and maturing of berries. The active/final yield of a given vine is elaborated over two years (

Figure 1) [

13] and can be calculated as the product of three main components: The number of clusters, the number of mature berries per cluster and the average mature berry weight. Equation (1) summarizes this breakdown.

Yield elaboration begins the year before harvest (

n − 1) around bud break and ends year

n at harvest. The number of clusters per vine, which relates to how productive the vine is, can be estimated by the number of inflorescences when no green grapes are cut (as in the Mediterranean region). The inflorescences were initialized and differentiated from March to August in year

n − 1 (

Figure 1). Each winter, the vines are pruned. Pruning reduces the potential number of clusters—and therefore the potential yield—to a value known as achievable yield, or the maximum value that can be achieved at harvest in the absence of limiting factors. Winegrowers manage achievable yield to get as close as possible to the objective yield determined for the plot. Pruning strongly reduces the variability in the number of clusters per vine and, therefore, yield variability. Inflorescence development occurs year n after bud break.

The number of mature berries per cluster is linked to the number of flowers determined per inflorescence for year n − 1 as well as to the number of buds that bloomed into a flower from April to May for year n. In year n, the flowers turn into green berries just after flowering depending on the fruit set rate.

The number of mature berries per cluster at harvest is associated with the third yield component: The average mature berry weight. The green berries grow from fruit set stage to berry closing stage and the ripening phase continues until harvest, which takes place in September in the French Mediterranean region.

During all these stages, the inflorescences and flowers, and later the clusters and berries, can be limited in growth and number, or damaged or destroyed. This leads to lower yields due to limiting and reducing factors such as climate, pests and diseases or hydric and mineral deficits.

During conversion to organic farming, technical changes can influence yield components and yield in various ways. Considering the grapevine yield elaboration, we can hypothesize that:

- (i)

if the number of inflorescences is affected by the technical changes implemented during the conversion, the impacts will not be noticeable until the second year of conversion

- (ii)

if the number of flowers per inflorescence is affected by the technical changes implemented during the conversion, the impacts may be observed from the first year of conversion

- (iii)

if the number of berries per cluster is affected by the technical changes implemented during the conversion, the impacts may be observed from the first year of conversion

- (iv)

if the berry weight is affected by the technical changes implemented during the conversion, the impacts may be observed from the first year of conversion

- (v)

if the yield is affected by the technical changes implemented during the conversion, impacts may be noticeable from the first year of conversion as well as during the second year of conversion.

2.2. Experimental Design

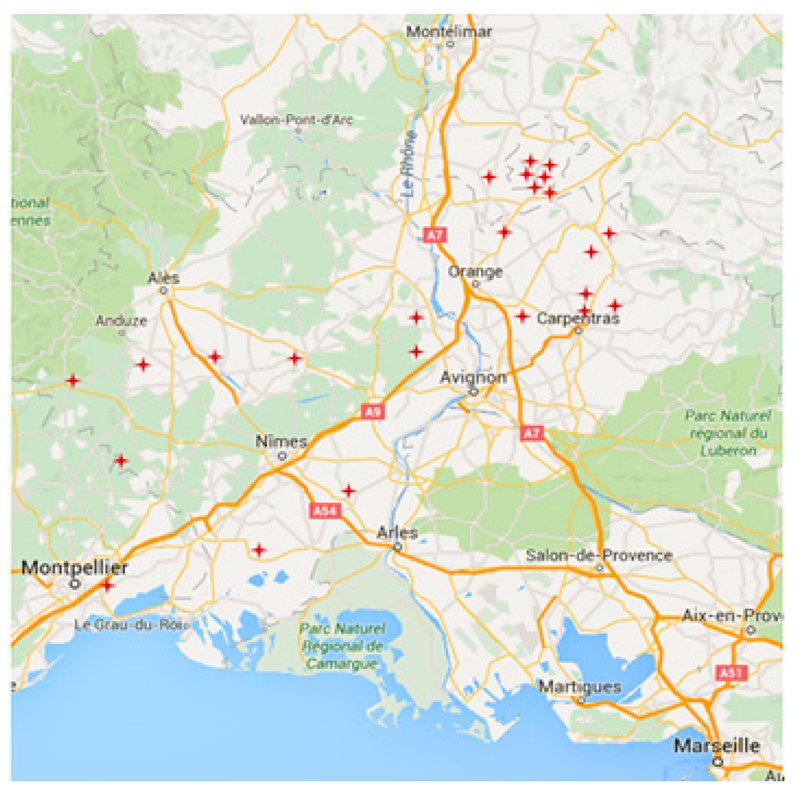

2.2.1. Vineyard Network

The four-year study was undertaken on a plot network of 26 vineyards all planted with the same cultivar (Grenache) of

Vitis vinifera in southeastern France.

Table 1 presents the characteristics of the plot network [

14]. Some of the plots were monitored for two successive years. The vineyard network extended over an area measuring 200 km in length and 50 km wide from the eastern part of the Languedoc region to the southern Rhone Valley. The area covered a wide range of pedoclimatic, pest and disease, and management conditions. The entire network produces red wine in individual or cooperative wineries. The winegrowers used a variety of pruning systems with and without trellis systems. All vineyards were cultivated in a context of voluntary yield limitation to ensure the wine quality met growers’ criteria. Each plot therefore had a specific yield objective that the winegrower sought to reach each year.

The modes of production were classified as follows: Conventional farming (Cv), first year of conversion to organic (C1), second year of conversion to organic (C2) and third year of conversion to organic (C3). To ensure compliance with organic farming specifications, winegrowers began implementing technical changes as early as C1. To distinguish the effect of the conversion from the effect of the vintage on yield dynamics, we decided to monitor several Cv, C1, C2 and C3 plots for each year of the study [

14]. We monitored between 10 and 15 vines per year from 2013 to 2016.

The protection strategies were also collected in each plot every year. During the conversion, plots were characterized by the absence of synthetic ingredients for crop protection and fertilization, as set out in the organic certification. Copper-based products were used in conversion towards organic farming and biocontrol products were used for pest control (e.g., Bacillus thuringiensis and mating disruption) and powdery mildew control Erysiphe necator (Schwein.) (sulfur-based products). Conventional plots mainly used synthetic products, although sulfur and copper treatments were also used occasionally, and mineral fertilization.

2.2.2. Year Characteristics

Pest and Disease Pressure from 2013 to 2016

The vineyard network was studied for four consecutive years in which phytosanitary conditions varied significantly.

Table 2 shows the specific pest and disease issues for all four years. Downy mildew

Plasmopara viticola (Berk. & M.A. Curtis) was predominant in 2013 whereas powdery mildew

Erysiphe necator (Schwein.) was the main problem in 2014. The salient feature of 2015 was an outbreak of black rot caused by

Guignardia bidwellii (Viala & Ravaz, 1892) (anamorph

Phyllosticta ampelicida) in the region, and 2016 was a typical year for all grapevine pests and diseases. Berry moth larvae of

Lobesia botrana (Denis and Schiffermüller, 1775) and

Eupoecilia ambiguella (Hübner, 1796) were present but populations were moderate across the four-year period.

Climatic Conditions

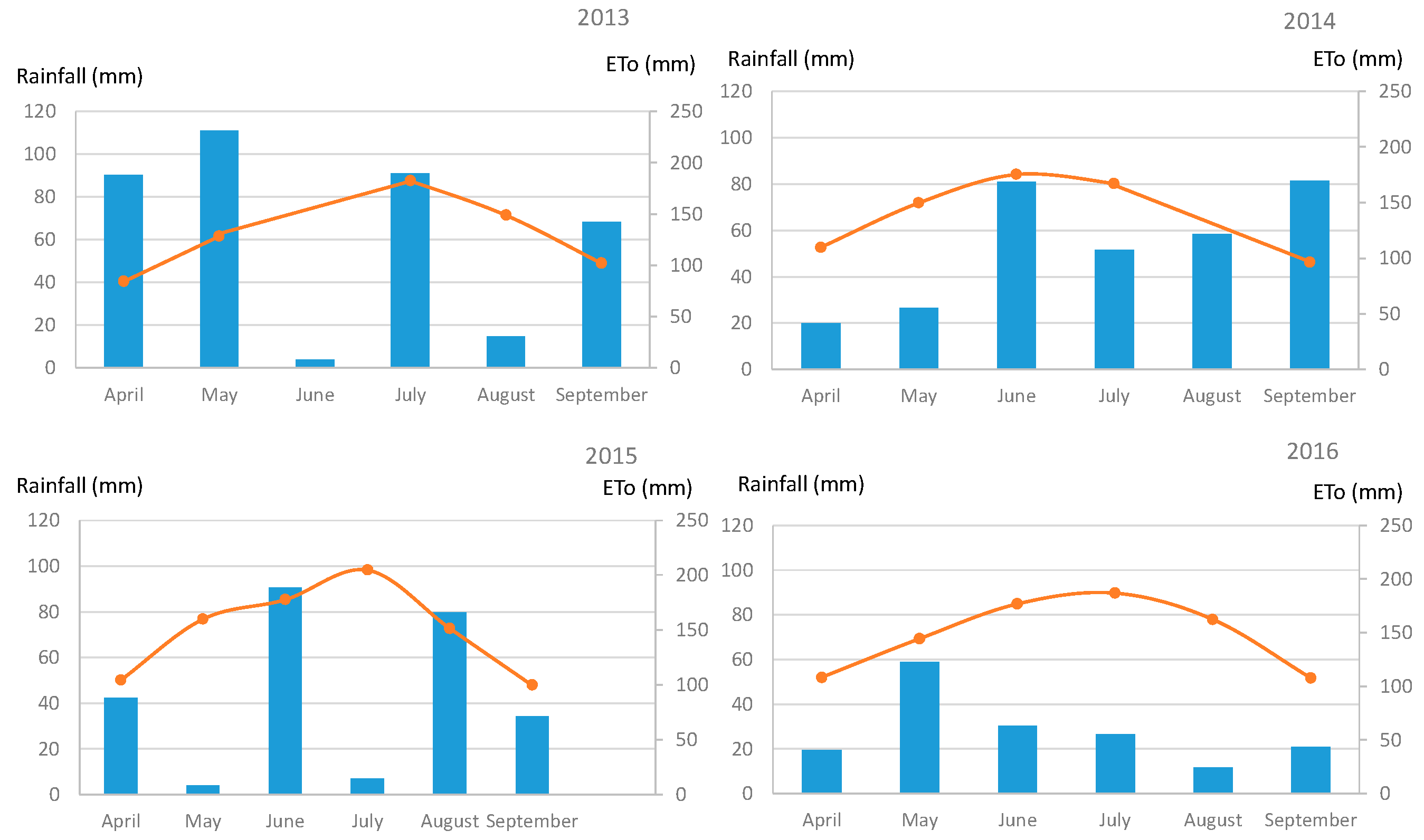

The vineyard network is located in a typical Mediterranean climate (

Figure 2). The average annual climatic features (data from Meteo France—Station Carpentras-Serres 1981–2010) are as follows: (i) minimal temperature, 8.1 °C; (ii) maximal temperature, 20.6 °C; (iii) rainfall, about 648 mm; and (iv) number of rainy days, 65.7 d [

14]. In 2013, total rainfall was higher than average from April to September. May and July were particularly rainy whereas June and August were dry. Evapotranspiration (ETo) levels were lower than average from April to September. In 2014, the area experienced a rainfall deficit in April and May. In summer, cumulated ETo was close to average. The years 2015 and 2016 presented a similar profile, with a rainfall deficit in summer compared to average and higher ETo.

2.2.3. Data Collection in the Plot Network

Yield Component Sampling

In each monitored plot, we selected 30 regularly distributed vines and numbered them from 1 to 30. They covered the entire plot area except for a buffer zone delimited by at least two rows and three plants on the edges of the plot.

On each selected vine, we chose one shoot located on the extremity of the vine (the first shoot on the right with at least one inflorescence in the direction of the row). On each selected shoot, we marked the first inflorescence nearest to the trunk. In the area’s climate conditions, every shoot of Grenache can carry up to three inflorescences. We monitored 30 inflorescences in each plot—one per vine—for a total of 1440 inflorescences/clusters for the whole network. In each plot x year situation, we tracked several variables in order to document the conversion process and its effects on grape yield and its components. Depending on the type of variable and the collection method, the number of data per plot x year situation can vary.

Number of inflorescences per vine: On each of the 30 vines marked in the plot, we counted the number of inflorescences at mid-flowering. We did not observe, in our plot x year situations, significant cluster loss between flowering and harvest, although this can happen. We therefore used the number of inflorescences at flowering as a proxy for the number of clusters per vine.

Number of flowers per inflorescence: On each of the 30 marked inflorescences per plot, we used an indirect method to assess the number of flowers per inflorescence. Ten days before flowering or at mid-flowering, we measured the two lengths (

L1 and

L2) of the rachis as shown in

Figure 3 without taking off the flower buds. In fact, Casteran et al. [

16] established a specific relationship between the number of flowers and the length of (

L1 and

L2). The parameters of this relationship depend on the vine variety. In parallel to this study, we estimated these parameters for Grenache inflorescences on 30 inflorescences the same year on one plot in the network, by applying the same method to the Grenache noir variety 10 days before flowering Equation (2) and at mid-flowering Equation (3):

(10 days before flowering)

(mid-flowering)

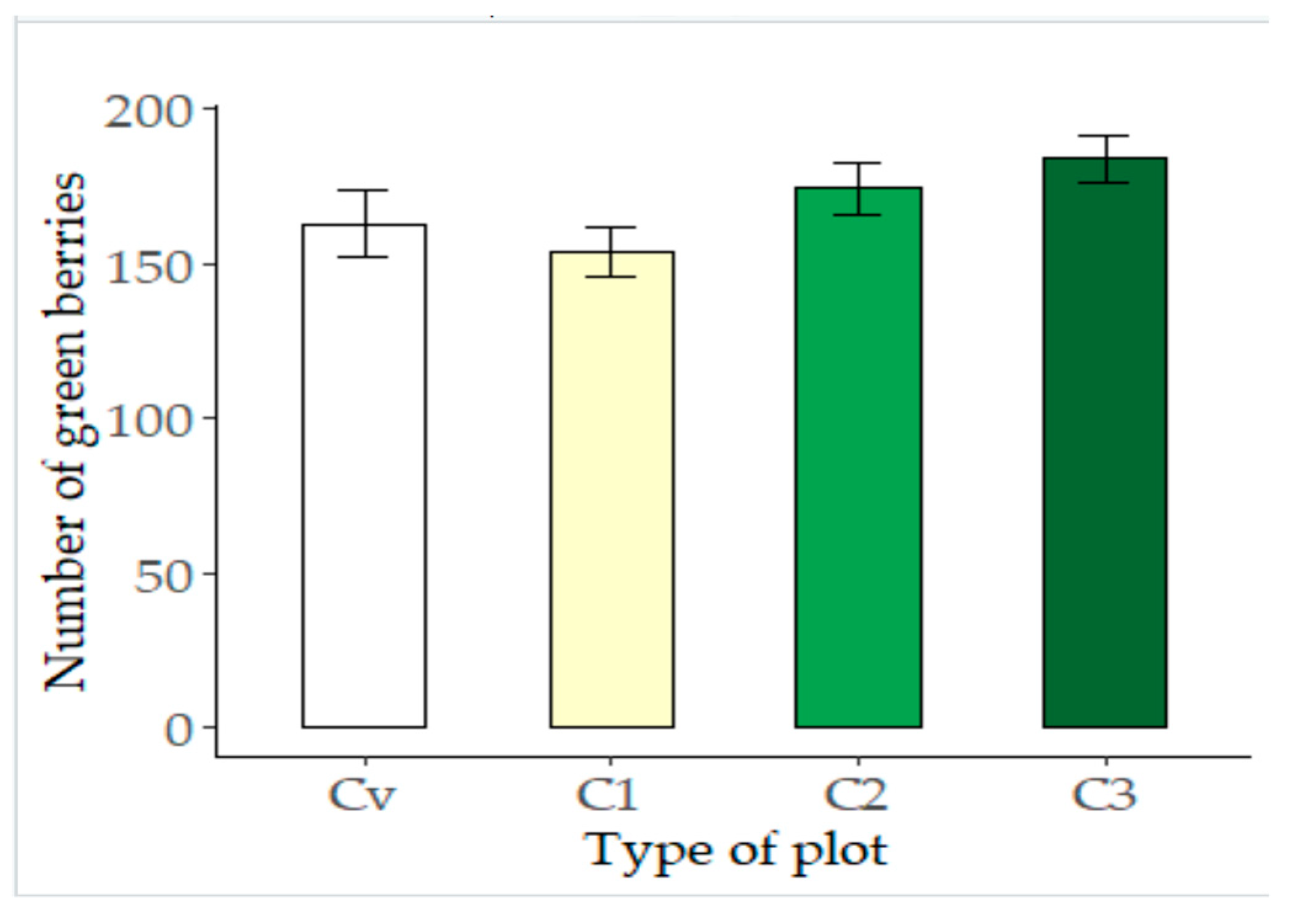

Number of green berries per cluster: We counted the number of green berries per cluster at late fruit set. This measurement required destructive sampling and extensive labor. Consequently, on every other identified vine—the 15 odd-numbered ones—we chose the shoot nearest to the marked shoot and picked the closest cluster from the trunk on this shoot. In the laboratory, we counted the number of berries on these 15 clusters per plot.

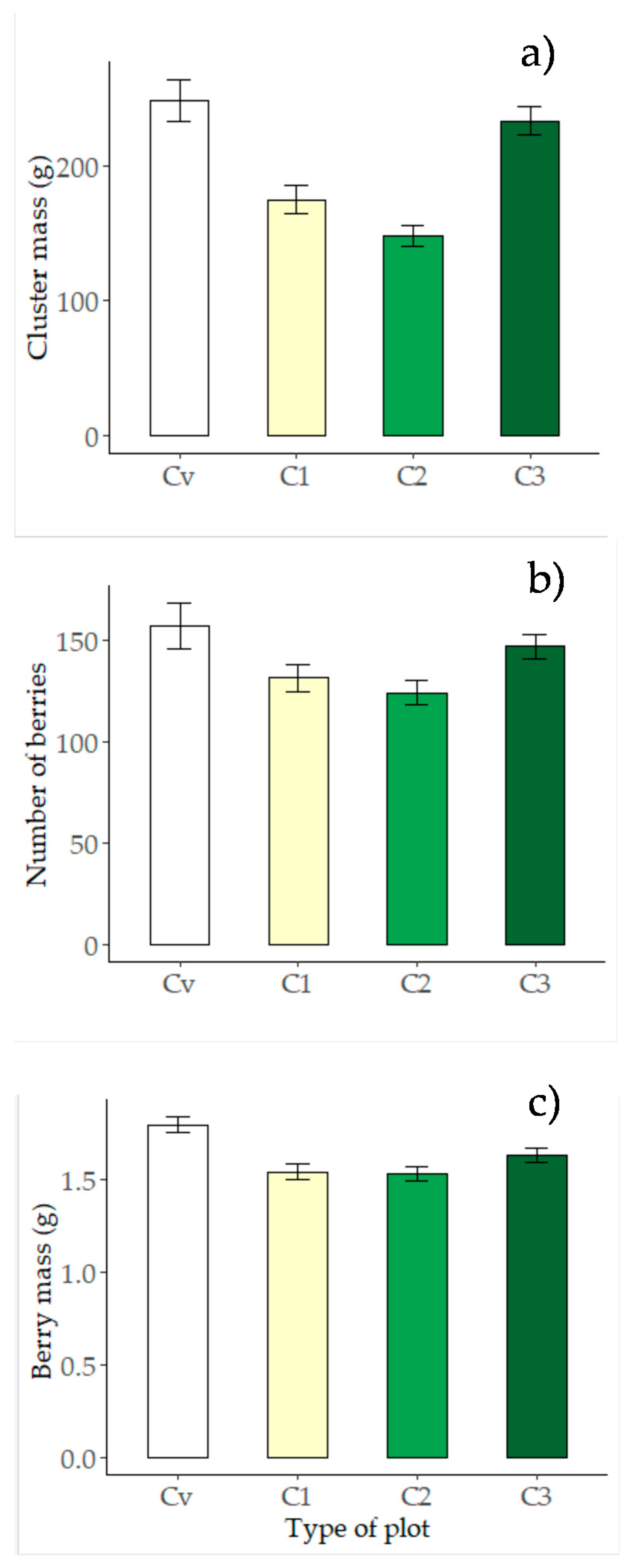

Cluster mass: At harvest, we picked all of the 30 marked clusters in each plot and weighed them.

Number of mature berries per cluster and average berry mass: At harvest after weighing, we divided the 30 sampled clusters into two sample groups: One group for the 15 clusters coming from the 15 even-numbered vines and 15 from the 15 odd-numbered vines. We used one sample to evaluate grape moth populations [

14]. On the second sample, we separated the berries from the rachis. We counted the number of berries and weighed the whole set of berries. The average berry mass was calculated as the ratio between the total berry mass divided by the number of berries on each cluster.

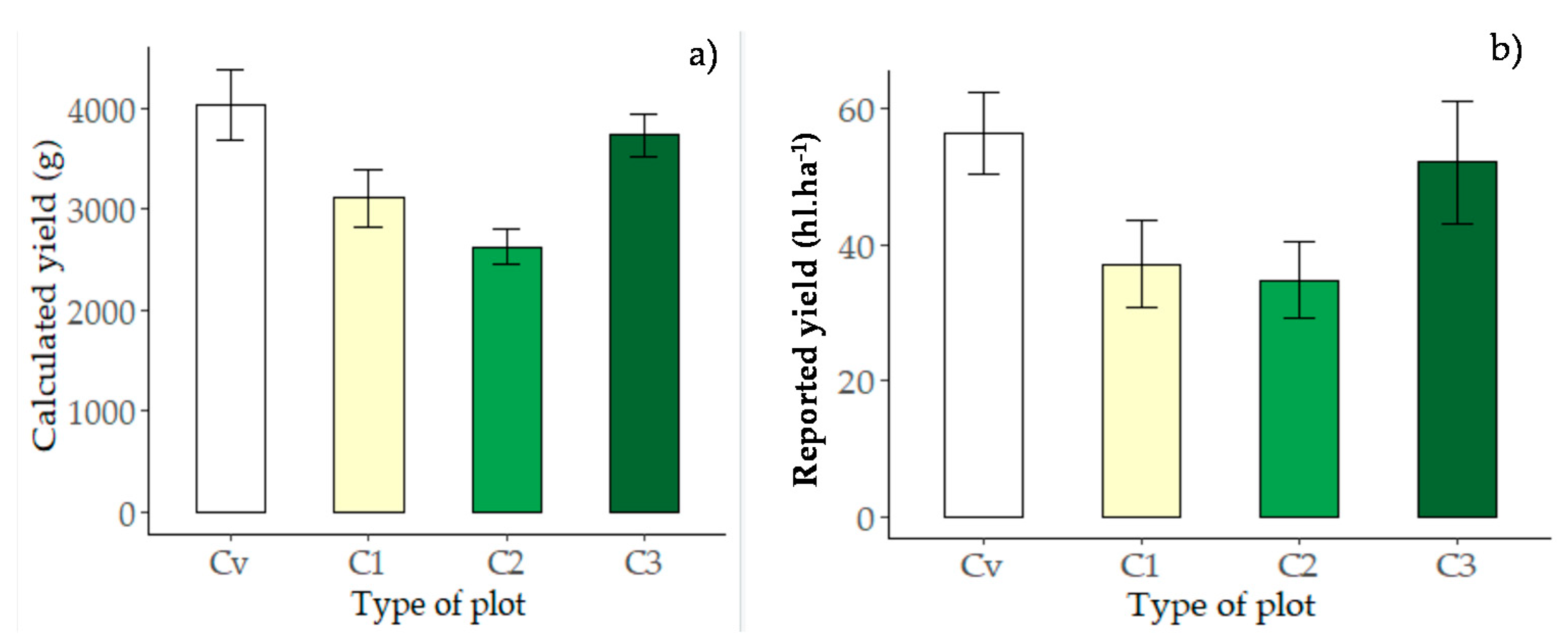

Yield Assessment

Calculated yield (kg.plant−1): We calculated the yield on each vine by multiplying the number of inflorescences per vine, as a proxy for the number of clusters per plant, by the cluster mass to obtain an estimate of the mass of clusters per vine.

Reported yield (hl.ha−1): At harvest, we collected information on the real quantitative production the growers obtained from their plots; we named it the reported yield. Since these grapes are used for wine production, the growers often measure their yield as a volume of grape juice (in liters or hl) instead of a mass of berries (in kg).

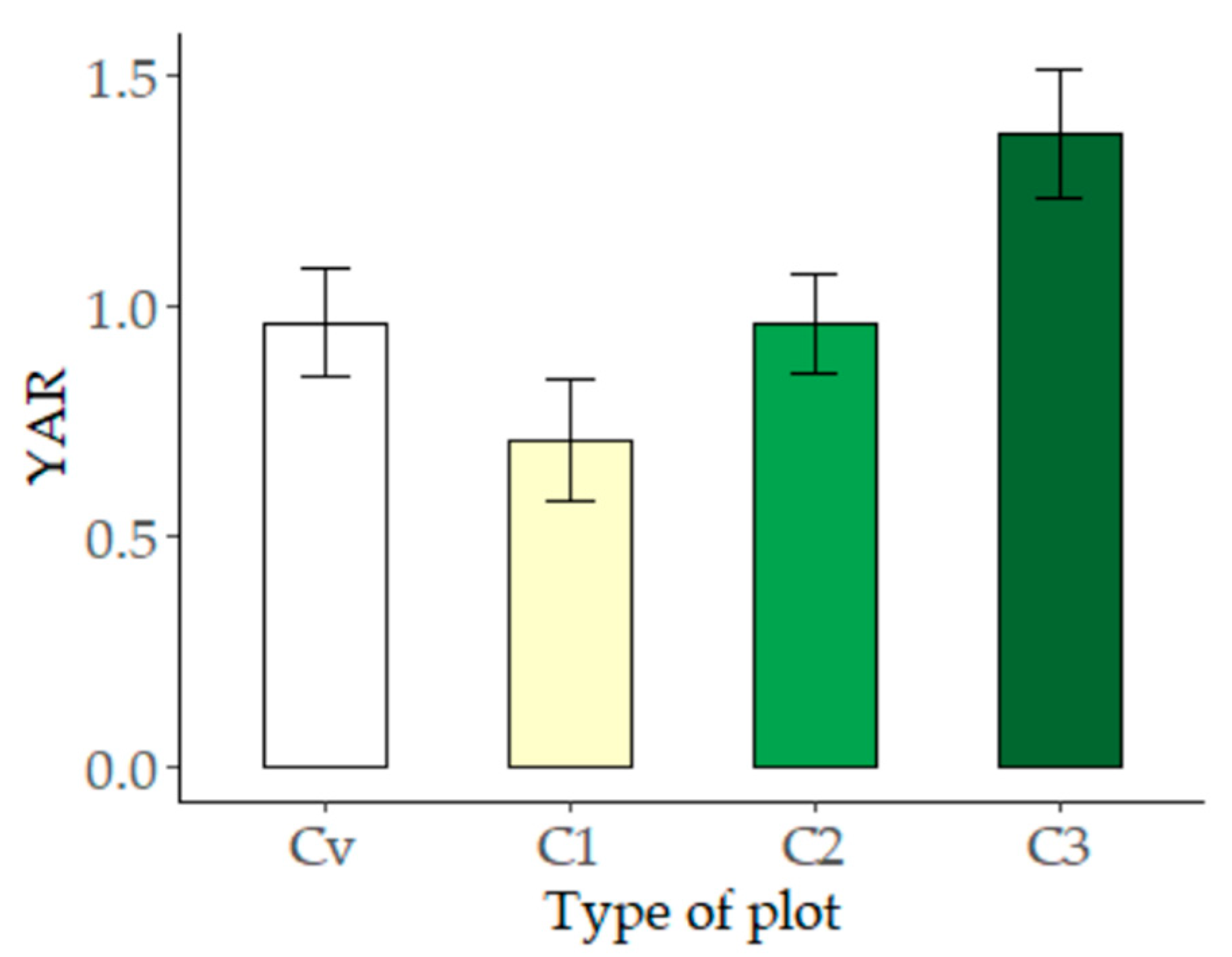

Target yield (hl.ha−1): In each monitored vineyard, we asked growers to report the yield they expected to obtain from their plots, which we called the target yield. This figure represents the quantitative production per hectare planned at the beginning of the season according to the economical context of the farm.

Yield achievement ratio: For each year and each vineyard, we calculated the yield achievement ratio initially targeted by the growers as follows Equation (4):

The yield achievement value YAR is expressed as a percentage that may be greater than 100% when the harvested yield exceeds the initial yield value targeted by the grower.

To summarize, we collected 720 to 1440 pieces of data (15 and 30 clusters sampled, respectively) to assess the impact of the conversion on yield components and 48 pieces of data to assess the yield dynamics.

2.3. Statistical Analysis

We used statistical analysis to study the effect of the conversion process to organic farming, characterized by the three years of conversion (C1, C2 and C3) compared to the conventional system (Cv), on the yield and yield component variables. We used generalized linear mixed models (GLMMs) to integrate both random effects and fixed effects [

17,

18]. We used R software version 3.5.0 [

19] for the analysis. For each variable (X), we assessed three candidate models for the GLMMS. The variable “type of plot,” indicated for the process of conversion to organic farming, was integrated in the model as a fixed effect (C). The “year” (Y) and the “plot” (P) were introduced as random effects in two models to take into consideration climatic inter-annual variations and individual particularities of the technical management, respectively. In particular, plot effect was used to take into account the various target yields in the whole network.

We hypothesized a Gaussian distribution in the GLMMs (function lme of R package nlme [

18,

20].

We used the Akaike information criterion (AIC) to select the best model for each variable [

21,

22], then used ANOVA on each variable to test the significance of the conversion process effect. Following the method proposed in [

14] and only when significant differences were found, we performed a multiple comparison Tukey’s test among the different “types of plot” on the model outputs to analyze the effect of the conversion in greater detail (R package multicomp [

23]). A classical 0.05 level of significance was considered.

4. Discussion

In this study, we analyzed the effect of the conversion to organic farming on the yield and its components. We used the detailed yield breakdown (yield potential elaboration year n − 1 and yield achievement year n, from inflorescences and flowers to clusters and berries) to thoroughly analyze the yield elaboration. Our main conclusion was that in the third year of conversion, yield reached a level similar to that observed in conventional farming. However, we observed a transitional decrease of productivity during the first and second years of the conversion process.

The yield ratio dynamics can be explained by both the cluster number and the cluster mass. The number of inflorescences, which is a proxy for the cluster number in this study, followed the same pattern as the yield. The impact of the conversion on this variable was mainly observed in C2. This can be explained by the fact that the change in practices implemented to shift from conventional to organic farming (as described, for example, in Merot et al.) [

11] impacted the inflorescence differentiation and initiation as early as the first year of the conversion process, but that its effect was measured only in C2. This is due to the two-year yield elaboration process: Inflorescence differentiation and initiation occurs the first year, and the consequences of its alteration are not noticed until the following year. The number of inflorescences in C3 was at the same level as in conventional farming, indicating that conversion to organic farming did not impact the inflorescence differentiation and initiation during the second year of conversion.

In addition to the number of clusters, the cluster mass evolution during conversion to organic farming can also explain the transitional decrease of the yield ratio. We found that the cluster mass followed the same dynamics as the yield ratio with a decrease in the first two years of the conversion, and the lowest cluster mass value occurred in C2. The cluster mass can be broken down into two components: The average berry mass and the number of berries per cluster at harvest. The detailed analysis of the average berry mass showed a particularly marked impact from the conversion process in C2. The decrease began in C1 but was not significant in the first year of conversion. This pattern can explain the high decrease in the cluster mass in C2 and the transitional decrease in both calculated yield and the yield ratio. Contrary to the average berry mass, we did not find any significant impact of the conversion to organic farming on the number of berries per cluster at harvest. However, we did see a trend: The number of berries per cluster followed a pattern with a transitional decrease in the first two years of the conversion to organic farming and a C3 level comparable to that observed in conventional farming. This pattern was also observed earlier in the season just after fruit set and even earlier at flowering. Indeed, the conversion to organic farming impacted the number of green berries per cluster and the number of flowers per inflorescence, and significantly so for the green berries. We also observed a loss of green berries and flowers per cluster during the first year of the conversion. This result showed that the conversion process mostly impacts flower development in C1 but not flower differentiation and initiation in C1 (corresponding to clusters harvested in C2), even if the number of mature berries per cluster in C2 was still lower on average than in Cv and C3.

The impact of conversion to organic farming on yield elaboration processes—mostly on inflorescences and flower initiation and differentiation—was high the first year of conversion with a limitation of the yield potential for the C2 harvest, with visible consequences in C2. Factors that explain this outcome include nitrogen and water stresses that may have limited inflorescence and flower initiation and differentiation the first year of yield elaboration around fruit set [

13,

24]. In fact, fruit set is a key stage for the development of the following year’s inflorescences [

13]. Moreover, it is also a critical period in terms of work organization in organic vineyards, with a high number of interventions being required for manual bud pruning, treatments against powdery and downy mildew and soil management, including weed management and mechanical tillage. All these interventions are more time consuming for organic than conventional farming [

11,

25] and poor management can result if winegrowers do not budget their time well. Since improper manual bud pruning can cause excessive vegetative vigor, it can in turn increase water and nitrogen needs. Furthermore, an excess of weeds or intercropping [

26], if mown or destroyed too late, may lead to increased competition for water and nitrogen. Fertilizer changes can also explain nitrogen and water stresses during the first year of conversion. In fact, some winegrowers shifted from mineral fertilizer to organic fertilizer depending on the mineralization process [

11]. Organic fertilizers must be applied differently than mineral fertilizers. The period of application is earlier in the season and can even be as early as the previous autumn, whereas in conventional farming fertilizer is generally applied at the beginning of spring. Nitrogen availability for the plant may be delayed the first year of conversion. Moreover, conversion to organic farming also involves introducing additional mechanical soil management, from bud burst to cluster closure. Advisers and winegrowers usually say that this change can cut the vine roots, which means that the volume of soil explored by the roots may be limited with a higher risk of nitrogen and water stresses.

We also observed that the berry and cluster development were impacted by the conversion process. Berry and cluster development are sensitive to nitrogen and water deficit after fruit set. The changes implemented during the conversion to organic farming mentioned previously can also limit cluster and berry development during the harvesting year. Clusters and berries are also exposed to pest and disease pressures. These cause, both direct and indirect, yield loss and reduce several of the yield components, therefore limiting yield. In French vineyards, powdery and downy mildews develop from flowering to harvest. They may cause severe to total loss in grapevine production [

8,

27]. Grape moths are a major pest in vineyards: They cause the direct loss of some berries from flowering to harvest [

28], while their boreholes in the berries also allow Botrytis infections with numerous qualitative and quantitative consequences [

29]. When converting to organic farming, growers are required to stop using all synthetic plant protection products. Yet synthetic products are systemic and less leachable than the products allowed in organic farming. Consequently, products must be applied more frequently and there is a higher risk of failing to control pests and diseases. [

14] showed that pest and disease incidences followed the same pattern as that observed on yield and yield components, with a transitional period in C1 and C2. Thus, we can put forward the hypothesis that pest and disease pressure severities could have been a major cause of yield losses in C1 and C2.