Benchmarking the Agronomic Performance of Biodegradable Mulches against Polyethylene Mulch Film: A Meta-Analysis

Abstract

:1. Introduction

2. Materials and Methods

Data Extraction and Analysis

3. Results and Discussion

3.1. Soil Moisture

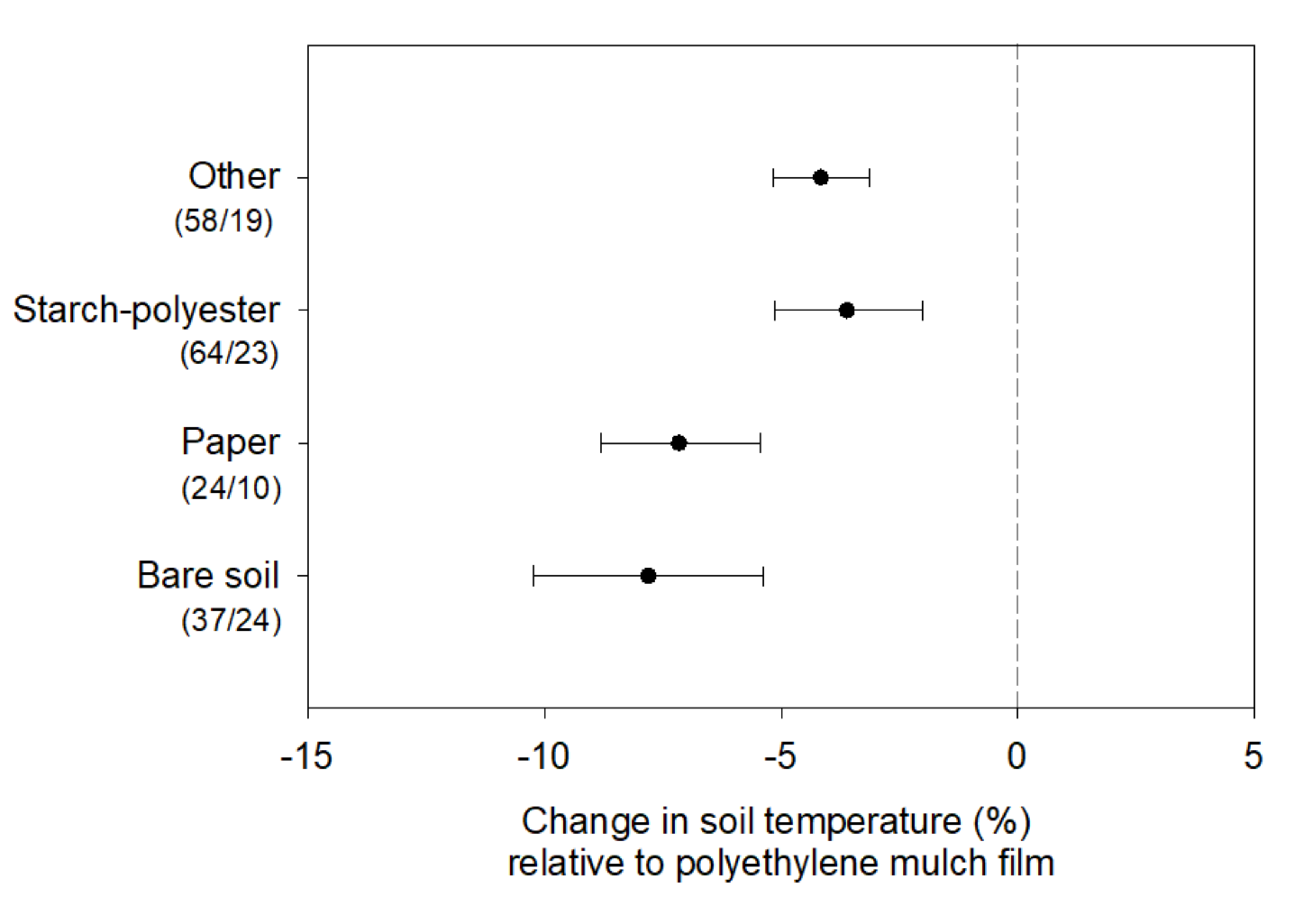

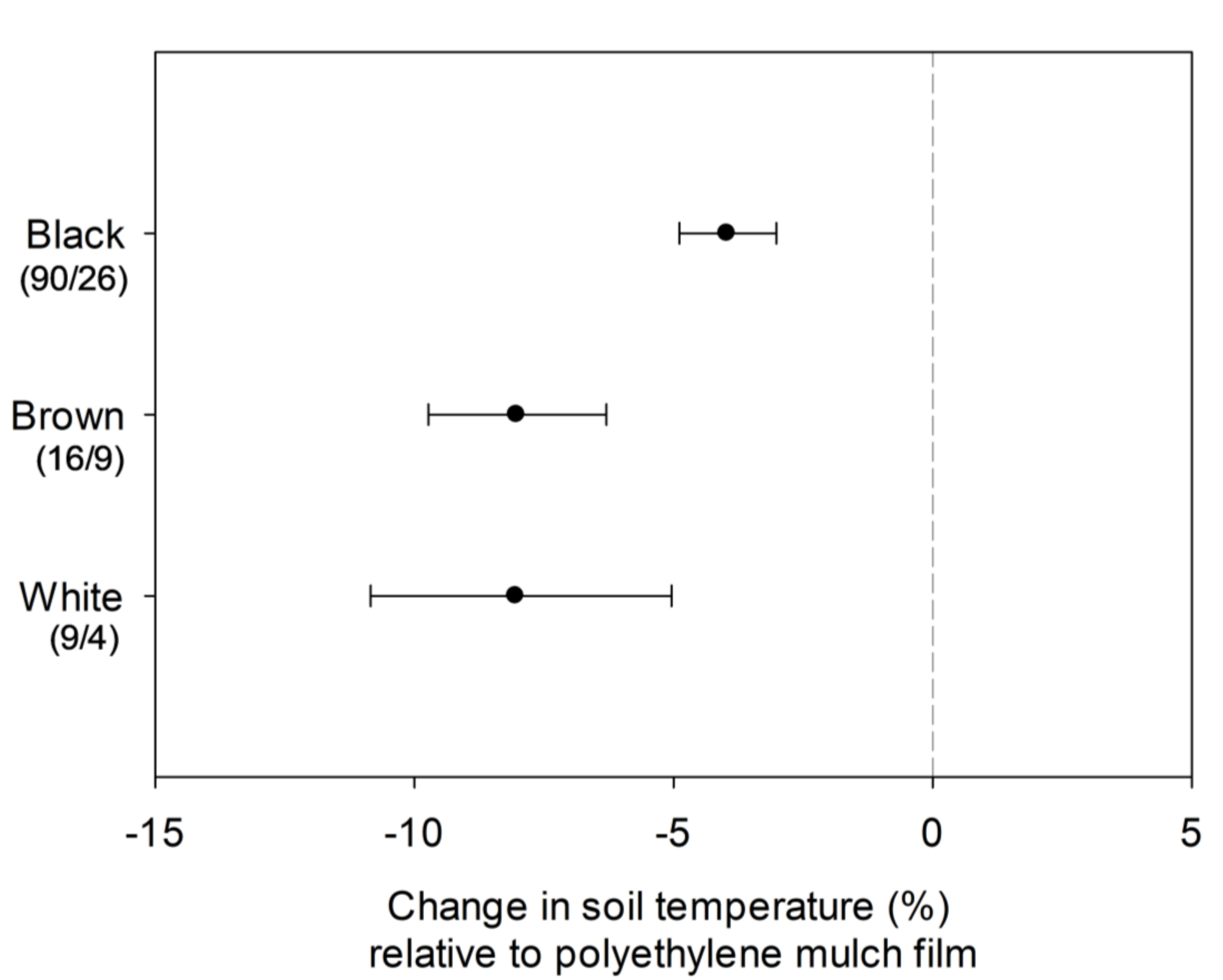

3.2. Soil Temperature

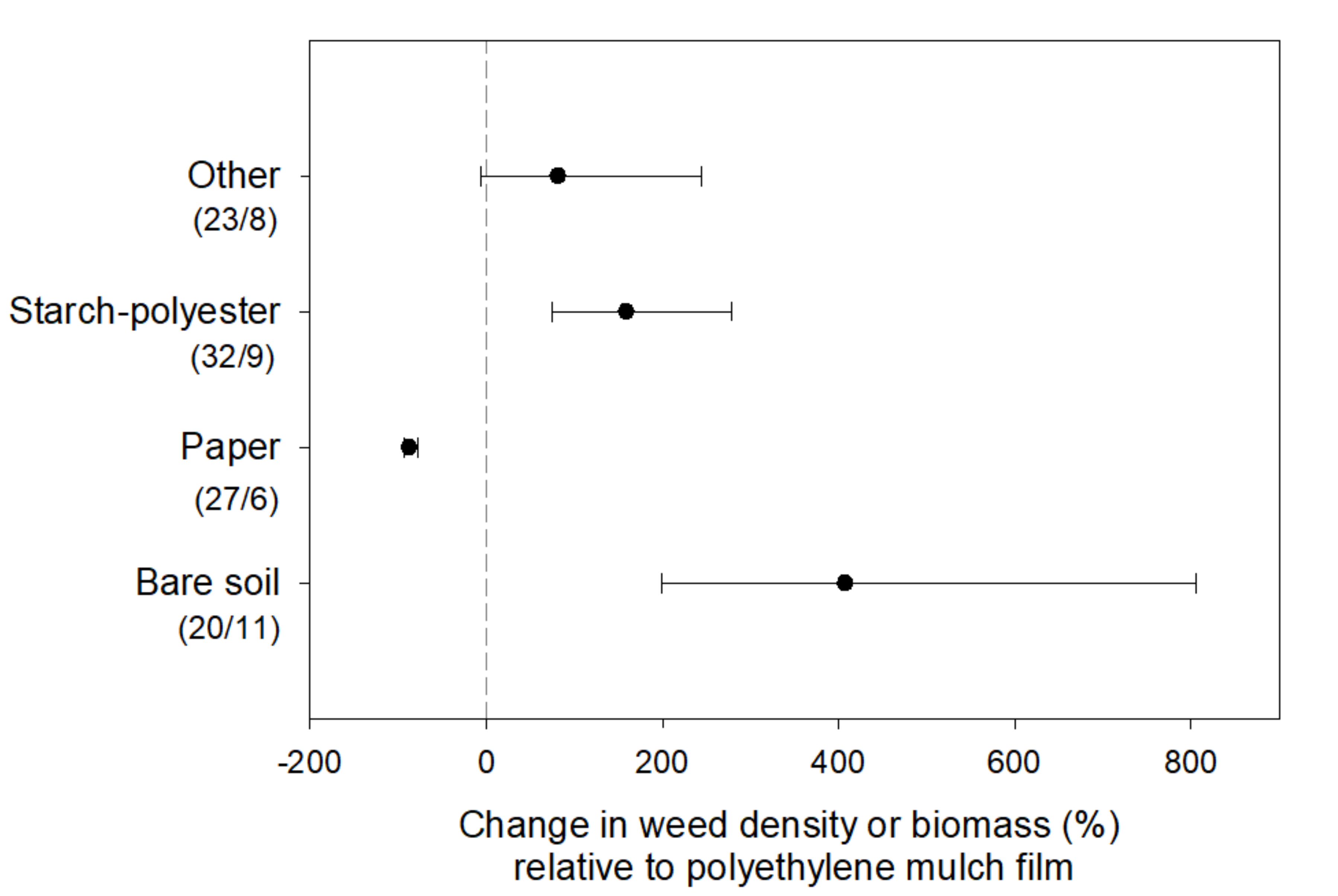

3.3. Weed Suppression

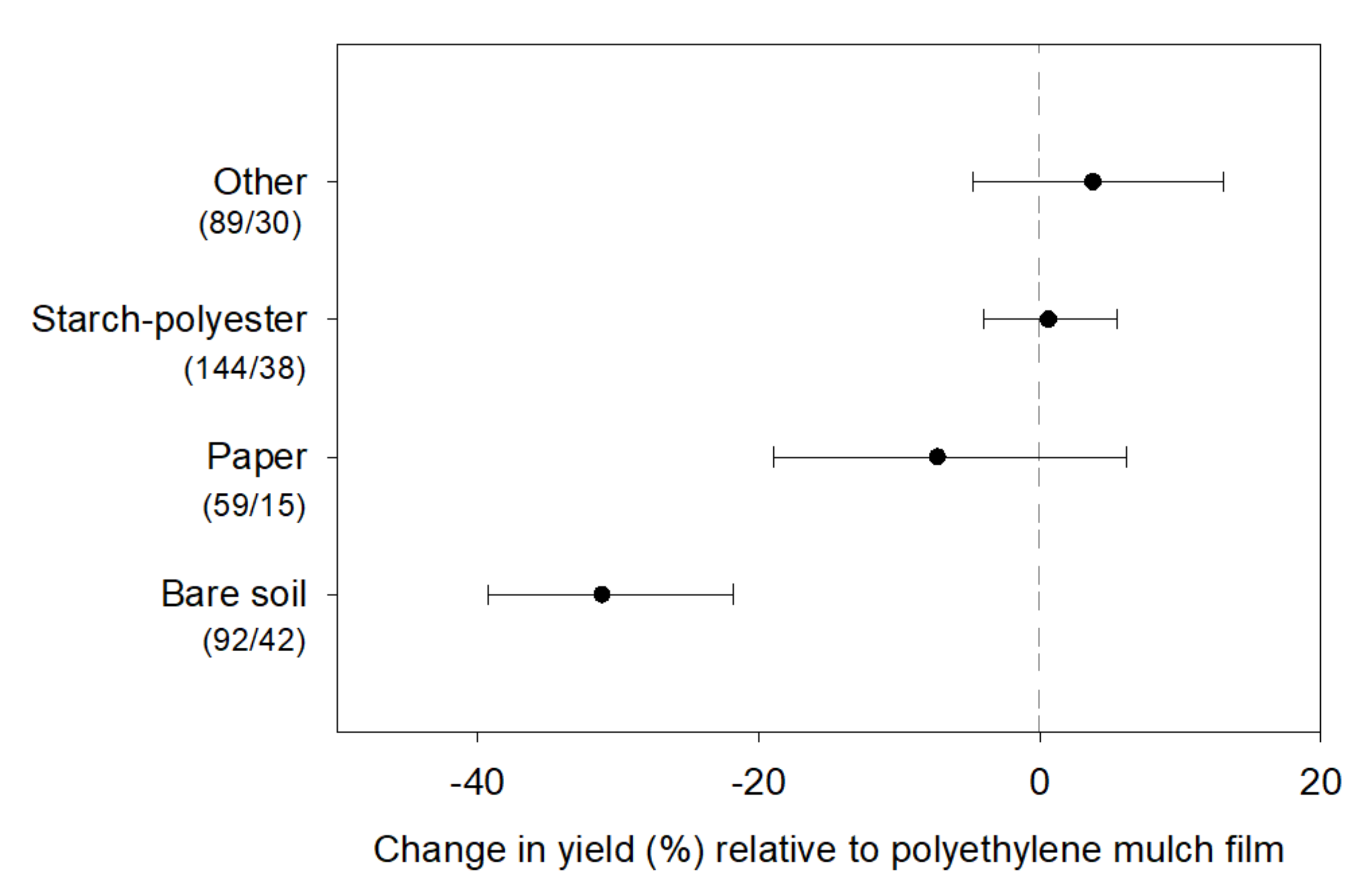

3.4. Crop Yield

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Bhattacharya, S.; Das, S.; Saha, T. Application of plasticulture in horticulture: A review. TPI Int. J. 2018, 7, 584–585. [Google Scholar]

- Job, M.; Bhakar, S.R.; Singh, P.K.; Tiwari, G.S.; Sharma, R.K.; Lakhawat, S.S.; Sharma, D. Evaluation of plastic mulch for changes in mechanical properties during onion cultivation. Int. J. Sci. Env. Tech. 2016, 5, 575–584. [Google Scholar]

- Siwek, P.; Domagala-Swiatkiewicz, I.; Bucki, P.; Puchalski, M. Biodegradable agroplastics in 21st century horticulture. Polimery 2019, 64, 480–486. [Google Scholar] [CrossRef]

- Anzalone, A.; Cirujeda, A.; Aibar, J.; Pardo, G.; Zaragoza, C. Effect of Biodegradable Mulch Materials on Weed Control in Processing Tomatoes. Weed Technol. 2010, 24, 369–377. [Google Scholar] [CrossRef]

- Wortman, S.E.; Kadoma, I.; Crandall, M.D. Biodegradable Plastic and Fabric Mulch Performance in Field and High Tunnel Cucumber Production. HortTechnology 2016, 26, 148–155. [Google Scholar] [CrossRef] [Green Version]

- Sintim, H.Y.; Flury, M. Is Biodegradable Plastic Mulch the Solution to Agriculture’s Plastic Problem? Environ. Sci. Technol. 2017, 51, 1068–1069. [Google Scholar] [CrossRef]

- Kasirajan, S.; Ngouajio, M. Polyethylene and biodegradable mulches for agricultural applications: A review. Agron. Sustain. Dev. 2012, 32, 501–529. [Google Scholar] [CrossRef]

- Lament, W.J. Plastic Mulches for the Production of Vegetable Crops. HortTechnology 1993, 3, 35–39. [Google Scholar] [CrossRef] [Green Version]

- Miles, C.A.; Devetter, L.; Ghimire, S.; Hayes, D.G. Suitability of Biodegradable Plastic Mulches for Organic and Sustainable Agricultural Production Systems. HortScience 2017, 52, 10–15. [Google Scholar] [CrossRef]

- Virtanen, S.; Chowreddy, R.R.; Irmak, S.; Honkapää, K.; Isom, L. Food Industry Co-streams: Potential Raw Materials for Biodegradable Mulch Film Applications. J. Polym. Environ. 2016, 25, 1110–1130. [Google Scholar] [CrossRef]

- Hou, L.; Xi, J.; Chen, X.; Li, X.; Ma, W.; Lu, J.; Xu, J.; Lin, Y. Biodegradability and ecological impacts of polyethylene-based mulching film at agricultural environment. J. Hazard. Mater. 2019, 378, 120774. [Google Scholar] [CrossRef]

- Goldberger, J.R.; Jones, R.E.; Miles, C.A.; Wallace, R.W.; Inglis, D.A. Barriers and bridges to the adoption of biodegradable plastic mulches for US specialty crop production. Renew. Agric. Food Syst. 2013, 30, 143–153. [Google Scholar] [CrossRef] [Green Version]

- ASTM D5988-18. Standard Test. Method for Determining Aerobic Biodegradation of Plastic Materials in Soil; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ISO 17556. Plastics–Determination of the Ultimate Aerobic Biodegradability of Plastic Materials in Soil by Measuring the Oxygen Demand in a Respirometer or the Amount of Carbon Dioxide Evolved; International Organization for Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- Thompson, A.A.; Samuelson, M.B.; Kadoma, I.; Soto-Cantu, E.; Drijber, R.; Wortman, S.E. Degradation Rate of Bio-based Agricultural Mulch is Influenced by Mulch Composition and Biostimulant Application. J. Polym. Environ. 2019, 27, 498–509. [Google Scholar] [CrossRef]

- Dentzman, K.; Goldberger, J.R. Plastic scraps: Biodegradable mulch films and the aesthetics of ‘good farming’ in US specialty crop production. Agric. Hum. Values 2019, 37, 83–96. [Google Scholar] [CrossRef]

- Eriksen, M.; Lebreton, L.C.M.; Carson, H.S.; Thiel, M.; Moore, C.J.; Borerro, J.C.; Galgani, F.; Ryan, P.G.; Reisser, J. Plastic Pollution in the World’s Oceans: More than 5 Trillion Plastic Pieces Weighing over 250,000 Tons Afloat at Sea. PLoS ONE 2014, 9, e111913. [Google Scholar] [CrossRef] [Green Version]

- Wortman, S.E.; Kadoma, I.; Crandall, M.D. Assessing the potential for spunbond, nonwoven biodegradable fabric as mulches for tomato and bell pepper crops. Sci. Hortic. 2015, 193, 209–217. [Google Scholar] [CrossRef]

- Briassoulis, D. An Overview on the Mechanical Behaviour of Biodegradable Agricultural Films. J. Polym. Environ. 2004, 12, 65–81. [Google Scholar] [CrossRef]

- Ghimire, S.; Wszelaki, A.L.; Moore, J.C.; Inglis, D.A.; Miles, C. The Use of Biodegradable Mulches in Pie Pumpkin Crop Production in Two Diverse Climates. HortScience 2018, 53, 288–294. [Google Scholar] [CrossRef] [Green Version]

- Haapala, T.; Palonen, P.; Korpela, A.; Ahokas, J. Feasibility of paper mulches in crop production—A review. Agric. Food Sci. 2014, 23, 60–79. [Google Scholar] [CrossRef] [Green Version]

- Kader, M.; Senge, M.; Mojid, M.; Ito, K. Recent advances in mulching materials and methods for modifying soil environment. Soil Tillage Res. 2017, 168, 155–166. [Google Scholar] [CrossRef]

- Gao, H.; Yan, C.; Liu, Q.; Ding, W.; Chen, B.; Li, Z. Effects of plastic mulching and plastic residue on agricultural production: A meta-analysis. Sci. Total. Environ. 2019, 651, 484–492. [Google Scholar] [CrossRef] [PubMed]

- Hedges, L.V.; Gurevitch, J.; Curtis, P.S. The Meta-Analysis of Response Ratios in Experimental Ecology. Ecology 1999, 80, 1150–1156. [Google Scholar] [CrossRef]

- Adams, D.C.; Gurevitch, J.; Rosenberg, M.S. Resampling Tests for Meta-Analysis of Ecological Data. Ecology 1997, 78, 1277–1283. [Google Scholar] [CrossRef]

- Borenstein, M.; Hedges, H.V.; Higgins, J.P.T.; Rothstein, H.R. Meta-regression. In Introduction to Meta-Analysis; John Wiley and Sons: Chichester, UK, 2009; pp. 187–203. [Google Scholar]

- Viechtbauer, W. Conducting Meta-Analyses in R with the meta for Package. J. Stat. Softw. 2010, 36, 1–48. [Google Scholar] [CrossRef] [Green Version]

- Philibert, A.; Loyce, C.; Makowski, D. Assessment of the quality of meta-analysis in agronomy. Agric. Ecosyst. Environ. 2012, 148, 72–82. [Google Scholar] [CrossRef]

- Nakagawa, S.; Santos, E.S.A. Methodological issues and advances in biological meta-analysis. Evol. Ecol. 2012, 26, 1253–1274. [Google Scholar] [CrossRef]

- Wortman, S.E.; Holmes, A.A.; Miernicki, E.; Knoche, K.; Pittelkow, C.M. First-Season Crop Yield Response to Organic Soil Amendments: A Meta-Analysis. Agron. J. 2017, 109, 1210–1217. [Google Scholar] [CrossRef] [Green Version]

- Costa, R.; Saraiva, A.; Carvalho, L.; Duarte, E. The use of biodegradable mulch films on strawberry crop in Portugal. Sci. Hortic. 2014, 173, 65–70. [Google Scholar] [CrossRef]

- Fortes Neto, P.; Souza, G.; Fortes, N.; Saraiva, A.; Costa, R.; Duarte, E. The role of mulching materials on Lactuca sativa production—Brazil case study. Acta Hortic 2016, 1242, 139–146. [Google Scholar] [CrossRef]

- Han, J.; Jia, Z.-K.; Han, Q.-F.; Zhang, J. Application of Mulching Materials of Rainfall Harvesting System for Improving Soil Water and Corn Growth in Northwest of China. J. Integr. Agric. 2013, 12, 1712–1721. [Google Scholar] [CrossRef] [Green Version]

- Li, R.; Hou, X.; Jia, Z.; Han, Q.; Yang, B. Effects of rainfall harvesting and mulching technologies on soil water, temperature, and maize yield in Loess Plateau region of China. Soil Res. 2012, 50, 105–113. [Google Scholar] [CrossRef]

- Li, R.; Hou, X.; Jia, Z.; Han, Q.; Ren, X.; Yang, B. Effects on soil temperature, moisture, and maize yield of cultivation with ridge and furrow mulching in the rainfed area of the Loess Plateau, China. Agric. Water Manag. 2013, 116, 101–109. [Google Scholar] [CrossRef]

- Li, R.; Hou, X.; Jia, Z.; Han, Q. Mulching materials improve soil properties and maize growth in the Northwestern Loess Plateau, China. Soil Res. 2016, 54, 708. [Google Scholar] [CrossRef]

- Nalayini, P.; Sankaranarayanan, K.; Velmourougane, K.; Suveetha, M. Biodegradable mulching for moisture conservation, weed control and enhanced productivity of winter irrigated cotton maize system. J. Cott. Res. Develop. 2017, 31, 205–212. [Google Scholar]

- Qi, W.; Xiang, R.; Xingyang, S.; Guangrong, H.; Enhe, Z.; Heling, W.; Vance, M.M. The optimum ridge–furrow ratio and suitable ridge-covering material in rainwater harvesting for oats production in semiarid regions of China. Field Crop. Res. 2015, 172, 106–118. [Google Scholar] [CrossRef]

- Saraiva, A.; Costa, R.; Carvalho, L.; Duarte, E. The use of biodegradable mulch films in muskmelon crop production. Basic Res. J. Agric. Sci. Rev. 2012, 1, 88–95. [Google Scholar]

- Wang, F.; Wang, Z.; Zhang, J.; Li, W. Combined Effect of Different Amounts of Irrigation and Mulch Films on Physiological Indexes and Yield of Drip-Irrigated Maize (Zea mays L.). Water 2019, 11, 472. [Google Scholar] [CrossRef] [Green Version]

- Moreno, M.M.; Moreno, A.; Mancebo, I. Comparison of different mulch materials in a tomato (Solanum lycopersicum L.) crop. Span. J. Agric. Res. 2009, 7, 454–464. [Google Scholar] [CrossRef] [Green Version]

- Waterer, D. Evaluation of biodegradable mulches for production of warm-season vegetable crops. Can. J. Plant. Sci. 2010, 90, 737–743. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Han, J.H.; Kim, G.N. Biodegradable Mulch Film Made of Starch-Coated Paper and Its Effectiveness on Temperature and Moisture Content of Soil. Commun. Soil Sci. Plant. Anal. 2008, 39, 1026–1040. [Google Scholar] [CrossRef]

- Moreno, M.; Moreno, A. Effect of different biodegradable and polyethylene mulches on soil properties and production in a tomato crop. Sci. Hortic. 2008, 116, 256–263. [Google Scholar] [CrossRef]

- Moore, J.C.; Wszelaki, A.L. The Use of Biodegradable Mulches in Pepper Production in the Southeastern United States. HortScience 2019, 54, 1031–1038. [Google Scholar] [CrossRef]

- Corbin, A.T.; Cowan, J.S.; Hayes, D.; Dorgan, J.R.; Inglis, D.; Miles, C.A. Using Biodegradable Plastics As Agricultural Mulches. Available online: http://vegetables.wsu.edu/MulchReport07.pdf (accessed on 10 September 2019).

- Cirujeda, A.; Aibar, J.; Anzalone, Á.; Martín-Closas, L.; Meco, R.; Moreno, M.M.; Pardo, A.; Pelacho, A.M.; Rojo, F.; Royo-Esnal, A.; et al. Biodegradable mulch instead of polyethylene for weed control of processing tomato production. Agron. Sustain. Dev. 2012, 32, 889–897. [Google Scholar] [CrossRef] [Green Version]

- Miles, C.A.; Wallace, R.; Wszelaki, A.; Martin, J.; Cowan, J.; Walters, T.; Inglis, D. Deterioration of Potentially Biodegradable Alternatives to Black Plastic Mulch in Three Tomato Production Regions. HortScience 2012, 47, 1270–1277. [Google Scholar] [CrossRef]

- Ngouajio, M.; Auras, R.; Fernandez, R.T.; Rubino, M.; Counts, J.W.; Kijchavengkul, T. Field Performance of Aliphatic-aromatic Copolyester Biodegradable Mulch Films in a Fresh Market Tomato Production System. HortTechnology 2008, 18, 605–610. [Google Scholar] [CrossRef]

- Jenni, S.; Brault, D.; Stewart, K. Degradable mulch as an alternative for weed control in lettuce produced on organic soils. Acta Hortic. 2004, 111–118. [Google Scholar] [CrossRef]

- Marí, A.I.; Pardo, G.; Cirujeda, A.; Martínez, Y. Economic Evaluation of Biodegradable Plastic Films and Paper Mulches Used in Open-Air Grown Pepper (Capsicum annum L.) Crop. Agronomy 2019, 9, 36. [Google Scholar] [CrossRef] [Green Version]

- Cirujeda, A.; Anzalone, A.; Aibar, J.; Moreno, M.M.; Zaragoza, C. Purple nutsedge (Cyperus rotundus L.) control with paper mulch in processing tomato. Crop. Prot. 2012, 39, 66–71. [Google Scholar] [CrossRef]

- Minuto, G.; Pisi, L.; Tinivella, F.; Bruzzone, C.; Guerrini, S.; Versari, M.; Pini, S.; Capurro, M. Weed control with biodegradable mulch in vegetable crops. Acta Hortic. 2008, 801, 291–298. [Google Scholar] [CrossRef]

- Díaz-Pérez, J.C.; Batal, K.D. Colored Plastic Film Mulches Affect Tomato Growth and Yield Via Changes in Root-zone Temperature. J. Am. Soc. Hortic. Sci. 2002, 127, 127–135. [Google Scholar] [CrossRef] [Green Version]

- Amador-Ramirez, M.D. Critical period of weed control in transplanted chilli pepper. Weed Res. 2002, 42, 203–209. [Google Scholar] [CrossRef]

- Cowan, J.S.; Inglis, D.A.; Miles, C.A. Deterioration of Three Potentially Biodegradable Plastic Mulches Before and After Soil Incorporation in a Broccoli Field Production System in Northwestern Washington. HortTechnology 2013, 23, 849–858. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tofanelli, M.B.D.; Wortman, S.E. Benchmarking the Agronomic Performance of Biodegradable Mulches against Polyethylene Mulch Film: A Meta-Analysis. Agronomy 2020, 10, 1618. https://doi.org/10.3390/agronomy10101618

Tofanelli MBD, Wortman SE. Benchmarking the Agronomic Performance of Biodegradable Mulches against Polyethylene Mulch Film: A Meta-Analysis. Agronomy. 2020; 10(10):1618. https://doi.org/10.3390/agronomy10101618

Chicago/Turabian StyleTofanelli, Mauro B. D., and Sam E. Wortman. 2020. "Benchmarking the Agronomic Performance of Biodegradable Mulches against Polyethylene Mulch Film: A Meta-Analysis" Agronomy 10, no. 10: 1618. https://doi.org/10.3390/agronomy10101618