Route Planning for Agricultural Machines with Multiple Depots: Manure Application Case Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Problem Definition

2.2. Mathematical Formulation

- Every path should start and end at the depot;

- Every track is covered exactly once;

- The total demand for any vehicle path should not exceed the capacity of the vehicle.

2.3. Methodology

2.3.1. Field Representation

- A path connects fieldwork tracks’ ends to adjacent fieldwork tracks’ ends (T2T);

- A path connecting each depot and to the first headland pass (D2H);

- A path connecting each headland pass to its adjacent headland pass (H2H);

- A path connecting fieldwork tracks ends at each headland pass (T2H).

2.3.2. Cost Matrix Generation

Simulated Annealing Algorithm

- Define the SA main parameters such as initial temperature = 200, temperature–damping rate = 0.9.

- SA main loop

- Generate initial solution

- Generate the initial solution based on the maximum capacity of the vehicle to determine when it is needed to go to the depot for refilling

- Calculate the cost of an initial solution by using the cost function that represents the total nonworking distances traveled by the vehicle

- Set the temperature (T) equal to the initial temperature (T0)

- Update the best solution ever found

- SA inner loop based on T

- Generate a neighborhood solution based on the initial solution

- Generate the neighborhood solution based on the maximum capacity of the vehicle

- Calculate the cost of neighborhood solution

- Compare the cost of the new solution with the initial solution

- If the new solution is convincing, then accept it as the best solution

- If the new solution is not convincing, then there is an opportunity to accept it by the condition based on T

- Update the best solution

- Reduce the T based on the damping rate (α).

Initial Solution Generation

- Each solution should be initiated and ended with a depot that can be the same or different.

- For simplicity, only one of each sibling arcs is presented in the solution.

- Based on the solution already constructed, if the remaining capacity of the agricultural machine is not sufficient to process the next track, then the nearest depot has to be selected for refilling service.

Solution Evaluation

Neighborhood Solution Generation

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, X.; Dietrich, J.P.; Lotze-Campen, H.; Biewald, A.; Stevanović, M.; Bodirsky, B.L.; Brümmer, B.; Popp, A. Beyond land-use intensity: Assessing future global crop productivity growth under different socioeconomic pathways. Technol. Forecast. Soc. Chang. 2020, 160, 120208. [Google Scholar] [CrossRef]

- Hamza, M.; Anderson, W. Soil compaction in cropping systems. Soil Tillage Res. 2005, 82, 121–145. [Google Scholar] [CrossRef]

- Edwards, G.T.; Hinge, J.; Skou-Nielsen, N.; Villa-Henriksen, A.; Sørensen, C.A.G.; Green, O. Route planning evaluation of a prototype optimised infield route planner for neutral material flow agricultural operations. Biosyst. Eng. 2017, 153, 149–157. [Google Scholar] [CrossRef]

- Sørensen, C.; Bochtis, D. Conceptual model of fleet management in agriculture. Biosyst. Eng. 2010, 105, 41–50. [Google Scholar] [CrossRef]

- Nilsson, R.S.; Zhou, K. Decision Support Tool for Operational Planning of Field Operations. Agronomy 2020, 10, 229. [Google Scholar] [CrossRef]

- Vahdanjoo, M.; Madsen, C.T.; Sørensen, C.G. Novel Route Planning System for Machinery Selection. Case: Slurry Application. AgriEngineering 2020, 2, 408–429. [Google Scholar] [CrossRef]

- Zhou, K.; Jensen, A.L.; Bochtis, D.; Nørremark, M.; Kateris, D.; Sørensen, C.G. Metric Map Generation for Autonomous Field Operations. Agronomy 2020, 10, 83. [Google Scholar] [CrossRef]

- Tsolakis, N.; Bechtsis, D.; Bochtis, D. AgROS: A Robot Operating System Based Emulation Tool for Agricultural Robotics. Agronomy 2019, 9, 403. [Google Scholar] [CrossRef]

- Zhou, K.; Jensen, A.L.; Sørensen, C.; Busato, P.; Bothtis, D. Agricultural operations planning in fields with multiple obstacle areas. Comput. Electron. Agric. 2014, 109, 12–22. [Google Scholar] [CrossRef]

- Hameed, I.; Bochtis, D.; Sørensen, C.; Nøremark, M. Automated generation of guidance lines for operational field planning. Biosyst. Eng. 2010, 107, 294–306. [Google Scholar] [CrossRef]

- Bochtis, D.; Vougioukas, S. Minimising the non-working distance travelled by machines operating in a headland field pattern. Biosyst. Eng. 2008, 101, 1–12. [Google Scholar] [CrossRef]

- Spekken, M.; De Bruin, S. Optimized routing on agricultural fields by minimizing maneuvering and servicing time. Precis. Agric. 2012, 14, 224–244. [Google Scholar] [CrossRef]

- Bochtis, D.D.; Sørensen, C.G.; Green, O. A DSS for planning of soil-sensitive field operations. Decis. Support Syst. 2012, 53, 66–75. [Google Scholar] [CrossRef]

- Augustin, K.; Kuhwald, M.; Brunotte, J.; Duttmann, R. Wheel Load and Wheel Pass Frequency as Indicators for Soil Compaction Risk: A Four-Year Analysis of Traffic Intensity at Field Scale. Geosciences 2020, 10, 292. [Google Scholar] [CrossRef]

- Pamosoaji, A.; Dewa, P.; Krisnanta, J. Proposed Modified Clarke-Wright Saving Algorithm for Capacitated Vehicle Routing Problem. Int. J. Ind. Eng. Eng. Manag. 2019, 1. [Google Scholar] [CrossRef]

- Gultom, P.; Napitupulu, N. The Development of Algorithm for Determining Optimal Route for Distribution of Goods Based on Distance, Time, And Road Quality Using Fuzzy Set and Clarke And Algorithm Wright Savings. J. Physics Conf. Ser. 2020, 1542. [Google Scholar] [CrossRef]

- Pahlavani, P.; Ghaderi, F. Multimodal multi-objective route planning using non-dominated sorting genetic algorithm-II and TOPSIS method. J. Geospat. Inf. Technol. 2017, 4, 123–142. [Google Scholar] [CrossRef][Green Version]

- Li, L.; Zhang, Y. Route Planning Based on Genetic Algorithm. J. Math. Res. 2018, 10, 122. [Google Scholar] [CrossRef][Green Version]

- Odziemczyk, W. Application of simulated annealing algorithm for 3D coordinate transformation problem solution. Open Geosci. 2020, 12, 491–502. [Google Scholar] [CrossRef]

- Deolia, V.K.; Sharma, A. Optimal Path Planning Approach for Unmanned Vehicles Using Modified Ant Colony Algorithm. JARDCS 2019, 11, 266–270. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Mahdavi, I.; Esfahani, M.M.S.; Weber, G.-W. A hybrid augmented ant colony optimization for the multi-trip capacitated arc routing problem under fuzzy demands for urban solid waste management. Waste Manag. Res. 2019, 38, 156–172. [Google Scholar] [CrossRef] [PubMed]

- Crevier, B.; Cordeau, J.-F.; Laporte, G. The multi-depot vehicle routing problem with inter-depot routes. Eur. J. Oper. Res. 2007, 176, 756–773. [Google Scholar] [CrossRef]

- Yalian, T. An Improved Ant Colony Optimization for Multi-Depot Vehicle Routing Problem. Int. J. Eng. Technol. 2016, 8, 385–388. [Google Scholar] [CrossRef][Green Version]

- Kunnapapdeelert, S.; Kachitvichyanukul, V. New enhanced differential evolution algorithms for solving multi-depot vehicle routing problem with multiple pickup and delivery requests. Int. J. Serv. Oper. Manag. 2018, 31, 370. [Google Scholar] [CrossRef]

- Stodola, P. Hybrid ant colony optimization algorithm applied to the multi-depot vehicle routing problem. Nat. Comput. 2020, 19, 463–475. [Google Scholar] [CrossRef]

- Samsuddin, S.; Shahizan Othman, M.; Mi Yusuf, L. Utilizing Ant Colony Optimization and Intelligent Water Drop for Solving Multi Depot Vehicle Routing Problem. IOP Conf. Ser. Mater. Sci. Eng. 2020, 864, 012095. [Google Scholar] [CrossRef]

- Bochtis, D.D.; Sørensen, C.G.; Busato, P.; Berruto, R. Benefits from optimal route planning based on B-patterns. Biosyst. Eng. 2013, 115, 389–395. [Google Scholar] [CrossRef]

- Moghadam, E.K.; Vahdanjoo, M.; Jensen, A.L.; Sharifi, M.; Sørensen, C.A.G. An Arable Field for Benchmarking of Metaheuristic Algorithms for Capacitated Coverage Path Planning Problems. Agronomy 2020, 10, 1454. [Google Scholar] [CrossRef]

- Conesa-Muñoz, J.; Bengochea-Guevara, J.M.; Andujar, D.; Ribeiro, A. Route planning for agricultural tasks: A general approach for fleets of autonomous vehicles in site-specific herbicide applications. Comput. Electron. Agric. 2016, 127, 204–220. [Google Scholar] [CrossRef]

- Orzech, K.; Załuski, D. Effect of soil compaction and different soil tillage systems on chemical properties of soil and presence of earthworms in winter oilseed rape fields. J. Elem. 2020. [Google Scholar] [CrossRef]

- De Neve, S.; Hofman, G. Influence of soil compaction on carbon and nitrogen mineralization of soil organic matter and crop residues. Biol. Fertil. Soils 2000, 30, 544–549. [Google Scholar] [CrossRef]

- Stark, J.C.; Thornton, M. Field Selection, Crop Rotations, and Soil Management. In Potato Production Systems; Springer Science and Business Media LLC: New York, NY, USA, 2020; pp. 87–100. [Google Scholar]

- Mirzavand, J.; Moradi-Talebbeigi, R. Relationships between field management, soil compaction, and crop productivity. Arch. Agron. Soil Sci. 2020, 2020, 1–12. [Google Scholar] [CrossRef]

- Saiz-Rubio, V.; Rovira-Más, F. From Smart Farming towards Agriculture 5.0: A Review on Crop Data Management. Agronomy 2020, 10, 207. [Google Scholar] [CrossRef]

- Hameed, I.A. Intelligent Coverage Path Planning for Agricultural Robots and Autonomous Machines on Three-Dimensional Terrain. J. Intell. Robot. Syst. 2013, 74, 965–983. [Google Scholar] [CrossRef]

- The Vehicle Routing Problem; Toth, P.; Vigo, D. Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 2002. [Google Scholar] [CrossRef]

- Sungur, I.; Ren, Y.; Ordóñez, F.; Dessouky, M.M.; Zhong, H. A Model and Algorithm for the Courier Delivery Problem with Uncertainty. Transp. Sci. 2010, 44, 193–205. [Google Scholar] [CrossRef]

| Random swaps | Random swaps of subsequences | |||||||||||||||||||||||||

| B * | 0 | 9 | 4 | 7 | 2 | 5 | 12 | 0 | 13 | 18 | 19 | 16 | 0 | 0 | 9 | 4 | 7 | 2 | 5 | 12 | 0 | 13 | 18 | 19 | 16 | 0 |

| A * | 0 | 9 | 4 | 7 | 2 | 5 | 12 | 0 | 18 | 13 | 19 | 16 | 0 | 0 | 5 | 12 | 2 | 9 | 4 | 7 | 0 | 13 | 18 | 19 | 16 | 0 |

| Random insertions | Random insertions of subsequences | |||||||||||||||||||||||||

| B | 0 | 9 | 4 | 7 | 2 | 5 | 12 | 0 | 13 | 18 | 19 | 16 | 0 | 0 | 9 | 4 | 7 | 2 | 5 | 12 | 0 | 13 | 18 | 19 | 16 | 0 |

| A | 0 | 9 | 4 | 5 | 7 | 2 | 12 | 0 | 13 | 18 | 19 | 16 | 0 | 0 | 9 | 2 | 5 | 12 | 4 | 7 | 0 | 13 | 18 | 19 | 16 | 0 |

| Reversing a subsequence | Random swaps of reversed subsequences | |||||||||||||||||||||||||

| B | 0 | 9 | 4 | 7 | 2 | 5 | 12 | 0 | 13 | 18 | 19 | 16 | 0 | 0 | 9 | 4 | 7 | 2 | 5 | 12 | 0 | 13 | 18 | 19 | 16 | 0 |

| A | 0 | 9 | 12 | 5 | 2 | 7 | 4 | 0 | 13 | 18 | 19 | 16 | 0 | 0 | 12 | 5 | 2 | 7 | 4 | 9 | 0 | 13 | 18 | 19 | 16 | 0 |

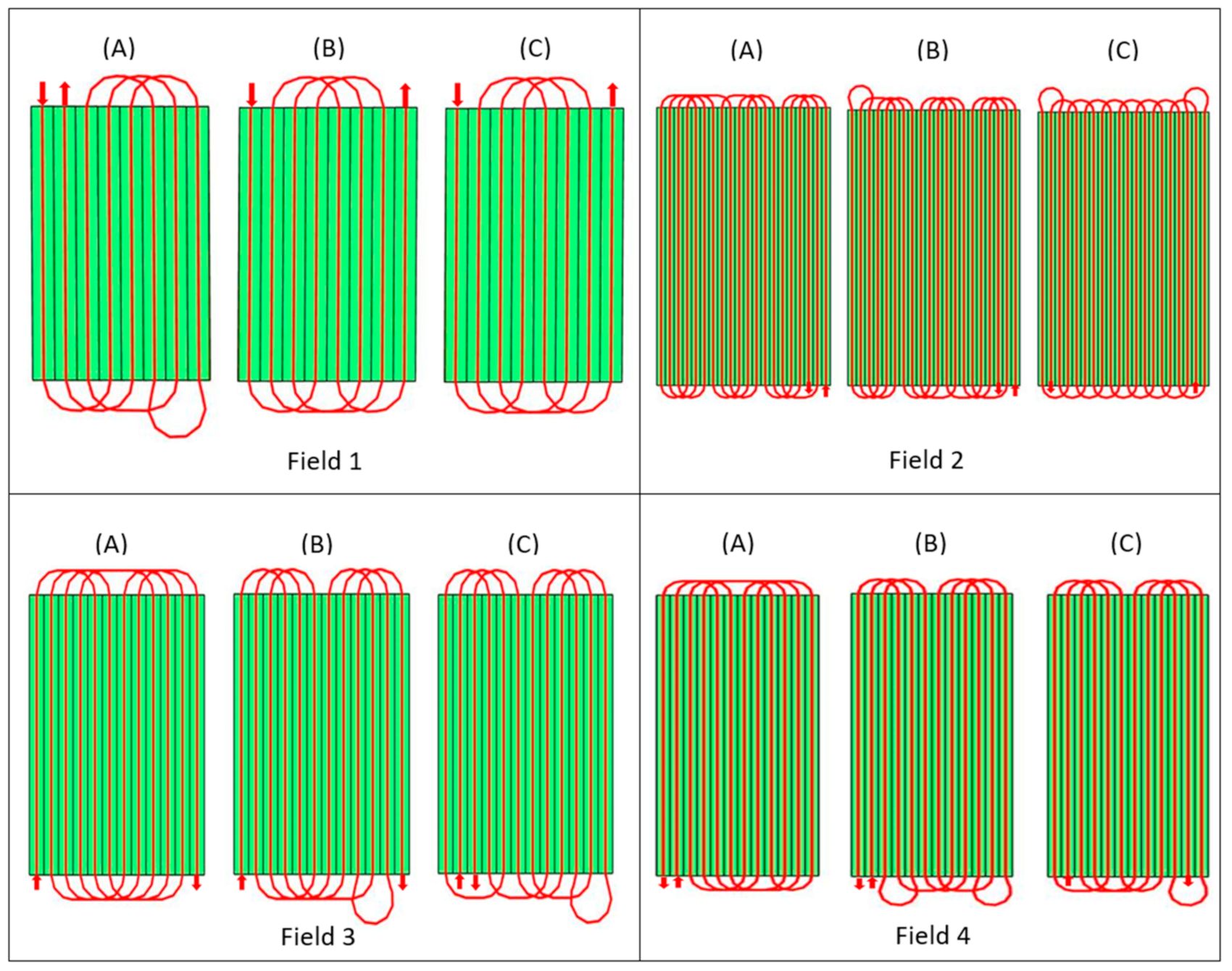

| Field | Field Size | Operating Width (m) | Minimum Turning Radius (m) |

|---|---|---|---|

| 1 | 24 m × 30 m | 2.89 | 3.5 |

| 2 | 50 m × 80 m | 2.5 | 3 |

| 3 | 30 m × 40 m | 2.5 | 3 |

| 4 | 30 m × 70 m | 2.5 | 3 |

| Proposed Approach by | Field | Solution (Track Order) | Headland Nonworking Distance (m) | Total Traversal Distance (m) |

|---|---|---|---|---|

| A ([11]) | 1 | <1,4,7,3,6,8,5,2> | 95.77 | 335.77 |

| 2 | <20,17,14,11,8,12,9,3,6,2,5,1,4,7,10,13,16,19,15,18> | 235.92 | 1835.92 | |

| 3 | <1,5,11,7,3,9,2,6,10,4,8,12> | 176.45 | 656.45 | |

| 4 | <2,6,10,4,8,12,9,3,7,11,5,1> | 166.45 | 1006.45 | |

| B ([29]) | 1 | <1,4,7,3,6,2,5,8> | 94.439 | 334.439 |

| 2 | <20,17,14,11,8,5,2,6,3,1,4,7,10,13,9,12,16,19,15,18> | 235.491 | 1835.491 | |

| 3 | <1,4,10,7,3,6,2,5,8,11,9,12> | 146.027 | 626.027 | |

| 4 | <2,5,3,6,9,12,10,7,11,8,4,1> | 145.602 | 985.602 | |

| C (This study) | 1 | <1,4,7,3,6,2,5,8> | 94.439 | 334.439 |

| 2 | <19,16,13,10,7,4,1,3,6,9,12,15,18,20,17,14,11,8,5,2> | 232.566 | 1832.566 | |

| 3 | <2,5,1,4,8,11,7,10,12,9,6,3> | 141.027 | 621.027 | |

| 4 | <2,5,1,4,7,10,12,9,6,3,8,11> | 141.027 | 981.027 |

| Properties | Latitude | Longitude |

|---|---|---|

| Sample field | 56°36′17.21″ N | 10°13′41.68″ E |

| Depot 1 | 56°36′4.6074″ N | 10°13′37.777″ E |

| Depot 2 | 56°36′11.0982″ N | 10°13′34.1601″ E |

| Depot 3 | 56°36′25.046″ N | 10°13′45.1398″ E |

| Technical Characteristics of the Distributor | Values |

|---|---|

| Capacity (m3) | 25 |

| Minimum turning radius (meter) | 9 |

| Operating width (meter) | 12 |

| Application rate (m3/ha) | 17 |

| Track Id | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Arcs | (1,2) | (3,4) | (5,6) | (7,8) | (9,10) | (11,12) | (13,14) | (15,16) | (17,18) |

| Demand | 12,157 | 12,205 | 12,252 | 12,300 | 12,348 | 12,395 | 12,443 | 12,491 | 12,538 |

| Track Id | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| Arcs | (19,20) | (21,22) | (23,24) | (25,26) | (27,28) | (29,30) | (31,32) | (33,34) | (35,36) |

| Demand | 12,583 | 9795 | 9186 | 9151 | 9116 | 9080 | 9045 | 9009 | 8974 |

| Track Id | 19 | 20 | 21 | 22 | 23 | 24 | 25 | ||

| Arcs | (37,38) | (39,40) | (41,42) | (43,44) | (45,46) | (47,48) | (49,50) | ||

| Demand | 8938 | 8646 | 8116 | 8038 | 7956 | 2047 | 629 |

| Scenario | Depot ID | Solution | Nonworking Distance (m) | Run Time (s) |

|---|---|---|---|---|

| 1 | (d1) | <d1, 22, 17, d1, 16, 11, d1, 32, 33, d1, 48, 49, 37, d1, 42, 46, 39, d1, 20, 23, d1, 30, 35, d1, 8, 3, d1, 10, 13, d1, 6, 1, d1, 28, 25, d1> | 5002.9 | 104 |

| 2 | (d2) | <d2, 40, 35, d2, 22, 13, d2, 44, 47, 49, d2, 8, 3, d2, 2, 5, d2, 42, 45, d2, 26, 31, d2, 34, 37, d2, 20, 23, d2, 30, 27, d2, 12, 15, d2, 18, 9, d2> | 5373 | 94 |

| 3 | (d3) | <d3, 9, 20, d3, 31, 36, d3, 21, 26, d3, 11, 16, d3, 13, 18, d3, 45, 50, 48, d3, 41, 38, d3, 1, 6, d3, 27, 24, d3, 3, 8, d3, 33, 30, d3, 39, 44, d3> | 3220.9 | 93 |

| 4 | (d1&d2) | <d1, 9, 2, d1, 5, 14, d1, 7, 16, d1, 17, 24, d2, 37, 32, d2, 27, 22, d2, 35, 30, d2, 49, 47, 44, d2, 45, 40, d2, 41, 34, d2, 25, 20, d1, 3, 12, d1> | 2978.4 | 130 |

| 5 | (d1&d3) | <d1, 1, 10, d1, 3, 12, d1, 7, 6, d1, 19, d3, 38, 29, d3, 18, 21, d3, 40, 41, d3, 24, 31, d3, 28, 25, d3, 36, 33, d3, 44, 49, 48, 45, d3, 14, 15, d3> | 2830 | 134 |

| 6 | (d2&d3) | <d2, 35, 30, d2, 37, 46, 43, d3, 22, 23, d3, 16,7, d3, 28, 25, d3, 12, 19, d3, 14, 5, d3, 18, 9, d3, 40, 47, 50, 41, d3, 2, 3, d3, 32, 33, d3 > | 2745.8 | 133 |

| 7 | (d1&d2&d3) | <d1, 9, 2, d1, 3, 12, d1, 7, 6, d1, 21, 30, d2, 37, 32, d2, 33, 42, d2, 35, 44, d2, 39, 46, 47, 50, d2, 27, 20, d1, 17, d3, 26, 23, d3, 14, 15, d3> | 2638.3 | 139 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vahdanjoo, M.; Zhou, K.; Sørensen, C.A.G. Route Planning for Agricultural Machines with Multiple Depots: Manure Application Case Study. Agronomy 2020, 10, 1608. https://doi.org/10.3390/agronomy10101608

Vahdanjoo M, Zhou K, Sørensen CAG. Route Planning for Agricultural Machines with Multiple Depots: Manure Application Case Study. Agronomy. 2020; 10(10):1608. https://doi.org/10.3390/agronomy10101608

Chicago/Turabian StyleVahdanjoo, Mahdi, Kun Zhou, and Claus Aage Grøn Sørensen. 2020. "Route Planning for Agricultural Machines with Multiple Depots: Manure Application Case Study" Agronomy 10, no. 10: 1608. https://doi.org/10.3390/agronomy10101608

APA StyleVahdanjoo, M., Zhou, K., & Sørensen, C. A. G. (2020). Route Planning for Agricultural Machines with Multiple Depots: Manure Application Case Study. Agronomy, 10(10), 1608. https://doi.org/10.3390/agronomy10101608