Herbicide Spray Deposition in Wheat Stubble as Affected by Nozzle Type and Application Direction

Abstract

:1. Introduction

2. Material and Methods

2.1. Field Set-Up

2.2. Experimental Design

2.3. Herbicide Spray Deposition Collection

2.4. Droplet Size Classification

2.5. Statistical Analysis

3. Results and Discussion

3.1. Spray Droplet Size

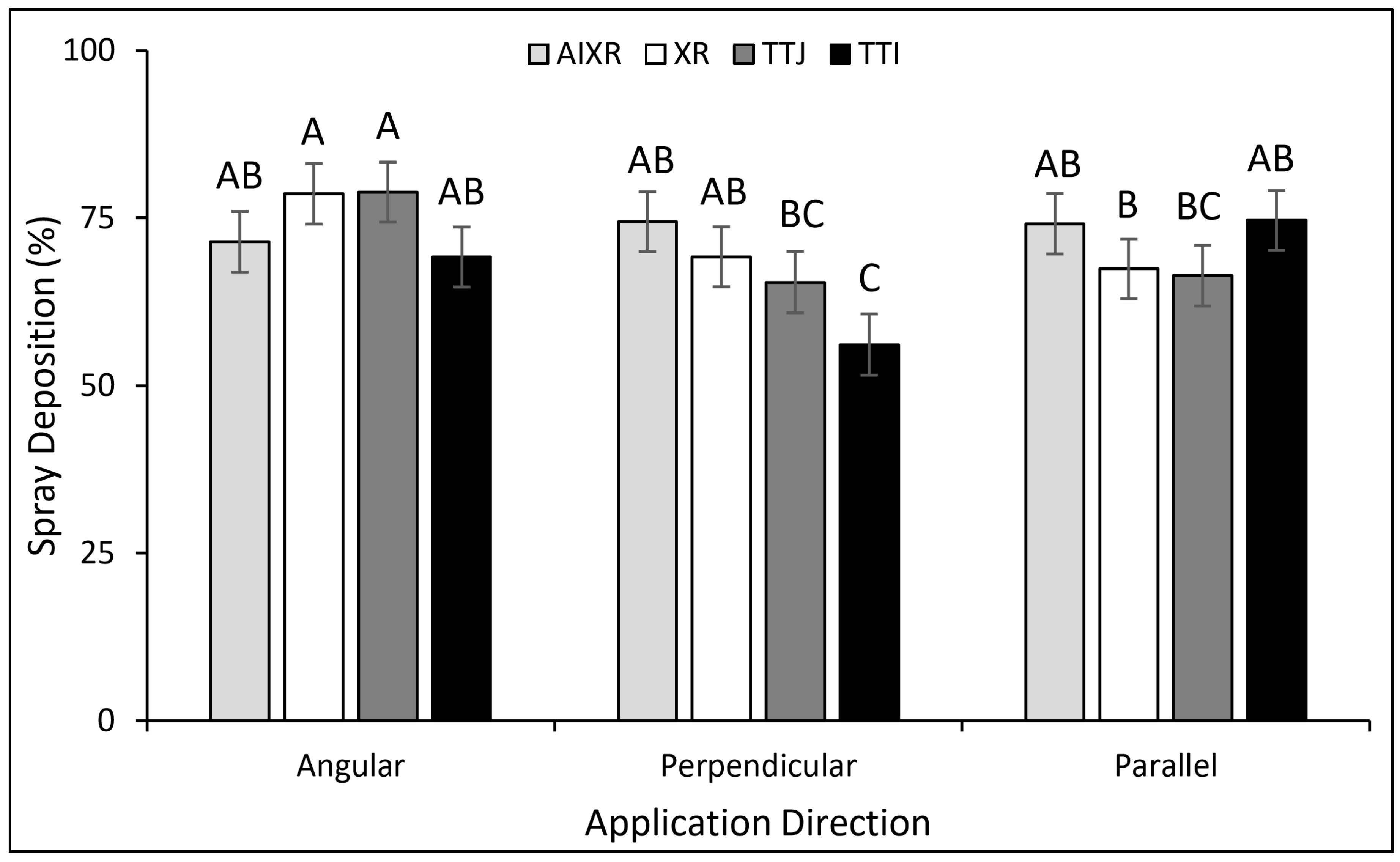

3.2. Nozzle Type and Application Direction Effects

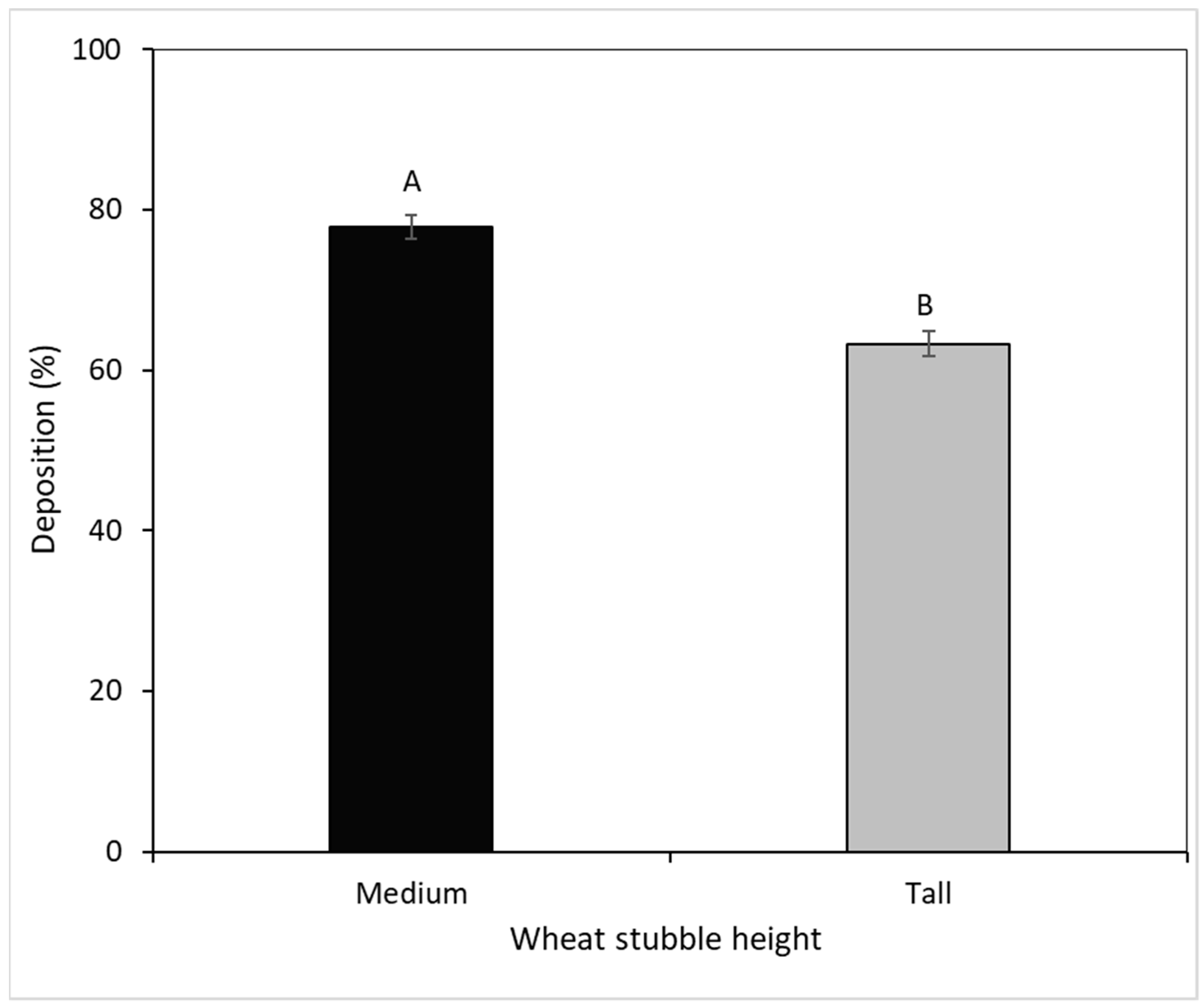

3.3. Wheat Stubble Height Effects

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rusinamhodzi, L.; Corbeels, M.; Van Wijk, M.T.; Rufino, M.C.; Justice Nyamangara, J.; Giller, K.E. A meta-analysis of long-term effects of conservation agriculture on maize grain yield under rain-fed conditions. Agron. Sustain. Dev. 2011, 31, 657. [Google Scholar] [CrossRef] [Green Version]

- Triplett, G.B., Jr.; Dick, W.A. No-tillage crop production: A revolution in agriculture! Agron. J. 2008, 100, S153–S165. [Google Scholar] [CrossRef]

- Unger, P.W.; Stewart, B.A.; Parr, J.F.; Singh, R.P. Crop residue management and tillage methods for conserving soil and water in semi-arid regions. Soil Tillage Res. 1991, 20, 219–240. [Google Scholar] [CrossRef]

- Unger, P.W. Infiltration of simulated rainfall: Tillage system and crop residue effects. Soil Sci. Soc. Am. J. 1992, 56, 283–289. [Google Scholar] [CrossRef]

- Nielsen, D.C.; Unger, P.W.; Miller, P.R. Efficient water use in dryland cropping systems in the Great Plains. Agron. J. 2005, 97, 364–372. [Google Scholar] [CrossRef] [Green Version]

- Schlegel, A.J.; Assefa, Y.; Haag, L.A.; Thompson, C.R.; Stone, L.R. Soil Water and Water Use in Long-Term Dryland Crop Rotations. Agron. J. 2019, 111, 2590–2599. [Google Scholar] [CrossRef] [Green Version]

- Sims, B.; Corsi, S.; Gbehounou, G.; Kienzle, J.; Taguchi, M.; Friedrich, T. Sustainable weed management for conservation agriculture: Options for smallholder farmers. Agriculture 2018, 8, 118. [Google Scholar] [CrossRef] [Green Version]

- Rosenzweig, S.T.; Schipanski, M.E. Landscape-scale cropping changes in the High Plains: Economic and environmental implications. Environ. Res. Lett. 2019, 14, 124088. [Google Scholar] [CrossRef]

- Hoefer, R.H.; Wicks, G.A.; Burnside, O.C. Grain Yields, Soil Water Storage, and Weed Growth in a Winter Wheat-Corn-Fallow Rotation 1. Agron. J. 1981, 73, 1066–1071. [Google Scholar] [CrossRef]

- Nordbo, E. Effects of nozzle size, travel speed and air assistance on deposition on artificial vertical and horizontal targets in laboratory experiments. Crop Prot. 1992, 11, 272–278. [Google Scholar] [CrossRef]

- Hoffmann, W.C.; Salyani, M. Spray deposition on citrus canopies under different meteorological conditions. Trans. ASAE 1996, 39, 17–22. [Google Scholar] [CrossRef]

- Foqué, D.; Nuyttens, D. Effects of nozzle type and spray angle on spray deposition in ivy pot plants. Pest Manag. Sci. 2011, 67, 199–208. [Google Scholar] [CrossRef] [PubMed]

- Creech Cody, F.; Henry, R.S.; Hewitt, A.J.; Kruger, G.R. Herbicide spray penetration into corn and soybean canopies using air-induction nozzles and a drift control adjuvant. Weed Technol. 2018, 32, 72–79. [Google Scholar] [CrossRef]

- Wolf, T.M.; Harrison, S.K.; Hall, F.R.; Cooper, J. Optimizing postemergence herbicide deposition and efficacy through application variables in no-till systems. Weed Sci. 2000, 48, 761–768. [Google Scholar] [CrossRef]

- Crutchfield, D.A.; Wicks, G.A.; Burnside, O.C. Effect of winter wheat (Triticum aestivum L.) straw mulch level on weed control. Weed Sci. 1986, 34, 110–114. [Google Scholar] [CrossRef]

- Ghadiri, H.; Shea, P.J.; Wicks, G.A. Interception and retention of atrazine by wheat (Triticum aestivum L.) stubble. Weed Sci. 1984, 32, 24–27. [Google Scholar] [CrossRef]

- Köppen, W. The warm zones of the earth, considered according to the duration of the hot, massed, and cold time and after the effect of the warm on the organic world. Meteorol. J. 1884, 1, 5–226. (In German) [Google Scholar]

- ASABE. Spray Nozzle Classification by Droplet Spectra; American Society of Agricultural Engineers: St. Joseph, MI, USA, 2009; pp. 1–3. [Google Scholar]

- Mueller, T.C.; Womac, A.R. Effect of formulation and nozzle type on droplet size with isopropylamine and trimesium salts of glyphosate. Weed Technol. 1997, 11, 639–643. [Google Scholar] [CrossRef]

- Creech Cody, F.; Henry, R.S.; Fritz, B.K.; Kruger, G.R. Influence of herbicide active ingredient, nozzle type, orifice size, spray pressure, and carrier volume rate on spray droplet size characteristics. Weed Technol. 2015, 29, 298–310. [Google Scholar] [CrossRef]

- Meyer, C.J.; Norsworthy, J.K.; Kruger, G.R.; Barber, T.L. Effect of nozzle selection and spray volume on droplet size and efficacy of Engenia tank-mix combinations. Weed Technol. 2016, 30, 377–390. [Google Scholar] [CrossRef]

- Etheridge, R.E.; Womac, A.R.; Mueller, T.C. Characterization of the spray droplet spectra and patterns of four venturi-type drift reduction nozzles. Weed Technol. 1999, 13, 765–770. [Google Scholar] [CrossRef]

- Anonymous. A User’s Guide to Spray Nozzles. Teejet Technol. 2013, 1, 1–60. [Google Scholar]

- Grisso, R.D.; Askew, S.; McCall, D.S. Nozzles: Selection and Sizing. 2019. Available online: https://www.pubs.ext.vt.edu/content/dam/pubs_ext_vt_edu/442/442-032/BSE-262.pdf (accessed on 28 January 2020).

- Richardson, R.G. Effect of Drop Trajectory on Spray Deposits on Crop and Weeds. Plant Prot. Q. 1987, 2, 108–111. [Google Scholar]

- Ferguson, J.C.; Chechetto, R.G.; Hewitt, A.J.; Chauhan, B.S.; Adkins, S.W.; Kruger, G.R.; O’Donnell, C.C. Assessing the deposition and canopy penetration of nozzles with different spray qualities in an oat (Avena sativa L.) canopy. Crop Prot. 2016, 81, 14–19. [Google Scholar] [CrossRef] [Green Version]

- Legleiter, T.R.; Johnson, W.G. Herbicide coverage in narrow row soybean as influenced by spray nozzle design and carrier volume. Crop Prot. 2016, 83, 1–8. [Google Scholar] [CrossRef]

- Zhu, H.; Dorner, J.W.; Rowland, D.L.; Derksen, R.C.; Ozkan, H.E. Spray penetration into peanut canopies with hydraulic nozzle tips. Biosyst. Eng. 2004, 87, 275–283. [Google Scholar] [CrossRef]

- Banks, P.A.; Robinson, E.L. The influence of straw mulch on the soil reception and persistence of metribuzin. Weed Sci. 1982, 30, 164–168. [Google Scholar] [CrossRef]

- Kim, D.S.; Marshall, E.J.P.; Brain, P.; Caseley, J.C. Effects of crop canopy structure on herbicide deposition and performance. Weed Res. 2011, 51, 310–320. [Google Scholar] [CrossRef]

- Teasdale, J.R.; Mohler, C.L. Light transmittance, soil temperature, and soil moisture under residue of hairy vetch and rye. Agron. J. 1993, 85, 673–680. [Google Scholar] [CrossRef]

| 2017 | 2019 | |||

|---|---|---|---|---|

| Field 1 | Field 2 | Field 3 | Field 4 | |

| Temperature | 21 °C | 21 °C | 22 °C | 22 °C |

| Humidity | 65% | 65% | 70% | 70% |

| Wind speed | 3 m s−1 | 3 m s−1 | 2.20 m s−1 | 2.20 m s−1 |

| Application time | 2:30 p.m. | 4:30 p.m. | 1:00 p.m. | 2:30 p.m. |

| Application date | September 20 | September 20 | August 15 | August 15 |

| Sprayer pressure | 270 kPa | 270 kPa | 270 kPa | 270 kPa |

| Tractor speed | 12 km h | 12 km h | 12 km h | 12 km h |

| Nozzle b | Droplet Size Characteristics a,c | Spray Classification f | ||||

|---|---|---|---|---|---|---|

| Dv0.1 | Dv0.5 | Dv0.9 | RS d | Driftable Fines e | ||

| ____________________ μm ____________________ | % | |||||

| XR11004 | 99 | 227 | 406 | 1.35 | 22 | Fine |

| TTJ11004 | 160 | 360 | 643 | 1.34 | 8.5 | Medium |

| AIXR11004 | 190 | 417 | 699 | 1.22 | 5 | Coarse |

| TTI11004 | 365 | 758 | 1193 | 1.09 | 0.5 | Ultra Coarse |

| Source of Variation (SV) | Number of Factors | p-Value | d.f. |

|---|---|---|---|

| Application Direction (D) | 3 | 0.0998 | 2 |

| Nozzle Type (N) | 4 | 0.0993 | 3 |

| D x N | 0.0340 * | 6 | |

| Stubble Height (H) | 2 | <0.0001 * | 1 |

| D x H x N | 0.8472 | 6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simão, L.M.; Easterly, A.C.; Kruger, G.R.; Creech, C.F. Herbicide Spray Deposition in Wheat Stubble as Affected by Nozzle Type and Application Direction. Agronomy 2020, 10, 1507. https://doi.org/10.3390/agronomy10101507

Simão LM, Easterly AC, Kruger GR, Creech CF. Herbicide Spray Deposition in Wheat Stubble as Affected by Nozzle Type and Application Direction. Agronomy. 2020; 10(10):1507. https://doi.org/10.3390/agronomy10101507

Chicago/Turabian StyleSimão, Luana M., Amanda C. Easterly, Greg R. Kruger, and Cody F. Creech. 2020. "Herbicide Spray Deposition in Wheat Stubble as Affected by Nozzle Type and Application Direction" Agronomy 10, no. 10: 1507. https://doi.org/10.3390/agronomy10101507

APA StyleSimão, L. M., Easterly, A. C., Kruger, G. R., & Creech, C. F. (2020). Herbicide Spray Deposition in Wheat Stubble as Affected by Nozzle Type and Application Direction. Agronomy, 10(10), 1507. https://doi.org/10.3390/agronomy10101507