Silica Treatments: A Fire Retardant Strategy for Hemp Fabric/Epoxy Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Hemp Fabric Coating

2.2.2. Manufacturing of Hemp Fabric/Epoxy Composites

2.3. Characterization Techniques

2.3.1. FTIR Spectroscopy Measurements

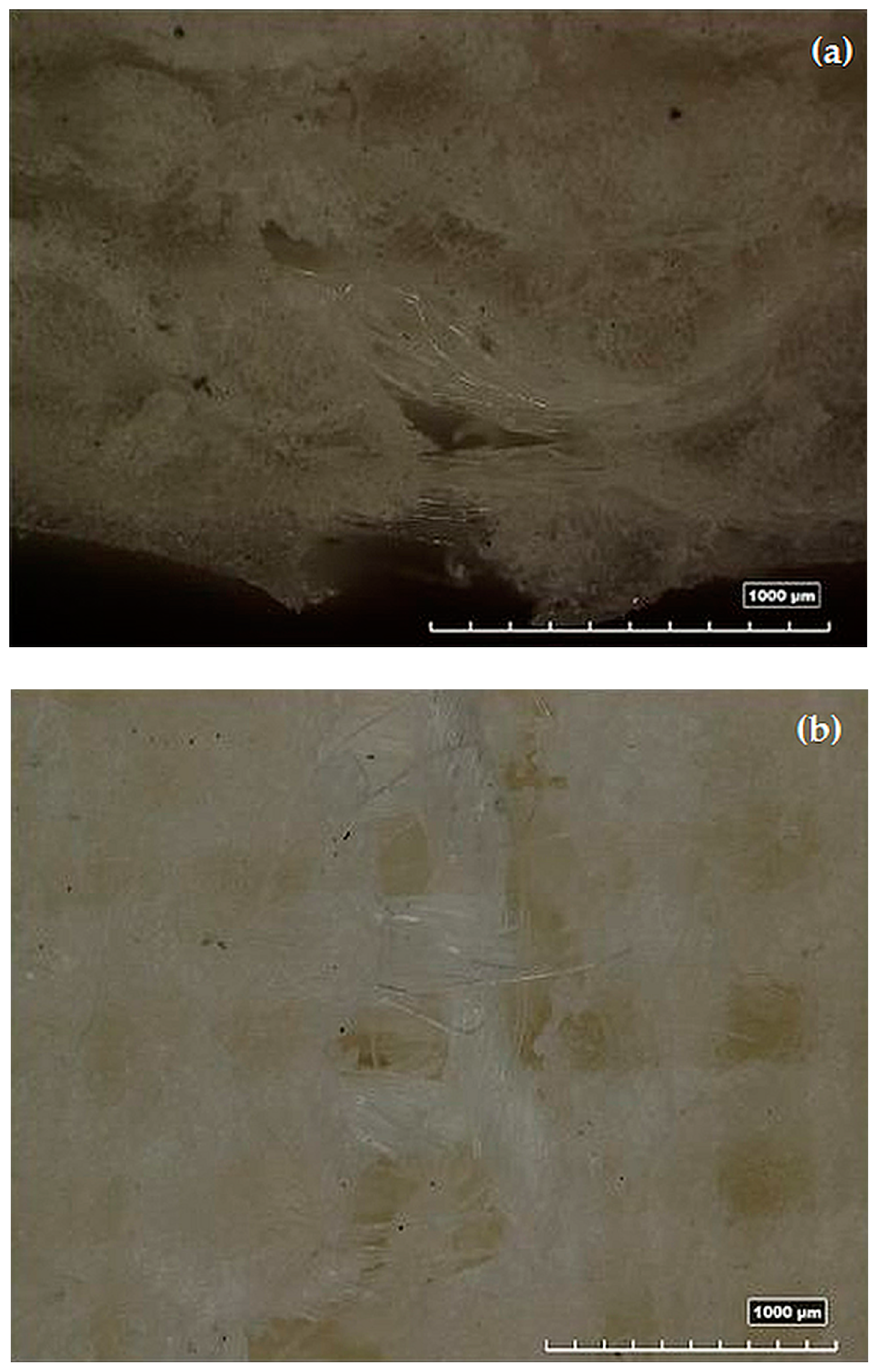

2.3.2. SEM-EDS-OM Microscopy

2.3.3. TGA

2.3.4. Solid-State NMR Spectroscopy

2.3.5. Cone Calorimetry Tests

2.3.6. Three-Point Bending Tests

2.3.7. Washing Fastness

3. Results and Discussion

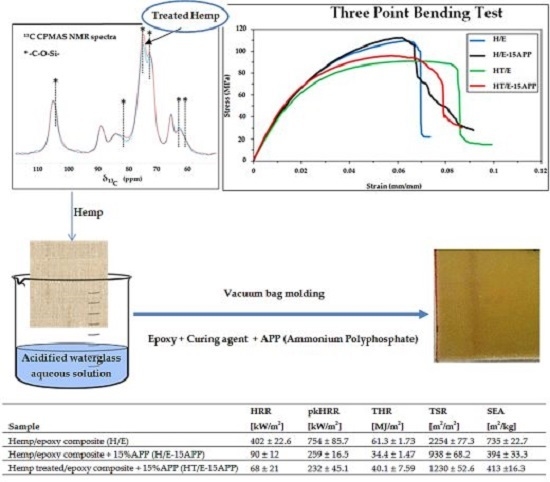

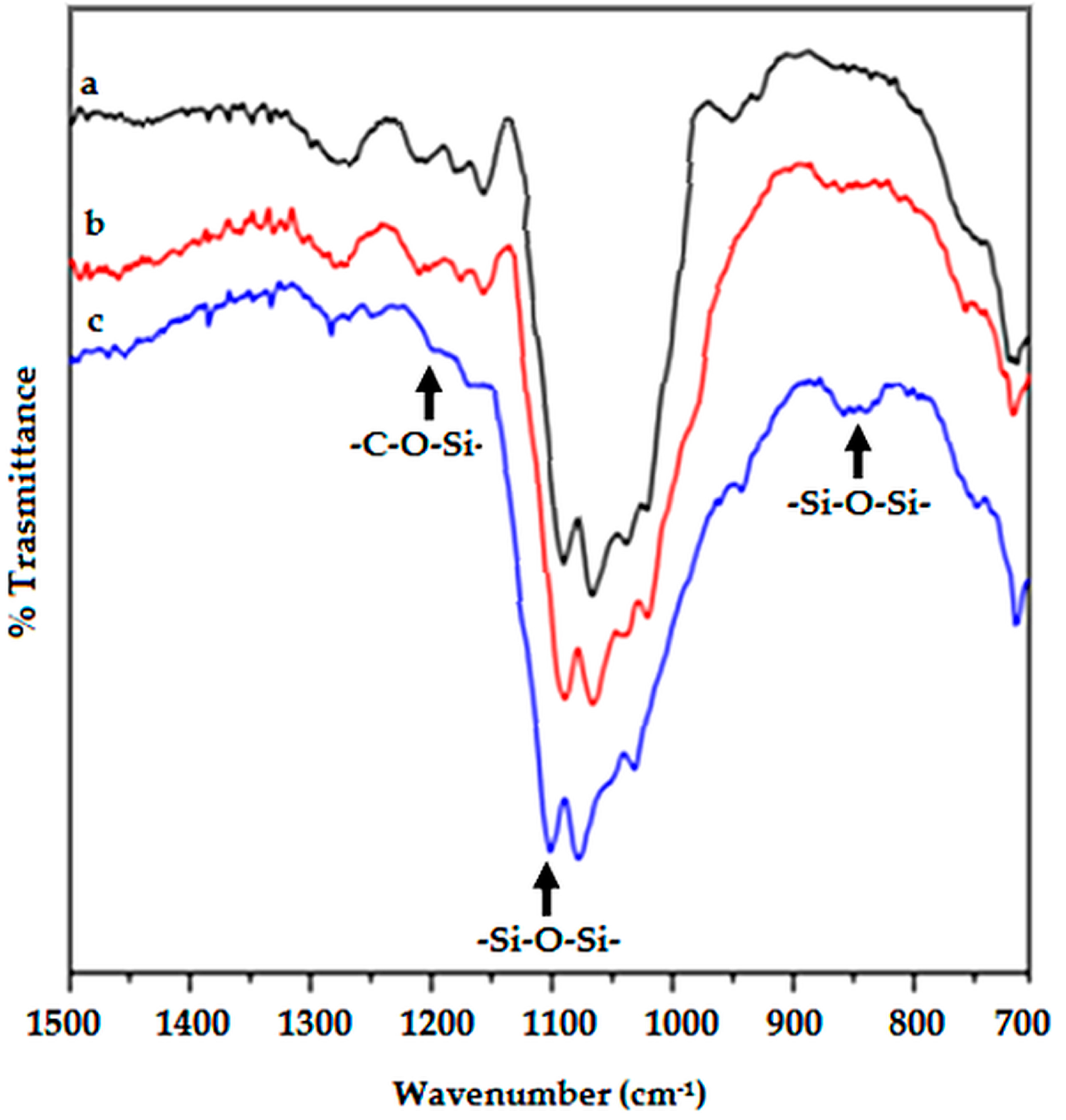

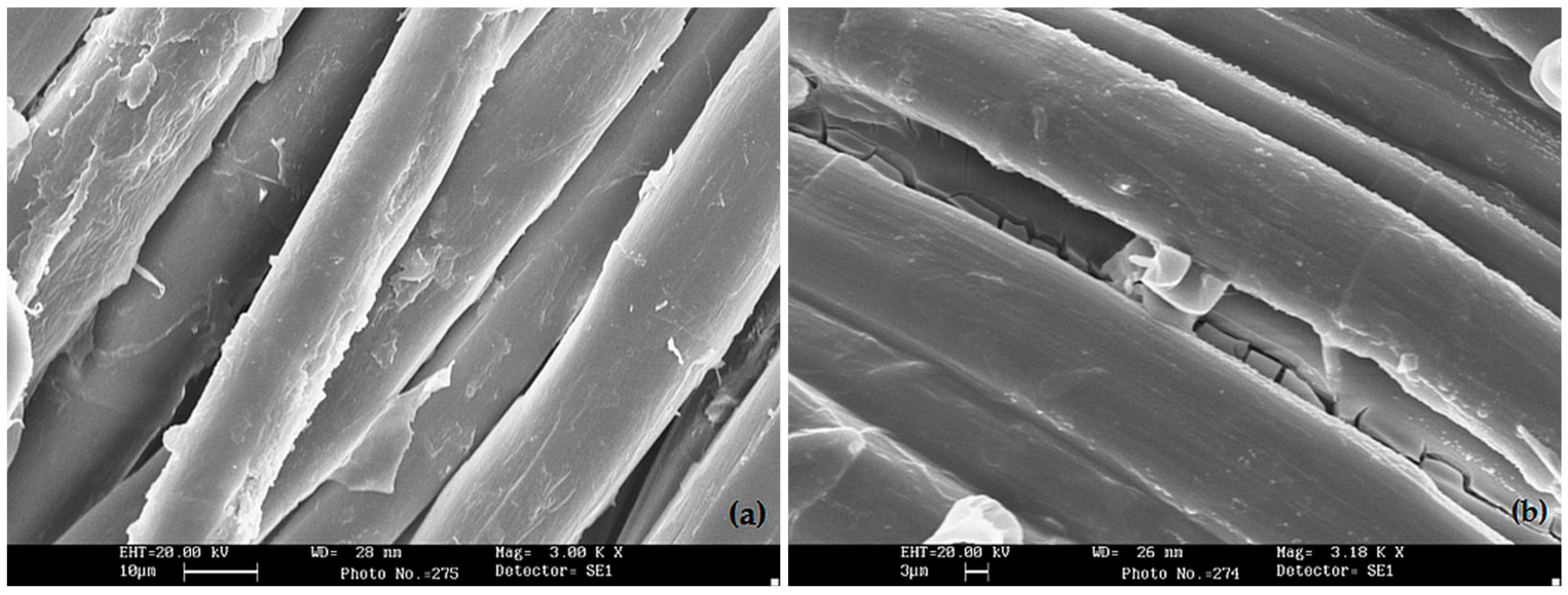

3.1. Characterization of the Silica Coating

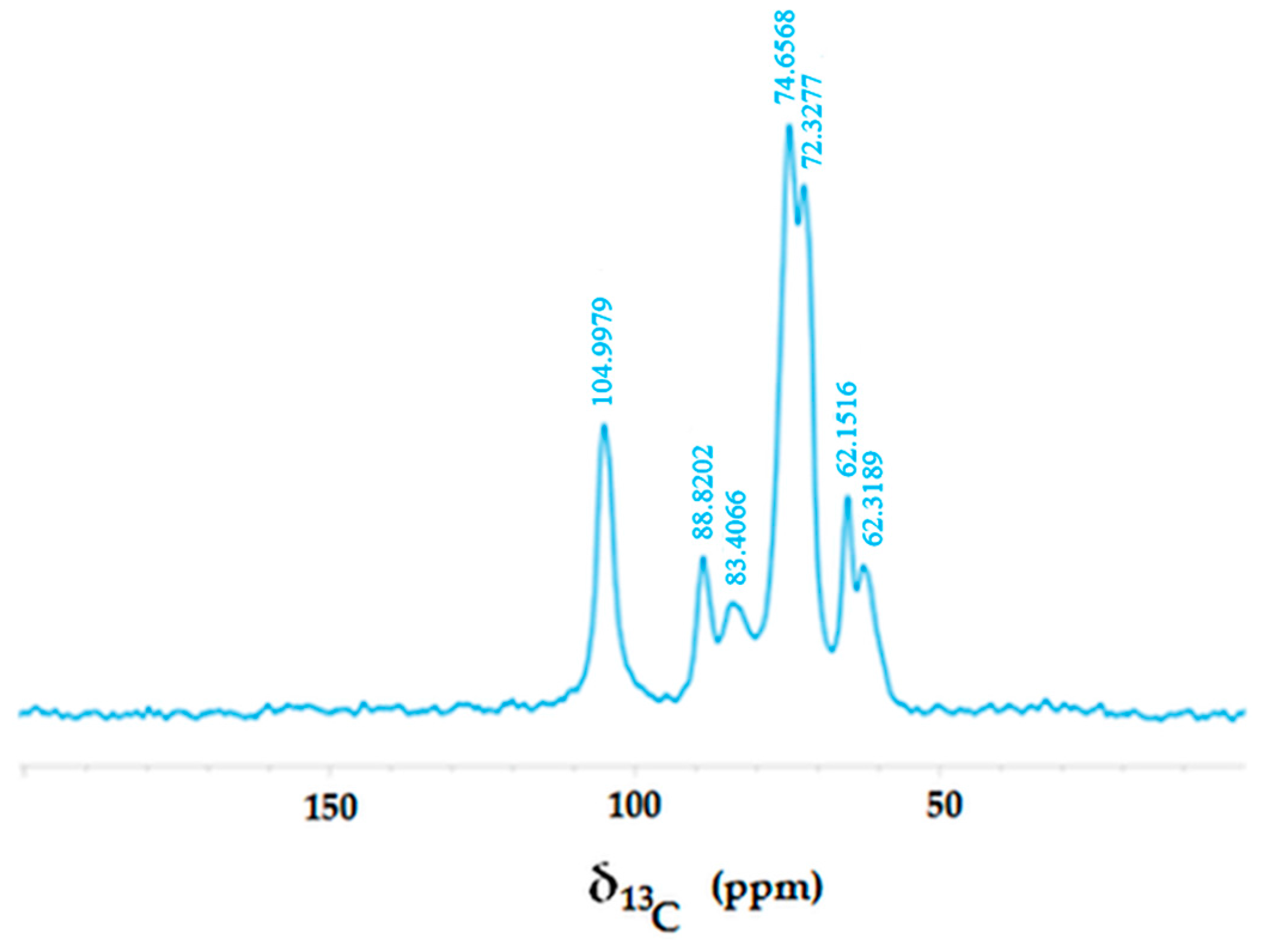

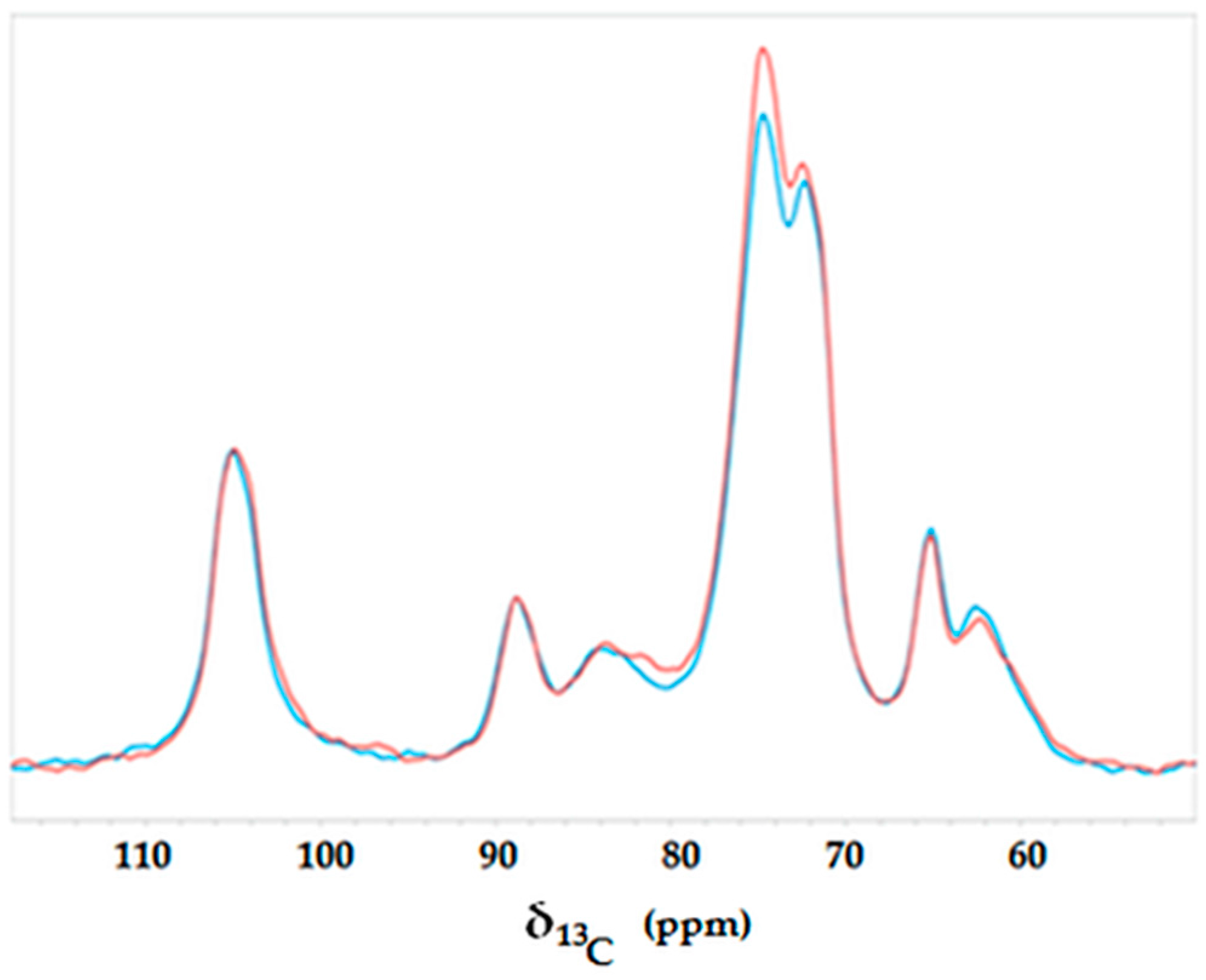

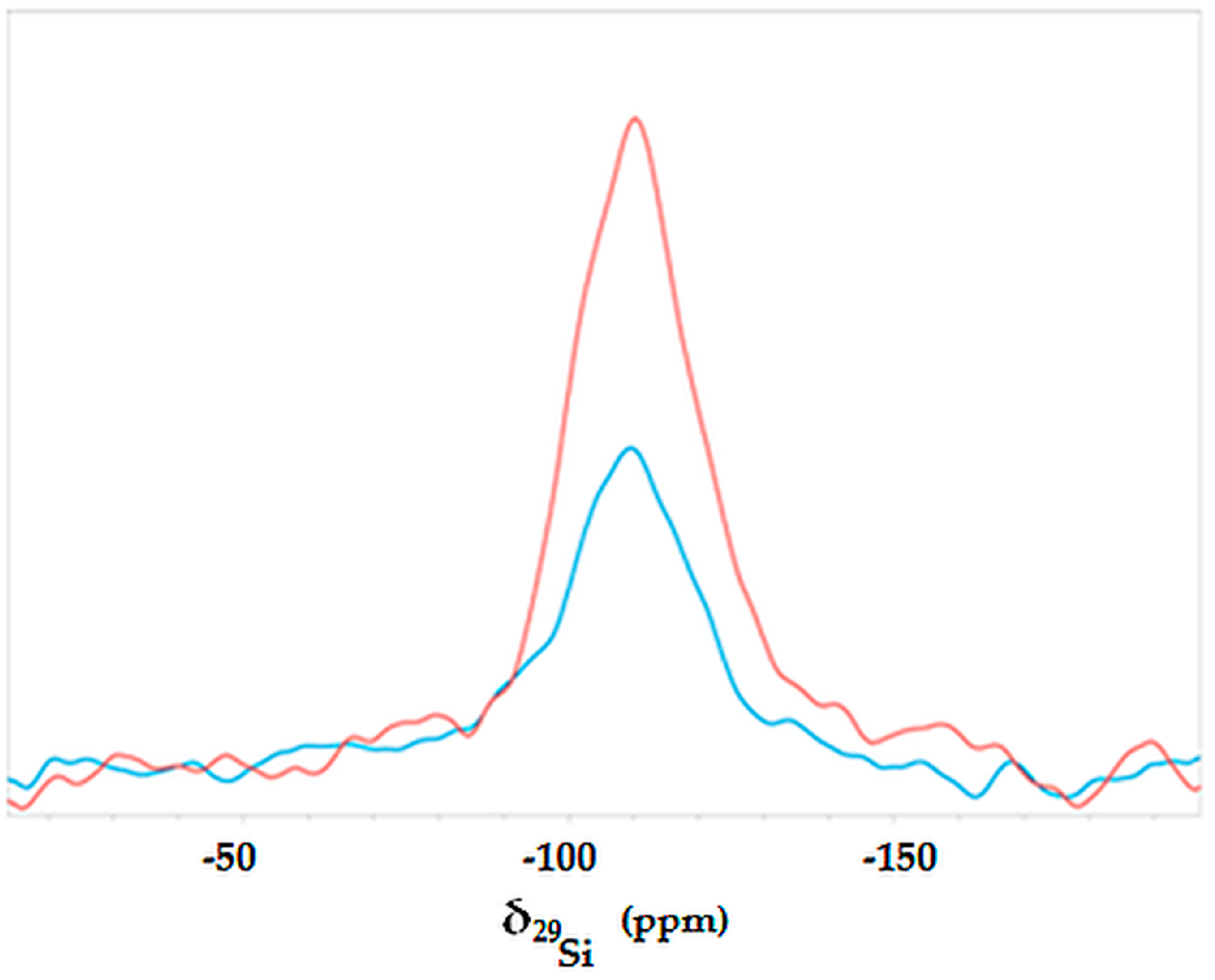

3.2. Solid-State NMR Spectroscopy

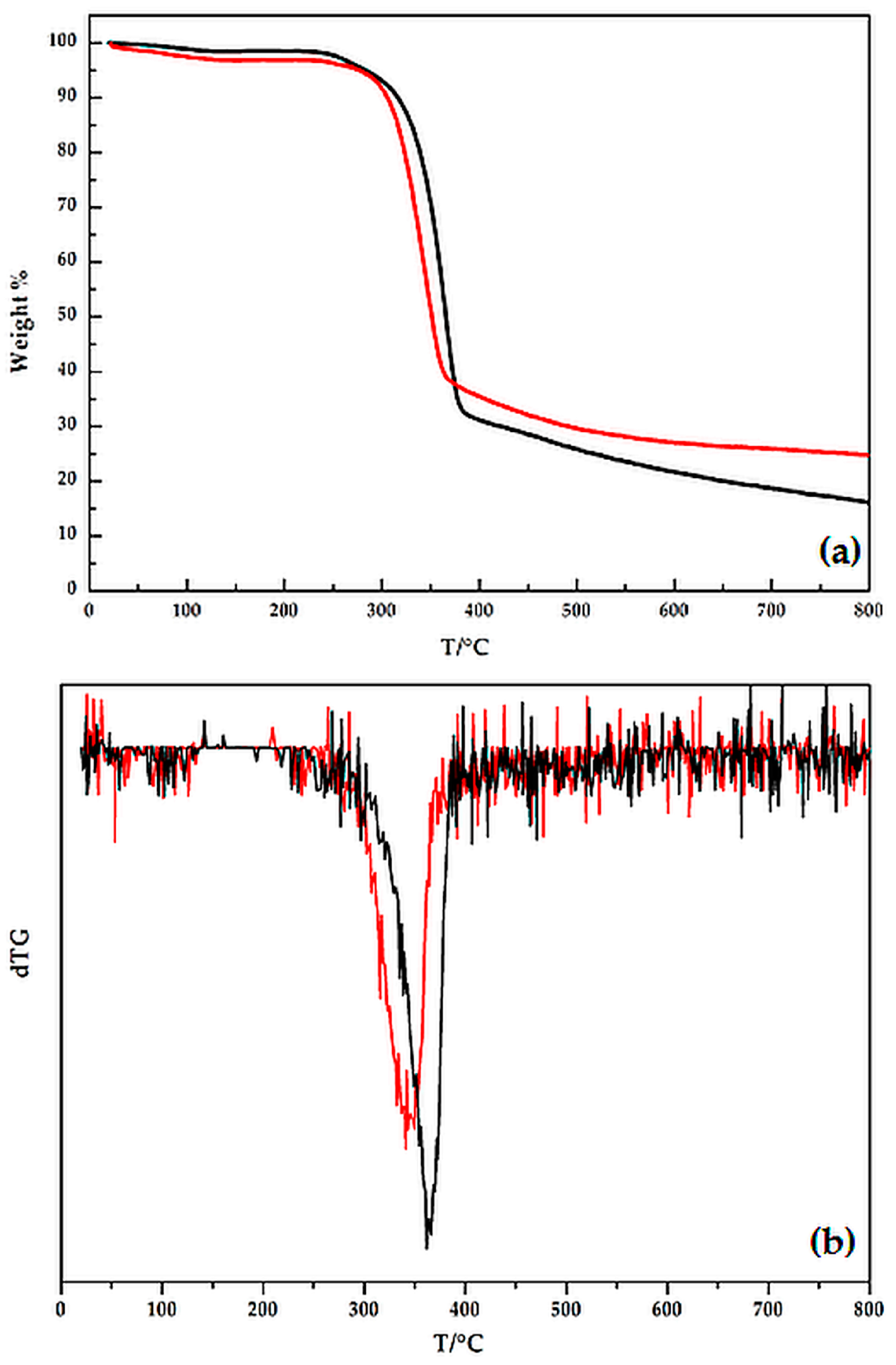

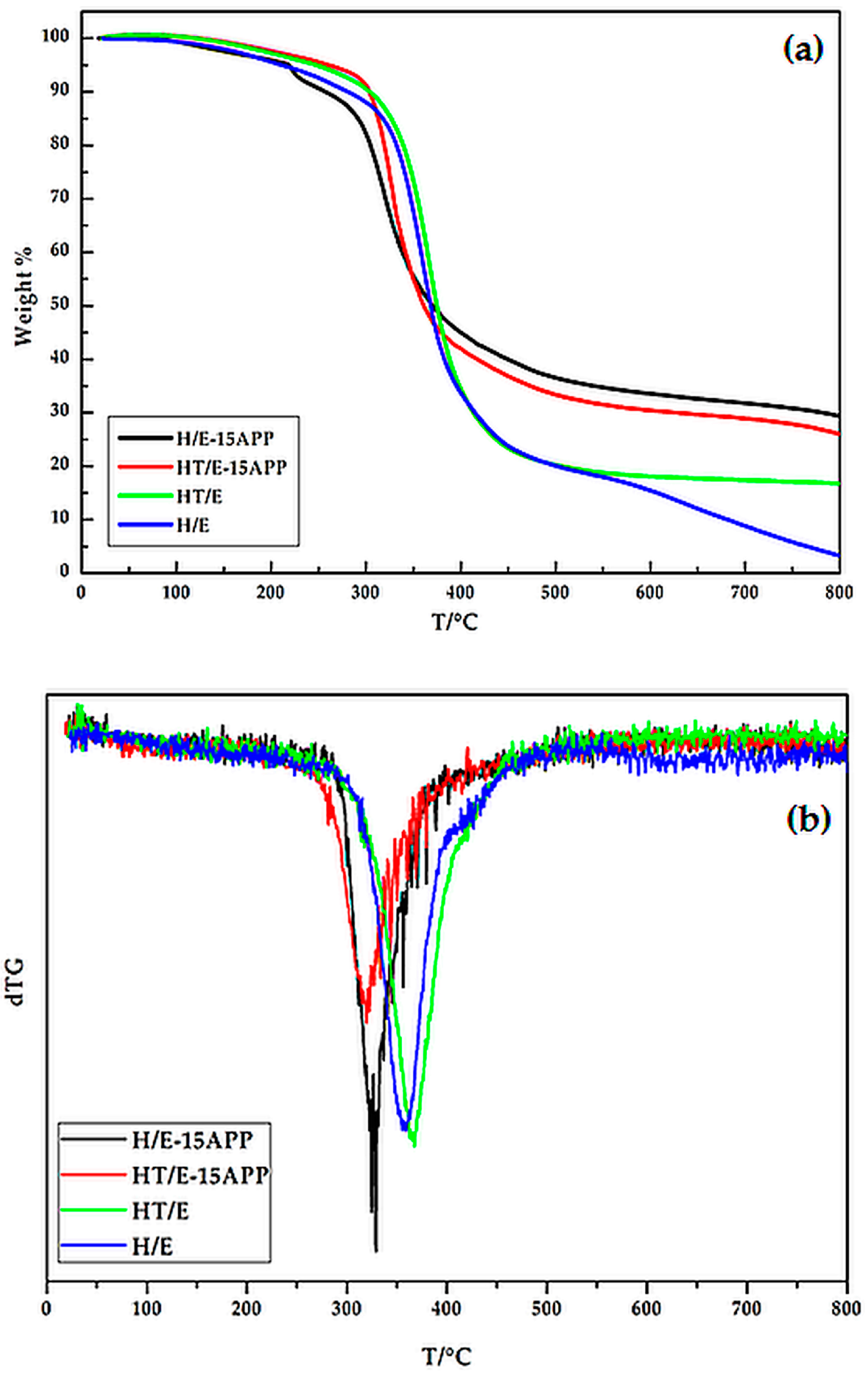

3.3. Thermogravimetric Analysis

3.4. Cone Calorimetry Tests

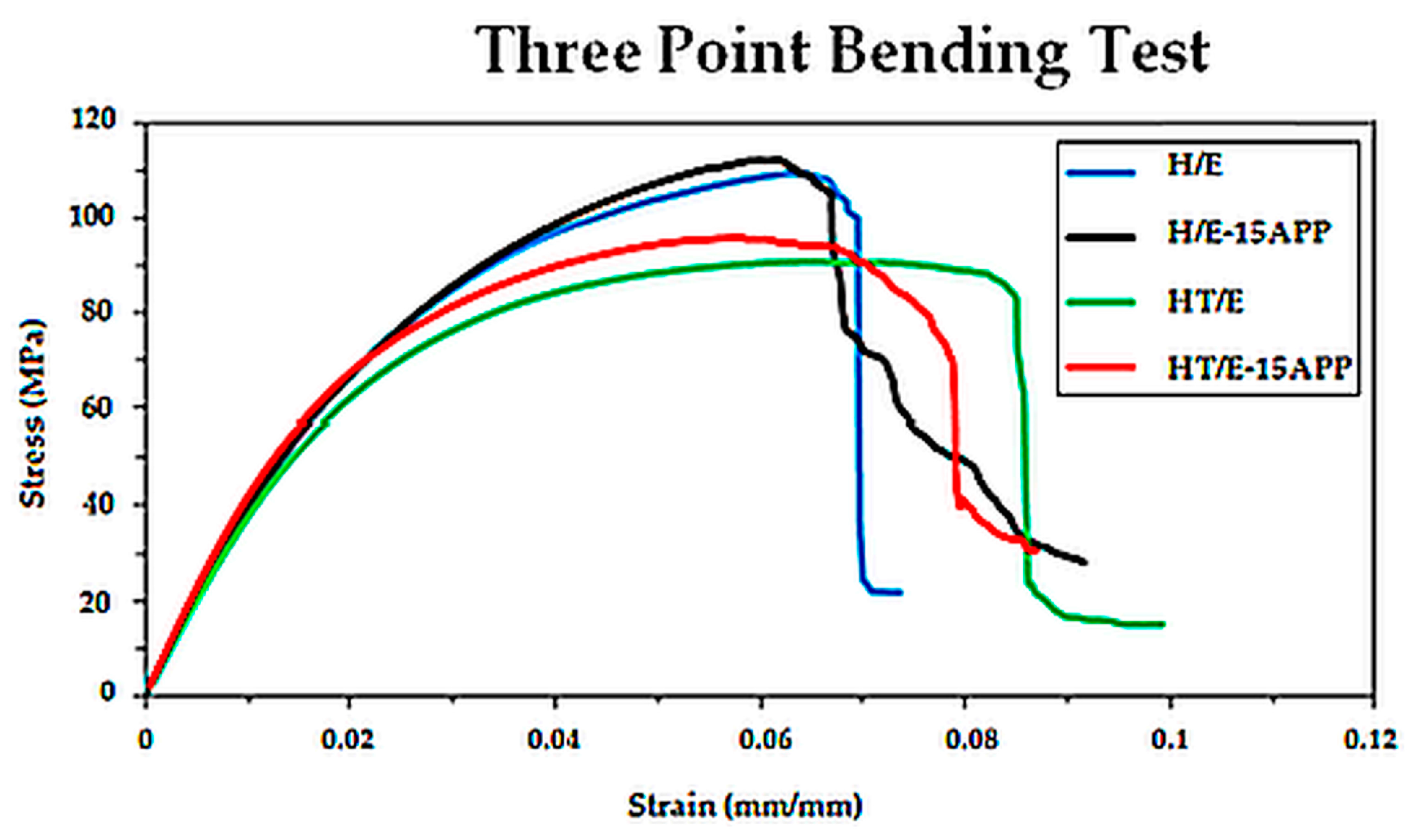

3.5. Three-Point Bending Tests

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Biagiotti, J.; Puglia, D.; Kenny, J.M. A review on natural fibre-based composites-Part I: Structure, processing and properties of vegetable fibres. J. Nat. Fibers 2004, 1, 37–68. [Google Scholar] [CrossRef]

- Puglia, D.; Biagiotti, J.; Kenny, J.M. A Review on natural fibre-based composites-Part II: Application of natural reinforcements in composite materials for automotive industry. J. Nat. Fibers 2004, 1, 23–65. [Google Scholar] [CrossRef]

- Saxena, M.; Pappu, A.; Sharma, A.; Haque, R.; Wankhede, S. Composite materials from natural resources: Recent trends and future potentials. In Advances in Composite Materials–Analysis of Natural and Man-Made Materials; Těšinova, P., Ed.; InTech: Rijeka, Croatia, 2011; pp. 121–162. [Google Scholar]

- Dittenber, D.B.; GangaRao, H.V.S. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part A 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibers. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Saheb, D.N.; Jog, J.P. Natural fiber polymer composites: A review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibers: Can they replace glass in fiber reinforced plastic? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Boccarusso, L.; Carrino, L.; Durante, M.; Formisano, A.; Langella, A.; Memola, F.; Minutolo, C. Hemp fabric/epoxy composites manufactured by infusion process: Improvement of fire properties promoted by ammonium polyphosphate. Compos. Part B 2016, 89, 117–126. [Google Scholar] [CrossRef]

- Szolnoki, B.; Bocz, K.; Sóti, P.L.; Bodzay, B.; Zimonyi, E.; Toldy, A.; Morlin, B.; Bujnowicz, K.; Wladyka-Przybylak, M.; Marosi, G. Development of natural fibre reinforced flame retarded epoxy resin composites. Polym. Degrad. Stab. 2015, 119, 68–76. [Google Scholar] [CrossRef]

- Dewey, L.H. “Hemp”. In U. S. Department of Agriculture Yearbook 1913; U.S. Government Publishing Office: Washington, DC, USA, 1914; pp. 283–346. [Google Scholar]

- Kandola, B.K. Flame retardant characteristics of natural fibre composites. In Natural Polymers: Composites; John, M.J., Thomas, S., Eds.; The Royal Society of Chemistry: Cambridge, UK, 2012; pp. 86–117. [Google Scholar]

- Grexa, O.; Lübke, H. Flammability parameters of wood tested on a cone calorimeter. Polym. Degrad. Stab. 2001, 74, 427–432. [Google Scholar] [CrossRef]

- Grexa, O.; Poutch, F.; Manikova, D.; Martvonova, H.; Bartekova, A. Intumescence in fire retardancy of lignocellulosic panels. Polym. Degrad. Stab. 2003, 82, 373–377. [Google Scholar] [CrossRef]

- Lazko, J.; Landercy, N.; Laoutid, F.; Dangreau, L.; Huguet, M.H.; Talon, O. Flame retardant treatments of insulating agro-materials from flax short fibres. Polym. Degrad. Stab. 2013, 98, 1043–1051. [Google Scholar] [CrossRef]

- Bourbigot, S.; Duquesne, S. Fire retardant polymers: Recent developments and opportunities. J. Mater. Chem. 2007, 17, 2283–2300. [Google Scholar] [CrossRef]

- Durin-France, A.; Ferry, L.; Lopez Cuesta, J.M.; Crespy, A. Magnesium hydroxide/zinc borate/talc compositions as flame-retardants in EVA copolymer. Polym. Int. 2000, 49, 1101–1105. [Google Scholar] [CrossRef]

- Kandola, B.K.; Horrocks, A.R. Complex char formation in flame-retarded fibre-intumescent combinations—IV. Mass loss and thermal barrier properties. Fire Mater. 2000, 24, 265–275. [Google Scholar] [CrossRef]

- Reti, C.; Casetta, M.; Duquesne, S.; Delobel, R.; Soulestin, J.; Bourbigot, S. Intumescent biobased-polylactide films to flame retard nonwovens. J. Eng. Fibers. Fabr. 2009, 4, 33–39. [Google Scholar]

- Suardana, N.P.G.; Ku, M.S.; Lim, J.K. Effects of diammonium phosphate on the flammability and mechanical properties of bio-composites. Mater. Des. 2011, 32, 1990–1999. [Google Scholar] [CrossRef]

- Mngomezulu, M.E.; John, M.J.; Jacobs, V.; Luyt, A.S. Review on flammability of biofibres and biocomposites. Carbohydr. Polym. 2014, 111, 149–182. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharyya, D.; Subasinghe, A.; Kim, N.K. Natural fibers: Their composites and flammability characterizations. In Multifunctionality of Polymer Composites: Challenges and New Solutions, 1st ed.; Friedrich, K., Breuer, U., Eds.; Elsevier: Waltham, MA, USA, 2015; pp. 102–143. [Google Scholar]

- Wu, Q.L.; Chi, K.; Wu, Y.Q.; Lee, S. Mechanical, thermal expansion, and flammability properties of co-extruded wood polymer composites with basalt fiber reinforced shells. Mater. Des. 2014, 60, 334–342. [Google Scholar] [CrossRef]

- Manfredi, L.B.; Rodríguez, E.S.; Wladyka-Przybylak, M.; Vázquez, A. Thermal degradation and fire resistance of unsaturated polyester, modified acrylic resins and their composites with natural fibres. Polym. Degrad. Stab. 2006, 91, 255–261. [Google Scholar] [CrossRef]

- Hapuarachchi, T.D.; Ren, G.; Fan, M.; Hogg, P.J.; Peijs, T. Fire retardancy of natural fibre reinforced sheet moulding compound. Appl. Compos. Mater. 2007, 14, 251–264. [Google Scholar] [CrossRef]

- Chai, M.W.; Bickerton, S.; Bhattacharyya, D.; Das, R. Influence of natural fibre reinforcements on the flammability of bio-derived composite materials. Compos. Part B 2012, 43, 2867–2874. [Google Scholar] [CrossRef]

- Rao, S.; Bhardwaj, A.; Beehag, A.; Bhattacharyya, D. Fire performance of flax laminates and their hybrids. Adv. Mater. Res. 2012, 410, 114–117. [Google Scholar] [CrossRef]

- Abdelmouleh, M.; Boufi, S.; Belgacem, M.N.; Duarte, A.P.; Ben Salah, A.; Gandini, A. Modification of cellulosic fibres with functionalised silanes: Development of surface properties. Int. J. Adhes. Adhes. 2004, 24, 43–54. [Google Scholar] [CrossRef]

- Britcher, L.G.; Kehoe, D.C.; Matisons, J.G.; Swincer, A.G. Siloxane coupling agent. Macromolecules 1995, 28, 3110–3118. [Google Scholar] [CrossRef]

- Freundlich, H.; Hatfield, H.S. Colloid and capillary chemistry; Methuen & Co. Ltd.: London, UK, 1926; pp. 387–390. [Google Scholar]

- Brinker, C.J.; Sherer, G.W. Sol-Gel Science: The Physics and Chemistry of Sol-Gel Processing; Academic Press Limited: London, UK, 1990; pp. 99–227. [Google Scholar]

- Branda, F. The sol-gel route to nanocomposites. In Advances in Nanocomposites–Synthesis, Characterization and Industrial Applications; Reddy, B., Ed.; InTech: Rijeka, Croatia, 2011; pp. 323–340. [Google Scholar]

- Iler, R.K. The Chemistry of Silica–Solubility, Polymerization, Colloid and Surface Properties, and Biochemistry; John Wiley and Sons: Chichester, UK, 1979; pp. 34–304. [Google Scholar]

- Harris, R.K.; Knight, C.T.G.; Hull, W.E. Soluble Silicates. In ACS Symposium Series 194; Falcone, J.S., Jr., Ed.; American Chemical Society: Washington, DC, USA, 1982; pp. 79–93. [Google Scholar]

- Islam, M.S.; Pickering, K.L.; Foreman, N.J. Influence of alkali fiber treatment and fiber processing on the mechanical properties of hemp/epoxy composites. J. Appl. Polym. Sci. 2011, 119, 3696–3707. [Google Scholar] [CrossRef]

- Vukcevic, M.; Pejic, B.; Lausevic, M.; Pajic-Lijakovic, I.; Kostic, M. Influence of chemically modified short hemp fiber structure on biosorption process of Zn2+ ions from waste water. Fibers. Polym. 2014, 15, 687–697. [Google Scholar] [CrossRef]

- Cheng, X.W.; Guan, J.P.; Chen, G.Q.; Yang, X.H.; Tang, R.C. Adsorption and flame retardant properties of bio-based phytic acid on wool fabric. Polymers 2016, 8, 122. [Google Scholar] [CrossRef]

- Savvas, D.; Ntatsi, G. Biostimulant activity of silicon in horticulture. Sci. Hortic. 2015, 196, 66–81. [Google Scholar] [CrossRef]

- Williams, A. The Chemistry of Organic Silicon Compounds; Rappoport, Z., Apeloig, Y., Eds.; John Wiley and Sons: New York, NY, USA, 1989; Volume 1, pp. 511–554. [Google Scholar]

- Alongi, J.; Malucelli, G. Thermal degradation of cellulose and cellulosic substrates. In Reactions and Mechanisms in Thermal Analysis of Advanced Materials; Tiwari, A., Raj, B., Eds.; Beverly: Hoboken, NJ, USA, 2015; pp. 301–332. [Google Scholar]

- Levchik, S.V.; Costa, L.; Camino, G. Effect of the fire-retardant, ammonium polyphosphate, on the thermal decomposition of aliphatic polyamides: Part II–Polyamide 6. Polym. Degrad. Stab. 1992, 36, 229–237. [Google Scholar] [CrossRef]

- Bismarck, A.; Aranberri-Askrgorta, I.; Springer, J.; Lampke, T.; Wielage, B.; Stamboulis, A.; Shenderovich, I.; Limbuch, H.H. Surface characterization of flax, hemp and cellulose fibers; surface properties and the water uptake behavior. Polym. Compos. 2002, 23, 872–894. [Google Scholar] [CrossRef]

- Hautala, M.; Pasila, A.; Pirilä, J. Use of hemp and flax in composite manufacture: A search for new production methods. Compos. Part A 2004, 35, 11–16. [Google Scholar] [CrossRef]

- Guillebaud-Bonnafous, C.; Vasconcellos, D.; Touchard, F.; Chocinski-Arnault, L. Experimental and numerical investigation of the interface between epoxy matrix and hemp yarn. Compos. Part A 2012, 43, 2046–2058. [Google Scholar] [CrossRef]

- Pickering, K.L.; Beckermann, G.W.; Alam, S.N.; Foreman, N.J. Optimising industrial hemp fibre for composites. Compos. Part A 2007, 38, 461–468. [Google Scholar] [CrossRef]

| Symbol | Hemp fabric and epoxy composite samples | Amount of APP added to the epoxy (wt %) |

|---|---|---|

| H | Hemp fabrics | 0 |

| HT | Hemp fabrics treated with waterglass | 0 |

| H/E | Hemp fabrics/epoxy composite | 0 |

| HT/E | Hemp fabrics treated with waterglass/epoxy composite | 0 |

| H/E-15APP | Hemp fabrics/epoxy composite | 15 |

| HT/E-15APP | Hemp fabrics treated with waterglass/epoxy composite | 15 |

| Sample | T5% (°C) | T10% (°C) | T50% (°C) | Tpeak (°C) | Residue at Tpeak (%) | Residue at 800 °C (%) |

|---|---|---|---|---|---|---|

| H | 274 | 296 | 338 | 367 | 36 | 22 |

| HT | 264 | 283 | 324 | 342 | 43 | 30 |

| H/E | 221 | 274 | 342 | 357 | 41 | 9.9 |

| HT/E | 248 | 289 | 349 | 357 | 40 | 23 |

| H/E-15APP | 203 | 251 | 364 | 328 | 57 | 35 |

| HT/E-15APP | 264 | 383 | 344 | 319 | 60 | 32 |

| Sample | TTI (s) | FO (s) | HRR (kW/m2) | PkHRR (kW/m2) | THR (MJ/m2) | Residue mass (%) |

|---|---|---|---|---|---|---|

| H | 28 ± 7.0 | 56 ± 2.5 | 13.2 ± 0.951 | 57.8 ± 9.77 | 1.80 ± 0.264 | 1 ± 0.6 |

| HT | 21 ± 2.6 | 45 ± 4.5 | 12.3 ± 1.48 | 51.8 ± 10.4 | 1.60 ± 0.252 | 4 ± 0.6 |

| E | 78 ± 6.9 | 166 ± 14.2 | 507 ± 120 | 1937 ± 119.3 | 95.8 ± 8.03 | 3 ± 0.6 |

| H/E | 55 ± 4.0 | 178 ± 11.9 | 402 ± 22.6 | 754 ± 85.7 | 61.3 ± 1.73 | 3 ± 0.6 |

| HT/E | 39 ± 4.0 | 187 ± 6.42 | 260 ± 13.3 | 642 ± 72.6 | 64.2 ± 4.65 | 6.71 ± 0.577 |

| H/E-15APP | 46 ± 8.1 | 336 ± 49.1 | 90 ± 12 | 259 ± 16.5 | 34.4 ± 1.47 | 28.7 ± 0.577 |

| HT/E-15APP | 44 ± 4.2 | 557 ± 97.1 | 68 ± 21 | 232 ± 45.1 | 40.1 ± 7.59 | 30.3 ± 0.577 |

| Sample | TSR (m2/m2) | SEA (m2/kg) | CO yield (kg/kg) | CO2 yield (kg/kg) |

|---|---|---|---|---|

| H | ND | ND | ND | ND |

| HT | ND | ND | ND | ND |

| E | 3,276 ± 449 | 849 ± 55.4 | 5.85 × 10−2 ± 4.91 × 10−3 | 1.96 ± 4.27 × 10−2 |

| H/E | 2,254 ± 77.3 | 735 ± 22.7 | 3.28 × 10−2 ± 1.08 × 10−3 | 1.69 ± 1.01 × 10−2 |

| HT/E | 2,094 ± 229 | 667 ± 43.7 | 4 × 10−2 ± 1 × 10−3 | 1.47 ± 7.37 × 10−2 |

| H/E-15APP | 938 ± 68.2 | 394 ± 33.3 | 5 × 10−2 ± 3 × 10−3 | 0.87 ± 2.6 × 10−1 |

| HT/E-15APP | 1,230 ± 52.6 | 413 ± 16.3 | 5 × 10−2 ± 2 × 10−3 | 1.02 ± 1.94 × 10−1 |

| Sample | Flexural modulus (MPa) | Flexural strength (MPa) | Maximum strain (%) |

|---|---|---|---|

| H/E | 4,550 ± 260.1 | 109 ± 5.61 | 7.1 ± 6.7 × 10−1 |

| H/E-15APP | 4,590 ± 324.3 | 110 ± 6.12 | 6.9 ± 7.7 × 10−1 |

| HT/E | 4,340 ± 194.1 | 92 ± 4.8 | 8.5 ± 8.8 × 10−1 |

| HT/E-15APP | 4,460 ± 258.2 | 94 ± 5.2 | 8.2 ± 9.1 × 10−1 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Branda, F.; Malucelli, G.; Durante, M.; Piccolo, A.; Mazzei, P.; Costantini, A.; Silvestri, B.; Pennetta, M.; Bifulco, A. Silica Treatments: A Fire Retardant Strategy for Hemp Fabric/Epoxy Composites. Polymers 2016, 8, 313. https://doi.org/10.3390/polym8080313

Branda F, Malucelli G, Durante M, Piccolo A, Mazzei P, Costantini A, Silvestri B, Pennetta M, Bifulco A. Silica Treatments: A Fire Retardant Strategy for Hemp Fabric/Epoxy Composites. Polymers. 2016; 8(8):313. https://doi.org/10.3390/polym8080313

Chicago/Turabian StyleBranda, Francesco, Giulio Malucelli, Massimo Durante, Alessandro Piccolo, Pierluigi Mazzei, Aniello Costantini, Brigida Silvestri, Miriam Pennetta, and Aurelio Bifulco. 2016. "Silica Treatments: A Fire Retardant Strategy for Hemp Fabric/Epoxy Composites" Polymers 8, no. 8: 313. https://doi.org/10.3390/polym8080313

APA StyleBranda, F., Malucelli, G., Durante, M., Piccolo, A., Mazzei, P., Costantini, A., Silvestri, B., Pennetta, M., & Bifulco, A. (2016). Silica Treatments: A Fire Retardant Strategy for Hemp Fabric/Epoxy Composites. Polymers, 8(8), 313. https://doi.org/10.3390/polym8080313