Fracture Resistance of Commercial and Novel Ceramic-Reinforced Polymer Crowns with Luting Cements of Varying Elastic Modulus

Abstract

1. Introduction

2. Materials and Methods

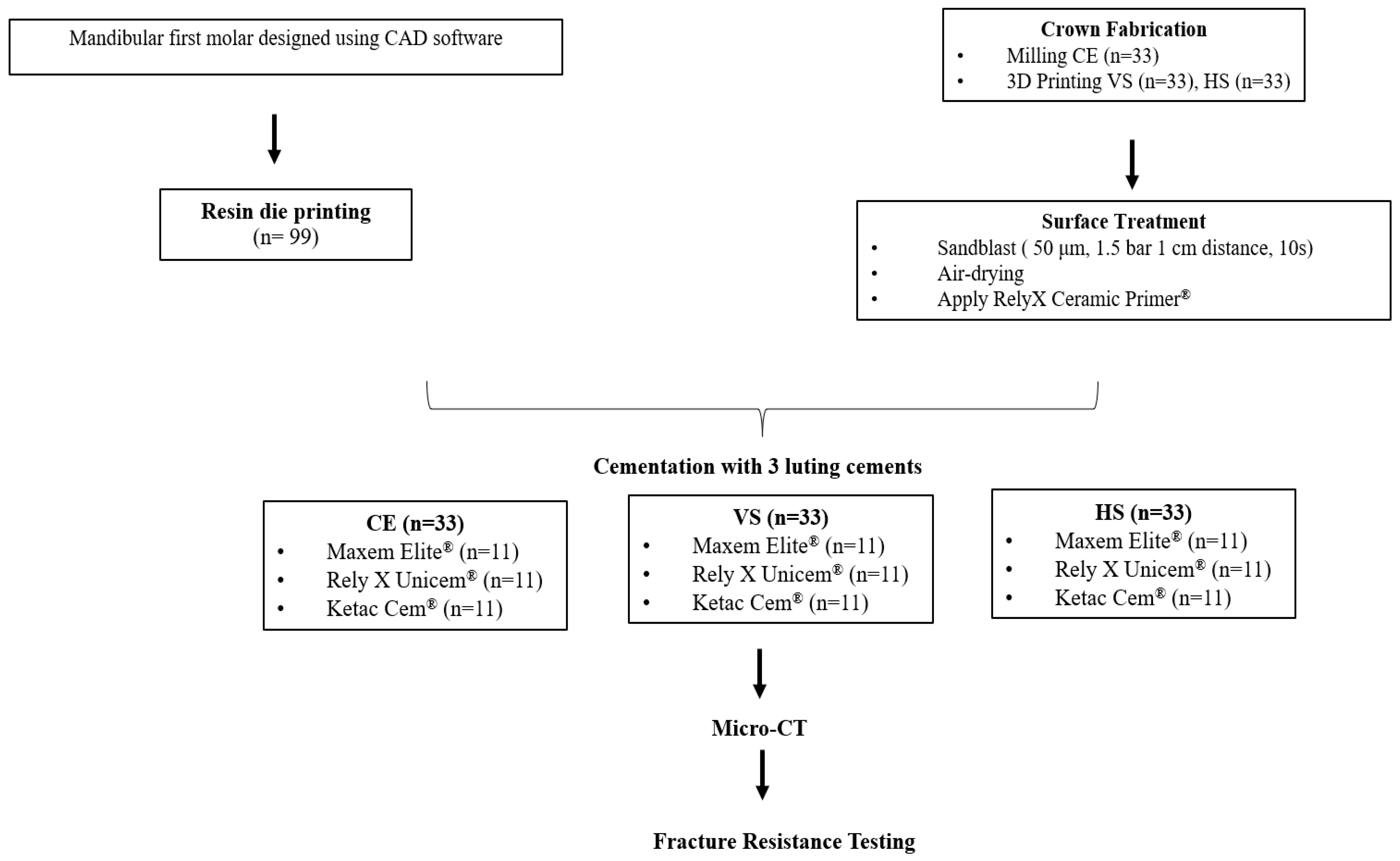

2.1. Study Design

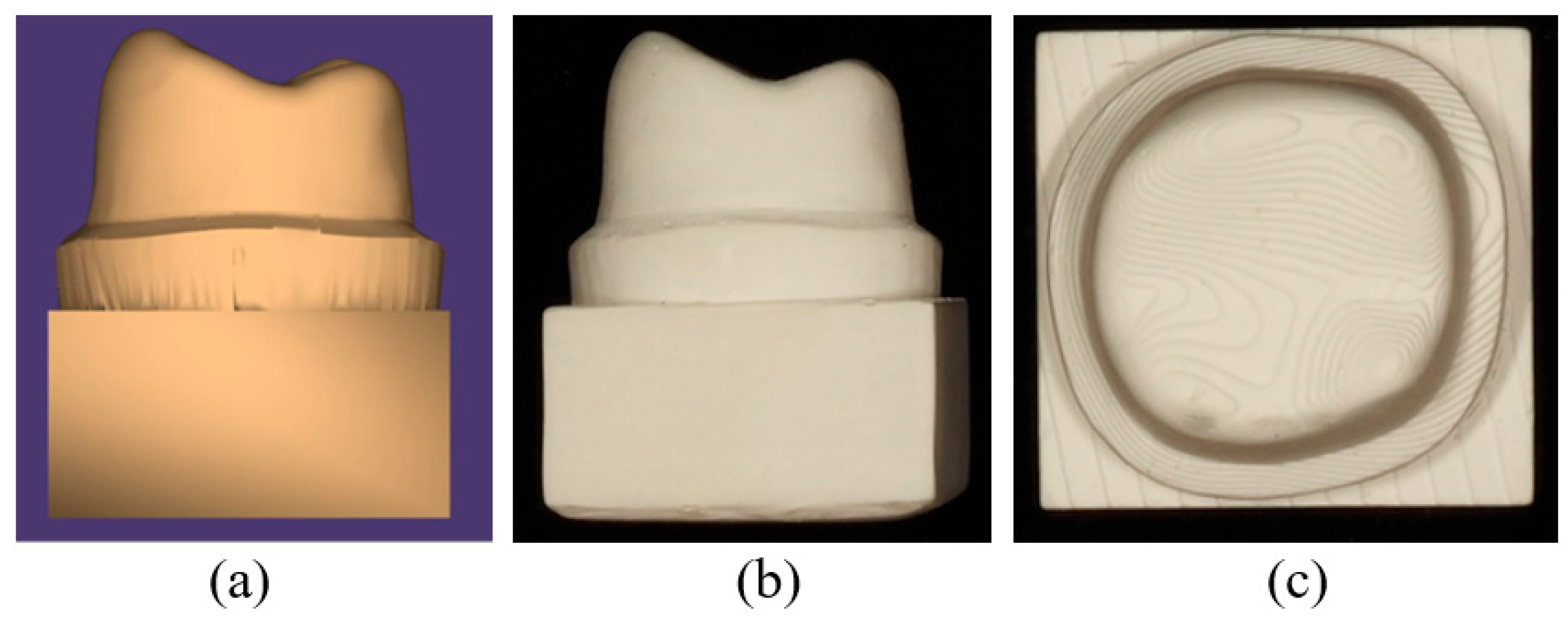

2.2. Virtual Design of Resin Die and CRP Crown Preparation

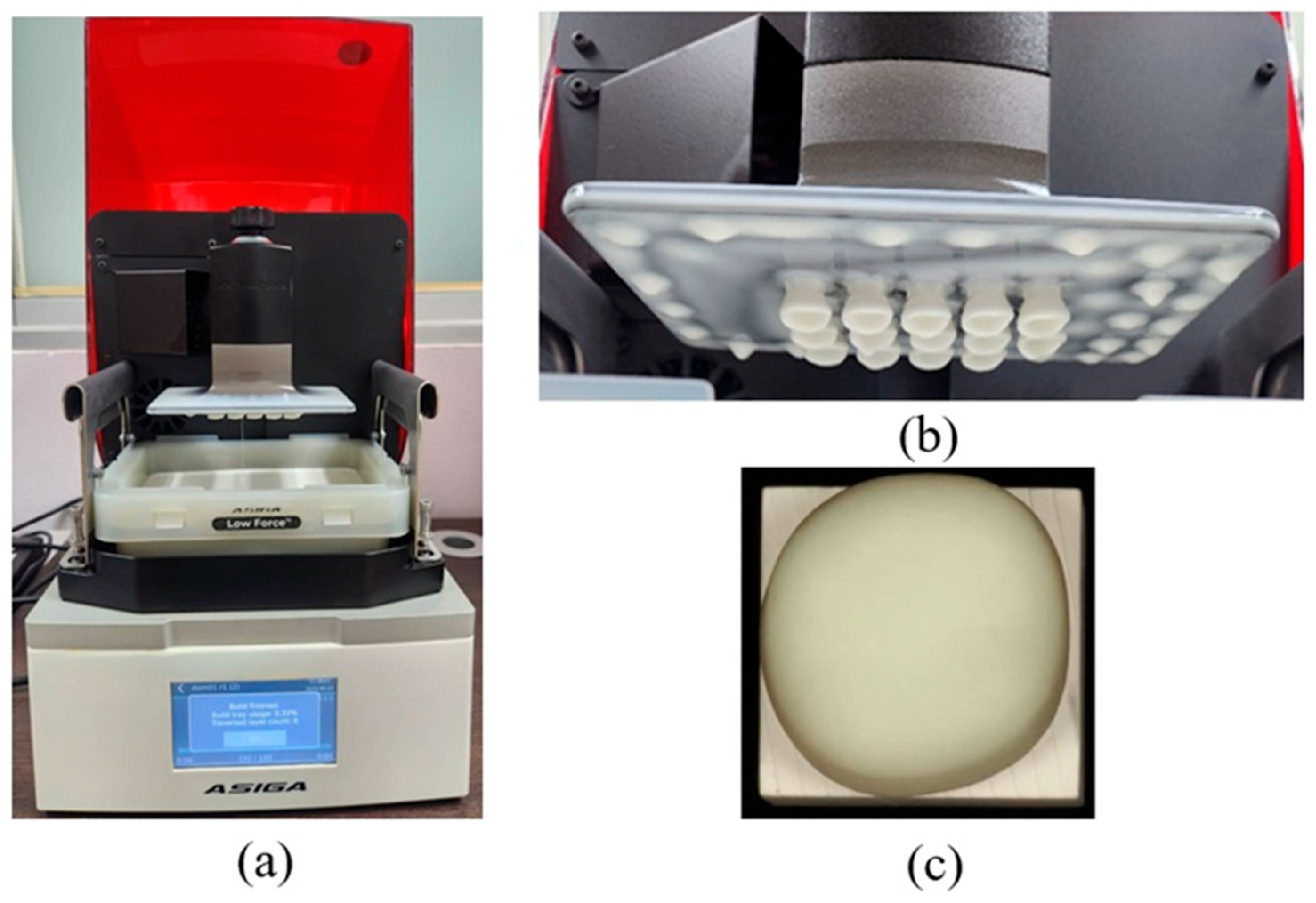

2.3. Fabrication of CRP Crown Specimens and Cementation

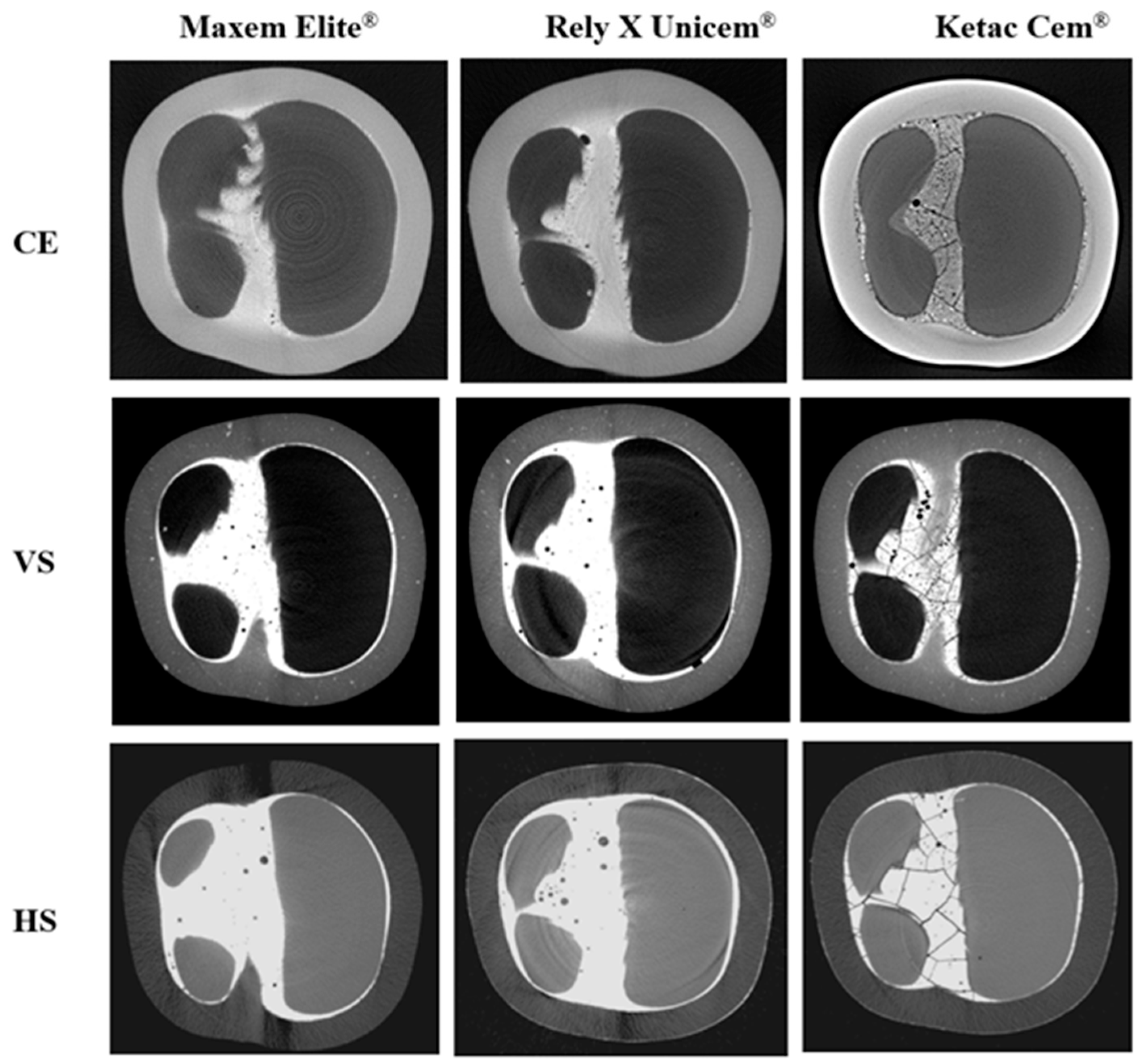

2.4. Micro-Computed Tomography (Micro-CT) Analysis

2.5. Fracture Resistance Test

2.6. Statistical Analysis

3. Results

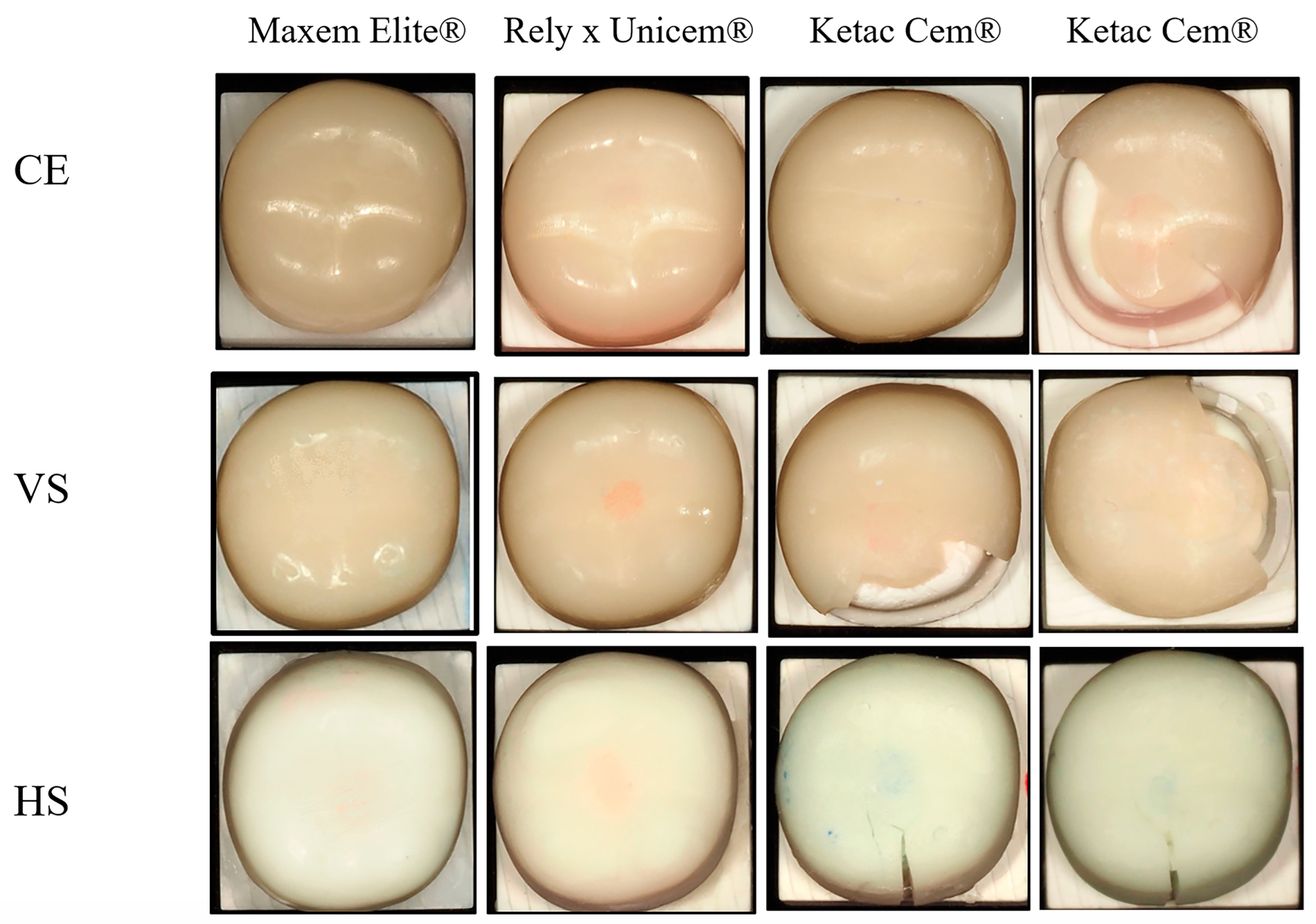

3.1. Fracture Resistance

3.2. Micro-CT Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CRP | Ceramic-Reinforced Polymer |

| CE | Cerasmart® 270 |

| VS | VarseoSmile Crown Plus® |

| HS | Hassawat-01 |

| BG | Barium-glass |

| UA | Urethane acrylate |

| GI | Glass ionomer cement |

| UDMA | Urethane dimethacrylate |

References

- Naffah, N.; Ounsi, H.; Ozcan, M.; Bassal, H.; Salameh, Z. Evaluation of the adaptation and fracture resistance of three CAD-CAM resin ceramics: An in vitro study. J. Contemp. Dent. Pract. 2019, 20, 571–576. [Google Scholar]

- Blatz, M.B.; Conejo, J. The current state of chairside digital dentistry and materials. Dent. Clin. N. Am. 2019, 63, 175–197. [Google Scholar] [CrossRef] [PubMed]

- Sulaiman, T.A. Materials in digital dentistry—A review. Dent. Clin. 2020, 32, 171–181. [Google Scholar] [CrossRef] [PubMed]

- Spitznagel, F.; Boldt, J.; Gierthmuehlen, P. CAD/CAM ceramic restorative materials for natural teeth. J. Dent. Res. 2018, 97, 1082–1091. [Google Scholar] [CrossRef]

- Bajraktarova-Valjakova, E.; Korunoska-Stevkovska, V.; Kapusevska, B.; Gigovski, N.; Bajraktarova-Misevska, C.; Grozdanov, A. Contemporary dental ceramic materials, a review: Chemical composition, physical and mechanical properties, indications for use. Open Access Maced. J. Med. Sci. 2018, 6, 1742. [Google Scholar] [CrossRef] [PubMed]

- Shi, H.Y.; Pang, R.; Yang, J.; Fan, D.; Cai, H.; Jiang, H.B.; Han, J.; Lee, E.-S.; Sun, Y. Overview of several typical ceramic materials for restorative dentistry. BioMed Res. Int. 2022, 2022, 8451445. [Google Scholar] [CrossRef]

- Rizzatto, L.V.; Meneghetti, D.; Di Domênico, M.; Facenda, J.C.; Weber, K.R.; Corazza, P.H.; Borba, M. Effect of the type of resin cement on the fracture resistance of chairside CAD-CAM materials after aging. J. Adv. Prosthodont. 2023, 15, 136. [Google Scholar] [CrossRef]

- Rameshbabu, A.P.; Mohanty, S.; Bankoti, K.; Ghosh, P.; Dhara, S. Effect of alumina, silk and ceria short fibers in reinforcement of Bis-GMA/TEGDMA dental resin. Compos. Part B Eng. 2015, 70, 238–246. [Google Scholar] [CrossRef]

- Liu, W.; Li, M.; Nie, J.; Wang, C.; Li, W.; Xing, Z. Synergy of solid loading and printability of ceramic paste for optimized properties of alumina via stereolithography-based 3D printing. J. Mater. Res. Technol. 2020, 9, 11476–11483. [Google Scholar] [CrossRef]

- Feng, Q.-K.; Liu, C.; Zhang, D.-L.; Song, Y.-H.; Sun, K.; Xu, H.-P.; Dang, Z.-M. Particle packing theory guided multiscale alumina filled epoxy resin with excellent thermal and dielectric performances. J. Mater. 2022, 8, 1058–1066. [Google Scholar] [CrossRef]

- Lee, E.H.; Ahn, J.S.; Lim, Y.J.; Kwon, H.B.; Kim, M.J. Effect of post-curing time on the color stability and related properties of a tooth-colored 3D-printed resin material. J. Mech. Behav. Biomed. Mater. 2022, 126, 104993. [Google Scholar] [CrossRef] [PubMed]

- Intralawan, N.; Wasanapiarnpong, T.; Didron, P.P.; Rakmanee, T.; Klaisiri, A.; Krajangta, N. Surface Discoloration of 3D Printed Resin-Ceramic Hybrid Materials against Various Stain Beverages. J. Int. Dent. Med. Res. 2022, 15, 1465–1471. [Google Scholar]

- Alsharif, S.O.; Akil, H.B.M.; El-Aziz, N.A.A.; Ahmad, Z.A.B. Effect of alumina particles loading on the mechanical properties of light-cured dental resin composites. Mater. Des. 2014, 54, 430–435. [Google Scholar] [CrossRef]

- Graf, T.; Erdelt, K.-J.; Güth, J.-F.; Edelhoff, D.; Schubert, O.; Schweiger, J. Influence of pre-treatment and artificial aging on the retention of 3D-printed permanent composite crowns. Biomedicines 2022, 10, 2186. [Google Scholar] [CrossRef]

- Grzebieluch, W.; Kowalewski, P.; Grygier, D.; Rutkowska-Gorczyca, M.; Kozakiewicz, M.; Jurczyszyn, K. Printable and machinable dental restorative composites for cad/cam application—Comparison of mechanical properties, fractographic, texture and fractal dimension analysis. Materials 2021, 14, 4919. [Google Scholar] [CrossRef]

- Prause, E.; Hey, J.; Beuer, F.; Yassine, J.; Hesse, B.; Weitkamp, T.; Gerber, J.; Schmidt, F. Microstructural investigation of hybrid CAD/CAM restorative dental materials by micro-CT and SEM. Dent. Mater. 2024, 40, 930–940. [Google Scholar] [CrossRef]

- Kuroda, K.; Okido, M. Osteoconductivity control based on the chemical properties of the implant surface. J. Biomater. Nanobiotechnol. 2017, 9, 26–40. [Google Scholar] [CrossRef]

- McGrath, L.M.; Parnas, R.S.; King, S.H.; Schroeder, J.L.; Fischer, D.A.; Lenhart, J.L. Investigation of the thermal, mechanical, and fracture properties of alumina–epoxy composites. Polymer 2008, 49, 999–1014. [Google Scholar] [CrossRef]

- Tzeng, J.-J.; Yang, T.-S.; Lee, W.-F.; Chen, H.; Chang, H.-M. Mechanical properties and biocompatibility of urethane acrylate-based 3D-printed denture base resin. Polymers 2021, 13, 822. [Google Scholar] [CrossRef] [PubMed]

- Idrees, M.; Yoon, H.; Palmese, G.R.; Alvarez, N.J. Engineering toughness in a brittle vinyl ester resin using urethane acrylate for additive manufacturing. Polymers 2023, 15, 3501. [Google Scholar] [CrossRef] [PubMed]

- Kuang, G.; Bakhshi, H.; Meyer, W. Urethane-acrylate-based photo-inks for digital light processing of flexible materials. J. Polym. Res. 2023, 30, 141. [Google Scholar] [CrossRef]

- Venturini, A.B.; Prochnow, C.; Pereira, G.K.; Segala, R.D.; Kleverlaan, C.J.; Valandro, L.F. Fatigue performance of adhesively cemented glass-, hybrid-and resin-ceramic materials for CAD/CAM monolithic restorations. Dent. Mater. 2019, 35, 534–542. [Google Scholar] [CrossRef] [PubMed]

- Sorrentino, R.; Nagasawa, Y.; Infelise, A.; Bonadeo, G.; Ferrari, M. In vitro analysis of the fracture resistance of CAD-CAM Cerasmart molar crowns with different occlusal thickness. Biomed. J. Sci. Tech. Res. 2018, 3, 3074–3079. [Google Scholar] [CrossRef]

- Singh, S.; Utreja, A.K.; Sandhu, N.; Dhaliwal, Y.S. An innovative miniature bite force recorder. Int. J. Clin. Pediatr. Dent. 2010, 4, 113. [Google Scholar] [CrossRef] [PubMed]

- de Abreu, R.A.M.; Pereira, M.D.; Furtado, F.; Prado, G.P.R.; Mestriner, W., Jr.; Ferreira, L.M. Masticatory efficiency and bite force in individuals with normal occlusion. Arch. Oral Biol. 2014, 59, 1065–1074. [Google Scholar] [CrossRef]

- Donmez, M.B.; Okutan, Y. Marginal gap and fracture resistance of implant-supported 3D-printed definitive composite crowns: An in vitro study. J. Dent. 2022, 124, 104216. [Google Scholar] [CrossRef]

- Suksuphan, P.; Krajangta, N.; Didron, P.P.; Wasanapiarnpong, T.; Rakmanee, T. Marginal adaptation and fracture resistance of milled and 3D-printed CAD/CAM hybrid dental crown materials with various occlusal thicknesses. J. Prosthodont. Res. 2023, 68, 326–335. [Google Scholar] [CrossRef]

- Zimmermann, M.; Ender, A.; Egli, G.; Özcan, M.; Mehl, A. Fracture load of CAD/CAM-fabricated and 3D-printed composite crowns as a function of material thickness. Clin. Oral Investig. 2019, 23, 2777–2784. [Google Scholar] [CrossRef]

- Dong, X.D.; Wang, H.R.; Darvell, B.W.; Lo, S.H. Effect of stiffness of cement on stress distribution in ceramic crowns. Chin. J. Dent. Res. 2016, 19, 217–223. [Google Scholar]

- Yucel, M.T.; Yondem, I.; Aykent, F.; Eraslan, O. Influence of the supporting die structures on the fracture strength of all-ceramic materials. Clin. Oral Investig. 2012, 16, 1105–1110. [Google Scholar] [CrossRef]

- Liu, B.; Lu, C.; Wu, Y.; Zhang, X.; Arola, D.; Zhang, D. The effects of adhesive type and thickness on stress distribution in molars restored with all-ceramic crowns. J. Prosthodont. Implant Esthet. Reconstr. Dent. 2011, 20, 35–44. [Google Scholar] [CrossRef]

- Papadogiannis, Y.; Boyer, D.; Helvatjoglu-Antoniades, M.; Lakes, R.; Kapetanios, C. Dynamic viscoelastic behavior of resin cements measured by torsional resonance. Dent. Mater. 2003, 19, 510–516. [Google Scholar] [CrossRef]

- Saskalauskaite, E.; Tam, L.E.; McComb, D. Flexural strength, elastic modulus, and pH profile of self-etch resin luting cements. J. Prosthodont. 2008, 17, 262–268. [Google Scholar] [CrossRef]

- Thompson, J. Microscopic and energy dispersive x-ray analysis of surface adaptation of dental cements to dental ceramic surfaces. J. Prosthet. Dent. 1998, 79, 378–383. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Zheng, Z.; Wu, M.; Zheng, C.; Zeng, Y.; Yan, W. Influence of restorative material and cement on the stress distribution of endocrowns: 3D finite element analysis. BMC Oral Health 2021, 21, 495. [Google Scholar] [CrossRef]

- Anusavice, K.; Tsai, Y. Stress distribution in ceramic crown forms as a function of thickness, elastic modulus, and supporting substrate. In Proceedings of the 16th Southern Biomedical Engineering Conference, Biloxi, MS, USA, 4–6 April 1997; IEEE: New York, NY, USA, 1997; pp. 264–267. [Google Scholar]

- Shahrbaf, S.; Van Noort, R.; Mirzakouchaki, B.; Ghassemieh, E.; Martin, N. Fracture strength of machined ceramic crowns as a function of tooth preparation design and the elastic modulus of the cement. Dent. Mater. 2014, 30, 234–241. [Google Scholar] [CrossRef] [PubMed]

- Lia, Z.C.; White, S.N. Mechanical properties of dental luting cements. J. Prosthet. Dent. 1999, 81, 597–609. [Google Scholar] [CrossRef] [PubMed]

- Ha, S.-R. Biomechanical three-dimensional finite element analysis of monolithic zirconia crown with different cement type. J. Adv. Prosthodont. 2015, 7, 475. [Google Scholar] [CrossRef]

- Shahrbaf, S.; Vannoort, R.; Mirzakouchaki, B.; Ghassemieh, E.; Martin, N. Effect of the crown design and interface lute parameters on the stress-state of a machined crown–tooth system: A finite element analysis. Dent. Mater. 2013, 29, e123–e131. [Google Scholar] [CrossRef]

- BEGO Bremer Goldschlägerei Wilh. Herbst GmbH & Co. KG. VarseoSmile Crown Plus: Instructions for Use; BEGO: Bremen, Germany, 2023. [Google Scholar]

- CERASMART™. The New Leader in Hybrid Ceramic Blocks; GC International AG: Luzern, Switzerland, 2019. [Google Scholar]

- Ben-Izhack, G.; Shely, A.; Naishlos, S.; Glikman, A.; Frishman, L.; Meirowitz, A.; Dolev, E. The Influence of Three Different Digital Cement Spacers on the Marginal Gap Adaptation of Zirconia-Reinforced Lithium Silicate Crowns Fabricated by CAD-CAM System. Appl. Sci. 2021, 11, 10709. [Google Scholar] [CrossRef]

- Wimmer, T.; Erdelt, K.J.; Raith, S.; Schneider, J.M.; Stawarczyk, B.; Beuer, F. Effects of differing thickness and mechanical properties of cement on the stress levels and distributions in a three-unit zirconia fixed prosthesis by FEA. J. Prosthodont. 2014, 23, 358–366. [Google Scholar] [CrossRef]

- Di Fiore, A.; Stellini, E.; Alageel, O.; Alhotan, A. Comparison of mechanical and surface properties of two 3D printed composite resins for definitive restoration. J. Prosthet. Dent. 2024, 132, 839.e1–839.e7. [Google Scholar] [CrossRef]

- Lassila, L.; Novotny, R.; Säilynoja, E.; Vallittu, P.K.; Garoushi, S. Wear behavior at margins of direct composite with CAD/CAM composite and enamel. Clin. Oral Investig. 2023, 27, 2419–2426. [Google Scholar] [CrossRef] [PubMed]

- Pallis, K.; Griggs, J.A.; Woody, R.D.; Guillen, G.E.; Miller, A.W. Fracture resistance of three all-ceramic restorative systems for posterior applications. J. Prosthet. Dent. 2004, 91, 561–569. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, K.; Harada, A.; Inagaki, R.; Kanno, T.; Niwano, Y.; Milleding, P.; Örtengren, U. Fracture resistance of monolithic zirconia molar crowns with reduced thickness. Acta Odontol. Scand. 2015, 73, 602–608. [Google Scholar] [CrossRef] [PubMed]

- Torkian, P.; Mortazavi Najafabadi, S.; Ghashang, M.; Grzelczyk, D. Glass-Ceramic Fillers Based on Zinc Oxide–Silica Systems for Dental Composite Resins: Effect on Mechanical Properties. Materials 2023, 16, 6268. [Google Scholar] [CrossRef]

- de Souza Balbinot, G.; Leitune, V.C.B.; Ogliari, F.A.; Collares, F.M. Niobium silicate particles as bioactive fillers for composite resins. Dent. Mater. 2020, 36, 1578–1585. [Google Scholar] [CrossRef]

- Shortall, A.; Palin, W.; Burtscher, P. Refractive index mismatch and monomer reactivity influence composite curing depth. J. Dent. Res. 2008, 87, 84–88. [Google Scholar] [CrossRef]

- Watts, D.C. Radiopacity vs. composition of some barium and strontium glass composites. J. Dent. 1987, 15, 38–43. [Google Scholar] [CrossRef]

- Bowen, R. X-Ray-Opaque Reinforcing Fillers for Composite Materials: Progress Report; National Institute of Standards and Technology: Gaithersburg, MD, USA, 1968. [Google Scholar]

- Lin, C.-H.; Lin, Y.-M.; Lai, Y.-L.; Lee, S.-Y. Mechanical properties, accuracy, and cytotoxicity of UV-polymerized 3D printing resins composed of Bis-EMA, UDMA, and TEGDMA. J. Prosthet. Dent. 2020, 123, 349–354. [Google Scholar] [CrossRef]

- Zattera, A.C.A.; Morganti, F.A.; de Souza Balbinot, G.; Della Bona, A.; Collares, F.M. The influence of filler load in 3D printing resin-based composites. Dent. Mater. 2024, 40, 1041–1046. [Google Scholar] [CrossRef]

- Elfakhri, F.; Alkahtani, R.; Li, C.; Khaliq, J. Influence of filler characteristics on the performance of dental composites: A comprehensive review. Ceram. Int. 2022, 48, 27280–27294. [Google Scholar] [CrossRef]

- Bora, P.V.; Sayed Ahmed, A.; Alford, A.; Pitttman, K.; Thomas, V.; Lawson, N.C. Characterization of materials used for 3D printing dental crowns and hybrid prostheses. J. Esthet. Restor. Dent. 2024, 36, 220–230. [Google Scholar] [CrossRef]

- Fidalgo-Pereira, R.; Carpio, D.; Torres, O.; Carvalho, O.; Silva, F.; Henriques, B.; Özcan, M.; Souza, J.C.M. The influence of inorganic fillers on the light transmission through resin-matrix composites during the light-curing procedure: An integrative review. Clin. Oral Investig. 2022, 26, 5575–5594. [Google Scholar] [CrossRef]

- Chen, H.; Lee, S.-Y.; Lin, Y.-M. Synthesis and Formulation of PCL-Based Urethane Acrylates for DLP 3D Printers. Polymers 2020, 12, 1500. [Google Scholar] [CrossRef] [PubMed]

- GC. CERASMART™270. Force Absorbing Hybrid Ceramic CAD/CAM Block. Available online: https://www.google.com/url?sa=i&url=https%3A%2F%2Fwww.gc.dental%2Findia%2Fsites%2Findia.gc.dental%2Ffiles%2Fproducts%2Fdownloads%2Fcerasmart270%2Fleaflet%2FLFL_CERASMART270_en.pdf&psig=AOvVaw2XtN_4TvLccOMbzEyjQ7la&ust=1743678127901000&source=images&cd=vfe&opi=89978449&ved=0CAYQrpoMahcKEwiYycW_mbmMAxUAAAAAHQAAAAAQBA (accessed on 2 April 2025).

- Mudhaffer, S.; Silikas, N.; Satterthwaite, J. Effect of print orientation on sorption, solubility, and monomer elution of 3D printed resin restorative materials. J. Prosthet. Dent. 2025, 134, 461.e1–461.e12. [Google Scholar] [CrossRef] [PubMed]

- Malacarne, J.; Carvalho, R.M.; de Goes, M.F.; Svizero, N.; Pashley, D.H.; Tay, F.R.; Yiu, C.K.; de Oliveira Carrilho, M.R. Water sorption/solubility of dental adhesive resins. Dent. Mater. 2006, 22, 973–980. [Google Scholar] [CrossRef]

- Berghaus, E.; Klocke, T.; Maletz, R.; Petersen, S. Degree of conversion and residual monomer elution of 3D-printed, milled and self-cured resin-based composite materials for temporary dental crowns and bridges. J. Mater. Sci. Mater. Med. 2023, 34, 23. [Google Scholar] [CrossRef]

- Ayad, N.M.; Badawi, M.F.; Fatah, A.A. Effect of reinforcement of high-impact acrylic resin with zirconia on some physical and mechanical properties. Arch. Oral Res. 2008, 4, 145–151. [Google Scholar]

- Ellakwa, A.E.; Morsy, M.A.; El-Sheikh, A.M. Effect of aluminum oxide addition on the flexural strength and thermal diffusivity of heat-polymerized acrylic resin. J. Prosthodont. 2008, 17, 439–444. [Google Scholar] [CrossRef]

- Liang, X.; Qiu, Y.; Zhou, S.; Hu, X.; Yu, G.; Deng, X. Preparation and properties of dental zirconia ceramics. J. Univ. Sci. Technol. Beijing Miner. Met. Mater. 2008, 15, 764–768. [Google Scholar] [CrossRef]

- Gain, A.K.; Song, H.-Y.; Lee, B.-T. Microstructure and mechanical properties of porous yttria stabilized zirconia ceramic using poly methyl methacrylate powder. Scr. Mater. 2006, 54, 2081–2085. [Google Scholar] [CrossRef]

- Bora, P.V.; Lawson, N.C.; Givan, D.A.; Arce, C.; Roberts, H. Enamel wear and fatigue resistance of 3D printed resin compared with lithium disilicate. J. Prosthet. Dent. 2025, 133, 523.e1–523.e9. [Google Scholar] [CrossRef]

- Raszewski, Z.; Kulbacka, J.; Nowakowska-Toporowska, A. Mechanical properties, cytotoxicity, and fluoride ion release capacity of bioactive glass-modified methacrylate resin used in three-dimensional printing technology. Materials 2022, 15, 1133. [Google Scholar] [CrossRef]

- Vohra, F.; Altwaim, M.; Alshuwaier, A.S.; Al Deeb, M.; Alfawaz, Y.; Alrabiah, M.; Abduljabbar, T. Influence of Bioactive, Resin and Glass Ionomer luting cements on the fracture loads of dentin bonded ceramic crowns. Pak. J. Med. Sci. 2020, 36, 416. [Google Scholar] [CrossRef]

- D’Addazio, G.; Santilli, M.; Rollo, M.L.; Cardelli, P.; Rexhepi, I.; Murmura, G.; Al-Haj Husain, N.; Sinjari, B.; Traini, T.; Özcan, M. Fracture resistance of Zirconia-reinforced lithium silicate ceramic crowns cemented with conventional or adhesive systems: An in vitro study. Materials 2020, 13, 2012. [Google Scholar] [CrossRef]

- Al-Wahadni, A.M.; Hussey, D.L.; Grey, N.; Hatamleh, M.M. Fracture resistance of aluminium oxide and lithium disilicate-based crowns using different luting cements: An in vitro study. J. Contemp. Dent. Pract. 2011, 10, 51–58. [Google Scholar] [CrossRef]

- Davidson, C.; Van Zeghbroeck, L.; Feilzer, A. Destructive stresses in adhesive luting cements. J. Dent. Res. 1991, 70, 880–882. [Google Scholar] [CrossRef] [PubMed]

- Uzun, İ.H.; Malkoç, M.A.; Keleş, A.; Öğreten, A.T. 3D micro-CT analysis of void formations and push-out bonding strength of resin cements used for fiber post cementation. J. Adv. Prosthodont. 2016, 8, 101–109. [Google Scholar] [CrossRef] [PubMed]

- Grandini, S.; Goracci, C.; Monticelli, F.; Borracchini, A.; Ferrari, M. SEM evaluation of the cement layer thickness after luting two different posts. J. Adhes. Dent. 2005, 7, 235. [Google Scholar]

- Chang, Y.-H.; Wang, H.-W.; Lin, P.-H.; Lin, C.-L. Evaluation of early resin luting cement damage induced by voids around a circular fiber post in a root canal treated premolar by integrating micro-CT, finite element analysis and fatigue testing. Dent. Mater. 2018, 34, 1082–1088. [Google Scholar] [CrossRef]

- Chang, Y.-H.; Lee, H.; Lin, C.-L. Early resin luting material damage around a circular fiber post in a root canal treated premolar by using micro-computerized tomographic and finite element sub-modeling analyses. J. Mech. Behav. Biomed. Mater. 2015, 51, 184–193. [Google Scholar] [CrossRef]

- Spinell, T.; Schedle, A.; Watts, D.C. Polymerization shrinkage kinetics of dimethacrylate resin-cements. Dent. Mater. 2009, 25, 1058–1066. [Google Scholar] [CrossRef] [PubMed]

- Baroudi, K.; Saleh, A.M.; Silikas, N.; Watts, D.C. Shrinkage behaviour of flowable resin-composites related to conversion and filler-fraction. J. Dent. 2007, 35, 651–655. [Google Scholar] [CrossRef]

- Mojon, P.; Kaltio, R.; Feduik, D.; Hawbolt, E.B.; MacEntee, M.I. Short-term contamination of luting cements by water and saliva. Dent. Mater. Dent. Mater. 1996, 12, 83–87. [Google Scholar] [CrossRef]

- Egilmez, F.; Ergun, G.; Cekic-Nagas, I.; Vallittu, P.K.; Lassila, L.V. Does artificial aging affect mechanical properties of CAD/CAM composite materials. J. Prosthodont. Res. 2018, 62, 65–74. [Google Scholar] [CrossRef]

- Sonmez, N.; Gultekin, P.; Turp, V.; Akgungor, G.; Sen, D.; Mijiritsky, E. Evaluation of five CAD/CAM materials by microstructural characterization and mechanical tests: A comparative in vitro study. BMC Oral Health 2018, 18, 5. [Google Scholar] [CrossRef] [PubMed]

- Lauvahutanon, S.; Takahashi, H.; Shiozawa, M.; Iwasaki, N.; Asakawa, Y.; Oki, M.; Finger, W.J.; Arksornnukit, M. Mechanical properties of composite resin blocks for CAD/CAM. Dent. Mater. J. 2014, 33, 705–710. [Google Scholar] [CrossRef] [PubMed]

- Druck, C.C.; Pozzobon, J.L.; Callegari, G.L.; Dorneles, L.S.; Valandro, L.F. Adhesion to Y-TZP ceramic: Study of silica nanofilm coating on the surface of Y-TZP. J. Biomed. Mater. Res. Part B Appl. Biomater. 2015, 103, 143–150. [Google Scholar] [CrossRef]

- Lassila, L.; Uctasli, M.B.; Wada, K.; Vallittu, P.K.; Garoushi, S. Effect of different beverages and polishing techniques on colour stability of CAD/CAM composite restorative materials. Biomater. Investig. Dent. 2024, 11, 40591. [Google Scholar] [CrossRef]

| Group | Product | Manufacturer | Composition | Elastic Modulus (Gpa) | Lot. No. |

|---|---|---|---|---|---|

| Milling | Cerasmart® 270 (CE) | GC, Tokyo, Japan | Bis-MEPP, UDMA, dimethacrylate, silica (20 nm), and barium glass (300 nm) 71 wt.% | 9.6 | 2108056 |

| 3D-Printing | VarseoSmile Crown Plus® (VE) | Bego, Bremen, Germany | Esterification products of 4.4′-isopropylidiphenol, ethoxylated and 2-methylprop-2enoic acid. Silanized dental glass, methyl benzoylformate, diphenyl (2,4,6-trimethylbenzoyl) phosphine oxide. Total content of inorganic fillers (particle size 0.7 μm) is 30–50 wt.% | 4.4 | 601817 |

| Hassawat-01 (HS) | Faculty of Science, Chulalongkorn University, Bangkok, Thailand | Urethane acrylate, 2-Phenoxyethyl acrylate, Tripropyleneglycol diacrylate, Trimethylolpropane triacrylate, Trimethyl benzoyl diphenyl phosphine oxide (61.5 wt.% total resin), and Aluminum oxide 0.7 μm 38.5 wt.% | 4.75 | N/A | |

| Luting cement | Maxcem Elite® | SDS Kerr, Orange, CA, USA | Glyceroldimethacrylate dihydrogen phosphate (GPDM) hydroxyethylmethacrylat (HEMA), 4-methoxyphenol (MEHQ), cumolhydroperoxid (CHPO), methacrylate ester monomers, titanium dioxide, pigments | 4 | A159983 |

| RelyX Unicem® | 3M ESPE, Saint Paul, MN, USA | Powder: glass fillers, silica, calcium hydroxide, self-curing initiators, pigments, light-curing initiators, substituted pyrimidine, peroxy compound. Liquid: methacrylated phosphoric esters, dimethacrylates, acetate, stabilizers, self-curing initiators, light-curing initiators | 13.0 | 10684647 | |

| Ketac Cem® | 3M ESPE, Saint Paul, MN, USA | non-reactive zirconia silica filler, the methacrylated polycarboxylic acid, HEMA, BisGMA, water and potassium persulfate. | 20 | 10605282 | |

| Silane Coupling Agent | RelyX Ceramic Primer® | 3M ESPE, Saint Paul, MN, USA | Ethyl alcohol, water, 3-methacryloxypropyltrimethoxysilane | - | NF44358 |

| Resin die | Rigid 10K Resin | Formlabs Inc., Somerville, MA, USA | Highly glass-filled resin-based methacrylate | 14.9 | N/A |

| Types of Ceramic | Luting Cement | Cracked Crowns (n) | Fractured Crowns (n) | Mean ± SD (N) | Min. (N) | Max. (N) |

|---|---|---|---|---|---|---|

| Cerasmart® 270 (CE) | Maxem Elite® (n = 11) | 0 | 0 | >2000 | N/A | N/A |

| Rely X Unicem® (n = 11) | 0 | 0 | >2000 | N/A | N/A | |

| Ketac Cem® (n = 11) | 0 | 4 | 2000 | 2000 | 2000 | |

| VarseoSmile Crown Plus® (VS) | Maxem Elite (n = 11) | 0 | 0 | >2000 | N/A | N/A |

| RelyX Unicem® (n = 11) | 0 | 0 | >2000 | N/A | N/A | |

| Ketac Cem® (n = 11) | 4 | 7 | 1795.2 ± 156.7 | 1689.9 | 1980.0 | |

| Hassawat-01 (HS) | Maxem Elite® (n = 11) | 0 | 0 | >2000 | N/A | N/A |

| RelyX Unicem® (n = 11) | 0 | 0 | >2000 | N/A | N/A | |

| Ketac Cem® (n = 11) | 11 | 0 | 1732.6 ± 127.3 | 1540.6 | 1875.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Sriprasert, N.; Krajangta, N.; Wasanapiarnpong, T.; Didron, P.P.; Rakmanee, T. Fracture Resistance of Commercial and Novel Ceramic-Reinforced Polymer Crowns with Luting Cements of Varying Elastic Modulus. Polymers 2026, 18, 25. https://doi.org/10.3390/polym18010025

Sriprasert N, Krajangta N, Wasanapiarnpong T, Didron PP, Rakmanee T. Fracture Resistance of Commercial and Novel Ceramic-Reinforced Polymer Crowns with Luting Cements of Varying Elastic Modulus. Polymers. 2026; 18(1):25. https://doi.org/10.3390/polym18010025

Chicago/Turabian StyleSriprasert, Naluemol, Nantawan Krajangta, Thanakorn Wasanapiarnpong, Pavinee Padipatvuthikul Didron, and Thanasak Rakmanee. 2026. "Fracture Resistance of Commercial and Novel Ceramic-Reinforced Polymer Crowns with Luting Cements of Varying Elastic Modulus" Polymers 18, no. 1: 25. https://doi.org/10.3390/polym18010025

APA StyleSriprasert, N., Krajangta, N., Wasanapiarnpong, T., Didron, P. P., & Rakmanee, T. (2026). Fracture Resistance of Commercial and Novel Ceramic-Reinforced Polymer Crowns with Luting Cements of Varying Elastic Modulus. Polymers, 18(1), 25. https://doi.org/10.3390/polym18010025