Evaluation of the Effect of Different Light-Curing Protocols on the Microhardness of Contemporary Bulk-Fill Resin Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Tested Materials and Light-Curing Protocols

2.2. Specimen Preparation

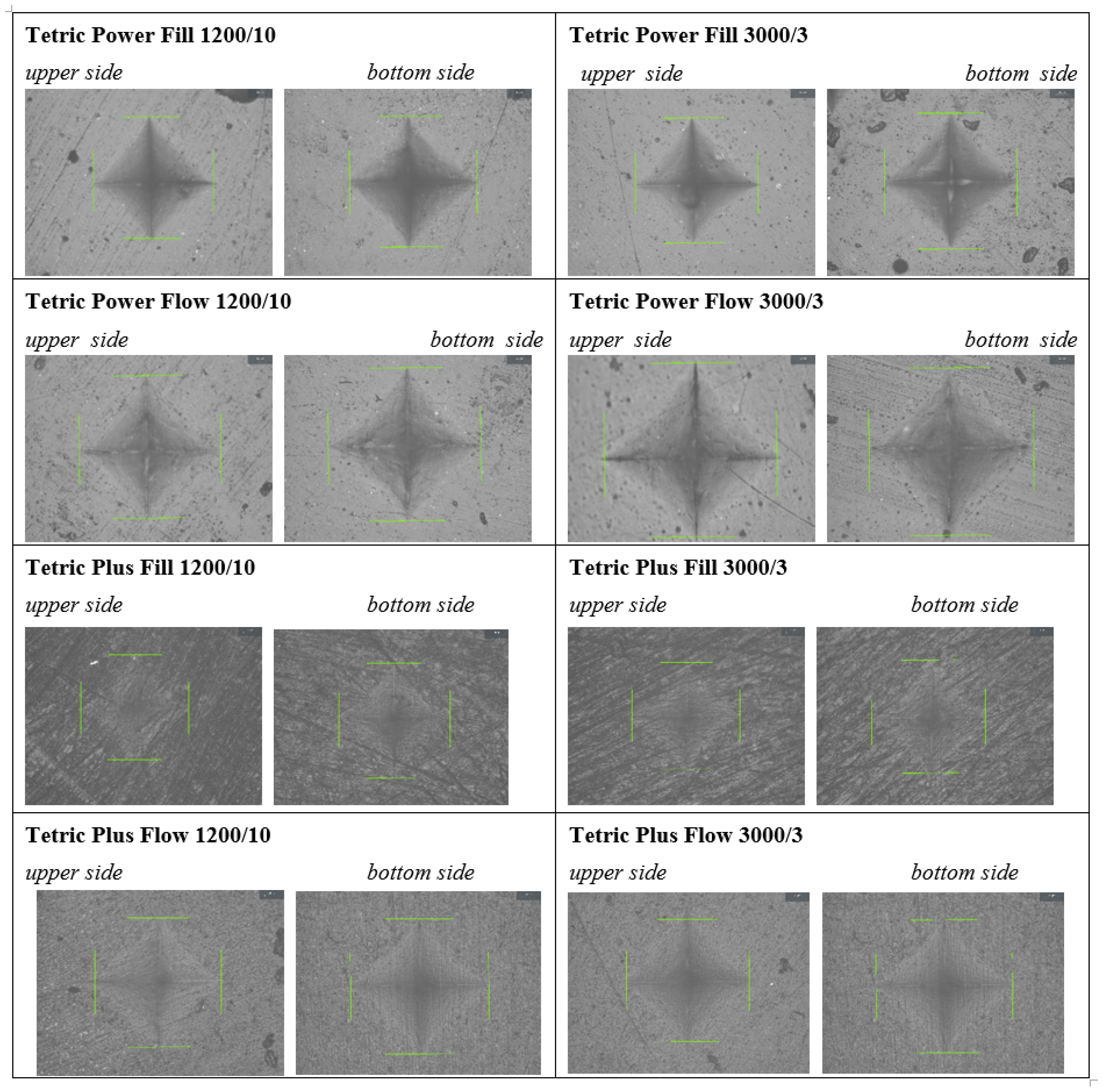

2.3. Microhardness Measurement Protocol

2.4. Statistical Analysis

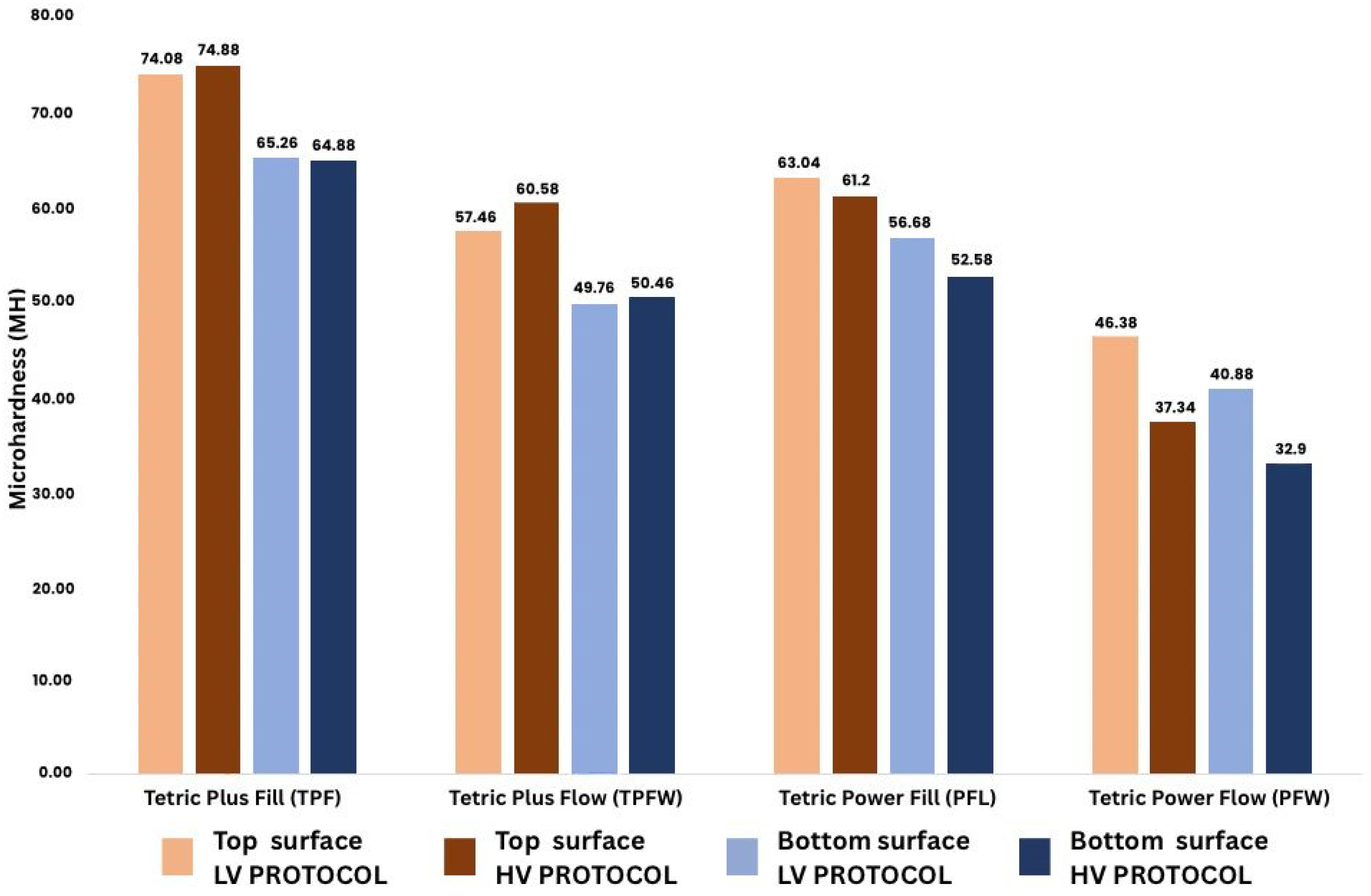

3. Results

4. Discussion

5. Conclusions

- The MH of RBCs is influenced by both material composition and the applied light-curing protocol.

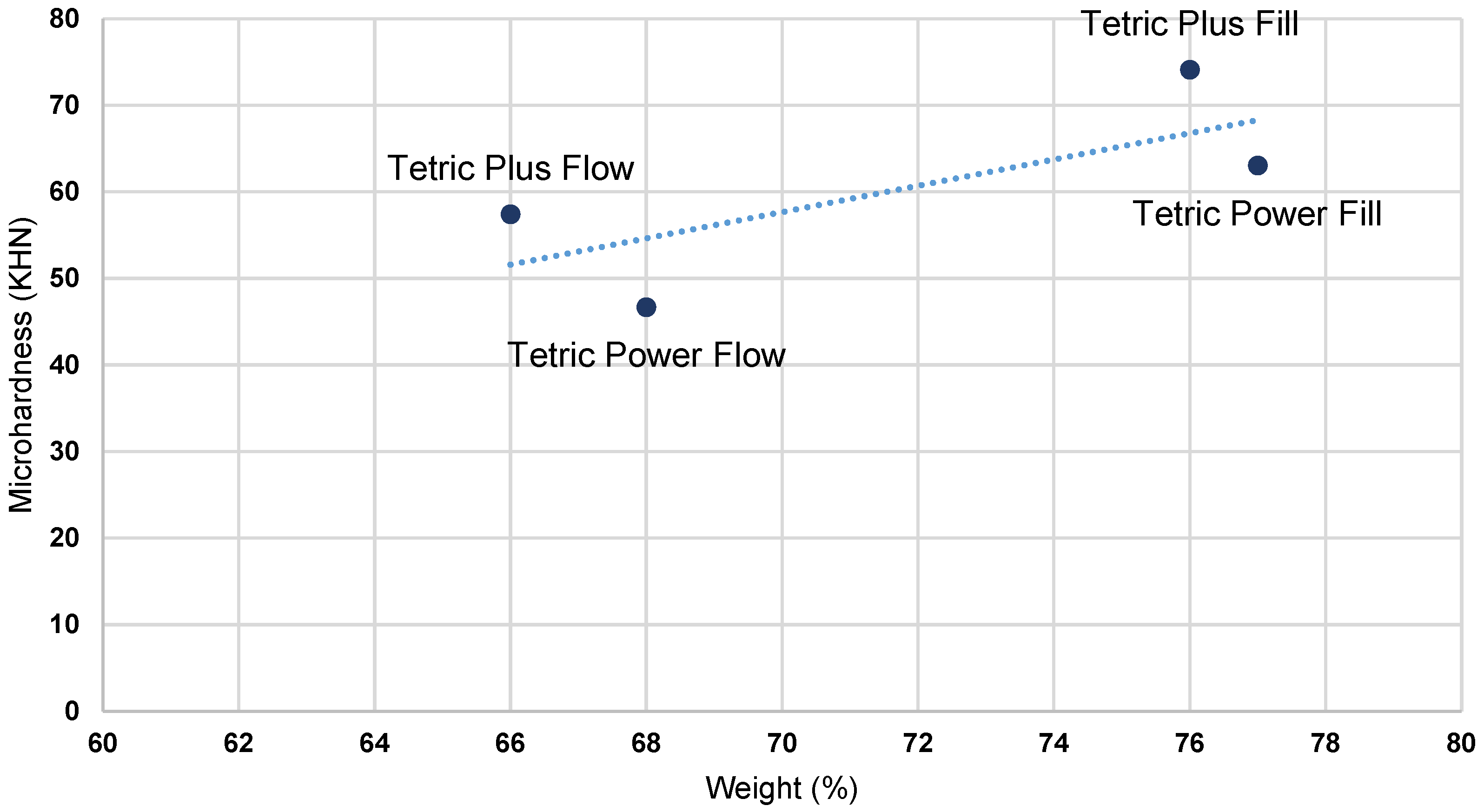

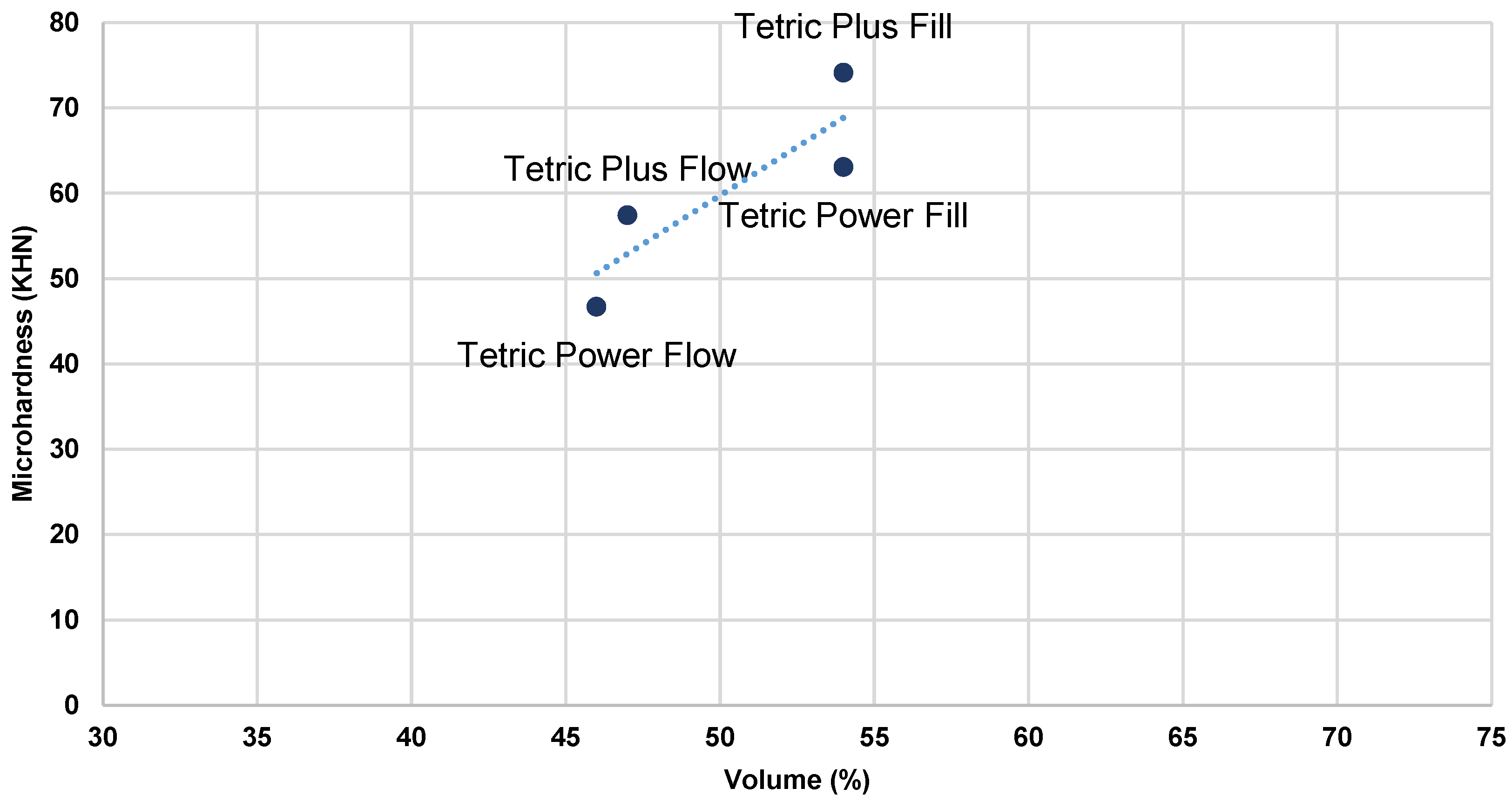

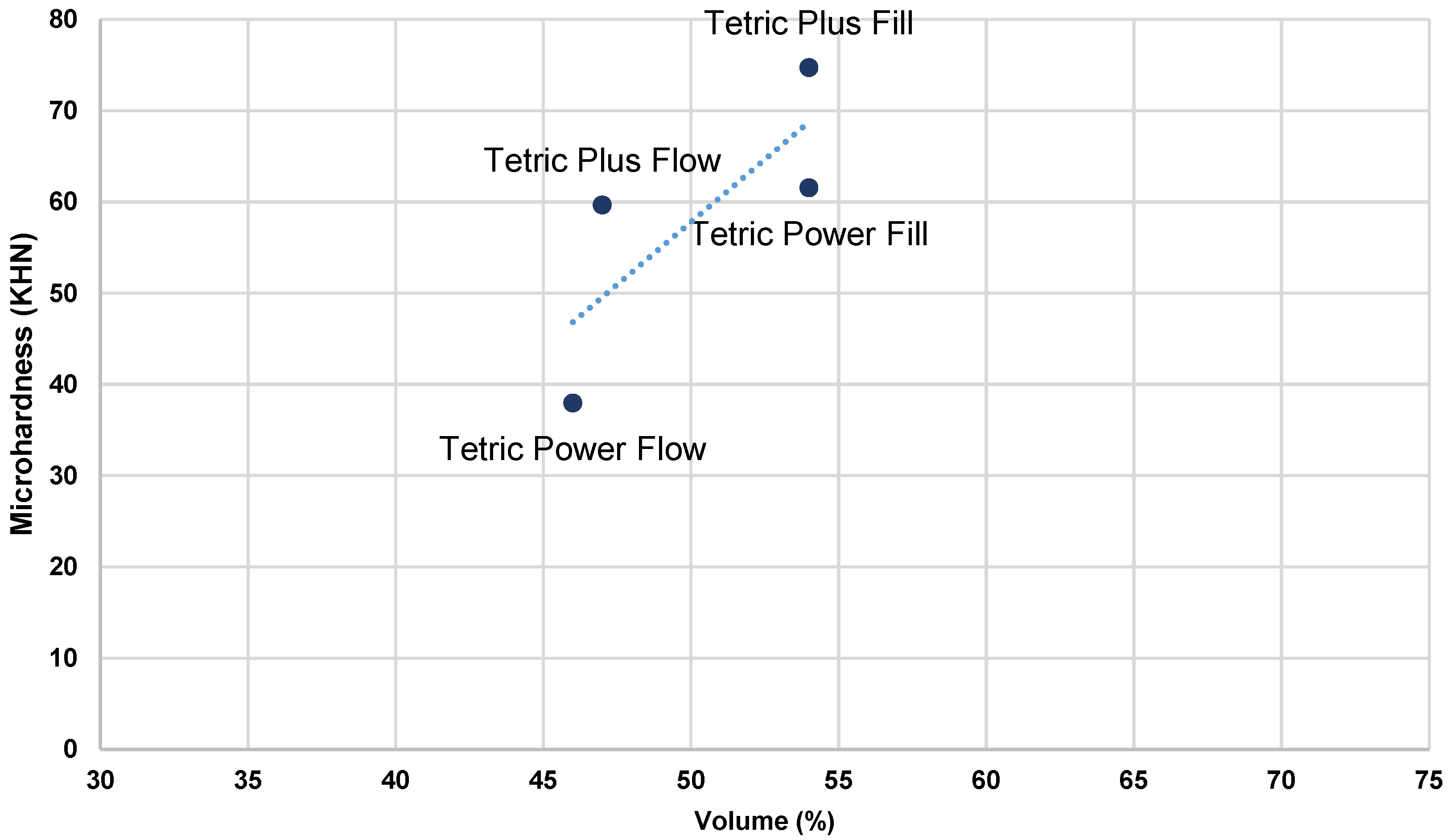

- Higher filler content, expressed both by weight and volume, was consistently associated with increased MH values under both LV and HV protocols, with filler volume demonstrating the stronger correlation.

- The effect of high-intensity light-curing on micromechanical properties was markedly dependent on material composition. Both flowable and sculptable Tetric Plus composites exhibited higher MH values under the HV protocol on both specimen surfaces, whereas the Tetric Power composites demonstrated greater initial hardness under the LV protocol. The flowable composite PFW showed the most pronounced reduction in MH under the HV protocol.

- Despite these differences, the bottom-to-top MH ratio exceeded 80% for all tested bulk-fill composites, indicating adequate polymerization throughout the composite layers.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ferracane, J.L. Resin composite—State of the art. Dent. Mater. 2011, 27, 29–38. [Google Scholar] [CrossRef] [PubMed]

- Rueggeberg, F.A. State-of-the-art: Dental photocuring—A review. Dent. Mater. 2011, 27, 39–52. [Google Scholar] [CrossRef]

- Ilie, N.; Hickel, R. Investigations on Mechanical Behaviour of Dental Composites. Clin. Oral Investig. 2009, 13, 427–438. [Google Scholar] [CrossRef]

- Demarco, F.F.; Collares, K.; Correa, M.B.; Cenci, M.; De Moraes, R.R.; Opdam, N.J. Should my composite restorations last forever? Why are they failing? Braz. Oral Res. 2017, 31, e56. [Google Scholar] [CrossRef] [PubMed]

- Singh, J.; Rajkumar, B.; Boruah, L.C.; Gupta, V.; Batt, A. Bulk fill composites in dentistry- A review. Indian J. Conserv. Endod. 2019, 4, 9–13. [Google Scholar] [CrossRef]

- Colombo, M.; Gallo, S.; Poggio, C.; Ricaldone, V.; Arciola, C.R.; Scribante, A. New Resin-Based Bulk-Fill Composites: In vitro Evaluation of Micro-Hardness and Depth of Cure as Infection Risk Indexes. Materials 2020, 13, 1308. [Google Scholar] [CrossRef]

- Baltacioğlu, İ.H.; Demirel, G.; Öztürk, B.; Aydin, F.; Orhan, K. Marginal adaptation of bulk-fill resin composites with different viscosities in class II restorations: A micro-CT evaluation. BMC Oral Health 2024, 24, 228. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Ivoclar Scientific Report. Tetric Plus—Scientific Report, Rev0, February 2025. Schaan, Liechtenstein: Ivoclar Vivadent AG; 2025. Available online: https://www.ivoclar.com/medias/Tetric-plus-ScientificReport-EN-Rev0-18Feb25.pdf?context=bWFzdGVyfGNlbHVtLWNvbm5lY3QyLWFzc2V0c3wzNzg1MzM4fGFwcGxpY2F0aW9uL3BkZnxhR0U1TDJoa1l5OHhNakEwTVRFMU5UQTRORE14T0M5VVpYUnlhV01nY0d4MWMxOVRZMmxsYm5ScFptbGpVbVZ3YjNKMFgwVk9YMUpsZGpCZk1UaEdaV0l5TlM1d1pHWXw1ZDVlMDgwZmFkNjZjNDhmMGYxZTEwYzMzODQzMzMyZDE3YjNmYWMzZTIzZjUwOWQ2N2JiOTI5Mzc3NTU5ZjBk (accessed on 24 October 2025).

- Marović, D.; Par, M.; Macan, M.; Klarić, N.; Plazonić, I.; Tarle, Z. Aging-dependent changes in mechanical properties of the new generation of bulk-fill composites. Materials 2022, 15, 902. [Google Scholar] [CrossRef] [PubMed]

- Atalı, P.Y.; Kaya, B.D.; Özen, A.M.; Tarçın, B.; Şenol, A.A.; Bayraktar, E.T.; Korkut, B.; Göçmen, G.B.; Tağtekin, D.; Türkmen, C. Assessment of Micro-Hardness, Degree of Conversion, and Flexural Strength for Single-Shade Universal Resin Composites. Polymers 2022, 14, 4987. [Google Scholar] [CrossRef]

- Marovic, D.; Par, M.; Crnadak, A.; Sekelja, A.; Negovetic Mandic, V.; Gamulin, O.; Rakić, M.; Tarle, Z. Rapid 3 s curing: What happens in deep layers of new generation bulk-fill resin composites? Materials 2021, 14, 515. [Google Scholar] [CrossRef]

- Steffen, T.; Par, M.; Attin, T.; Tauböck, T.T. Effect of Fast High-Irradiance Photo-Polymerization of Resin Composites on the Dentin Bond Strength. Materials 2022, 15, 7467. [Google Scholar] [CrossRef]

- Miranda, S.B.; Lins, R.B.E.; Santi, M.R.; Denucci, G.C.; Silva, C.C.S.; da Silva, S.d.F.F.; Marques, D.D.A.V.; Montes, M.A.J.R. Effect of rapid high-intensity light-curing on increasing transdentinal temperature and cell viability: An in vitro study. Polymers 2024, 16, 1466. [Google Scholar] [CrossRef] [PubMed]

- Par, M.; Burrer, P.; Prskalo, K.; Schmid, S.; Schubiger, A.L.; Marovic, D.; Tarle, Z.; Attn, T.; Tauböck, T.T. Polymerization kinetics and development of polymerization shrinkage stress in rapid high-intensity light-curing. Polymers 2022, 14, 3296. [Google Scholar] [CrossRef]

- Thomaidis, S.; Kampouropoulos, D.; Antoniadou, M.; Kakaboura, A. Evaluation of the depth of cure by microhardness of bulk-fill composites with monowave and polywave LED light-curing units. Appl. Sci. 2024, 14, 11532. [Google Scholar] [CrossRef]

- Kim, H.J.; Kwon, J.; Kim, H.-J.; Kim, R.H.; Kim, D.-S.; Jang, J.-H. Comparison of polymerization behaviors, microhardness and compressive strength between bulk-fill resin and dual-cured core resin. BMC Oral Health 2025, 25, 972. [Google Scholar] [CrossRef]

- Daugherty, M.M.; Lien, W.; Mansell, M.R.; Risk, D.L.; Savett, D.A.; Vandewalle, K.S. Effect of high-intensity curing lights on the polymerization of bulk-fill composites. Dent. Mater. 2018, 34, 1531–1541. [Google Scholar] [CrossRef]

- Scotti, N.; Venturello, A.; Migliaretti, G.; Pera, F.; Pasqualini, D.; Geobaldo, F.; Berutti, E. New-generation curing units and short irradiation time: the degree of conversion of microhybrid composite resin. Quintessence Int. 2011, 42, e89–e95. [Google Scholar] [PubMed]

- Gömleksiz, S.; Gömleksiz, O. Effect of cavity depth on degree of conversion and microhardness of low-shrinkage resin composites. BMC Oral Health. 2025, 25, 1091. [Google Scholar] [CrossRef] [PubMed]

- Georgiev, G.; Dikova, T. Hardness investigation of conventional, bulk fill and flowable dental composites. J. Achiev. Mater. Manuf. Eng. 2021, 109, 68–77. [Google Scholar] [CrossRef]

- Santini, A.; Miletic, V.; Swift, M.D.; Bradley, M. Degree of conversion and microhardness of TPO-containing resin-based composites cured by polywave and monowave LED units. J. Dent. 2012, 40, 577–584. [Google Scholar] [CrossRef]

- Ivoclar Scientific Documentation. 3sCure PowerSystem. Available online: https://www.ivoclar.com/medias/Scientific-Documentation-3sCure-PowerSystem-EN.pdf?context=bWFzdGVyfGNlbHVtLWNvbm5lY3QyLWFzc2V0c3wzNzg1MzM4fGFwcGxpY2F0aW9uL3BkZnxhR0U1TDJoa1l5OHhNakEwTVRFMU5UQTRORE14T0M5VVpYUnlhV01nY0d4MWMxOVRZMmxsYm5ScFptbGpVbVZ3YjNKMFgwVk9YMUpsZGpCZk1UaEdaV0l5TlM1d1pHWXw1ZDVlMDgwZmFkNjZjNDhmMGYxZTEwYzMzODQzMzMyZDE3YjNmYWMzZTIzZjUwOWQ2N2JiOTI5Mzc3NTU5ZjBk (accessed on 24 October 2025).

- Cho, K.; Wang, G.; Raju; Fang, J.; Rajan, G.; Stenzel, M.H.; Farrar, P.; Prusty, B.G. Selective atomic-level etching on short S-glass fibres to control interfacial properties for restorative dental composites. Sci. Rep. 2019, 9, 3851. [Google Scholar] [CrossRef]

- Odermatt, R.; Par, M.; Mohn, D.; Wiedemeier, D.B.; Attin, T.; Tauböck, T.T. Bioactivity and physico-chemical properties of dental composites functionalized with nano- vs. micro-sized bioactive glass. J. Clin. Med. 2020, 9, 772. [Google Scholar] [CrossRef]

- Par, M.; Marovic, D.; Attin, T.; Tarle, Z.; Tauböck, T.T. The effect of rapid high-intensity light-curing on micromechanical properties of bulk-fill and conventional resin composites. Sci. Rep. 2020, 10, 10560. [Google Scholar] [CrossRef]

- Jakupović, S.; Pervan, N.; Mešić, E.; Gavranović-Glamoč, A.; Bajsman, A.; Muratović, E.; Kazazić, L.; Kantardžić-Kovaćević, A. Assessment of microhardness of conventional and bulk-fill resin composites using different light-curing intensity. Polymers 2023, 15, 2250. [Google Scholar] [CrossRef]

- Duratbegović, D.; Pervan, N.; Jakupović, S.; Kobašlija, S. The effects of intensity, exposure time, and distance of polymerization light on Vickers microhardness and temperature rise of conventional resin-based composite. Polymers 2024, 16, 3175. [Google Scholar] [CrossRef]

- Duratbegović, D.; Kobašlija, S.; Jakupović, S.; Pervan, N.; Hodžić, D.; Katana, E.; Jakupović, S. Evaluation of the influence of polymerization light intensity, irradiation time, and source distance on the depth of cure of resin-based composite. Balk. J. Dent. Med. 2024, 28, 190–199. [Google Scholar] [CrossRef]

- Miletic, V.; Pongprueksa, P.; De Munck, J.; Brooks, N.R.; Van Meerbeek, B. Curing characteristics of flowable and sculptable bulk-fill composites. Clin. Oral Investig. 2017, 21, 1201–1212. [Google Scholar] [CrossRef] [PubMed]

- Marovic, D.; Panduric, V.; Tarle, Z.; Ristic, M.; Sariri, K.; Demoli, N.; Klaric, E.; Jankovic, B.; Prskalo, K. Degree of conversion and microhardness of dental composite resin materials. J. Mol. Struct. 2013, 1044, 299–302. [Google Scholar] [CrossRef]

- Price, R.B.T.; Ferracane, J.L.; Shortall, A.C. Light-curing units: A review of what we need to know. J. Dent. Res. 2015, 94, 1179–1186. [Google Scholar] [CrossRef] [PubMed]

- Alshali, R.Z.; Salim, N.A.; Satterthwaite, J.D.; Silikas, N. Post-irradiation hardness development, chemical softening, and thermal stability of bulk-fill and conventional resin-composites. Dent. Mater. 2015, 31, e183–e193. [Google Scholar] [CrossRef] [PubMed]

- Mierzejewska, Ż.A.; Łukaszuk, K.; Choromańska, M.; Zalewska, A.; Borys, J.; Antonowicz, B.; Kulesza, E. Influence of Different Polishing Methods on Surface Roughness and Microhardness of Dental Composites. Adv. Sci. Technol. Res. J. 2024, 18, 268–279. [Google Scholar] [CrossRef]

- Lassila, L.; Dupont, A.; Lahtinen, K.; Vallittu, P.K.; Garoushi, S. Effects of Different Polishing Protocols and Curing Time on Surface Properties of a Bulk-fill Composite Resin. Chin. J. Dent. Res. 2020, 23, 63–69. [Google Scholar]

- Par, M.; Repusic, I.; Skenderovic, H.; Milat, O.; Spajic, J.; Tarle, Z. The effects of extended curing time and radiant energy on microhardness and temperature rise of conventional and bulk-fill resin composites. Clin. Oral Investig. 2019, 23, 3777–3788. [Google Scholar] [PubMed]

- Wang, L.; Zhang, Y.; Li, X. Effect of shade and thickness on the microhardness of resin-based composite specimens at different points considering curing light beam’s inhomogeneity. BMC Oral Health. 2024, 24, 865. [Google Scholar] [CrossRef]

- İyibilir, A.F.; Demirci, M.; Tuncer, S.; Tekçe, N.; Duman, Ö. The effect of different light curing modes on the microhardness value of different composite resins. Essent. Dent. 2024, 3, 39–44. [Google Scholar] [CrossRef]

- Shobana, S.; Sujareetha, A.; Balagopal, S.; Kumar, S.; Angusamy, S.; Anisha, S. Effect of Two Different Ultrafast Curing Exposure Durations on the Surface Hardness of Bulk Fill Composite—An In-Vitro Study. Indian J. Dent. Res. 2023, 34, 438–442. [Google Scholar] [CrossRef] [PubMed]

- Leprince, J.G.; Hadis, M.; Shortall, A.C.; Ferracane, J.L.; Devaux, J.; Leloup, G.; Palin, W.M. Photoinitiator type and applicability of exposure reciprocity law in filled and unfilled photoactive resins. Dent. Mater. 2011, 27, 157–164. [Google Scholar] [CrossRef]

- Santin, D.C.; Velo, M.M.A.C.; Camim, F.d.S.; Brondino, N.C.M.; Honório, H.M.; Mondelli, R.F.L. Effect of thickness on shrinkage stress and bottom-to-top hardness ratio of conventional and bulk-fill composites. Eur. J. Oral Sci. 2021, 129, e12825. [Google Scholar] [CrossRef]

- Marzouk, A.M.; Niazi, H.A.A.; Mohammed, M.N.; Afifi, R.H. Effect of curing time on top to bottom microhardness of bulk-fill composite. Egypt. Dent. J. 2019, 65, 1733–1739. [Google Scholar] [CrossRef]

- Bouschlicher, M.R.; A Rueggeberg, F.; Wilson, B.M. Correlation of bottom-to-top surface microhardness and conversion ratios for a variety of resin composite compositions. Oper Dent. 2005, 29, 698–704. [Google Scholar] [PubMed]

- Bucuta, S.; Ilie, N. Light transmittance and micro-mechanical properties of bulk-fill vs. conventional resin-based composites. Clin. Oral Investig. 2014, 18, 1991–2000. [Google Scholar] [CrossRef]

- Cekic-Nagas, I.; Egilmez, F.; Ergun, G. The effect of irradiation distance on microhardness of resin composites cured with different light curing units. Eur. J. Dent. 2010, 4, 440–446. [Google Scholar] [CrossRef] [PubMed]

- Feng, L.; Suh, B.I. Exposure reciprocity law in photopolymerization of multi-functional acrylates and methacrylates. Macromol. Chem. Phys. 2007, 208, 295–306. [Google Scholar] [CrossRef]

- Hadis, M.; Leprince, J.G.; Shortall, A.C.; Devaux, J.; Leloup, G.; Palin, W.M. High irradiance curing and anomalies of exposure reciprocity law in resin-based materials. J. Dent. 2011, 39, 549–557. [Google Scholar] [CrossRef] [PubMed]

| Composite Viscosity | Composite Type | Composite Name | Composition | Filler Content (wt%/vol%) | Manufacturer |

|---|---|---|---|---|---|

| Sculptable | Bulk-fill | Tetric PlusFill (TPF) Shade A2 | Strontium glass, copolymer, mixed oxide (SiO2/ZrO2), UDMA, ytterbium trifluoride, Bis-GMA, aromatic-aliphatic UDMA, DCP, Bis-EMA | 70/52 | Ivoclar Vivadent, Schaan, Liechtenstein |

| Tetric PowerFill (TPF) Shade IVA | Barium glass, copolymer, Si-Zr mixed oxide, Bis-GMA, ytterbium trifluoride, Bis-PMA, UDMA, Bis-EMA | 77/54 | |||

| Flowable | Bulk-fill | Tetric PlusFlow(TPFW) Shade A2 | Barium glass, co-polymer, mixed oxide (SiO2/ZrO2), BPEMA, MOMA, Bis-GMA, Bis-EMA, DCP, UDMA, ytterbium fluoride, AFCT | 65/51 | |

| Tetric PowerFlow(PFW) Shade IVA | Barium glass, Bis-EMA, copolymer, aromatic methacrylate, Bis-GMA, ytterbium trifluoride, DCP | 68/46 |

| Group | Resin Composite Material | Curing Protocol | Sample Size, n |

|---|---|---|---|

| 1. | Tetric plus Fill | LV-1200 mW/cm2/10 s | 7 |

| 2. | Tetric plus Fill | HV-3000 mW/cm2/3 s | 7 |

| 3. | Tetric power Fill | LV-1200 mW/cm2/10 s | 7 |

| 4. | Tetric power Fill | HV-3000 mW/cm2/3 s | 7 |

| 5. | Tetric plus Flow | LV-1200 mW/cm2/10 s | 7 |

| 6. | Tetric plus Flow | HV-3000 mW/cm2/3 s | 7 |

| 7. | Tetric power Flow | LV-1200 mW/cm2/10 s | 7 |

| 8. | Tetric power Flow | HV-3000 mW/cm2/3 s | 7 |

| Material | Average | Standard Deviation | Min. | Max. |

|---|---|---|---|---|

| Tetric Plus Fill | 69.85 | 4.68 | 64.66 | 75.24 |

| Tetric Plus Flow | 54.35 | 4.39 | 48.36 | 60.58 |

| Tetric Power Fill | 58.38 | 4.21 | 52.40 | 63.38 |

| Tetric Power Flow | 39.47 | 5.15 | 32.12 | 47.22 |

| Top Surface | Bottom Surface | |||

|---|---|---|---|---|

| p | Partial η2 | p | Partial η2 | |

| Material | <0.001 | 0.99 | <0.001 | 1 |

| Curing protocol | <0.001 | 0.94 | <0.001 | 0.95 |

| Material–curing protocol | <0.001 | 0.99 | <0.001 | 0.97 |

| Correlated Variables | Correlation Coefficient, r | p-Value |

|---|---|---|

| wt%–LV protocol | 0.74 | < 0.001 |

| wt%–HV protocol | 0.61 | < 0.001 |

| vol%–LV protocol | 0.87 | < 0.001 |

| vol%–HV protocol | 0.78 | < 0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jakupović, S.; Pervan, N.; Duratbegović, D.; Jakupović, V.; Muratović, E.; Kobašlija, S. Evaluation of the Effect of Different Light-Curing Protocols on the Microhardness of Contemporary Bulk-Fill Resin Composites. Polymers 2025, 17, 2889. https://doi.org/10.3390/polym17212889

Jakupović S, Pervan N, Duratbegović D, Jakupović V, Muratović E, Kobašlija S. Evaluation of the Effect of Different Light-Curing Protocols on the Microhardness of Contemporary Bulk-Fill Resin Composites. Polymers. 2025; 17(21):2889. https://doi.org/10.3390/polym17212889

Chicago/Turabian StyleJakupović, Selma, Nedim Pervan, Damir Duratbegović, Vedran Jakupović, Enis Muratović, and Sedin Kobašlija. 2025. "Evaluation of the Effect of Different Light-Curing Protocols on the Microhardness of Contemporary Bulk-Fill Resin Composites" Polymers 17, no. 21: 2889. https://doi.org/10.3390/polym17212889

APA StyleJakupović, S., Pervan, N., Duratbegović, D., Jakupović, V., Muratović, E., & Kobašlija, S. (2025). Evaluation of the Effect of Different Light-Curing Protocols on the Microhardness of Contemporary Bulk-Fill Resin Composites. Polymers, 17(21), 2889. https://doi.org/10.3390/polym17212889