1. Introduction

Coaxial sealing systems are specialized sealing solutions often used in various industrial applications to prevent the leakage of fluids. These systems typically consist of concentric sealing elements that are arranged in a way to provide effective sealing under different operational conditions. This design helps to distribute stresses evenly and can accommodate thermal expansion and contraction. The concentric design allows for better control over the sealing pressure and reduces the risk of leaks, even in high-pressure or high-temperature environments [

1].

The main fields of applicability of these sealing systems are aerospace and automotive (engine seals and fuel systems), sectors like oil and gas, chemical processing, and manufacturing (used in cylinders and valves to maintain pressure and prevent the escape of hydraulic fluids or gases).

Coaxial sealing systems can be designed for both dynamic (moving parts) and static (stationary parts) applications, making them versatile for various types of machinery and equipment. These systems can be tailored to fit specific applications, including those that require resistance to extreme temperatures, chemicals, or high pressures. While coaxial sealing systems can offer an enhanced performance, they may also come with a higher initial cost compared to simpler sealing solutions [

2].

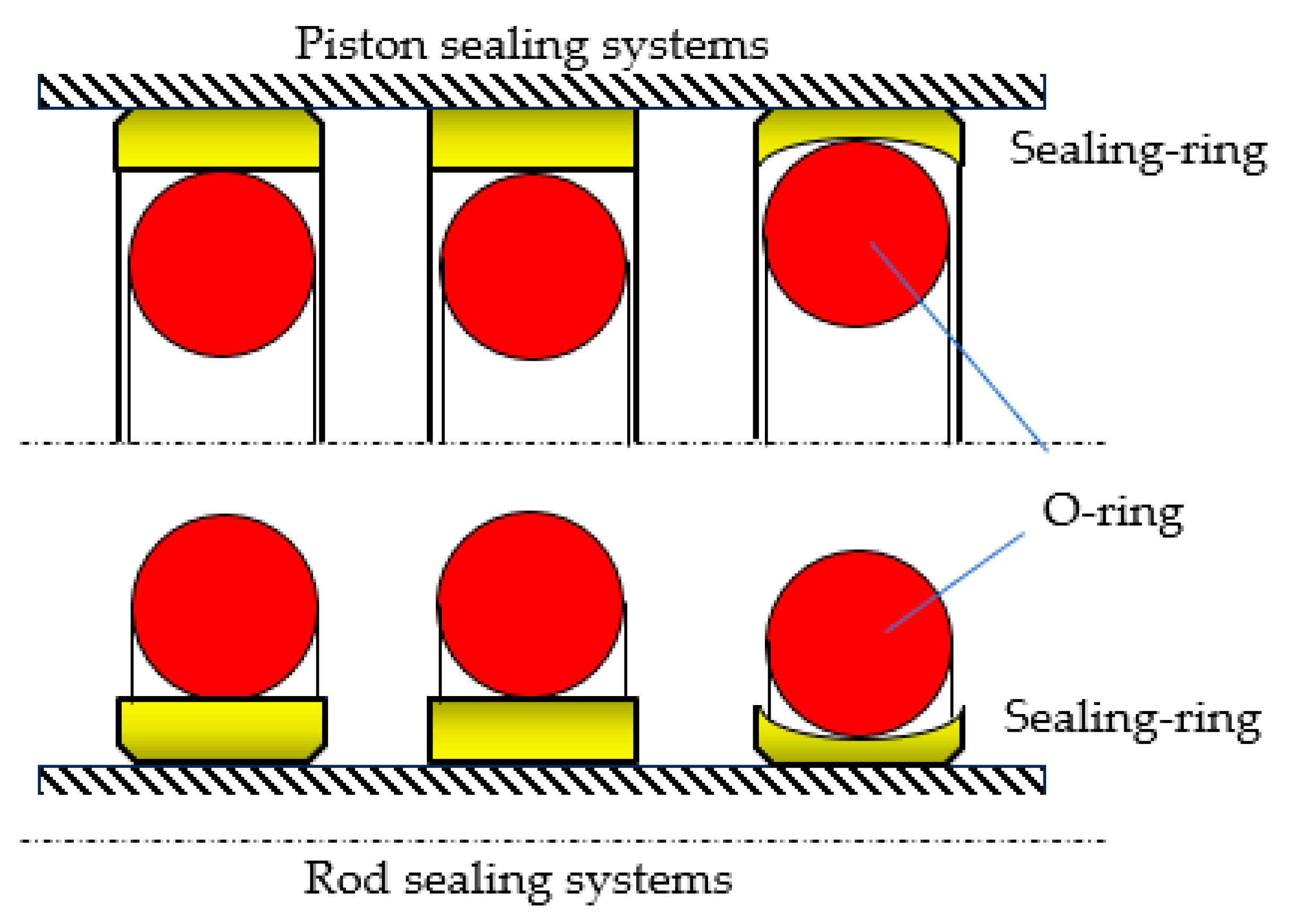

A coaxial sealing system consists of two elements: (i) a ring (seal) made from a material with excellent friction properties that comes into contact with the sealed-off surface, and (ii) an O-ring that ensures the tensioning of the entire assembly (

Figure 1) [

3]. An efficient sealing is obtained by applying a radial compression force onto the seal by the O-ring and the pressure of the sealed-off fluid. In order to generate the radial pressure, the O-ring is placed in its groove in a pre-compressed state, with a specific initial radial deformation of 10–25%. Once the fluid pressure in the hydraulic motor increases, the O-ring deforms additionally, which leads to the generation of an even greater radial pressure [

4,

5].

While the O-ring plays a significant role in the sealing process, only a few studies have been published about its behavior within coaxial sealing systems. One such study, authored by Wang et al. [

6], analyzes the behavior of coaxial sealings of GS (gland seal) type used in hydro-pneumatic suspensions. The research results provide a theoretical basis for the design of GS sealing of hydro-pneumatic springs and the effective improvement of the life and reliability of related equipment. The contact pressures generated by the O-rings on the surfaces of the sealing system were studied in ref. [

7,

8]. In ref. [

7], a physical–mathematical model of the contact between the sealing O-ring and the sealing surfaces is discussed, and the maximum values of the contact pressures between the sealing ring and the cylindrical sealing surfaces are calculated. Aissaoui et al. present in ref. [

8] the contact stress profiles and the peak contact stresses generated by O-rings onto the contact surfaces. An important research direction in the field of hydraulic systems sealing concerns the materials these systems are made from. The majority of seals are made from polymers, in particular elastomers, plastomers, or thermoplastic elastomers. The choice of material depends on the specific operating conditions, including compatibility with the sealed-off fluid, its pressure, temperature, etc. A long lifetime for sealing systems calls for in-depth knowledge of the used materials. Selecting the most adequate materials for a specific application is crucial for ensuring compatibility with the sealed-off fluids and the working environment. The most frequently used material for seals is polytetrafluoroethylene (virgin or filled PTFE), while O-rings are made from various types of elastomers: nitrile rubber (NBR), hydrogenated nitrile rubber (HNBR), fluorocarbon (FKM), fluorosilicone (FVMQ), ethylene propylene diene monomer rubber (EPDM), and silicone rubber (Q) [

4].

Research related to the materials used for hydraulic sealing systems dates back more than 90 years [

9]. In ref. [

10], B.S. Nau summarizes the knowledge to date of the factors that influence the performance of hydraulic seals made from polymers, and in ref. [

11], the same author addresses rubber seals.

Studies concerning the use of plastomers for sealing systems can be found in numerous articles, like in refs. [

12,

13,

14,

15,

16]. These papers highlight phenomena like abrasive wear and adhesion of PTFE seals, as well as the effects of fatigue caused by the high temperatures of the working fluid. Virgin PTFE has limited applications due to its low wear strength. Such obstacles are overcome by inserting additives into the PTFE matrix, yielding PTFE-based composites more suitable for hydraulic actuation systems. Additives used together with PTFE are glass fibers, carbon fibers, graphite, copper particles, molybdenum disulfide, and mixes thereof [

17]. Additives like bronze, glass fibers, Mo

2S, or carbon present in the PTFE composition have different influences on the behavior of seals. Thus, for example, bronze improves wear strength at environmental temperatures, but has the opposite effect at high temperatures.

Over the last year, numerous research works have studied the behavior of O-rings made from various materials during the sealing process. In ref. [

18], the authors studied the behavior of O-rings made from EPDM under extremely high and low temperature conditions. The conclusions show that the stress concentration phenomenon of the EPDM rubber O-ring is lighter under high temperature conditions, but the sealing performance decreases. At low temperatures, the stress concentration is significant, but the sealing performance is better. Kömmling et al. present in ref. [

19] a method for determining a specific end-of-lifetime criterion for O-ring seals. Determining a suitable and reliable end-of-lifetime criterion for O-ring seals is an important issue for long-term seal applications.

Müller et al. studied in ref. [

20] the compatibility of elastomer-based sealing O-rings with methanol, ethanol, and hydrotreated vegetable oil for fueling internal combustion engines. Among the different elastomer O-rings tested, the best performance in terms of material compatibility and dependence on the fuels was exhibited by the FVMQ (fluorosilicone elastomer) type O-rings.

Huang et al. developed in ref. [

21] a model for predicting the leakage rate that affects the sealing performance of O-rings made from ethylene propylene diene monomer rubber (EPDM). The model was proven to be an accurate predictor of the onset of leakage and was validated by a vacuum test.

The numerous and intensive endeavors leading up to the current state of development of coaxial sealing systems underpin the fact that these systems are a significant aspect of future sealing technology. As industry evolves and is faced with new challenges, the development and optimization of coaxial sealing systems remain critical areas of attention. In this regard, this paper proposes to analyze a less explored area, namely the operational behavior of O-rings made from polymeric materials. The analyzed O-rings are used for the sealing of hydraulic cylinders that carry out linear motions. This paper includes the following sections: after the introductory chapter, the second part of the paper describes the structure of a coaxial sealing system and introduces the main materials used at present in the manufacturing of O-rings. Further on,

Section 3 presents the behavior of the O-ring during mounting and under pressure. The pressure distributions in the contact areas of the O-ring with the adjacent walls are described, and hypotheses are developed leading to the relationships used to calculate the contact area widths. Based on the obtained relationship, graphs are presented describing the dependencies of contact area widths and contact pressure on the specific radial deformation, on the hardness of the O-ring material, and on the pressure of the working fluid. The fourth section of the paper contains the discussion of the obtained results, and the fifth section presents the main conclusions of the conducted study.

2. Materials

The O-ring included by coaxial sealing systems is described by two dimensional characteristics (

Figure 2): the interior diameter

d1 and the diameter of the cross section

d2.

O-rings are made mainly from rubber materials, as these are cost-effective and hold their shape well, making them ideal for use in sealing applications. The most frequently used materials are NBR (nitrile butadiene rubber), EPDM (ethylene propylene diene monomer rubber), VITON (fluoroelastomer synthetic rubber), VMQ (silicone rubber), and CR (neoprene/chloroprene rubber). These are used in a wide range of engineering applications (static and dynamic seals, belts, support inserts, vibration insulators, etc.).

Table 1 shows a number of the polymeric materials used for O-rings, together with their characteristics [

22,

23].

In most industrial applications, the polymeric composites O-rings are made from have a hardness of 70–80 Shore A. In dynamic applications, a greater hardness (90 Shore A) can compromise the sealing by leaking a few drops of liquid, while a smaller hardness (50 Shore A) can cause abrasion, wear, or extrusion [

23]. Strictly in the case of coaxial systems, the O-ring ensures static sealing that will be analyzed further on.

3. Method and Results

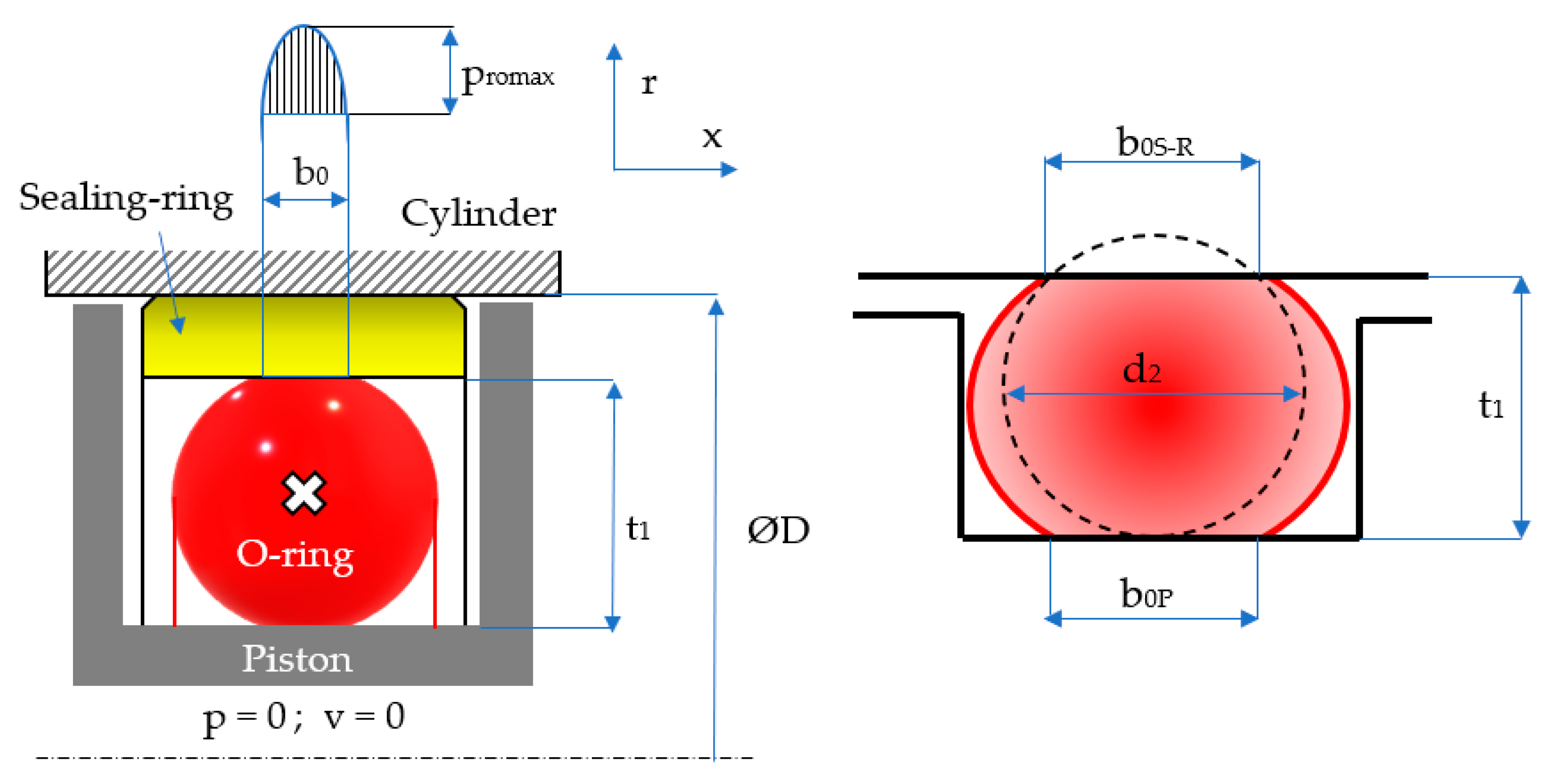

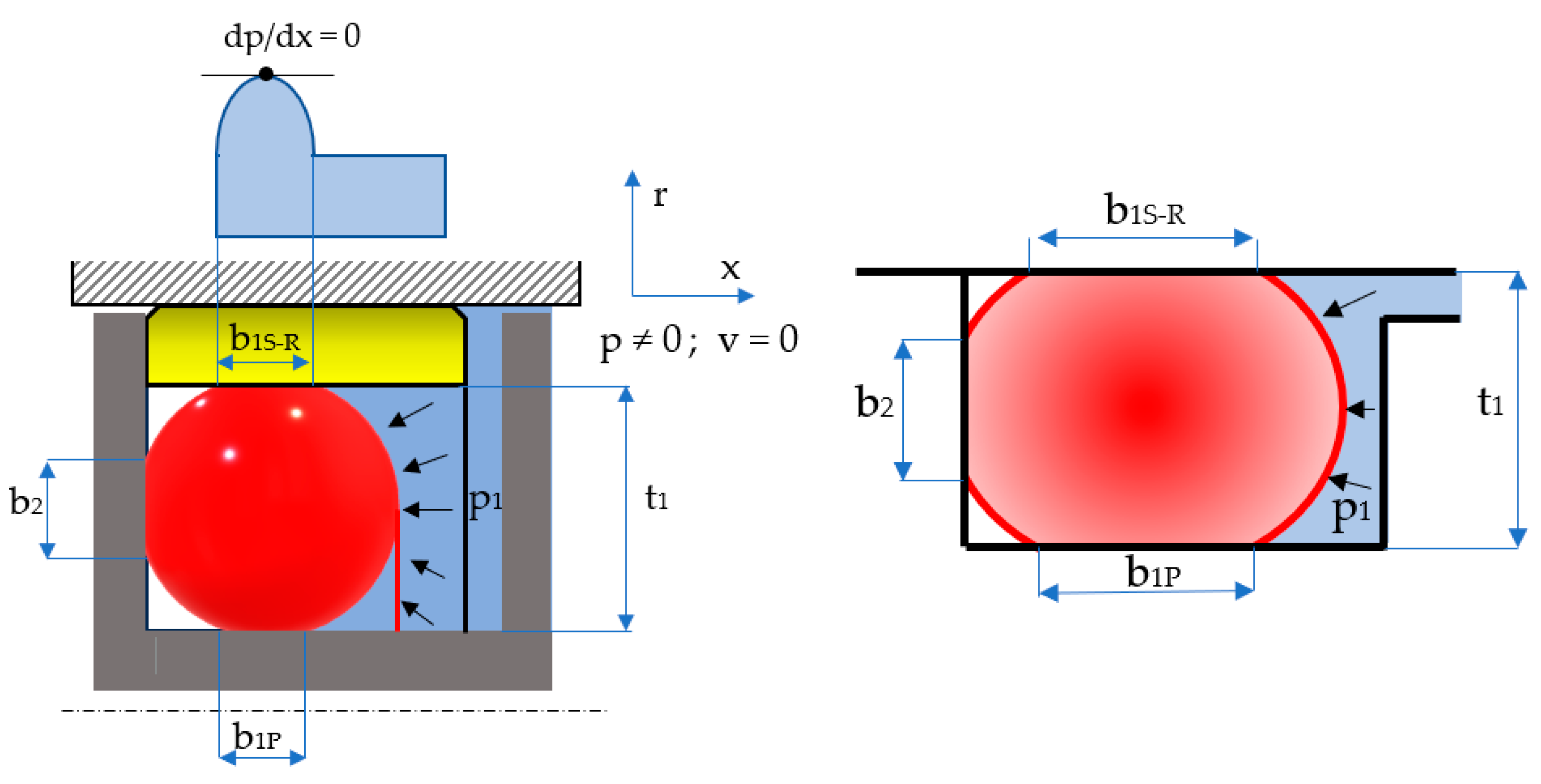

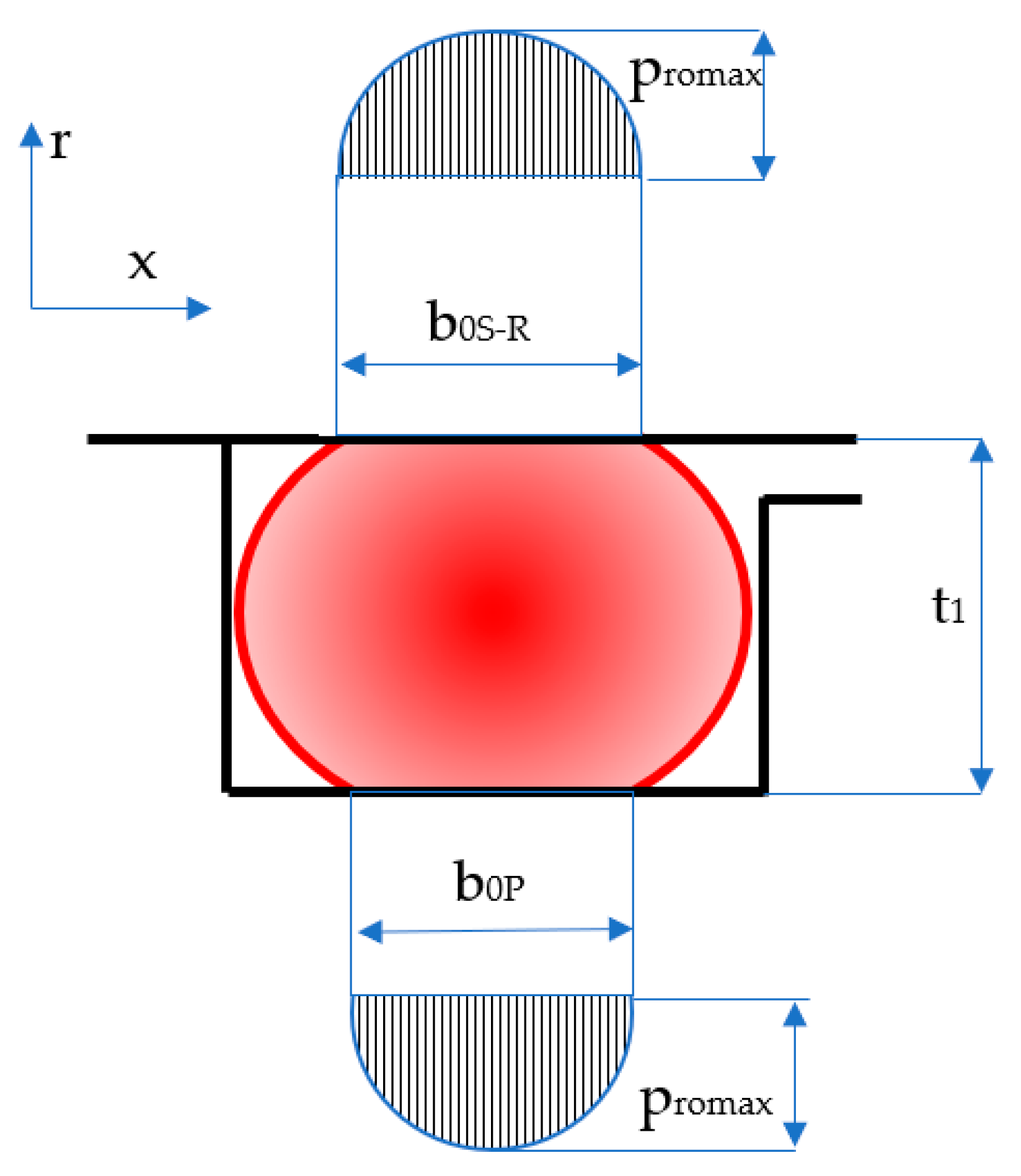

Sealing the pistons of hydraulic cylinders by means of coaxial sealing systems is achieved through a number of steps. Initially, the O-ring is placed in its groove in a pre-compressed state while fluid pressure is zero (

Figure 3). Once pressure is applied, the O-ring deforms additionally, proportionally to the magnitude of the pressure (

Figure 4).

The notations in the figures above are:

b0S-R and

b0P are the widths of the contact areas between the O-ring and the adjacent walls in the absence of working fluid pressure (index

S-

R refers to the contact of the O-ring with the sealing ring, and index

P is attributed to the contact area with the piston walls); and

b1S-R and

b1P are the widths of the contact areas in the presence of working fluid pressure. The simplified representation on the right-hand side of

Figure 4 highlights the behavior of the O-ring similar to a static sealing system, as its only role is to generate the radial tensioning of the sealing ring. This figure also shows that the O-ring is closed in on three sides, thus preventing extrusion.

3.1. Behavior of the O-Ring in the Absence of the Fluid Pressure to Be Sealed-Off

Upon being mounted in its groove, the O-ring modifies its geometry due to deformation in two directions, an axial and a radial one. The specific radial deformation (

εr0) is dependent on the initial diameter of the O-ring cross-section (

d2) and on the depth of the groove (

t1); this dependency is described by Equation (1):

Depending on the specific deformation, the shape of the O-ring cross-section is modified by the increase in the contact area width

b0. The relationships calculating these quantities have been presented in a number of papers. Thus, for example, Lindley proposes in ref. [

24,

25] a formula for calculating the width of the contact area:

Karaszkiewicz also proposes such a formula in ref. [

26]:

In order to determine the magnitude of the contact area, the following relationships can be deduced using the notations in

Figure 3:

where

εx0 is the specific axial deformation, and:

In the absence of fluid pressure, the relationship describing the dependency between the specific radial and axial deformations is:

where

ν is Poisson’s coefficient for the O-ring’s material. For the analyzed materials (

Table 1), a value of

ν = 0.496 is adopted in calculations. The value of Poisson’s coefficient in the case of elastomers (

ν ≈ 0.5) means that they deform without changing their volume (perfectly incompressible isotropic materials).

Upon introducing Equation (6) into (5), there results:

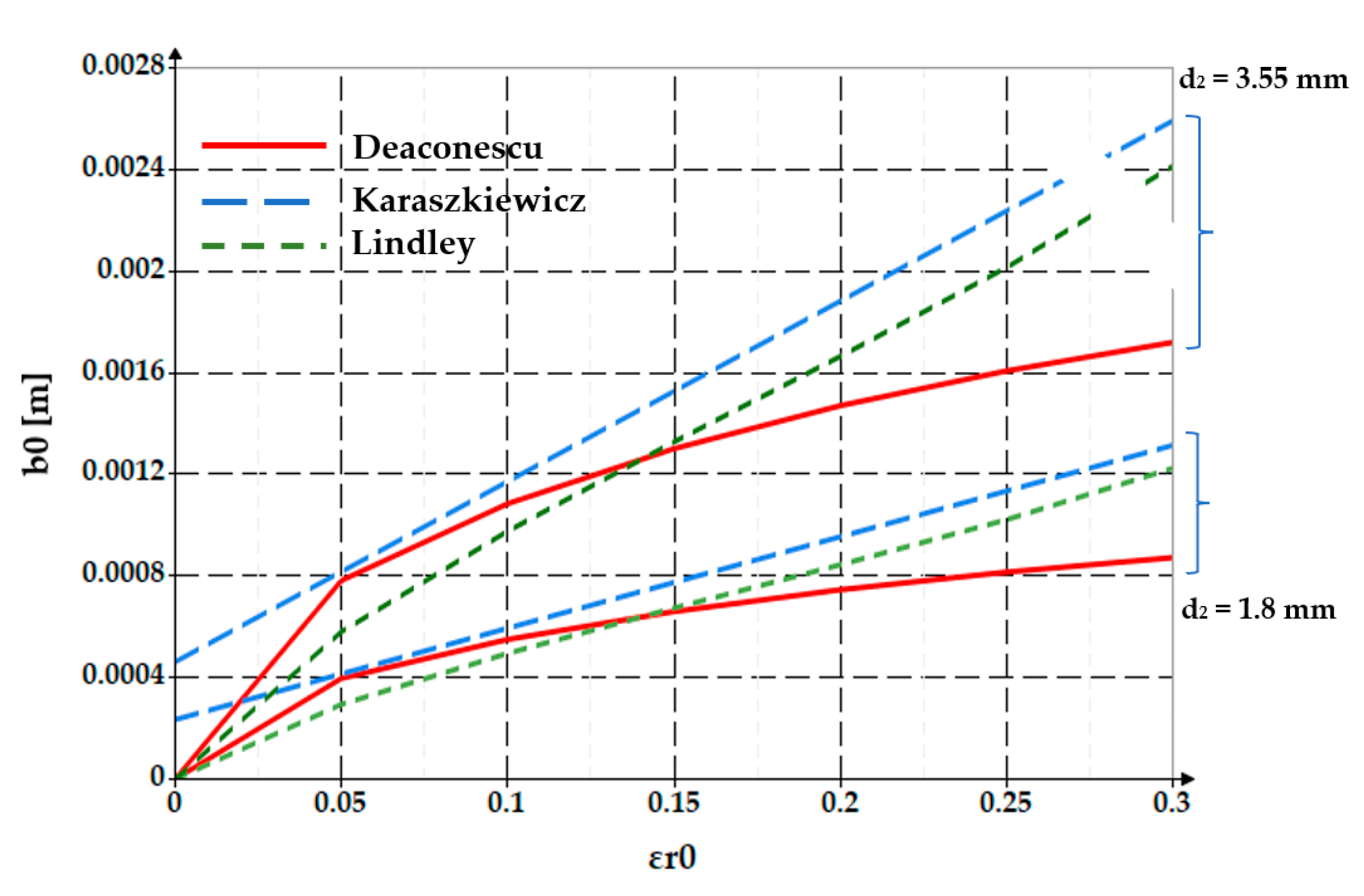

Figure 5 shows comparatively the dependencies

b0 = f(

εr0) obtained by Equations (2), (3) and (7). Two values of O-ring diameters were considered, namely

d2 = 1.8 mm and

d2 = 3.55 mm.

The same dependency is shown as a 3D graph in

Figure 6.

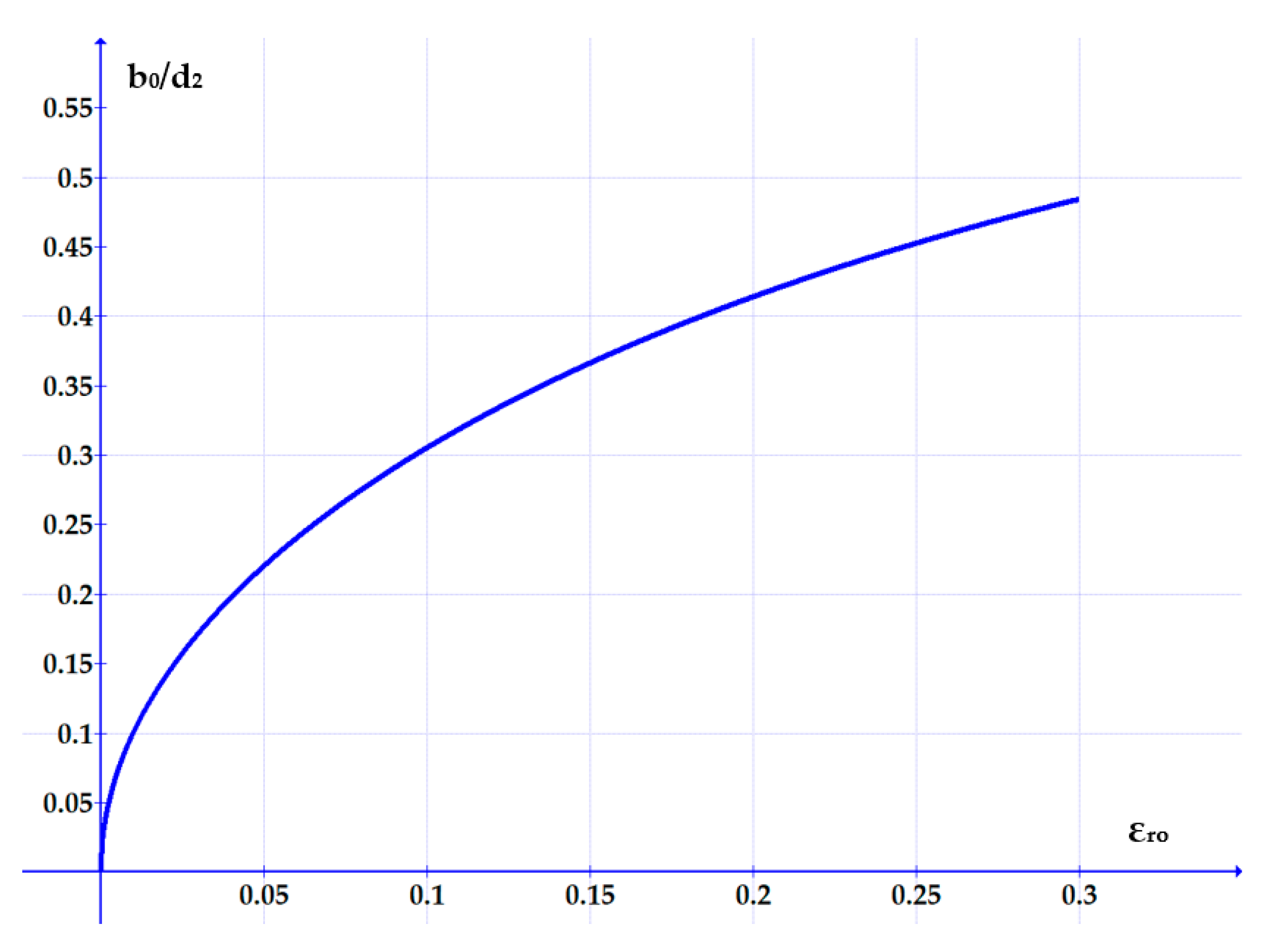

The two figures show that as the specific radial deformation increases, the width of the contact area grows. The differences between the three approaches (Lindley, Karaszkiewicz, and the authors of this paper) are not significant in the interval εr0 = 0… 0.2. Beyond this value of the specific radial deformation, the relationship proposed by the authors provides smaller values of the contact area width.

Starting from Equation (7), the dependency

b0/d2 = f(

εr0) can also be plotted (

Figure 7).

Over the entire width

b0, contact pressures are generated at the interface of the O-ring and its adjacent surfaces, as shown in

Figure 8. The width of the contact between the O-ring and the seal was denoted by

b0S-R, while

b0P is the width of the contact between the O-ring and the piston of the hydraulic cylinder.

The maximum value of the contact pressures (

pr0max) was determined starting from Hertz’ theory, resulting in Equation (8):

where

E is the equivalent elasticity modulus for the materials of the two contacting bodies, calculated by Equation (9):

where

Ee is the elasticity modulus of the O-ring material (elastomer), and

ES is the elasticity modulus of the material in contact with the O-ring. In the case of coaxial sealing systems, the O-ring comes into contact with the piston body, on one hand, and on the other, with the seal. For the contact of the O-ring with the piston body (generally made from steel),

Ee << ES, so that Equation (9) can be simplified to:

In case of the contact between O-ring and seal (generally made from PTFE), there is also a great difference between the values of the elasticity moduli of the contacting materials. Hence, Equation (10) is applicable in this situation too. It can thus be asserted that b0S-R = b0P = b0.

In the literature, numerous relationships between

Ee and hardness

H (Shore A) have been put forward. In ref. [

27,

28], a finite element simulation study leads to a linear relationship between the logarithm of the elastic modulus and the hardness:

With the

c1 and

c2 empirical constants determined from the best fit as

c1 = 0.0235 and

c2 = 0.6403 for 20 <

H < 80. Thus, it follows that:

For the hardness being expressed in Shore A [

27,

28], the elasticity modulus is obtained in [MPa]. Upon introducing this latter relationship into Equation (8), the maximum contact pressure becomes:

Figure 9 shows the dependency of the maximum contact pressure on the specific radial deformation and the hardness of the O-ring material.

The distribution of the radial pressure

pr0 on the width of the contact area is described by the following parable:

and the dependency

pr0 = f(

x/b0, H) for

εr0 = 0.10 and

εr0 = 0.30 are presented in

Figure 10.

It can be noticed that the maximum contact pressure grows with the increase in specific radial deformation and the O-ring’s material hardness.

3.2. Behavior of the O-Ring in the Presence of the Fluid Pressure to Be Sealed-Off

Upon pressure onset in the system, the O-ring will deform additionally, the geometry of its cross-section being modified as shown in

Figure 11. Noticeably, three contact areas are generated between the O-ring and the walls of its groove of widths

b1 and

b2.

Experimental research has revealed that due to the viscous component of the O-ring material, the pressure of the working fluid is not transmitted integrally, but is adjusted by a less-than-unity transmission coefficient denoted by

s that is dependent on Poisson’s coefficient:

For the studied materials, the considered Poisson’s coefficient was ν = 0.496, so that s = 0.984.

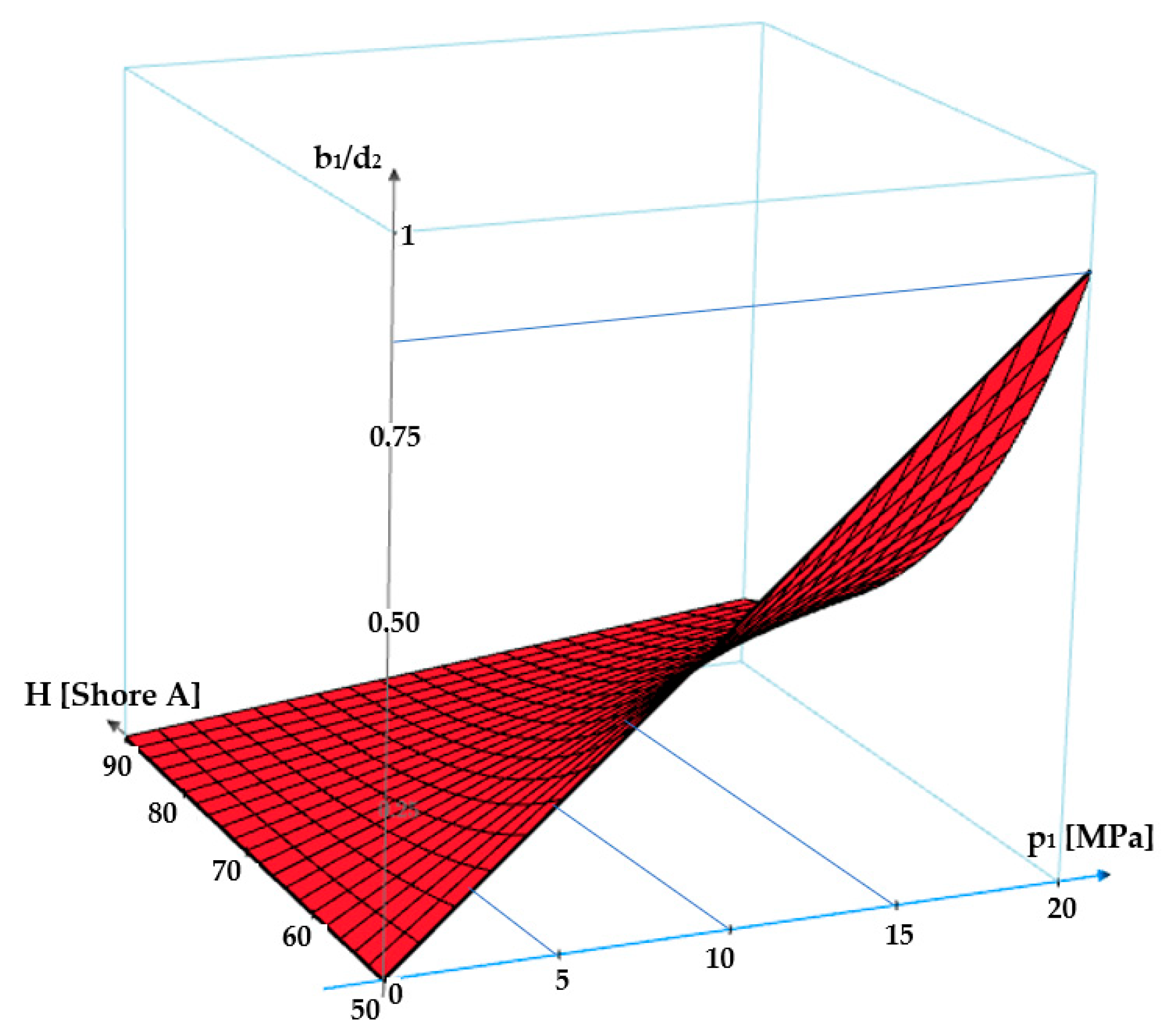

Starting from Equation (8), the ratio of the contact area width

b1 and the diameter of the O-ring cross section (

d2) can be written as:

where

cf is a coefficient of value 0.083 that describes the modification of shape. The graph in

Figure 12 presents the dependency

b1/

d2 = f(

εr0,

p1,

H). It can be noticed that for zero fluid pressure, the width of the contact area is

b0. As the pressure increases, depending on the specific axial deformation and the hardness of the O-ring material, the contact width grows and the value of the

b1/

d2 ratio approaches unity. These findings agree with finite element analyses in large elastic deformations [

29] as well as with the experimental measurements [

30].

A similar calculation yields the ratio

b2/d2, namely the ratio of the lateral contact area width and the O-ring diameter.

Figure 13 shows the dependency

b2/d2 = f(

p1,

H).

4. Discussion

The graph in

Figure 12 shows that an increase in the sealed-off fluid pressure causes greater values of the

b1/

d2 ratio. Furthermore, the less hard the O-ring material is, the greater the ratio

b1/

d2 will be. The specific radial deformation (

εr0) also influences the ratio

b1/

d2, in the sense that a greater value of

εr0 determines a larger width of the contact area.

The variation of the ratio

b2/

d2 is similar (

Figure 13). Upon an increase in the pressure of the sealed-off fluid and a decrease in the O-ring material hardness, the ratio

b2/

d2 becomes greater. The specific radial deformation has no influence in this case. The two figures show that

b1/

d2 >

b2/

d2.

In general, it is necessary to know the value of the ratio

b2/

d2 when designing sealing systems with O-rings that work at high pressures. The width of the contact area

b2 exceeding the value

t1 (see

Figure 4) causes the extrusion of the O-ring with a negative impact on its durability. In order to avoid extrusion, the use of materials of great hardness (90 Shore A) is recommended. Coaxial sealing systems are not exposed to the risk of extrusion because the length of the lateral contact is restricted by the three walls that support the O-ring (

Figure 4).

Regarding the materials used for O-rings, it is recommended to select ones with a hardness of 70 Shore A. The recommended specific radial deformation of the O-ring should fall in a range of 0.18–0.25.