Study on the Effects of Vibration Force Field on the Mixing and Structural Properties of PLA/PBS/EGMA Blends

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Plan

2.3. Experiment

2.3.1. Equipment and Instruments

2.3.2. Sample Preparation and Characterization

3. Results and Discussion

3.1. Research on the Influence of Vibration Force Field on Mechanical Properties

3.2. Research on the Impact of Vibration Force Field on System Performance

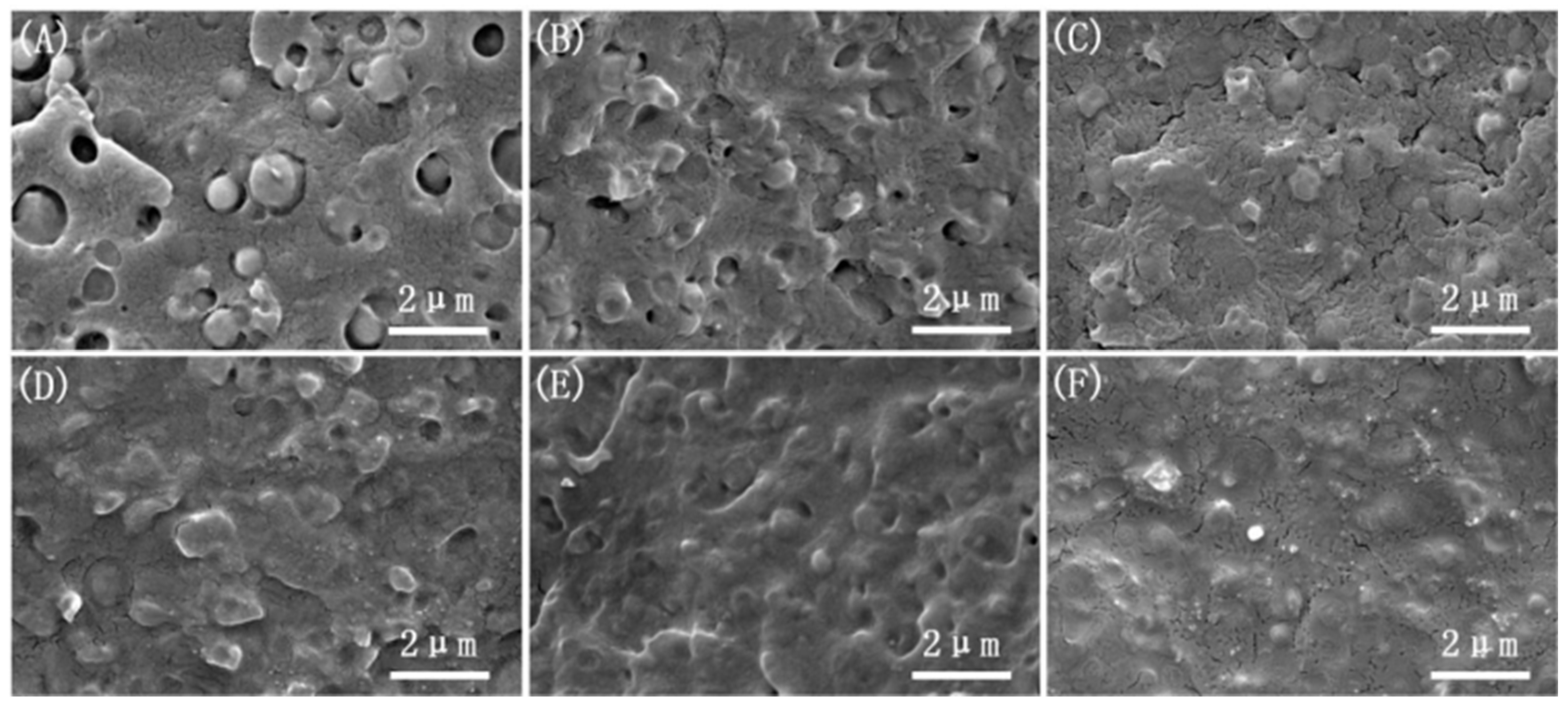

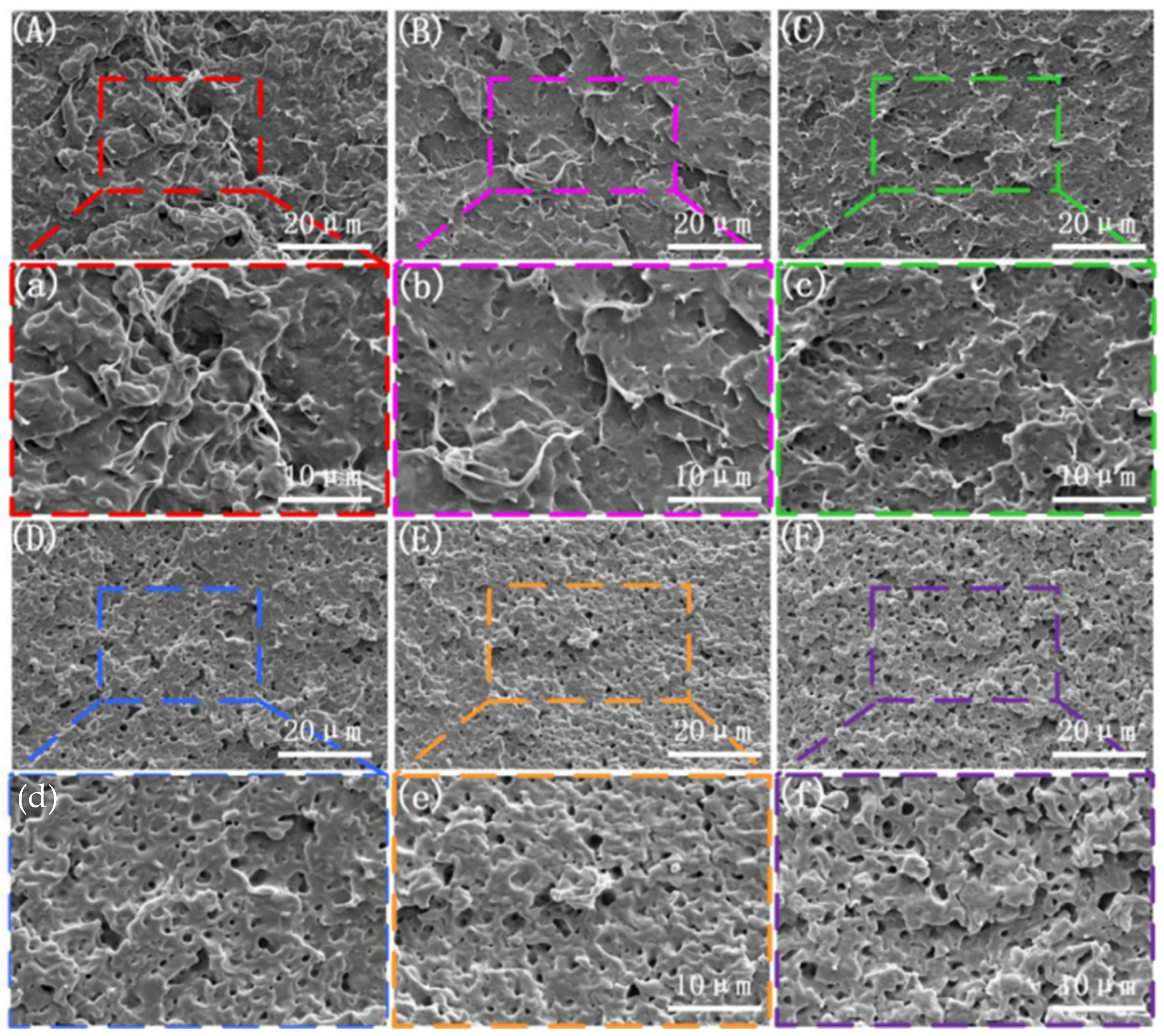

3.2.1. The Influence of Vibration Force Field on the Micro-Morphology of the System

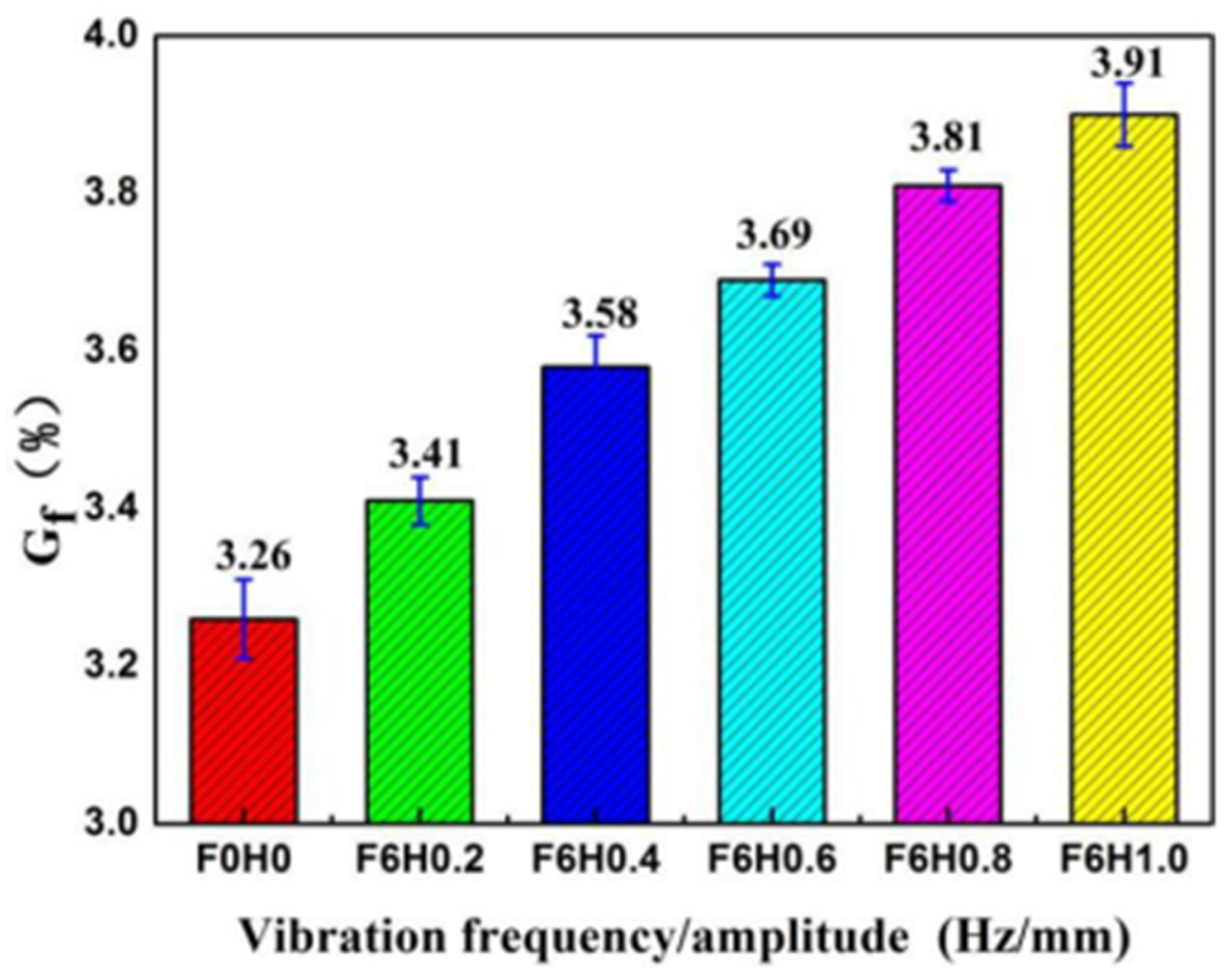

3.2.2. The Influence of Vibration Force Field on the Gel Fraction of the System

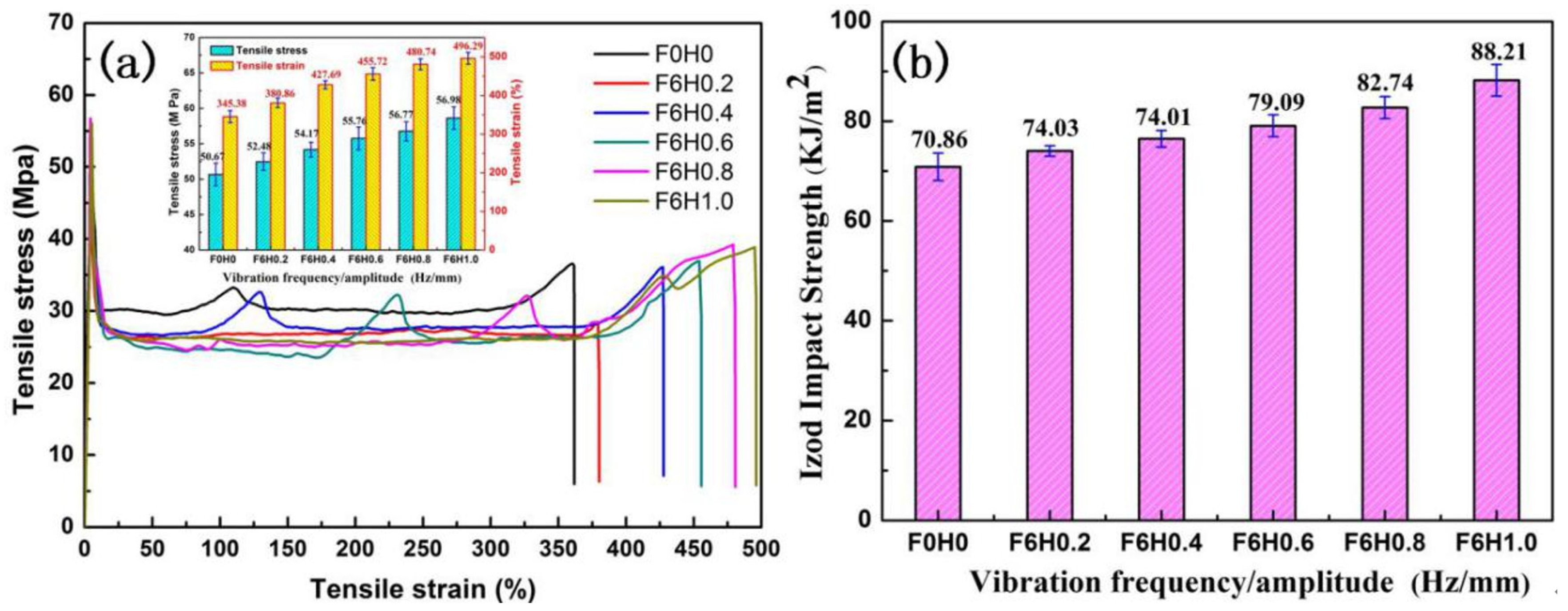

3.2.3. The Influence of Vibration Force Field on the Mechanical Properties of the System

- Tensile strength: 52.48 MPa, 54.17 MPa, 55.76 MPa, 56.77 MPa, 58.63 MPa.

- Elongation at break: 380.66%, 427.69%, 455.72%, 480.74%, 496.29%.

- Tensile strength: 51.25 MPa, 52.45 MPa, 54.17 MPa, 55.32 MPa, 56.67 MPa.

- Elongation at break: 380.42%, 415.67%, 427.69%, 445.12%, 475.89%.

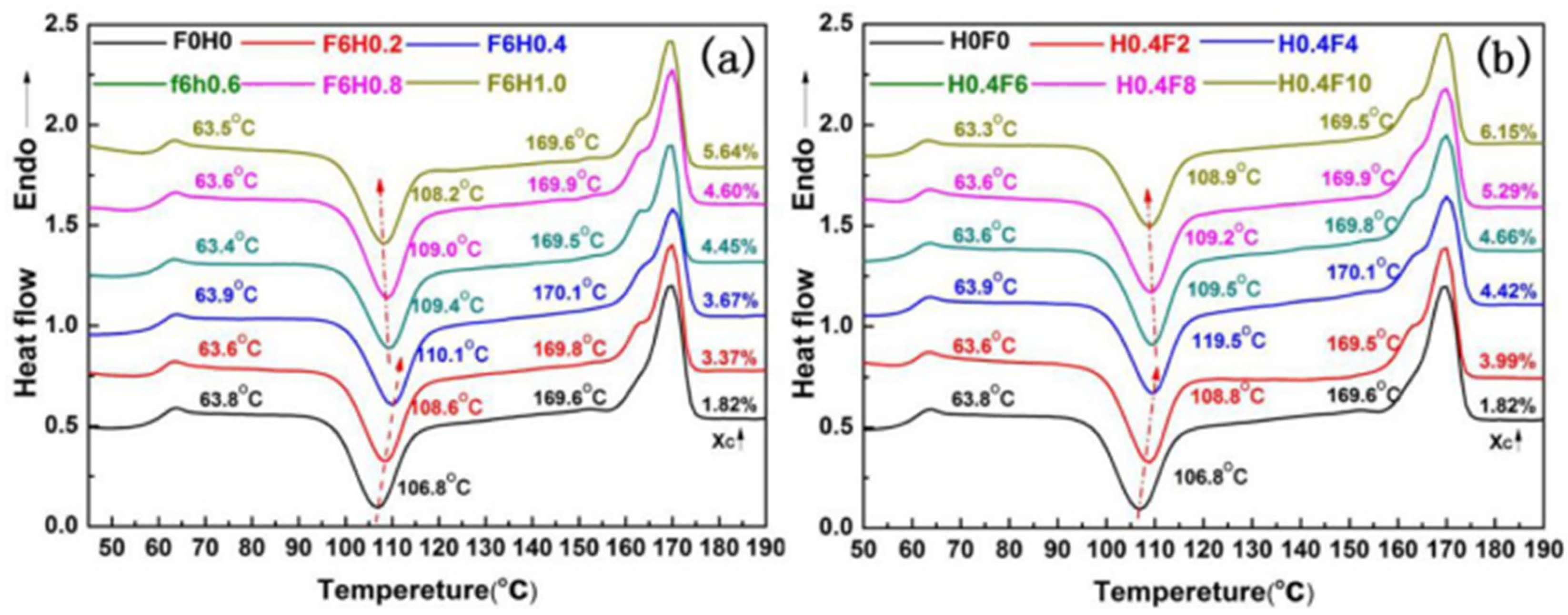

3.2.4. The Influence of Vibration Force Field on the Crystallization Behavior of the System

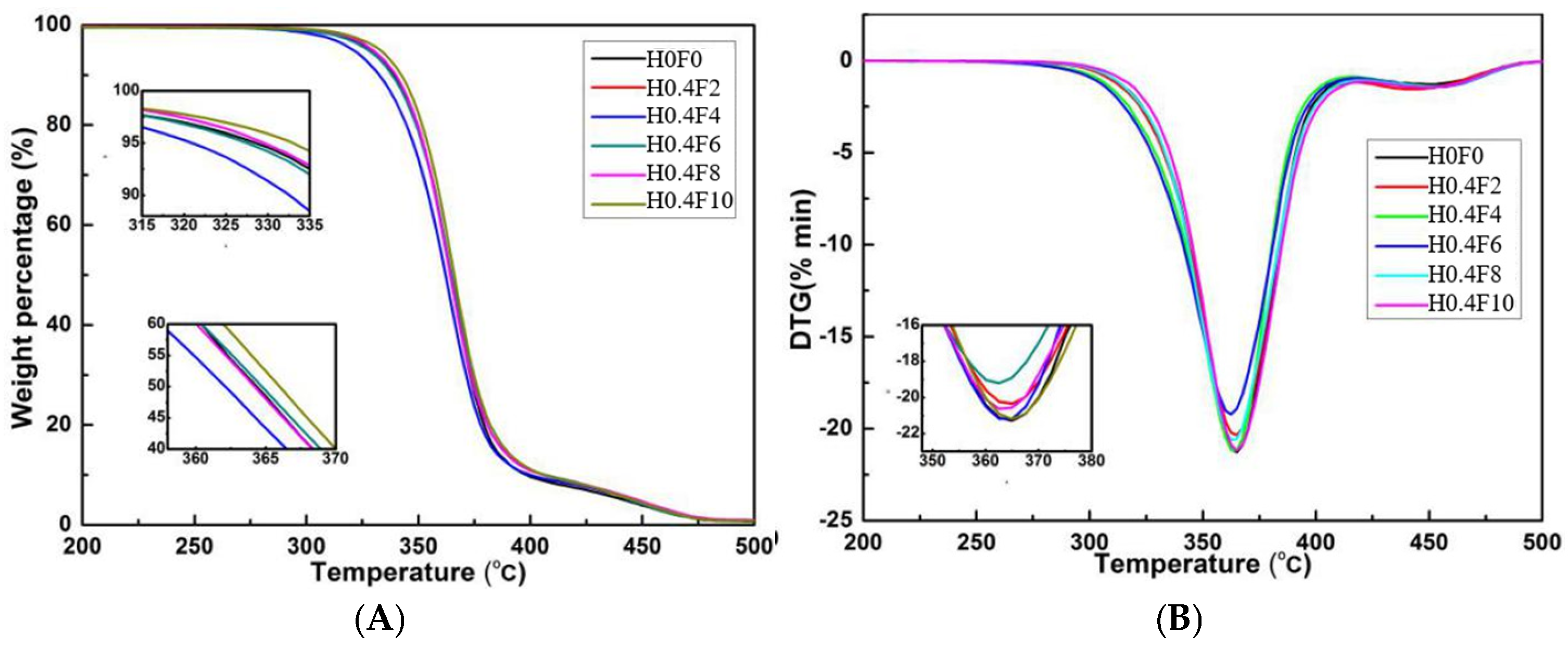

3.2.5. The Influence of Vibration Force Field on the Thermal Stability of the System

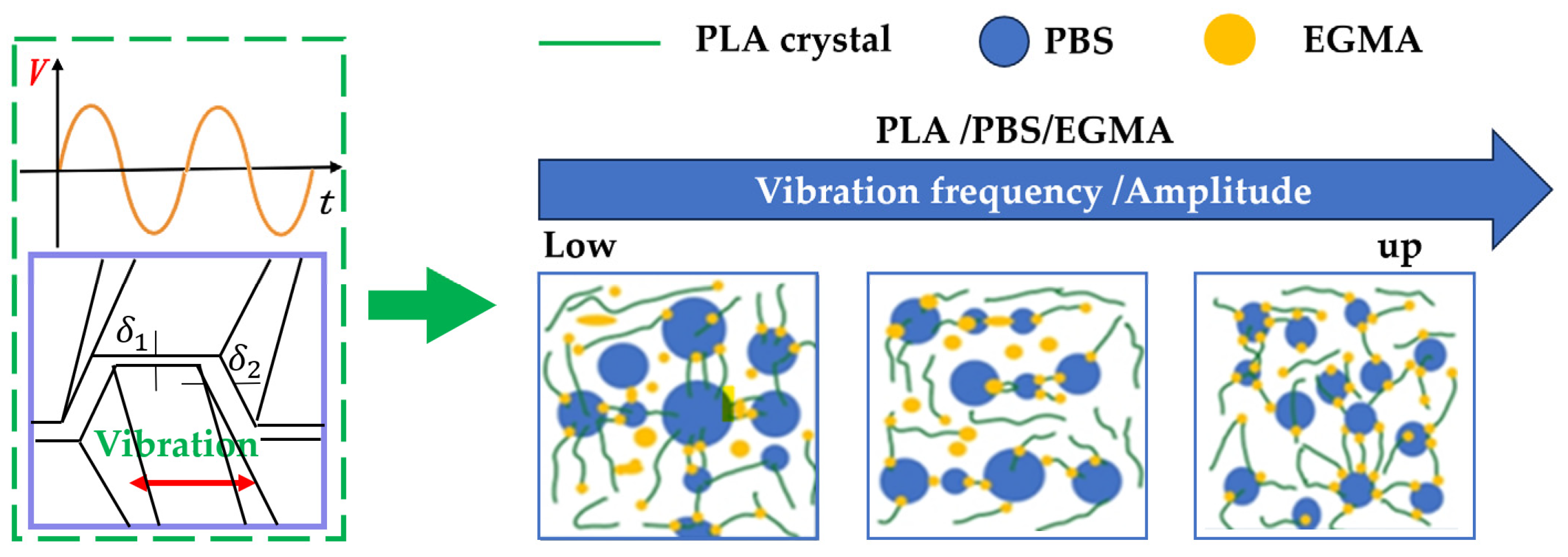

3.2.6. The Dispersion and Mixing Mechanism of the Action of the Vibration Force Field on the System

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Samir, A.; Ashour, F.H.; Hakim, A.A.A.; Bassyouni, M. Recent advances in biodegradable polymers for sustainable applications. NPJ Mater. Degrad. 2022, 6, 68. [Google Scholar] [CrossRef]

- Gunatillake, P.; Mayadunne, R.; Adhikari, R. Recent developments in biodegradable synthetic polymers. Biotechnol. Annu. Rev. 2006, 12, 301–347. [Google Scholar] [PubMed]

- Kadhim, M.A.; Yan, X.; Li, Q.; Zhou, Z.; Chen, G. Towards sustainable electronics: High-performance biodegradable polymer-based dielectric composite utilizing hydroxyapatite from cattle bone waste. J. Energy Storage 2024, 101, 113905. [Google Scholar] [CrossRef]

- Kurowiak, J.; Klekiel, T.; Będziński, R. Biodegradable Polymers in Biomedical Applications: A Review—Developments, Perspectives and Future Challenges. Int. J. Mol. Sci. 2023, 24, 16952. [Google Scholar] [CrossRef]

- Zhou, Y.; Lei, L.; Yang, B.; Li, J.; Ren, J. Preparation of PLA-based nanocomposites modified by nano-attapulgite with good toughness-strength balance. Polym. Test. 2017, 60, 78–83. [Google Scholar] [CrossRef]

- Wang, P.; Gao, S.; Chen, X.; Yang, L.; Wu, X.; Feng, S.; Hu, X.; Liu, J.; Xu, P.; Ding, Y. Effect of hydroxyl and carboxyl-functionalized carbon nanotubes on phase morphology, mechanical and dielectric properties of poly(lactide)/poly(butylene adipate-co-terephthalate) composites. Int. J. Biol. Macromol. 2022, 206, 661–669. [Google Scholar] [CrossRef]

- Jalali Dil, E.; Arjmand, M.; Otero Navas, I.; Sundararaj, U.; Favis, B.D. Interface Bridging of Multiwalled Carbon Nanotubes in Polylactic Acid/Poly(butylene adipate-co-terephthalate): Morphology, Rheology, and Electrical Conductivity. Macromolecules 2020, 53, 10267–10277. [Google Scholar]

- Fu, Y.; Wu, G.; Bian, X.; Zeng, J.; Weng, Y. Biodegradation Behavior of Poly(Butylene Adipate-Co-Terephthalate) (PBAT), Poly(Lactic Acid) (PLA), and Their Blend in Freshwater with Sediment. Molecules 2020, 25, 3946. [Google Scholar] [CrossRef]

- Wu, D.D.; Guo, Y.; Huang, A.P.; Xu, R.W.; Liu, P. Effect of the multi-functional epoxides on the thermal, mechanical and rheological properties of poly(butylene adipate-co-terephthalate)/polylactide blends. Polym. Bull. 2021, 78, 5567–5591. [Google Scholar] [CrossRef]

- Hussain, M.; Khan, S.M.; Shafiq, M.; Khan, S.U.; Raza, M.R.; Tlili, I. ZnO-modified PLA/PBAT composites: A study on mechanical strength and biodegradability for sustainable packaging applications. J. Korean Phys. Soc. 2025, 86, 180–188. [Google Scholar] [CrossRef]

- Zhou, Y.; Qiu, S.; Waterhouse, G.I.N.; Zhang, K.; Xu, J. Enhancing the properties of PBAT/PLA composites with novel phosphorus-based ionic liquid compatibilizers. Mater. Today Commun. 2021, 27, 102407. [Google Scholar] [CrossRef]

- Yang, X.-M.; Qiu, S.; Yusuf, A.; Sun, J.; Zhai, Z.; Zhao, J.; Yin, G.-Z. Recent advances in flame retardant and mechanical properties of polylactic acid: A review. Int. J. Biol. Macromol. 2023, 243, 125050. [Google Scholar] [CrossRef]

- Fatchurrohman, N.; Muhida, R.; Maidawati. From Corn to Cassava: Unveiling PLA Origins for Sustainable 3D Printing. J. Teknol. 2023, 13, 87–93. [Google Scholar] [CrossRef]

- Ogunrinola, T.M.; Akpan, U.G. Production of Cassava Starch Bioplastic Film Reinforced with Poly-Lactic Acid (PLA). Int. J. Eng. Res. Adv. Technol. 2018, 4, 56–61. [Google Scholar]

- Farid, T.; Herrera, V.N.; Kristiina, O. Investigation of crystalline structure of plasticized poly (lactic acid)/Banana nanofibers composites. IOP Conf. Ser. Mater. Sci. Eng. 2018, 369, 012031. [Google Scholar] [CrossRef]

- Gao, P.; Masato, D. The Effects of Nucleating Agents and Processing on the Crystallization and Mechanical Properties of Polylactic Acid: A Review. Micromachines 2024, 15, 776. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, D.; Li, B.; Wan, G.; Zhao, G.; Zhang, A. Strong and thermal-resistance glass fiber-reinforced polylactic acid (PLA) composites enabled by heat treatment. Int. J. Biol. Macromol. 2019, 129, 448–459. [Google Scholar] [CrossRef]

- Ramos, M.V.; Govindan, S.; Al-Jumaily, A.M. Property Improvement of Polybutylene Succinate (PBS), Polyhydroxybutyrate (PHB), and Polylactic Acid (PLA) Films with PCL (Polycaprolactone) for Flexible Packaging Application. Mater. Sci. Forum 2023, 1087, 41–50. [Google Scholar] [CrossRef]

- Govindan, S.; Ramos, M.V.; Al-Jumaily, A.M. A Review of Biodegradable Polymer Blends and Polymer Composite for Flexible Food Packaging Application. Mater. Sci. Forum 2023, 1094, 51–60. [Google Scholar]

- Puchalski, M.; Szparaga, G.; Biela, T.; Gutowska, A.; Sztajnowski, S.; Krucińska, I. Molecular and Supramolecular Changes in Polybutylene Succinate (PBS) and Polybutylene Succinate Adipate (PBSA) Copolymer during Degradation in Various Environmental Conditions. Polymers 2018, 10, 251. [Google Scholar] [CrossRef]

- Chen, L.; Wang, L.; Wan, Y.; Zhang, Y.; Qi, Z.; Wu, X.; Xu, H. Acetylene and Diacetylene Functionalized Covalent Triazine Frameworks as Metal-Free Photocatalysts for Hydrogen Peroxide Production: A New Two-Electron Water Oxidation Pathway. Adv. Mater. 2020, 32, 1904433. [Google Scholar] [CrossRef]

- Su, S.; Kopitzky, R.; Tolga, S.; Kabasci, S. Polylactide (PLA) and Its Blends with Poly(butylene succinate) (PBS): A Brief Review. Polymers 2019, 11, 1193. [Google Scholar] [CrossRef] [PubMed]

- Ullah, M.S.; Yildirim, R.; Kodal, M.; Ozkoc, G. Reactive compatibilization of PLA/PBS bio-blends via a new generation of hybrid nanoparticles. J. Vinyl Addit. Technol. 2023, 29, 737–757. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, L.; Zhou, X.; Liu, Z. Morphology-Dependent Electrochemical Performance of Zinc Hexacyanoferrate Cathode for Zinc-Ion Battery. Sci. Rep. 2015, 5, 18263. [Google Scholar] [CrossRef]

- Zhou, A.; Jiang, L.; Yue, J.; Tong, Y.; Zhang, Q.; Lin, Z.; Liu, B.; Wu, C.; Suo, L.; Hu, Y.-S.; et al. Water-in-Salt Electrolyte Promotes High-Capacity FeFe(CN)6 Cathode for Aqueous Al-Ion Battery. ACS Appl. Mater. Interfaces 2019, 11, 41356–41362. [Google Scholar] [CrossRef]

- Aversa, C.; Barletta, M.; Puopolo, M.; Vesco, S. Cast extrusion of low gas permeability bioplastic sheets in PLA/PBS and PLA/PHB binary blends. Polym.-Plast. Technol. Mater. 2020, 59, 231–240. [Google Scholar] [CrossRef]

- Zhao, X.-Y. Influence of Copolymer Compatibilizers on the Morphology and Rheological Behavior of Immiscible Polymer Blends. Polym. Bull. 2014, 27, 25–31. [Google Scholar]

- Lee, H.; Lee, T.H.; Kim, H.J.; Jang, K.S. Poly(butylene terephthalate)/poly(ethylene glycol) blends with compatibilizers. J. Appl. Polym. Sci. 2024, 141, e55230. [Google Scholar]

- Wei, B.; Lin, Q.; Zheng, X.; Gu, X.; Zhao, L.; Li, J.; Li, Y. Reactive splicing compatibilization of immiscible polymer blends: Compatibilizer synthesis in the melt state and compatibilizer architecture effects. Polymer 2019, 185, 121952. [Google Scholar] [CrossRef]

- Hosseinnezhad, R.; Vozniak, I.; Rozanski, A.; Kulagin, R.; Beloshenko, V.; Galeski, A. Compatibilization of Polymer Blends under Conditions of High Pressure and Shear Deformation. Macromol. Symp. 2024, 413, 2300244. [Google Scholar] [CrossRef]

- Ajitha, A.R.; Mathew, L.P.; Thomas, S. Chapter 6—Compatibilization of polymer blends by micro and nanofillers. In Compatibilization of Polymer Blends; Ajitha, A.R., Thomas, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 179–203. [Google Scholar]

- Bijarimi, M.; Ahmad, S.; Rasid, R.; Khushairi, M.A.; Zakir, M. Poly(lactic acid) / Poly(ethylene glycol) blends: Mechanical, thermal and morphological properties. AIP Conf. Proc. 2016, 1727, 020002. [Google Scholar] [CrossRef]

- Zeng, S.; Wang, H.; Li, X.; Guo, H.; Dong, L.; Guo, C.; Chen, Z.; Zhou, J.; Sun, Y.; Sun, W.; et al. Composition design of fullerene-based hybrid electron transport layer for efficient and stable wide-bandgap perovskite solar cells. J. Energy Chem. 2025, 102, 172–178. [Google Scholar] [CrossRef]

- Xue, B.; He, H.; Zhu, Z.; Li, J.; Huang, Z.; Wang, G.; Chen, M.; Zhan, Z. A Facile Fabrication of High Toughness Poly(lactic Acid) via Reactive Extrusion with Poly(butylene Succinate) and Ethylene-Methyl Acrylate-Glycidyl Methacrylate. Polymers 2018, 10, 1401. [Google Scholar] [CrossRef]

- Watanabe, S.; Yamada, S.; Takeshita, H.; Tokumitsu, K. Effect of Mixing Conditions on Dispersion and Degradation Behavior of HDPE/UHMWPE Blends. J. Soc. Mater. Sci. Jpn. 2023, 72, 392–397. [Google Scholar] [CrossRef]

- Wu, M.; Wang, K.; Zhang, Q.; Fu, Q. Manipulation of multiphase morphology in the reactive blending system OBC/PLA/EGMA. RSC Adv. 2015, 5, 96353–96359. [Google Scholar] [CrossRef]

- Qin, S.; Xu, W.-H.; Jiang, H.-W.; Zhang, H.-H.; He, Y.; Wu, T.; Qu, J.-P. Simultaneously achieving self-toughening and self-reinforcing of polyethylene on an industrial scale using volume-pulsation injection molding. Polymer 2021, 213, 123324. [Google Scholar] [CrossRef]

- Zhou, L.; Fu, X.-P.; Wang, R.; Wang, C.-X.; Luo, F.; Yan, H.; He, Y.; Jia, C.-J.; Li, J.; Liu, J.-C. Dynamic phase transitions dictate the size effect and activity of supported gold catalysts. Sci. Adv. 2024, 10, eadr4145. [Google Scholar] [CrossRef]

- Qu, J.-P.; Xu, G.; Hu, D.-N. The Effect of Vibration on Mechanical Properties of Blends of EPDM/PP in a Tri-screw Dynamic Mixing Extruder. Polym.-Plast. Technol. Eng. 2007, 46, 795–799. [Google Scholar] [CrossRef]

- Liu, T.; Dong, T.; Liu, B. Effect of sinusoidal pulsating speed enhancement on the mixing performance of plastics machinery. Int. Polym. Process. 2024, 39, 260–272. [Google Scholar] [CrossRef]

- Guo, M.; Ye, Y.; Jiang, X.; Wu, C. Comprehensive effect of multi-parameters on vibration in high-speed precision milling. Int. J. Adv. Manuf. Technol. 2020, 108, 2187–2195. [Google Scholar] [CrossRef]

| Factors | Temperature | Rotational Speed | Vibration Frequency | Amplitude |

|---|---|---|---|---|

| Level | (A) | (B) | (C) | (D) |

| 1 | 190 °C | 70 r/min | 2 Hz | 0.2 mm |

| 2 | 200 °C | 80 r/min | 4 Hz | 0.4 mm |

| 3 | 210 °C | 90 r/min | 6 Hz | 0.6 mm |

| 4 | 220 °C | 100 r/min | 8 Hz | 0.8 mm |

| Experimental Number and Factors | A | B | C | D | Empty | Tensile Strength (MPa) | Elongation at Break (%) | Impact Strength (KJ/m2) | Comprehensive Score |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 | 42.01 | 458.06 | 62.94 | 88.51 |

| 2 | 1 | 2 | 2 | 2 | 2 | 41.28 | 475.41 | 66.31 | 92.44 |

| 3 | 1 | 3 | 3 | 3 | 3 | 41.3 | 432.42 | 63.36 | 86.99 |

| 4 | 1 | 4 | 4 | 4 | 4 | 41.2 | 432.73 | 60.44 | 84.58 |

| 5 | 2 | 1 | 2 | 3 | 4 | 44.03 | 465.23 | 52.57 | 80.60 |

| 6 | 2 | 2 | 1 | 4 | 3 | 36.94 | 458.07 | 68.18 | 92.35 |

| 7 | 2 | 3 | 4 | 1 | 2 | 41.67 | 448.39 | 60.81 | 86.03 |

| 8 | 2 | 4 | 3 | 2 | 1 | 41.31 | 444.07 | 63.14 | 87.62 |

| 9 | 3 | 1 | 3 | 4 | 2 | 41.77 | 468.2 | 53.86 | 81.65 |

| 10 | 3 | 2 | 4 | 3 | 1 | 40.41 | 462.9 | 63.33 | 89.01 |

| 11 | 3 | 3 | 1 | 2 | 4 | 42.09 | 479.95 | 70.46 | 96.29 |

| 12 | 3 | 4 | 2 | 1 | 3 | 42.62 | 462.74 | 68.02 | 93.11 |

| 13 | 4 | 1 | 4 | 2 | 3 | 42.69 | 464.53 | 51.79 | 79.77 |

| 14 | 4 | 2 | 3 | 1 | 4 | 41.81 | 462.91 | 67.94 | 92.97 |

| 15 | 4 | 3 | 2 | 4 | 1 | 42.49 | 470.51 | 58.12 | 85.42 |

| 16 | 4 | 4 | 1 | 3 | 2 | 41.79 | 469.88 | 74.79 | 99.15 |

| K1j | 88.130 | 89.030 | 94.075 | 86.633 | 87.640 | ||||

| K2j | 86.650 | 90.155 | 87.892 | 91.692 | 89.817 | ||||

| K3j | 90.015 | 88.938 | 87.308 | 86.683 | 88.055 | ||||

| K4j | 89.328 | 86.000 | 84.847 | 91.115 | 86.610 | ||||

| Range | 3.35 | 4.155 | 9.228 | 9.059 | 2.177 | ||||

| set priorities | C > D > B > A | ||||||||

| Factors | Sum of Squares of Deviations | Degree of Freedom f | Mean Square Sum S | The Value of F | Significant Value |

|---|---|---|---|---|---|

| A | 26.143 | 3 | 2.437 | 9.280 | |

| B | 37.830 | 3 | 3.527 | 9.280 | |

| C | 184.835 | 3 | 17.231 | 9.280 | * |

| D | 205.950 | 3 | 19.199 | 9.280 | * |

| error | 10.73 | 3 |

| Sample | T5% (°C) | T50% (°C) | Tmax (°C) |

|---|---|---|---|

| F0H0 | 328.6 | 364.6 | 365.3 |

| F6H0.2 | 321.2 | 361.7 | 363.6 |

| F6H0.4 | 320.1 | 360.1 | 362.3 |

| F6H0.6 | 316.5 | 359.5 | 363.7 |

| F6H0.8 | 330.5 | 365.0 | 365.2 |

| F6H1.0 | 331.7 | 365.2 | 365.1 |

| Sample | T5% (°C) | T50% (°C) | Tmax (°C) |

|---|---|---|---|

| H0f0 | 328.6 | 364.6 | 365.2 |

| H0.4f2 | 327.6 | 364.7 | 364.2 |

| H0.4f4 | 321.0 | 362.1 | 363.6 |

| H0.4f6 | 320.0 | 361.7 | 362.3 |

| H0.4f8 | 329.8 | 364.2 | 363.6 |

| H0.4f10 | 333.1 | 366.0 | 365.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, B.; Li, J.; Yang, Q.; Wei, D.; Wu, G. Study on the Effects of Vibration Force Field on the Mixing and Structural Properties of PLA/PBS/EGMA Blends. Polymers 2025, 17, 947. https://doi.org/10.3390/polym17070947

Xue B, Li J, Yang Q, Wei D, Wu G. Study on the Effects of Vibration Force Field on the Mixing and Structural Properties of PLA/PBS/EGMA Blends. Polymers. 2025; 17(7):947. https://doi.org/10.3390/polym17070947

Chicago/Turabian StyleXue, Bin, Jun Li, Qu Yang, Danxiang Wei, and Guiting Wu. 2025. "Study on the Effects of Vibration Force Field on the Mixing and Structural Properties of PLA/PBS/EGMA Blends" Polymers 17, no. 7: 947. https://doi.org/10.3390/polym17070947

APA StyleXue, B., Li, J., Yang, Q., Wei, D., & Wu, G. (2025). Study on the Effects of Vibration Force Field on the Mixing and Structural Properties of PLA/PBS/EGMA Blends. Polymers, 17(7), 947. https://doi.org/10.3390/polym17070947