Mechanical and Solvothermal Recycling of End-of-Life Carbon Fibre-Reinforced Plastic Products: Process Feasibility and Flexural Performance of Recycled Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Recycling Method

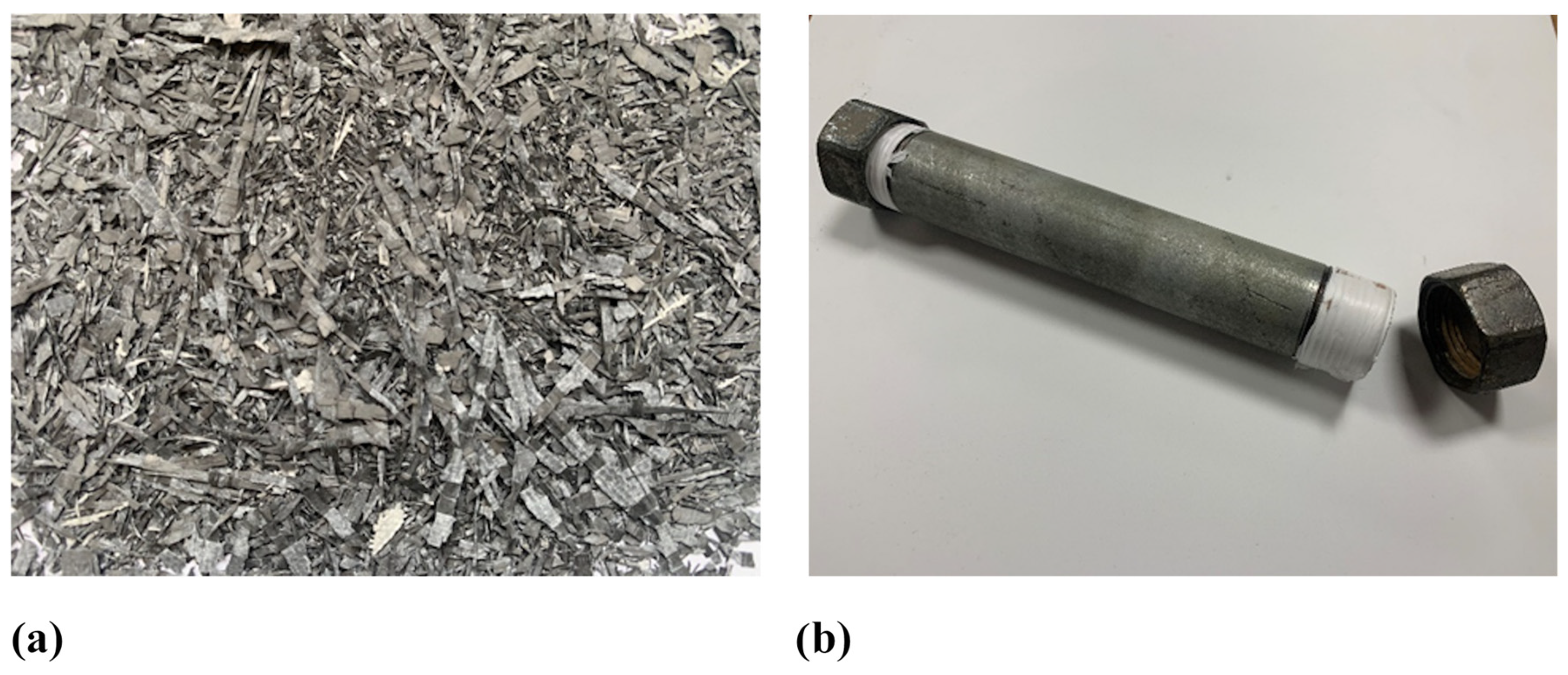

- In the first step, the recovered fibres were treated with an 11% acetic acid solution by volume to promote the swelling of the chip material. The fibres were placed in a Teflon-lined stainless-steel reactor vessel measuring 200 mm in length and 28 mm in diameter (Figure 2b). The vessel was sealed with the chemical solution, maintaining a fibre-to-solution weight ratio of 1:5, and heated in an oven at 150 °C for 8 h. Then, the reactor was removed and allowed to cool down naturally. Once the chemical treatment was completed, the recovered fibres were thoroughly washed with acetone.

- In the second step, the reactor vessel was sealed with a pure acetone solution, maintaining the same fibre-to-solution weight ratio of 1:5. As in the first step, the treated fibres were sealed in the reactor and heated in an oven at 150 °C for 8 h. Following this treatment, the vessel was allowed to cool naturally, and the fibres were washed again with acetone to remove any residual traces of dissolved matrix from their surface.

2.3. Chemical Characterisation

2.4. Mechanical Characterisation

3. Results

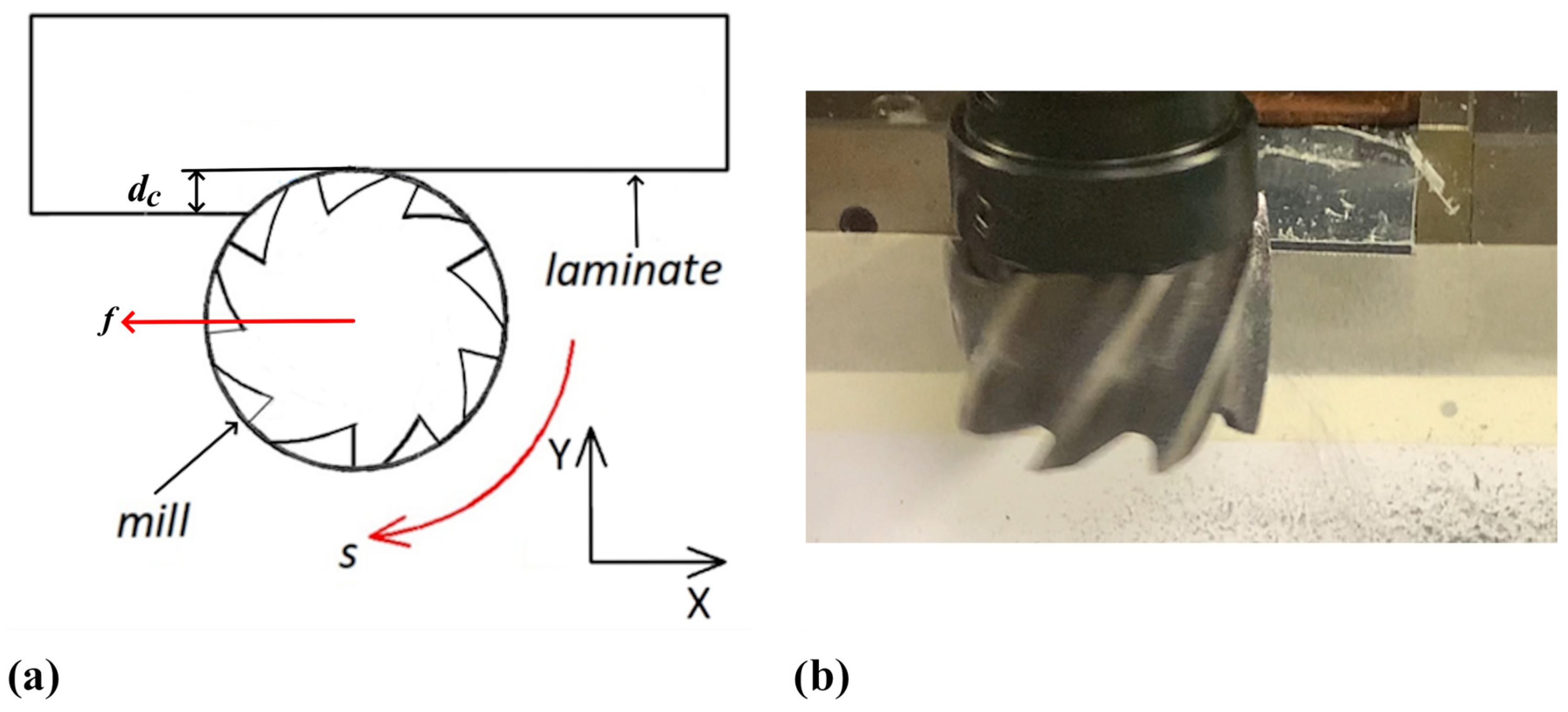

3.1. Mechanical Recycling

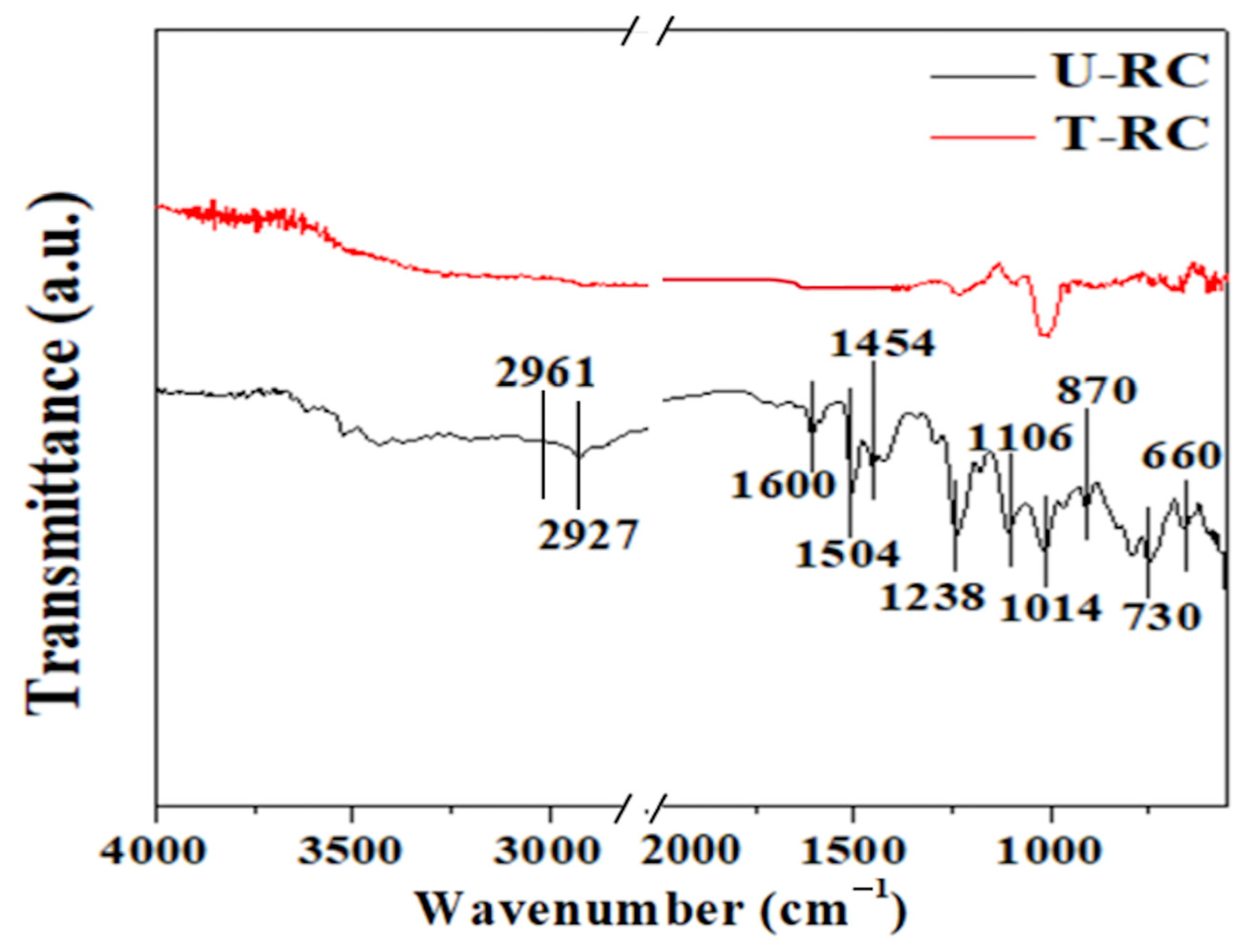

3.2. Chemical Results

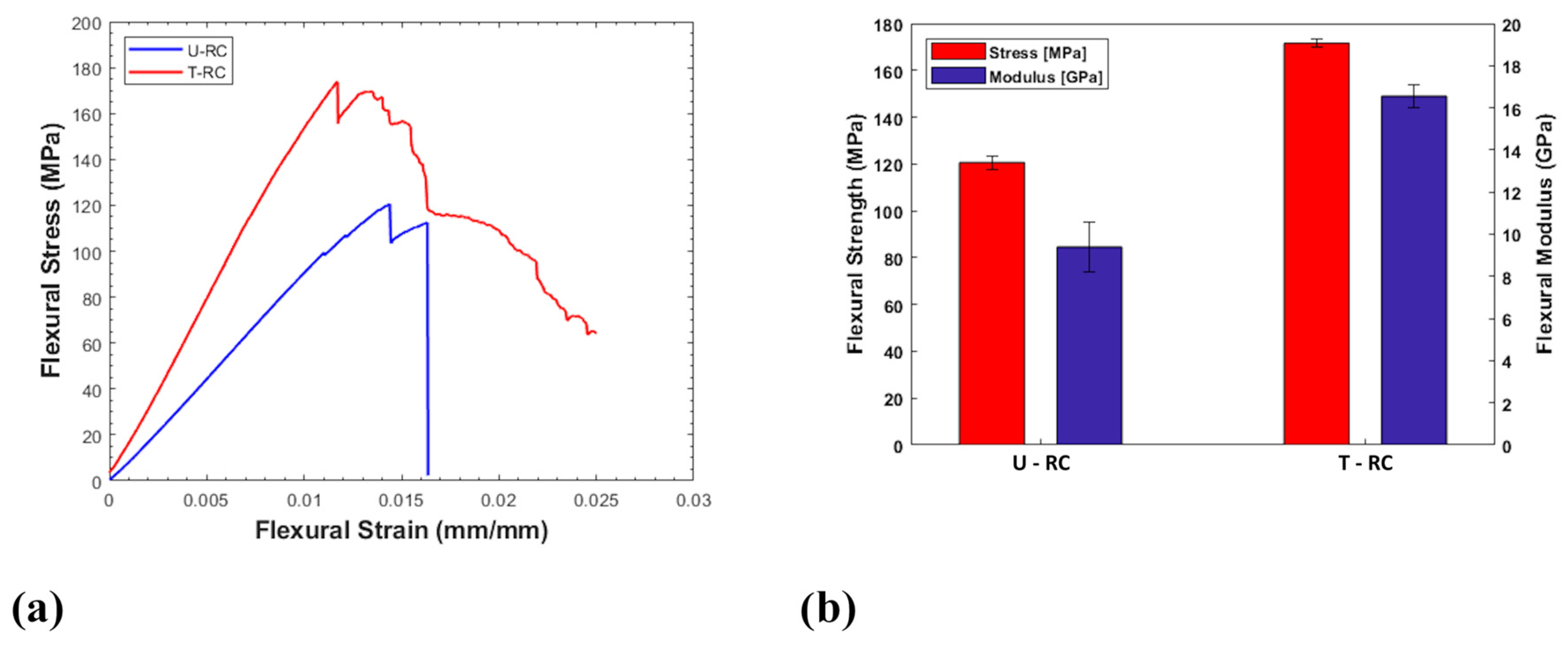

3.3. Flexural Properties

4. Conclusions

- The milling process can be considered a suitable method to recycle the end-of-life composite materials. The selected process parameters promoted the formation of fibre-rich chips like fine fibres, minimising resin-rich powder production. More than the 75% of the processed material was fine fibres, while powders accounted for only 16%.

- The two-step soft chemical treatment enhanced the fibre bundle’s swelling and matrix dissolution, achieving swelling ratio and mass loss values of approximately 55% and 24%, respectively.

- The FTIR analysis confirmed the total removal of the epoxy resin and the flame-retardant agents from the fibre’s surface testified by the absence of all the bands between 1014 cm−1 and 1600 cm−1. However, the presence of the 1014 cm−1 band indicates a partial fibre’s oxidation that in turn promotes improved fibre–matrix interaction and adhesion.

- The flexural tests revealed a significant increase in the mechanical properties of the T-RC sample because of the additional soft solvothermal recycling process in improving the flexural performance of the recycled composite material. Flexural strength and modulus increased by 42.24% and 76.25%, respectively, due to the enhanced adhesion from the additional chemical treatment.

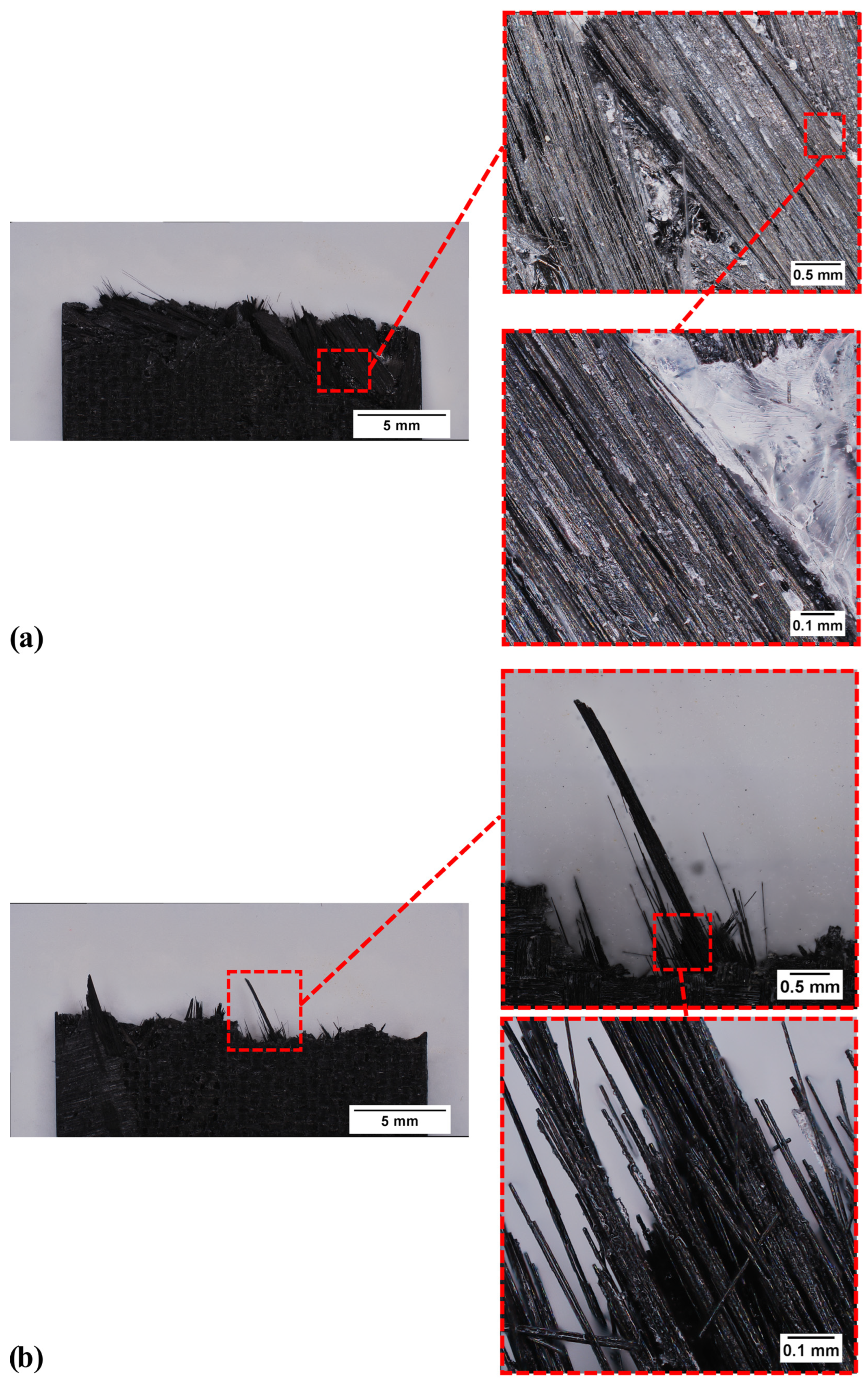

- Microscopic inspection revealed strong bonding in the T-RC sample with no visible debonding and a minimal fibre pull-out, while the U-RC sample exhibited weak bonding with the instauration of these phenomena. These findings confirm that the soft solvothermal process improves fibre–matrix interaction, leading to superior mechanical performance and highlighting the importance of chemical surface modification in recycled composites.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Krishnaraj, V.; Prabukarthi, A.; Ramanathan, A.; Elanghovan, N.; Senthil Kumar, M.; Zitoune, R.; Davim, J.P. Optimization of Machining Parameters at High Speed Drilling of Carbon Fiber Reinforced Plastic (CFRP) Laminates. Compos. Part B Eng. 2012, 43, 1791–1799. [Google Scholar] [CrossRef]

- Joshi, R.S.; Singh, H.; Singh, I. Modulation-Assisted Drilling of Glass-Fiber-Reinforced Plastics. Mater. Manuf. Process. 2014, 29, 370–378. [Google Scholar] [CrossRef]

- Tan, C.L.; Azmi, A.I.; Muhammad, N. Delamination and Surface Roughness Analyses in Drilling Hybrid Carbon/Glass Composite. Mater. Manuf. Process. 2016, 31, 1366–1376. [Google Scholar] [CrossRef]

- Cousins, D.S.; Suzuki, Y.; Murray, R.E.; Samaniuk, J.R.; Stebner, A.P. Recycling Glass Fiber Thermoplastic Composites from Wind Turbine Blades. J. Clean. Prod. 2019, 209, 1252–1263. [Google Scholar] [CrossRef]

- Hadigheh, S.A.; Ke, F.; Kashi, S. 3D Acid Diffusion Model for FRP-Strengthened Reinforced Concrete Structures: Long-Term Durability Prediction. Constr. Build. Mater. 2020, 261, 120548. [Google Scholar] [CrossRef]

- Pinto, F.; Boccarusso, L.; De Fazio, D.; Cuomo, S.; Durante, M.; Meo, M. Carbon/Hemp Bio-Hybrid Composites: Effects of the Stacking Sequence on Flexural, Damping and Impact Properties. Compos. Struct. 2020, 242, 112148. [Google Scholar] [CrossRef]

- De Fazio, D.; Boccarusso, L.; Formisano, A.; Viscusi, A.; Durante, M. A Review on the Recycling Technologies of Fibre-Reinforced Plastic (FRP) Materials Used in Industrial Fields. J. Mar. Sci. Eng. 2023, 11, 851. [Google Scholar] [CrossRef]

- Lin, L.; Schlarb, A.K. Recycled Carbon Fibers as Reinforcements for Hybrid PEEK Composites with Excellent Friction and Wear Performance. Wear 2019, 432–433, 202928. [Google Scholar] [CrossRef]

- Zhang, J.; Chevali, V.S.; Wang, H.; Wang, C.-H. Current Status of Carbon Fibre and Carbon Fibre Composites Recycling. Compos. Part B Eng. 2020, 193, 108053. [Google Scholar] [CrossRef]

- He, D.; Soo, V.K.; Kim, H.C.; Compston, P.; Doolan, M. Comparative Life Cycle Energy Analysis of Carbon Fibre Pre-Processing, Processing and Post-Processing Recycling Methods. Resour. Conserv. Recycl. 2020, 158, 104794. [Google Scholar] [CrossRef]

- Lin, G. Global Carbon Fibre Composite Market Report; Clean Energy Manufacturing Analysis Center: Golden, CO, USA, 2016. [Google Scholar]

- Melendi-Espina, S.; Morris, C.N.; Turner, T.A.; Pickering, S.J. Recycling of Carbon Fibre Composites. In Proceedings of the Carbon 2016, Penn State University, State College, PA, USA, 10–15 July 2016. [Google Scholar]

- Pickering, S.; Turner, T.A. Research and Development in Support of Carbon Fibre Recycling. In Proceedings of the CAMX 2014-Composite and Advanced Materials Expo: Combined Strength, Unsurpassed Innovation, Orlando, FL, USA, 13–16 October 2014. [Google Scholar]

- Naqvi, S.R.; Prabhakara, H.M.; Bramer, E.A.; Dierkes, W.; Akkerman, R.; Brem, G. A Critical Review on Recycling of End-of-Life Carbon Fibre/Glass Fibre Reinforced Composites Waste Using Pyrolysis towards a Circular Economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef]

- Rademacker, T. Challenges in CFRP Recycling. In Breaking & Sifting—Expert Exchange on the End-of-Life of Wind Turbine; Federal Ministry for Economic Affairs and Energy: Washington, DC, USA, 2018; pp. 24–25. [Google Scholar]

- McConnell, V.P. Launching the Carbon Fibre Recycling Industry. Reinf. Plast. 2010, 54, 33–37. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C.; Wang, Y. Mechanical Performance Evolution and Life Prediction of Prestressed CFRP Plate Exposed to Hygrothermal and Freeze-Thaw Environments. Compos. Struct. 2022, 293, 115719. [Google Scholar] [CrossRef]

- Kim, J.; Kang, S.; Seong, I.; Jeon, J.W.; Lee, D.; Kim, J.-H.; Kwon, D.-J. Advancing CFRP Durability: Interfacial and Weathering Performance of Epoxy and Acrylic Matrices. Compos. Part B Eng. 2025, 297, 112315. [Google Scholar] [CrossRef]

- Miyano, Y.; Nakada, M. Integrated Accelerated Testing Methodology for CFRP Durability. Compos. Part B Eng. 2024, 281, 111527. [Google Scholar] [CrossRef]

- Bai, J.; Yang, Y.; Huang, P.; Guo, X.; Chen, Z.; Wan-Wendner, R.; Li, W. Durability of CFRP Strengthened RC Beam after Six Years Exposure to Natural Hygrothermal Environment with Sustained Loads. Int. J. Fatigue 2024, 181, 108126. [Google Scholar] [CrossRef]

- ETIPWind Webinar on Blade Reycling and Innovative Materials for New Blade Design. 2019. Available online: https://etipwind.eu/past-events/webinar-blade-recycling-and-innovative-materials-for-new-blade-design/ (accessed on 20 January 2025).

- Shuaib, N.A.; Mativenga, P.T.; Kazie, J.; Job, S. Resource Efficiency and Composite Waste in UK Supply Chain. Procedia CIRP 2015, 29, 662–667. [Google Scholar] [CrossRef]

- Hagnell, M.K.; Åkermo, M. The Economic and Mechanical Potential of Closed Loop Material Usage and Recycling of Fibre-Reinforced Composite Materials. J. Clean. Prod. 2019, 223, 957–968. [Google Scholar] [CrossRef]

- Rybicka, J.; Tiwari, A.; Alvarez Del Campo, P.; Howarth, J. Capturing Composites Manufacturing Waste Flows through Process Mapping. J. Clean. Prod. 2015, 91, 251–261. [Google Scholar] [CrossRef]

- Ferrari, K.; Gamberini, R.; Rimini, B. The Waste Hierarchy: A Strategic, Tactical and Operational Approach for Developing Countries. the Case Study of Mozambique. Int. J. Sustain. Dev. Plan. 2016, 11, 759–770. [Google Scholar] [CrossRef]

- Lalhmangaihzuala, S.; Laldinpuii, Z.; Lalmuanpuia, C.; Vanlaldinpuia, K. Glycolysis of Poly(Ethylene Terephthalate) Using Biomass-Waste Derived Recyclable Heterogeneous Catalyst. Polymers 2020, 13, 37. [Google Scholar] [CrossRef] [PubMed]

- Palola, S.; Laurikainen, P.; García-Arrieta, S.; Goikuria Astorkia, E.; Sarlin, E. Towards Sustainable Composite Manufacturing with Recycled Carbon Fiber Reinforced Thermoplastic Composites. Polymers 2022, 14, 1098. [Google Scholar] [CrossRef] [PubMed]

- Rosenstock Völtz, L.; Di Guiseppe, I.; Geng, S.; Oksman, K. The Effect of Recycling on Wood-Fiber Thermoplastic Composites. Polymers 2020, 12, 1750. [Google Scholar] [CrossRef] [PubMed]

- Türker, Y.S.; Öztürk, F.; Öz, Y. Review of Recycling Methods of Thermoplastic Composite Materials. Polym. Technol. Mater. 2024, 63, 1693–1713. [Google Scholar] [CrossRef]

- Du, H.; Xian, G.; Tian, J.; Ma, Z.; Li, C.; Xin, M.; Zhang, Y. Effect of Fiber Surface Treatment with Silane Coupling Agents and Carbon Nanotubes on Mechanical Properties of Carbon Fiber Reinforced Polyamide 6 Composites. Polym. Compos. 2025, 46, 1267–1283. [Google Scholar] [CrossRef]

- Meng, F.; Olivetti, E.A.; Zhao, Y.; Chang, J.C.; Pickering, S.J.; McKechnie, J. Comparing Life Cycle Energy and Global Warming Potential of Carbon Fiber Composite Recycling Technologies and Waste Management Options. ACS Sustain. Chem. Eng. 2018, 6, 9854–9865. [Google Scholar] [CrossRef]

- Petterson, J.; Nilsson, P. Recycling of SMC and BMC in Standard Process Equipment. J. Thermoplast. Compos. Mater. 1994, 7, 56–63. [Google Scholar] [CrossRef]

- Overcash, M.; Twomey, J.; Asmatulu, E.; Vozzola, E.; Griffing, E. Thermoset Composite Recycling—Driving Forces, Development, and Evolution of New Opportunities. J. Compos. Mater. 2018, 52, 1033–1043. [Google Scholar] [CrossRef]

- Gastelu, N.; Lopez-Urionabarrenechea, A.; Solar, J.; Acha, E.; Caballero, B.; López, F.; de Marco, I. Thermo-Catalytic Treatment of Vapors in the Recycling Process of Carbon Fiber-Poly (Benzoxazine) Composite Waste by Pyrolysis. Catalysts 2018, 8, 523. [Google Scholar] [CrossRef]

- Karuppannan Gopalraj, S.; Kärki, T. A Review on the Recycling of Waste Carbon Fibre/Glass Fibre-Reinforced Composites: Fibre Recovery, Properties and Life-Cycle Analysis. SN Appl. Sci. 2020, 2, 433. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling Technologies for Thermoset Composite Materials—Current Status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Pickering, S.J.; Kelly, R.M.; Kennerley, J.R.; Rudd, C.D.; Fenwick, N.J. A Fluidised-Bed Process for the Recovery of Glass Fibres from Scrap Thermoset Composites. Compos. Sci. Technol. 2000, 60, 509–523. [Google Scholar] [CrossRef]

- Buggy, M.; Farragher, L.; Madden, W. Recycling of Composite Materials. J. Mater. Process. Technol. 1995, 55, 448–456. [Google Scholar] [CrossRef]

- Oliveux, G.; Bailleul, J.-L.; Salle, E.L.G. La Chemical Recycling of Glass Fibre Reinforced Composites Using Subcritical Water. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1809–1818. [Google Scholar] [CrossRef]

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.-J.; Kuiper, P.; de Wit, H. Recycling of Composite Materials. Chem. Eng. Process. Process Intensif. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current Status of Recycling of Fibre Reinforced Polymers: Review of Technologies, Reuse and Resulting Properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Piñero-Hernanz, R.; García-Serna, J.; Dodds, C.; Hyde, J.; Poliakoff, M.; Cocero, M.J.; Kingman, S.; Pickering, S.; Lester, E. Chemical Recycling of Carbon Fibre Composites Using Alcohols under Subcritical and Supercritical Conditions. J. Supercrit. Fluids 2008, 46, 83–92. [Google Scholar] [CrossRef]

- Jiang, G.; Pickering, S.; Lester, E.; Turner, T.; Wong, K.; Warrior, N. Characterisation of Carbon Fibres Recycled from Carbon Fibre/Epoxy Resin Composites Using Supercritical n-Propanol. Compos. Sci. Technol. 2009, 69, 192–198. [Google Scholar] [CrossRef]

- Vincent, G.A.; de Bruijn, T.A.; Wijskamp, S.; Abdul Rasheed, M.I.; van Drongelen, M.; Akkerman, R. Shredding and Sieving Thermoplastic Composite Scrap: Method Development and Analyses of the Fibre Length Distributions. Compos. Part B Eng. 2019, 176, 107197. [Google Scholar] [CrossRef]

- Heibeck, M.; Rudolph, M.; Modler, N.; Reuter, M. Characterizing Material Liberation of Multi-Material Lightweight Structures from Shredding Experiments and Finite Element Simulations. Miner. Eng. 2021, 172, 107142. [Google Scholar] [CrossRef]

- Vincent, G.; De Bruijn, T.A.; Iqbal, M.; Rasheed, A.; Akkerman, R.; Distribution, F.L. Fibre Length Distribution of Shredded Thermoplastic Composite Scrap. In Proceedings of the 21st International Conference on Composite Materials, Xi’an, China, 20–25 August 2017; pp. 20–25. [Google Scholar]

- Anane-Fenin, K.; Akinlabi, E.T. Recycling of Fibre Reinforced Composites: A Review of Current Technologies. In Proceedings of the DII-2017 Conference on Infrastructure Development and Investment Strategies for Africa, Livingstone, Zambia, 30 August–1 September 2017; Volume 7. [Google Scholar]

- Shuaib, N.A.; Mativenga, P.T. Energy Demand in Mechanical Recycling of Glass Fibre Reinforced Thermoset Plastic Composites. J. Clean. Prod. 2016, 120, 198–206. [Google Scholar] [CrossRef]

- Kim, Y.N.; Kim, Y.-O.; Kim, S.Y.; Park, M.; Yang, B.; Kim, J.; Jung, Y.C. Application of Supercritical Water for Green Recycling of Epoxy-Based Carbon Fiber Reinforced Plastic. Compos. Sci. Technol. 2019, 173, 66–72. [Google Scholar] [CrossRef]

- Kuang, X.; Zhou, Y.; Shi, Q.; Wang, T.; Qi, H.J. Recycling of Epoxy Thermoset and Composites via Good Solvent Assisted and Small Molecules Participated Exchange Reactions. ACS Sustain. Chem. Eng. 2018, 6, 9189–9197. [Google Scholar] [CrossRef]

- Mazzocchetti, L.; Benelli, T.; D’Angelo, E.; Leonardi, C.; Zattini, G.; Giorgini, L. Validation of Carbon Fibers Recycling by Pyro-Gasification: The Influence of Oxidation Conditions to Obtain Clean Fibers and Promote Fiber/Matrix Adhesion in Epoxy Composites. Compos. Part A Appl. Sci. Manuf. 2018, 112, 504–514. [Google Scholar] [CrossRef]

- Kim, K.-W.; Lee, H.-M.; An, J.-H.; Chung, D.-C.; An, K.-H.; Kim, B.-J. Recycling and Characterization of Carbon Fibers from Carbon Fiber Reinforced Epoxy Matrix Composites by a Novel Super-Heated-Steam Method. J. Environ. Manag. 2017, 203, 872–879. [Google Scholar] [CrossRef]

- Huo, S.; Song, P.; Yu, B.; Ran, S.; Chevali, V.S.; Liu, L.; Fang, Z.; Wang, H. Phosphorus-Containing Flame Retardant Epoxy Thermosets: Recent Advances and Future Perspectives. Prog. Polym. Sci. 2021, 114, 101366. [Google Scholar] [CrossRef]

- Velencoso, M.M.; Battig, A.; Markwart, J.C.; Schartel, B.; Wurm, F.R. Molecular Firefighting—How Modern Phosphorus Chemistry Can Help Solve the Challenge of Flame Retardancy. Angew. Chem. Int. Ed. 2018, 57, 10450–10467. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, D.; Li, Z.; Li, Z.; Peng, X.; Liu, C.; Zhang, Y.; Zheng, P. Recent Developments in the Flame-Retardant System of Epoxy Resin. Materials 2020, 13, 2145. [Google Scholar] [CrossRef]

- Zheng, P.; Zhao, H.; Li, J.; Liu, Q.; Ai, H.; Yang, R.; Xing, W. Recent Advances in Constructing New Type of Epoxy Resin Flame Retardant System Using Ammonium Polyphosphate. J. Saf. Sci. Resil. 2024, 5, 179–193. [Google Scholar] [CrossRef]

- Yang, S.; Wang, J.; Huo, S.; Wang, M.; Wang, J.; Zhang, B. Synergistic Flame-Retardant Effect of Expandable Graphite and Phosphorus-Containing Compounds for Epoxy Resin: Strong Bonding of Different Carbon Residues. Polym. Degrad. Stab. 2016, 128, 89–98. [Google Scholar] [CrossRef]

- Wu Klingler, W.; Bifulco, A.; Polisi, C.; Huang, Z.; Gaan, S. Recyclable Inherently Flame-Retardant Thermosets: Chemistry, Properties and Applications. Compos. Part B Eng. 2023, 258, 110667. [Google Scholar] [CrossRef]

- Liu, T.; Shao, L.; Zhao, B.; Chang, Y.; Zhang, J. Progress in Chemical Recycling of Carbon Fiber Reinforced Epoxy Composites. Macromol. Rapid Commun. 2022, 43, 2200538. [Google Scholar] [CrossRef]

- Durante, M.; Boccarusso, L.; De Fazio, D.; Formisano, A.; Langella, A. Investigation on the Mechanical Recycling of Carbon Fiber-Reinforced Polymers by Peripheral Down-Milling. Polymers 2023, 15, 854. [Google Scholar] [CrossRef] [PubMed]

- Durante, M.; Boccarusso, L.; De Fazio, D.; Formisano, A.; Langella, A. Machining Approach for Recycling of CFRP Laminates. In International Symposium on Dynamic Response and Failure of Composite Materials; Springer International Publishing: Cham, Switzerland, 2023; pp. 180–185. [Google Scholar]

- De Fazio, D.; Boccarusso, L.; Formisano, A.; Langella, A.; Memola Capece Minutolo, F.; Durante, M. Durante Mechanical Recycling of CFRPs: Manufacturing and Characterization of Recycled Laminates. In Italian Manufacturing Association Conference: XVI AITeM; Materials Research Forum LLC: Millersville, PA, USA, 15 October 2023; pp. 402–410. [Google Scholar]

- Wang, Y.; Cui, X.; Ge, H.; Yang, Y.; Wang, Y.; Zhang, C.; Li, J.; Deng, T.; Qin, Z.; Hou, X. Chemical Recycling of Carbon Fiber Reinforced Epoxy Resin Composites via Selective Cleavage of the Carbon–Nitrogen Bond. ACS Sustain. Chem. Eng. 2015, 3, 3332–3337. [Google Scholar] [CrossRef]

- Ellerbrock, R.; Stein, M.; Schaller, J. Comparing Amorphous Silica, Short-Range-Ordered Silicates and Silicic Acid Species by FTIR. Sci. Rep. 2022, 12, 11708. [Google Scholar] [CrossRef]

| Label | Reinforcement | Chemical Treatment | Fibre Weight Percentage [%] | Thickness [mm] |

|---|---|---|---|---|

| U-RC | Fine fibres | - | 35.00 | 2.77 |

| T-RC | Fine fibres | Two-step solvolysis | 35.00 | 2.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Fazio, D.; Boccarusso, L.; Formisano, A.; Grappa, R.; Luciani, G.; Branda, F.; Durante, M. Mechanical and Solvothermal Recycling of End-of-Life Carbon Fibre-Reinforced Plastic Products: Process Feasibility and Flexural Performance of Recycled Composites. Polymers 2025, 17, 878. https://doi.org/10.3390/polym17070878

De Fazio D, Boccarusso L, Formisano A, Grappa R, Luciani G, Branda F, Durante M. Mechanical and Solvothermal Recycling of End-of-Life Carbon Fibre-Reinforced Plastic Products: Process Feasibility and Flexural Performance of Recycled Composites. Polymers. 2025; 17(7):878. https://doi.org/10.3390/polym17070878

Chicago/Turabian StyleDe Fazio, Dario, Luca Boccarusso, Antonio Formisano, Rossella Grappa, Giuseppina Luciani, Francesco Branda, and Massimo Durante. 2025. "Mechanical and Solvothermal Recycling of End-of-Life Carbon Fibre-Reinforced Plastic Products: Process Feasibility and Flexural Performance of Recycled Composites" Polymers 17, no. 7: 878. https://doi.org/10.3390/polym17070878

APA StyleDe Fazio, D., Boccarusso, L., Formisano, A., Grappa, R., Luciani, G., Branda, F., & Durante, M. (2025). Mechanical and Solvothermal Recycling of End-of-Life Carbon Fibre-Reinforced Plastic Products: Process Feasibility and Flexural Performance of Recycled Composites. Polymers, 17(7), 878. https://doi.org/10.3390/polym17070878