Abstract

Road safety systems are critical engineering solutions designed to minimize the effects of traffic accidents and increase the safety of transportation infrastructures. Traditional road safety structures are generally manufactured using steel, concrete and polymer materials. However, manufacturing processes with these materials are high-cost, limited in terms of design flexibility and can lead to material waste. In recent years, rapidly developing additive manufacturing (AM) technologies stand out as an important alternative in the production of road safety systems. AM enables the production of complex geometries and enables the development of lightweight and high-strength structures that can absorb impact energy more effectively. This study focuses on the use of AM methods in road safety systems, examining the performance and applicability of polymer, metal and composite materials. The advantages of AM-produced road safety barriers, traffic signs, speed bumps and shock absorbing structures, depending on the material type, are evaluated. In addition, the advantages offered by AM, such as design flexibility, sustainable production processes and material efficiency, are discussed, and technical challenges and applicability limitations are also discussed. This review evaluates the current and potential applications of AM for road safety systems, providing insights into how this technology can be used more effectively in the future. The findings of the study provide significant contributions towards improving the integration of AM technologies into road safety systems from both academic and industrial perspectives. The findings of the study provide important contributions to the development of the integration of AM technologies into road safety systems from both academic and industrial perspectives. Future research can further enhance the innovative potential of AM in road safety systems, with a particular focus on sustainable material use, design optimization and energy efficiency in manufacturing processes. However, overcoming technical challenges in large-scale applications and compliance with regulatory standards are critical research areas for the widespread adoption of this technology.

1. Introduction

Road safety is an important interdisciplinary engineering branch that aims to prevent traffic accidents and minimize their effects. Road safety is important not only for drivers, but also for other road users such as pedestrians and cyclists. Road construction techniques, road safety systems and vehicle safety technologies are developing every day. However, traffic accidents are still one of the biggest causes of death and disability in the world. According to the World Health Organization, more than one million people lose their lives in traffic accidents every year worldwide [1]. At the same time, traffic accidents also cause great economic damage to societies. The damage caused by traffic accidents is estimated to be USD 1.8 trillion, equivalent to approximately 10–12% of the global average gross domestic product [2]. Therefore, studies on road safety are of great importance in terms of creating safer transportation systems. Road safety, which depends on factors such as drivers, other road users, vehicles, road design, road safety elements, traffic management, etc., is developing with multidisciplinary approaches every day.

Road safety elements stand out as structures that increase the safety of road users, guide drivers to stay on the road route and reduce the effects of collisions. These elements can be classified as speed bumps, warning systems, traffic signs, road markings, lighting systems and safety barriers. Road safety barriers are important in terms of helping to prevent loss of life by absorbing collision energy and preventing vehicles from leaving the road route [3]. Modern road safety barriers aim to protect pedestrians and other road users as well as ensuring the safety of drivers and passengers. Therefore, the physical, mechanical and environmental properties of the material they are made of directly affect the protection, performance and contribution of road safety barriers. Traditional safety barriers and road safety elements are mainly produced using steel, concrete and polymer materials [4]. Although these materials offer significant advantages in terms of durability, energy absorption capacity and longevity, their production processes can be costly and time-consuming. In addition, traditional production methods often lead to excessive material waste and create limitations in the design of structures with complex geometries. In this context, AM technologies, which have developed rapidly in recent years, stand out as an innovative and sustainable alternative in the production of road safety structures.

AM works with the principle of layered production, allowing the production of lightweight, high-strength, high-impact-resistant and customizable structures. This technology enables the production of complex designs with detailed internal structures that are difficult to produce with traditional methods, thus, enabling the development of road safety elements that can absorb collision energy more effectively [5,6,7]. In addition, by increasing material usage efficiency, it significantly reduces waste and speeds up production processes, making AM an attractive option in terms of sustainable production. Today, AM applications with metal, polymer and composite materials have become widespread in various road safety systems such as safety barriers, traffic signs, speed bumps, crash-absorbing structures and modular road elements. While polymer-based AM provides lightness and cost advantages, metal AM enables the production of high-strength and durable structures [8]. The use of composite materials contributes to the development of multifunctional, high energy absorption capacity and long-lasting security systems.

In this study, the current and potential applications of additive manufacturing in road safety systems are examined and the effects of different types of materials (polymers, metals and composites) on road safety structures are evaluated. In addition, the advantages offered by additive manufacturing and the technical challenges that may be encountered are discussed and perspectives on how this technology can transform road safety systems in the future are presented.

2. Additive Manufacturing Technologies in Road Safety Elements

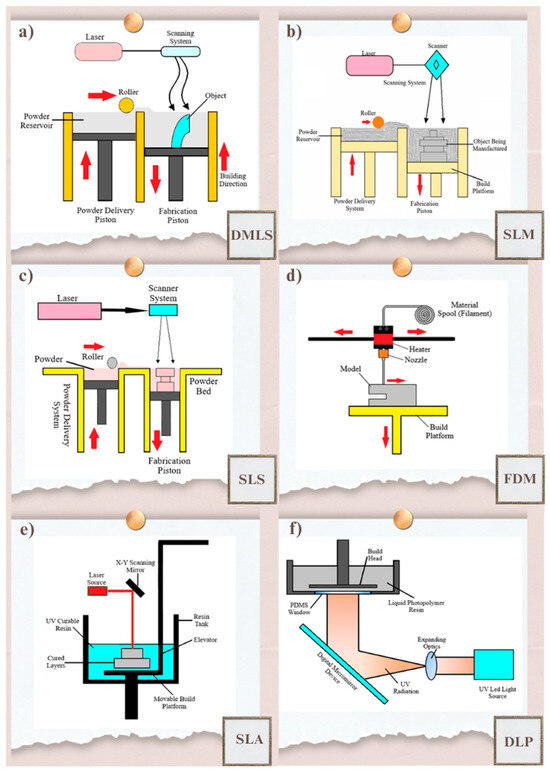

AM is one of the advanced manufacturing methods that combines materials in layers to produce three-dimensional structures. This technology, which was first developed for prototype production, has developed over time and has become widespread in many industries such as aviation, automotive, defense and biomedical [9,10]. AM has become an important alternative to traditional manufacturing methods thanks to its design freedom, material savings, customizable production and cost advantages. It has an important place especially in applications where parts with high strength, lightness and complex geometries need to be produced. In the aviation sector, high-performance materials such as titanium alloys and superalloys are used in the production of aircraft engine components and lightweight structural elements. The production of these parts with AM reduces the weight of the part, increases durability and contributes to fuel efficiency [11,12]. In the automotive industry, it has become possible to quickly produce special prototypes, functional parts and spare components at low cost [13]. AM is becoming increasingly common in the production of safety-focused components such as electric vehicle battery cases and bumper support elements that increase crashworthiness [14,15]. In the defense industry, AM methods are preferred to produce durable, lightweight and impact-resistant structural parts [16,17]. Resin-based methods that provide high-precision production in applications such as personalized implants, prostheses and organ models in the biomedical field come to the fore [18]. In transportation infrastructure, AM technology is considered an innovative solution in the production of road safety systems and traffic components. In the production of parts such as collision barriers, energy absorbing elements, traffic direction signs and reflector housings, lightweight and durable material compositions that increase impact resistance are used with AM. Geometric structures that are difficult to manufacture with traditional manufacturing techniques can be manufactured with AM, thus, increasing the functionality of the equipment used in road safety systems. AM processes are divided into different categories according to the types of materials used and manufacturing principles. Among the AM methods, powder bed fusion methods are based on the principle of combining a thin layer of powder with energy sources such as laser or electron beam layer by layer. These methods make it possible to produce high-performance components from materials such as metal, polymer and ceramic [19,20,21]. Direct Metal Laser Sintering (DMLS—Figure 1a) and Selective Laser Melting (SLM—Figure 1b) are processes in which metal powders are melted or sintered with the help of a controlled laser beam. DMLS allows the production of high-strength parts, especially from steel, aluminum and titanium alloys [22]. Since the SLM method provides complete melting, it is used in the production of dense and non-porous parts [23,24]. In transportation and road safety systems, aluminum and titanium-based SLM structures are widely used in the production of safety barriers that effectively absorb impact energy [25,26]. Selective Laser Sintering (SLS) produces flexible parts with high mechanical strength by sintering polymer-based powders (Figure 1c). SLS is especially preferred in the production of fasteners and modular components that require lightness and flexibility [27,28].

Figure 1.

Illustration of various AM techniques and their operating principles: (a) DMLS, (b) SLM, (c) SLS, (d) FDM, (e) SLA and (f) DLP.

Fused Deposition Modeling (FDM) is based on the principle of combining thermoplastic filaments layer by layer by heating them in a controlled manner (Figure 1d). This extrusion-based method is widely preferred in prototype production because it offers a cost-effective production process. Flexible and durable structural elements can be produced with materials such as ABS, PLA and carbon fiber reinforced filaments. It is used in the transportation sector, especially in the production of modular connections, reflector covers and impact simulation components [29,30]. The integration of composite and hybrid polymers into the production process allows the production of components with high impact resistance. The FDM method plays an important role in the production of low-cost but high-strength components in road safety systems thanks to the material additives made to increase the mechanical properties of thermoplastics [31]. Another AM method, the resin-based AM method, is based on the solidification of liquid photopolymers using a light source. Stereolithography (SLA—Figure 1e) and Digital Light Processing (DLP—Figure 1f) methods offer significant advantages in the production of parts with complex geometries thanks to their high precision production capacity. SLA is preferred in the production of parts with high surface quality [32,33]. This method is used in the production of fine and detailed structures and is widely preferred in the production of optical components such as reflector lenses and signaling components. DLP works similarly to the SLA method but offers faster production and higher resolution with projection technology [34]. It is widely used in the production of traffic signal lamps and parts containing delicate details. These methods are important for the production of durable materials with optical properties. In addition, material additives to photopolymer resins increase impact resistance and provide UV resistance [35]. The use of resin-based methods in transportation safety systems such as accident simulation models and optical guidance elements enables the production of sensitive and functional components. As a result, AM is seen as an important transformation tool in today’s manufacturing world. The innovations offered by this technology have the potential to make manufacturing processes more agile, sustainable and efficient. Future research and technological advances will contribute to making AM more accessible both technically and economically, thus, enabling it to reach a wider range of industrial applications. A comparative summary of the key characteristics of the discussed AM processes is presented in Table 1. This table aims to support the reader in evaluating each method in terms of accuracy, surface quality, material compatibility, cost, production speed and practical limitations.

Table 1.

Comparative overview of AM techniques.

When AM technologies are compared with traditional manufacturing methods, it is seen that AM offers significant advantages, especially in the production of low-volume, customized parts with complex geometries [36]. In traditional methods, production is usually based on mold preparation, machining and machining processes that require high initial costs, are time-consuming and generate a significant amount of material waste during production [37]. In contrast, AM processes, thanks to their additive nature, use only the required amount of material, thereby reducing raw material waste and significantly shortening the total production time. This increases cost-effectiveness, especially in prototyping and low-volume production. From an efficiency perspective, AM methods make it possible to produce customized products quickly with less energy consumption; at the same time, they make processes suitable for automation by reducing the dependence on human intervention in the production process [5]. From a sustainability perspective, the ability to integrate recycled thermoplastics and biobased materials into production processes through AM contributes to the reduction of carbon footprint and circular economy principles [38]. With these features, AM is considered an alternative that offers lower environmental impact and greater design freedom compared to traditional methods while supporting the concept of environmentally friendly production.

3. Materials Used in Road Safety and Transportation Applications

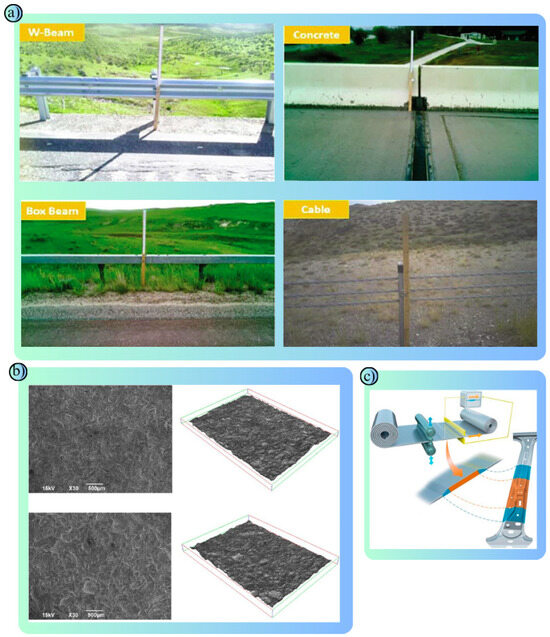

As one of the most important parts of today’s modern transportation systems, road safety aims to ensure sustainability in transportation and reduce fatal/injury accidents [39]. Road safety is highly correlated not only with drivers respecting the rules, but also with vehicles, road materials, road design, traffic regulation equipment and environmental impacts. Road materials, asphalt, concrete, etc., are used to improve the strength, durability and performance of roads [40,41]. Signboards made of reflective materials and paints used in road safety lines aim to improve road visibility [42]. Road safety barriers are of particular importance in minimizing the impact of traffic accidents, reducing fatal/injury accidents and preventing vehicles from leaving the road route (Figure 2a) [43]. Road safety barriers are designed to reduce the impact of collisions, ensure the safety of drivers and other road users, and prevent vehicles from skidding off the roadway [44]. Their performance depends on the properties and type of material from which they are made. Each type of material, selected according to specific use scenarios, has different physical and mechanical properties [45]. In this study, polymers, metals and composites commonly used in road safety barriers are examined. Polymers have advantages such as corrosion resistance and their light weight. Metals are preferred due to their durability and high strength. Composites combine the advantages of these two materials to provide superior performance in terms of both energy absorption and durability. The most used metals in road safety barriers are steel and aluminum. These metals aim to reduce the impact of accidents through their energy absorption capacity and high strength (Figure 2c) [46]. However, their surfaces should be coated for corrosion resistance (Figure 2b) [47]. Polymers stand out with their flexibility, lightness and low-cost advantages and are naturally resistant to corrosion and environmental conditions [48]. Composites, on the other hand, offer a combination of a long life, high-energy absorption and light weight [49]. Composites, which are more costly than traditional materials, are increasingly preferred for their long life and low maintenance costs [50]. Used to improve road safety, these materials play an important role in protecting drivers and other road users and reducing the impact of accidents.

Figure 2.

Combined figure showing various experimental and conceptual aspects of the studies together: (a) Different barrier systems are shown: W-Beam absorbs energy with its undulating steel structure; Concrete barrier changes vehicle direction with its rigid structure; Box Beam is structurally similar to W-Beam but has different deformation properties; Cable barrier reduces the severity of accidents by absorbing impact energy [43]. (b) Two different blasting methods were compared: Field blasting produces an irregular surface structure, while factory centrifugal blasting provides a more homogeneous surface. Three-dimensional models show the surface roughness and height variations [47]. (c) Tailor Rolled Blank (TRB) technology allows specific areas of sheet metal to be produced with different thicknesses. This method offers weight optimization while improving crash safety, especially in the automotive sector. The diagram shows the manufacturing process and its application to an automotive component [46].

3.1. Polymers

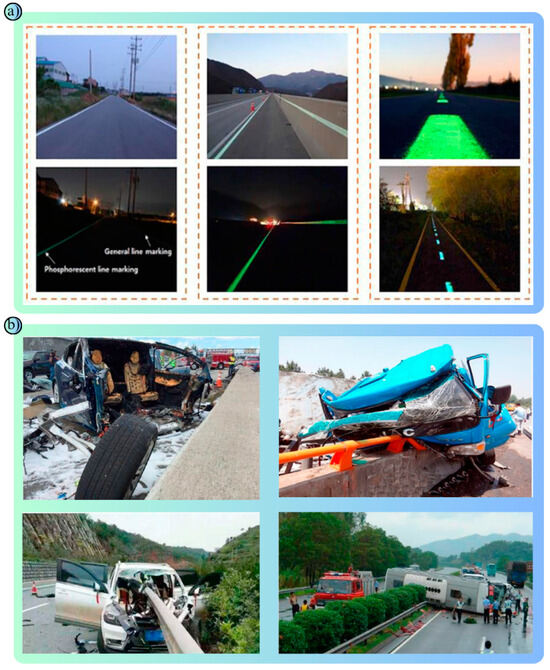

Polymers are an important material with a wide range of applications in road safety. Resistant to environmental conditions, lightweight, flexible and durable, they provide both technical and economic advantages. Polymers are preferred not only in road safety applications but also in many transportation areas such as pedestrian safety, vehicle safety, traffic management and environmental protection. For example, polymer road safety barriers (Table 1) absorb the impact of a collision, reducing damage and fatal/injury accidents (Figure 3b) [51,52]. Thermoplastic road markings are polymer-based and increase road safety by providing high visibility at road borders (Figure 3a) [53,54].

Figure 3.

A combined figure presenting the various experimental and modeling components of the studies: (a) Phosphorescent road markings applied in different regions: support driving safety by improving road visibility in low light conditions. It is observed to provide better guidance at night compared to traditional lines [53,54], (b) Accidents with different types of barriers are shown: Concrete barriers keep vehicles on the road but can increase crash severity due to their heavy construction. W-Beam barriers pose a risk of penetration for small vehicles but can be overcome by large vehicles [51,52].

Asphalt pavements modified with polymers extend the life of the road surface, reducing rutting, cracking and deformations and improving ride quality (Figure 4a–c) [55,56,57]. In addition, energy-absorbing systems such as crash cushions and polymer coatings help prevent accidents by increasing friction on the road surface [58,59]. Signs, traffic cones and reflective materials made of polymer materials guide drivers both day and night [60]. In terms of environmental protection, polymer-based water-filled barriers and road equipment made from recycled polymers offer both environmentally friendly and economical solutions. All these advantages make polymers an important part of road safety systems. In the future, the integration of polymers with sensor technologies and the development of new climate-resistant types will offer even greater opportunities for road safety. Polymer road safety barriers are designed to prevent vehicles from leaving the road in the case of an accident (Table 2). In the case of an accident, it minimizes the damage to both drivers and passengers and other road users by absorbing the impact energy. They are durable and long-lasting. At the same time, their modular design offers portability and easy installation. This provides a quick and effective solution for temporary road arrangements. The use of polymer road safety barriers has attracted attention in recent years due to their potential advantages over traditional materials (concrete/steel). They prevent vehicles from leaving the road route and contribute to reducing the severity of accidents [61,62].

Figure 4.

Comprehensive composite visualization representing the experimental and modeling processes of the studies in an integrated manner: (a) Microstructural analysis of bitumen modified with Styrene-Butadiene-Styrene (SBS): Polymer fluorescence microscope images of bitumen modified with different SBS ratios are shown. It is observed that the polymer phase distribution becomes more homogeneous and denser as the SBS content increases [55]. (b) Four different types of polymers used in asphalt modification are shown: SBS (Styrene-Butadiene-Styrene): Provides elasticity. EVA (Ethylene-Vinyl Acetate): Provides rigidity and high-temperature resistance. SBR (Styrene-Butadiene Rubber): Improves bonding properties. Waste Rubber: Offers the advantage of recyclability and flexibility [56,57]. (c) Fluorescence microscope images of asphalt modified with different SBS ratios are shown. With increasing SBS content, the polymer phase became more visible, and the elastic properties of the asphalt increased [57].

Road safety equipment made with polymers allows waste to be recycled. Recycled polymers make a major contribution to environmental protection and sustainability [63,64]. Waste polymers, which would cause great harm if thrown into the environment, are recycled and contribute to road safety. Barriers made from plastic waste directly serve waste management and sustainability goals. This process reduces both the landfill of waste polymers and the carbon footprint [65,66].

Table 2.

Recent studies on road safety barriers produced using polymer materials.

Table 2.

Recent studies on road safety barriers produced using polymer materials.

| Year | Materials | Objective | Input Parameter | Conclusion |

|---|---|---|---|---|

| 2022 | Recycled tire rubber and Polypropylene (PP) [67] | Energy and carbon analysis of recycled materials in road safety barriers |

| Option B achieved 38% less CO2 and 47% less non-renewable energy consumption. Option C showed a 69% CO2 reduction and 86% less energy consumption. |

| 2023 | Flexible polymer barrier [69] | Develop a flexible and reusable barrier system for runaway vehicles |

| The proposed system ensured passenger safety while successfully stopping runaway vehicles. It is also cost-effective as it is reusable. |

| 2024 | Ethylene-Vinyl Acetate (EVA) foam [70] | Design optimization of roadside safety barriers |

| EVA foam improved the crash performance of the barrier by reducing impact energy by 30%. Better design parameters were developed through parallel Bayesian optimization. |

| 2023 | Modular Rotating Polymer Barrier [71] | Analyzing the crash performance of the new mountable roll barrier |

| The rotating barrier caused less damage than conventional steel barriers, increased energy absorption and improved passenger safety. |

| 2021 | Assembled Anti-Collision Barrier (Polymer Composite) [72] | Analyzing the crash impact of a new erected barrier |

| The new barrier provided better energy absorption than traditional steel barriers and prevented vehicles from driving off the bridge. |

| 2019 | Water Filled Plastic Barrier (MDPE) [73] | Evaluating the crash performance of water-filled barriers |

| MDPE plastic barriers were effective at low speeds (≤20 km/h) but did not provide sufficient safety at high speeds (>50 km/h). |

3.2. Metals

Metals have a wide range of applications in road safety due to their long life, durability and robustness. In road safety systems, metals are used in many different components, from energy-absorbing systems to barriers, road surface coatings and traffic signs. These applications of metals in transportation are designed to improve vehicle, passenger and pedestrian safety [75,76]. Steel is the most widely used metal in road safety applications. In particular, steel road safety barriers are used on highways and bridges to prevent vehicles from running off the road (Figure 5a) [77]. These barriers reduce the speed of vehicles by absorbing the impact energy and dispersing the impact of the crash, allowing passengers to survive the accident with minimal damage (Figure 5b) [78]. Thanks to their high-strength construction, steel barriers (Table 3) prevent even heavy vehicles from breaching them. It is also made resistant to corrosion by a type of coating method called galvanizing, which makes it resistant to harsh environmental conditions. Stainless steel is often used in road safety products that require long-term use and aesthetics (Figure 5c) [79]. For example, stainless steel is preferred for bridge railings and pedestrian crossings. Stainless steel materials are little affected by environmental influences and provide high performance with minimum maintenance.

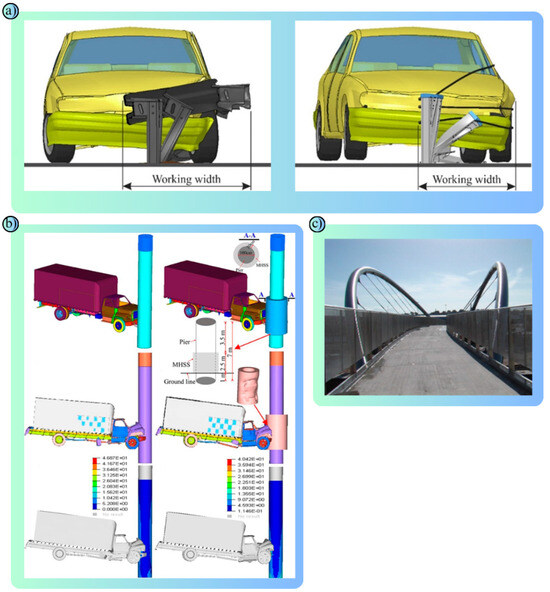

Figure 5.

A unified visual that presents the experimental and modeling approaches of the studies in a holistic way: (a) The post-crash deformation behavior of different barrier designs is shown: The conventional barrier has a wider working width, while the enhanced barrier shows a more controlled deformation, helping to steer the vehicle [77]. (b) Simulation of bridge abutment impact in the finite element method (FEM) analysis; the impact of a truck on a bridge abutment is modeled. While the unprotected abutment is severely affected by the impact, the abutment protected with MHSS (Metal Honeycomb Safety Structure) shows lower stresses and maintains its structural integrity better [78]. (c) It is a modern pedestrian bridge in Holyhead, United Kingdom: Made of stainless steel, it is an important example of aesthetic and engineering design [79].

Aluminum is often preferred for barrier components, directional boards and traffic signs due to its corrosion resistance and light weight [80,81]. With their visibility and reflectivity, aluminum sheets provide drivers with information that cannot be missed. At the same time, its light weight makes it easy to install and transport. In addition, aluminum is environmentally friendly as it is recyclable. Cast iron is widely used in household drainage systems, especially roadside gratings. They withstand heavy loads and allow surface water to drain safely off the road [82]. Its robust structure increases the deformation resistance of cast iron. Due to these properties, cast iron is preferred in infrastructure applications [83]. The role of metals in energy absorbing systems is very important [84]. Steel barriers and crash cushions increase the safety of vehicle occupants, pedestrians and other road users by absorbing energy on impact. Ductile dissipation of impact energy is achieved by utilizing the high flexibility and strength properties of metals [85]. In the future, the use of metals in road safety will be further enhanced by advancing smart technologies. Smart barrier systems made with metals such as aluminum and steel integrated with sensors will enable real-time data collection and analysis processes. These systems can provide instant warnings to road users by monitoring collision risks and traffic density. Furthermore, the use of innovative techniques that increase energy efficiency in the production processes of metals will contribute to reducing environmental impacts. As a result, the use of metals in road safety systems provides advantages such as longevity, high durability and energy absorption. Metals such as steel, stainless steel, cast iron and aluminum play an important role in both sustainability and safety. In the future, these materials are expected to feed into more advanced technologies to create more efficient and safer transportation infrastructures.

Table 3.

Recent studies on road safety barriers produced using metal materials.

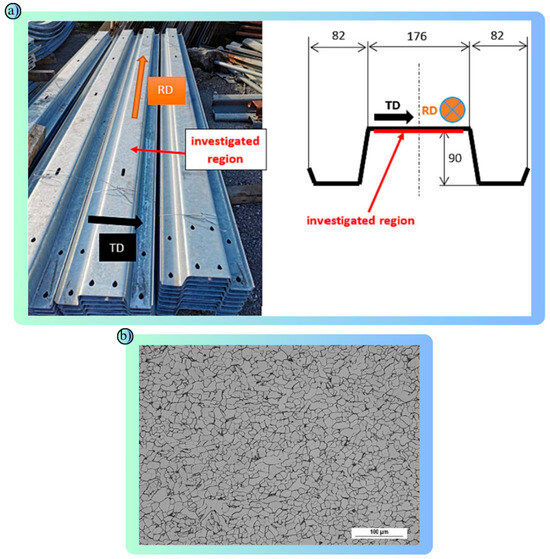

Figure 6.

Comprehensive illustrative representation that brings together experimental data and modeling results from studies: (a) The analyzed region of the traffic barrier flanges and the orientation axes are shown: RD (Rolling Direction) and TD (Transverse Direction) are indicated and the region where the mechanical tests were performed is marked, (b) The sample shows a ferritic matrix structure and irregularly distributed pearlite islands: The 1% Nital etched microstructure was studied to evaluate the homogeneity and mechanical properties of the steel [92].

Table 3.

Recent studies on road safety barriers produced using metal materials.

| Year | Material | Objective | Input Parameter | Conclusion |

|---|---|---|---|---|

| 2022 | Three-wave steel beam [86] | Increase crashworthiness. |

| Improved strength with new design. Maximum displacement 568.48 mm meeting Class 8 standards. |

| 2023 | Steel barrier [87] | Improving safety in freight car collisions |

| Absorbed 60% of the momentum. Reduced accident severity transferred to passengers. |

| 2023 | Q690 material [88] | Developing a passage system without a wing wall |

| Successful transition reducing the risk of snagging. Absorbed 280 KJ of crash energy. SB class protection. |

| 2023 | Ti-Nb Microalloyed steel [91] | Matching microstructure properties to crash loads. Microalloyed steel analyzed by laboratory tests |

| Microstructure developed for crash loads. Yield strength 729 MPA, tensile strength 813 MPa. |

| 2024 | Steel flange (Figure 6a,b) [92] | Reliably measure the load-bearing capacity. Material properties were evaluated with the non-destructive Barkhausen method |

| The load-bearing capacity was reliably assessed. A correlation was found between notch toughness and magnetic hardness. |

| 2024 | Crash barriers [93] | Optimizing barrier design and reducing impact in derailments of high-speed trains. Modeling with ABAQUS |

| Optimized design for high-speed trains. Effective in terms of dynamic damage prevention. |

| 2022 | W-beam barrier [95] | Poles in metal sleeves were evaluated. |

| Comparable performance to buried poles, compliant with MASH standards. |

| 2024 | Al 6061-T6 material [96] | Increase deformation resistance and moment of inertia. Beam optimization using LS-DYNA software |

| Higher inertia and reduced deformation. Deformation reduced by 12.8%, moment of inertia increased by 28.6%. |

| 2022 | Triple beam barrier [98] | Making bridge barrier connections safe. Crash tests were conducted in accordance with MASH standards. |

| Safe and effective bridge barrier connection. Compliant with MASH TL-3 standards, prevents vehicle entrapment. |

| 2024 | Movable steel barrier [99] | Improving highway safety with fast opening and closing barriers. |

| Fast installation for highway safety. Installation speed 12 m/min, closing speed 2 min. |

| 2021 | Cable barriers and strong post barriers [100] | Analyzing crash outcomes with cable barriers and pole barriers. Data analysis was performed with mixed logit models. |

| Cable barriers have the lowest share of fatal/injury accidents with 24%. |

3.3. Composites

Composite materials have an important place in the field of road safety with their flexibility, lightness, durability and resistance to corrosion (Figure 7a–c) [101]. A composite is a material formed by combining two or more materials. High performance is achieved by combining the best properties of each material. In road safety, composites are particularly used in road safety barriers, energy-absorbing systems, crash cushions, road markings and structural reinforcement applications (Figure 7d) [102].

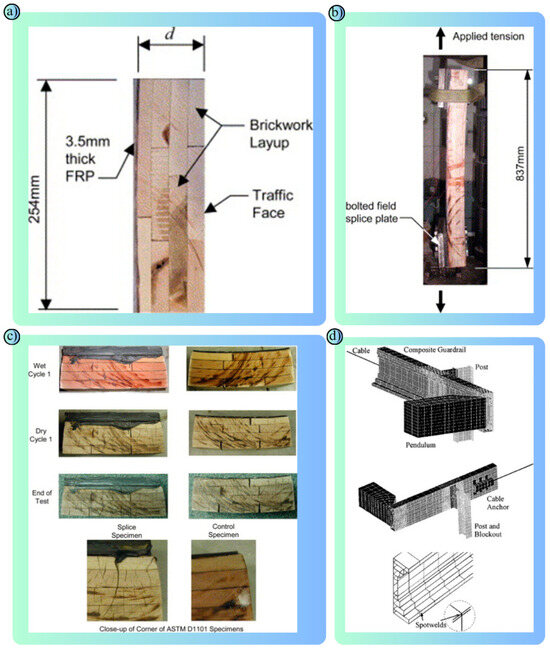

Figure 7.

Comprehensive schema that integrally visualizes the experimental analyses and modeling components of the studies: (a) FRP-Glulam Barrier Section: 3.5 mm FRP cladding and a cross-section of a barrier with laminated timber in a brick pattern are shown [101]. (b) Tensile Test Specimen: The 837 mm long specimen was subjected to a tensile test with a bolted connection plate. Strain gauges were used to monitor the maximum stresses on the FRP [101]. (c) ASTM D1101 Test Results: Specimens exposed to moisture and drying cycles showed no delamination in the steel-reinforced specimens, while small cracks were detected in the control specimens [101]. (d) LS-DYNA Composite Barrier Model: The crash behavior of the barrier was modeled using the finite element method (FEM). Spotwelds were used to connect the composite parts [102].

Composites are used to reinforce structural elements, increase the durability of road markings, reduce the impact of collisions and prevent vehicles from running off the road. They are used in road safety barriers and crash cushions due to their lightweight and high energy absorption properties. The use of composites in road safety barriers (Table 4) minimizes deformation and allows the barriers to be reused after a crash. Composites such as composite-steel barriers, glass fiber-reinforced plastic (GFRP) or carbon fiber-reinforced plastic (CFRP) absorb crash energy in systems such as barriers and crash cushions and make the system reusable.

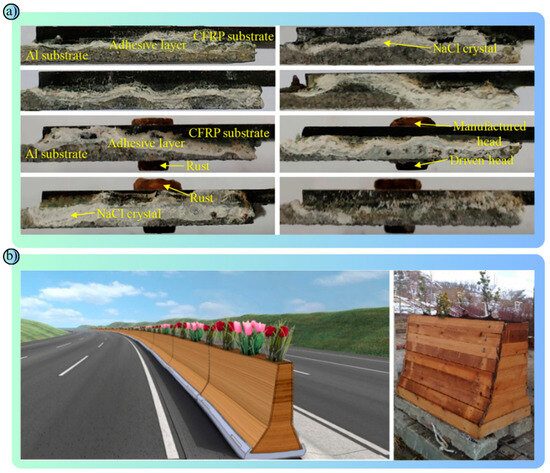

Due to their light weight and corrosion resistance, composites are also used in road marking signs. Composite plates, which are a combination of polymer and aluminum, have a longer life compared to traditional materials. In addition, reflective coatings can be applied to composite-based surfaces to provide drivers with night vision comfort. GFRP, a composite of glass fiber and polymer, is a widely used composite in road safety systems. It is both economical, durable and lightweight. Used in road safety barriers, traffic signs and drainage coatings [103,104]. Offering higher flexibility and strength than glass fiber, CFRP is used in energy-absorbing barriers, crash cushions and bridge reinforcements thanks to its high energy absorption capacity. CFRP is also highly resistant to chemical effects and corrosion (Figure 8a) [105,106,107,108,109,110,111]. Kevlar-reinforced composites are preferred for pedestrian protection systems due to their high impact resistance. Kevlar-reinforced composites, which have a light and flexible structure, are also suitable for high-performance road safety systems [112]. Thermoplastic matrix composites produced by reinforcing polypropylene and polyethylene matrices with fibers are used in temporary barriers and traffic cones used in road management [113,114]. Aluminum composite panels are a combination of aluminum and polymers. Thanks to their lightweight and durable structure, they are used in directional boards, road signs and road safety barriers. They are also long-lasting and aesthetic [115,116,117].

Figure 8.

Integrated display that presents the experimental findings and modeling approaches of the studies in a holistic perspective: (a) Corrosion Damage to CFRP/Al Connections: CFRP provided protection against corrosion. NaCl crystals and rust were concentrated in the adhesive layer and at the rivet heads. While corrosion was more limited in areas covered with CFRP, significant galvanic corrosion occurred between the steel rivet and the Al substrate. This indicates that CFRP improves corrosion resistance but requires additional protection at the metal joint areas [111]. (b) A design visualization and prototype of a hybrid traffic barrier consisting of a concrete base, steel profiles, wood panels and vegetation is presented: This design aims to enhance environmental sustainability and aesthetic harmony while ensuring traffic safety [118].

Table 4.

Recent studies on road safety barriers produced using composite materials.

Table 4.

Recent studies on road safety barriers produced using composite materials.

| Year | Material | Objective | Input Parameter | Conclusion |

|---|---|---|---|---|

| 2024 | Glass fiber/LDPE composite [119] | Production and characterization for W-beam barrier |

| Glass fiber-reinforced barriers have better energy absorption capacity compared to the steel alternative. |

| 2023 | Natural stem (Stipa tenacissima) composite [122] | Increase impact energy absorption |

| The composite barrier absorbed 67.7% more impact energy than steel. |

| 2021 | Basalt fiber reinforced polymer [125] | Improving crash performance |

| It absorbed more energy than steel barriers, keeping vehicle acceleration under 200%. |

| 2022 | Composite blocks [126] | W-beam barrier height increase |

| MASH Test 3-11 standard was found compliant, passenger safety was increased. |

| 2023 | Composite-steel double-layer barrier [127] | Increasing the crashworthiness of bridge barriers |

| The double-layer barrier provided energy absorption equivalent to 59.1% of the concrete barrier. |

| 2023 | Carbon/Epoxy and Fiber Metal Laminated [128] | Compare the impact resistance of different barriers |

| The FML-B barrier was found to have the highest energy absorption capacity. |

| 2023 | Renewable hybrid barrier (RHB) [129] | Impact resistance of innovative hybrid barrier systems |

| The hybrid barrier was found to be as safe as steel and as comfortable as concrete. |

| 2022 | Hybrid barrier with waste materials (Figure 8b) [118] | To investigate the usability of waste materials in barriers |

| An environmentally friendly barrier compliant with EN 1317 tests was proposed. |

| 2024 | Recycled foam concrete [130] | Increasing energy absorption in road barriers |

| Reduced impact force by 54.46%, reduced cost by 5.5%. |

| 2021 | Steel-concrete composite beam [131] | Analyzing the effect of parapets | Simple beam composite bridge model | A 26.92% lower load distribution was detected with the parapet effect. |

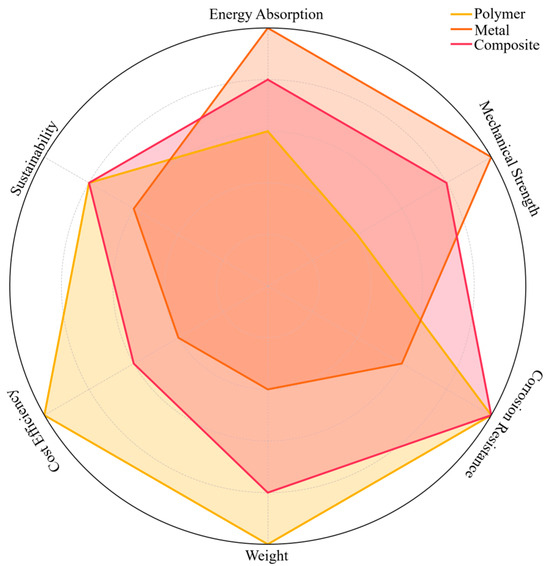

The polymer, metal and composite materials examined in this study offer various advantages in terms of different performance criteria in road safety systems. Polymer materials stand out especially in temporary safety applications due to their light weight, low cost, corrosion resistance and easy portability. However, they have some limitations in terms of impact resistance and longevity. Metal materials are widely used in permanent security barriers due to their high mechanical strength, energy absorption capacity and long-term durability. However, they have disadvantages such as weight, cost and corrosion risk. Composite materials, on the other hand, combine the advantages of polymer and metal-based structures and offer superior properties such as high energy absorption capacity, light weight, corrosion resistance and long life (Figure 9). However, their widespread use is still limited due to high production costs and complex manufacturing processes. As a result, each type of material is suitable for different usage scenarios, and the optimum choice of material for road safety systems should be made by considering the application location, environmental conditions, economic factors and performance expectations.

Figure 9.

Comparative evaluation of material types in road safety systems.

4. AMed Materials and Its Road Safety and Transportation Structures

AM technologies have become widely used in various industrial applications in recent years due to their advantages such as design flexibility, material savings and easy production of complex geometries [132,133,134,135]. These advantages have increased the use of AM methods in areas such as defense, aviation, automotive and medicine, and have recently begun to be seen as a potential solution in infrastructure projects. In particular, design freedom allows for the production of structures optimized to meet performance requirements by allowing structural details that cannot be produced with traditional methods to be obtained [136,137]. In this context, AM stands out in the production of materials that must have critical properties such as strength, flexibility, energy absorption and lightness, such as road barriers, crash cushions, safety parapets, vehicle bumpers and aircraft equipment [138,139]. Absorption of kinetic energy and controlled deformation at the time of collision is one of the basic functions of barrier systems. Therefore, the applicability of different types of materials used in AM in road barrier systems has become an important area of research. Road barriers are structural elements designed to ensure the safe direction of traffic and to reduce the effects of collisions [140]. These structures must offer high mechanical strength and energy absorption capacity, as well as being economically viable. In barrier designs for different road types, especially urban and highway, modularity and easy installation features are gaining importance along with cost-effectiveness. Since barrier systems produced with traditional production methods are generally heavy and require maintenance, it is of great importance to ensure the balance between lightness and durability [141]. It is a common problem that barriers manufactured with traditional materials such as steel and concrete to achieve this balance deform over time or lose performance due to environmental conditions [101]. AM stands out as an innovative production method that can meet these requirements. Thanks to the layered production approach offered by AM, material density and structural durability can be optimized in different areas. This enables the use of stronger structural elements in areas requiring energy absorption in barrier systems, and thinner and lighter structures in areas requiring lightness. In addition, geometric structures can be tested with simulation-supported optimization methods in design processes and performance improvements can be made.

As a result, road safety structures that can be produced with AM technologies offer an innovative solution in future infrastructure projects not only with their mechanical strength and lightness, but also with their advantages such as customizability, fast production processes and ease of maintenance [142]. Advances in this area will continue to contribute to the development of safer and more durable barrier systems.

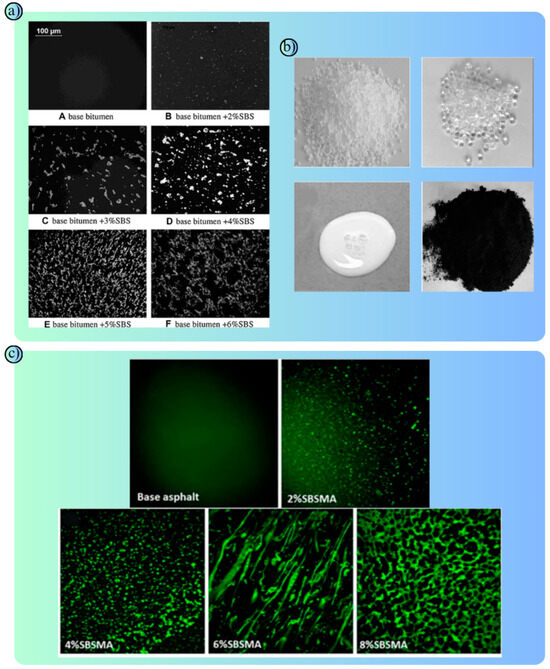

4.1. Polymer-Based Materials

Polymer-based materials are a widely preferred material group in AM technologies and offer many advantages in road safety structures. Thanks to their lightness, corrosion resistance and high energy absorption capacity, polymers can absorb kinetic energy in the event of a collision, distribute deformation in a controlled manner and increase safety performance in structural elements such as barriers and crash cushions. In addition, the modular structure of polymers contributes to the development of easily transportable and mountable safety systems by providing cost-effective solutions in production and installation processes. In addition, improving the resistance levels of polymer materials to temperature changes and external environmental conditions is important for the longevity of safety structures [143,144]. In particular, high temperature differences can negatively affect the mechanical properties of some polymers. For this reason, the use of polymer composites with AM technologies has become increasingly important. Polymer composites offer higher strength, heat resistance and impact absorption capacity compared to traditional polymers thanks to their reinforcement materials [145,146]. The design flexibility offered by AM allows for the optimization of material density and structural strength locally. In this way, areas requiring energy absorption in road barrier systems are reinforced with thicker and more durable structures, while areas requiring lightness can be produced with thinner layers [147]. Thus, safety structures offer an innovative solution in future infrastructure projects not only in terms of mechanical strength and lightness, but also with advantages such as customizability, rapid production and ease of maintenance. In this context, literature studies that include the use of polymer materials with AM methods provide important findings that reveal the potential of materials and production methods that can be used in the production of equipment in road safety structures. In this study conducted by Alqahtani et al., the effects of cage topology on the thermal and mechanical performance of polymer cage structures produced by AM were investigated. In the study, different cage designs aimed at increasing energy efficiency and load-carrying capacity for structural applications were examined. Layered manufacturing was carried out using polylactic acid (PLA) filament. Cage structures were produced with the FDM method and designs were made with CAD software. Triangular, diamond, honeycomb, star, cubic and gyroid-type cage structures were examined (Figure 10a). Thermal Conductivity (K-value) was measured with a heat flow meter. Thermal Transmittance (U-value) was determined with a hot-box calorimeter. Mechanical properties were evaluated with a compression test. As a result of the study, the U-value and K-value changed according to cage density. The K-value increased by 53% in the transition from 20% density to 80% density. Triangular and diamond lattice structures exhibited optimum thermal and mechanical performance at 40% density. Triangular and diamond structures showed compressive strength above 27 Mpa. Gyroid and cubic structures exhibited high performance in energy absorption capacity, but lower values were recorded in initial strength. The study provides basic information for the design of lattice structures with high mechanical strength and low thermal conductivity that can be used in many applications. Triangular and diamond topologies in particular stand out in terms of ease of production and energy efficiency [148]. Jikke de Winter et al. investigated the damping behavior of microbeams produced using the two-photon polymerization (2PP) method. This study aimed to evaluate the potential of microresonators for use in biosensor and microsystem applications by improving their quality. IP-S resin was used in the Nanoscribe Professional GT device. This resin was preferred due to its high elastic modulus. Thick and thin type beams, cantilever and double-ended bridges were produced. The resonance frequencies and quality factors of the structures were measured using laser Doppler vibrometry (LDV). The tests were carried out at room temperature and in a high vacuum environment (≤5 × 10⁻5 mbar). As a result of the study, the quality factor of the 200 µm-long bridges increased from 522 to 1819 after thermal treatment. The increase in the resonance frequency in the thin bridges was attributed to the stress induction caused by thermal treatment. Structural losses were found to be the main source of damping. Thermal elastic damping and anchorage losses did not show a dominant effect. This study successfully used the thermal strain engineering approach to optimize the quality factors of 3D-printed polymer microresonators. With a quality factor of 1819, these microresonators are promising for high-precision measurements in mass sensors and biomolecular detection devices. However, more extensive investigations with different material types and manufacturing parameters are recommended [149]. Md Aminul Islam et al. have examined the role of AM technology in polymer production over the last thirty years, emphasizing the advantages of AM such as design flexibility, reduction of material waste and rapid prototyping. In the study, a comparative analysis of AM techniques such as FDM, SLA, PolyJet, SLS and LOM was made; SEM, TGA, DSC and DMA tests were applied using polymers such as PLA, ABS and polyamide and composite materials. It was stated that AM is used in areas such as biomedical implants, aerospace parts and industrial components. It provides up to 40% material savings and shortens the production time of structures with complex geometries by 50%. In thermal analyses, the glass transition temperatures and mechanical strength values of thermoplastic materials such as PLA were compared for different printing techniques. Studies conducted especially on multi-material structures and hybrid composites have shown the success of AM in producing customizable functional parts. As a result, AM is predicted to revolutionize sustainability and production efficiency in the aerospace, automotive and medical sectors and will further evolve with AI-assisted design [150]. Amin Safi Jahanshahi et al. investigated the simultaneous impregnation extrusion-based AM process to increase the compressive strength of PLA composites reinforced with continuous glass fibers (CGF). In the study, continuous fibers were fed into the molten polymer through a side nozzle and placed in layers on the substrate. In the compression tests, the alignment of the glass fibers parallel and perpendicular to the load direction was evaluated. The test results showed that parallel alignment of the fibers in the PLA matrix caused delamination and provided a strength of 40.7 Mpa, while perpendicular alignment increased the strength up to 93 Mpa. The perpendicular orientation of the fibers increased the mechanical strength by approximately 10.5% by creating transverse stresses against the applied load. SEM analysis showed that the crack propagation in the PLA matrix was concentrated especially in the corner regions and separation occurred at the fiber-matrix interface under load. These results reveal that structures with high energy absorption capacity can be used to increase crashworthiness in the automotive industry [151].

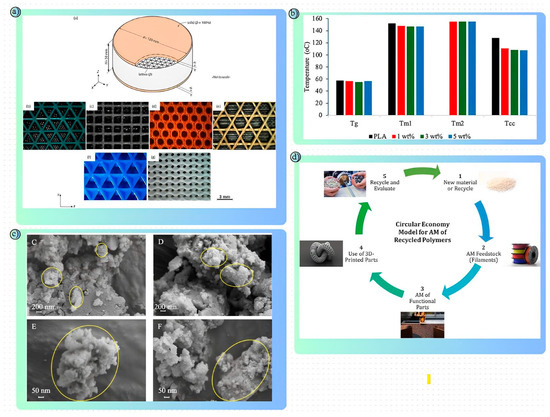

Figure 10.

Merged plot showing various experimental and conceptual aspects of the studies: (a) Lattice-based test specimen geometry and optical microscopy images of various 3D printed lattice structures (Triangle, Diamond, Honeycomb, Star, Cubic, and Gyroid) highlighting structural differences [148]. (b) Differential Scanning Calorimetry (DSC) results showing thermal transitions (Tg, Tm1, Tm2, and Tcc) for PLA and PLA/ESP composites at various weight percentages [152]. (c) SEM image of PLA/ESP composite showing nanostructural details of embedded particles [152], and (d) proposed circular economy model for recycled polymers in value-added manufacturing, showing the life cycle from material preparation to part reuse and valorization [153].

In a study conducted to improve the thermomechanical properties of polylactic acid (PLA) composites reinforced with eggshell microparticles (ESP), David K. Orisekeh et al. produced and characterized PLA filaments with ESP additives at different weight ratios (0%, 1%, 3% and 5%) via extrusion. XRD and FTIR analyses showed that the eggshell powder contained high-purity calcium carbonate (CaCO3). In TGA and DSC tests, it was observed that the melting temperature of the PLA sample with 5% ESP additive decreased from 152 °C to 147 °C, but the crystallization rate increased (Figure 10b,c). According to the dynamic mechanical analysis (DMA) results, the samples with 3% ESP additive reached the highest storage modulus with a 5.2% increase at room temperature. The compressive strength of the composites was measured as 66.5 MPa in the sample with 5% ESP additive. However, it was observed that the eggshell additive provided limited improvement in mechanical strength in tensile and flexural tests. As a result, it was stated that ESP additive partially improved the thermomechanical properties of PLA and is promising for biomedical applications. The study suggested finer particles and improved extrusion processes to increase the homogeneity of the filler distribution [152]. Alianna Maguire et al. investigated the mechanical properties and application areas of polymer-based structures used in extrusion-based AM. The study highlighted the flexibility and low-cost advantages offered by extrusion-based techniques such as FDM and direct ink writing (DIW) for the production of high-performance structures in the automotive, aerospace, medical and electronics sectors. In particular, multi-material structures consisting of thermoplastic and thermoset materials were produced with the DIW technique and the effects of different geometries on mechanical strength were examined. Different architectures increased the load-carrying capacity of the structures and improved their energy absorption properties. Composite structures to which reinforcement materials such as carbon fiber were added exhibited twice the mechanical strength compared to standard polymers. The study stated that biomimetic designs allow innovative structures to be created in AM and that these processes open new horizons in areas such as biomedical implants and energy-absorbing structures. In the future, it is suggested that production processes will be improved with artificial intelligence-supported design and better optimization of rheological properties [154]. S.C. Daminabo et al. investigated FDM-based AM processes for polymer material systems and evaluated the effects of different parameters on mechanical, thermal and surface properties. Different filament types such as PLA, ABS, PETG and TPU were used in the study; the effects of factors such as printing temperature, speed, layer height and filling ratio on performance were analyzed. According to the findings, PLA showed high compressive and tensile strength but exhibited brittleness, while ABS offered superior performance in impact resistance thanks to its flexible structure, but its layer bonding strength was found to be low. TPU stands out as a material with high energy absorption capacity and elasticity, while PETG’s high glass transition temperature increased its thermal stability. Reducing the layer height increased surface smoothness, but extended the production time. When the filling ratio was changed from 50% to 100%, the mechanical strength increased by 35% and the production time was extended by 70%. It was emphasized that porous structures are promising for cellular proliferation in biomedical applications, but biocompatible filaments need to be developed further. The research revealed that FDM-based manufacturing processes can be further improved with the use of carbon fiber-reinforced filaments and multifunctional material systems [155]. Ans Al Rashid and Muammer Koç conducted a study on the use of recycled polymeric waste in AM and evaluated the needs, challenges and opportunities of this approach within the framework of circular economy and sustainability (Figure 10d). The study stated that 8.3 billion tons of plastic have been produced worldwide since 1950 and a large part of this cannot be recycled. It was emphasized that mechanical, chemical and thermal recycling methods are used in the recycling of polymers; however, factors such as separation difficulties, additives, coatings and contamination make recycling difficult. While mechanical recycling stands out as a low-cost and environmentally friendly method, problems such as quality loss and microparticle formation have been identified. Chemical recycling, on the other hand, provides high-purity polymer production, but it is an energy-intensive and expensive process. The study showed that the use of recycled polymers in AM is possible; it was stated that polymers such as PET, ABS, PLA and PP can be evaluated in rapid prototyping and functional part production. The researchers emphasized that local recycling and AM projects initiated at laboratory scale would be effective in reducing the amount of waste and drew attention to the importance of cooperation between states, industry and research institutions to achieve sustainability goals in the future [153].

4.2. Metal Materials

Metal materials used in road safety structures in AM have an important place thanks to their superior mechanical strength, energy absorption capacity and long-lasting usage features [156]. While steel and steel alloys are frequently preferred in barrier systems due to their high strength and energy absorption capacity, types such as stainless steel provide advantages in terms of corrosion resistance [157,158]. Aluminum alloys stand out particularly in crash buffer systems and modular barriers with their properties such as lightness and high corrosion resistance [159]. Titanium alloys, which stand out with their high strength-to-weight ratio and chemical resistance, are used in the production of critical load-carrying fasteners [160]. Nickel-based superalloys offer a suitable option for security structures exposed to heavy traffic loads thanks to their wear and high-temperature resistance [161]. AM methods allow for topology optimization of metal materials and the production of complex geometries, reducing the weight of structures and increasing material efficiency. Metal structures produced with methods such as laser metal deposition (LMD) and selective laser melting (SLM) in particular increase the effectiveness of road safety systems by meeting high-impact resistance and long-lasting performance requirements [162,163]. Thus, metal safety structures produced with AM technologies contribute to modern traffic safety standards by providing sustainable and cost-effective solutions. In this context, metal safety structures produced with AM technologies contribute to modern traffic safety standards by providing sustainable and cost-effective solutions. Comprehensive studies are conducted in the literature on metal materials used in AM. These studies reveal the performance properties of materials that can be used in road safety structures and show that research in the field continues uninterruptedly. Peng et al. investigated the effects of C, Mn and Cu alloy elements on the microstructure and mechanical properties of high manganese steels in the wire arc additive manufacturing (WAAM) method. In the study, samples with fully austenitic microstructure were produced using powder filler wire and the effect of the contribution of the compositions on the material strength was analyzed. The experiments were grouped according to different C (0.49%, 0.79%, 1.10%), Mn (17.95%, 20.98%, 23.98%) and Cu (0.3%, 0.98%, 2.00%) ratios. The results showed that with the increase in C content, the tensile strength increased from 731 MPa to 897 MPa and the elongation increased from 21.8% to 30.2%. As the Mn content increased, the tensile strength decreased but the elongation increased. The best impact toughness value was recorded as 64.5 J at 20.98% Mn content. The increase in Cu content increased the yield strength and elongation; the highest yield strength was obtained as 495 MPa at 0.98% Cu. The study revealed that the best mechanical properties were obtained with the optimal composition of 1.10% C, 21% Mn and 0.3% Cu and that the structure was suitable for production via WAAM with low solidification crack sensitivity. It was stated that high manganese austenitic steels have promising applications in areas such as aviation, petrochemicals and rail transportation [164]. Zhang et al. aimed to increase the bond strength by producing large-scale steel-aluminum (Fe-Al) components via modified friction stir additive manufacturing (M-FSAM). Mg-O and Al-Fe-Si rich amorphous layers (~20 nm and ~120 nm) were developed to prevent the formation of brittle intermetallic compounds at the Al-Fe interface. It was observed that the thermal stability of the amorphous layer was maintained after heat treatment (20 min at 500 °C and 7 h at 170 °C). High homogeneity was achieved both along the interface and material layers by using a 2 mm overlap length with the M-FSAM method. The tensile strength increased from 160 MPa to 250 MPa and the fractures occurred on the aluminum alloy side. In addition, an increase in hardness (~80 HV) was observed after heat cycling (Figure 11a). As a result, the presence of the amorphous interlayer and the controlled application of heat treatment provided high mechanical strength and stability. This method has the potential to be used in large-scale engineering applications such as train and ship production [165]. Wessels et al. developed the Stabilized Optimal Transportation Meshfree (OTM) method to model the fusion process of metal particles using Selective Laser Melting (SLM). The main purpose of the study was to investigate the phase changes that occur during melting and cooling and the coalescence processes of metal particles. Physical phenomena such as surface tension, phase change stress, thermal expansion and recoil pressure affecting particle coalescence in the SLM process were modeled. In the simulations, the heating and melting of two metal particles with a laser were analyzed. Thanks to the OTM method, calculations of complex boundary surfaces were performed more accurately compared to traditional mesh-based methods. It was observed that surface tension accelerates the fusion of particles and increases the quality of the coalescence. The effect of laser power and cooling conditions on the coalescence bond was evaluated with a parametric study. The results showed that laser power and cooling parameters are decisive in the fusion quality and coalescence does not occur without surface tension. This method is considered a promising computational tool for determining optimum process parameters, especially in SLM processes [166]. Wawryniuk et al. examined the wide-ranging applications of 3D printing technology in the aerospace, automotive, and space industries. The study evaluated multiple AM technologies (e.g., FDM, SLA, DLP, SLS, SLM) and discussed the advantages of these methods in various sectors such as prototyping, functional parts production, and component repair. Three-dimensional printing offers unparalleled design freedom, especially in the production of lightweight structures with complex geometries. The study emphasized that metal-based 3D printing increases fuel efficiency and saves energy. In addition, high-impact structures were obtained in the aerospace industry using lattice structures and TPMS (Three-Way Periodic Minimal Surface) systems. In the automotive sector, the advantages of rapid prototyping of individually designed parts and low-volume production processes were emphasized. For example, components produced via 3D printing in a hypercar reduced the vehicle weight by 20%. The paper also focuses on the integration of AM technology into sustainable manufacturing practices and the environmental benefits arising from its combination with Industry 4.0. However, it is noted that challenges such as material properties, post-production processes and production scalability need to be overcome. The study highlights the innovative potential of 3D printing technology in the transportation sector, while suggesting that further research is needed to address future regulatory hurdles and material improvements [167]. Hwang et al. investigated the production of metal mesh structures using AISI 304 stainless steel powder via selective laser melting (SLM). In the study, the production process of thin-layer mesh structures was optimized using a copper base plate with high thermal conductivity. During the experiments, the effects of parameters such as laser scanning speed, powder layer thickness and laser power on the dimensional accuracy of the obtained mesh structures were evaluated. The results showed that the heat of the molten pool was rapidly dissipated by the copper plate and the thin-layer structures were prevented from sticking to the surface (Figure 11b). In the experiments conducted with a powder layer thickness of 0.5 mm and a laser power of 200 W, a homogeneous fusion and a smooth layer formation were achieved. In addition, in the scanning path analysis of the mesh structures, it was determined that the straight scanning path reduced the residual stress and increased the material stability. It was observed that mesh structures of various sizes and shapes could be produced in a single step with this method. The study highlights the potential use in engineering applications such as filtration systems and liquid permeable components. Additionally, it was stated that surface quality could be improved by laser remelting process [168]. Luca Giorleo and Kudret İrem Deniz investigated the performance of molds produced with the 3D printing method for the steel bending process using polymer composite materials. This study compared horizontally and vertically-oriented molds produced using the Fused Filament Fabrication (FFF) method in order to reduce production costs and develop customizable molds for complex geometries. AISI 304 stainless steel sheets (100 mm length, 2 mm thickness, 20 mm width) and a “V” shaped punch and matrix produced from “Onyx” material with nylon-carbon fiber filling content were used. The production of the parts was done with two different printing orientations, horizontal (H) and vertical (V), with a 0.1 mm layer thickness. A total of 10 bending processes were performed for each orientation. Steel sheets were bent to a 90° angle with a hydraulic press at 1 mm/s speed (Figure 11c). The geometric measurements of the bent sheets and dies were analyzed using a coordinate measuring machine (CMM) over 180 data points. As a result of the study, the dies in the horizontal printing orientation showed deviations from the desired angle in some tests. For example, the angle was measured as 89.69° in the fifth test. The dies in the vertical printing orientation showed more stable performance with an angle deviation of 0.3%. In the horizontal dies, the punch height was reduced by 2.4% and the matrix width was widened by 10%. Horizontal printing lasted 1 day and 14 h, while vertical printing lasted 2 days and 4 h. This study showed that polymer-based dies are applicable for prototype production in steel bending processes. The vertical printing orientation provided higher stability, while the horizontal orientation shortened the production time [169]. Wang et al. produced materials using the selective laser melting (SLM) method by adding nickel (Ni) nanoparticles to AlSi10Mg alloy at different ratios (0%, 1%, 3%, 5%) and investigated their effects on microstructure and mechanical properties. The study analyzed the formation of in-situ Ala3Ni nanoparticles and Si network structures. The obtained structures consisted of α-Al matrix, Si network and Al3Ni phases. The increase in Ni content increased the continuity of Si networks, but microstructure deterioration was observed at 5% Ni level. The sample containing 3% Ni showed the best mechanical performance with 401 MPa tensile strength, 6.23% elongation and 144 HV microhardness value. This was attributed to the strength increase due to the strong interfacial bonding and dislocation accumulation of Al3Ni nanoparticles. At 5% Ni content, excessive energy absorption in the melt pool caused a “balling” effect and increased porosity, which reduced the strength. In the friction coefficient and wear tests, the samples containing 3% Ni exhibited the best performance with low wear volume (0.11 mm3) and stable friction coefficient (0.608). This study shows that Ni addition has the potential to improve the mechanical properties in AlSi10Mg alloy and excellent strength and wear resistance are achieved with an optimum 3% Ni content. These findings indicate important applications for the production of lightweight and durable structures, especially in the aerospace and automotive industries [170].

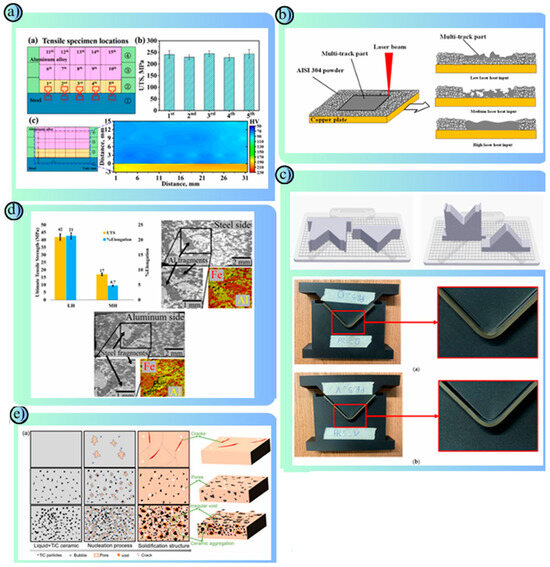

Figure 11.

Composite figure showing multiple experimental and modeling aspects of the studies: (a) Tensile specimen locations and results: Tensile strength distribution along the aluminum–steel composite with hardness mapping for cross-sectional analysis [165]. (b) Schematic of multi-piece SLM process: Variations in laser energy heat input affecting the formation of multi-piece parts [168]. (c) Deformation analysis of 3D printed tools: Comparison of horizontal and vertical printed tools after bending process [169]. (d) Tensile testing and fracture analysis: UTS and elongation of LH and MH specimens, together with SEM images and EDS mapping showing the material distribution on the fracture surfaces [171], and (e) effect of TiC ceramic content: Schematic showing the mechanism of cracks, pores, and void formation during solidification in TiC ceramic composites [172].

Katsuyama et al. investigated 3D carbon (3D-C) lattices fabricated using the low-cost stereolithography (SLA) type 3D printing method and carbonized via the pyrolysis process for structural lithium metal batteries. The research evaluated the mechanical strength of these carbon skeletons and their potential to enhance battery performance. The 3D-C lattice showed high mechanical stability with a maximum stress of 5.15 ± 0.15 MPa and Young’s modulus of 81.2 ± 6.4 MPa. SEM analysis showed that surface roughness due to AM was minimal and excellent contact was achieved between Li metal and the carbon skeleton. In battery performance tests, 3D-C lattices exhibited much more stable cycling stability compared to bare Cu foil collectors in symmetric cell configurations. When using the 3D-C cage, only 0.073 V low overpotential was observed for 3 mAh cm−2 capacity at 1 mA cm−2 current density for 100 cycles. In contrast, the overpotential in bare Cu foil cell reached 0.74 V at cycle 96 and failed due to a short circuit. The pores in the internal structure of the 3D-C skeleton prevented dendrite formation by controlling lithium accumulation and extended cell life. This study showed that 3D carbon skeletons have significant potential for increasing energy density, improving safety and providing lightweight structures in structural lithium metal batteries [173]. Ozlati et al. produced stainless steel (AISI 316L) and aluminum (AA5183) bi-metal walls using roll bonding transition joints using the WAAM method. The study investigated the effect of the transition joint, which prevents the formation of brittle Al-Fe intermetallic compounds by preventing direct contact between the steel and aluminum layers. Aluminum layers were deposited at low (LH), medium (MH) and high (HH) heat input levels (Figure 11d). The results showed that no intermetallic compounds were formed at the steel/aluminum interface and no cracks were observed when low heat input (LH) was used. The maximum tensile strength was measured as 42 MPa and the elongation was 21% in these samples. It was found that at medium and high heat input levels (MH and HH), the Al-Fe intermetallic compounds thickened and cracks formed at the interface. This was associated with increased thermal stresses and decreased material deformation. The HH sample, which was applied with high heat input, showed fracture during sample preparation during mechanical testing. The study revealed that low heat input limits the formation of Al-Fe intermetallic compounds in the WAAM process and improves mechanical performance. These findings highlight the potential use of the WAAM method in the production of bi-metal components with complex geometries such as heat exchangers in the energy sector [171]. Yang et al. developed an analytical temperature-based thermomechanical (ATTM) finite element (FE) model to predict residual stresses and deformations in the metal AM process. The model uses an analytical temperature approach to predict the temperature history and uses this thermal field as input data for mechanical calculations. The accuracy of the ATTM model was evaluated by comparing it with experimental data and other models in the literature. In the study, the simulations performed with the ATTM model accurately captured the temperature, stress, and deformation distributions for different geometry and material parameters of layered structures. The model was especially successful in studying the stress oscillation and thermal behavior of thin-walled and large-sized parts such as complex lattice structures. In addition, a simulation tool called AM-builder was developed in the study, which automatically generated process parameters by slicing the 3D model geometries according to the layer thickness. The ATTM model significantly reduced the computational time while providing high accuracy in mechanical calculations. In particular, the model’s prediction accuracy increased when the heat source was moved away from the boundary in the AM process. This approach offers a promising method to optimize temperature and mechanical stress analyses in AM processes [174]. Latte et al. developed a monitoring system using a prototype laser line scanner (LL) for the evaluation of layer and trace quality in the laser metal deposition (LMD) process. The study determined key performance indicators (KPIs) with a special data processing algorithm to detect problems such as geometrical defects and substrate porosity. Samples produced with AISI 316L stainless steel powders were deposited at different overlap ratios (10%, 30% and 50%). The prototype LL system scanned the layer surface using a laser line scanner and a CMOS camera to obtain the 3D profile of each layer. It was observed that the layer heights and contact angle values increased as the overlap ratio increased. Especially in the sample with a 50% overlap ratio, the contact angle reached a critical level of 55.8°, which led to porosity formation between the layers. However, the sample with a 10% overlap ratio showed mechanical risks due to deep valleys and surface waviness. Metallographic analysis results showed that the predictions obtained with the LL system were accurate and the proposed model was effective in detecting substrate defects. This study revealed that quality control can be performed during production without the need for destructive tests with laser-based monitoring systems [175]. Li et al. investigated the microstructure, mechanical strength and thermal expansion properties of structures produced using the laser metal deposition (LMD) method by adding TiC ceramic particles to Invar 36 alloy. In the study, TiC ratios ranging from 0% to 7% were used and the SEM, EBSD and XRD methods were used for microstructure analysis. The results showed that TiC addition significantly reduced the grains and increased the tensile strength. Between 0.8% and 2% TiC content, the tensile strength increased from approximately 130 MPa to 560 MPa, and the elongation ratio increased from 2% to 35%. However, at a TiC content above 3%, powder clusters were formed, which caused increased porosity and increased brittleness (Figure 11e). XRD analyses showed that the phase was too little to be detected at low TiC ratios, but the TiC phase became apparent after 3%. In thermal expansion tests, it was observed that the expansion coefficient of TiC-added samples increased, but the total expansion was lower than alloys commonly used in engineering applications. In particular, the expansion behavior was controlled in the region up to the Curie temperature. The study revealed that the addition of TiC to the Invar 36 alloy increased the mechanical strength and thermal stability, increasing its potential for use in aerospace and precision measurement devices [172]. Wu et al. aimed to increase the mechanical strength of bionic ceramic–metal composites using AM techniques. In this study, bionic structures inspired by tortoise shell structures in turtle shells and the deep-sea mollusk Crysomallon squamiferum were produced using the photopolymerization (VPP) and powder bed fusion (PBF) methods. The composites were reinforced with epoxy resin infiltration onto the Al2O3 ceramic base and a 316L stainless steel metal layer. Microstructure analyses were performed with SEM and EDS, and mechanical strength tests were performed with three-point bending tests. The results showed that the bionic layered structure increased fracture toughness by 41.83% and flexural strength by 41.79%. In particular, the 3D bionic structure increased the load-carrying capacity and prevented crack propagation thanks to the physical interlocking of the layered ceramic and metal phases. The finite element method (FEM) and molecular dynamics (MD) simulations detailed the load distribution and fracture mechanisms. It was found that bionic structures increased the energy absorption capacity by 554.94% compared to homogeneous structures. This study revealed that a 3D layered bionic structure has significant potential in the design of high-performance composite materials by increasing fracture strength and energy absorption [176].

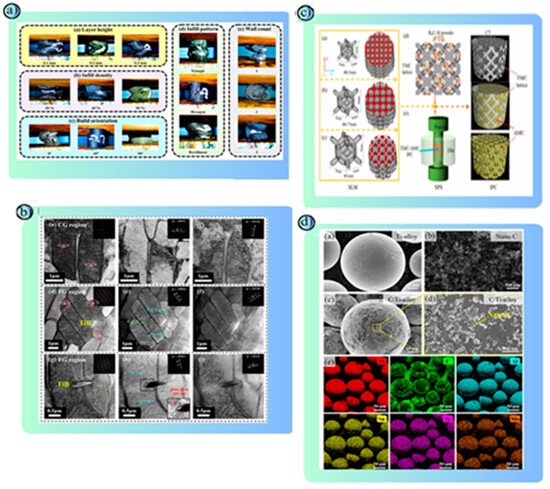

4.3. Composite Materials