Re-Use of Polycarbonate from Compact Discs to Enhance the Thermal Stability of Polylactic Acid Blends

Abstract

1. Introduction

2. Experimental Section

2.1. Materials and Sample Preparation

2.2. Characterization

2.2.1. Thermogravimetric Analysis (TGA)

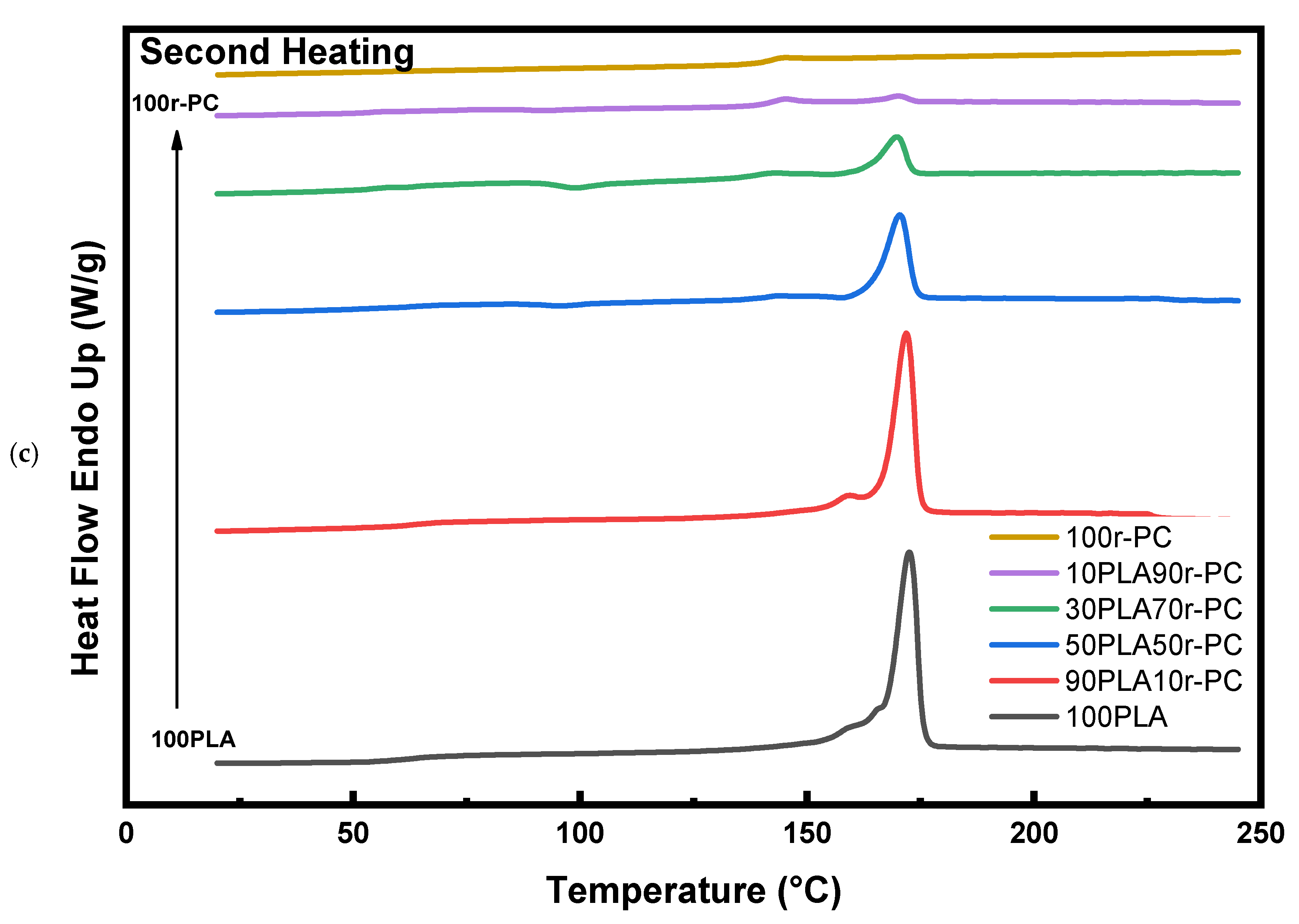

2.2.2. Differential Scanning Calorimetry (DSC)

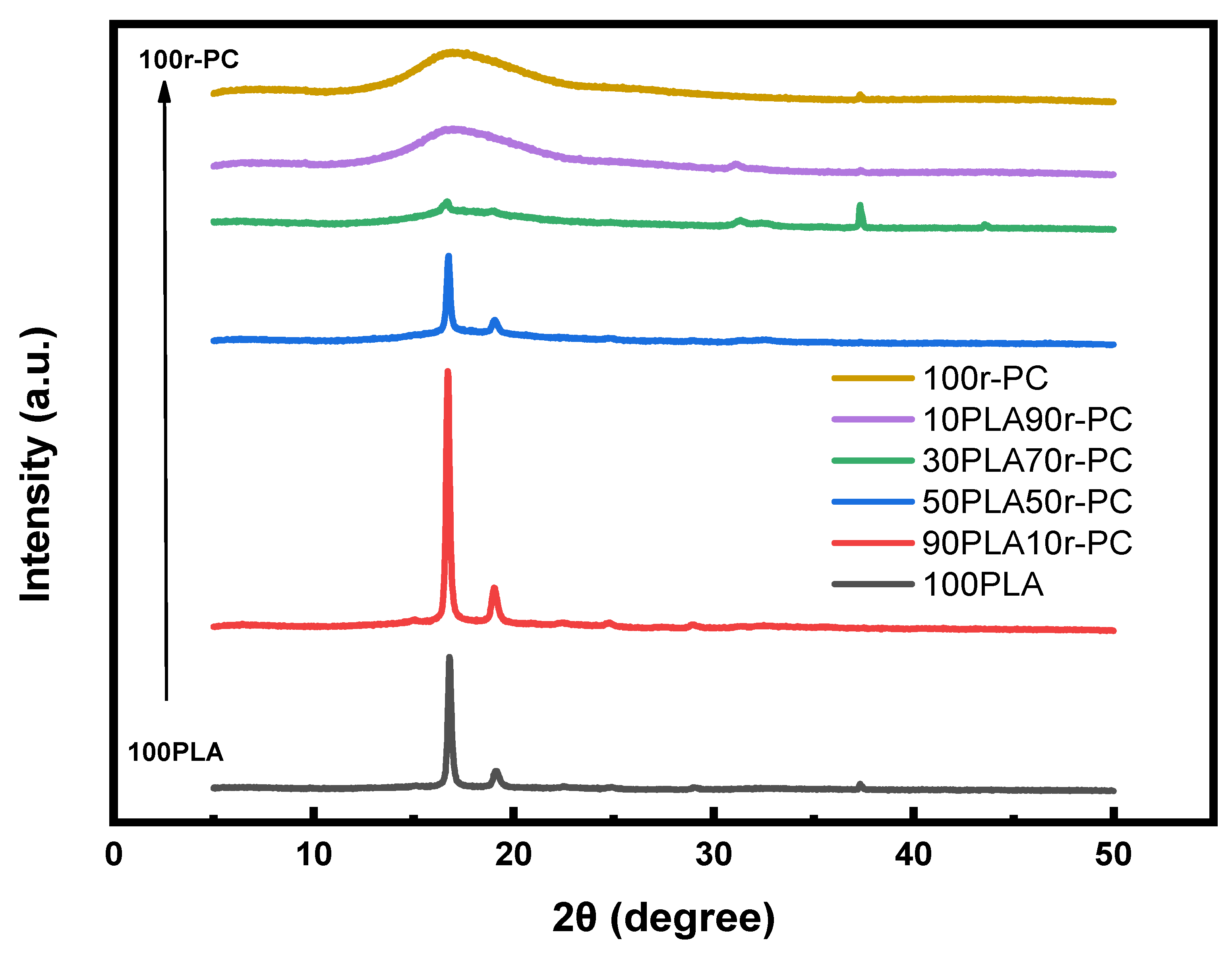

2.2.3. X-Ray Diffraction (XRD) Analysis

2.2.4. Tensile Analysis

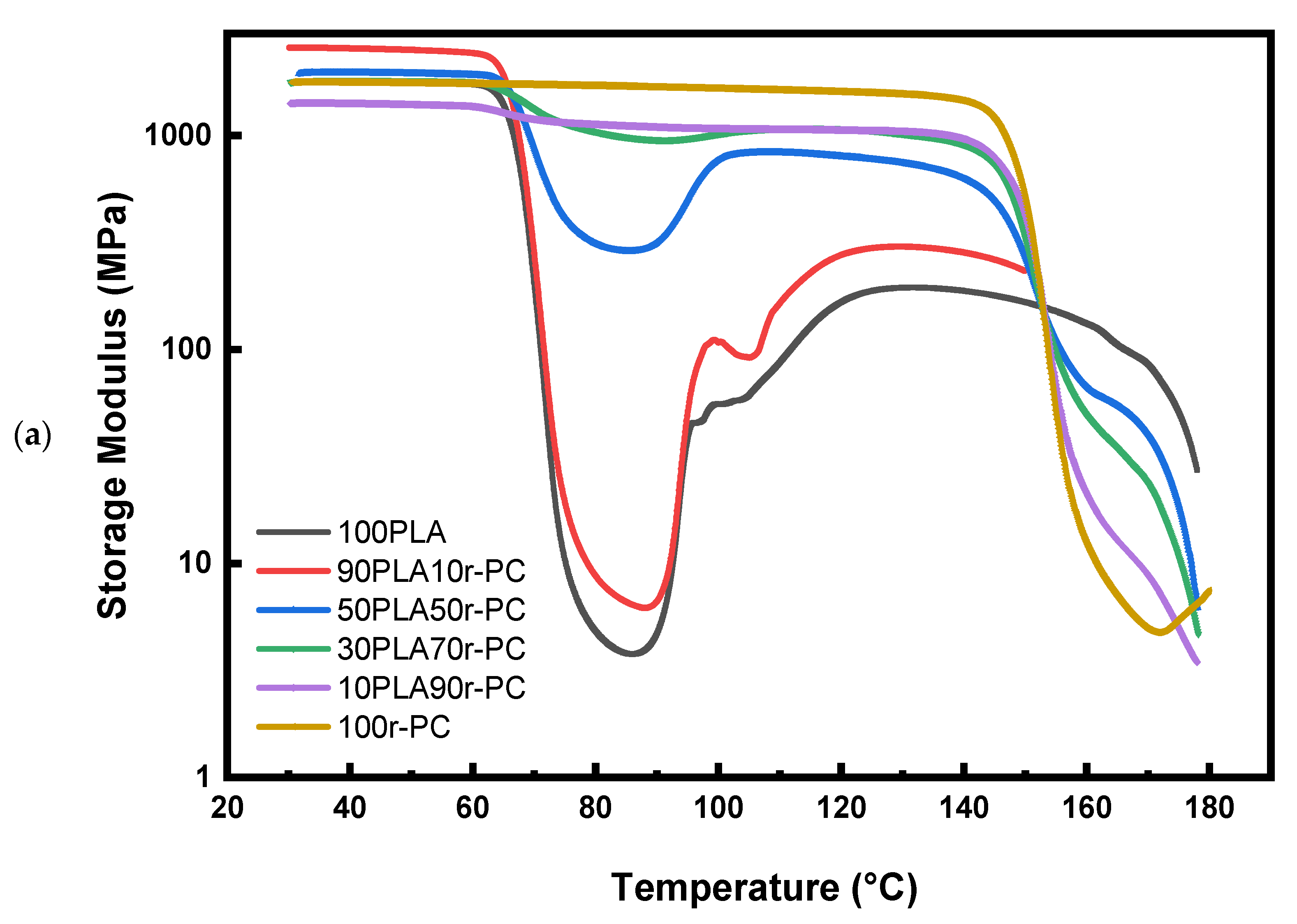

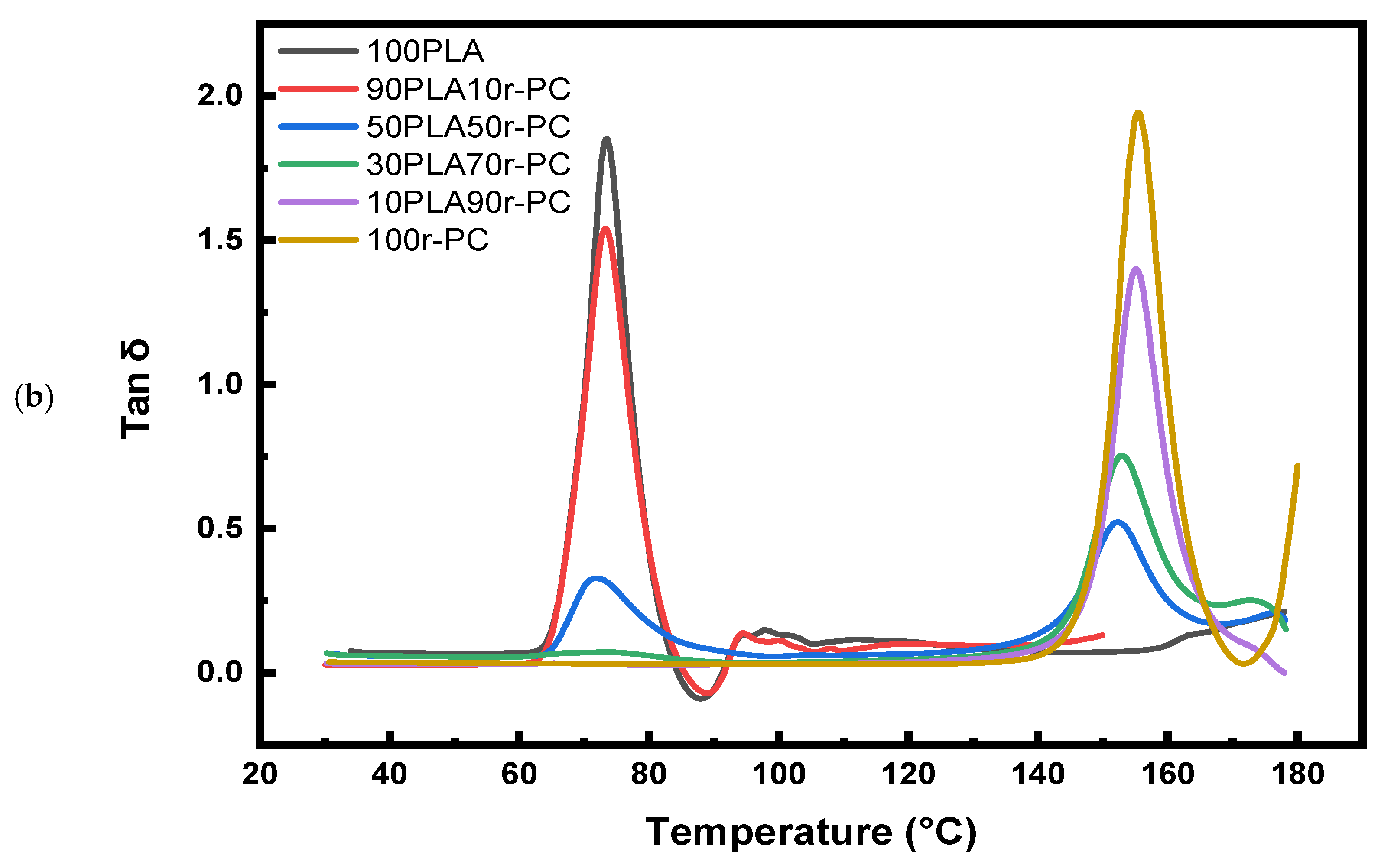

2.2.5. Dynamic Mechanical Thermal Analysis (DMTA)

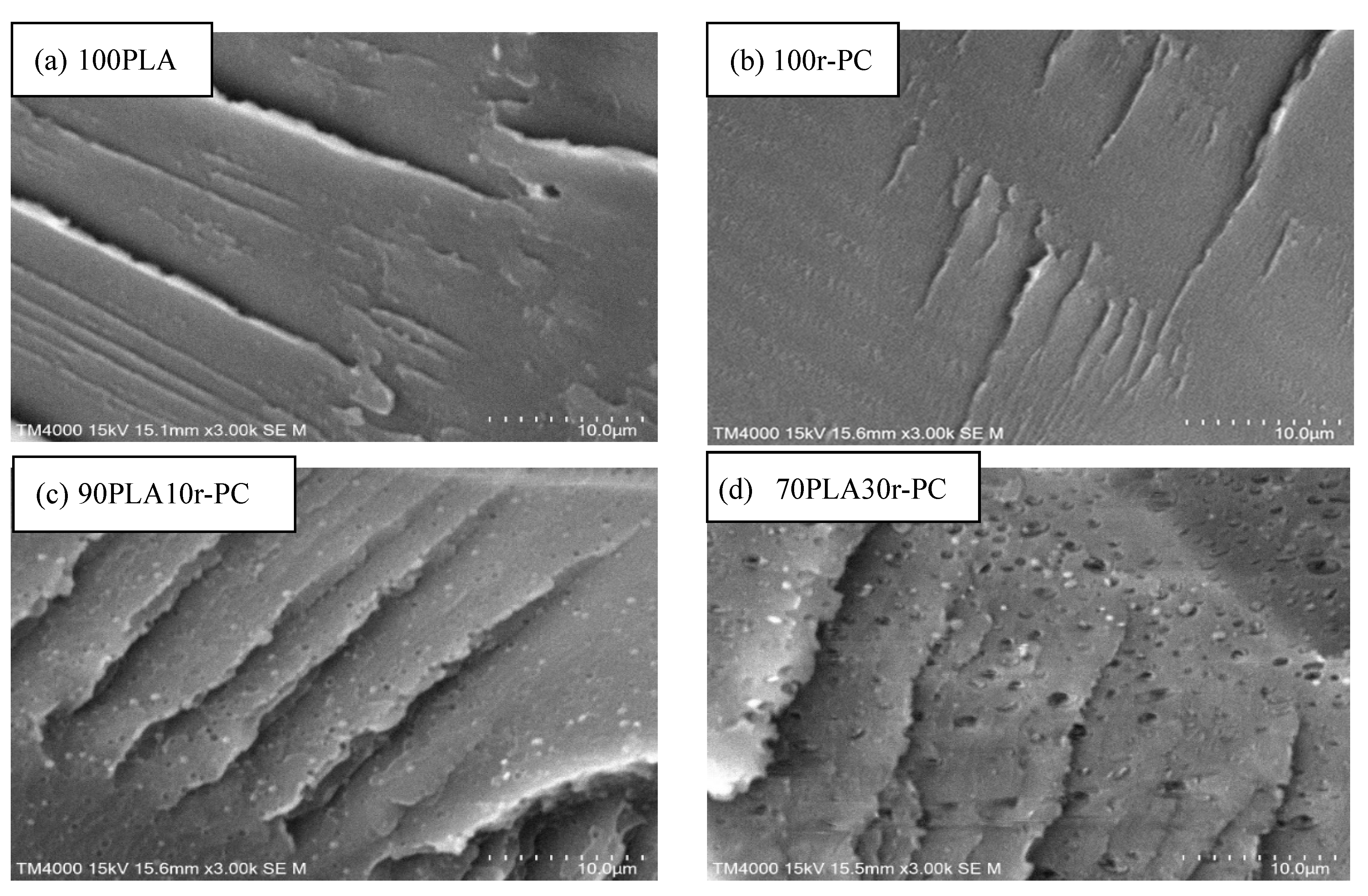

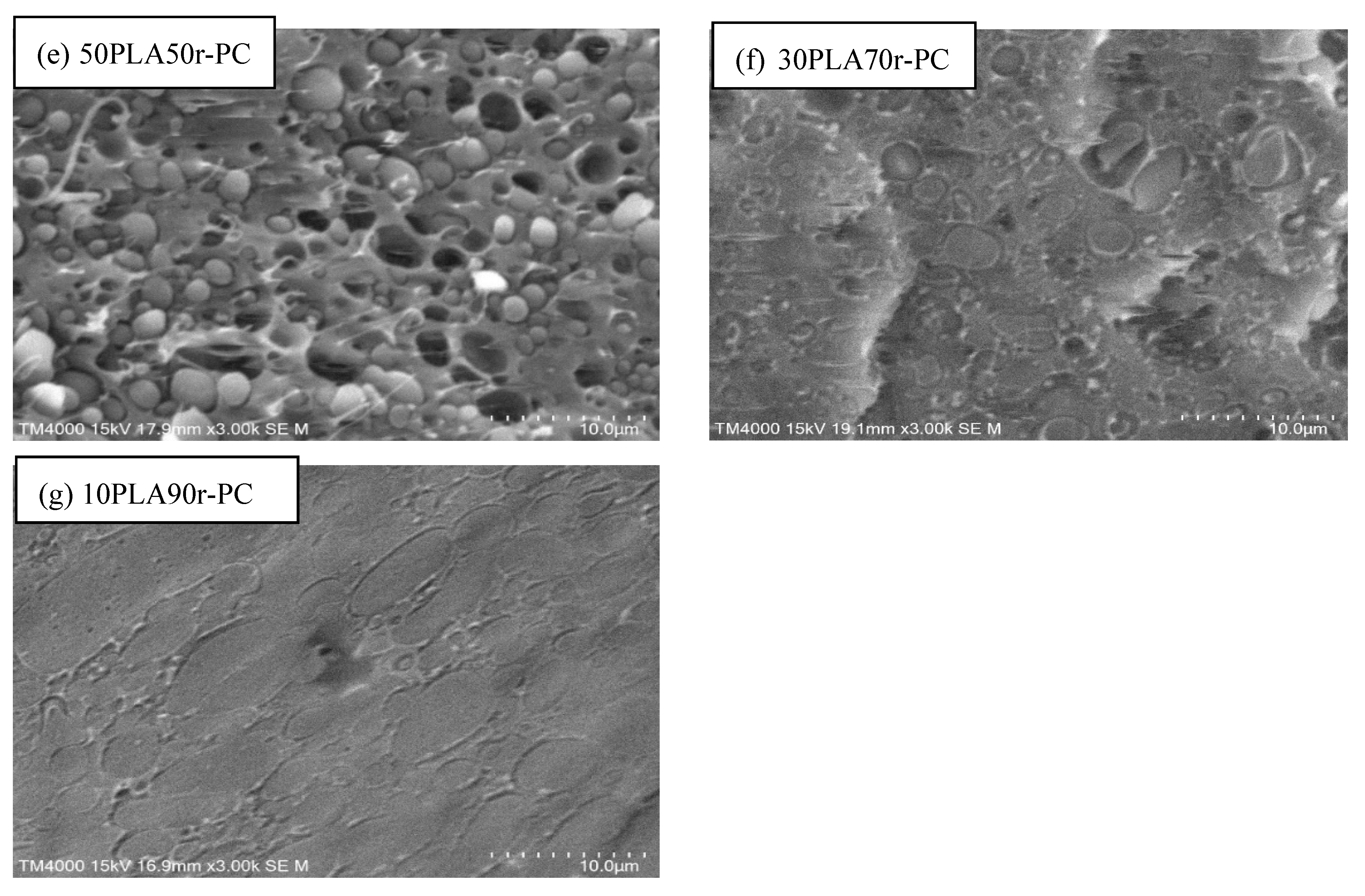

2.2.6. Scanning Electron Microscopy (SEM) Analysis

3. Results and Discussion

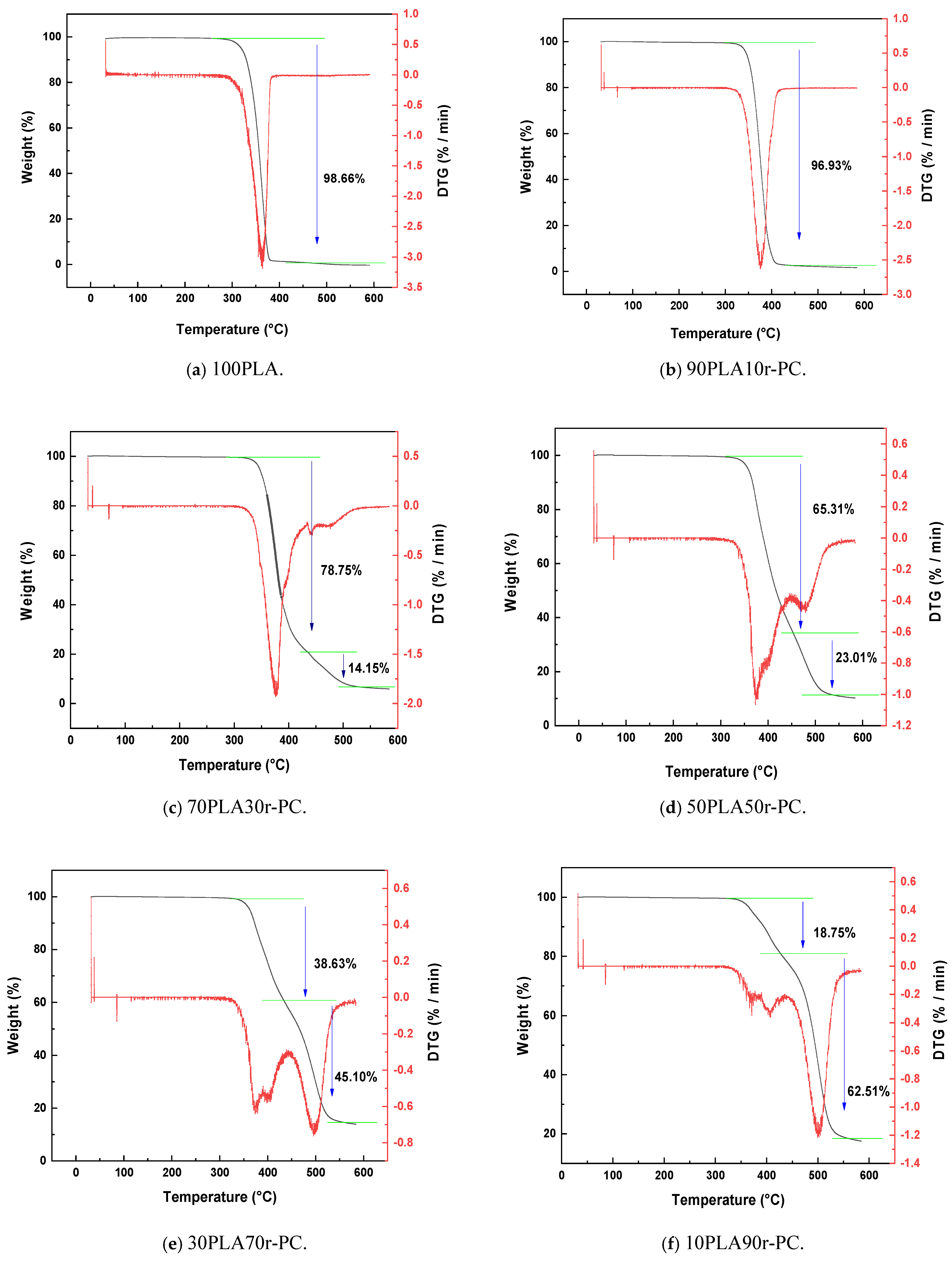

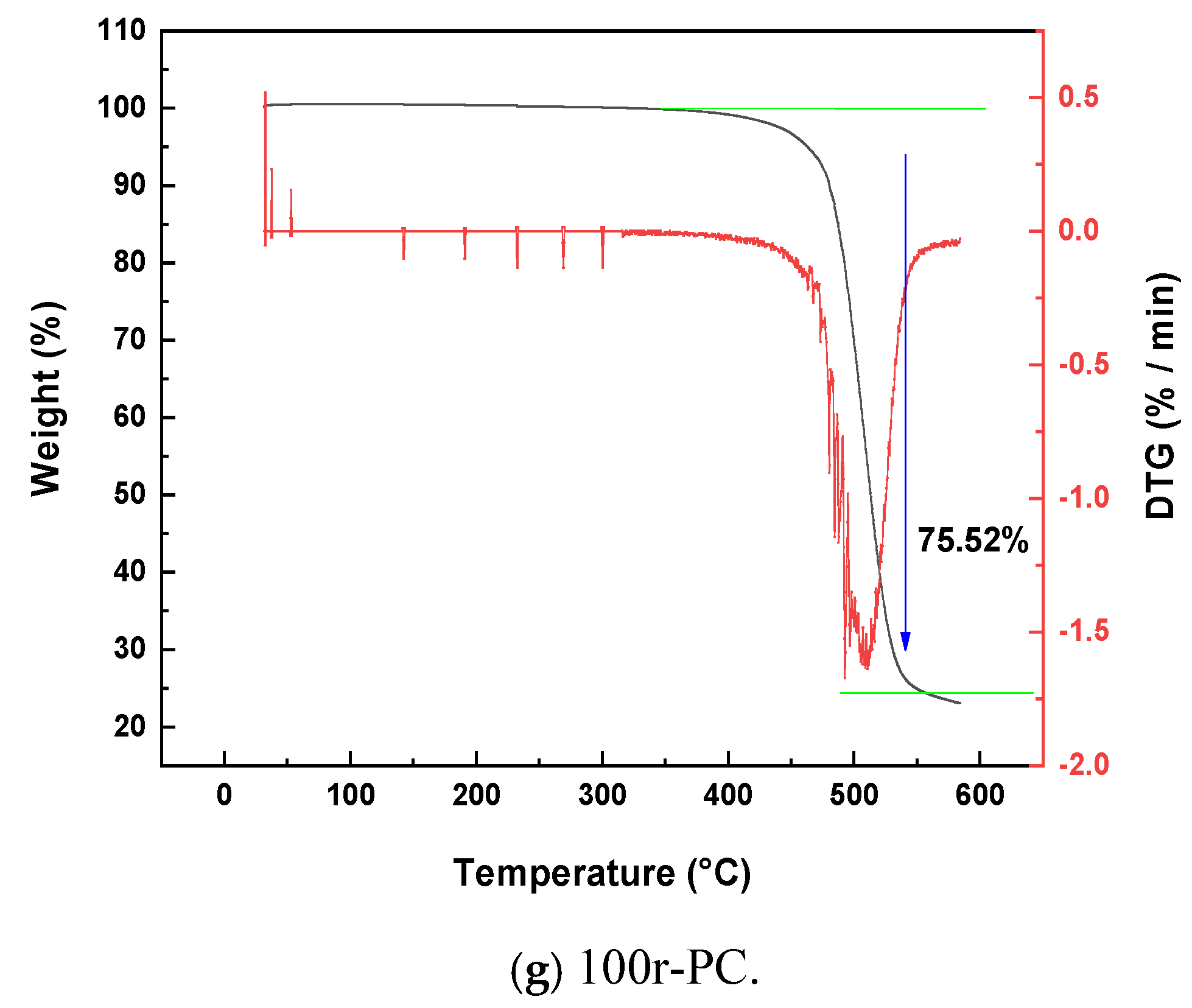

3.1. Effect of r-PC Addition on Thermal Stability of PLA

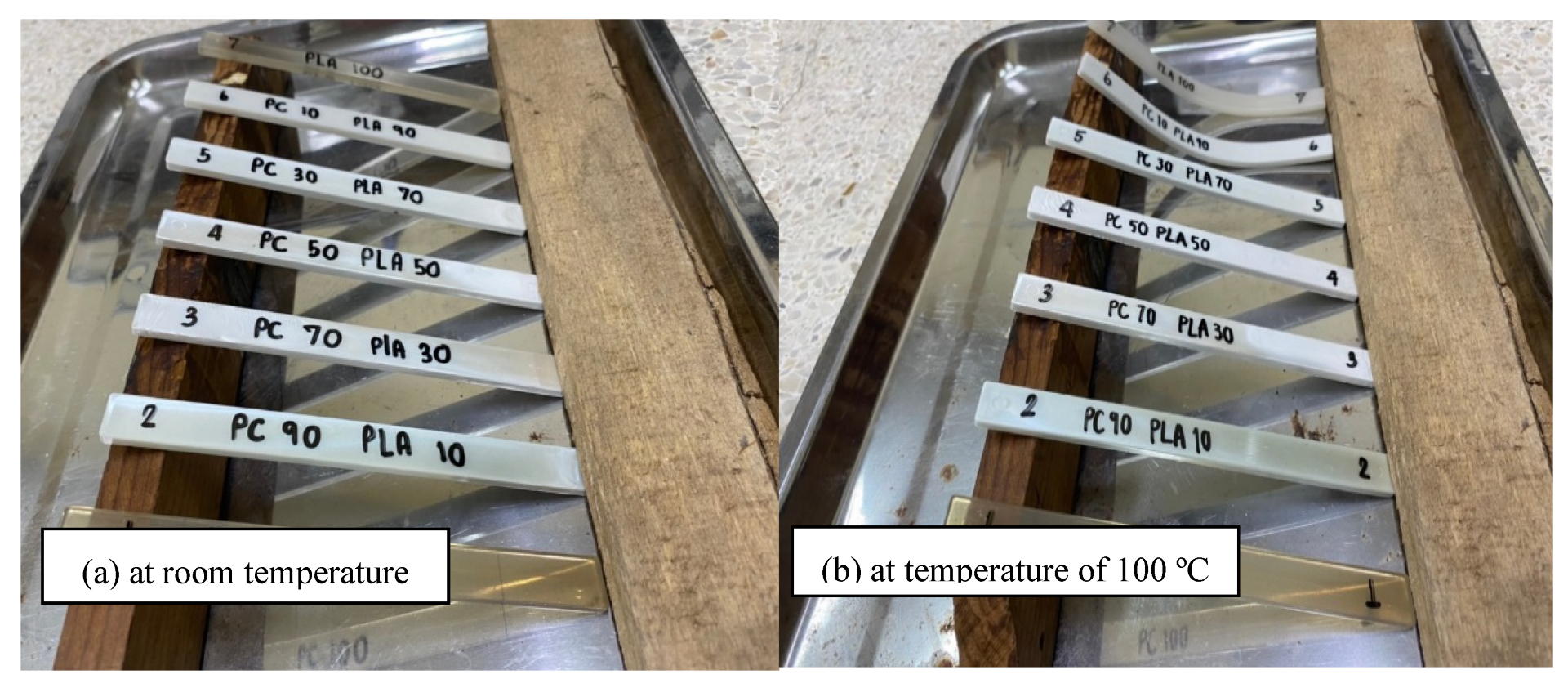

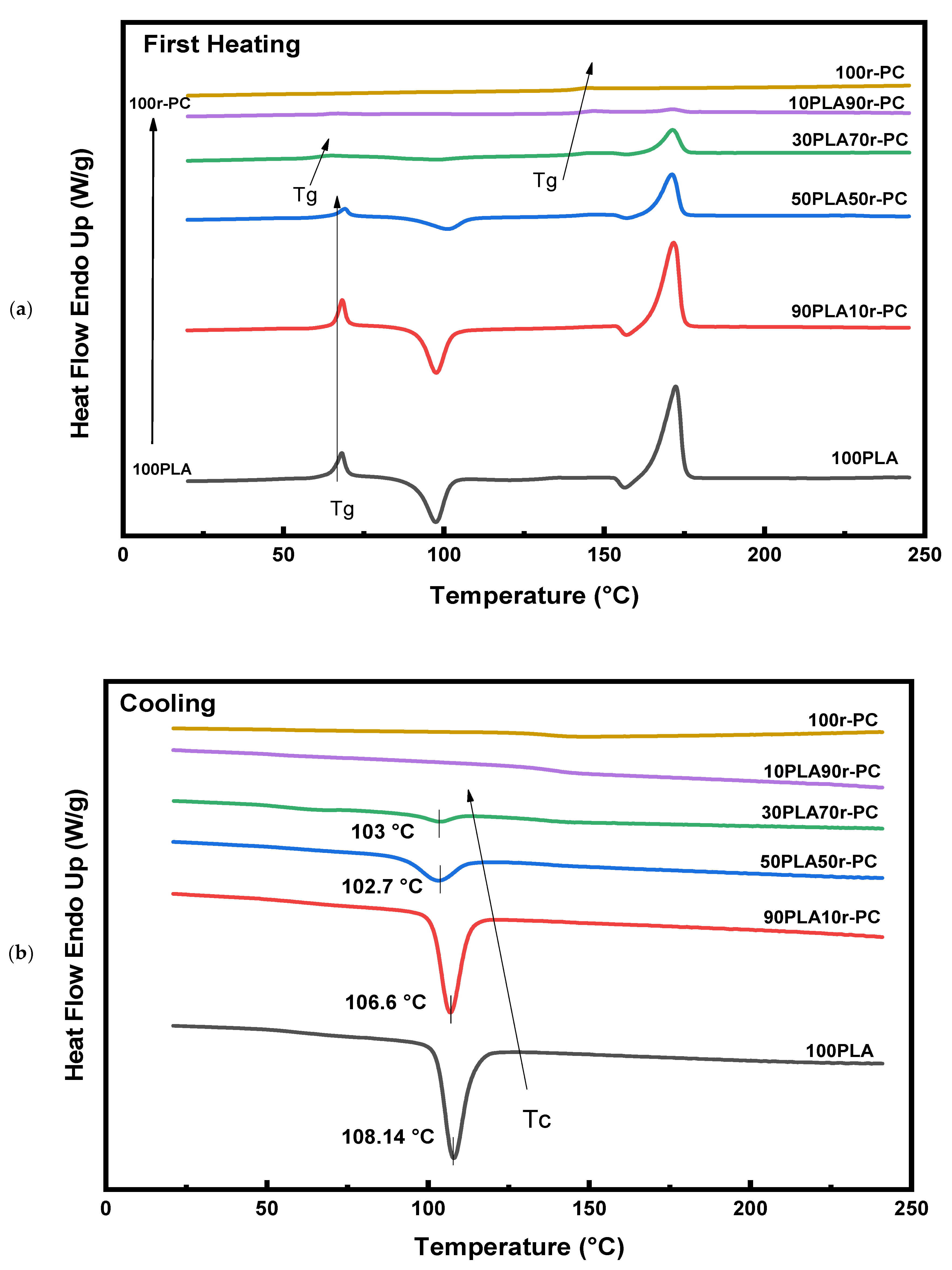

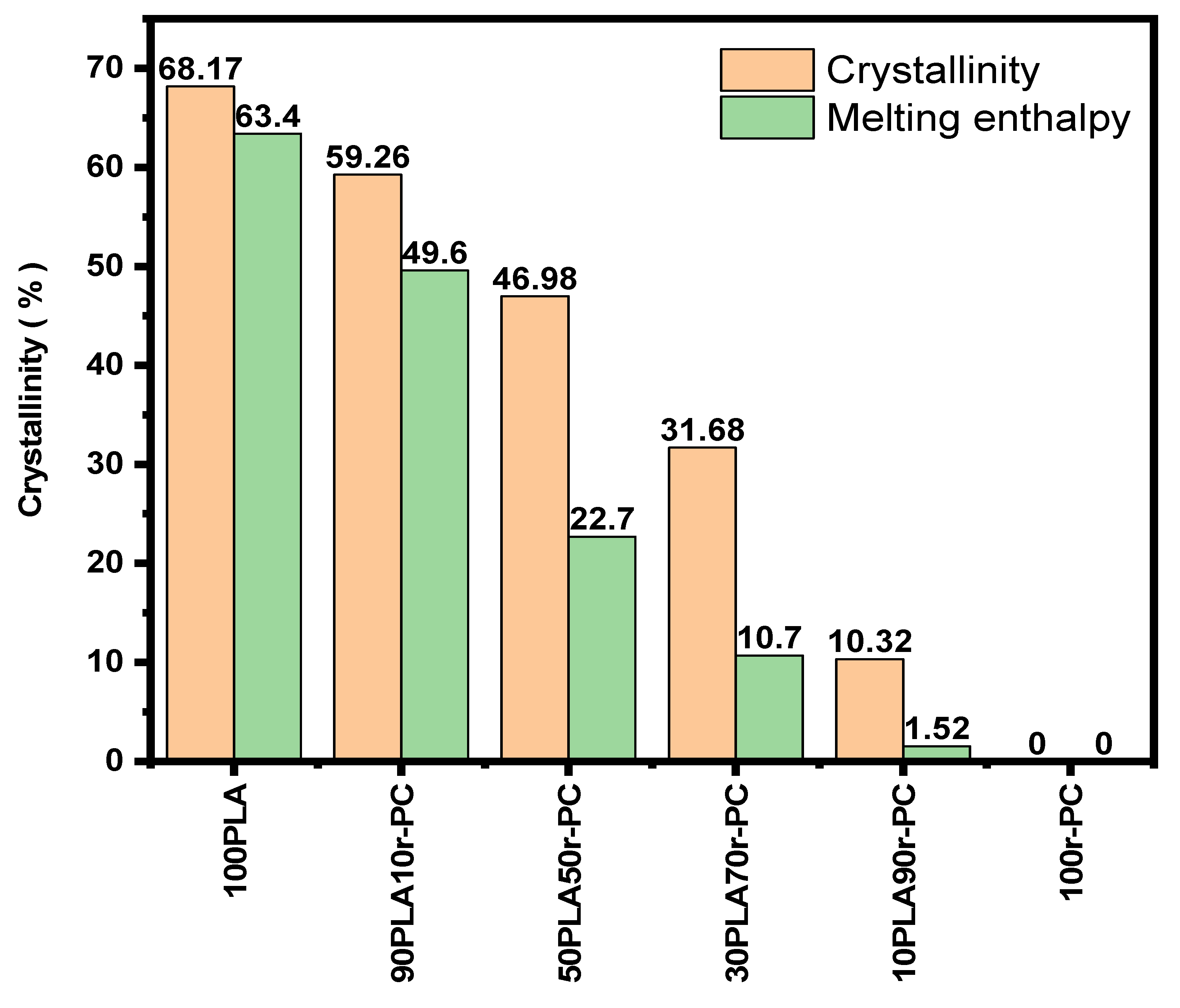

3.2. Effect of r-PC Addition on the Crystallinity of PLA Blends

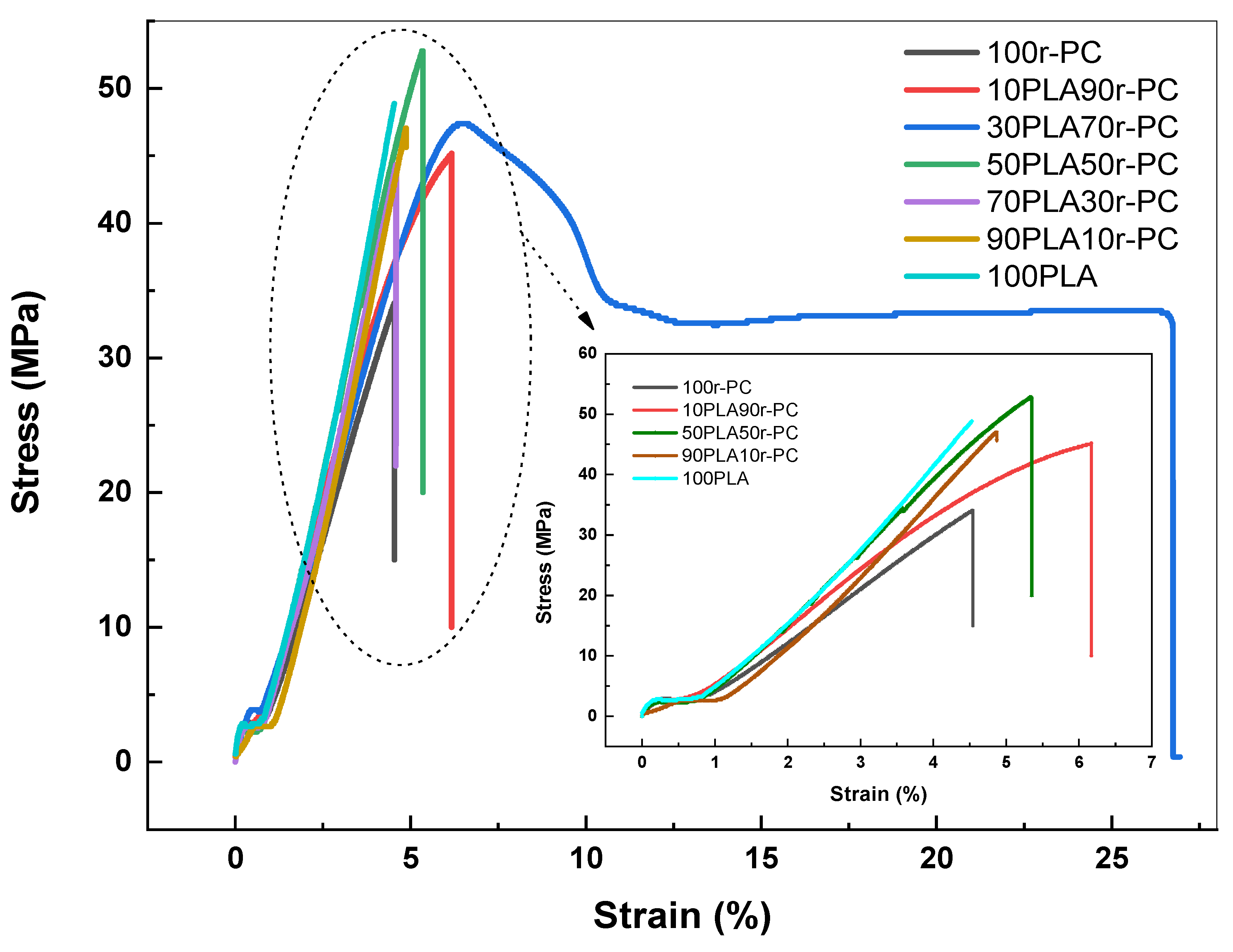

3.3. Effect of r-PC Addition on the Tensile Toughness of PLA Blends

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abdelshafy, A.; Hermann, A.; Herres-Pawlis, S.; Walther, G. Opportunities and Challenges of Establishing a Regional Bio-based Polylactic Acid Supply Chain. Glob. Chall. 2023, 7, 2200218. [Google Scholar] [CrossRef] [PubMed]

- Choi, K.; Gil, J.; Ju, J.; Li, Z.; Jung, H.W.; Bang, J. Enhanced Extrusion Processability of PLA Blends through Rheology Control Using Biodegradable PLA-based Graft Polymers. ACS Appl. Polym. Mater. 2024, 7, 54–62. [Google Scholar] [CrossRef]

- Tripathi, N.; Misra, M.; Mohanty, A.K. Durable polylactic acid (PLA)-based sustainable engineered blends and biocomposites: Recent developments, challenges, and opportunities. ACS Eng. Au 2021, 1, 7–38. [Google Scholar] [CrossRef]

- Castro-Aguirre, E.; Iniguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly (lactic acid)—Mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef]

- Simmons, H.; Tiwary, P.; Colwell, J.E.; Kontopoulou, M. Improvements in the crystallinity and mechanical properties of PLA by nucleation and annealing. Polym. Degrad. Stab. 2019, 166, 248–257. [Google Scholar] [CrossRef]

- Tümer, E.H.; Erbil, H.Y. Extrusion-based 3D printing applications of PLA composites: A review. Coatings 2021, 11, 390. [Google Scholar] [CrossRef]

- Yao, T.; Deng, Z.; Zhang, K.; Li, S. A method to predict the ultimate tensile strength of 3D printing polylactic acid (PLA) materials with different printing orientations. Compos. Part B Eng. 2019, 163, 393–402. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Vahabi, H.; Janbaz, S.; Darafsheh, A.; Mazur, T.R.; Ramakrishna, S. 4D printing of shape memory polylactic acid (PLA). Polymer 2021, 230, 124080. [Google Scholar] [CrossRef]

- Frone, A.N.; Popa, M.S.; Uşurelu, C.D.; Panaitescu, D.M.; Gabor, A.R.; Nicolae, C.A.; Raduly, M.F.; Zaharia, A.; Alexandrescu, E. Bio-based poly (lactic acid)/poly (butylene sebacate) blends with improved toughness. Polymers 2022, 14, 3998. [Google Scholar] [CrossRef]

- Naser, A.Z.; Deiab, I.; Darras, B.M. Poly (lactic acid)(PLA) and polyhydroxyalkanoates (PHAs), green alternatives to petroleum-based plastics: A review. RSC Adv. 2021, 11, 17151–17196. [Google Scholar] [CrossRef]

- Torabi, H.; McGreal, H.; Zarrin, H.; Behzadfar, E. Effects of Rheological Properties on 3D Printing of Poly (lactic acid)(PLA) and Poly (hydroxy alkenoate) (PHA) Hybrid Materials. ACS Appl. Polym. Mater. 2023, 5, 4034–4044. [Google Scholar] [CrossRef]

- Olejnik, O.; Masek, A.; Zawadziłło, J. Processability and mechanical properties of thermoplastic polylactide/polyhydroxybutyrate (PLA/PHB) bioblends. Materials 2021, 14, 898. [Google Scholar] [CrossRef] [PubMed]

- Palai, B.; Mohanty, S.; Nayak, S.K. A comparison on biodegradation behaviour of polylactic acid (PLA) based blown films by incorporating thermoplasticized starch (TPS) and poly (butylene succinate-co-adipate)(PBSA) biopolymer in soil. J. Polym. Environ. 2021, 29, 2772–2788. [Google Scholar] [CrossRef]

- Mayekar, P.C.; Limsukon, W.; Bher, A.; Auras, R. Breaking it down: How thermoplastic starch enhances poly (lactic acid) biodegradation in compost─ A comparative analysis of reactive blends. ACS Sustain. Chem. Eng. 2023, 11, 9729–9737. [Google Scholar] [CrossRef]

- Dmitruk, A.; Ludwiczak, J.; Skwarski, M.; Makuła, P.; Kaczyński, P. Influence of PBS, PBAT and TPS content on tensile and processing properties of PLA-based polymeric blends at different temperatures. J. Mater. Sci. 2023, 58, 1991–2004. [Google Scholar] [CrossRef]

- George, J.; Gracia, F.C.; Neilson, M.; Somashekar, A.A. Three-dimensional printing of a high-impact resistant polylactic acid-based ternary polymer blend. Mater. Today Proc. 2023, in press. [CrossRef]

- Chen, J.; Rong, C.; Lin, T.; Chen, Y.; Wu, J.; You, J.; Wang, H.; Li, Y. Stable co-continuous PLA/PBAT blends compatibilized by interfacial stereocomplex crystallites: Toward full biodegradable polymer blends with simultaneously enhanced mechanical properties and crystallization rates. Macromolecules 2021, 54, 2852–2861. [Google Scholar] [CrossRef]

- Mohammadi, M.; Heuzey, M.-C.; Carreau, P.J.; Taguet, A. Morphological and rheological properties of PLA, PBAT, and PLA/PBAT blend nanocomposites containing CNCs. Nanomaterials 2021, 11, 857. [Google Scholar] [CrossRef]

- Song, X.; Zhang, C.; Yang, Y.; Weng, Y. Effect of oligomers from epoxidized soybean oil and sebacic acid on the toughness of polylactic acid/bamboo fiber composites. J. Appl. Polym. Sci. 2022, 139, 51583. [Google Scholar] [CrossRef]

- Ge, Q.; Dou, Q. Preparation of supertough polylactide/polybutylene succinate/epoxidized soybean oil bio-blends by chain extension. ACS Sustain. Chem. Eng. 2023, 11, 9620–9629. [Google Scholar] [CrossRef]

- Curtzwiler, G.W.; Schweitzer, M.; Li, Y.; Jiang, S.; Vorst, K.L. Mixed post-consumer recycled polyolefins as a property tuning material for virgin polypropylene. J. Clean. Prod. 2019, 239, 117978. [Google Scholar] [CrossRef]

- Dehghani, S.; Salehiyan, R.; Srithep, Y. Mechanical recycling of polyamide 6 and polypropylene for automotive applications. Polym. Eng. Sci. 2024, 65, 250–257. [Google Scholar] [CrossRef]

- Cecon, V.S.; Da Silva, P.F.; Vorst, K.L.; Curtzwiler, G.W. The effect of post-consumer recycled polyethylene (PCRPE) on the properties of polyethylene blends of different densities. Polym. Degrad. Stab. 2021, 190, 109627. [Google Scholar] [CrossRef]

- Morgani, M.S.; Dil, E.J.; Ajji, A. Effect of processing condition and antioxidants on visual properties of multilayer post-consumer recycled high density polyethylene films. Waste Manag. 2021, 126, 239–246. [Google Scholar] [CrossRef]

- Yu, E.; Jan, K.; Chen, W.-T. Separation and Solvent Based Material Recycling of Polycarbonate from Electronic Waste. ACS Sustain. Chem. Eng. 2023, 11, 12759–12770. [Google Scholar] [CrossRef]

- Wijerathne, D.; Gong, Y.; Afroj, S.; Karim, N.; Abeykoon, C. Mechanical and thermal properties of graphene nanoplatelets-reinforced recycled polycarbonate composites. Int. J. Light. Mater. Manuf. 2023, 6, 117–128. [Google Scholar] [CrossRef]

- Gkaliou, K.; Benedini, L.; Sárossy, Z.; Jensen, C.D.; Henriksen, U.B.; Daugaard, A.E. Recycled PMMA prepared directly from crude MMA obtained from thermal depolymerization of mixed PMMA waste. Waste Manag. 2023, 164, 191–199. [Google Scholar] [CrossRef]

- Romani, A.; Levi, M.; Pearce, J.M. Recycled polycarbonate and polycarbonate/acrylonitrile butadiene styrene feedstocks for circular economy product applications with fused granular fabrication-based additive manufacturing. Sustain. Mater. Technol. 2023, 38, e00730. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Liarda, D.; Ceraulo, M.; Mistretta, M.C. A Green approach for recycling compact discs. Polymers 2023, 15, 491. [Google Scholar] [CrossRef]

- Zhou, X.; Zhai, Y.; Ren, K.; Cheng, Z.; Shen, X.; Zhang, T.; Bai, Y.; Jia, Y.; Hong, J. Life cycle assessment of polycarbonate production: Proposed optimization toward sustainability. Resour. Conserv. Recycl. 2023, 189, 106765. [Google Scholar] [CrossRef]

- Parida, D.; Aerts, A.; Vanbroekhoven, K.; Van Dael, M.; Mitta, H.; Li, L.; Eevers, W.; Van Geem, K.M.; Feghali, E.; Elst, K. Monomer recycling of polyethylene terephthalate, polycarbonate and polyethers: Scalable processes to achieve high carbon circularity. Prog. Polym. Sci. 2024, 149, 101783. [Google Scholar] [CrossRef]

- Lin, L.; Deng, C.; Lin, G.; Wang, Y. Mechanical properties, heat resistance and flame retardancy of glass fiber-reinforced PLA-PC alloys based on aluminum hypophosphite. Polym. Plast. Technol. Eng. 2014, 53, 613–625. [Google Scholar] [CrossRef]

- Hazer, S.; Coban, M.; Aytac, A. A study on carbon fiber reinforced poly (lactic acid)/polycarbonate composites. J. Appl. Polym. Sci. 2018, 135, 46881. [Google Scholar] [CrossRef]

- Lin, L.; Deng, C.; Wang, Y. Improving the impact property and heat-resistance of PLA/PC blends through coupling molecular chains at the interface. Polym. Adv. Technol. 2015, 26, 1247–1258. [Google Scholar] [CrossRef]

- Khojasteh-Khosro, S.; Shalbafan, A.; Thoemen, H. Improving the compatibility of polylactic acid/polycarbonate blends with nanoclay and Joncryl as chain extenders. J. Appl. Polym. Sci. 2024, 141, e56081. [Google Scholar] [CrossRef]

- Lin, L.; Deng, C.; Lin, G.-P.; Wang, Y.-Z. Super toughened and high heat-resistant poly (lactic acid)(PLA)-based blends by enhancing interfacial bonding and PLA phase crystallization. Ind. Eng. Chem. Res. 2015, 54, 5643–5655. [Google Scholar] [CrossRef]

- Chelghoum, N.; Mayouf, I.; Larous, A.; Guessoum, M.; Fois, M.; Haddaoui, N. Addition of Organo-Modified Nanoclay for Tuning the Microstructure, Thermal Stability, and Biodegradability of Poly (lactic acid)/Polycarbonate Immiscible Blends. Polym. Sci. Ser. A 2022, 64, 519–531. [Google Scholar] [CrossRef]

- Deng, H.; Yu, J.; Liu, C.; Zhao, Y.; Pan, H.; Ni, H.; Wang, Z.; Bian, J.; Han, L.; Zhang, H. Crystallization and heat resistance properties of poly (glycolic acid) reinforced poly (lactic acid)/poly (butylene adipate-co-terephthalate) blends. Thermochim. Acta 2024, 731, 179628. [Google Scholar] [CrossRef]

- Ramlee, N.A.; Tominaga, Y. Preparation and characterization of poly (ethylene carbonate)/poly (lactic acid) blends. J. Polym. Res. 2018, 25, 54. [Google Scholar] [CrossRef]

- Qu, Z.; Hu, X.; Pan, X.; Bu, J. Effect of compatibilizer and nucleation agent on the properties of poly (lactic acid)/polycarbonate (PLA/PC) blends. Polym. Sci. Ser. A 2018, 60, 499–506. [Google Scholar] [CrossRef]

- Yuryev, Y.; Mohanty, A.K.; Misra, M. Novel super-toughened bio-based blend from polycarbonate and poly (lactic acid) for durable applications. RSC Adv. 2016, 6, 105094–105104. [Google Scholar] [CrossRef]

- Guo, Y.; Zuo, X.; Xue, Y.; Zhou, Y.; Yang, Z.; Chuang, Y.-C.; Chang, C.-C.; Yuan, G.; Satija, S.K.; Gersappe, D. Enhancing impact resistance of polymer blends via self-assembled nanoscale interfacial structures. Macromolecules 2018, 51, 3897–3910. [Google Scholar] [CrossRef]

| Samples | T₅ wt% (°C) | T₅₀ wt% (°C) | Tmax PLA (°C) | Tmaxr-PC (°C) | PLA Weight Loss (%) | r-PC Weight Loss(%) | Total Weight Loss (%) | Char Residue (%) |

|---|---|---|---|---|---|---|---|---|

| 100PLA | 330 | 370 | 370 | - | 98.66 | - | 98.65 | 1.35 |

| 90PLA10r-PC | 340 | 380 | 375 | - | 96.93 | - | 96.93 | 3.07 |

| 70PLA30r-PC | 345 | 410 | 370 | 500 | 78.75 | 14.15 | 92.88 | 7.12 |

| 50PLA50r-PC | 350 | 420 | 375 | 510 | 65.31 | 23.01 | 88.31 | 11.69 |

| 30PLA70r-PC | 360 | 450 | 380 | 515 | 38.63 | 45.10 | 84.61 | 15.39 |

| 10PLA90r-PC | 370 | 480 | 385 | 520 | 18.75 | 62.51 | 81.25 | 18.75 |

| 100r-PC | 400 | 520 | - | 520 | - | 75.52 | 75.58 | 24.42 |

| Samples | Tg (°C) | Tm (°C) | Tc (°C) | ∆Hm (J/g) | ∆Hcc (J/g) | Xc (%) | |

|---|---|---|---|---|---|---|---|

| First Heating | 100PLA | 66 | 172.5 | 108.14 | 59 | 31 | 30.11 |

| 90PLA10r-PC | 67 | 172 | 106.6 | 56.5 | 29 | 32.85 | |

| 50PLA50r-PC | 66.7, 143 | 171.1 | 102.7 | 25.7 | 12.5 | 28.39 | |

| 30PLA70r-PC | 61, 142 | 171.4 | 103 | 15.0 | 4.0 | 39.43 | |

| 10PLA90r-PC | 64, 144 | 171.2 | - | 1.45 | - | 15.59 | |

| 100r-PC | 141.4 | - | - | - | - | - | |

| Second Heating | 100PLA | 61 | 172.5 | 108.14 | 63.4 | - | 68.17 |

| 90PLA10r-PC | 64 | 172 | 106.6 | 49.6 | - | 59.26 | |

| 50PLA50r-PC | 65, 138.5 | 170.4 | 102.7 | 22.7 | 0.86 | 46.98 | |

| 30PLA70r-PC | 55.2, 139 | 170 | 103 | 10.7 | 1.86 | 31.68 | |

| 10PLA90r-PC | 54, 142 | 170 | - | 1.52 | 0.56 | 10.32 | |

| 100r-PC | 141.2 | - | - | - | - | - | |

| The following method was used to calculate the percentage crystallinity (Xc) of the blends: | |||||||

| Xc (%) = (ΔHm − ΔHcc)/(ΔHm0 × w) × 100 ΔHm0: Theoretical enthalpy of melting for 100% crystalline PLA, ΔHm0 = 93 J/g; w: Weight fraction of PLA. | |||||||

| Samples | 2Theta (deg) | FWHM (deg) | L (nm) |

|---|---|---|---|

| 100PLA | 16.80 19.14 24.85 37.34 | 0.19 0.33 0.47 0.15 | 43.72 25.75 17.95 58.27 |

| 90PLA10r-PC | 16.71 19.04 24.75 28.99 | 0.19 0.31 0.37 0.40 | 43.95 27.04 22.76 21.28 |

| 50PLA50r-PC | 16.74 19.05 24.74 28.98 32.18 | 0.19 0.39 0.70 0.53 9.10 | 42.72 21.22 12.05 16.09 0.95 |

| 30PLA70r-PC | 17.56 31.69 37.34 43.59 | 6.03 2.63 0.15 0.21 | 1.39 3.28 57.83 42.32 |

| 10PLA90r-PC | 17.60 31.13 37.35 | 6.06 0.41 0.15 | 1.38 21.16 55.52 |

| 100r-PC | 17.63 37.33 | 5.92 0.14 | 1.42 60.84 |

| Samples | Tensile Strength (MPa) | Young’s Modulus (MPa) | Elongation at Break (%) | Toughness (kJ/m3) |

|---|---|---|---|---|

| 100PLA | 48.8 ± 3.5 | 1255 ± 4.94 | 4.50 ± 1.5 | 924 ± 150 |

| 90PLA10r-PC | 47.00 ± 2.2 | 1224 ± 3.65 | 4.87 ± 3.2 | 908 ± 130 |

| 50PLA50r-PC | 52.78 ± 2.5 | 941 ± 4.85 | 5.40 ± 3.5 | 1293 ± 180 |

| 30PLA70r-PC | 47.39 ± 2.5 | 1006 ± 119.2 | 27.00 ± 4.5 | 8725 ± 350 |

| 10PLA90r-PC | 45.00 ± 3.1 | 918 ± 2.75 | 6.00 ± 2.2 | 1477 ± 210 |

| 100r-PC | 34.00 ± 2.8 | 879 ± 3.86 | 4.50 ± 2.5 | 698 ± 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dehghani, S.; Pholharn, D.; Srithep, Y. Re-Use of Polycarbonate from Compact Discs to Enhance the Thermal Stability of Polylactic Acid Blends. Polymers 2025, 17, 606. https://doi.org/10.3390/polym17050606

Dehghani S, Pholharn D, Srithep Y. Re-Use of Polycarbonate from Compact Discs to Enhance the Thermal Stability of Polylactic Acid Blends. Polymers. 2025; 17(5):606. https://doi.org/10.3390/polym17050606

Chicago/Turabian StyleDehghani, Samaneh, Dutchanee Pholharn, and Yottha Srithep. 2025. "Re-Use of Polycarbonate from Compact Discs to Enhance the Thermal Stability of Polylactic Acid Blends" Polymers 17, no. 5: 606. https://doi.org/10.3390/polym17050606

APA StyleDehghani, S., Pholharn, D., & Srithep, Y. (2025). Re-Use of Polycarbonate from Compact Discs to Enhance the Thermal Stability of Polylactic Acid Blends. Polymers, 17(5), 606. https://doi.org/10.3390/polym17050606