The Influence of Mixed Powder Ageing on the Structural, Chemical, and Crystalline Morphological Properties of the PA12 Used to Manufacture Laser Sintering

Abstract

1. Introduction

2. Materials and Methods

2.1. Powder

2.2. Infrared Spectroscopy (FTIR)

2.3. Differential Scanning Calorimetry (DSC)

2.4. X-Ray Diffraction (XRD)

2.5. Microtome

2.6. Statistical Analysis

3. Results and Discussion

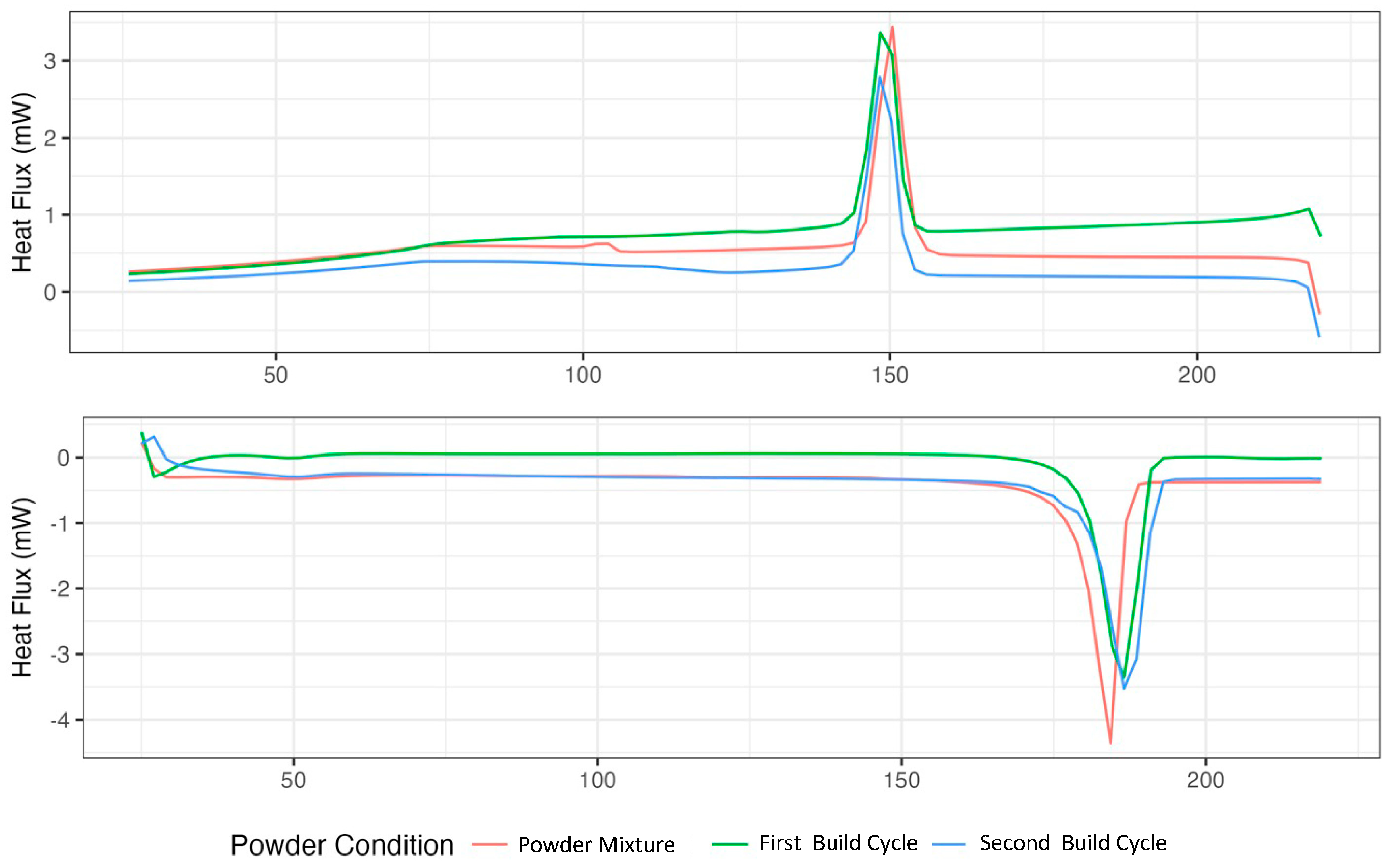

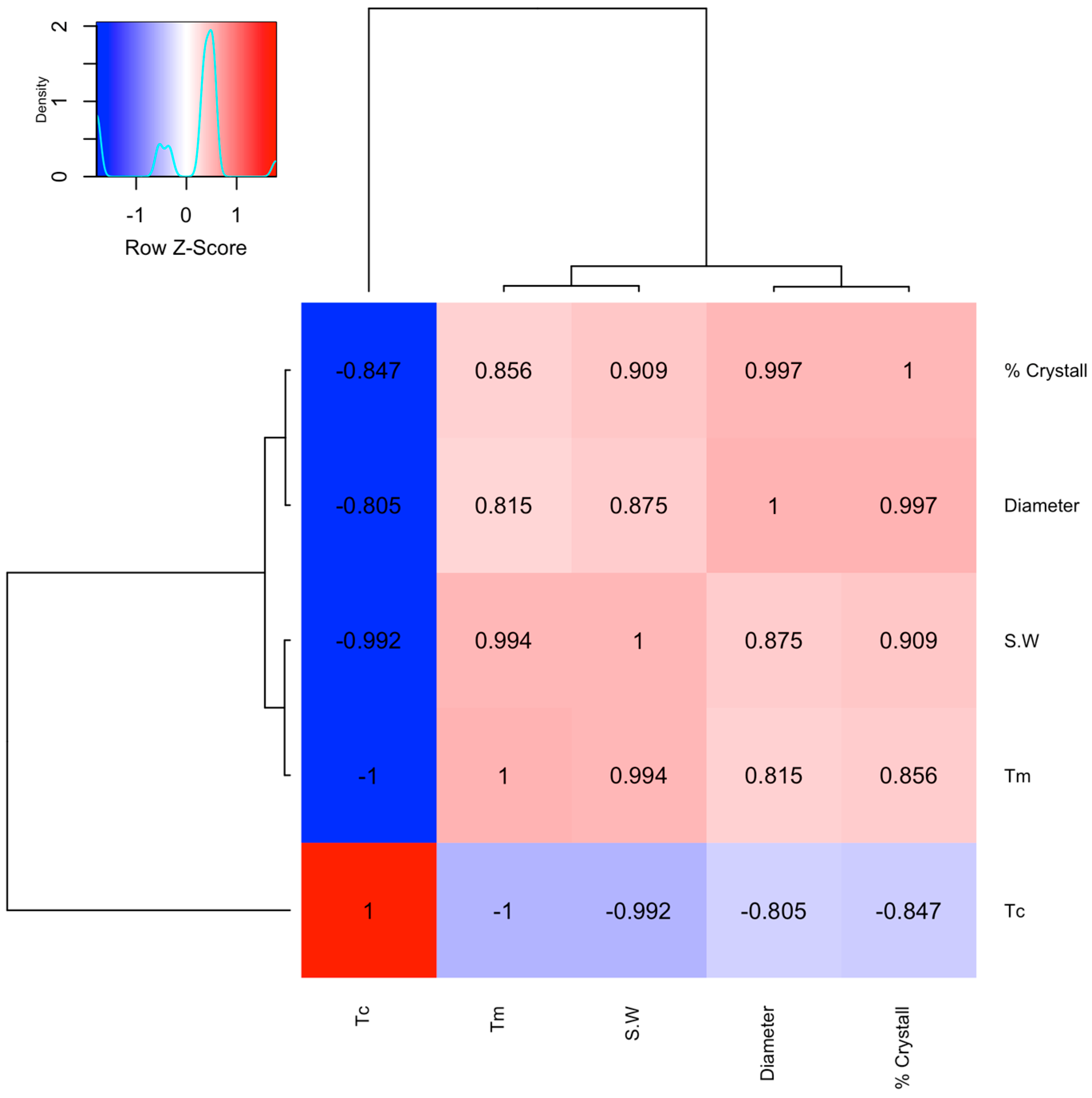

3.1. Differential Scanning Calorimetry (DSC)

| Property | Powder Condición | Present Study | Dadbakhsh et al. [27] | Cai et al. [28] | Yang et al. [18] | Yang et al. [29] | Yang et al. [26] |

|---|---|---|---|---|---|---|---|

| Tc (°C) | Powder mixture | 150.28 | 158.35 | 148.20 | 148.23 | 141.94 | 155.46 |

| First build cycle | 149.28 | 158.50 | --- | 146.48 | 142.46 | 155.63 | |

| Second build cycle | 148.84 | 156.75 | 147.02 | 142.78 | 155.67 | ||

| Tf (°C) | Powder mixture | 182.58 | 184.05 | 188.90 | 186.38 | 182.53 | 180.15 |

| First build cycle | 185.49 | 185.15 | ---- | 188.18 | 182.53 | 180.13 | |

| Second build cycle | 188.1 | 185.60 | 187.71 | 182.87 | 180.87 | ||

| C.P (%) | Powder mixture | 59.93 | 55.2 ± 0.5 | 48.20 | 46.60 | 45.48 | 51.98 |

| First build cycle | 67.11 | 51.7 ± 0.1 | --- | 50.02 | 44.92 | 51.17 | |

| Second build cycle | 65.78 | 51.1 ± 1.8 | 49.35 | 40.17 | 47.26 | ||

| S.W (°C) | Powder mixture | 18.44 | 17.80 | --- | 25.70 | 29.92 | --- |

| First build cycle | 18.75 | 17.30 | 27.70 | 30.31 | --- | ||

| Second build cycle | 8.86 | 9.20 | 28.50 | 31.00 | --- |

3.2. X-Ray Diffraction (XRD)

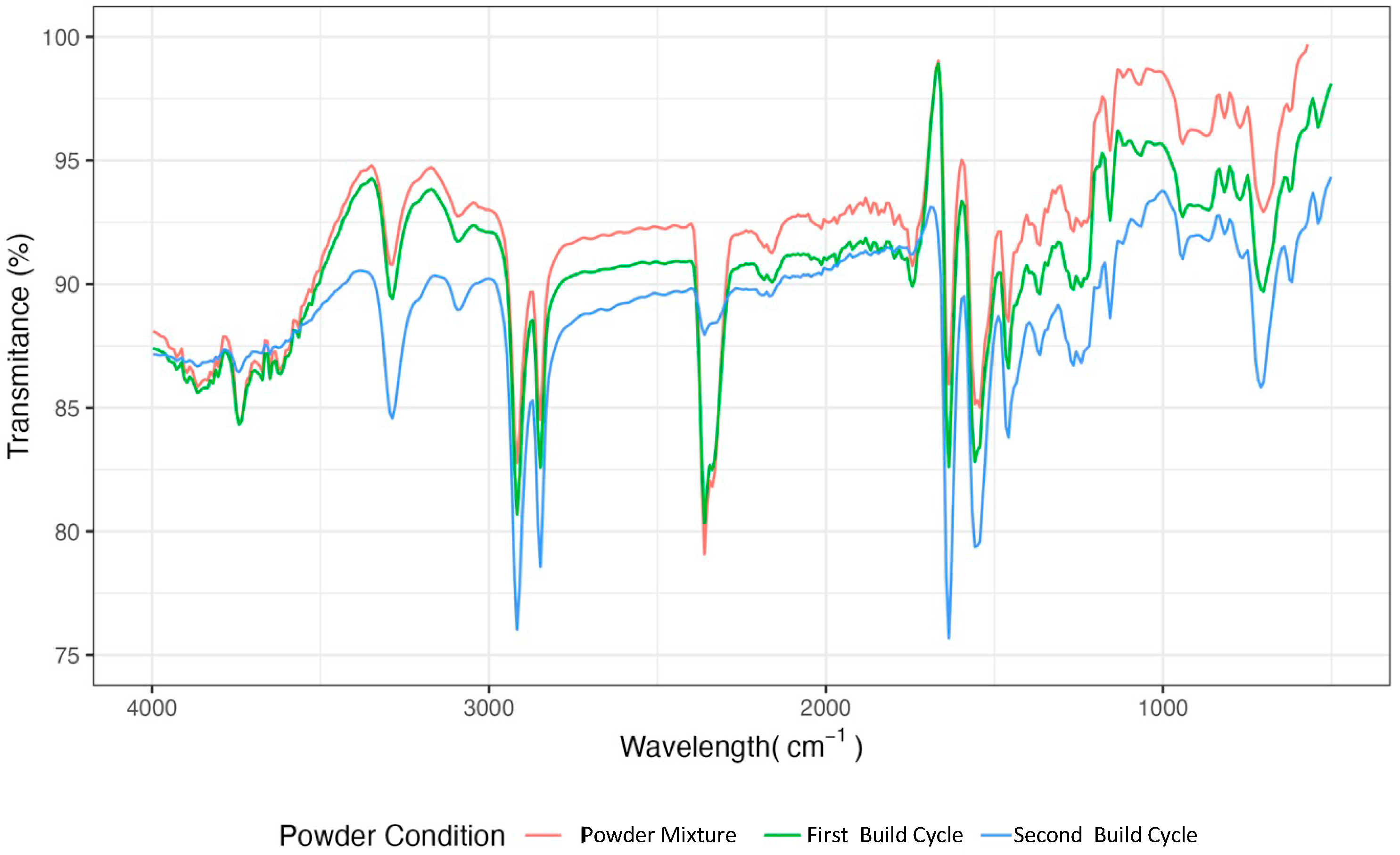

3.3. Fourier Transform Infrared Spectroscopy (FTIR)

3.4. Size of the Particles

3.5. Morphology of the Particle Crystal

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Rodríguez, A.G.; Mora, E.E.; Velasco, M.A.; Tovar, C.A.N. Mechanical properties of polyamide 12 manufactured by means of SLS: Influence of wall thickness and build direction. Mater. Res. Express 2023, 10, 105304. [Google Scholar] [CrossRef]

- Rodriguez, A.G.; Peña, M.A.V.; Narváez-Tovar, C.A.; Mora, E.E. Experimental analysis of failure behaviour of PA12 specimens manufactured by SLS as a function of wall thickness and build direction. Rapid Prototyp. J. 2024, 30, 1537–1555. [Google Scholar] [CrossRef]

- Traxel, K.D.; Malihi, D.; Starkey, K.; Bandyopadhyay, A. Model-driven directed-energy-deposition process workflow incorporating powder flowrate as key parameter. Manuf. Lett. 2020, 25, 88–92. [Google Scholar] [CrossRef]

- Baserinia, R.; Brockbank, K.; Dattani, R. Correlating polyamide powder flowability to mechanical properties of parts fabricated by additive manufacturing. Powder Technol. 2022, 398, 117147. [Google Scholar] [CrossRef]

- Hejmady, P.; van Breemen, L.C.A.; Hermida-Merino, D.; Anderson, P.D.; Cardinaels, R. Laser sintering of PA12 particles studied by in-situ optical, thermal and X-ray characterization. Addit. Manuf. 2022, 52, 102624. [Google Scholar] [CrossRef]

- Kruth, P.; Wang, X.; Laoui, T. Lasers and materials in selective laser sintering. Assem. Autom. 2003, 23, 357–371. [Google Scholar] [CrossRef]

- Greiner, S.; Jaksch, A.; Cholewa, S.; Drummer, D. Advanced Industrial and Engineering Polymer Research Development of material-adapted processing strategies for laser sintering of polyamide 12. Adv. Ind. Eng. Polym. Res. 2021, 4, 251–263. [Google Scholar]

- Sivadas, B.O.; Ashcroft, I.; Khobystov, A.N.; Goodridge, R.D. Laser sintering of polymer nanocomposites. Adv. Ind. Eng. Polym. Res. 2021, 4, 277–300. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Yusoff, W.; Pham, D.T.; Dotchev, K. Effect of Employing Different Grades of Recycled Polyamide 12 on the Surface Texture of Laser Sintered (Ls) Parts. In Proceedings of the International Conference on Advances in Materials & Processing Technology (AMPT 2009), Kuala, Lumpur, 26–29 October 2009. [Google Scholar]

- Jiang, X.; Shen, W.; Jiang, L.; Qin, H. Effects of Particle Size Distribution and Impact Speed on Printing Quality in Direct Energy Deposition. Manuf. Lett. 2022, 33, 521–526. [Google Scholar] [CrossRef]

- Starr, T.L.; Gornet, T.J.; Usher, J.S. The effect of process conditions on mechanical properties of laser-sintered nylon. Rapid Prototyp. J. 2011, 17, 418–423. [Google Scholar] [CrossRef]

- Salmoria, G.V.; Leite, J.L.; Paggi, R.A. The microstructural characterization of PA6/PA12 blend specimens fabricated by selective laser sintering. Polym. Test. 2009, 28, 746–751. [Google Scholar] [CrossRef]

- Chou, B.F.E.K. Build surface study of single-layer raster scanning in selective laser melting: Surface roughness prediction using deep learning. Manuf. Lett. 2022, 33, 701–711. [Google Scholar] [CrossRef]

- Gawade, V.; Galkin, G.; Guo, Y.B.; Guo, W.G. Quantifying and modeling overheating using 3D pyrometry map in powder bed fusion. Manuf. Lett. 2022, 33, 880–892. [Google Scholar] [CrossRef]

- Wegener, M.S.E.K. Additive Manufacturing: Polymers applicable for laser sintering (LS). Procedia Eng. 2016, 149, 457–464. [Google Scholar] [CrossRef]

- Damanhuri, A.A.M.; Hariri, A.; Ghani, S.A.; Mustafa, M.S.S.; Herawan, S.G.; Paiman, N.A. The Effects of Virgin and Recycled PA12 Powders in SLS Processes on Occupational Exposures. Int. J. Environ. Sci. Dev. 2021, 12, 339–345. [Google Scholar] [CrossRef]

- Yang, F.; Zobeiry, N.; Mamidala, R.; Chen, X. A review of aging, degradation, and reusability of PA12 powders in selective laser sintering additive manufacturing. Mater. Today Commun. 2022, 34, 105279. [Google Scholar] [CrossRef]

- Bonten, S.W.E.C. Recycling of pa12 powder for selective laser sintering. In AIP Conference Proceedings; American Institute of Physics Inc.: College Park, MD, USA, 2020. [Google Scholar] [CrossRef]

- Yang, F.; Jiang, T.; Lalier, G.; Bartolone, J.; Chen, X. A process control and interlayer heating approach to reuse polyamide 12 powders and create parts with improved mechanical properties in selective laser sintering. J. Manuf. Process. 2020, 57, 828–846. [Google Scholar] [CrossRef]

- Martynková, G.S.; Slíva, A.; Kratošová, G.; Barabaszová, K.Č.; Študentová, S.; Klusák, J.; Brožová, S.; Dokoupil, T.; Holešová, S. Polyamide 12 materials study of morpho-structural changes during laser sintering of 3d printing. Polymers 2021, 13, 810. [Google Scholar] [CrossRef] [PubMed]

- Launhardt, M.; Fischer, C.; Drummer, D. Research on the Influence of Geometry and Positioning on Laser Sintered Parts. Appl. Mech. Mater. 2015, 805, 105–114. [Google Scholar] [CrossRef]

- Pham, D.T.; Dotchev, K.D.; Yusoff, W.A.Y. Deterioration of polyamide powder properties in the laser sintering process. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2008, 222, 2163–2176. [Google Scholar] [CrossRef]

- Schuk, M.K. Laser Sintering with Plastics; HANSER: Cincinnati, OH, USA, 2018. [Google Scholar]

- Majewski, C.E.; Zarringhalam, H.; Hopkinson, N. Effects of degree of particle melt and crystallinity in SLS Nylon-12 parts. In Proceedings of the 19th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 4–6 August 2008; pp. 45–54. [Google Scholar]

- Yang, W.; Liu, F.; Zhang, J.; Zhang, E.; Qiu, X.; Ji, X. Influence of thermal treatment on the structure and mechanical properties of one aromatic BPDA-PDA polyimide fibers. Eur. Polym. J. 2017, 96, 429–442. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Verbelen, L.; Verkinderen, O.; Strobbe, D.; Van Puyvelde, P.; Kruth, J.P. Effect of PA12 powder reuse on coalescence behaviour and microstructure of SLS parts. Eur. Polym. J. 2017, 92, 250–262. [Google Scholar] [CrossRef]

- Cai, C.; Tey, W.S.; Chen, J.; Zhu, W.; Liu, X.; Liu, T.; Zhao, L.; Zhou, K. Comparative study on 3D printing of polyamide 12 by selective laser sintering and multi jet fusion. J. Mech. Work. Technol. 2020, 288, 116882. [Google Scholar] [CrossRef]

- Yang, F.; Jiang, T.; Chen, X. Process control of surface quality and part microstructure in selective laser sintering involving highly degraded polyamide 12 materials. Polym. Test. 2020, 93, 106920. [Google Scholar] [CrossRef]

- El Magri, A.; Bencaid, S.E.; Vanaei, H.R.; Vaudreuil, S. Effects of Laser Power and Hatch Orientation on Final Properties of PA12 Parts Produced by Selective Laser Sintering. Polymers 2022, 14, 3674. [Google Scholar] [CrossRef]

- Yao, B.; Li, Z.; Zhu, F. Effect of powder recycling on anisotropic tensile properties of selective laser sintered PA2200 polyamide. Eur. Polym. J. 2020, 141, 110093. [Google Scholar] [CrossRef]

- Alo, O.A.; Otunniyi, I.O.; Mauchline, D. Aging due to successive reuse of polyamide 12 powder during laser sintering: Extrinsic powder properties and quality of sintered parts. MATEC Web Conf. 2022, 370, 03011. [Google Scholar] [CrossRef]

- Verbelen, L.; Dadbakhsh, S.; Van Den Eynde, M.; Kruth, J.P.; Goderis, B.; Van Puyvelde, P. Characterization of polyamide powders for determination of laser sintering processability. Eur. Polym. J. 2016, 75, 163–174. [Google Scholar] [CrossRef]

- Balemans, C.; Jaensson, N.O.; Hulsen, M.A.; Anderson, P.D. Temperature-dependent sintering of two viscous particles. Addit. Manuf. 2018, 24, 528–542. [Google Scholar] [CrossRef]

| Phase PA 12 | Powder Condition | Present Study | Yao et al. [31] | Cai et al. [28] | Yang et al. [29] |

|---|---|---|---|---|---|

| Gamma (100) | Powder mixture | 21.221 | 20.3 | 21.2 | 20.3 |

| First build cycle | 21.283 | ||||

| Second build cycle | 21.393 | ||||

| Alpha (010/110) | Powder mixture | 22.253 | 23.2 | 22.1 | 23.9 |

| First build cycle | 22.274 | ||||

| Second build cycle | 22.340 |

| Condition | Present Study (μm) | Cai et al. [28] | Dadbakhsh et al. [27] | Yang et al. [29] | Jiang et al. [11] | Alo et al. [32] |

|---|---|---|---|---|---|---|

| Powder Mixture | 52.5 | 52.6 | 55–60 | 50–60 | 63 | 55.75 |

| First Build Cycle | 56.0 | |||||

| Second Build Cycle | 55.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García Rodríguez, A.; Espejo Mora, E.; Velasco Peña, M.A.; Narváez Tovar, C.A. The Influence of Mixed Powder Ageing on the Structural, Chemical, and Crystalline Morphological Properties of the PA12 Used to Manufacture Laser Sintering. Polymers 2025, 17, 577. https://doi.org/10.3390/polym17050577

García Rodríguez A, Espejo Mora E, Velasco Peña MA, Narváez Tovar CA. The Influence of Mixed Powder Ageing on the Structural, Chemical, and Crystalline Morphological Properties of the PA12 Used to Manufacture Laser Sintering. Polymers. 2025; 17(5):577. https://doi.org/10.3390/polym17050577

Chicago/Turabian StyleGarcía Rodríguez, Alejandro, Edgar Espejo Mora, Marco Antonio Velasco Peña, and Carlos Alberto Narváez Tovar. 2025. "The Influence of Mixed Powder Ageing on the Structural, Chemical, and Crystalline Morphological Properties of the PA12 Used to Manufacture Laser Sintering" Polymers 17, no. 5: 577. https://doi.org/10.3390/polym17050577

APA StyleGarcía Rodríguez, A., Espejo Mora, E., Velasco Peña, M. A., & Narváez Tovar, C. A. (2025). The Influence of Mixed Powder Ageing on the Structural, Chemical, and Crystalline Morphological Properties of the PA12 Used to Manufacture Laser Sintering. Polymers, 17(5), 577. https://doi.org/10.3390/polym17050577