Study of a Single Joint Between Two FDM-Printed PLA Filaments

Abstract

1. Introduction

- There is excellent complexity in understanding the isolated effect of any variable on the interlayer strength. As discussed by Allum J. et al. [8], the literature assessing interlayer adhesion presents a variety of geometrical designs, which makes the comparison of results difficult and yields opposing conclusions for the effect of the same variable on interlayer strength.

- A lack of studies focusing exclusively on the characterization of a single, isolated, interlayer joint under controlled conditions. This specific approach is crucial for understanding the intrinsic properties of the interlayer bond by using the simplest possible joint that can be produced.

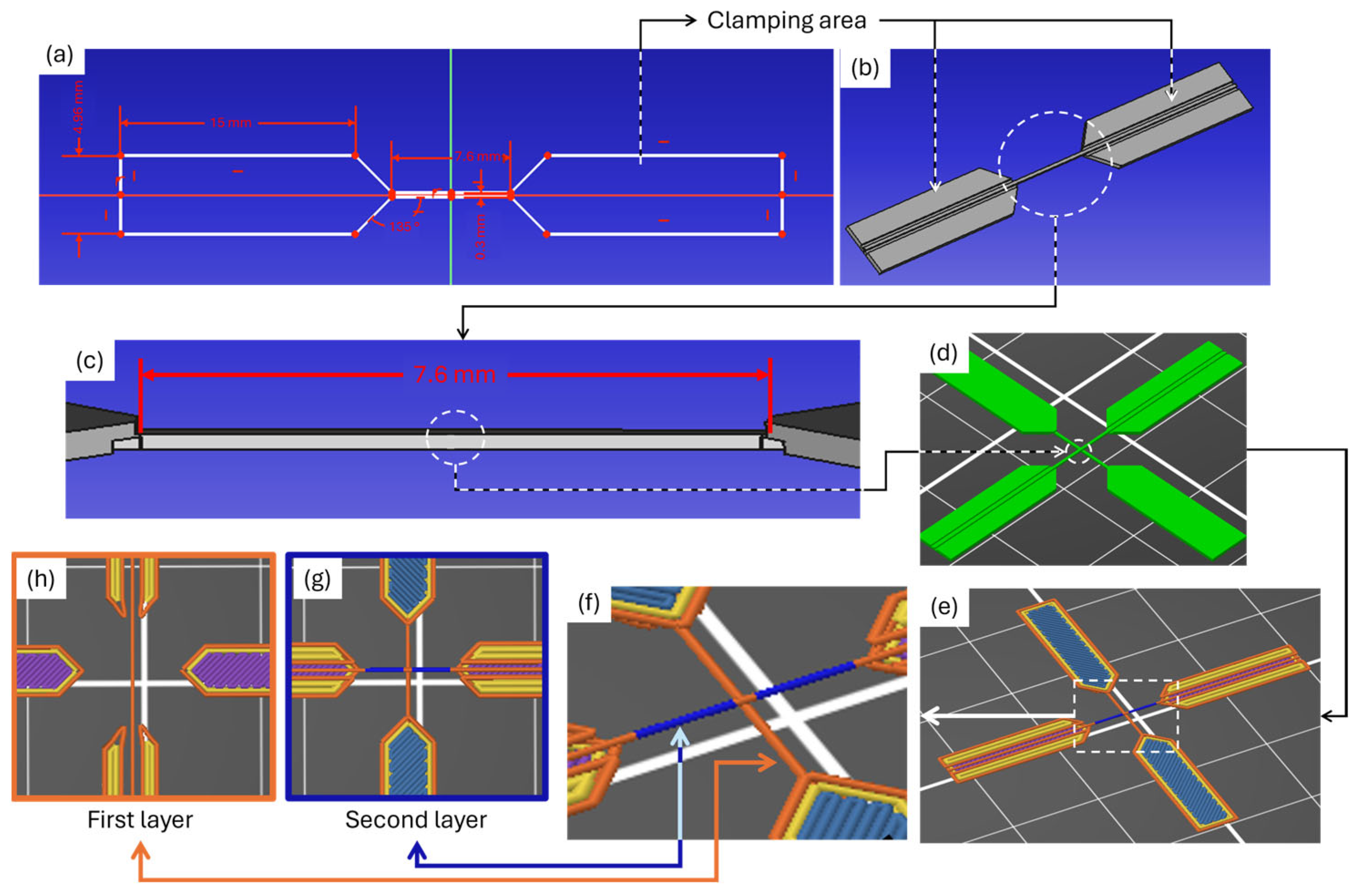

- Design of a specimen and fixturing system: to design a cruciform specimen incorporating a single PLA–PLA interlayer joint, together with a rapid, reliable, and reproducible clamping protocol suitable for high-throughput testing.

- Characterize the mechanical properties of the single joint and its failure modes: to quantify the mechanical response of the isolated joint and to classify its failure modes under tensile loading (e.g., joint-controlled vs. filament-controlled).

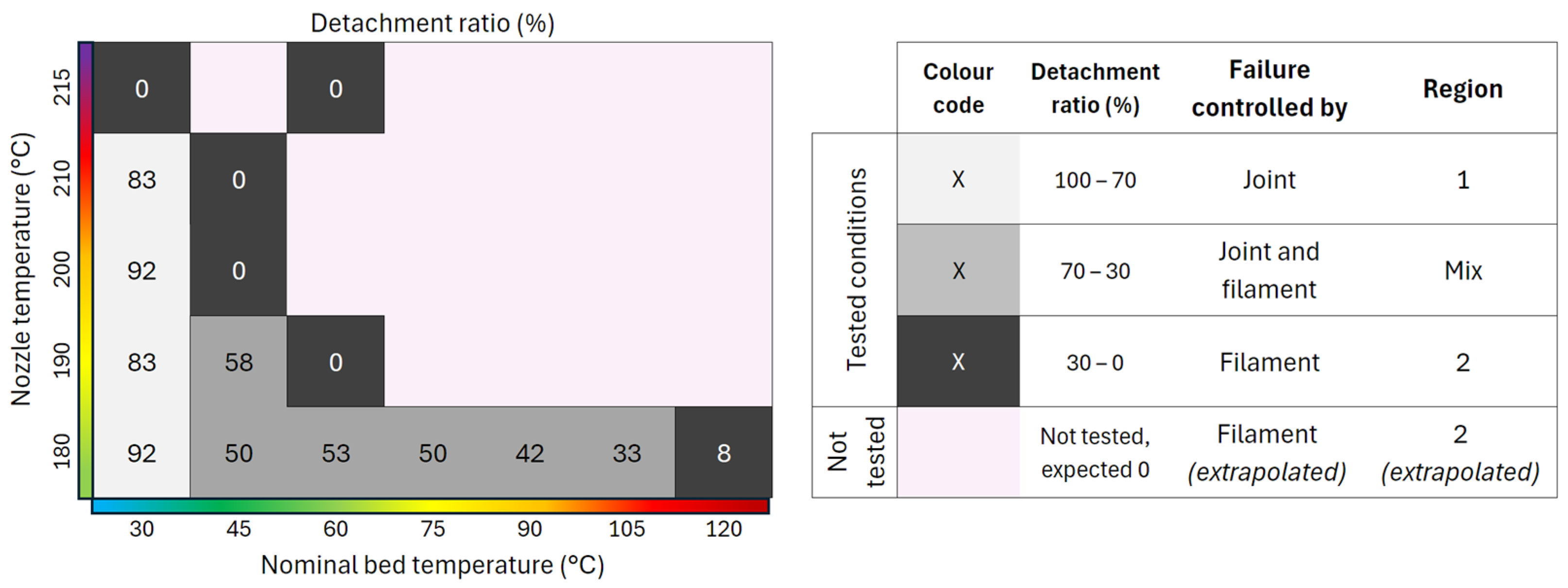

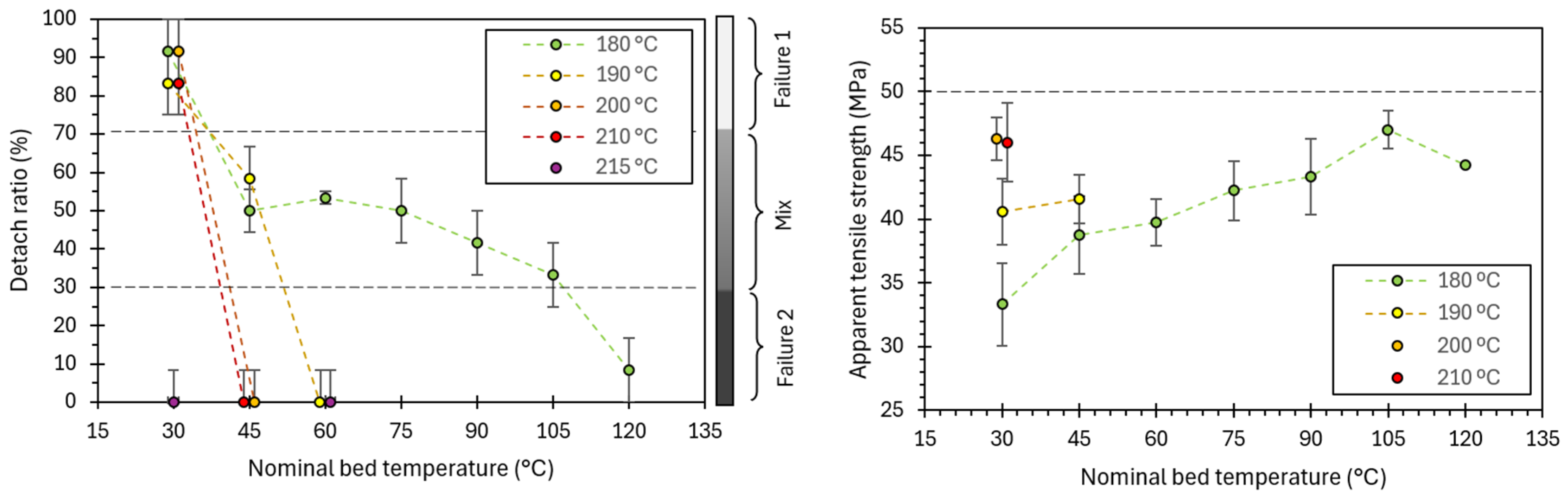

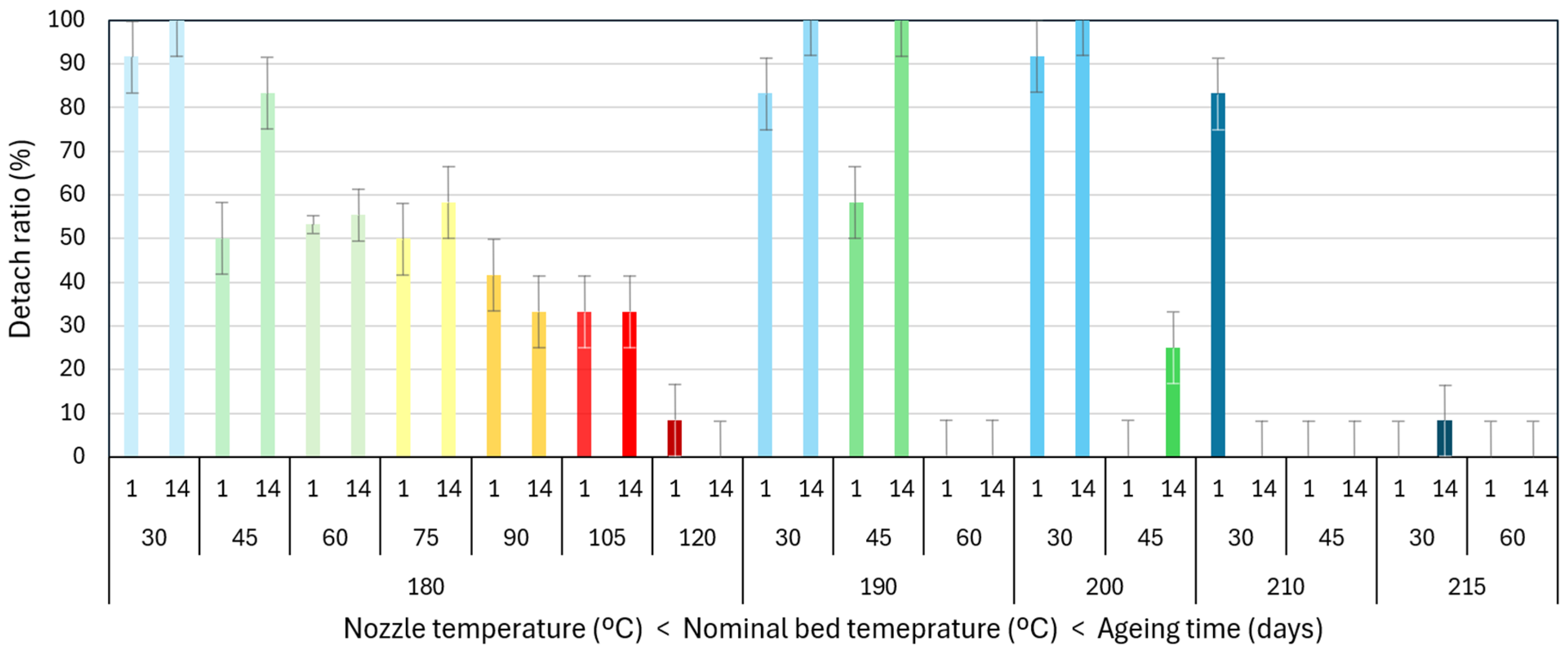

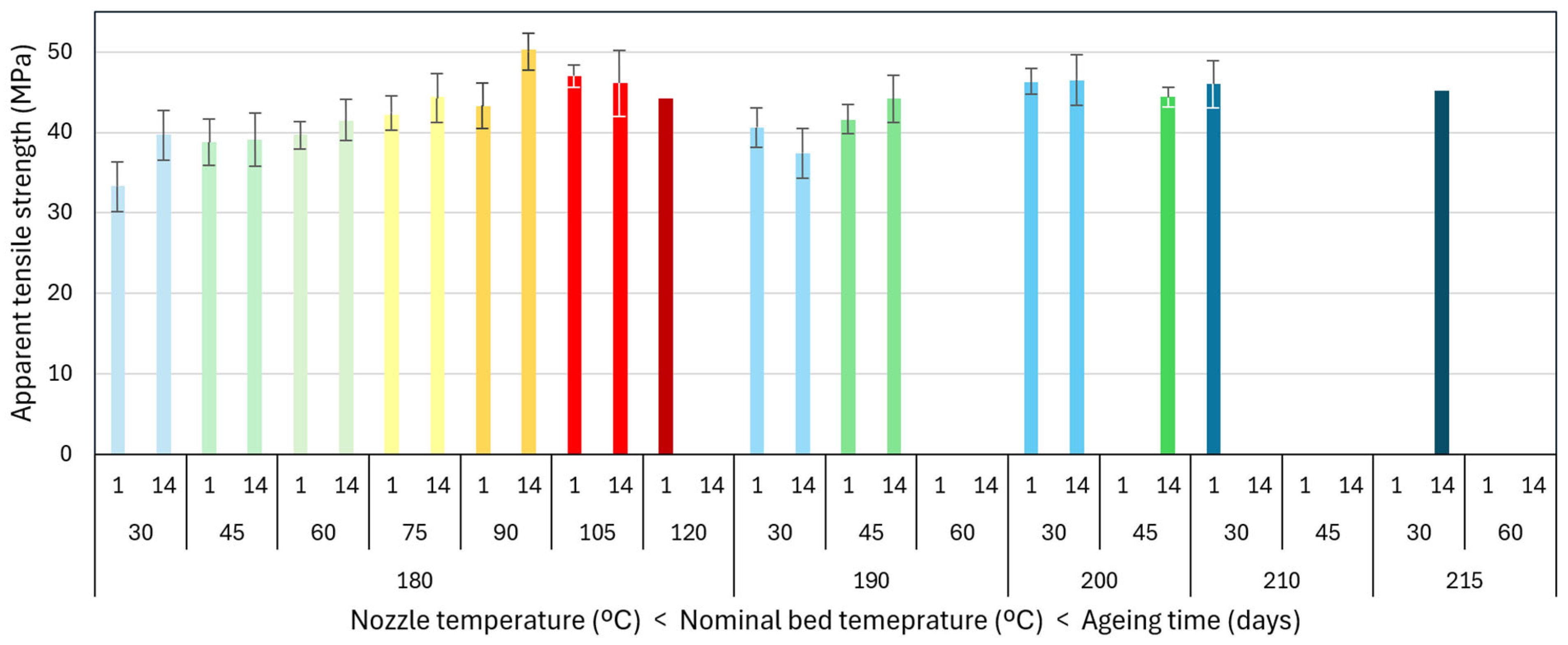

- Analyze the effect of the nozzle temperature (NT) and bed temperature (BT) on both the joint’s mechanical properties (apparent tensile strength) and the dominant failure mechanism.

- Additional findings and methodological scope, to document and critically interpret any additional observations of interest, clarifying the validity, limitations, and applicability of the proposed method.

2. Materials and Methods

2.1. Materials

2.2. Design of Samples and Clamps

2.2.1. Final Sample Design

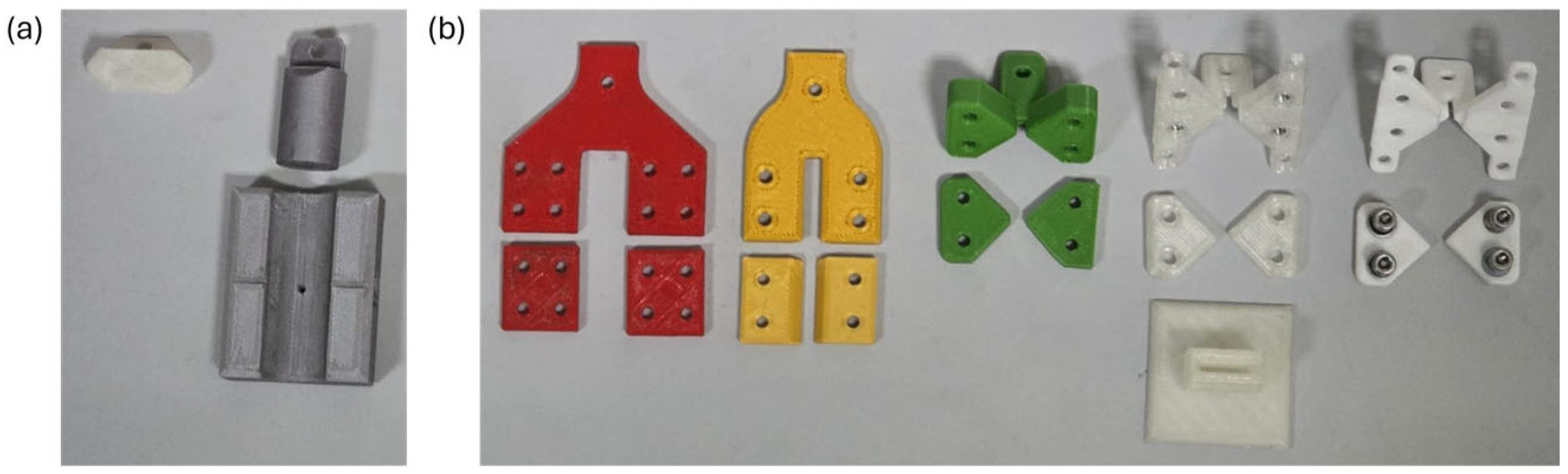

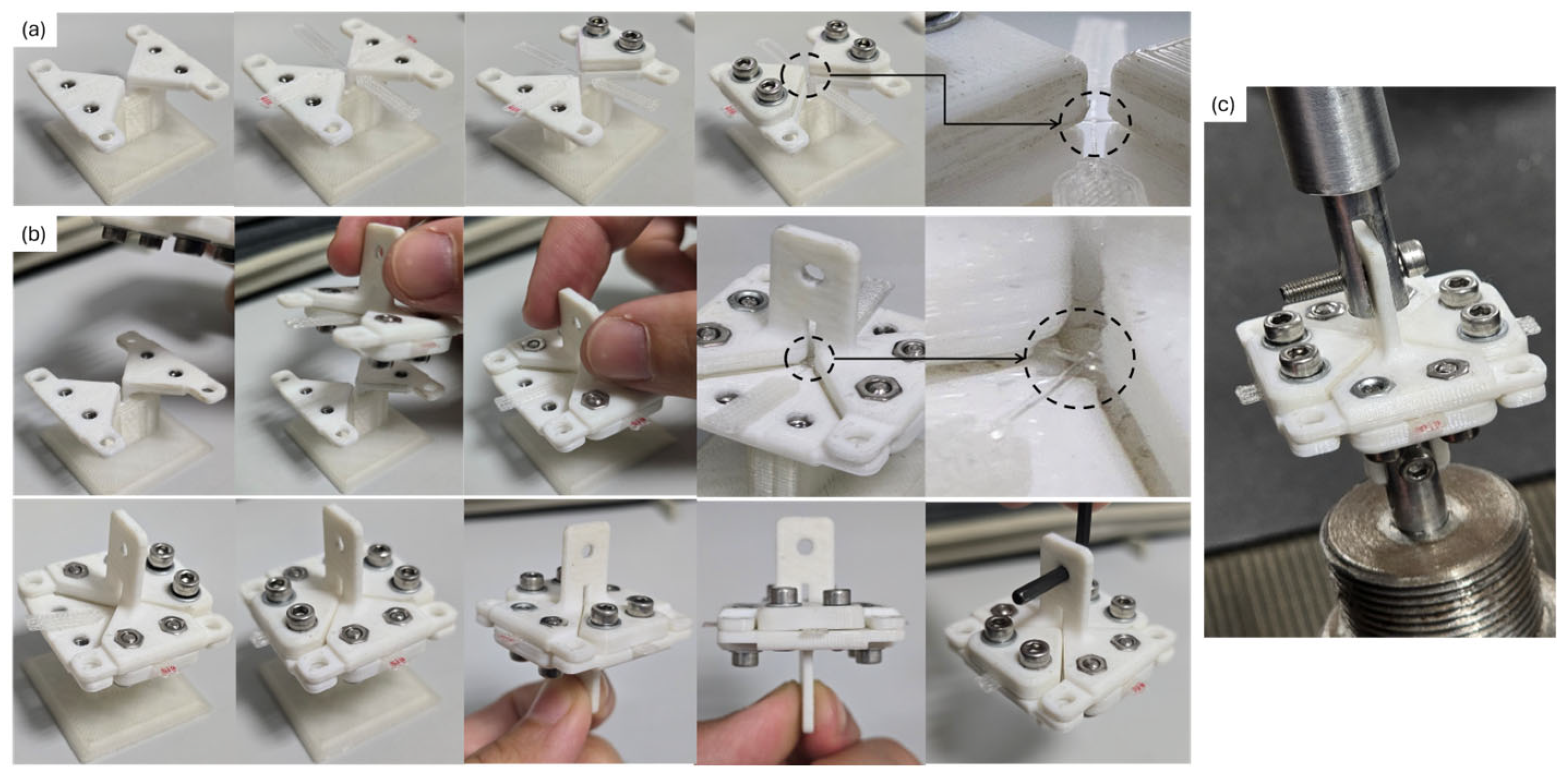

2.2.2. Clamp Designs for Mechanical Test Fixturing

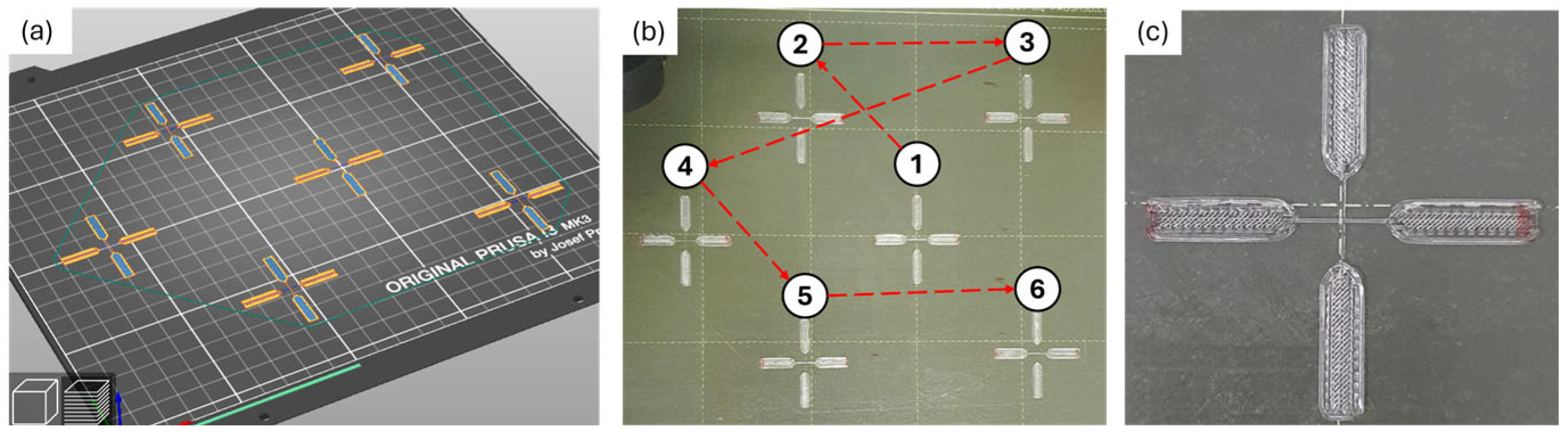

2.3. FDM Sample Production

2.3.1. FDM Printer

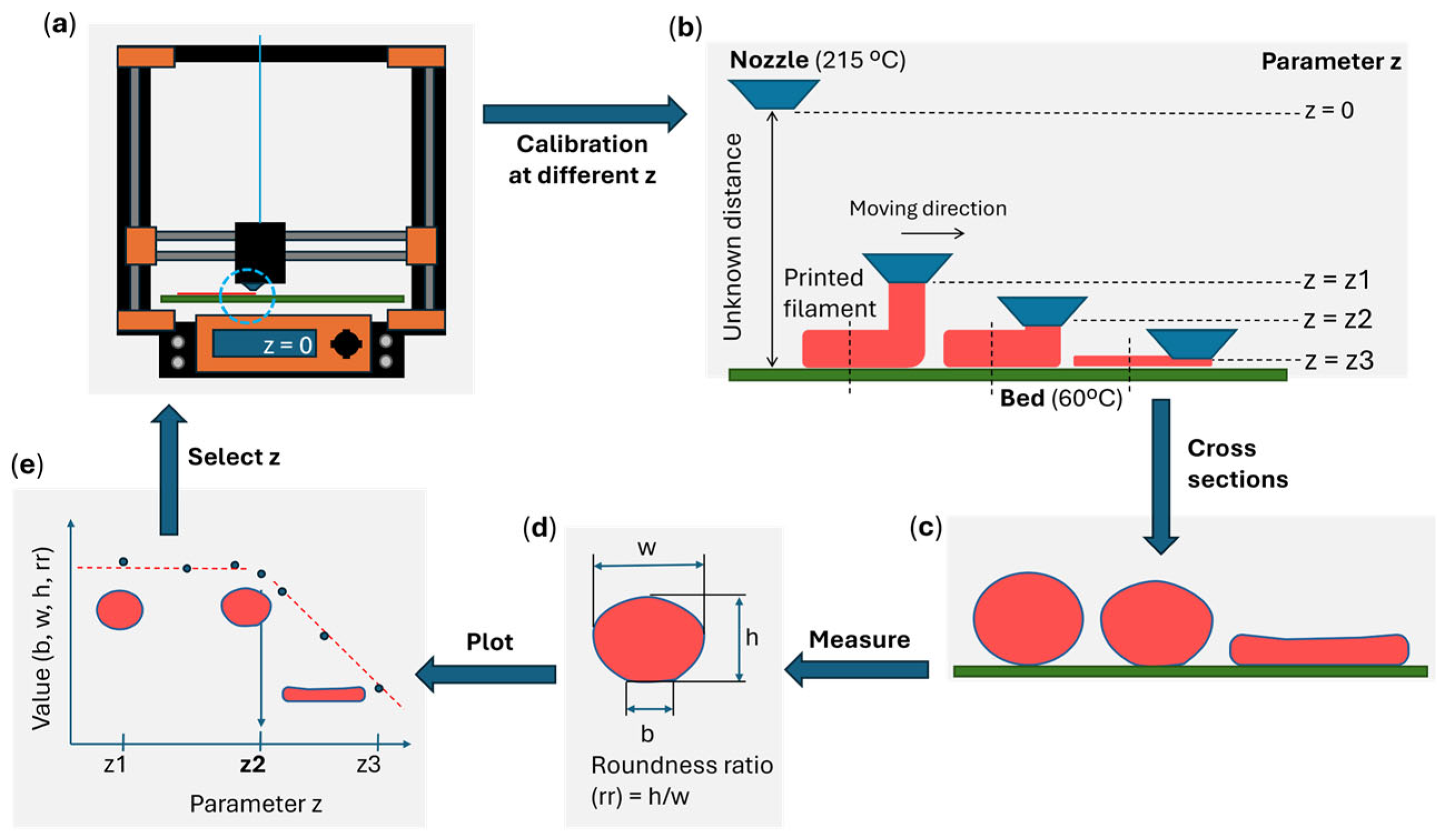

2.3.2. First-Layer Calibration

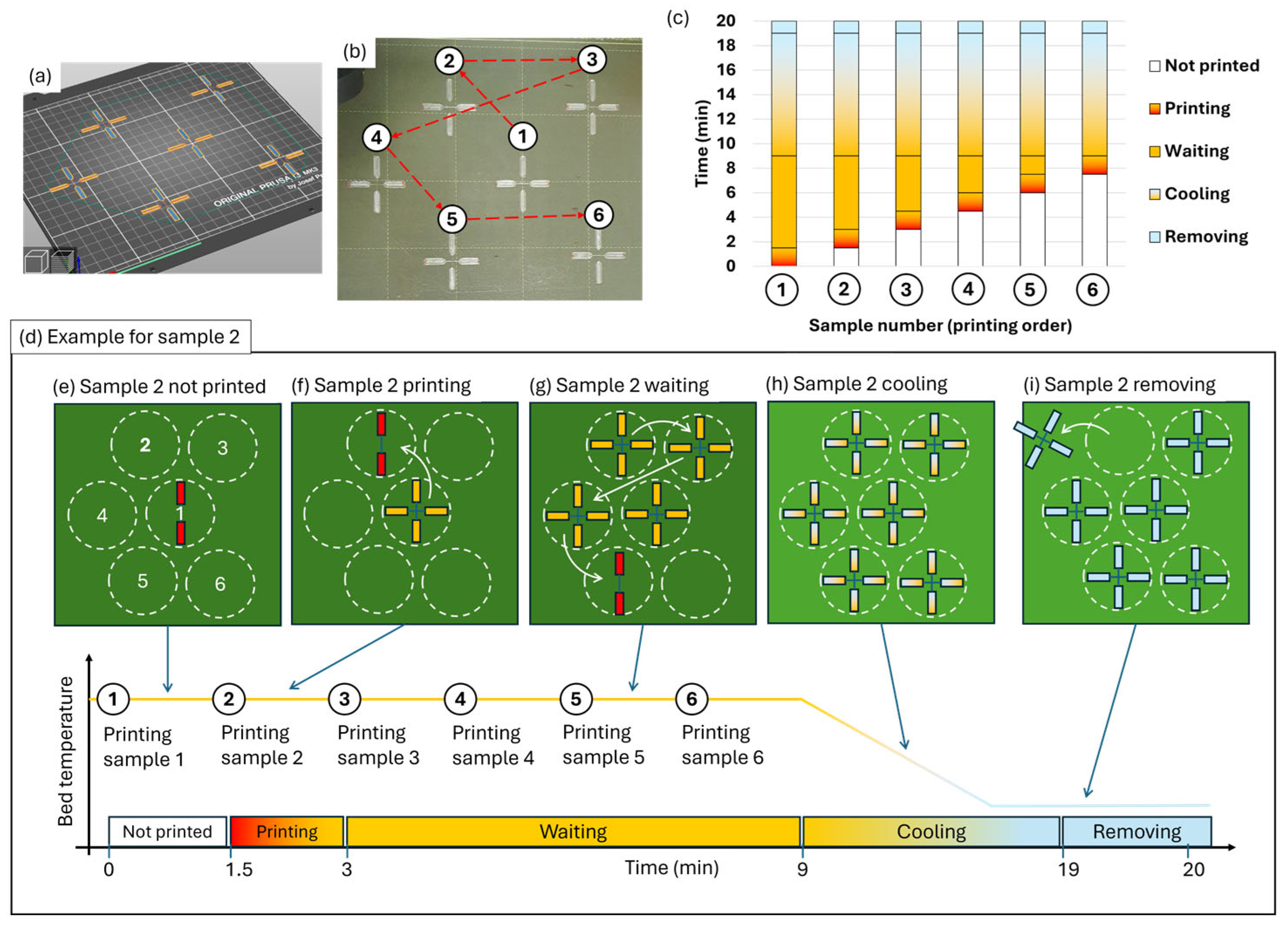

2.3.3. Printing Samples and Storage

2.3.4. Deciding Printing Temperatures

2.4. Characterization of Printed Samples

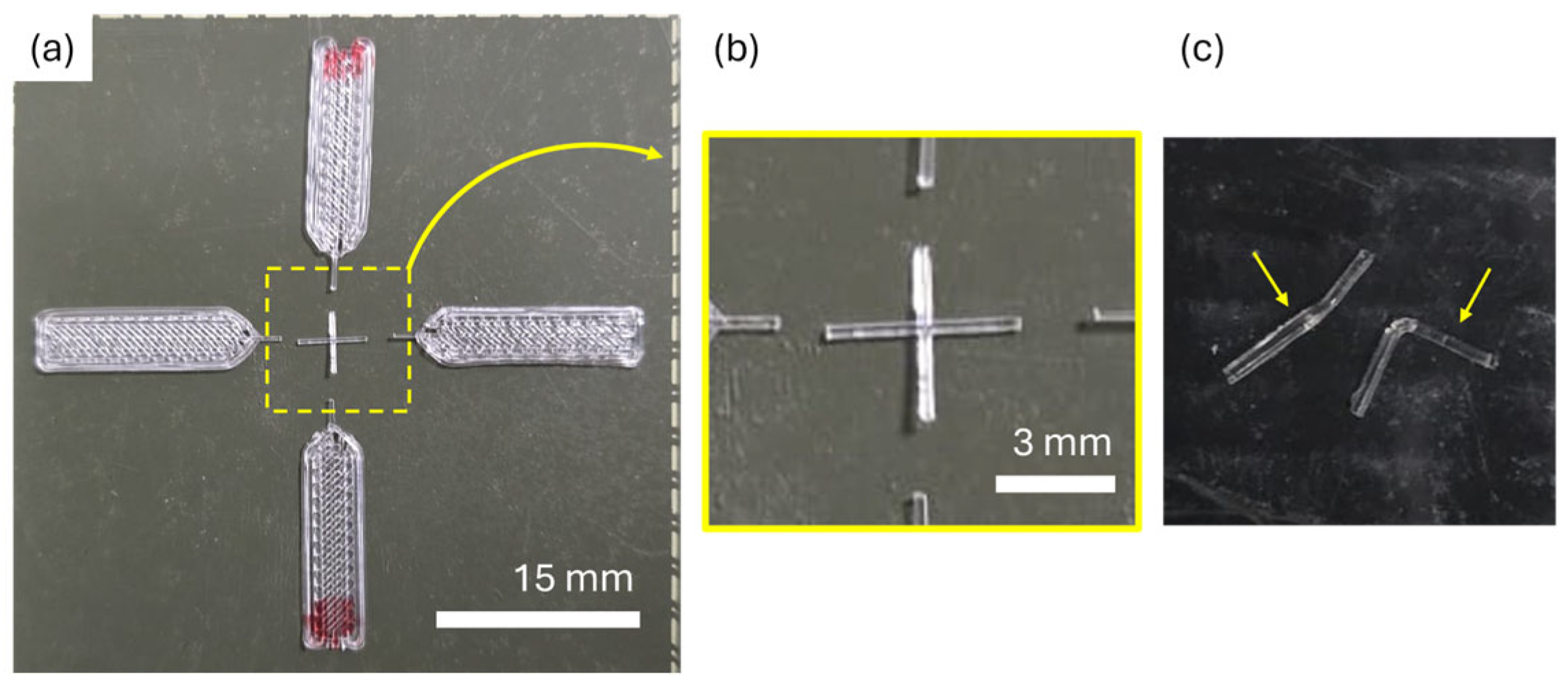

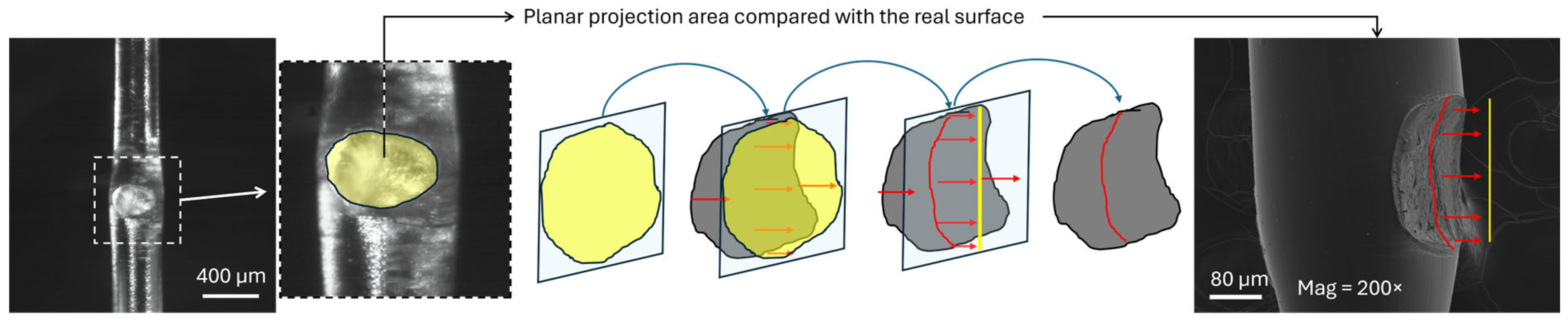

2.4.1. Optical and Fractographical Characterization

2.4.2. Thermal Characterization

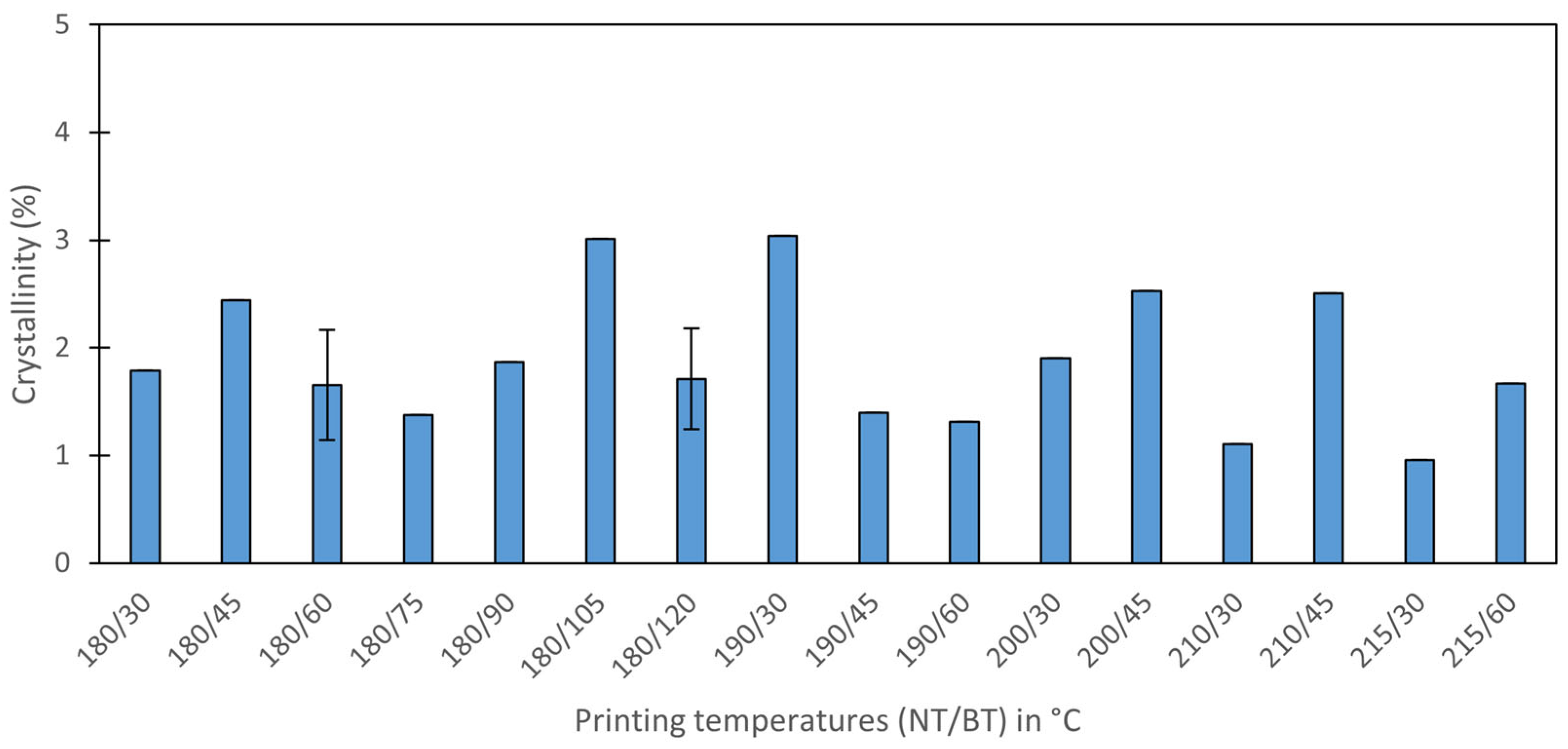

2.4.3. Mechanical Characterization

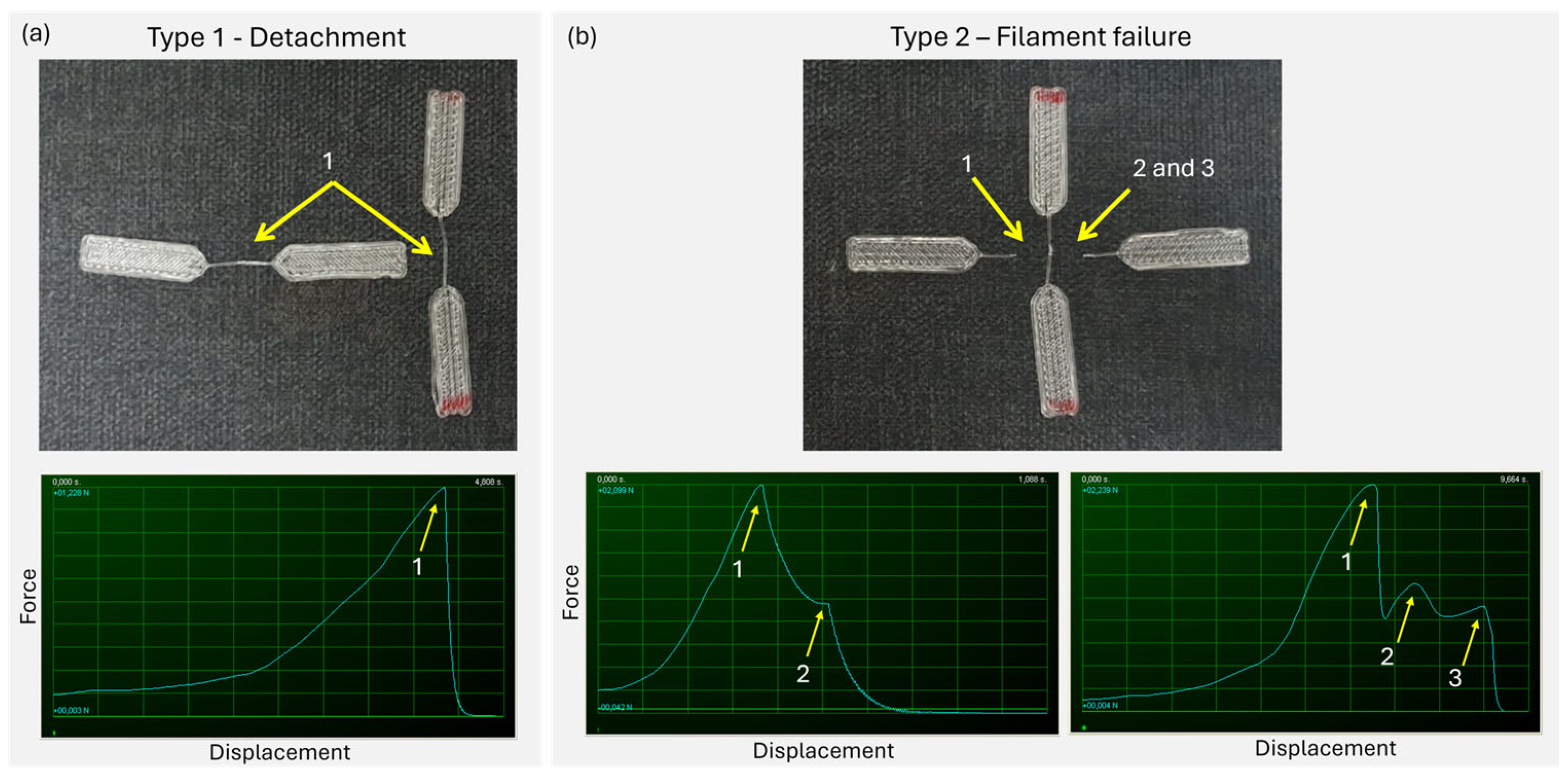

- Type 1: joint-controlled failure.

- Type 2: filament-controlled failure.

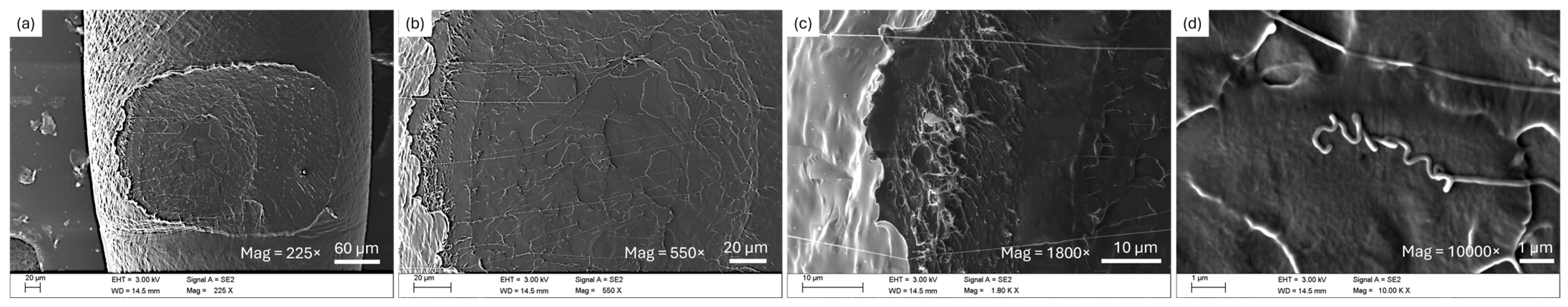

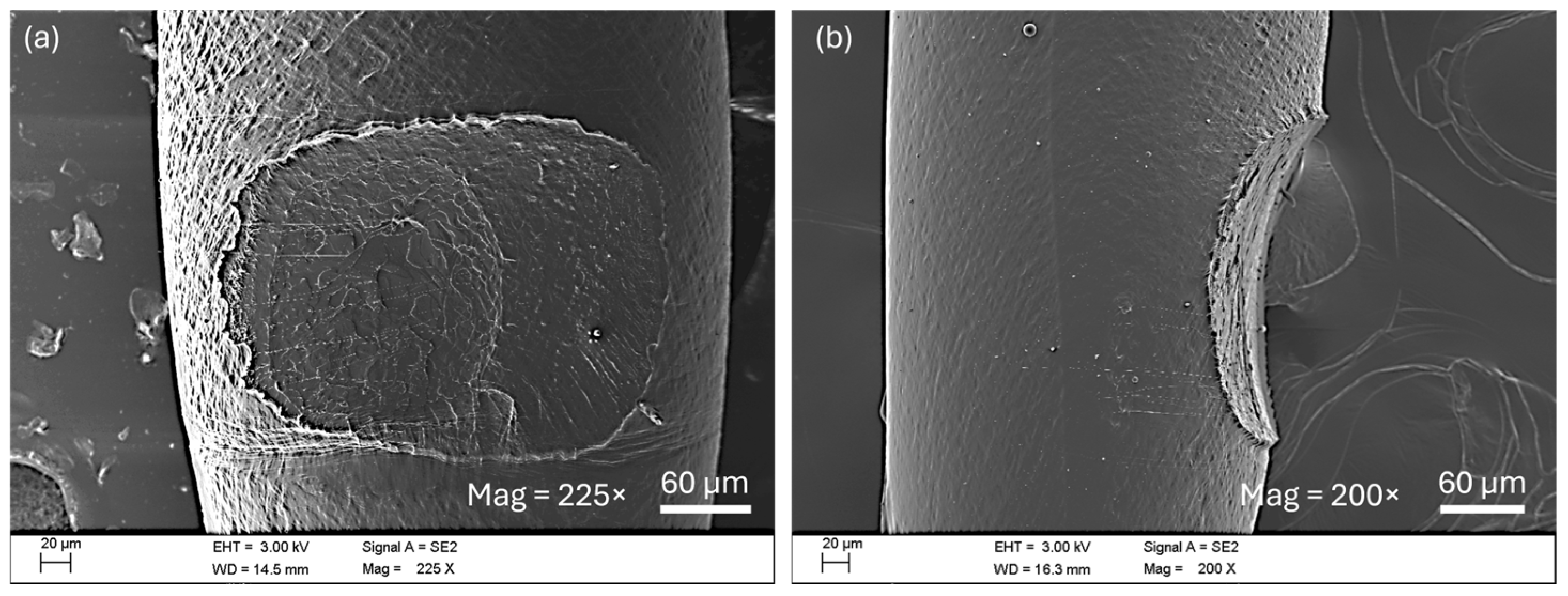

2.4.4. Fractographical Characterization

3. Results

3.1. Bed Temperature Characterization

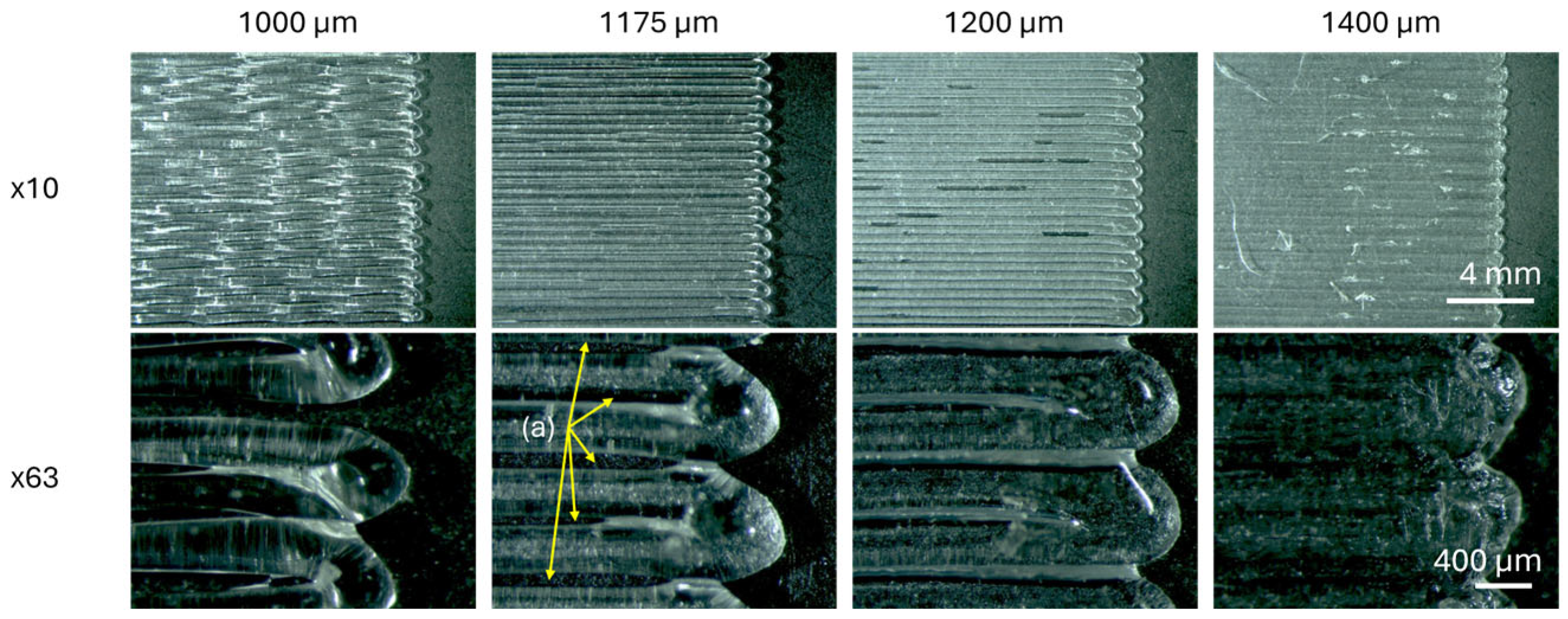

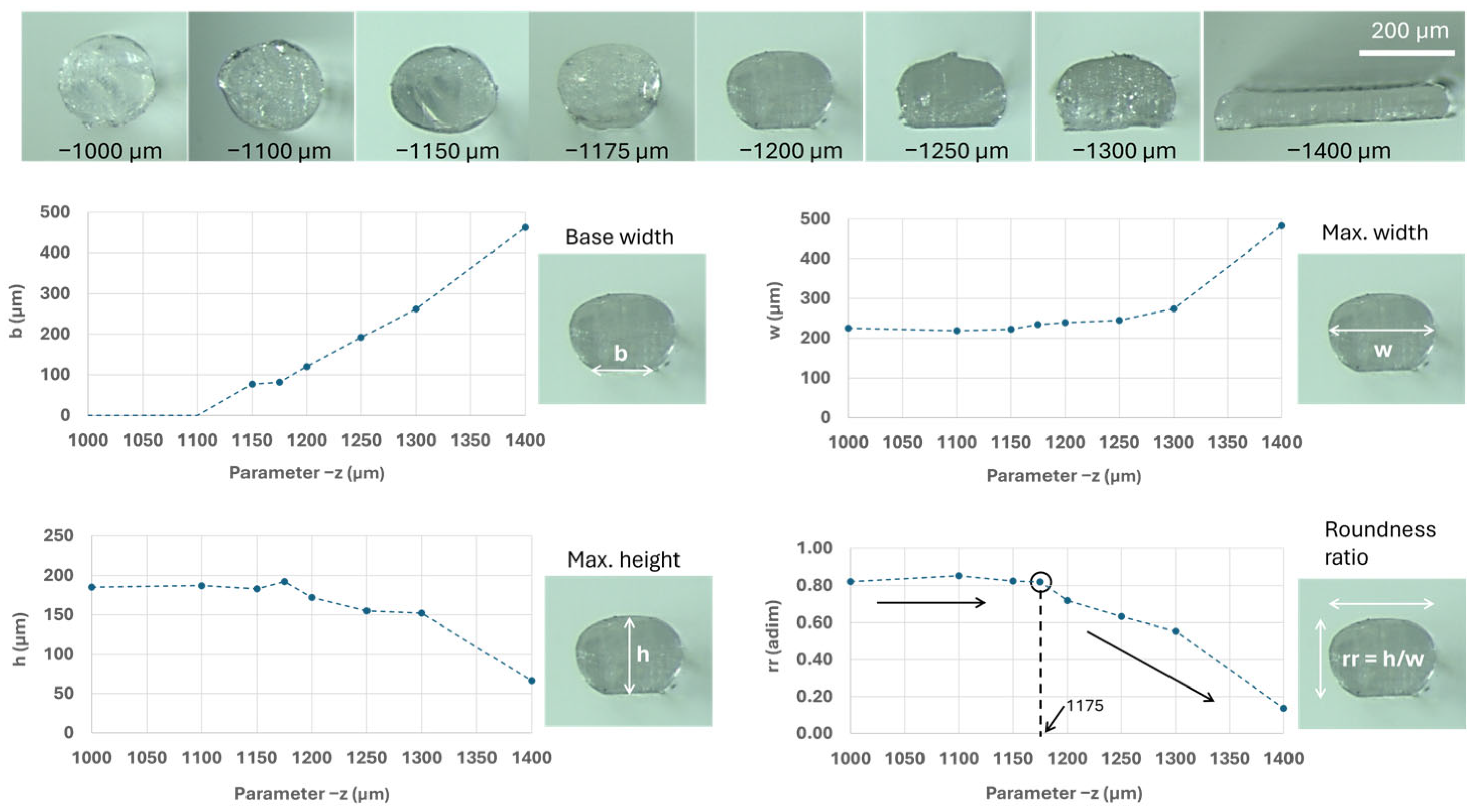

3.2. Calibration of Parameter z

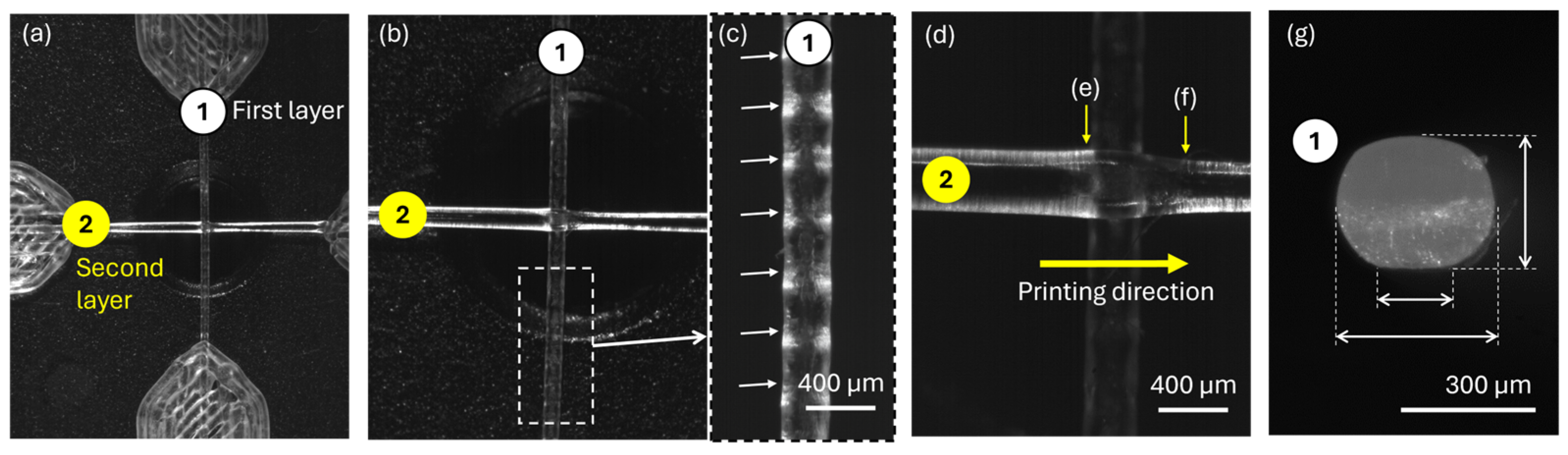

3.3. Optical Characterization of Printed Samples

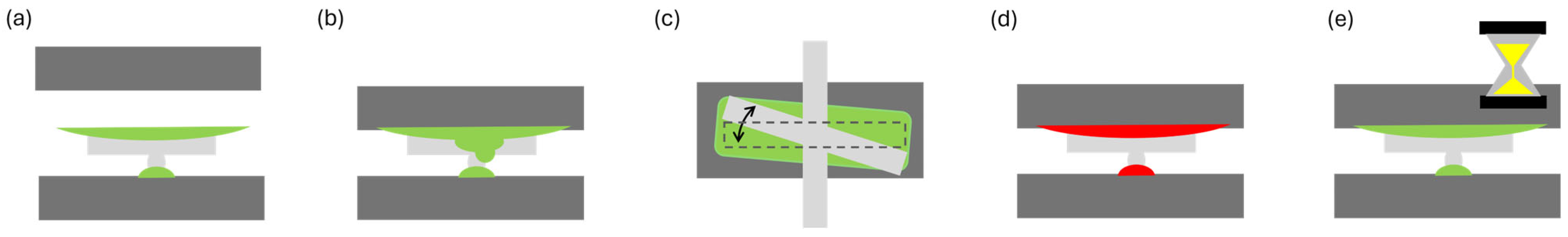

3.4. Clamping Methods

- Interface debonding: specimens frequently detached at the specimen–platen interface rather than failing at the intended interlayer bond, Figure 11a.

- Adhesive flow: capillary action causes the adhesive to flow into the joint region, locally reinforcing the joint, as shown in Figure 11b.

- Geometric distortion: differential adhesion to the support plates introduces twist and eccentricity, promoting bending and parasitic stresses in the joint (Figure 11c).

- Heating: specific formulations exhibited exothermic curing reactions, altering the thermal history of the printed polymer prior to testing (Figure 11d).

- Time penalties: epoxy and PU-based adhesives used required extended curing times to achieve adequate bond strength, thereby undermining the throughput objective of the method (Figure 11e).

- Clamp reusability: Each clamp had to be discarded after each test. It required printing many clamps, resulting in a subsequent time delay and increased material and energy consumption.

3.5. Tensile Test Failure Types

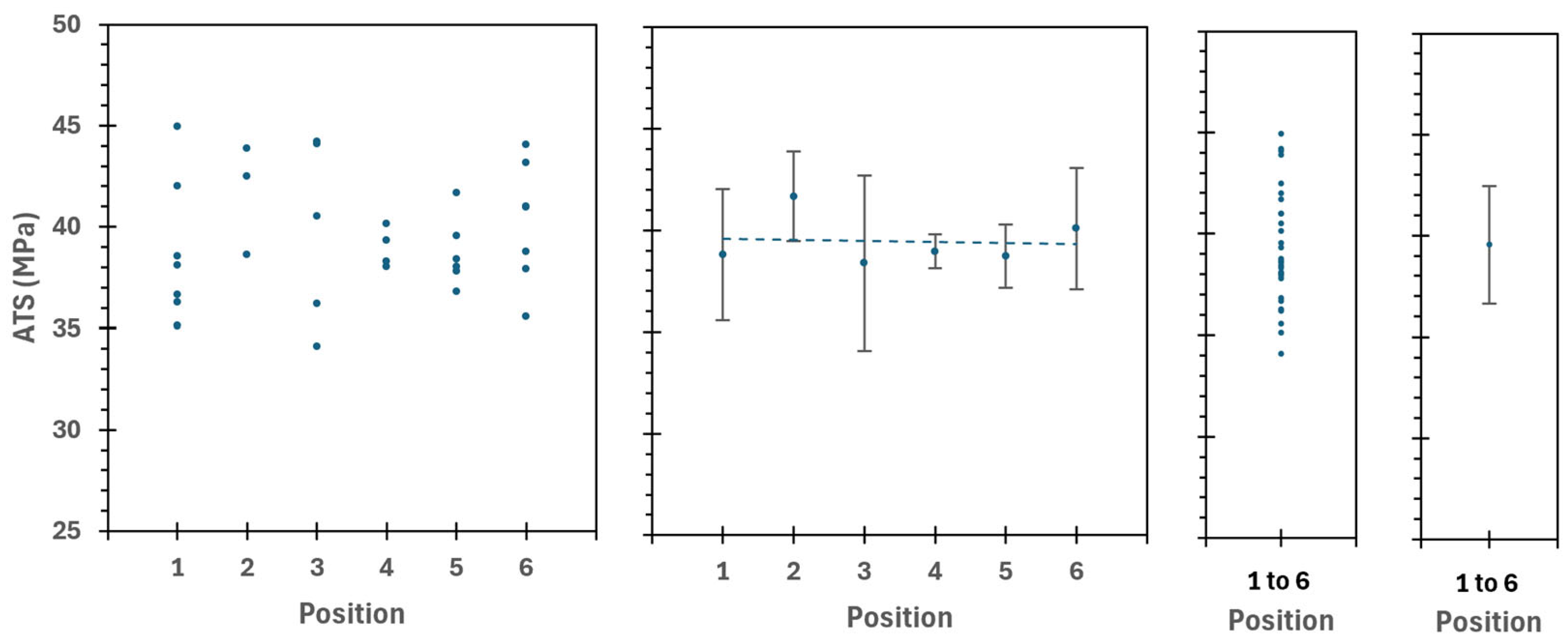

3.6. Effect of Printing Position

3.7. Effect of Printing Temperature

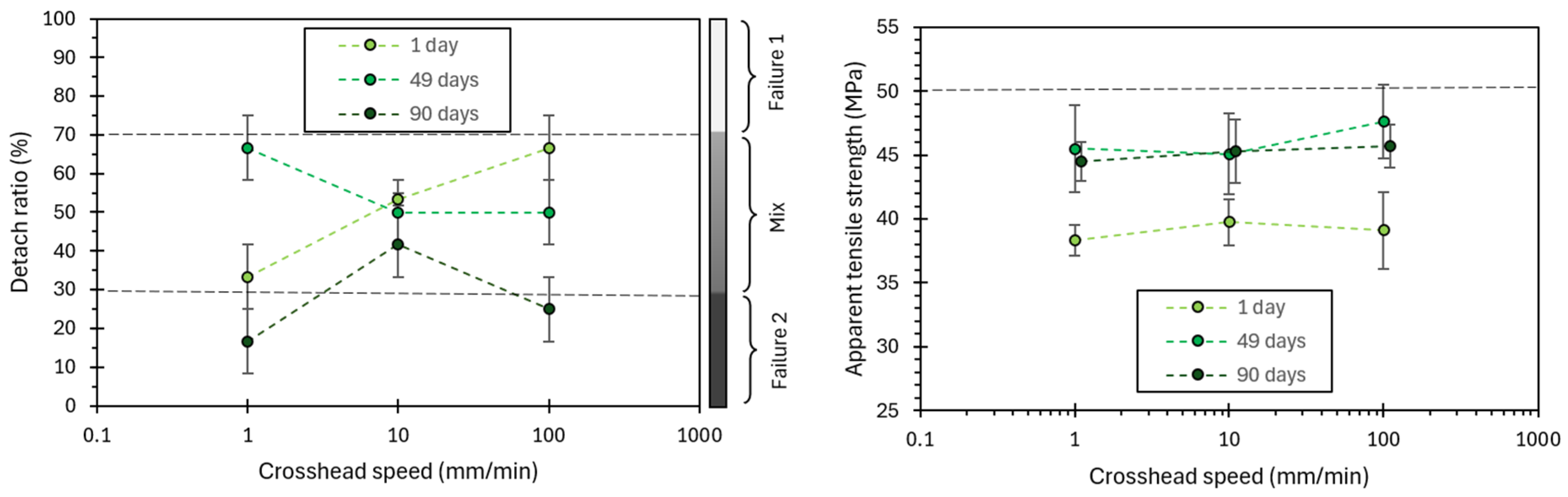

- Region 1 (joint-controlled): detachment ratio ≥ 70%.

- Mixed region: detachment ratio 30–70%, indicating coexistence of joint- and filament-controlled failures.

- Region 2 (filament-controlled): detachment ratio ≤ 30%. Extrapolation of the trends observed was used to extend this region.

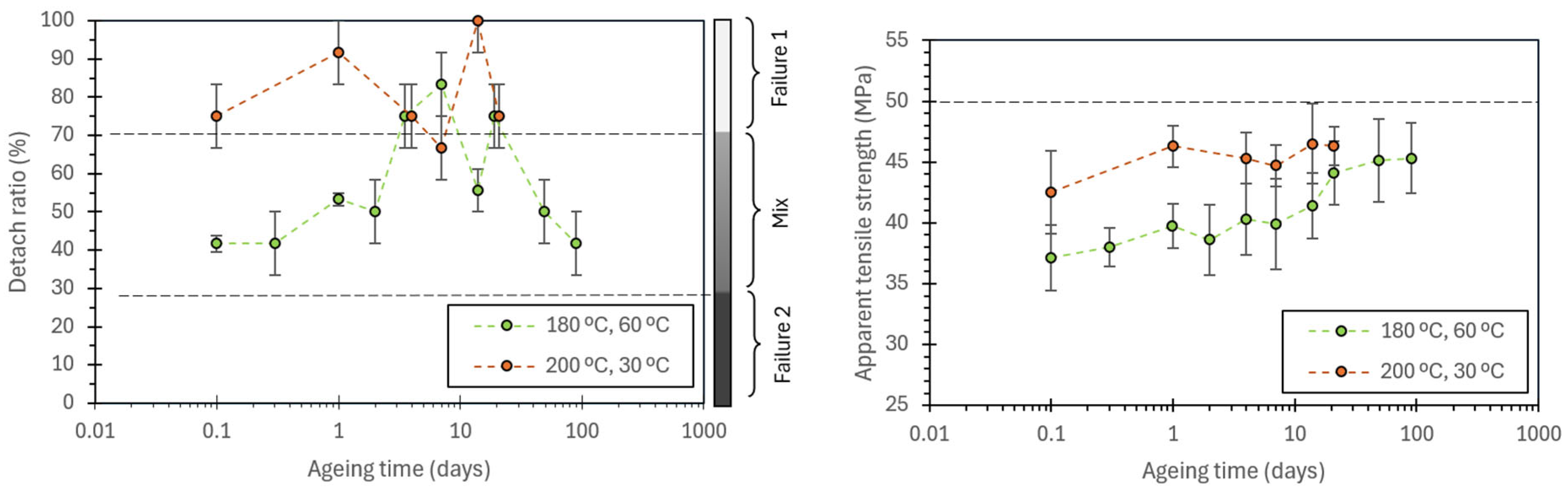

3.8. Effect of Storage Time

3.9. Effect of Crosshead Speed

4. Conclusions

- Sample design and fixturing. A cruciform specimen incorporating a single filament–filament joint was designed and evaluated under alternative clamping strategies. A rapid mechanical clamp proved the most reliable and operationally straightforward approach for high-throughput testing. Nevertheless, the current geometry constrains difficult direct tensile loading through the joint, which should be addressed in future iterations to reduce parasitic bending stresses.

- Failure mapping and strength metric. Cross-shaped specimens were printed, stored, and evaluated under controlled conditions, enabling a contextualized analysis of joint response. A detachment ratio (probability of detachment failure) was introduced to capture the binary nature of failure mechanisms (Type-1 vs. Type-2). For joints that detached, the apparent joint tensile strength, ATS, was computed from tensile data assisted by optical micrographs. This framework yielded a temperature–failure map that distinguishes joint-controlled from filament-controlled regimes.

- Thermal-processing effects. Nozzle temperature (NT) and bed temperature (BT) exerted significant and distinct influences. Increasing NT and BT reduced detachment probability and raised ATS. The response to NT displayed a threshold-like transition, consistent with enhanced chain mobility and interdiffusion at the weld, requiring a minimum of energy for it to happen. In contrast, BT produced a smoother trend, plausibly due to decreased cooling rates, slightly increasing the time that the joint is at the required temperatures for the interdiffusion of polymeric chains in contact in the joint.

- Upper bound in apparent tensile strength. A maximum value for the ATS was observed around 50 MPa. This plateau likely reflects that the limit is governed more by specimen geometry and boundary conditions than by the intrinsic strength of the polymer, which properties are closer to 62-65 MPa [43,44,45]. Within these boundaries, the ATS metrics remain coherent with the literature and was found useful for a first approach.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, L.; Miller, J.; Vezza, J.; Mayster, M.; Raffay, M.; Justice, Q.; Al Tamimi, Z.; Hansotte, G.; Sunkara, L.D.; Bernat, J. Additive Manufacturing: A Comprehensive Review. Sensors 2024, 24, 2668. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Patel, V.; Kumar, A.; Koppad, P.G. A Review of Various Materials for Additive Manufacturing: Recent Trends and Processing Issues. J. Mater. Res. Technol. 2022, 21, 2612–2641. [Google Scholar] [CrossRef]

- Danila, A.I.; Breban-Schwarzkopf, D.; Daescu, E.; Olariu, I.; Dinu, S. Systematic Review of the Quality of Stereolithographic Three-Dimensionally Printed Materials for Provisional Dental Restorations. Materials 2025, 18, 721. [Google Scholar] [CrossRef]

- Afridi, A.; Al Rashid, A.; Koç, M. Recent Advances in the Development of Stereolithography-Based Additive Manufacturing Processes: A Review of Applications and Challenges. Bioprinting 2024, 43, e00360. [Google Scholar] [CrossRef]

- Freire, J.J.; Vlahos, C.H.; Bol, R.J.M.; Šavija, B. Micromechanical Models for FDM 3D-Printed Polymers: A Review. Polymers 2023, 15, 4497. [Google Scholar] [CrossRef] [PubMed]

- Ben Said, L.; Ayadi, B.; Alharbi, S.; Dammak, F. Recent Advances in Additive Manufacturing: A Review of Current Developments and Future Directions. Machines 2025, 13, 813. [Google Scholar] [CrossRef]

- Elkaseer, A.; Chen, K.J.; Janhsen, J.C.; Refle, O.; Hagenmeyer, V.; Scholz, S.G. Material Jetting for Advanced Applications: A State-of-the-Art Review, Gaps and Future Directions. Addit. Manuf. 2022, 60, 103270. [Google Scholar] [CrossRef]

- Sivarupan, T.; Balasubramani, N.; Saxena, P.; Nagarajan, D.; El Mansori, M.; Salonitis, K.; Jolly, M.; Dargusch, M.S. A Review on the Progress and Challenges of Binder Jet 3D Printing of Sand Moulds for Advanced Casting. Addit. Manuf. 2021, 40, 101889. [Google Scholar] [CrossRef]

- Ghanadi, N.; Pasebani, S. A Review on Wire-Laser Directed Energy Deposition: Parameter Control, Process Stability, and Future Research Paths. J. Manuf. Mater. Process. 2024, 8, 84. [Google Scholar] [CrossRef]

- Jiao, M.; Long, H.; Xiao, B.; Liang, X.; Lin, F. Electron Beam Powder Bed Fusion Additive Manufacturing: A Comprehensive Review and Its Development in China. Addit. Manuf. Front. 2024, 3, 200177. [Google Scholar] [CrossRef]

- Alami, A.H.; Ghani Olabi, A.; Alashkar, A.; Alasad, S.; Aljaghoub, H.; Rezk, H.; Abdelkareem, M.A. Additive Manufacturing in the Aerospace and Automotive Industries: Recent Trends and Role in Achieving Sustainable Development Goals. Ain Shams Eng. J. 2023, 14, 102516. [Google Scholar] [CrossRef]

- Mobarak, M.H.; Abid, A.S.; Munna, M.S.; Dutta, M.; Rimon, M.I.H. Additive Manufacturing in Biomedical: Applications, Challenges, and Prospects. Hybrid. Adv. 2025, 10, 100467. [Google Scholar] [CrossRef]

- Kokane, S.B.; Anjaly, P.R.; Thangalakshmi, S.; Arora, V.K. Current Trends in Additive Manufacturing Based 4D Food Printing Technology: A Review. Future Foods 2024, 10, 100450. [Google Scholar] [CrossRef]

- Hamza, A.; Bousnina, K.; Dridi, I.; Ben Yahia, N. Revolutionizing Automotive Design: The Impact of Additive Manufacturing. Vehicles 2025, 7, 24. [Google Scholar] [CrossRef]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM Process Parameters Influence over the Mechanical Properties of Polymer Specimens: A Review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Li, H.; Wang, T.; Sun, J.; Yu, Z. The Effect of Process Parameters in Fused Deposition Modelling on Bonding Degree and Mechanical Properties. Rapid Prototyp. J. 2018, 24, 80–92. [Google Scholar] [CrossRef]

- Alzahrani, F.J.; Noor, H.; Coulter, J.P. An Investigation of the Effect of Layer-Building Time on the Interlayer Adhesion Strength in Polymer Additive Manufacturing. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), New Orleans, LA, USA, 29 October–2 November 2023; ASME: New York, NY, USA, 2024; Volume 3. [Google Scholar] [CrossRef]

- von Windheim, N.; Collinson, D.W.; Lau, T.; Brinson, L.C.; Gall, K. The Influence of Porosity, Crystallinity and Interlayer Adhesion on the Tensile Strength of 3D Printed Polylactic Acid (PLA). Rapid Prototyp. J. 2021, 27, 1327–1336. [Google Scholar] [CrossRef]

- Allum, J.; Moetazedian, A.; Gleadall, A.; Silberschmidt, V.V. Interlayer Bonding Has Bulk-Material Strength in Extrusion Additive Manufacturing: New Understanding of Anisotropy. Addit. Manuf. 2020, 34, 101297. [Google Scholar] [CrossRef]

- Fitzharris, E.R.; Watt, I.; Rosen, D.W.; Shofner, M.L. Interlayer Bonding Improvement of Material Extrusion Parts with Polyphenylene Sulfide Using the Taguchi Method. Addit. Manuf. 2018, 24, 287–297. [Google Scholar] [CrossRef]

- Perez, D.B.; Celik, E.; Karkkainen, R.L. Investigation of Interlayer Interface Strength and Print Morphology Effects in Fused Deposition Modeling 3D-Printed PLA. 3D Print Addit. Manuf. 2021, 8, 23. [Google Scholar] [CrossRef] [PubMed]

- Shanmugam, V.; Das, O.; Babu, K.; Marimuthu, U.; Veerasimman, A.; Johnson, D.J.; Neisiany, R.E.; Hedenqvist, M.S.; Ramakrishna, S.; Berto, F. Fatigue Behaviour of FDM-3D Printed Polymers, Polymeric Composites and Architected Cellular Materials. Int. J. Fatigue 2021, 143, 106007. [Google Scholar] [CrossRef]

- Liaw, C.Y.; Tolbert, J.W.; Chow, L.W.; Guvendiren, M. Interlayer Bonding Strength of 3D Printed PEEK Specimens. Soft Matter 2021, 17, 4775–4789. [Google Scholar] [CrossRef]

- Aliheidari, N.; Christ, J.; Tripuraneni, R.; Nadimpalli, S.; Ameli, A. Interlayer Adhesion and Fracture Resistance of Polymers Printed through Melt Extrusion Additive Manufacturing Process. Mater. Des. 2018, 156, 351–361. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, G.; Zheng, X.; Ni, Y.; Liu, F.; Liu, Y.; Xu, L.R. Efficient Characterization on the Interlayer Shear Strengths of 3D Printing Polymers. J. Mater. Res. Technol. 2023, 22, 2768–2780. [Google Scholar] [CrossRef]

- Davis, C.S.; Hillgartner, K.E.; Han, S.H.; Seppala, J.E. Mechanical Strength of Welding Zones Produced by Material Extrusion Additive Manufacturing. Addit. Manuf. 2017, 16, 162. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Parametric Appraisal of Mechanical Property of Fused Deposition Modelling Processed Parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Noori, H. Interlayer Fracture Energy of 3D-Printed PLA Material. Int. J. Adv. Manuf. Technol. 2019, 101, 1959–1965. [Google Scholar] [CrossRef]

- Pereira, R.B.D.; Pereira, E.B.; Oliveira, P.R.; Christoforo, A.L.; del Pino, G.G.; Panzera, T.H. The Effect of Printing Parameters on the Tensile Properties of Bidirectional PLA Structures: A Statistical Approach. Prog. Addit. Manuf. 2023, 8, 519–527. [Google Scholar] [CrossRef]

- Kuznetsov, V.E.; Solonin, A.N.; Urzhumtsev, O.D.; Schilling, R.; Tavitov, A.G. Strength of PLA Components Fabricated with Fused Deposition Technology Using a Desktop 3D Printer as a Function of Geometrical Parameters of the Process. Polymers 2018, 10, 313. [Google Scholar] [CrossRef] [PubMed]

- Hashemi Sanatgar, R.; Campagne, C.; Nierstrasz, V. Investigation of the Adhesion Properties of Direct 3D Printing of Polymers and Nanocomposites on Textiles: Effect of FDM Printing Process Parameters. Appl. Surf. Sci. 2017, 403, 551–563. [Google Scholar] [CrossRef]

- Coogan, T.J.; Kazmer, D.O. Healing Simulation for Bond Strength Prediction of FDM. Rapid Prototyp. J. 2017, 23, 551–561. [Google Scholar] [CrossRef]

- Quan, R.; Cantero Chinchilla, S.; Liu, F. Investigation of the Effects of 3D Printing Parameters on the Mechanical Properties of Bone Scaffolds: Experimental Study Integrated with Artificial Neural Networks. Bioengineering 2025, 12, 315. [Google Scholar] [CrossRef]

- Sabyrov, N.; Abilgaziyev, A.; Ali, M.H. Enhancing Interlayer Bonding Strength of FDM 3D Printing Technology by Diode Laser-Assisted System. Int. J. Adv. Manuf. Technol. 2020, 108, 603–611. [Google Scholar] [CrossRef]

- ELDeeb, I.S.; Esmael, E.; Ebied, S.; Diab, M.R.; Dekis, M.; Petrov, M.A.; Zayed, A.A.; Egiza, M. Optimization of Nozzle Diameter and Printing Speed for Enhanced Tensile Performance of FFF 3D-Printed ABS and PLA. J. Manuf. Mater. Process. 2025, 9, 221. [Google Scholar] [CrossRef]

- Allum, J.; Moetazedian, A.; Gleadall, A.; Mitchell, N.; Marinopoulos, T.; McAdam, I.; Li, S.; Silberschmidt, V.V. Extra-Wide Deposition in Extrusion Additive Manufacturing: A New Convention for Improved Interlayer Mechanical Performance. Addit. Manuf. 2023, 61, 103334. [Google Scholar] [CrossRef]

- Collinson, D.W.; von Windheim, N.; Gall, K.; Brinson, L.C. Direct Evidence of Interfacial Crystallization Preventing Weld Formation during Fused Filament Fabrication of Poly(Ether Ether Ketone). Addit. Manuf. 2022, 51, 102604. [Google Scholar] [CrossRef]

- Zatloukal, J.; Viry, M.; Mizera, A.; Stoklásek, P.; Miškařík, L.; Bednařík, M. Optimizing Interfacial Adhesion and Mechanical Performance of Multimaterial Joints Fabricated by Material Extrusion. Materials 2025, 18, 3846. [Google Scholar] [CrossRef]

- Batista, M.; Ramirez-Peña, M.; Salguero, J.; Vazquez-Martinez, J.M. Optimization of Fused Filament Fabrication for High-Performance Polylactic Acid Parts under Wear Conditions. Lubricants 2024, 12, 281. [Google Scholar] [CrossRef]

- Naveed, N. Investigating the Material Properties and Microstructural Changes of Fused Filament Fabricated PLA and Tough-PLA Parts. Polymers 2021, 13, 1487. [Google Scholar] [CrossRef]

- Balaji, D.; Arulmurugan, B.; Bhuvaneswari, V. Effects of Infill Patterns on the Mechanical and Tribological Behaviour of 3D-Printed Polylactic Acid/Bamboo Biocomposites for Structural Applications. Polymers 2025, 17, 448. [Google Scholar] [CrossRef]

- Aktepe, E.; Ergün, U. Machine Learning Approaches for FDM-Based 3D Printing: A Literature Review. Appl. Sci. 2025, 15, 10001. [Google Scholar] [CrossRef]

- Orellana-Barrasa, J.; Tarancón, S.; Pastor, J.Y. Effects of Accelerating the Ageing of 1D PLA Filaments after Fused Filament Fabrication. Polymers 2023, 15, 69. [Google Scholar] [CrossRef]

- Molinari, G.; Parlanti, P.; Passaglia, E.; Aiello, F.; Gemmi, M.; Lazzeri, A.; Righetti, M.C. Dependence of the Crystal Structure on the D-Units Amount in Semi-Crystalline Poly(Lactic Acid). Int. J. Biol. Macromol. 2024, 281, 136296. [Google Scholar] [CrossRef]

- Barrasa, J.O.; Ferrández-Montero, A.; Ferrari, B.; Pastor, J.Y. Characterisation and Modelling of PLA Filaments and Evolution with Time. Polymers 2021, 13, 2899. [Google Scholar] [CrossRef]

- ISO 527-1:2019; Plastics—Determination of Tensile Properties—Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 291:2008; Plastics—Standard Atmospheres for Conditioning and Testing. International Organization for Standardization: Geneva, Switzerland, 2008.

- Hsieh, Y.T.; Nozaki, S.; Kido, M.; Kamitani, K.; Kojio, K.; Takahara, A. Crystal Polymorphism of Polylactide and Its Composites by X-Ray Diffraction Study. Polym. J. 2020, 52, 755–763. [Google Scholar] [CrossRef]

- Pastor, J.Y.; Orellana-Barrasa, J.; Ferrández-Montero, A.; Ferrari, B.; Boccaccini, A.R. Mechanical, Thermal, and Chemical Properties of PLA-Mg Filaments Produced via Colloidal Route for Fused Filament Fabrication. Polymers 2022, 14, 5414. [Google Scholar] [CrossRef]

- Ferrández-Montero, A.; Lieblich, M.; Benavente, R.; González-Carrasco, J.L.; Ferrari, B. Study of the Matrix-Filler Interface in PLA/Mg Composites Manufactured by Material Extrusion Using a Colloidal Feedstock. Addit. Manuf. 2020, 33, 101142. [Google Scholar] [CrossRef]

- Aliotta, L.; Sciara, L.M.; Cinelli, P.; Canesi, I.; Lazzeri, A. Improvement of the PLA Crystallinity and Heat Distortion Temperature Optimizing the Content of Nucleating Agents and the Injection Molding Cycle Time. Polymers 2022, 14, 977. [Google Scholar] [CrossRef]

| Nominal (°C) | Minimum (°C) | Maximum (°C) | Average (°C) | Difference (°C) |

|---|---|---|---|---|

| 30 | 29.0 | 30.6 | 29.8 | −0.2 |

| 45 | 44.8 | 45.9 | 45.4 | +0.4 |

| 60 | 55.4 | 58.4 | 56.9 | −3.1 |

| 75 | 68.4 | 71.5 | 70.0 | −5.0 |

| 90 | 81.7 | 83.1 | 82.4 | −7.6 |

| 105 | 96.0 | 96.9 | 96.5 | −8.5 |

| 120 | 109.6 | 112.3 | 111.0 | −9.0 |

| Nozzle Temperature (°C) | Nominal Bed Temperature (°C) | Ageing Time (Days) | Position | Samples Tested (n) | Crystallinity (%) |

|---|---|---|---|---|---|

| 180 | 30 | 0 | 1 | 1 | 1.8 |

| 180 | 45 | 0 | 1 | 1 | 2.4 |

| 180 | 60 | 0 | 1 | 3 | 1.7 ± 0.5 |

| 180 | 75 | 0 | 1 | 1 | 1.4 |

| 180 | 90 | 0 | 1 | 1 | 1.9 |

| 180 | 105 | 0 | 1 | 1 | 3.0 |

| 180 | 120 | 0 | 1 | 3 | 1.7 ± 0.5 |

| 190 | 30 | 0 | 1 | 1 | 3.1 |

| 190 | 45 | 0 | 1 | 1 | 1.4 |

| 190 | 60 | 0 | 1 | 1 | 1.3 |

| 200 | 30 | 0 | 1 | 1 | 1.9 |

| 200 | 45 | 0 | 1 | 1 | 2.5 |

| 210 | 30 | 0 | 1 | 1 | 1.1 |

| 210 | 45 | 0 | 1 | 1 | 2.5 |

| 215 | 30 | 0 | 1 | 1 | 1.0 |

| 215 | 60 | 0 | 1 | 1 | 1.6 |

| Nozzle Temperature (°C) | Nominal Bed Temperature (°C) | Ageing Time (Days) | Crosshead Speed (mm/min) | Samples Tested | Detachment Ratio | Apparent Tensile Strength (MPa) |

|---|---|---|---|---|---|---|

| 180 | 30 | 1 | 10 | 12 | 0.92 ± 0.08 | 33 ± 3 |

| 180 | 45 | 1 | 10 | 18 | 0.50 ± 0.06 | 39 ± 3 |

| 180 | 60 | 1 | 10 | 60 | 0.53 ± 0.02 | 40 ± 3 |

| 180 | 75 | 1 | 10 | 12 | 0.50 ± 0.06 | 42 ± 2 |

| 180 | 90 | 1 | 10 | 12 | 0.42 ± 0.08 | 43 ± 3 |

| 180 | 105 | 1 | 10 | 12 | 0.33 ± 0.08 | 47 ± 2 |

| 180 | 120 | 1 | 10 | 12 | 0.08 ± 0.08 | 44 ± 2 |

| 190 | 30 | 1 | 10 | 12 | 0.83 ± 0.08 | 41 ± 3 |

| 190 | 45 | 1 | 10 | 12 | 0.58 ± 0.08 | 42 ± 2 |

| 190 | 60 | 1 | 10 | 12 | 0.00 + 0.08 | - |

| 200 | 30 | 1 | 10 | 12 | 0.92 ± 0.08 | 46 ± 2 |

| 200 | 45 | 1 | 10 | 12 | 0.00 + 0.08 | - |

| 210 | 30 | 1 | 10 | 12 | 0.83 ± 0.08 | 46 ± 3 |

| 210 | 45 | 1 | 10 | 12 | 0.00 + 0.08 | - |

| 215 | 30 | 1 | 10 | 12 | 0.00 + 0.08 | - |

| 215 | 60 | 1 | 10 | 12 | 0.00 + 0.08 | - |

| Nozzle Temperature (°C) | Nominal Bed Temperature (°C) | Ageing Time (Days) | Crosshead Speed (mm/min) | Samples Tested | Detachment Ratio | Apparent Tensile Strength (MPa) |

|---|---|---|---|---|---|---|

| 180 | 60 | 0.1 | 10 | 48 | 0.42 ± 0.02 | 37 ± 3 |

| 180 | 60 | 0.3 | 10 | 12 | 0.42 ± 0.08 | 38 ± 2 |

| 180 | 60 | 1 | 10 | 60 | 0.53 ± 0.02 | 40 ± 3 |

| 180 | 60 | 2 | 10 | 12 | 0.50 ± 0.08 | 39 ± 3 |

| 180 | 60 | 4 | 10 | 12 | 0.75 ± 0.08 | 40 ± 3 |

| 180 | 60 | 7 | 10 | 12 | 0.83 ± 0.08 | 40 ± 4 |

| 180 | 60 | 14 | 10 | 18 | 0.56 ± 0.06 | 41 ± 3 |

| 180 | 60 | 21 | 10 | 12 | 0.75 ± 0.08 | 44 ± 3 |

| 180 | 60 | 49 | 10 | 12 | 0.50 ± 0.08 | 45 ± 4 |

| 180 | 60 | 90 | 10 | 12 | 0.42 ± 0.08 | 45 ± 3 |

| 200 | 30 | 0.1 | 10 | 12 | 0.75 ± 0.08 | 43 ± 3 |

| 200 | 30 | 1 | 10 | 12 | 0.92 ± 0.08 | 46 ± 2 |

| 200 | 30 | 4 | 10 | 12 | 0.75 ± 0.08 | 45 ± 2 |

| 200 | 30 | 7 | 10 | 12 | 0.67 ± 0.08 | 45 ± 2 |

| 200 | 30 | 14 | 10 | 12 | 1.00 ± 0.08 | 47 ± 3 |

| 200 | 30 | 21 | 10 | 12 | 0.75 + 0.08 | 46 ± 2 |

| Nozzle Temperature (°C) | Nominal Bed Temperature (°C) | Ageing Time (Days) | Crosshead Speed (mm/min) | Samples Tested | Detach Ratio | Apparent Tensile Strength (MPa) |

|---|---|---|---|---|---|---|

| 180 | 30 | 14 | 10 | 12 | 1.00 − 0.08 | 40 ± 3 |

| 180 | 45 | 14 | 10 | 12 | 0.83 ± 0.08 | 39 ± 3 |

| 180 | 60 | 14 | 10 | 18 | 0.56 ± 0.06 | 41 ± 3 |

| 180 | 75 | 14 | 10 | 12 | 0.58 ± 0.08 | 44 ± 3 |

| 180 | 90 | 14 | 10 | 12 | 0.33 ± 0.08 | 50 ± 2 |

| 180 | 105 | 14 | 10 | 12 | 0.33 ± 0.08 | 46 ± 4 |

| 180 | 120 | 14 | 10 | 12 | 0.00 + 0.08 | - |

| 190 | 30 | 14 | 10 | 12 | 1.00 − 0.08 | 37 ± 3 |

| 190 | 45 | 14 | 10 | 12 | 1.00 − 0.08 | 44 ± 3 |

| 190 | 60 | 14 | 10 | 12 | 0.00 + 0.08 | - |

| 200 | 30 | 14 | 10 | 12 | 1.00 ± 0.08 | 47 ± 3 |

| 200 | 45 | 14 | 10 | 12 | 0.25 ± 0.08 | 44 ± 1 |

| 210 | 30 | 14 | 10 | 12 | 0.00 + 0.08 | - |

| 210 | 45 | 14 | 10 | 12 | 0.00 + 0.08 | - |

| 215 | 30 | 14 | 10 | 12 | 0.08 ± 0.08 | 45 |

| 215 | 60 | 14 | 10 | 12 | 0.00 + 0.08 | - |

| Nozzle Temperature (°C) | Nominal Bed Temperature (°C) | Ageing Time (Days) | Crosshead Speed (mm/min) | Samples Tested | Detachment Ratio | Apparent Tensile Strength (MPa) |

|---|---|---|---|---|---|---|

| 180 | 60 | 1 | 1 | 12 | 0.33 ± 0.08 | 38 ± 1 |

| 180 | 60 | 1 | 10 | 60 | 0.53 ± 0.02 | 40 ± 3 |

| 180 | 60 | 1 | 100 | 12 | 0.67 ± 0.08 | 39 ± 3 |

| 180 | 60 | 49 | 1 | 12 | 0.67 ± 0.08 | 46 ± 3 |

| 180 | 60 | 49 | 10 | 12 | 0.50 ± 0.08 | 45 ± 4 |

| 180 | 60 | 49 | 100 | 12 | 0.50 ± 0.08 | 48 ± 3 |

| 180 | 60 | 90 | 1 | 12 | 0.17 ± 0.08 | 45 ± 2 |

| 180 | 60 | 90 | 10 | 12 | 0.42 ± 0.08 | 45 ± 3 |

| 180 | 60 | 90 | 100 | 12 | 0.25 ± 0.08 | 46 ± 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orellana-Barrasa, J.; Carrasco-Otermín, E.A.; Pastor, J.Y. Study of a Single Joint Between Two FDM-Printed PLA Filaments. Polymers 2025, 17, 3106. https://doi.org/10.3390/polym17233106

Orellana-Barrasa J, Carrasco-Otermín EA, Pastor JY. Study of a Single Joint Between Two FDM-Printed PLA Filaments. Polymers. 2025; 17(23):3106. https://doi.org/10.3390/polym17233106

Chicago/Turabian StyleOrellana-Barrasa, Jaime, Emilio Antón Carrasco-Otermín, and José Ygnacio Pastor. 2025. "Study of a Single Joint Between Two FDM-Printed PLA Filaments" Polymers 17, no. 23: 3106. https://doi.org/10.3390/polym17233106

APA StyleOrellana-Barrasa, J., Carrasco-Otermín, E. A., & Pastor, J. Y. (2025). Study of a Single Joint Between Two FDM-Printed PLA Filaments. Polymers, 17(23), 3106. https://doi.org/10.3390/polym17233106