Thermoformability of Biopolymer Composites with Coffee Silverskin

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Samples Preparation

2.2.1. Masterbatch

2.2.2. Sheet Extrusion

2.3. Structural and Morphological Characterization

2.4. Melt Flow Index

2.5. Thermal Characterization

2.6. Mechanical Characterization

2.7. Optical Microscopy

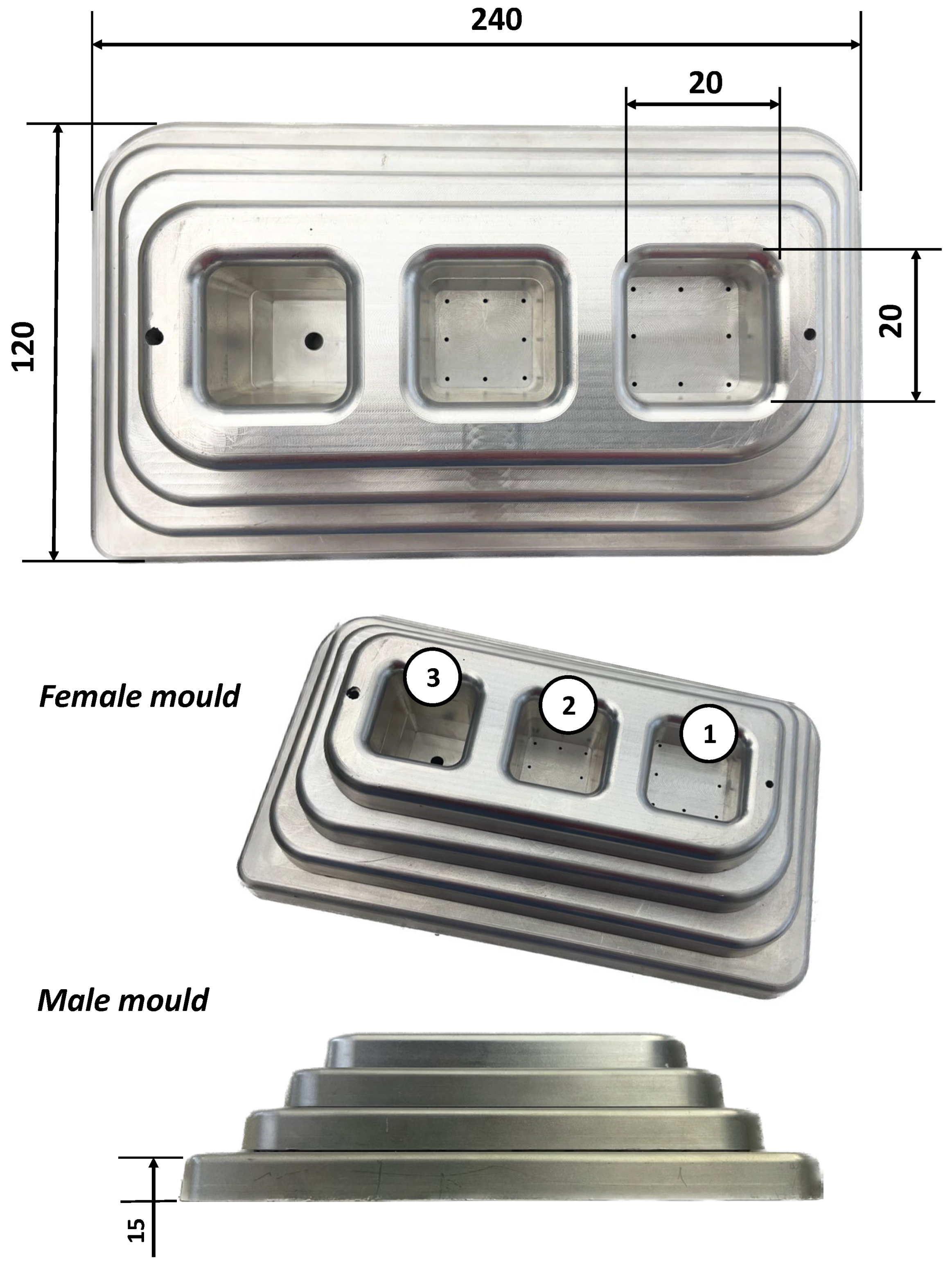

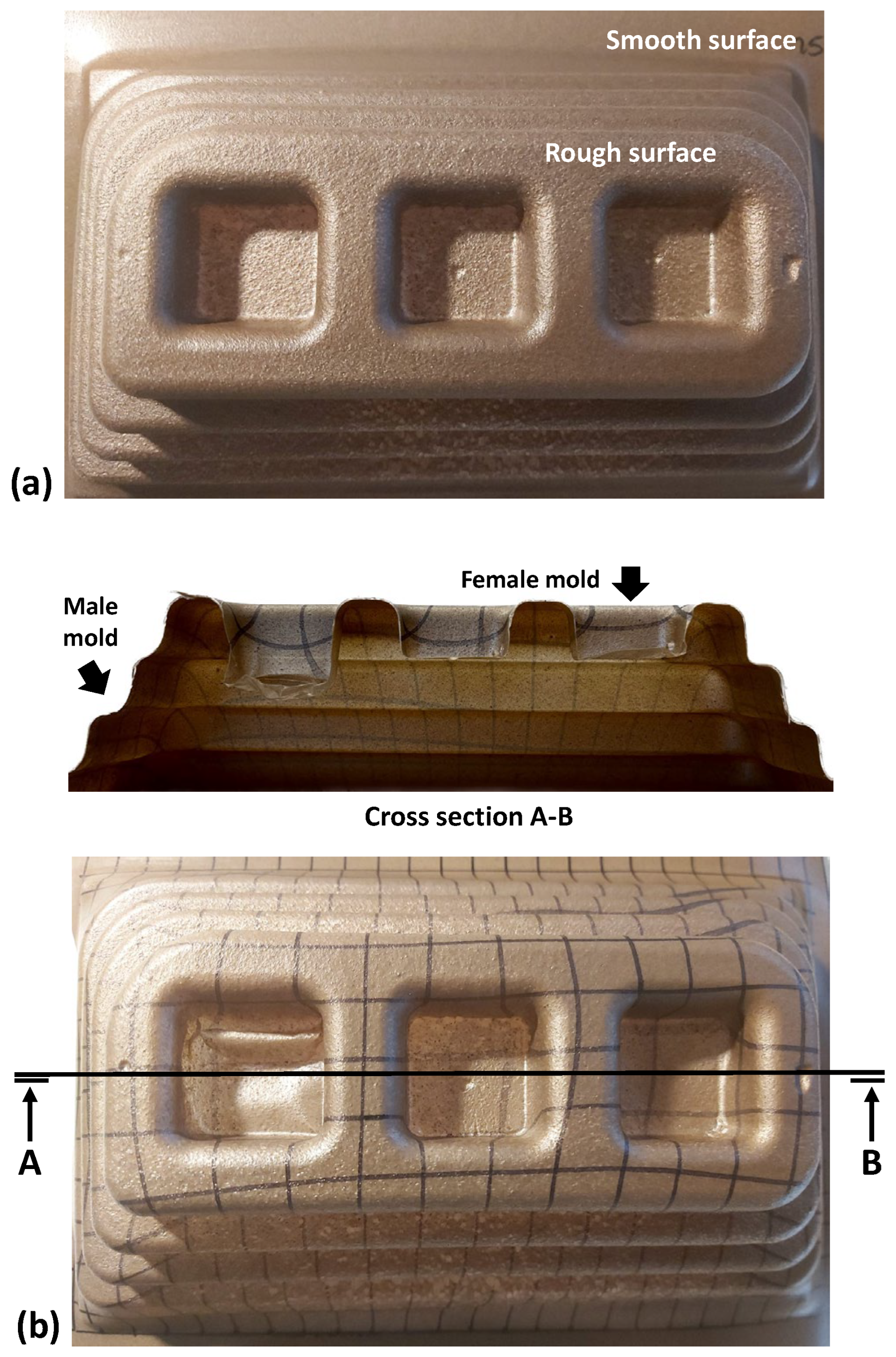

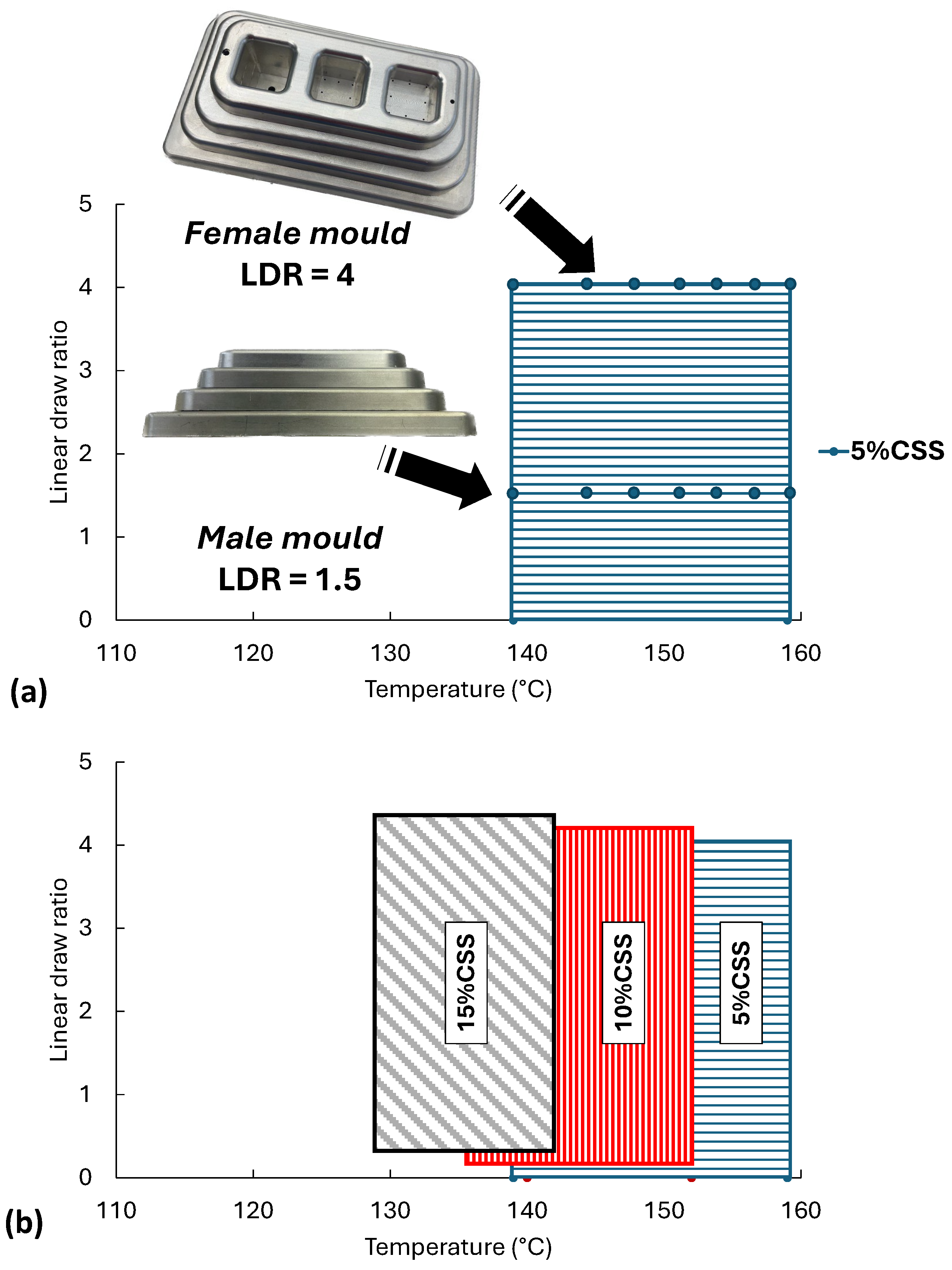

2.8. Thermoforming Characterization

3. Results and Discussion

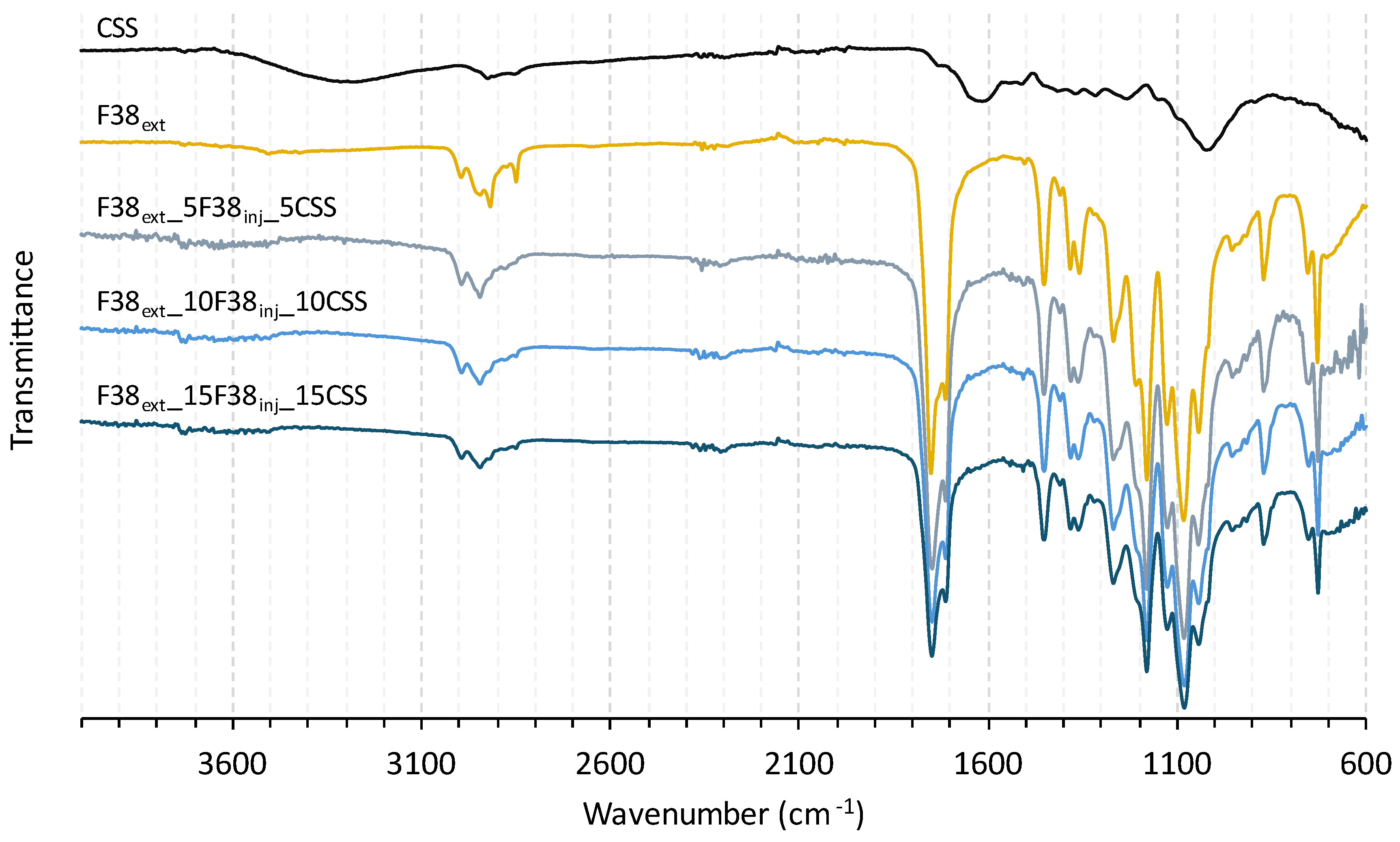

3.1. Structural and Morfological Analysis

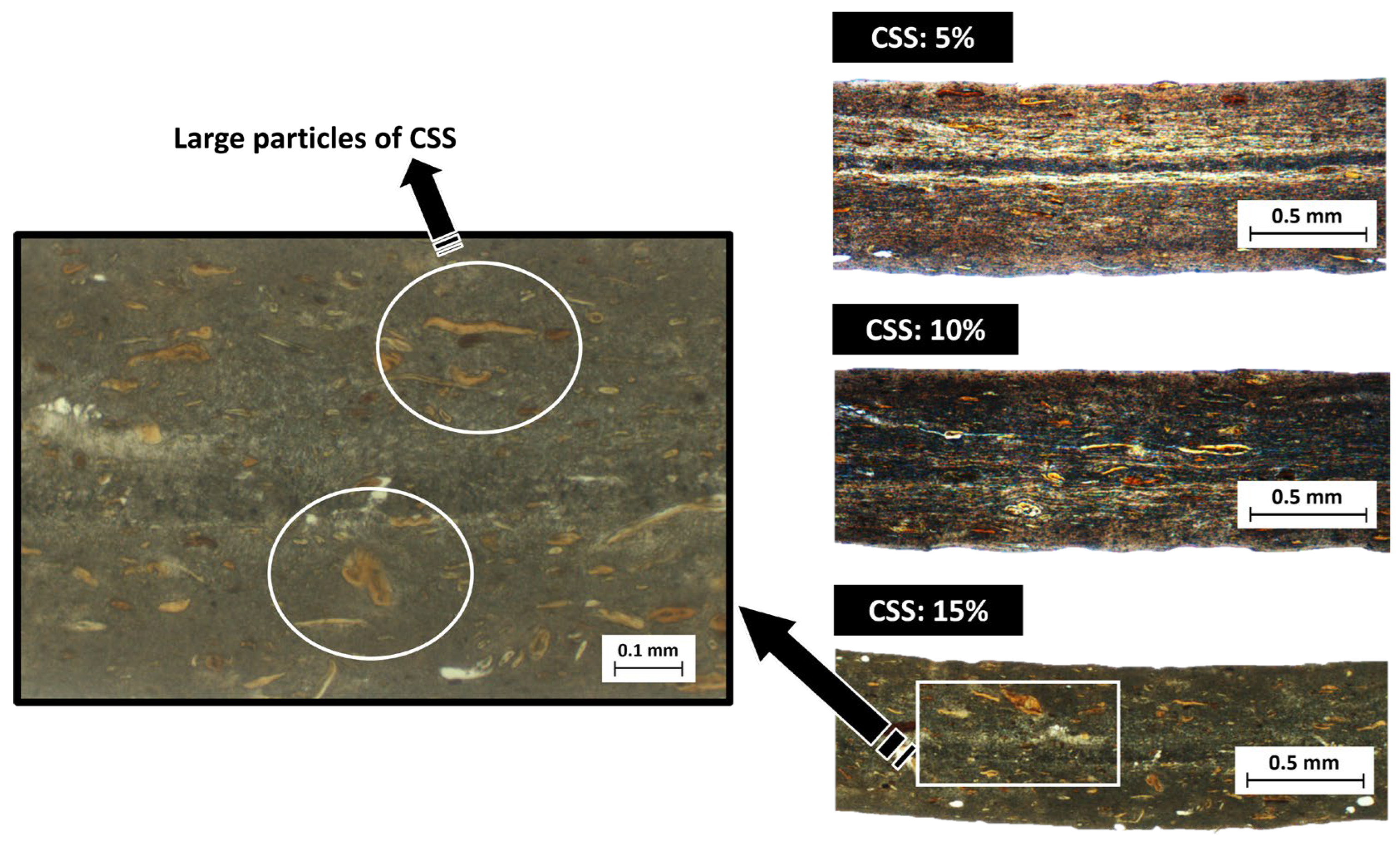

3.2. Morphological Analysis

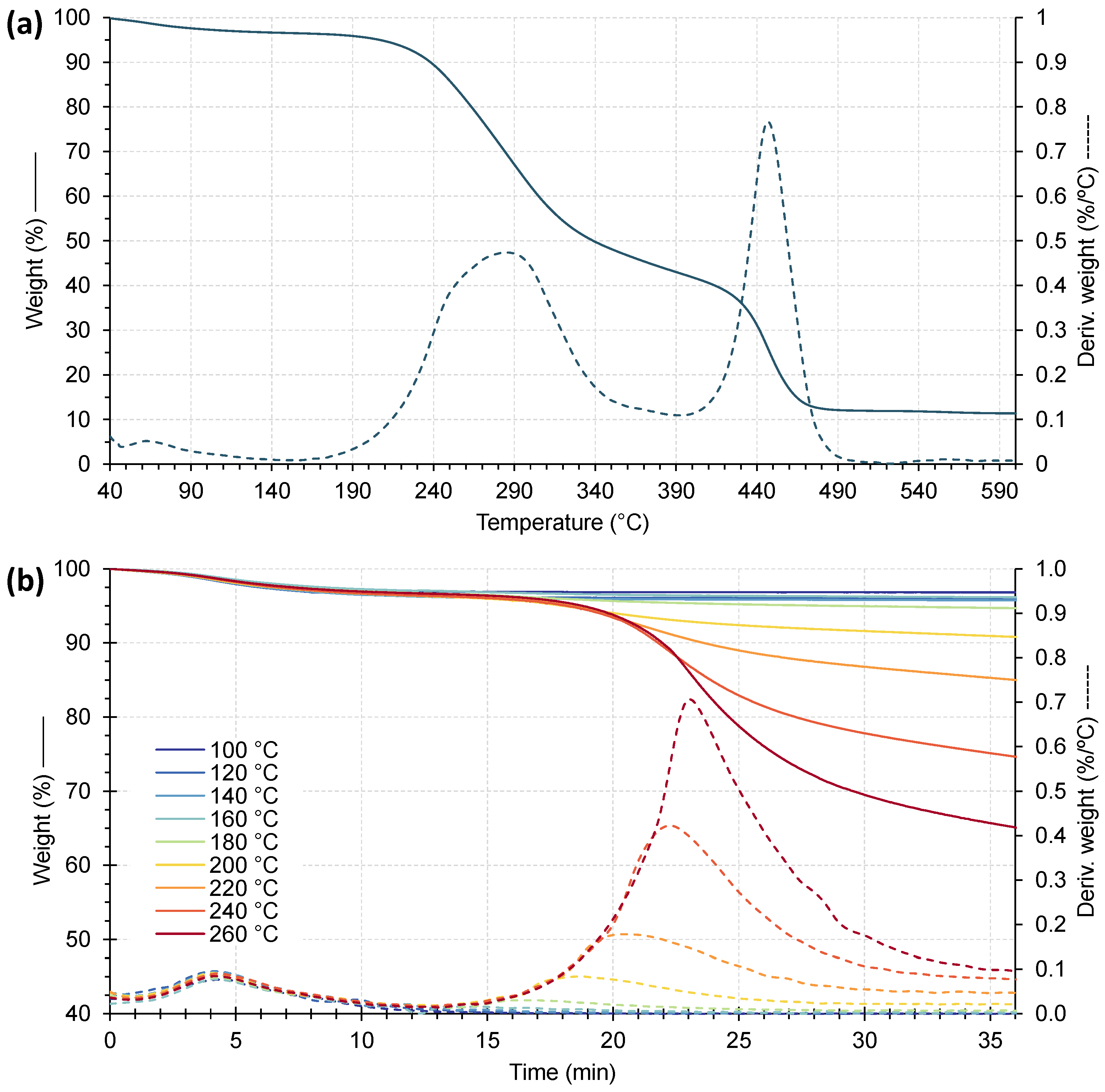

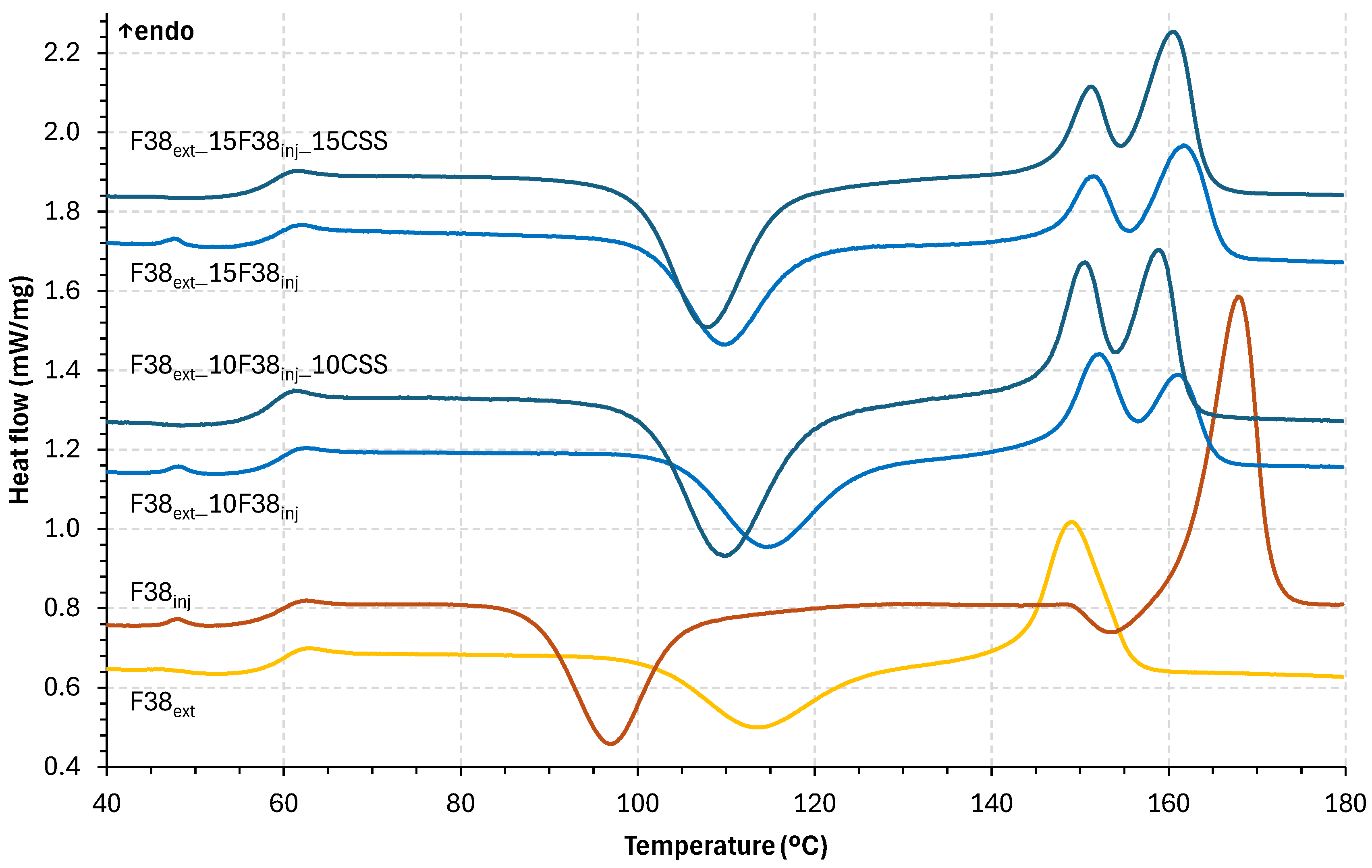

3.3. Thermal Analysis

- (i)

- The first region, corresponding to a weight loss of approximately 5 wt.%, occurs between the initial temperature and around 110 °C, and is attributed to moisture evaporation of the CSS [26].

- (ii)

- The second region, observed between 200 °C and 340 °C, corresponds to the thermal decomposition of hemicellulose and cellulose, characterized by a pronounced weight loss of about 45 wt.% of the total mass loss. Similar results were reported by Kumar et al., where the main degradation stage was, likewise, attributed to the breakdown of hemicellulose and cellulose components [26].

- (iii)

- The third region, corresponding to the gradual weight loss observed above 400 °C is attributed to the decomposition of lignin and proteins, as also reported by Gigante et al. [27].

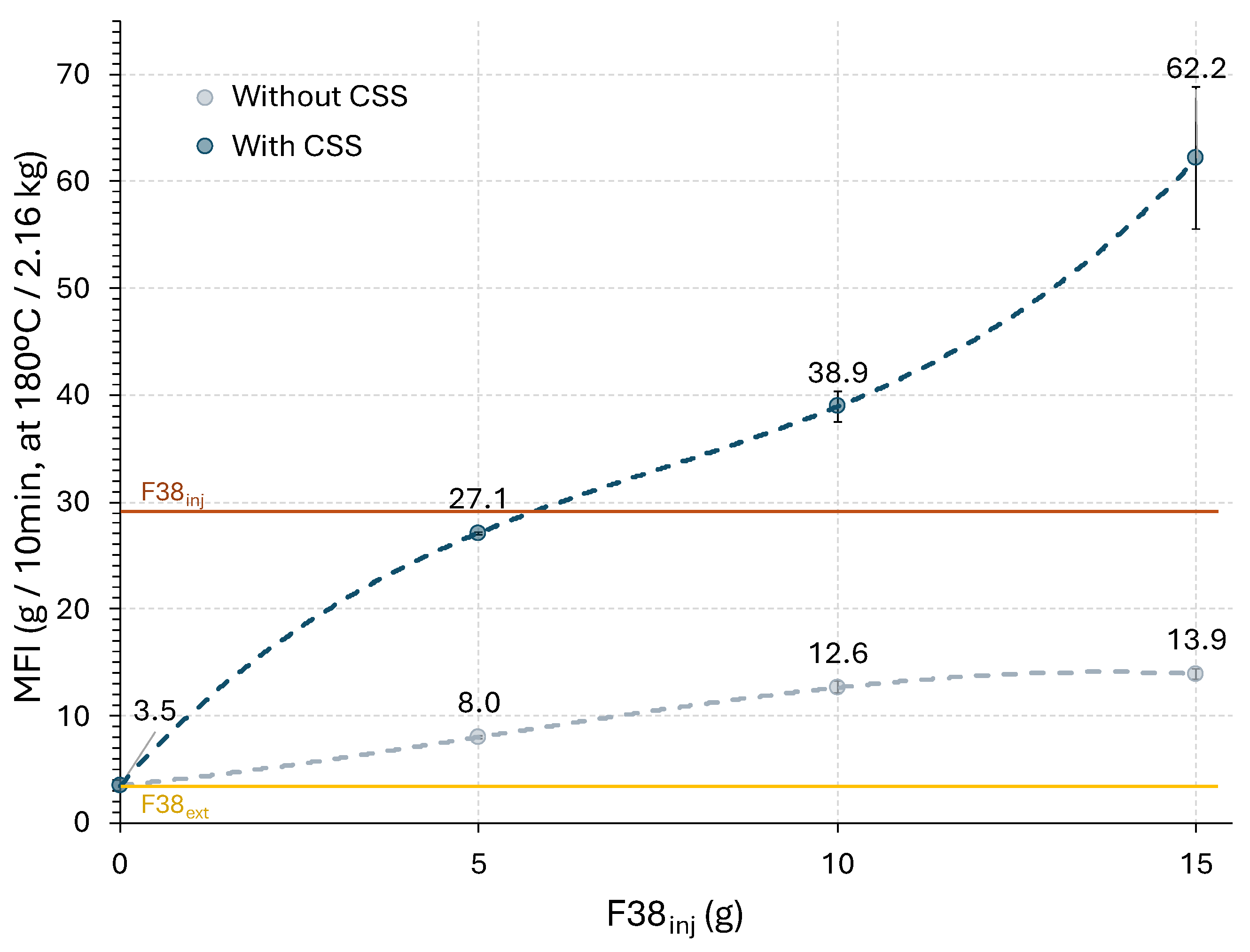

3.4. Melt Flow Index

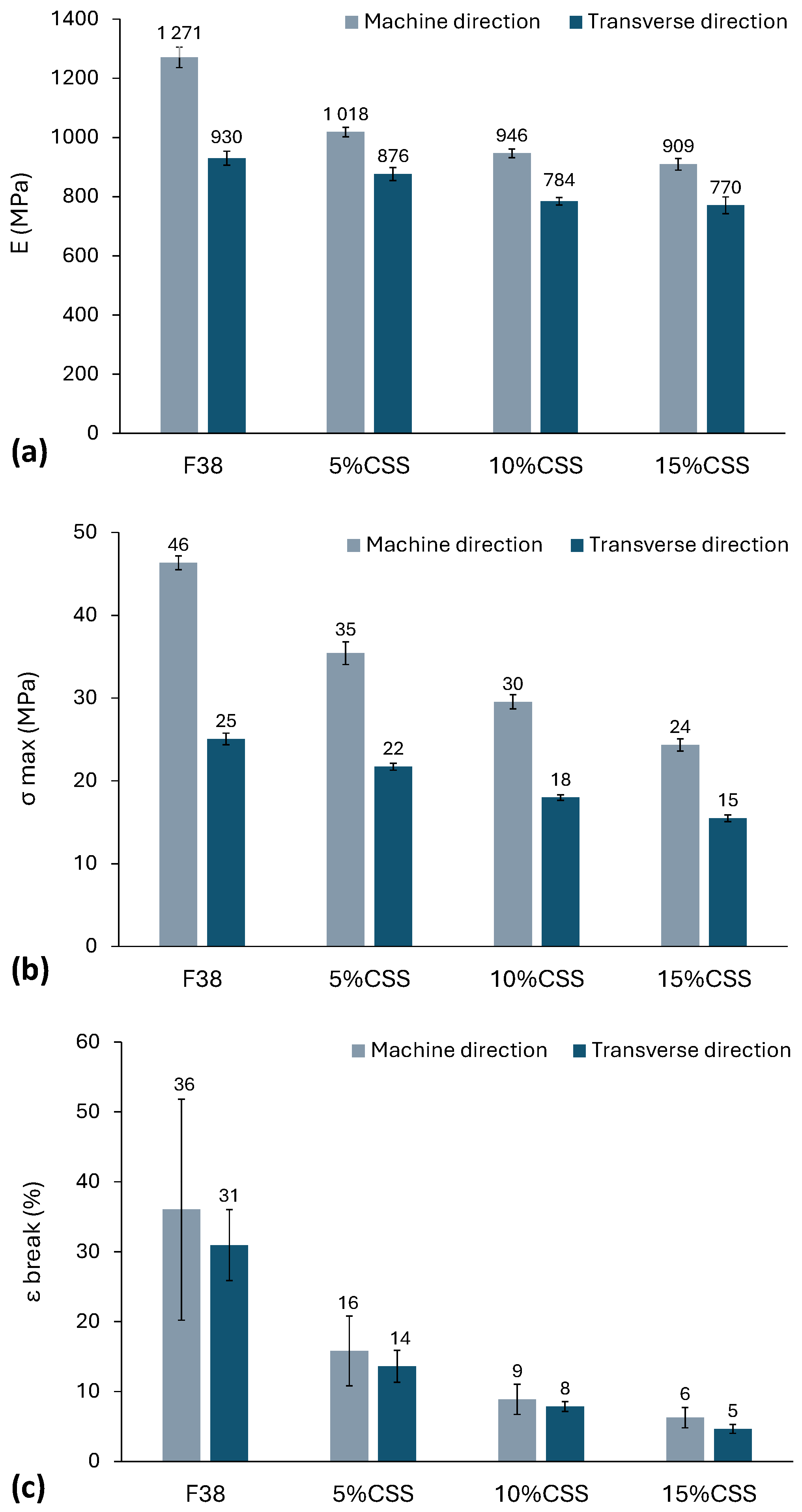

3.5. Mechanical Properties

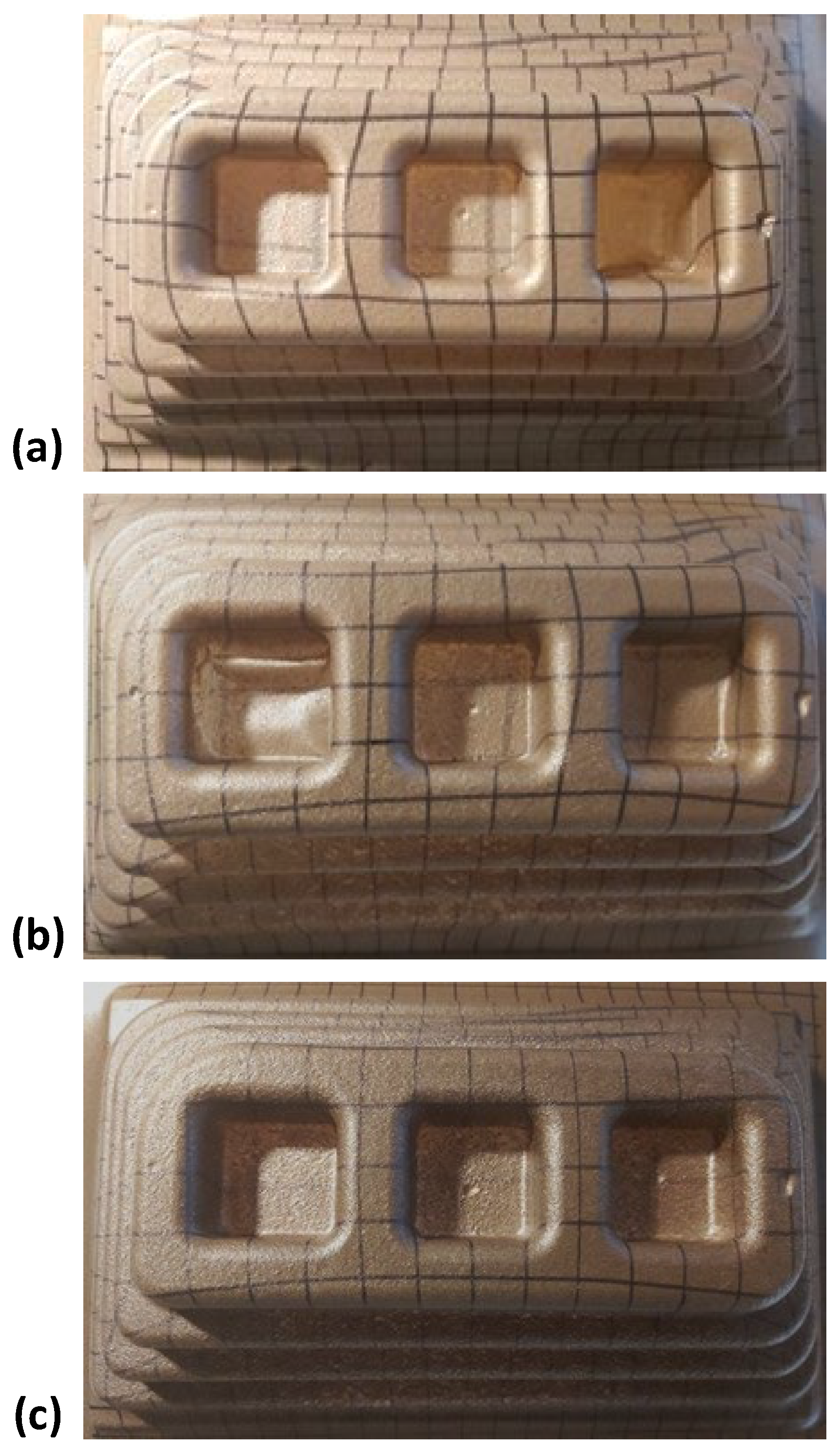

3.6. Thermoformability

4. Conclusions

- DSC analysis indicated that the incorporation of CSS fillers did not affect the glass transition temperature of the PLA matrix but caused a slight decrease in the cold crystallization temperature, indicating a nucleating effect that promotes crystal growth. The melting temperature showed only minor, statistically insignificant variations, suggesting that CSS addition does not adversely impact the processing temperature of the composites.

- In all the resulting biopolymer blends, the elastic modulus, tensile strength, and elongation at break were all reduced. This behaviour is likely due to factors such as the irregular particle size of the filler, the absence of a compatibilizer agent, and differences in chemical structures and polarity between the filler and the polymer matrix.

- SEM observations confirmed the presence of CSS particles within the PLA matrices. The polymer fibres appeared well interwoven and relatively uniform. Compared to the neat polymer, the addition of the filler tends to moderate the blend fluidity while maintaining sufficient deformation resistance, making it possible to thermoform all compositions.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Valdés, A.; Mellinas, A.C.; Ramos, M.; Garrigós, M.C.; Jiménez, A. Natural Additives and Agricultural Wastes in Biopolymer Formulations for Food Packaging. Front. Chem. 2014, 2, 6. [Google Scholar] [CrossRef]

- Reichert, C.L.; Bugnicourt, E.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A.; Canesi, I.; Braca, F.; Martínez, B.M.; Alonso, R.; Agostinis, L.; et al. Bio-Based Packaging: Materials, Modifications, Industrial Applications and Sustainability. Polymers 2020, 12, 1558. [Google Scholar] [CrossRef]

- Ahmad, M.N.; Ishak, M.R.; Taha, M.M.; Mustapha, F.; Leman, Z. Rheological Properties of Natural Fiber Reinforced Thermoplastic Composite for Fused Deposition Modeling (FDM): A Short Review. J. Adv. Res. Fluid Mech. Therm. Sci. 2022, 98, 157–164. [Google Scholar] [CrossRef]

- Pulikkalparambil, H.; Varghese, S.A.; Chonhenchob, V.; Nampitch, T.; Jarupan, L.; Harnkarnsujarit, N. Recent Advances in Natural Fibre-Based Materials for Food Packaging Applications. Polymers 2023, 15, 1393. [Google Scholar] [CrossRef] [PubMed]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical Treatments on Plant-Based Natural Fibre Reinforced Polymer Composites: An Overview. Compos. B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- McKay, I.; Vargas, J.; Yang, L.; Felfel, R.M. A Review of Natural Fibres and Biopolymer Composites: Progress, Limitations, and Enhancement Strategies. Materials 2024, 17, 4878. [Google Scholar] [CrossRef] [PubMed]

- Moutinho, L.G.; Soares, E.; Oliveira, M. Thermoforming of Bio-Based Polylactic Acid (PLA) Sheets Reinforced with Cork Powder. Mater. Today Commun. 2025, 46, 112867. [Google Scholar] [CrossRef]

- Nurul Fazita, M.R.; Jayaraman, K.; Bhattacharyya, D. Formability Analysis of Bamboo Fabric Reinforced Poly (Lactic) Acid Composites. Materials 2016, 9, 539. [Google Scholar] [CrossRef]

- Morcillo-Martín, R.; Rabasco-Vílchez, L.; Jiménez-Jiménez, F.; Espinosa, E.; Tarrés, Q.; Rodríguez, A. Thermoformed Fiber-Polyethylene Biocomposites: A Circular Food Packaging on Cherry Tomatoes. Food Bioproc. Technol. 2025, 18, 2447–2461. [Google Scholar] [CrossRef]

- Afshariantorghabeh, S.; Kärki, T.; Leminen, V. Thermoformability Study of Wood Flour–HDPE Composites with Variations in Wood Content Under Vacuum Forming. Heliyon 2023, 9, e22174. [Google Scholar] [CrossRef]

- Bhattacharyya, D.; Bowis, M.; Jayaraman, K. Thermoforming Woodfibre-Polypropylene Composite Sheets. Compos. Sci. Technol. 2003, 63, 353–365. [Google Scholar] [CrossRef]

- Afshariantorghabeh, S.; Kärki, T.; Leminen, V. Three-Dimensional Forming of Plastic-Coated Fibre-Based Materials Using a Thermoforming Process. Packag. Technol. Sci. 2022, 35, 543–555. [Google Scholar] [CrossRef]

- Mishra, B.; Mohanta, Y.K.; Reddy, C.N.; Reddy, S.D.M.; Mandal, S.K.; Yadavalli, R.; Sarma, H. Valorization of Agro-Industrial Biowaste to Biomaterials: An Innovative Circular Bioeconomy Approach. Circ. Econ. 2023, 2, 100050. [Google Scholar] [CrossRef]

- Toschi, T.G.; Cardenia, V.; Bonaga, G.; Mandrioli, M.; Rodriguez-Estrada, M.T. Coffee Silverskin: Characterization, Possible Uses, and Safety Aspects. J. Agric. Food Chem. 2014, 62, 10836–10844. [Google Scholar] [CrossRef]

- Petaloti, A.I.; Achilias, D.S. The Development of Sustainable Biocomposite Materials Based on Poly(Lactic Acid) and Silverskin, a Coffee Industry By-Product, for Food Packaging Applications. Sustainability 2024, 16, 5075. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2022.

- ISO 527-4:2023; Plastics—Determination of Tensile Properties Part 4: Test Conditions for Isotropic and Orthotropic Fibre-Reinforced Plastic Composites. ISO: Geneva, Switzerland, 2023.

- Ballesteros, L.F.; Teixeira, J.A.; Mussatto, S.I. Chemical, Functional, and Structural Properties of Spent Coffee Grounds and Coffee Silverskin. Food Bioproc. Technol. 2014, 7, 3493–3503. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Zuorro, A.; Maffei, G.; Lavecchia, R.; Puglia, D.; Dominici, F.; Luzi, F.; Valente, T.; Torre, L. Recycling Coffee Silverskin in Sustainable Composites Based on a Poly(Butylene Adipate-Co-Terephthalate)/Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) Matrix. Ind. Crops Prod. 2018, 118, 311–320. [Google Scholar] [CrossRef]

- Ribeiro, J.S.; Salva, T.J.; Ferreira, M.M.C. Chemometric Studies for Quality Control of Processed Brazilian Coffees Using Drifts. J. Food Qual. 2010, 33, 212–227. [Google Scholar] [CrossRef]

- Wang, J.; Jun, S.; Bittenbender, H.C.; Gautz, L.; Li, Q.X. Fourier Transform Infrared Spectroscopy for Kona Coffee Authentication. J. Food Sci. 2009, 74, 385–391. [Google Scholar] [CrossRef]

- Craig, A.P.; Franca, A.S.; Oliveira, L.S. Evaluation of the Potential of FTIR and Chemometrics for Separation between Defective and Non-Defective Coffees. Food Chem. 2012, 132, 1368–1374. [Google Scholar] [CrossRef]

- Kemsley, E.K.; Ruault, S.; Wilson, R.H. Analytical, Nutritional and Clinical Methods Section Discrimination Between Co&a Arabica and Co&a Canephora Variant Robusta Beans Using Infrared Spectroscopy. Food Chem. 1995, 54, 321–326. [Google Scholar] [CrossRef]

- Wu, C.S.; Liao, H.T. A New Biodegradable Blends Prepared from Polylactide and Hyaluronic Acid. Polymer 2005, 46, 10017–10026. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Luyt, A.S.; Tábi, T.; Kovács, J. Comparison of Injection Moulded, Natural Fibre-Reinforced Composites with PP and PLA as Matrices. J. Thermoplast. Compos. Mater. 2012, 25, 927–948. [Google Scholar] [CrossRef]

- Kumar, K.S.; Gairola, S.; Singh, I. Waste Coffee Silverskin as a Potential Filler in Sustainable Composites: Mechanical, Thermal, and Microstructural Analysis. Ind. Crops Prod. 2024, 210, 118088. [Google Scholar] [CrossRef]

- Gigante, V.; Seggiani, M.; Cinelli, P.; Signori, F.; Vania, A.; Navarini, L.; Amato, G.; Lazzeri, A. Utilization of Coffee Silverskin in the Production of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) Biopolymer-Based Thermoplastic Biocomposites for Food Contact Applications. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106172. [Google Scholar] [CrossRef]

- Colaers, M.; Thielemans, W.; Goderis, B. Quantitative DSC Assessment of the Polymorph-Specific Crystallinity of Poly(Lactic Acid) and the Impact of a Self-Assembling Nucleating Agent and PEG Plasticizer. Polymers 2025, 17, 1267. [Google Scholar] [CrossRef]

- Novák, J.; Běhálek, L.; Borůvka, M.; Lenfeld, P. The Physical Properties and Crystallization Kinetics of Biocomposite Films Based on PLLA and Spent Coffee Grounds. Materials 2022, 15, 8912. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López, J.; Ferrándiz, S.; Peltzer, M.A. Characterization of PLA-Limonene Blends for Food Packaging Applications. Polym. Test. 2013, 32, 760–768. [Google Scholar] [CrossRef]

- Luzi, F.; Fortunati, E.; Jiménez, A.; Puglia, D.; Pezzolla, D.; Gigliotti, G.; Kenny, J.M.; Chiralt, A.; Torre, L. Production and Characterization of PLA_PBS Biodegradable Blends Reinforced with Cellulose Nanocrystals Extracted from Hemp Fibres. Ind. Crops Prod. 2016, 93, 276–289. [Google Scholar] [CrossRef]

- Huang, L.; Mu, B.; Yi, X.; Li, S.; Wang, Q. Sustainable Use of Coffee Husks For Reinforcing Polyethylene Composites. J. Polym. Environ. 2018, 26, 48–58. [Google Scholar] [CrossRef]

- Speer, K.; Kölling-Speer, I. The Lipid Fraction of the Coffee Bean. Braz. J. Plant Physiol. 2006, 18, 201–216. [Google Scholar] [CrossRef]

- Siparsky, G.L.; Voorhees, K.J.; Miao, F. Hydrolysis of Polylactic Acid (PLA) and Polycaprolactone (PCL) in Aqueous Acetonitrile Solutions: Autocatalysis. J. Environ. Polym. Degrad. 1998, 6, 31–41. [Google Scholar] [CrossRef]

- Elsawy, M.A.; Kim, K.H.; Park, J.W.; Deep, A. Hydrolytic Degradation of Polylactic Acid (PLA) and Its Composites. Renew. Sustain. Energy Rev. 2017, 79, 1346–1352. [Google Scholar] [CrossRef]

- Li, X.; Lin, Y.; Liu, M.; Meng, L.; Li, C. A Review of Research and Application of Polylactic Acid Composites. J. Appl. Polym. Sci. 2023, 140, e53477. [Google Scholar] [CrossRef]

- Wan Ishak, W.H.; Rosli, N.A.; Ahmad, I. Influence of Amorphous Cellulose on Mechanical, Thermal, and Hydrolytic Degradation of Poly(Lactic Acid) Biocomposites. Sci. Rep. 2020, 10, 11342. [Google Scholar] [CrossRef]

- Momeni, S.; Craplewe, K.; Safder, M.; Luz, S.; Sauvageau, D.; Elias, A. Accelerating the Biodegradation of Poly(Lactic Acid) through the Inclusion of Plant Fibers: A Review of Recent Advances. ACS Sustain. Chem. Eng. 2023, 11, 15146–15170. [Google Scholar] [CrossRef]

- Xu, S.; Tahon, J.F.; De-Waele, I.; Stoclet, G.; Gaucher, V. Brittle-to-Ductile Transition of Pla Induced by Macromolecular Orientation. Express Polym. Lett. 2020, 14, 1034–1047. [Google Scholar] [CrossRef]

- Sarasini, F.; Luzi, F.; Dominici, F.; Maffei, G.; Iannone, A.; Zuorro, A.; Lavecchia, R.; Torre, L.; Carbonell-Verdu, A.; Balart, R.; et al. Effect of Different Compatibilizers on Sustainable Composites Based on a PHBV/PBAT Matrix Filled with Coffee Silverskin. Polymers 2018, 10, 1256. [Google Scholar] [CrossRef]

- Ghazvini, A.K.A.; Ormondroyd, G.; Curling, S.; Saccani, A.; Sisti, L. An Investigation on the Possible Use of Coffee Silverskin in PLA/PBS Composites. J. Appl. Polym. Sci. 2022, 139, e52264. [Google Scholar] [CrossRef]

- Moustafa, H.; Guizani, C.; Dufresne, A. Sustainable Biodegradable Coffee Grounds Filler and Its Effect on the Hydrophobicity, Mechanical and Thermal Properties of Biodegradable PBAT Composites. J. Appl. Polym. Sci. 2016, 134, 44498. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Garcia-Garcia, D.; Carbonell-Verdu, A.; Balart, R.; Torres-Giner, S. Effect of Different Compatibilizers on Injection-Molded Green Composite Pieces Based on Polylactide Filled with Almond Shell Flour. Compos. B Eng. 2018, 147, 76–85. [Google Scholar] [CrossRef]

- Vannini, M.; Marchese, P.; Sisti, L.; Saccani, A.; Mu, T.; Sun, H.; Celli, A. Integrated Efforts for the Valorization of Sweet Potato By-Products within a Circular Economy Concept: Biocomposites for Packaging Applications Close the Loop. Polymers 2021, 13, 1048. [Google Scholar] [CrossRef]

- Suaduang, N.; Ross, S.; Ross, G.M.; Pratumshat, S.; Mahasaranon, S. Effect of Spent Coffee Grounds Filler on the Physical and Mechanical Properties of Poly(Lactic Acid) Bio-Composite Films. Mater. Today Proc. 2019, 17, 2104–2110. [Google Scholar] [CrossRef]

- Yang, H.S.; Wolcott, M.P.; Kim, H.S.; Kim, S.; Kim, H.J. Effect of Different Compatibilizing Agents on the Mechanical Properties of Lignocellulosic Material Filled Polyethylene Bio-Composites. Compos. Struct. 2007, 79, 369–375. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Y.; Cai, H.; Lin, X.; Yi, W.; Zhang, J. Properties Comparison of High Density Polyethylene Composites Filled with Three Kinds of Shell Fibers. Results Phys. 2019, 12, 1542–1546. [Google Scholar] [CrossRef]

| F38ext (g) | F38inj (g) | CSS (g) | |

|---|---|---|---|

| F38ext_5F38inj | 90 | 5 | - |

| F38ext_5F38inj_5CSS | 90 | 5 | 5 |

| F38ext_10F38inj | 80 | 10 | - |

| F38ext_10F38inj_10CSS | 80 | 10 | 10 |

| F38ext_15F38inj | 70 | 15 | - |

| F38ext_15F38inj_15CSS | 70 | 15 | 15 |

| Samples | Tg (°C) | Tc (°C) | Tm (°C) |

|---|---|---|---|

| F38ext | 61 | 114 | 149 |

| F38inj | 59 | 97/154 | 168 |

| F38ext_10F38inj | 60 | 115 | 152/161 |

| F38ext_10F38inj_10CSS | 59 | 110 | 150/159 |

| F38ext_15F38inj | 60 | 110 | 151/162 |

| F38ext_15F38inj_15CSS | 59 | 108 | 151/161 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Machado, A.C.; Beltrão, M.; Castro, M.C.R.; Martins, C.I.; Cruz, V.; Rodrigues, P.V.; Duarte, F.M. Thermoformability of Biopolymer Composites with Coffee Silverskin. Polymers 2025, 17, 3067. https://doi.org/10.3390/polym17223067

Machado AC, Beltrão M, Castro MCR, Martins CI, Cruz V, Rodrigues PV, Duarte FM. Thermoformability of Biopolymer Composites with Coffee Silverskin. Polymers. 2025; 17(22):3067. https://doi.org/10.3390/polym17223067

Chicago/Turabian StyleMachado, Ana C., Mariana Beltrão, Maria C. R. Castro, Carla I. Martins, Vasco Cruz, Pedro V. Rodrigues, and Fernando M. Duarte. 2025. "Thermoformability of Biopolymer Composites with Coffee Silverskin" Polymers 17, no. 22: 3067. https://doi.org/10.3390/polym17223067

APA StyleMachado, A. C., Beltrão, M., Castro, M. C. R., Martins, C. I., Cruz, V., Rodrigues, P. V., & Duarte, F. M. (2025). Thermoformability of Biopolymer Composites with Coffee Silverskin. Polymers, 17(22), 3067. https://doi.org/10.3390/polym17223067