Application of Gelatin for Sustainable Stabilization of Low-Compressible Silt–Clay Mixtures: Geotechnical Behavior and Carbon Emission Considerations

Abstract

1. Introduction

2. Materials and Methods

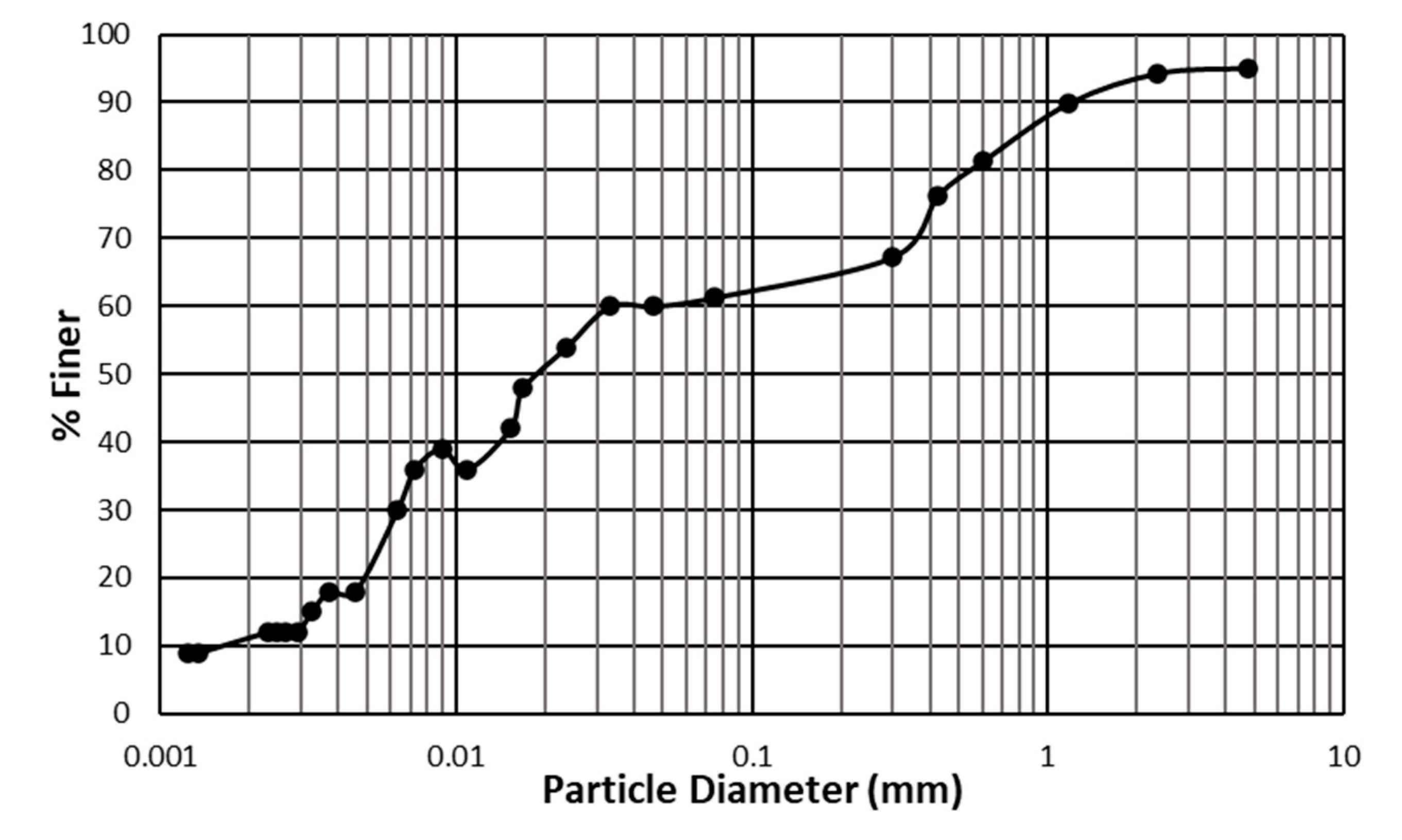

2.1. Soil

2.2. Gelatin

3. Experimental Investigation

4. Results and Discussion

4.1. Liquid and Plastic Limit

4.2. Compaction Behavior

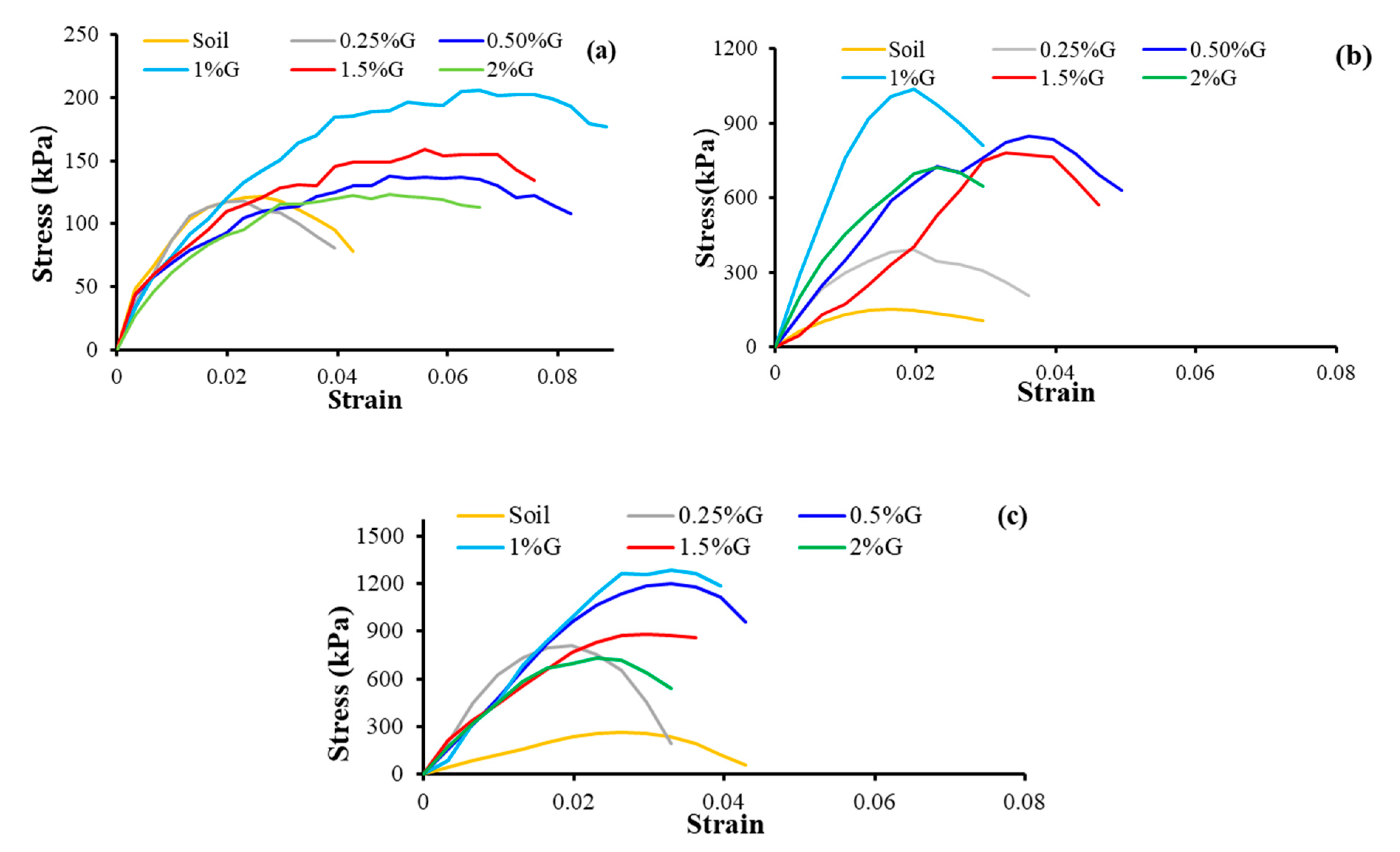

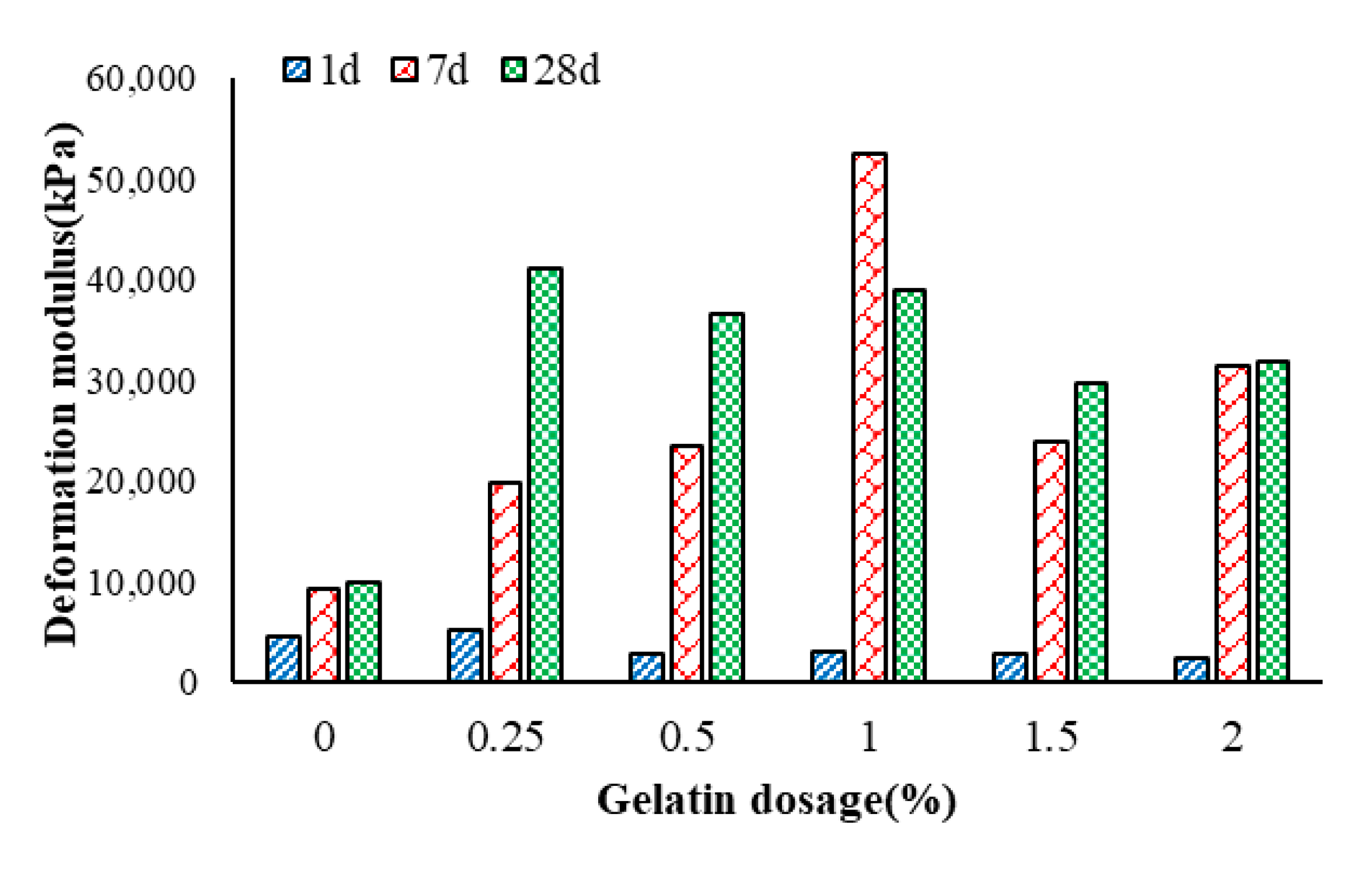

4.3. Deformation Behavior

4.4. UCS

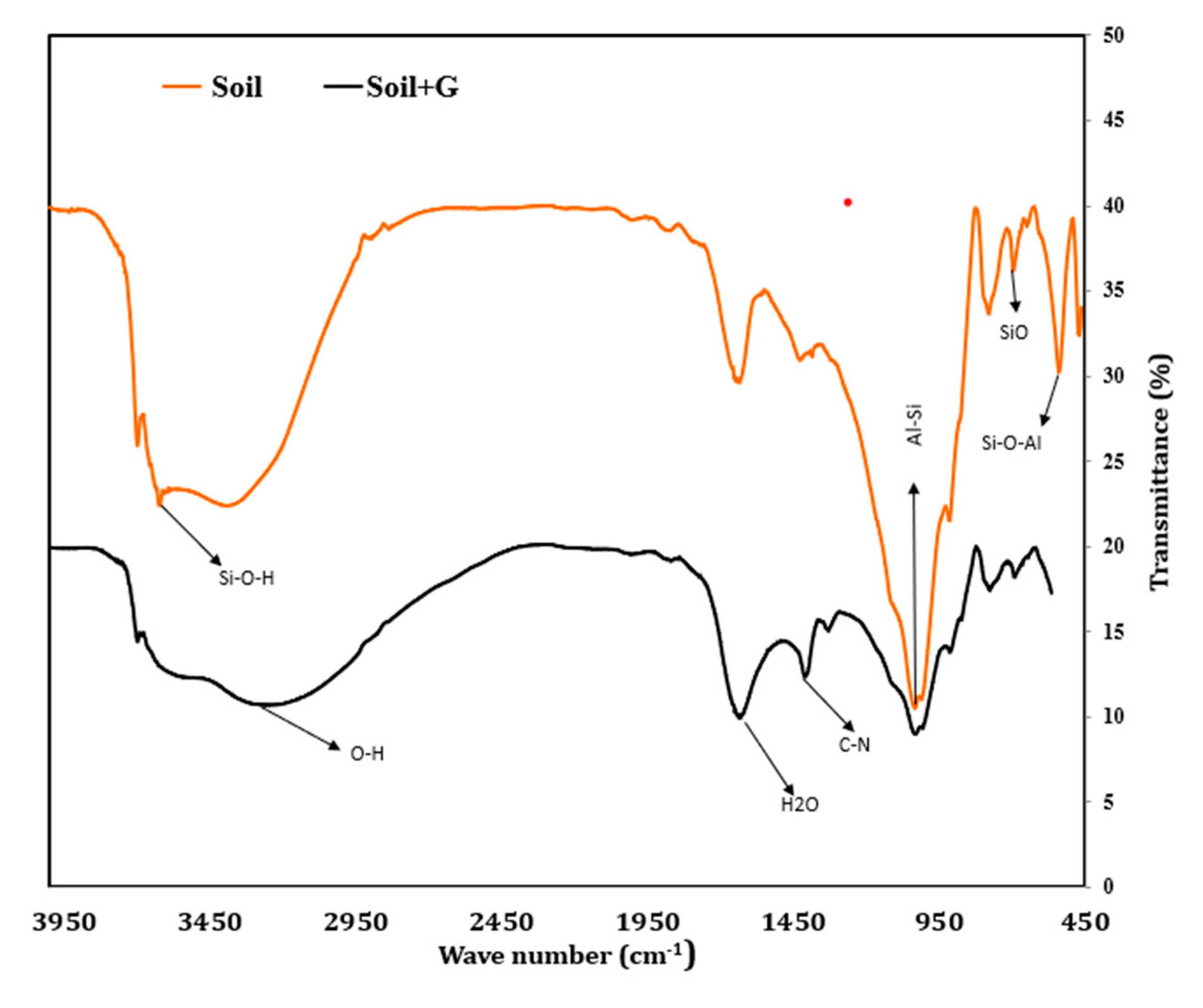

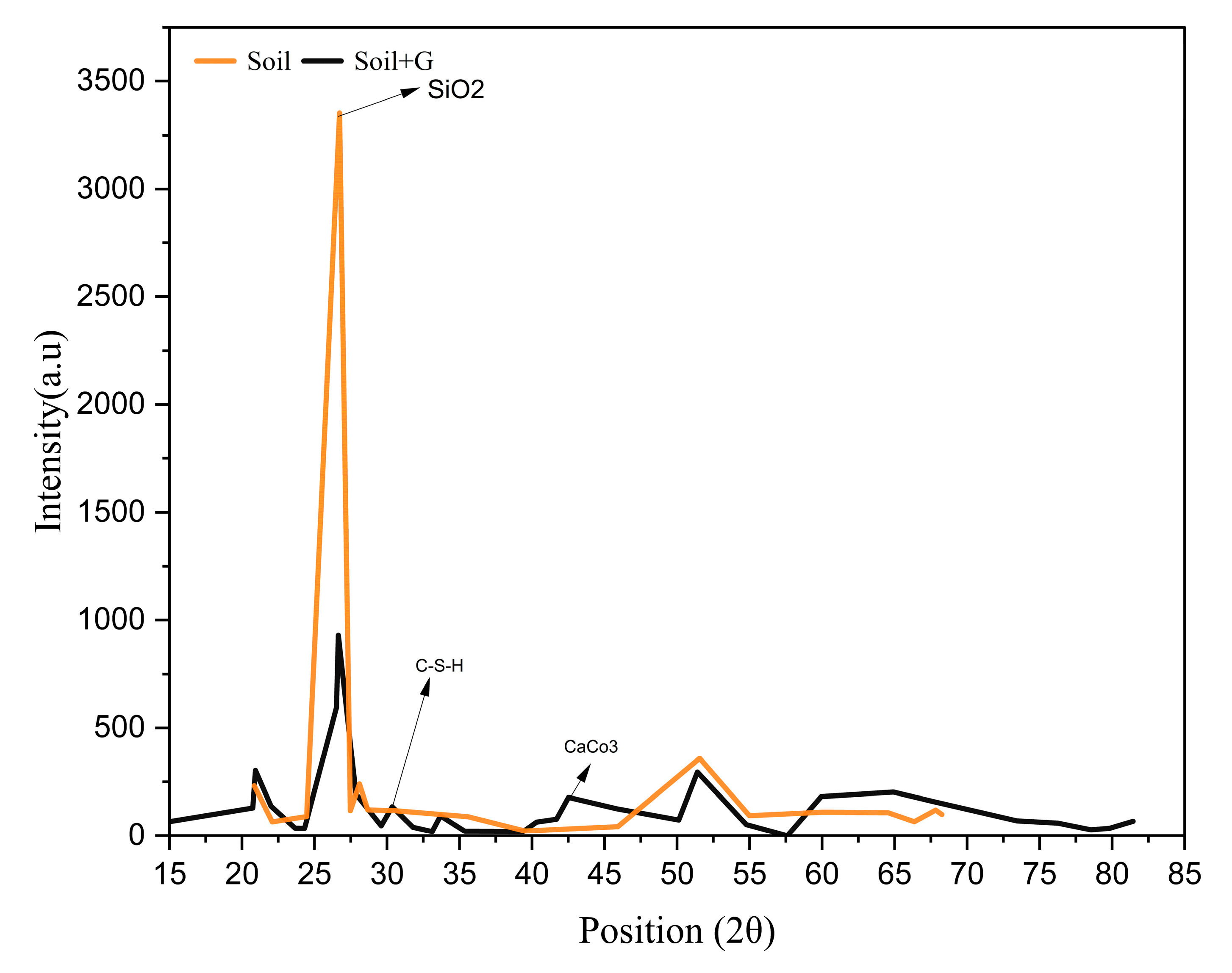

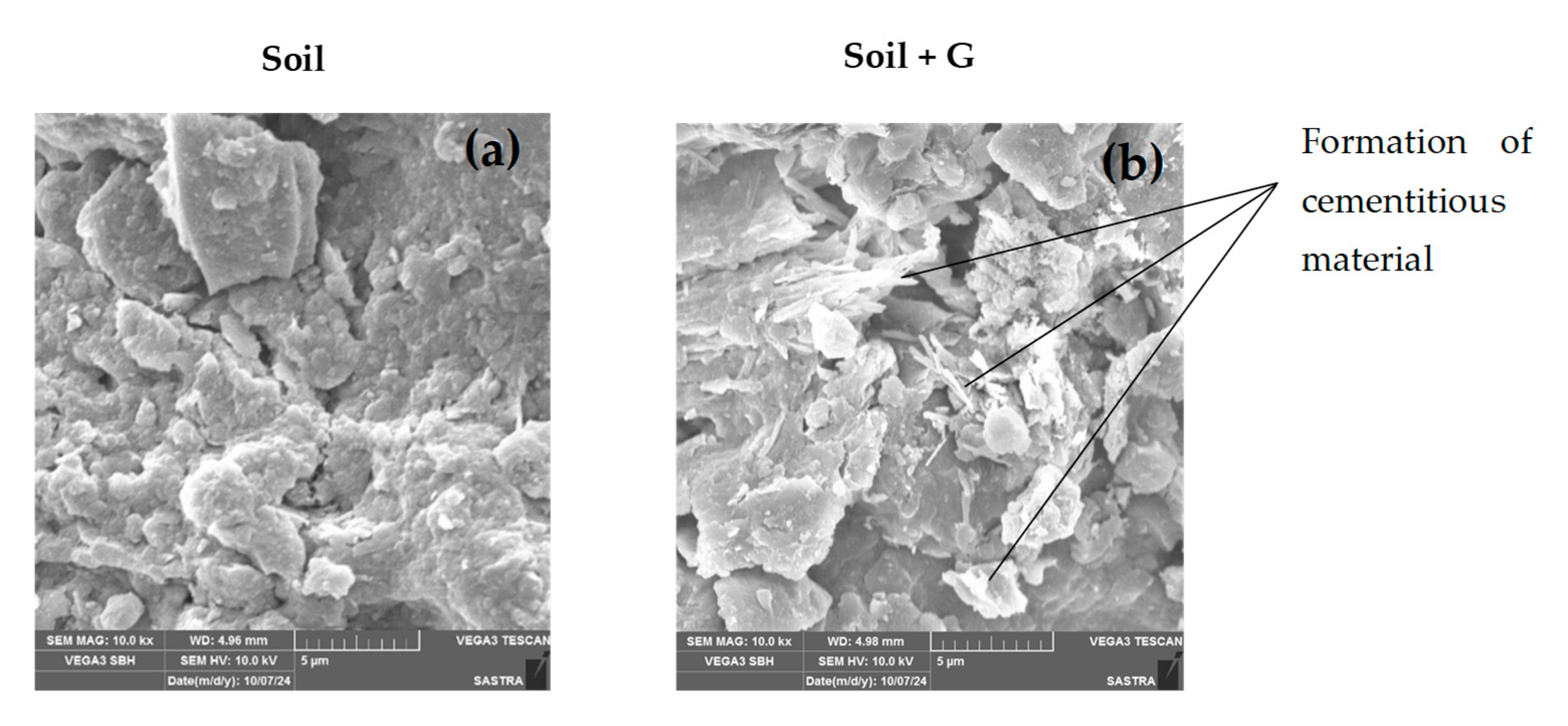

4.5. Mechanism of Improvement

4.6. Carbon Footprint Analysis of Gelatin-Stabilized Footing

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hamzah, H.N.; Al Bakri Abdullah, M.M.; Yong, H.C.; Zainol, M.R.R.A.; Hussin, K. Review of soil stabilization techniques: Geopolymerization method one of the new technique. In Key Engineering Materials; Trans Tech Publications Ltd.: Zurich, Switzerland, 2015; pp. 298–304. [Google Scholar] [CrossRef]

- Makusa, G.P. State of the Art Review Soil Stabilization Methods and Materials in Engineering 480 Practice; Luleå University of Technology: Luleå, Sweden, 2012. [Google Scholar]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Bauer, V.M. Global Cement Production, Responsible for 8% of the World’s CO2 Emissions. 2021. Available online: https://www.timber-online.net/other_economic_matters/2018/12/global-cement-production.html (accessed on 25 January 2025).

- Mendonça, A.; Morais, P.V.; Pires, A.C.; Chung, A.P.; Oliveira, P.V. A review on the importance of microbial biopolymers such as xanthan gum to improve soil properties. Appl. Sci. 2020, 11, 170. [Google Scholar] [CrossRef]

- Kalkan, E. A Review on the Microbial Induced Carbonate Precipitation (MICP) for Soil Stabilization. Int. J. Earth Sci. Knowl. Appl. 2020, 2, 38–47. [Google Scholar]

- Rong, H.; Qian, C.; Wang, R. A cementation method of loose particles based on microbe-based cement. Sci. China Technol. Sci. 2011, 54, 1722–1729. [Google Scholar] [CrossRef]

- Kumara, S.A.; Sujatha, E.R. Performance evaluation of β-glucan treated lean clay and efficacy of its choice as a sustainable alternative for ground improvement. Geomech. Eng. 2020, 21, 413–422. [Google Scholar]

- Mallik, T. Issue 1 www.jetir.org (ISSN-2349-5162), JETIR. 2022. Available online: www.jetir.org (accessed on 25 January 2025).

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.C. Effects of Xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Cho, G.C. Soil strengthening using thermo-gelation biopolymers. Constr. Build. Mater. 2015, 77, 430–438. [Google Scholar] [CrossRef]

- Chang, I.; Cho, G.C. Strengthening of Korean residual soil with β-1,3/1,6-glucan biopolymer. Constr. Build. Mater. 2012, 30, 30–35. [Google Scholar] [CrossRef]

- Kannan, G.; Sujatha, E.R. Crustacean polysaccharides for the geotechnical enhancement of organic silt: A clean and green alternative. Carbohydr. Polym. 2023, 299, 120227. [Google Scholar] [CrossRef]

- Fatehi, H.; Ong, D.E.L.; Yu, J.; Chang, I. The Effects of Particle Size Distribution and Moisture Variation on Mechanical Strength of Biopolymer-Treated Soil. Polymers 2023, 15, 1549. [Google Scholar] [CrossRef]

- Kannan, G.; Sujatha, E.R. A study on the efficacy of low viscous nanosized biopolymer on the mechanical and hydraulic properties of organic silt. Geomech. Eng. 2023, 34, 221–231. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Chung, M.K.; Cho, G.C. Bovine casein as a new soil strengthening binder from diary wastes. Constr. Build. Mater. 2018, 160, 1–9. [Google Scholar] [CrossRef]

- Babatunde, Q.O.; Byun, Y.H. Soil Stabilization Using Zein Biopolymer. Sustainability 2023, 15, 2075. [Google Scholar] [CrossRef]

- Vishweshwaran, M.; Sujatha, E.R. Geotechnical Investigation of Gelatin Biopolymer on Cohesive Soils. Sustainability 2023, 15, 2041. [Google Scholar] [CrossRef]

- Sieger, J.L.; Lottermoser, B.G.; Freer, J. Evaluation of Protein and Polysaccharide Biopolymers as Dust Suppressants on Mine Soils: Laboratory Experiments. Appl. Sci. 2023, 13, 1010. [Google Scholar] [CrossRef]

- Alipal, J.; Pu’AD, N.M.; Lee, T.; Nayan, N.; Sahari, N.; Basri, H.; Idris, M.; Abdullah, H. A review of gelatin: Properties, sources, process, applications, and commercialisation. Mater. Today Proc. 2019, 42, 240–250. [Google Scholar] [CrossRef]

- Lee, M.; Chang, I.; Cho, G.C. Hydraulic erosion mitigation in sandy soil using cation-crosslinked gelation biopolymer. Acta Geotech. 2025. [Google Scholar] [CrossRef]

- ASTM D4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM D2166; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM International: West Conshohocken, PA, USA, 2016.

- Tinti, A.; Tugnoli, V.; Bonora, S.; Francioso, O. Recent applications of vibrational mid-infrared (IR) spectroscopy for studying soil components: A review. J. Cent. Eur. Agric. 2015, 16, 1–22. [Google Scholar] [CrossRef]

- Arun, L.; Sujatha, E.R.; Baldovino, J.A.; de la Rosa, Y.E.N. Microcrystalline Cellulose—A Green Alternative to Conventional Soil Stabilizers. Polymers 2024, 16, 2043. [Google Scholar] [CrossRef]

- Nouri, H.; Ghadir, P.; Fatehi, H.; Shariatmadari, N.; Saberian, M. Effects of Protein-Based Biopolymer on Geotechnical Properties of Salt-Affected Sandy Soil. Geotech. Geol. Eng. 2022, 40, 5739–5753. [Google Scholar] [CrossRef]

- Schrieber, R.; Gareis, H. Gelatine Handbook Theory and Industrial Practice; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar]

- Wiedmann, T.; Minx, J. A Definition of ‘Carbon Footprint’ ISA UK Research Report 07-01. 2007. Available online: www.censa.org.uk (accessed on 1 March 2025).

- IS 6403 (1981); Code of Practice for Determination of Bearing Capacity of Shallow Foundations. Bureau of Indian Standards: New Delhi, India, 1981.

- Hammond, G.; Jones, C.; Lowrie, E.F.; Tse, P. Embodied Carbon. The Inventory of Carbon and Energy (ICE). BSRIA BG10/2011. 2011. Available online: https://greenbuildingencyclopaedia.uk/wp-content/uploads/2014/07/Full-BSRIA-ICE-guide.pdf (accessed on 1 April 2023).

- Ashfaq, M.; Lal, M.H.; Moghal, A.A.B.; Murthy, V.R. Carbon Footprint Analysis of Coal Gangue in Geotechnical Engineering Applications. Indian Geotech. J. 2020, 50, 646–654. [Google Scholar] [CrossRef]

- Shillaber, C.M.; Mitchell, J.K.; Dove, J.E. Energy and Carbon Assessment of Ground Improvement Works. II: Working Model and Example. J. Geotech. Geoenviron. Eng. 2016, 142, 04015084. [Google Scholar] [CrossRef]

- Davis, S.C.; Boundy, R.G. Transportation Energy data Book: Edition 39; No. ORNL/TM-2020/1770; Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 2021. [Google Scholar]

- Kecojevic, V.; Komljenovic, D. Impact of Bulldozer’s Engine Load Factor on Fuel Consumption, CO2 Emission and Cost. Am. J. Environ. Sci. 2011, 7, 125–131. [Google Scholar] [CrossRef]

- Prusinski, J.R.; Bhattacharja, S. Effectiveness of Portland Cement and Lime in Stabilizing Clay Soils. Transp. Res. Rec. J. Transp. Res. Board 1999, 1652, 215–227. [Google Scholar] [CrossRef]

- Garzón, E.; Cano, M.; ÒKelly, B.C.; Sánchez-Soto, P.J. Effect of lime on stabilization of phyllite clays. Appl. Clay Sci. 2016, 123, 329–334. [Google Scholar] [CrossRef]

- Worrell, E.; Price, L.; Martin, N.; Hendriks, C.; Meida, L.O. Carbon Dioxide Emissions from the Global Cement Industry. 2001. Available online: www.annualreviews.org (accessed on 1 March 2025).

- Chang, I.; Lee, M.; Tran, A.T.P.; Lee, S.; Kwon, Y.-M.; Im, J.; Cho, G.-C. Review on biopolymer-based soil treatment (BPST) technology in geotechnical engineering practices. Transp. Geotech. 2020, 24, 100385. [Google Scholar] [CrossRef]

- Hammond, G.; Jones, C. Inventory of Carbon & Energy (ICE) Version 1.6a. 2008. Available online: https://perigordvacance.typepad.com/files/inventoryofcarbonandenergy.pdf (accessed on 15 February 2025).

| Geotechnical Properties | Value |

|---|---|

| Liquid limit (%) | 25 |

| Plastic limit (%) | 18.28 |

| Plasticity index (%) | 6.72 |

| Specific gravity | 2.71 |

| Maximum dry unit weight (MDUW) (kN/m3) | 19.23 |

| Optimum moisture content (OMC) (%) | 10 |

| Stage I | Materials (1) | Amount (m3) (2) | Unit Weight (t/m3) (3) | Weight (t) (4) | ECF (5) | CO2 e/t (6) = (4)*(5) |

|---|---|---|---|---|---|---|

| Embodied carbon of material | Soil | 3.33 | 1.92 | 6.39 | 0.02 | 0.127 |

| Gelatin | 0.037 | 1.74 | 0.064 | 10.5 | 0.67 | |

| Water | 1.03 | 1 | 1.03 | 0.0010 | 1.03 × 10−3 | |

| Total CO2 (t) emissions in Stage I = 0.79 | ||||||

| Stage II | Process | Vehicle | Capacity (t/L) | No of Loadings | Fuel (L) | ECF | CO2 e/t | |

|---|---|---|---|---|---|---|---|---|

| Excavation and procurement | Soil procurement | Pickup excavator | 10 | 0.639 | 0.639 | 3.25 | 2.07 | |

| Gelatin procurement | Pickup excavator | 10 | 0.0064 | 0.0064 | 3.25 | 0.020 | ||

| 2.09 | ||||||||

| Stage II | Process | Vehicle | Capacity (t/L) | Distance (km) | Trips | Fuel (L) | ECF | CO2 e/t |

| Haulage | Soil | Heavy-duty dumper | 25 | 1 | 1 | 0.31 | 3.25 | 1.007 |

| Gelatin | Heavy-duty dumper | 25 | 1 | 1 | 1.28 × 10−3 | 3.25 | 0.00416 | |

| Total CO2(t) emissions in Stage II = 3.54 1.011 | ||||||||

| Stage III | Process | Vehicle | Capacity (t/L) | Trips | Fuel (L) | ECF | CO2 e/t |

|---|---|---|---|---|---|---|---|

| Site operations | Spreading | Bull dozers | 10 | 0.63 | 0.63 | 3.25 | 2.04 |

| Mixing | Slurry mixer | 0.5 | 14.9 | 14.9 | 3.25 | 48.42 | |

| Compaction | Smooth wheel roller | 12 | 0.623 | 0.623 | 3.25 | 2.02 | |

| Total CO2(t) emissions in Stage III = 52.48 | |||||||

| Stage | Operation | Embodied Carbon (CO2 e/t) |

|---|---|---|

| Stage I | Materials | 0.79 |

| Stage II | Procurement and haulage | 3.54 |

| Stage III | Site operations | 52.48 |

| Total CO2(t) emissions = 56.81 | ||

| Material | Dosage (%) | Quantity Required (t) | ECF | Embodied Carbon (CO2 e/t) |

|---|---|---|---|---|

| Gelatin | 1 | 0.064 | 0.8 | 0.051 |

| Lime | 6 | 3349.17 | 0.76 | 2545.3 |

| Cement | 4 | 2232.78 | 0.95 | 2121.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sujatha, E.R.; Pratheeba, V.R.; Baldovino, J.D.J.A.; Nunez de la Rosa, Y.E. Application of Gelatin for Sustainable Stabilization of Low-Compressible Silt–Clay Mixtures: Geotechnical Behavior and Carbon Emission Considerations. Polymers 2025, 17, 1954. https://doi.org/10.3390/polym17141954

Sujatha ER, Pratheeba VR, Baldovino JDJA, Nunez de la Rosa YE. Application of Gelatin for Sustainable Stabilization of Low-Compressible Silt–Clay Mixtures: Geotechnical Behavior and Carbon Emission Considerations. Polymers. 2025; 17(14):1954. https://doi.org/10.3390/polym17141954

Chicago/Turabian StyleSujatha, Evangelin Ramani, Veera Ragavan Pratheeba, Jair De Jesus Arrieta Baldovino, and Yamid E. Nunez de la Rosa. 2025. "Application of Gelatin for Sustainable Stabilization of Low-Compressible Silt–Clay Mixtures: Geotechnical Behavior and Carbon Emission Considerations" Polymers 17, no. 14: 1954. https://doi.org/10.3390/polym17141954

APA StyleSujatha, E. R., Pratheeba, V. R., Baldovino, J. D. J. A., & Nunez de la Rosa, Y. E. (2025). Application of Gelatin for Sustainable Stabilization of Low-Compressible Silt–Clay Mixtures: Geotechnical Behavior and Carbon Emission Considerations. Polymers, 17(14), 1954. https://doi.org/10.3390/polym17141954