Coupled Mechanical/Dielectric Behavior of Bio-Modified PP/PBS Nanocomposites Reinforced with Organically Modified Montmorillonite

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Processing

2.3. Microstructural Analysis

2.4. Mechanical Testing Procedure

2.5. Dynamic Rheological Characterization

3. Experimental Results and Discussion

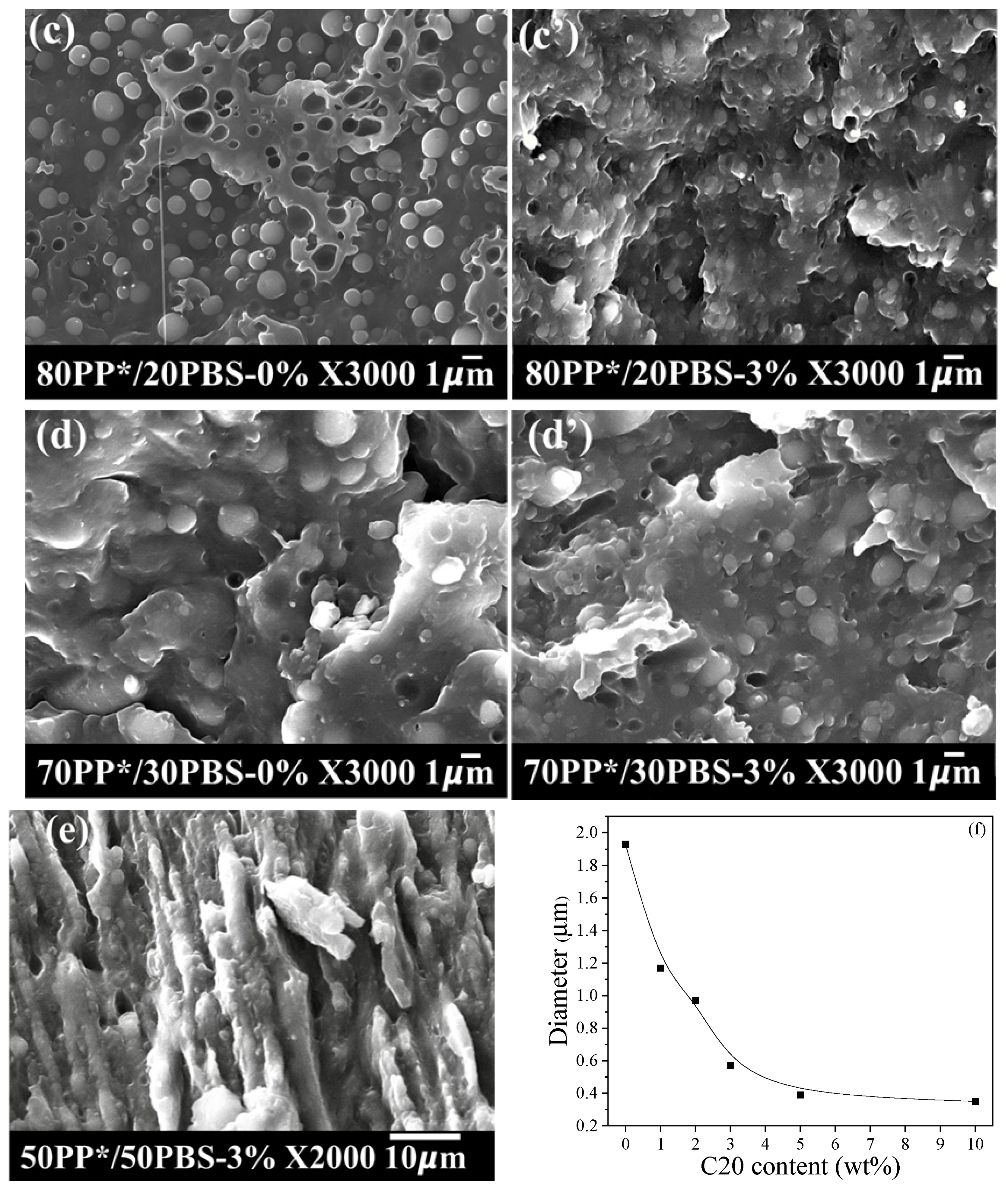

3.1. SEM Microstructural Observations

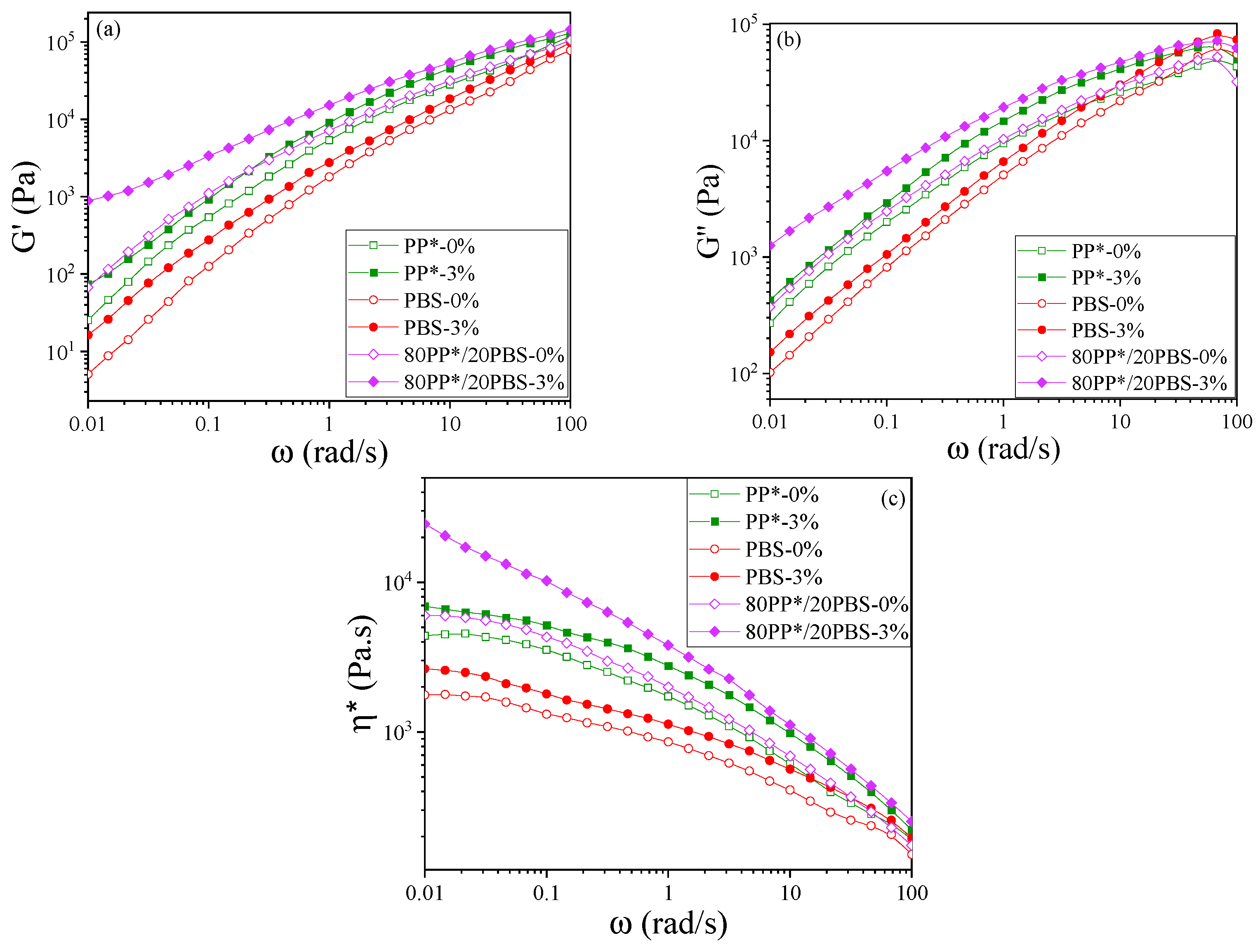

3.2. Rheological Characteristics

3.3. Mechanical Characterization

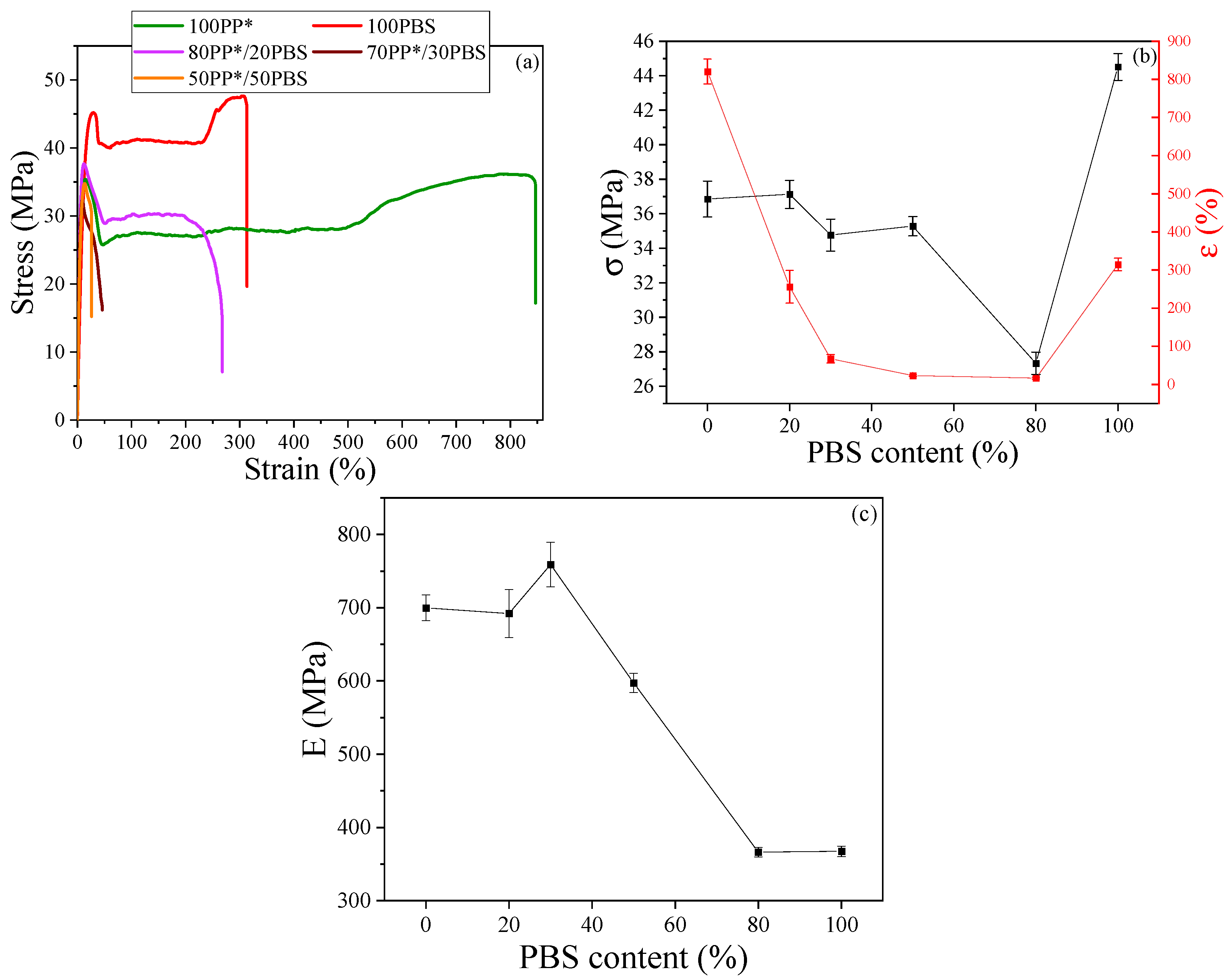

3.3.1. Mechanical Characterization of PP*/PBS Blends

3.3.2. Correlation Between Mechanical and Dielectric Responses in PP*/PBS Blends

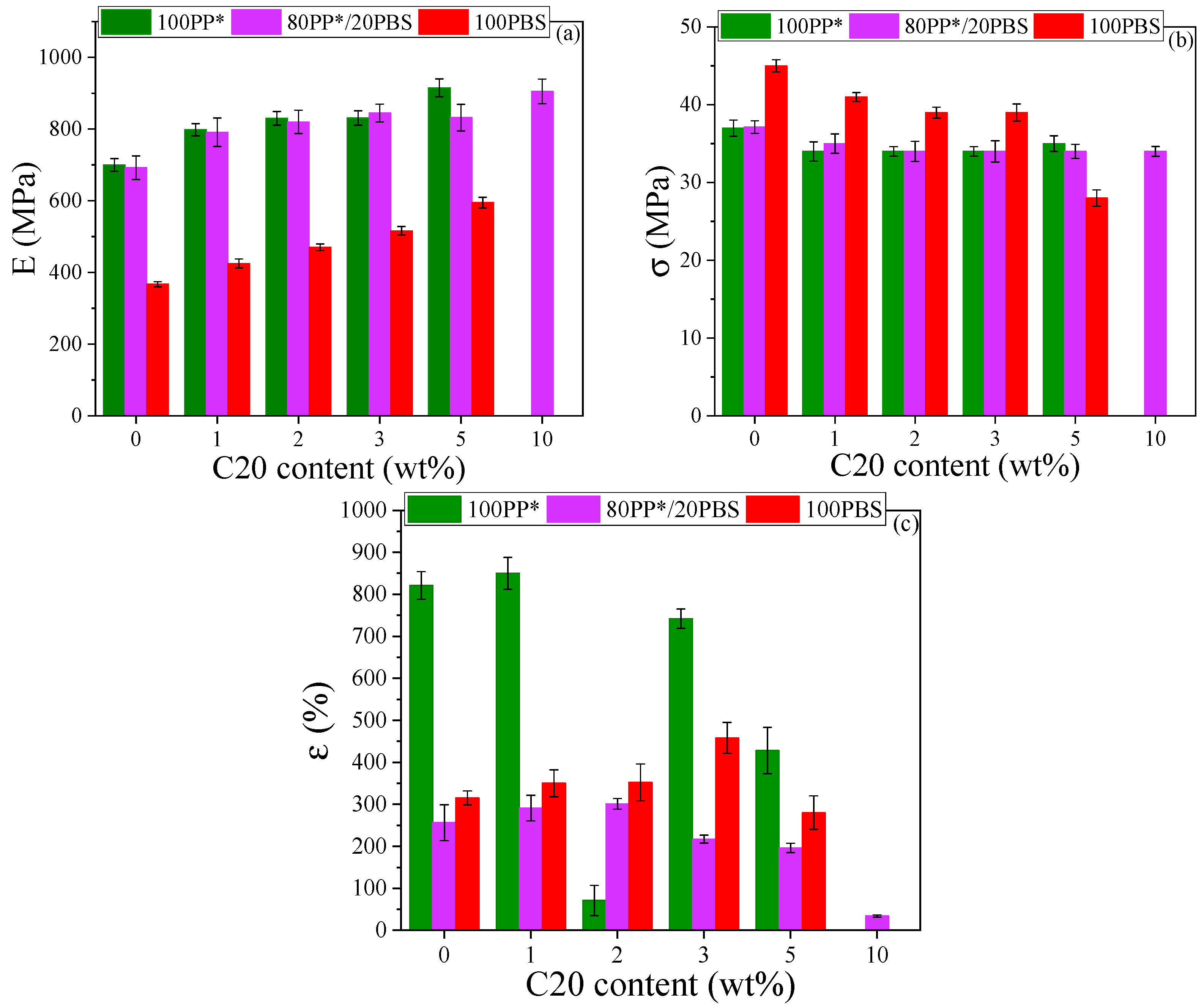

3.3.3. Effect of Cloisite 20 on the Mechanical Behavior of PP*, PBS, and PP*/PBS (80/20) Nanocomposites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PP | Polypropylene |

| PP-g-MA | Polypropylene grafted with Maleic Anhydride |

| PBS | Poly (butylene succinate) |

| PLA | Poly (lactic acid) |

| PCL | Poly (ε-caprolactone) |

| MFI | Melt Flow Index |

| C20 | Cloisite20 |

| BDS | Broadband Dielectric Spectroscopy |

| FE-SEM | Field Emission Scanning Electron Microscope |

| G′ | Storage modulus |

| G″ | Loss modulus |

| η* | Complex viscosity |

| ω | Angular frequency |

| λ | Relaxation time |

| α | Yasuda parameter |

| n | Power-law index |

| σ0 | Melt yield stress |

| σ | Tensile strength |

| ε | Elongation at break |

| E | Young’s modulus |

| MWS | Maxwell–Wagner–Sillars |

| IP | Interfacial Polarization |

| HN | Havriliak–Negami |

| Ea | activation energy |

| Δε | Relaxation strength |

References

- Jordá-Reolid, M.; Ibáñez-García, A.; Catani, L.; Martínez-García, A. Development of Blends to Improve Flexibility of Biodegradable Polymers. Polymers 2022, 14, 5223. [Google Scholar] [CrossRef] [PubMed]

- Rajeshkumar, L. Biodegradable Polymer Blends and Composites from Renewable Resources. In Biodegradable Polymers, Blends and Composites; Elsevier: Amsterdam, The Netherlands, 2022; pp. 527–549. [Google Scholar]

- Ramesh, M.; Muthukrishnan, M. 25—Biodegradable Polymer Blends and Composites for Food-Packaging Applications. In Biodegradable Polymers, Blends and Composites; Mavinkere Rangappa, S., Parameswaranpillai, J., Siengchin, S., Ramesh, M., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2022; pp. 693–716. ISBN 978-0-12-823791-5. [Google Scholar]

- Taktak, S.; Ghorbel, N.; Hammami, H.; Fakhfakh, S.; Rondot, S.; Jbara, O. Characterization of Compatibility of Polypropylene/Poly(Butylene Succinate) Blends: Impact of Weight Ratios on Interfacial Polarization. J. Mol. Liq. 2022, 368, 120633. [Google Scholar] [CrossRef]

- Bencharki, M.; Rondot, S.; Tara, A.; Jbara, O.; Berzin, F. Electrical and Mechanical Properties of Partially Bio-based PP/PBS Blends Nanocomposites Elaborated by Twin-screw Extrusion. J. Appl. Polym. Sci. 2021, 138, 51401. [Google Scholar] [CrossRef]

- Kim, H.-S.; Kim, H.-J. Miscibility and Performance Evaluation of Natural-Flour-Filled PP/PBS and PP/PLA Bio-Composites. Fibers Polym. 2013, 14, 793–803. [Google Scholar] [CrossRef]

- Maddah, H.A. Polypropylene as a Promising Plastic: A Review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar]

- Hossain, T.; Shahid, A.; Mahmud, N.; Habib, A.; Rana, M.; Khan, S.A.; Hossain, D. Research and Application of Polypropylene: A Review. Discov. Nano 2024, 19, 2. [Google Scholar] [CrossRef]

- Aliotta, L.; Seggiani, M.; Lazzeri, A.; Gigante, V.; Cinelli, P. A Brief Review of Poly (Butylene Succinate) (PBS) and Its Main Copolymers: Synthesis, Blends, Composites, Biodegradability, and Applications. Polymers 2022, 14, 844. [Google Scholar] [CrossRef]

- Rajgond, V.; Mohite, A.; More, N.; More, A. Biodegradable Polyester-Polybutylene Succinate (PBS): A Review. Polym. Bull. 2024, 81, 5703–5752. [Google Scholar] [CrossRef]

- Pracella, M. Blends and Alloys. In Modification of Polymer Properties; Elsevier: Amsterdam, The Netherlands, 2017; pp. 155–184. [Google Scholar]

- Ajitha, A.R.; Thomas, S. Introduction: Polymer Blends, Thermodynamics, Miscibility, Phase Separation, and Compatibilization. In Compatibilization of Polymer Blends; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–29. [Google Scholar]

- Arjomand, N.; Mohamadi, M.; Kaklar, J.A. Development of a Morphological-Based Predictive Model for Mechanical Properties of Binary Immiscible Polymer Blends Considering Interfacial Effects. Sci. Rep. 2025, 15, 7177. [Google Scholar] [CrossRef]

- Gcwabaza, T.; Ray, S.S.; Focke, W.W.; Maity, A. Morphology and Properties of Nanostructured Materials Based on Polypropylene/Poly(Butylene Succinate) Blend and Organoclay. Eur. Polym. J. 2009, 45, 353–367. [Google Scholar]

- Sivanjineyulu, V.; Chang, Y.-H.; Chiu, F.-C. Characterization of Carbon Nanotube- and Organoclay-Filled Polypropylene/Poly(Butylene Succinate) Blend-Based Nanocomposites with Enhanced Rigidity and Electrical Conductivity. J. Polym. Res. 2017, 24, 130. [Google Scholar] [CrossRef]

- Ain, S.N.; Bijarimi, M.; Ahmad, M.N.; Normaya, E.; Mulkiyan, L.O.M.Z. Preparation and Characterization of Poly (Lactic Acid) (PLA)/Polypropylene (PP) Binary Blend with Graphene Nanoplatelet (GNP). In Proceedings of the 3rd Energy Security and Chemical Engineering Congress (ESChE 2023), Langkawi, Malaysia, 28–30 August 2023; AIP Publishing LLC: Melville, NY, USA, 2025; Volume 3225, p. 020017. [Google Scholar]

- Raj, A.; Rithik, P.; Sudheer, P.S.; Vachan, K.S.; Kannan, M. Effect of Compatibilizer and Nanosilica on the Mechanical, Thermal, and Degradation Kinetic Properties of Polypropylene/Polylactic Acid Blends. Polyolefins J. 2024, 11, 43–59. [Google Scholar]

- Taktak, S.; Ghorbel, N.; Fakhfakh, S.; Rondot, S.; Jbara, O.; Arous, M. Organoclay-Filled PP/PBS Polymer Blends: Insights into Morphology, Thermal Stability, and Dielectric Behavior. J. Mol. Liq. 2025, 437, 128338. [Google Scholar] [CrossRef]

- Taktak, S.; Fakhfakh, S.; Rondot, S.; Tara, A.; Jbara, O. Behavior Under Electron Irradiation of Two Clay-Based Polymer Nanocomposites PPgMA/OMMT and PBS/OMMT. Mater. Chem. Phys. 2022, 275, 125230. [Google Scholar] [CrossRef]

- Lertwimolnun, W.; Vergnes, B. Influence of Compatibilizer and Processing Conditions on the Dispersion of Nanoclay in a Polypropylene Matrix. Polymer 2005, 46, 3462–3471. [Google Scholar] [CrossRef]

- Yousfi, M.; Livi, S.; Dumas, A.; Crépin-Leblond, J.; Greenhill-Hooper, M.; Duchet-Rumeau, J. Compatibilization of Polypropylene/Polyamide 6 Blends Using New Synthetic Nanosized Talc Fillers: Morphology, Thermal, and Mechanical Properties. J. Appl. Polym. Sci. 2014, 131, app.40453. [Google Scholar] [CrossRef]

- Hong, J.S.; Namkung, H.; Ahn, K.H.; Lee, S.J.; Kim, C. The Role of Organically Modified Layered Silicate in the Breakup and Coalescence of Droplets in PBT/PE Blends. Polymer 2006, 47, 3967–3975. [Google Scholar] [CrossRef]

- Sivanjineyulu, V.; Behera, K.; Chang, Y.-H.; Chiu, F.-C. Selective Localization of Carbon Nanotube and Organoclay in Biodegradable Poly(Butylene Succinate)/Polylactide Blend-Based Nanocomposites with Enhanced Rigidity, Toughness and Electrical Conductivity. Compos. Part. A Appl. Sci. Manuf. 2018, 114, 30–39. [Google Scholar] [CrossRef]

- Huitric, J.; Ville, J.; Médéric, P.; Moan, M.; Aubry, T. Rheological, Morphological and Structural Properties of PE/PA/Nanoclay Ternary Blends: Effect of Clay Weight Fraction. J. Rheol. 2009, 53, 1101–1119. [Google Scholar]

- Yasuda, K.; Armstrong, R.C.; Cohen, R.E. Shear Flow Properties of Concentrated Solutions of Linear and Star Branched Polystyrenes. Rheol. Acta 1981, 20, 163–178. [Google Scholar] [CrossRef]

- Vergnes, B. The Use of Apparent Yield Stress to Characterize Exfoliation in Polymer Nanocomposites. Int. Polym. Process. 2011, 26, 229–232. [Google Scholar] [CrossRef]

- Li, J.; Zhou, C.; Wang, G.; Zhao, D. Study on Rheological Behavior of Polypropylene/Clay Nanocomposites. J. Appl. Polym. Sci. 2003, 89, 3609–3617. [Google Scholar] [CrossRef]

- Gu, S.; Ren, J.; Wang, Q. Rheology of Poly(Propylene)/Clay Nanocomposites. J. Appl. Polym. Sci. 2004, 91, 2427–2434. [Google Scholar] [CrossRef]

- Okamoto, K.; Sinha Ray, S.; Okamoto, M. New Poly(Butylene Succinate)/Layered Silicate Nanocomposites. II. Effect of Organically Modified Layered Silicates on Structure, Properties, Melt Rheology, and Biodegradability. J. Polym. Sci. B Polym. Phys. 2003, 41, 3160–3172. [Google Scholar] [CrossRef]

- Mezger, T. The Rheology Handbook: For Users of Rotational and Oscillatory Rheometers; Vincentz Verlag: Hannover, Germany, 2002. [Google Scholar]

- Yeh, S.; Kim, K.; Gupta, R.K. Synergistic Effect of Coupling Agents on Polypropylene-based Wood–Plastic Composites. J. Appl. Polym. Sci. 2013, 127, 1047–1053. [Google Scholar] [CrossRef]

- Bahar, E.; Ucar, N.; Onen, A.; Wang, Y.; Oksüz, M.; Ayaz, O.; Ucar, M.; Demir, A. Thermal and Mechanical Properties of Polypropylene Nanocomposite Materials Reinforced with Cellulose Nano Whiskers. J. Appl. Polym. Sci. 2012, 125, 2882–2889. [Google Scholar] [CrossRef]

- Choi, I.S.; Kim, Y.K.; Hong, S.H.; Seo, H.-J.; Hwang, S.-H.; Kim, J.; Lim, S.K. Effects of Polybutylene Succinate Content on the Rheological Properties of Polylactic Acid/Polybutylene Succinate Blends and the Characteristics of Their Fibers. Materials 2024, 17, 662. [Google Scholar] [CrossRef]

- Choudhary, P.; Mohanty, S.; Nayak, S.K.; Unnikrishnan, L. Poly(L-lactide)/Polypropylene Blends: Evaluation of Mechanical, Thermal, and Morphological Characteristics. J. Appl. Polym. Sci. 2011, 121, 3223–3237. [Google Scholar] [CrossRef]

- Okada, K.; Mitsunaga, T.; Nagase, Y. Properties and Particles Dispersion of Biodegradable Resin/Clay Nanocomposites. Korea-Aust. Rheol. J. 2003, 15, 43–50. [Google Scholar]

- Yetgin, S.H.; Unal, H.; Ermis, K. The Effect of Nanoclay Filler Addition on the Foaming and Mechanical Properties of Polypropylene. Polym. Int. 2024, 73, 719–726. [Google Scholar] [CrossRef]

- Tarapow, J.A.; Bernal, C.R.; Alvarez, V.A. Mechanical Properties of Polypropylene/Clay Nanocomposites: Effect of Clay Content, Polymer/Clay Compatibility, and Processing Conditions. J. Appl. Polym. Sci. 2009, 111, 768–778. [Google Scholar] [CrossRef]

- Phua, Y.J.; Chow, W.S.; Mohd Ishak, Z.A. Poly(Butylene Succinate)/ Organo-Montmorillonite Nanocomposites: Effects of the Organoclay Content on Mechanical, Thermal, and Moisture Absorption Properties. J. Thermoplast. Compos. Mater. 2011, 24, 133–151. [Google Scholar] [CrossRef]

- Perez, C.J.; Alvarez, V.A. Overall Crystallization Behavior of Polypropylene–Clay Nanocomposites; Effect of Clay Content and Polymer/Clay Compatibility on the Bulk Crystallization and Spherulitic Growth. J. Appl. Polym. Sci. 2009, 114, 3248–3260. [Google Scholar] [CrossRef]

- Qu, Y.; Lin, L.; Gao, S.; Yang, Y.; Huang, H.; Li, X.; Ren, H.; Luo, W. A Molecular Dynamics Study on Adsorption Mechanisms of Polar, Cationic, and Anionic Polymers on Montmorillonite. RSC Adv. 2023, 13, 2010–2023. [Google Scholar] [CrossRef]

- Pavlidou, S.; Papaspyrides, C.D. A Review on Polymer–Layered Silicate Nanocomposites. Prog. Polym. Sci. 2008, 33, 1119–1198. [Google Scholar] [CrossRef]

- Bordes, P.; Pollet, E.; Avérous, L. Nano-Biocomposites: Biodegradable Polyester/Nanoclay Systems. Prog. Polym. Sci. 2009, 34, 125–155. [Google Scholar] [CrossRef]

- Alexandre, M.; Dubois, P. Polymer-Layered Silicate Nanocomposites: Preparation, Properties and Uses of a New Class of Materials. Mater. Sci. Eng. R Rep. 2000, 28, 1–63. [Google Scholar] [CrossRef]

| Name | PP (wt%) | PPgMA (wt%) | PBS (wt%) |

|---|---|---|---|

| PBS | 0 | 0 | 100 |

| PP* | 90 | 10 | 0 |

| 80PP*/20PBS | 70 | 10 | 20 |

| 70PP*/30PBS | 60 | 10 | 30 |

| 50PP*/50PBS | 40 | 10 | 50 |

| 20PP*/80PBS | 10 | 10 | 80 |

| PP* | PBS | 80PP*/20PBS | ||||

|---|---|---|---|---|---|---|

| 0%C20 | 3%C20 | 0%C20 | 3%C20 | 0%C20 | 3%C20 | |

| σ0 (Pa) | 0 | 20 | 0 | 15 | 0 | 165 |

| η0 (Pa·s) | 4400 | 5800 | 1750 | 1900 | 9400 | 13,500 |

| λ (s) | 3.2 | 1.7 | 0.90 | 0.75 | 2.9 | 3.9 |

| α | 0.7 | 0.75 | 0.46 | 0.61 | 0.39 | 0.58 |

| n | 0.46 | 0.38 | 0.5 | 0.49 | 0.35 | 0.34 |

| Name | Δε | Ea |

|---|---|---|

| 50PP*/50PBS | 1.75 | 0.40 ± 0.010 |

| 70PP*/30PBS | 0.72 | 0.45 ± 0.005 |

| 80PP*/20PBS | 0.52 | 0.54 ± 0.008 |

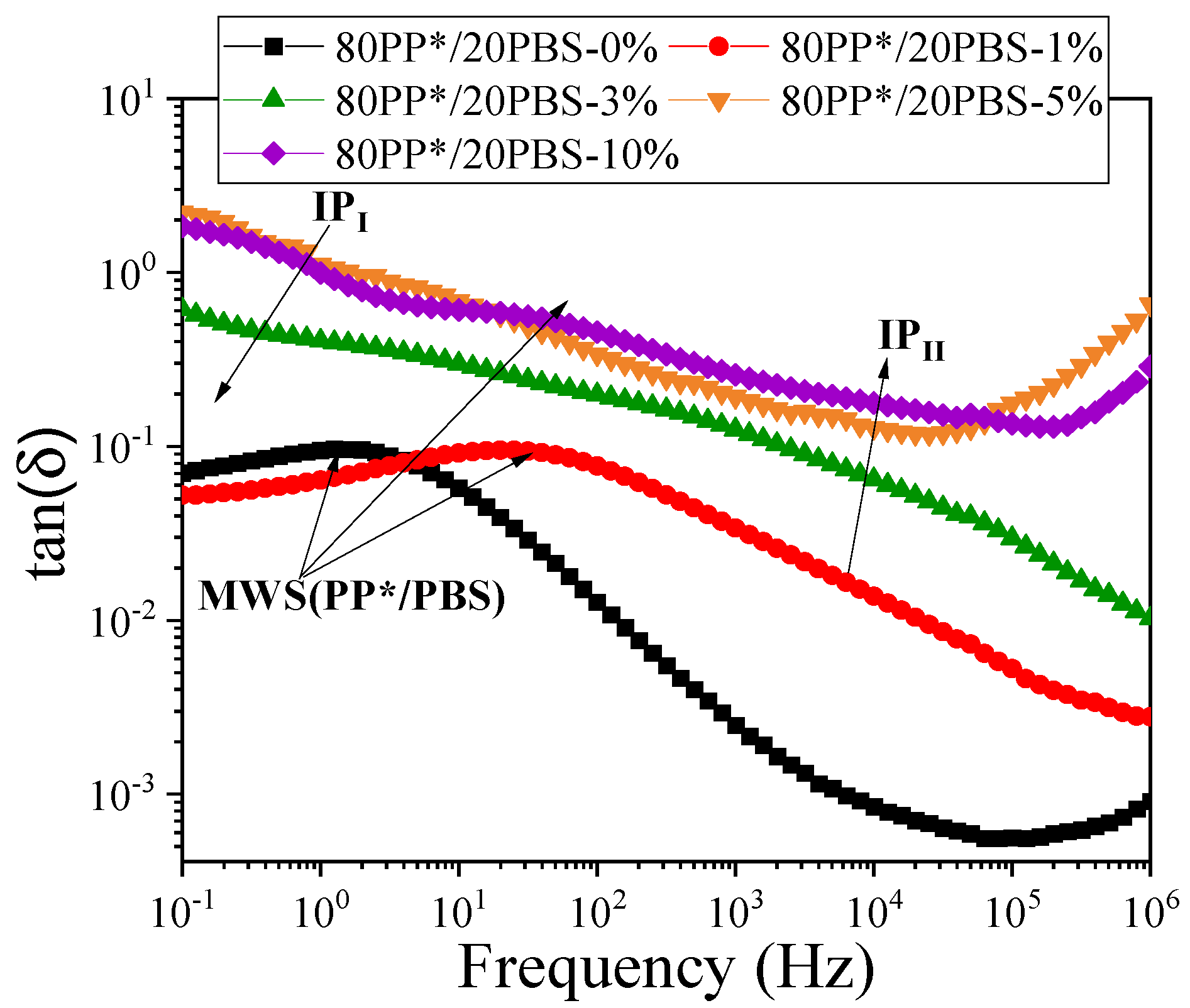

| Name | Ea (MWS) | Ea (IPI) | Ea (IPII) |

|---|---|---|---|

| 80PP*/20PBS-0% | 0.54 ± 0.008 | - | - |

| 80PP*/20PBS-1% | 0.54 ± 0.007 | 0.35 ± 0.006 | 0.40 ± 0.003 |

| 80PP*/20PBS-3% | 0.58 ± 0.004 | 0.48 ± 0.006 | 0.50 ± 0.003 |

| 80PP*/20PBS-5% | 0.66 ± 0.001 | 0.42 ± 0.003 | 0.53 ± 0.003 |

| 80PP*/20PBS-10% | 0.69 ± 0.003 | 0.36 ± 0.001 | 0.6 ± 0.006 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taktak, S.; Ghorbel, N.; Rondot, S.; Jbara, O.; Tara, A. Coupled Mechanical/Dielectric Behavior of Bio-Modified PP/PBS Nanocomposites Reinforced with Organically Modified Montmorillonite. Polymers 2025, 17, 3063. https://doi.org/10.3390/polym17223063

Taktak S, Ghorbel N, Rondot S, Jbara O, Tara A. Coupled Mechanical/Dielectric Behavior of Bio-Modified PP/PBS Nanocomposites Reinforced with Organically Modified Montmorillonite. Polymers. 2025; 17(22):3063. https://doi.org/10.3390/polym17223063

Chicago/Turabian StyleTaktak, Sirine, Nouha Ghorbel, Sébastien Rondot, Omar Jbara, and Ahmed Tara. 2025. "Coupled Mechanical/Dielectric Behavior of Bio-Modified PP/PBS Nanocomposites Reinforced with Organically Modified Montmorillonite" Polymers 17, no. 22: 3063. https://doi.org/10.3390/polym17223063

APA StyleTaktak, S., Ghorbel, N., Rondot, S., Jbara, O., & Tara, A. (2025). Coupled Mechanical/Dielectric Behavior of Bio-Modified PP/PBS Nanocomposites Reinforced with Organically Modified Montmorillonite. Polymers, 17(22), 3063. https://doi.org/10.3390/polym17223063