Abstract

Carbon fiber reinforced polymer (CFRP) components require precise curing process control to ensure quality, but traditional phenomenological cure kinetics models face limitations in handling nonlinearity and data diversity. This study addresses the challenges in modeling the cure kinetics of carbon fiber reinforced polymer (CFRP) composites, where traditional phenomenological models lack generalizability and neural networks suffer from robustness issues due to their numerous hyperparameters and data dependency. To overcome these limitations, a novel machine learning model called the angle information-enhanced radial basis function (RBF) model is proposed, which integrates both Euclidean distance and angular relationships between data points to improve prediction stability and accuracy. The performance of this machine learning approach is systematically compared against an autocatalytic model and a neural network using dynamic DSC data from T700/2626 epoxy resin at multiple heating rates. The angle-enhanced RBF model balances accuracy, efficiency, and robustness, offering a reliable data-driven alternative for CFRP cure kinetics prediction without requiring extensive data or complex hyperparameter optimization, thus facilitating better process control in manufacturing.

1. Introduction

Carbon fiber reinforced polymer (CFRP) has been extensively utilized in various fields to replace conventional materials, owing to its excellent characteristics, such as higher specific strength and stiffness, design flexibility, and monolithic molding [1,2,3]. These characteristics make it particularly suitable for manufacturing critical aircraft components (e.g., wing skins, U-shaped flat tail leading edges, and tail structural components) that endure significant dynamic and vibratory loads during service [4,5]. In order to meet the strict requirements for size accuracy and quality of these components, they are usually manufactured using an autoclave process that involves hot-press curing of CFRP. During the autoclave process, CFRP is subjected to heating according to a predetermined thermal cure cycle while simultaneously being pressurized to a specified level [6]. This process involves a series of complex thermochemical and physical changes, including heat transfer, polymerization reaction, curing exotherm, and property evolution. These reactions may result in uneven distribution of temperature gradients and non-uniform distribution of degree of cure (DoC), which eventually leads to component deformation and quality deterioration. Among the numerous factors influencing the quality of CFRP components, the curing process and final curing state of resin play a critical role [7]. The curing of thermosetting resins is an irreversible process characterized by crosslinking and hardening, which progresses monotonically toward a fully cured state, and the response of the resin is often nonlinear. Therefore, modeling reliable cure kinetics of the resin in CFRP composites is indispensable for predicting material behavior, designing efficient processes, and controlling the performance quality of components [8,9].

To date, researchers have developed numerous modeling methodologies for cure kinetics. Cure kinetics models are generally categorized as either mechanistic or phenomenological models [10]. Mechanism models are derived from the equilibrium of various reactants involved in the complex reaction, which can make their development challenging. In comparison, phenomenological models describe the overall reaction rate without accounting for the complex details of the reactants and their reaction, offering a flexible, intuitive, and practical approach for studying cure kinetics across diverse formulations and curing conditions [11]. As a result, phenomenological models are widely adopted as the preferred framework for describing resin cure kinetics, with notable examples including the autocatalytic model, the n-order model, the Kamal–Sourour model, etc. Among them, the Kamal–Sourour model is the most widely studied model [12,13]. Lopez et al. [14] utilized the activation energy proposed by Kissinger to determine the parameters of the Kamal–Sourour model and successfully described the vulcanization process of silicone rubber. Hernandez-Ortiz et al. [15] developed a numerical methodology that fitted the autocatalytic Kamal–Sourour model exclusively to dynamic DSC data, bypassing traditional isothermal methods, and validated it on silicone rubber and phenolic resins. Sun et al. [16] focused on methods dealing with variable activation energy for epoxy-based systems; their investigation into autocatalytic behavior was conceptually aligned with the kinetic principles that the Kamal model described. Liu et al. [17] introduced a variable activation energy concept to account for ultrasonic non-thermal effects and incorporated this energy into the Sun–Gang modified autocatalytic equation.

However, Hardis and Muphalilele [18,19] demonstrated that the heat generated by the resin increases as the heating rate increases, including the initial curing temperature, peak curing temperature, and final curing temperature. Furthermore, the inherent discreteness and diversity of cure kinetics phenomenological models lead to difficulty in forming a unified and general model [20]. Due to the high nonlinearity of this inverse problem, determining the coefficients is challenging in the case of differential equations. Although researchers have recognized this issue and endeavored to predict cure kinetics through one-by-one fitting of experimental data, this approach does not permit continuous fitting of cure kinetics behavior. Consequently, it is unsuitable for continuous learning from the growing volume of resin cure kinetics data and hinders synchronous application of this knowledge in component manufacturing.

In recent years, alongside advances in big data and computational power, data-driven methods have demonstrated significant potential. Neural network models can learn the complex mappings inherent in cure kinetics in a black-box manner, providing novel approaches to handle the highly nonlinear problems encountered during the curing and molding process of CFRP [4,21,22]. Many researchers have reported that they have employed various neural network algorithms to predict problems related to cure kinetics. Carlone et al. [23] coupled an artificial neural network (ANN) with a finite element thermochemical model to optimize the thermal curing process of high-temperature composites. Fan et al. [24] demonstrated the application of a convolutional neural network (CNN) combined with the finite element (FE) method to predict process-induced deformation cloud maps of composite structures. Hui et al. [20] replaced conventional cure kinetics models with neural networks to comprehensively model the CFRP cure process. Yang et al. [4] developed lightweight neural networks with incremental learning capability that effectively addressed generalization and continuous learning challenges in cure kinetics modeling. Generally, the core of neural networks lies in stacking hidden layers or increasing the number of convolutional kernels to enhance their ability to learn essential features from cure kinetics data [25,26]. This inevitably necessitates the use of additional optimization operators, such as batch or stochastic gradient descent methods, to determine the values of their numerous hyperparameters. The large number of parameters, on the one hand, requires extra optimization methods to identify their optimal values; on the other hand, it demands a substantial amount of sample data to provide sufficient essential feature information for accurate parameter estimation. As a result, the specific outcomes of each prediction may vary significantly, indicating poor robustness, which may not fully meet the robustness requirements of the prediction results required by the cure kinetics model.

In contrast, classical machine learning models such as Gaussian Process (GP), Radial Basis Function (RBF), and Support Vector Machine (SVM) are typically derived from strict mathematical assumptions or principles to build mathematical models capable of fitting the core features of real cure kinetics data, and these models feature a rigorous derivation process and fewer hyperparameters [27,28,29]. Compared with neural networks, machine learning models provide stable prediction results and are less susceptible to the influence of hyperparameters. However, so far, almost no researchers have constructed accurate machine learning prediction models for curing behavior. Therefore, how to build a machine learning model that can balance predictive robustness and accuracy is the first research focus of this paper.

Moreover, although plenty of studies have reported that the curing behavior can be modeled through dynamic or isothermal processes utilizing various models and algorithms, the existing research results remain highly fragmented. Firstly, most studies are limited to the application and validation of a single model, lacking a systematic comparative analysis of phenomenological versus multiple data-driven models under a unified dataset and evaluation framework. Secondly, there is an insufficiently clear delineation of the relative strengths and weaknesses of different models regarding prediction accuracy, computational efficiency, and generalizability, which creates confusion for engineers in selecting appropriate models. Therefore, how to systematically experiment and analyze the machine learning model proposed in this paper with other models in terms of prediction accuracy, computational efficiency, and generalization ability is the second research focus.

Considering the above issues, this paper innovatively designed an angle information-enhanced RBF, in which both the angle information and Euclidean distance were simultaneously integrated, to improve the stability and accuracy for fitting the complex features in cure kinetics. Moreover, this work also focused on investigating the theoretical foundations of the existing cure kinetics modeling approaches—namely, the autocatalytic model and the neural network model—and conducted a comprehensive evaluation between the angle information-enhanced RBF and these models to validate the performance. Specifically, the dynamic heat flow of the resin was measured at various heating rates using differential scanning calorimetry (DSC), and the resulting data were integrated to serve as the foundation for subsequent cure kinetics modeling. In the developed network architecture, the degree of cure (DoC), temperature, and heating rate served as the input variables, while the reaction rate was the output; the entire dataset was utilized to train this model. Subsequently, the theoretical basis and model development process for the phenomenological neural network and the proposed machine learning model were examined. Finally, a comprehensive comparative evaluation was performed across multiple dimensions, including prediction accuracy, computational cost, and model robustness.

2. Materials and Experimental

T700/2626 epoxy composites are developed in the aerospace field. The 2626 epoxy resin used in this study was a thermoset and toughened epoxy resin, provided by Nanchang Jiading Company, Nanchang, China. The resins were frozen and stored at 253 K until use. The manufacturer’s recommended cure cycle is as follows: (1) Resin is heated from room temperature to 398 K at 2–3 K/min. (2) Temperature is held at 398 K for 120 min and finally cooled at 2 K/min.

To comprehensively study the thermomechanical behavior of 2626 epoxy resin, all DSC non-isothermal experiments were performed on a Netzsch DSC 3500 instrument, Selb, Bavaria, Germany (enthalpy accuracy: ±0.01%) [30]. Resin specimens weighing about 10 mg were sealed in aluminum hermetic pans and placed in the DSC for each measurement. The gas used in the experiment was a nitrogen atmosphere with a flow rate of 40 mL/min. Based on the cure characteristics of 2626 epoxy resin, the dynamic scans were ramped up from 293 K to 523 K at six various heating rates of 1.0, 2.5, 5.0, 10.0, 15.0, and 20.0 K/min, and the corresponding temperature and heat flow data during the process were monitored and used to calculate the degree of conversion rate.

3. Experimental Results

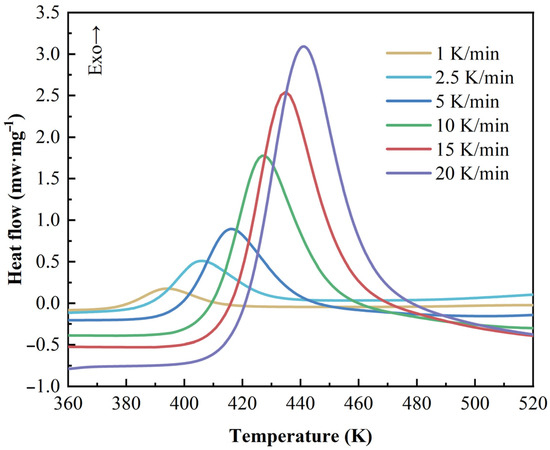

As shown in Figure 1, from the dynamic scans, the normalized heat flow curves versus temperature can be obtained at different heating rates. With increasing temperature, the reaction is activated when the exothermic heat flux rate starts to deviate gradually from its steady-state value. The 2626 resin exhibits only one exothermic peak that shifts to a higher temperature with an increase in the heating rate. This phenomenon is mainly due to more external energy being applied to the resin within the relatively shorter total reaction time. The average amount of ultimate reaction heat per unit mass is calculated to be 156.62 J/g by the area under the curve. The results show that the 2626 resin releases energy mainly within a relatively long temperature range, and total exothermal energy is not that high.

Figure 1.

Dynamic DSC curves of epoxy resin at different heating rates (the ‘Exo’ arrow indicates the direction of an exothermic signal in the DSC curve).

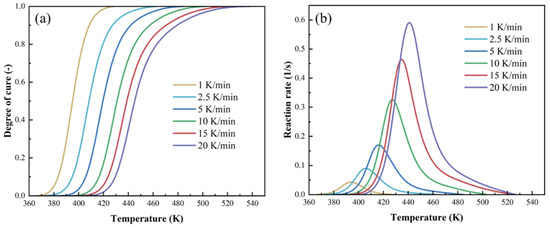

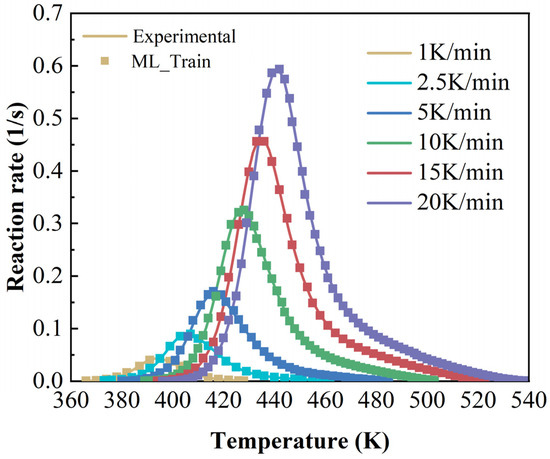

In Figure 2a, the degree of cure obtained from heat flow integration at different heating rates is plotted, and the curing reaction rate of the resin is presented in Figure 2b. The reaction mainly occurred between 370 K and 520 K. The curing curve demonstrates a tendency to shift toward higher temperatures with increasing heating rates. The conversion of resin proceeds as a sigmoidal curve at different heating rates. Furthermore, the temperature sensitivity of resin makes the interval between degree-of-cure (DoC) curves narrow at higher heating rates. Obviously, the reaction rate also increases as the heating rate rises.

Figure 2.

(a) Curves of the relationship between degree of cure and temperature at different heating rates; (b) curves of the relationship between reaction rate and temperature.

4. Cure Kinetics Methodology

To ensure the accuracy and reliability of the determined kinetics, three distinct methods were adopted. This multi-faceted strategy allows for cross-validation and enhances confidence in the final estimated values. More details are given below.

4.1. Autocatalytic Model

The curing reaction of epoxy resin is exothermic, and DSC can monitor the heat flow signal during the curing process. The heat flow measured by DSC, denoted as dH/dt, represents the curing reaction rate [31]. This rate can be integrated to determine α, which indicates the degree of cure or conversion. The reaction rate is typically described by a temperature-dependent rate function K(T) and a conversion function f(α) as expressed in Equation (1):

where dα/dt is the cure kinetics rate, α is the curing degree of the resin, and t is the curing time. K(T) is the temperature relationship of the rate constant, and f(α) is the reaction mechanism function.

For epoxy resin, the phenomenological model is the most prevalent approach for predicting the cure kinetics behavior, typically based on fitting empirical equations. The crucial step for cure kinetics modeling is to understand the reaction progression for selecting the appropriate reaction mechanism function. These models can principally be classified into two major types: nth order and autocatalytic. As shown in Figure 3, the heat evolution of 2626 resin reaches its maximum at 30–40% of the reaction progress, demonstrating cure kinetics behavior characteristic of an autocatalytic reaction. The autocatalytic model uses a single rate constant to simulate the entire curing process. In practice, multiple events may lead to highly complex mechanisms. Therefore, using multiple rate constants can yield more accurate modeling outcomes. The autocatalytic model, a phenomenological model that incorporates two rate constants, has been widely used to model numerous resin systems [32]. Equation (2) can be expressed as follows:

Figure 3.

(a) FWO method fitting curves for resin at different degrees of cure; (b) variation in resin activation energy with degree of cure.

Therein, A is the pre-exponential factor, Eα is the activation energy, R is the ideal gas constant, and T is the absolute temperature, and m and n represent the reaction orders.

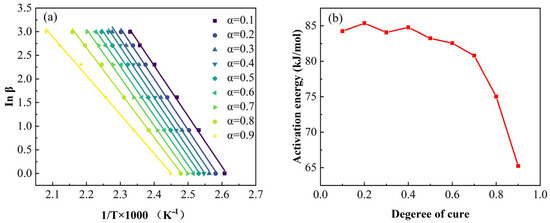

Another critically important parameter is the apparent activation energy Eα. In non-isothermal curing processes with constant heating rate β, these parameters can be determined through the isoconversional method and single-speed method. Given that isoconversional methods provide theoretically rigorous results, the Flynn–Wall–Ozawa (FWO) isoconversional method was employed to calculate both Eα and the pre-exponential factor A [33]. The FWO method’s Equation (3) is as follows:

where β is the heating rate, and g(α) is the integral function of conversion.

In the FWO model, when selecting a fixed degree of cure α, the integral form of the kinetic mechanism function g(α) remains constant. If the curve of lnβ versus 1/Tα (where Tα is the temperature at the selected conversion α) is plotted for different heating rates, the apparent activation energy Eα can be determined from the slope of the linear fit. As shown in Figure 4, the corresponding linear fitting curves and the variation in the activation energy (Eα) as a function of the degree of cure (α). Analysis revealed a significant change in activation energy when the degree of cure exceeded 0.4. Given the substantial variation in activation energy during the curing process, the conventional constant Eα model proves inadequate. The modified Sun–Gang variable activation energy framework was consequently employed to characterize the cure kinetics of 2626 epoxy resin [34]. This model assumes that the activation energy Eα and pre-exponential factor lnA are functions of α (degree of cure). Equation (4) can be expressed as follows:

Figure 4.

Comparison curves of experimental and calculated values of dα/dT~T at different heating rates (autocatalytic model).

Through polynomial fitting, the values of each parameter can be determined. Taking α (degree of cure) and T (temperature) as independent variables, and β·dα/dT (heating rate multiplied by the rate of cure conversion) as the dependent variable, the model parameters were regressed using the Particle Swarm Optimization (PSO) algorithm [35] to obtain the global optimal solution, as listed in Table 1.

Table 1.

Modified Sun–Gang model kinetic parameters.

The accuracy of the cure kinetics equation obtained using the modified Sun–Gang model can be verified by comparing the experimentally derived and model-calculated dα/dT~T curves. The comparison curves are shown in Figure 4 (Auto_train means autocatalytic model—training).

4.2. Neural Network Model

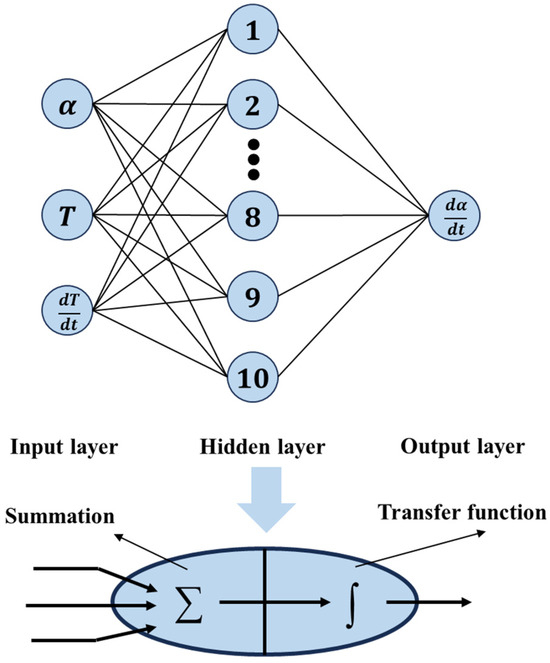

The artificial neural network (ANN) is a biologically inspired computational system composed of interconnected processing units (neurons) organized in layered architectures. The backpropagation neural network (BPNN) represents a prominent subclass of ANN [36,37]. BPNN has two core attributes: (1) a strictly feedforward multilayer architecture including input, hidden, and output layers, and (2) an error-driven learning algorithm called backpropagation. This error-driven learning mechanism enables BPNN to iteratively refine synaptic weights by propagating output discrepancies backward through the network, making it exceptionally effective for modeling complex relationships in tasks like non-isothermal DSC data prediction. In non-isothermal DSC analysis of resins, BPNN employs a layered architecture where the input layer receives experimental parameters, one or more hidden layers perform nonlinear transformational processing, and the output layer generates critical predictions. Figure 5 illustrates schematically the concepts of BPNN.

Figure 5.

The structure of the proposed BP neural network.

Equation (5) serves to describe the BPNN model [38]:

where xi represents the input layer; zj represents the hidden layer; yk represents the output layer; wij and wjk are weights, where the weight between the i neuron in the input layer and the j neuron in the hidden layer is represented by wij, and the weight between the j neuron in the hidden layer and the k neuron in the output layer is represented by wjk; and bj and bk are biases. Each neuron processes the inputs using weight factors wij and biases bj to produce an output result. Every neuron estimates the output signal by computing the sum of weighted inputs and biases, then transforming this sum through a sigmoid transfer, as shown in Equation (6):

Any BPNN must be trained using available input/output datasets before being applied to practical problems. During training, the network first processes inputs forward through weighted connections and a transfer function to generate predictions, then calculates prediction errors against experimental DSC data. These errors are backpropagated through the network layers, where gradients for each weight are computed using the chain rule of calculus, and then updated via optimization methods to minimize the loss. Based on the cure kinetics results, a BPNN with a three-layer structure was designed, comprising an input layer, a hidden layer, and an output layer. Each layer contains multiple neurons composed of a fully connected adder and activation function. Three factors serve as the input, and one factor serves as the output. Empirical formulas and refereed literature revealed that the BPNN model adequately meets training requirements when configured with 10 nodes for each hidden layer. The inputs to the network are the curing degree α, temperature T, and heating rate dT/dt. The output is the curing reaction rate. The dataset used was a series of cure cycle data obtained from the previous DSC test. This dataset was randomly divided into three subsets: training (70%), validation (15%), and testing (15%). The network was trained using the Levenberg–Marquardt backpropagation algorithm, with mean squared error (MSE) as the optimization objective. Training terminated when the MSE reached the target threshold of ≤0.001. The training model implementation result in Matlab R2025a was as follows: After 506 training iterations, the MSE meets the preset error requirements, with a total runtime of 1.57 s. After multiple training iterations, the network converges to an optimized function that can provide effective responses to any similar inputs. Upon completion of training, the model must be validated using the test dataset. Validation data was employed to assess the generalization capability of the network prediction and guard against overfitting.

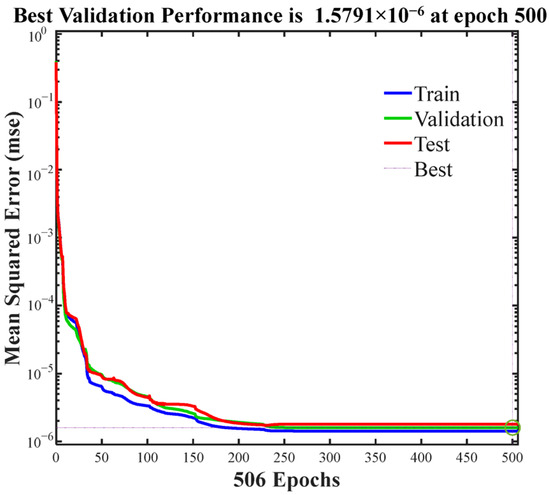

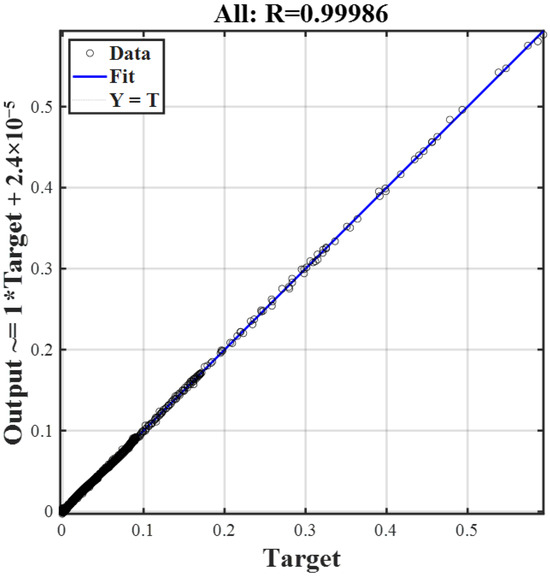

The cure kinetics are typically highly nonlinear. The multilayer perceptron architecture of BP neural networks, coupled with its activation functions, makes it particularly well-suited to handle this complexity. As shown in Figure 6, the maximum training epochs is set to 1000, and the actual training ends in the 506th epoch. The loss function curve exhibits a sharp decline during the initial phase of training and subsequently plateaus in the later stages. It can be concluded that the training process has reached convergence and has thus come to an end. The mean square error (MSE) of the validation data indicates that the training process effectively avoided overfitting. Furthermore, a multiple regression analysis is conducted to evaluate the goodness of fit, as illustrated in Figure 7. The coefficient of determination R reaches a value of 0.99986 across all datasets, indicating excellent agreement between the experimental data and the predictions generated by BPNN. Therefore, the trained model can be confidently utilized for further validation and practical applications.

Figure 6.

Convergence performance of the NN model.

Figure 7.

Multiple regression analysis of the NN model.

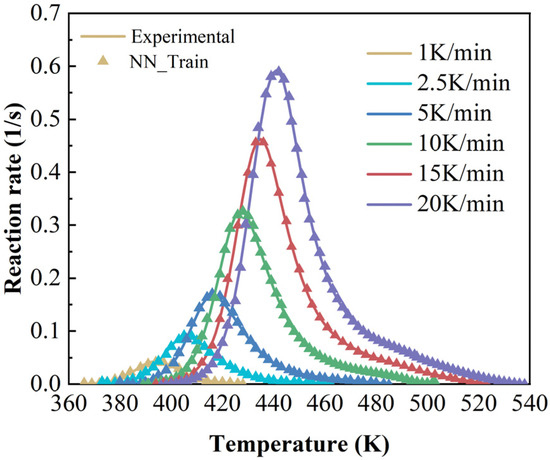

The accuracy of the cure kinetics equations derived from the BPNN model can be verified by comparing the experimentally derived dα/dT~T curves with those calculated by the model. The comparative curves are presented in Figure 8.

Figure 8.

Comparison curves of experimental and calculated values of dα/dT~T at different heating rates (neural network model).

4.3. Machine Learning Model

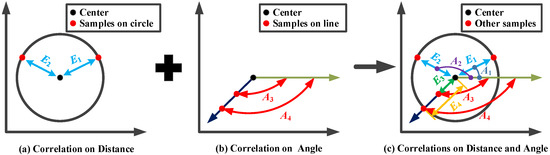

Radial Basis Function (RBF) has been widely adopted as a machine learning model in many real-world engineering problems due to its exceptional balance between computational efficiency and predictive accuracy [39,40]. Existing implementations predominantly employ the conventional RBF architectures, particularly those utilizing cubic kernels, for machine learning modeling. These traditional approaches construct basis functions exclusively through Euclidean distance metrics between center points and sample data, inherently limiting correlation representation to scalar distance information. In fact, pure Euclidean distance fails to capture the intrinsic angular relationships between data points. Inspired by polar coordinate systems, an angle information-enhanced radial basis function is constructed, which synergistically integrates both angular positional information (quantified through angle values) and Euclidean distance metrics, thereby establishing a more comprehensive geometric representation. This dual-information framework significantly enhances the model’s capacity to characterize complex optimization landscapes by preserving both magnitude and directional relationships between solution candidates.

Figure 9 illustrates the correlation calculated by three different approaches. If the correlation is measured only based on Euclidean distance in Figure 9a, the built RBF cannot distinguish these samples on a circle centered on the center point; thus, the predicted values will be unreliable. By contrast, as shown in Figure 9b, if the RBF is constructed only based on the angle information-based correlation, such a model cannot provide accurate prediction when these samples are all on the same straight line as the center point. Hence, we incorporated both the angle information and Euclidean distance information to formulate the basis functions, as shown in Figure 9c. Then, the constructed RBF can better adapt to complex landscapes to provide high accuracy.

Figure 9.

Illustration of correlation calculated by three different approaches.

For β samples, i.e., and the objective values , the angle information-enhanced RBF may be expressed via Equation (7):

where donates the RBF prediction; and are the basis functions measured based on Euclidean distance and angle information, respectively; is the i-th center; and are the i-th weights of the weight vectors such as and for both basis functions, respectively; and donates the first-order linear polynomial. Thus, the indefinite equation system can be rewritten in matrix form, as shown in Equation (8):

In Equation (8), Eβ×β and Aβ×β are the matrices calculated by Euclidean distance-based and angle information-based basis functions, respectively, i.e., and ; donates the weight vector for Poly(t); and Polyβ×(n+1) represents the vector of the for the input matrix . Then, we expand Equation (8) to determine all the parameters as follows:

Then, the equation system in Equation (9) can be expressed as Equation (10) below:

Thus, all the parameters can be derived theoretically based on Equation (11).

In Equation (11), HT donates the transpose of H, and M(2β+n+1)×1 contains all the derived parameters. Therefore, the angle information-enhanced RBF is rigorously derived through mathematical theory, which means that the designed RBF with the same modeling data have uniqueness.

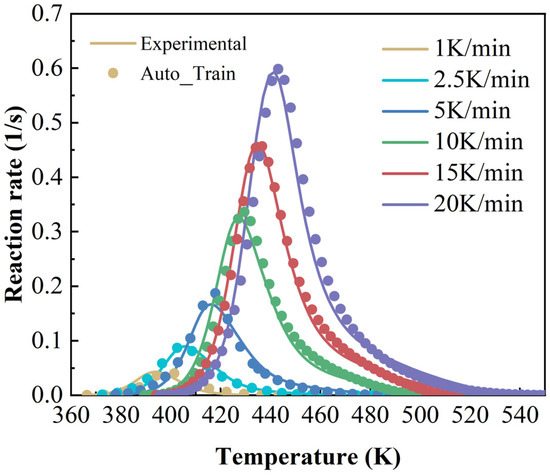

The accuracy of the cure kinetics equations derived from the angle information-enhanced RBF model can be verified by comparing the experimentally derived dα/dT~T curves with those calculated by the model. The comparative curves are presented in Figure 10.

Figure 10.

Comparison curves of experimental and calculated values of dα/dT~T at different heating rates (machine learning model).

5. Discussion

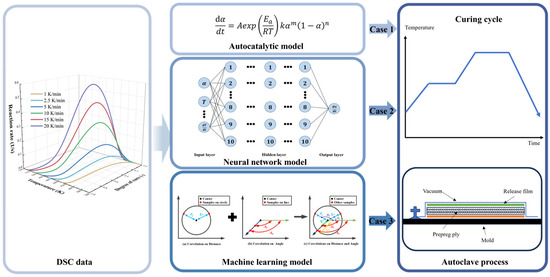

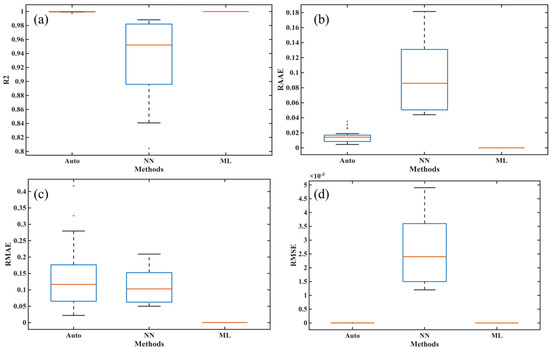

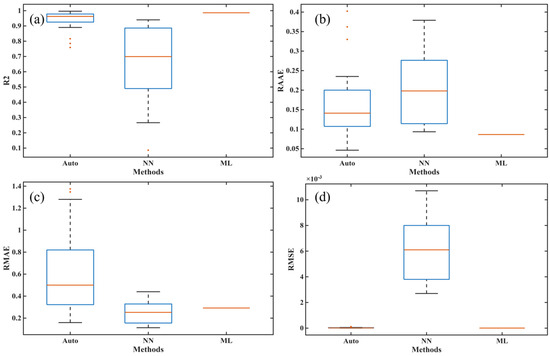

In order to fully verify the robustness and ensure the fairness of the comparison, we independently ran the training and prediction processes of each algorithm 30 times, and we also calculated the training and prediction time of each algorithm in the same hardware and software environments. Specifically, the training and prediction of NN (neural network model) and ML (machine learning model) were performed on a laptop with a CPU with CPU@13900HX (2.2 GHz, 24 cores, 32 threads) and 16 GB of memory using Matlab R2025a. Furthermore, to ensure the correctness of the NN program, we used the built-in net function in the Deep Learning Toolbox of Matlab R2025a to train the NN. Figure 11 presents the operation of the three methods and the architecture diagrams for their application in the autoclave process. Table 2 and Table 3 show the performance of all comparison methods in five metrics, including four core metrics widely used to validate model accuracy, such as R2, RAAE, RMAE, and RMSE, as well as a time metric, where Time1 and Time2 represent the time taken for the methods to complete the training and prediction processes, respectively. Figure 12 and Figure 13 show the box plots corresponding to the four accuracy indicators obtained by three methods in 30 runs during the training and prediction processes. Figure 14, Figure 15 and Figure 16 present the results of a single run during the prediction process.

Figure 11.

The operation conditions of the three methods and their application framework in the autoclave process.

Table 2.

Comparison of three methods on five metrics for training data.

Table 3.

Comparison of three methods on five metrics for testing data.

Figure 12.

The training effects of different models on the DSC dataset: (a) R2, (b) RAAE, (c) RMAE, and (d) RMSE.

Figure 13.

The fitting effects of different models on the DSC dataset: (a) R2, (b) RAAE, (c) RMAE, and (d) RMSE.

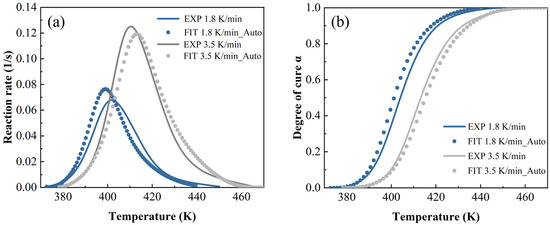

Figure 14.

The autocatalytic model predictions at a heating rate of 1.8 K/min and 3.5 K/min: (a) reaction rate and (b) DoC.

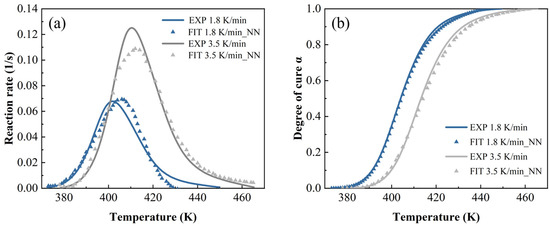

Figure 15.

The neural network model predictions at a heating rate of 1.8 K/min and 3.5 K/min: (a) reaction rate and (b) DoC.

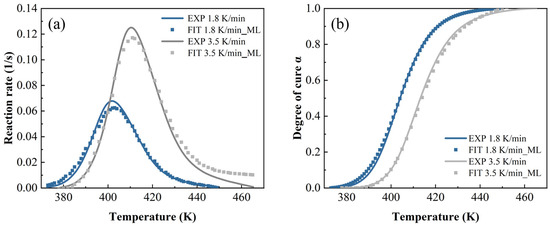

Figure 16.

The machine learning model predictions at a heating rate of 1.8 K/min and 3.5 K/min: (a) reaction rate and (b) DoC.

In Table 2, it can be observed that the mean values of all metrics obtained by Auto (autocatalysis approach) are worse than those of both NN and ML models, which directly means that Auto performed worst in terms of accuracy and efficiency during the training process. Moreover, ML’s performance is better than NN in terms of mean values for four accuracy metrics, indicating that ML has higher accuracy. The Std values obtained by ML are zero, indicating that the results are completely consistent after multiple runs, which is consistent with the rigorous theoretical derivation of ML given in Section 4.3. Similar results can also be seen in Table 3. Thus, the proposed ML not only shows the best performance in terms of training and predicting accuracies but also provides the strongest robustness.

As shown in Figure 12 and Figure 13, the training and fitting effects of both NN and Auto are also worse than those of ML. Furthermore, the Auto has outliers in both the training and prediction stages, and the NN also has outliers in the prediction process, indicating significant instability in the results obtained from multiple runs of these two methods. The reason the NN performs unstably is that the process of determining its many hyperparameters through optimizers such as batch or stochastic gradient descent has randomness. Also, the instability of the autocatalytic model lies in its highly coupled and complex nonlinear model, and solving its parameters is an ill-posed inverse problem that heavily relies on the performance of optimization algorithms and initial conditions.

In Figure 14, Figure 15 and Figure 16, both the autocatalytic and NN have biases in predicting peak size and temperature occurrence, while NN only has slight biases in predicting peak size. This indicates that ML is more accurate in predicting trends throughout the entire process. By contrast, when the heating rate is high and the temperature is high, ML’s prediction is slightly worse than other methods.

In summary, compared to Auto and NN, ML has stronger robustness and higher prediction accuracy because it does not involve complex optimization operators to determine hyperparameters. Considering that ML models can maintain consistent results in multiple runs, designing more accurate ML models based on the characteristics of cure kinetics data may be one of the important directions worth studying in the future.

6. Conclusions

This study addresses the limitations of traditional modeling methods in CFRP cure kinetics by proposing an angle information-enhanced radial basis function (RBF) model and conducting a systematic comparative analysis with autocatalytic and neural network models. Based on the comprehensive comparative analysis of autocatalytic, neural network, and angle information-enhanced RBF models for predicting the cure kinetics of T700/2626 epoxy resin, it can be conclusively determined that the proposed angle information-enhanced RBF model demonstrates superior performance. The model achieved perfect training accuracy (R2 = 1.000) with zero standard deviation across 30 independent runs, demonstrating exceptional robustness. Its prediction accuracy (R2 = 0.986) significantly outperformed both the neural network (R2 = 0.941) and autocatalytic (R2 = 0.666) models while maintaining computational efficiency, with training and prediction times of 1.79 s and 0.151 s, respectively. The neural network, despite reasonable accuracy, showed variability (Std = 0.0602) due to its optimization-dependent hyperparameters, while the autocatalytic model suffered from both inaccuracy and instability (Std = 0.230). The RBF model’s minimal prediction errors (RMSE = 6.90 × 10−6) and consistent performance across all heating rates confirm its reliability. This research validates that the angle information-enhanced RBF model provides a high-performance data-driven alternative for CFRP cure kinetics prediction. It not only improves the precision of tracking thermochemical changes during curing but also facilitates the design of more efficient autoclave processes and better control of CFRP component quality. In the future, this method will be applied to various epoxy resin systems to comprehensively evaluate the universality of this model.

Author Contributions

Conceptualization, X.W. and X.Y.; methodology, L.W.; software, M.Z. and Z.Y.; validation, Z.L. and B.X.; formal analysis, M.Z. and L.W.; investigation, X.W., L.W. and X.Y.; resources, X.W.; writing—original draft preparation, Z.Y., X.W. and X.Y.; writing—review and editing, X.W. and Z.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Jiangxi Provincial Natural Science Foundation under Grant No. 20232BAB214008, No. 20252BAC200632, the Jiangxi Province Contract System Pilot Project under Grant No. ZBG20230428005, the Nanchang University Innovation Fund under Grant No. XX202506030031, the National Science Foundation of China under Grant No. 52305369, the Project of State Key Laboratory of Precision Manufacturing for Extreme Service Performance under Grant No. Kfkt2022-02, the Gansu Provincial Science and Technology Plan Project under Grant No. 23JRRA859, and the Nanchang Major Science and Technology Research Project under Grant No. 2024zdxm018.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author Zhongling Liu was employed by the Nanchang Jardine Advanced Composite Material Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as potential conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CFRP | Carbon fiber reinforced polymer |

| RBF | Radial basis function |

| DoC | Degree of cure |

| ANN | Artificial neural network |

| CNN | Convolutional neural network |

| FE | Finite element |

| GP | Gaussian Process |

| SVM | Support Vector Machine |

| DSC | Differential scanning calorimetry |

| FWO | Flynn–Wall–Ozawa |

| PSO | Particle Swarm Optimization |

| BPNN | Backpropagation neural network |

| MSE | Mean squared error |

| NN | Neural network model |

| ML | Machine learning model |

References

- Liu, L.; Jia, C.; He, J.; Zhao, F.; Fan, D.; Xing, L.; Wang, M.; Wang, F.; Jiang, Z.; Huang, Y. Interfacial characterization, control and modification of carbon fiber reinforced polymer composites. Compos. Sci. Technol. 2015, 121, 56–72. [Google Scholar] [CrossRef]

- Vafayan, M.; Abedini, H.; Ghoreishy, M.H.R.; Beheshty, M.H. Effect of cure kinetic simulation model on optimized thermal cure cycle for thin-sectioned composite parts. Polym. Compos. 2013, 34, 1172–1179. [Google Scholar] [CrossRef]

- Zhang, S.; Song, H.; Xu, L.; Cai, K. Application Research on the Lightweight Design and Optimization of Carbon Fiber Reinforced Polymers (CFRP) Floor for Automobile. Polymers 2022, 14, 4768. [Google Scholar] [CrossRef]

- Yang, B.; Huang, H.; Bi, F.; Yin, L.; Yang, Q.; Shen, H. Analysis of cure kinetics of CFRP composites molding process using incremental thermochemical information aggregation networks. Compos. Struct. 2024, 331, 117904. [Google Scholar] [CrossRef]

- Bheemreddy, V.; Huo, Z.; Chandrashekhara, K.; Brack, R.A. Modeling and Simulation of Cure Kinetics and Flow in Cavity-Molded Composites. J. Am. Helicopter Soc. 2016, 61, 1–10. [Google Scholar] [CrossRef]

- Baghad, A.; Mabrouk, K.E. Autoclave process parameters affecting mechanical and thermomechanical properties of CFRP laminates using response surface methodology. J. Reinf. Plast. Compos. 2024, 43, 14. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, M.; Liu, Z.; Fu, X.; Liu, H.; Zhang, Y.; Yang, X. Cure Kinetics-Driven Compression Molding of CFRP for Fast and Low-Cost Manufacturing. Polymers 2025, 17, 2154. [Google Scholar] [CrossRef]

- Kresalek, V.; Mikulicova, M. Luminescence spectroscopy as a tool for testing of cure kinetics of epoxy resins. Polym. Test. 2020, 86, 106496. [Google Scholar] [CrossRef]

- Tao, Q.; Pinter, G.; Antretter, T.; Krivec, T.; Fuchs, P. Model free kinetics coupled with finite element method for curing simulation of thermosetting epoxy resins. J. Appl. Polym. Sci. 2018, 135, 46408. [Google Scholar] [CrossRef]

- Abliz, D.; Artys, T.; Ziegmann, G. Influence of model parameter estimation methods and regression algorithms on curing kinetics and rheological modelling. J. Appl. Polym. Sci. 2017, 134, 45137. [Google Scholar] [CrossRef]

- Abali, B.E.; Zecchini, M.; Daisse, G.; Czabany, I.; Gindl-Altmutter, W.; Wan-Wendner, R. Cure Kinetics and Inverse Analysis of Epoxy-Amine Based Adhesive Used for Fastening Systems. Materials 2021, 14, 3853. [Google Scholar] [CrossRef]

- Javdanitehran, M.; Berg, D.C.; Duemichen, E.; Ziegmann, G. An iterative approach for isothermal curing kinetics modelling of an epoxy resin system. Thermochim. Acta 2016, 623, 72–79. [Google Scholar] [CrossRef]

- Sourour, S.; Kamal, M.R. Differential scanning calorimetry of epoxy cure: Isothermal cure kinetics. Thermochim. Acta 1976, 14, 41–59. [Google Scholar] [CrossRef]

- Lopez, L.M.; Cosgrove, A.B.; Hernandez-Ortiz, J.P.; Osswald, T.A. Modeling the vulcanization reaction of silicone rubber. Polym. Eng. Sci. 2010, 47, 675–683. [Google Scholar] [CrossRef]

- Hernandez-Ortiz, J.P.; Osswald, T.A. A Novel Cure Reaction Model Fitting Technique Based on DSC Scans. J. Polym. Eng. 2005, 25, 23–38. [Google Scholar] [CrossRef]

- Sun, G.; Sun, H.; Liu, Y.; Zhao, B.; Zhu, N.; Hu, K. Comparative study on the curing kinetics and mechanism of a lignin-based-epoxy/anhydride resin system. Polymer 2007, 48, 330–337. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, H.; Chen, Y.; Kang, G.; Hua, L.; Feng, J. Study on Curing Kinetics and the Mechanism of Ultrasonic Curing of an Epoxy Adhesive. Polymers 2022, 14, 512. [Google Scholar] [CrossRef]

- Hardis, R.; Jessop, J.L.P.; Peters, F.E.; Kessler, M.R. Cure kinetics characterization and monitoring of an epoxy resin using DSC, Raman spectroscopy, and DEA. Compos. Part A Appl. Sci. Manuf. 2013, 49, 100–108. [Google Scholar] [CrossRef]

- Mphahlele, K.; Ray, S.S.; Kolesnikov, A. Cure kinetics, morphology development, and rheology of a high-performance carbon-fiber-reinforced epoxy composite. Compos. Part B Eng. 2019, 176, 107300. [Google Scholar] [CrossRef]

- Hui, X.; Xu, Y.; Zhang, W.; Zhang, W. Cure process evaluation of CFRP composites via neural network: From cure kinetics to thermochemical coupling. Compos. Struct. 2022, 288, 115341. [Google Scholar] [CrossRef]

- Yang, X.; Zou, X.; Zhang, J.; Guo, R.; Xiang, H.; Zhan, L.; Wu, X. A Parametric Study of Epoxy-Bonded CF/QF-BMI Composite Joints Using a Method Combining RBF Neural Networks and NSGA-II Algorithm. Polymers 2025, 17, 1769. [Google Scholar] [CrossRef]

- Jahromi, P.E.; Shojaei, A.; Pishvaie, S.M.R. Prediction and optimization of cure cycle of thick fiber-reinforced composite parts using dynamic artificial neural networks. J. Reinf. Plast. Compos. 2012, 31, 1201–1215. [Google Scholar] [CrossRef]

- Carlone, P.; Aleksendric, D.; Cirovic, V.; Palazzo, G.S. Modelling of thermoset matrix composite curing process. In Proceedings of the Material Forming Esaform 2014, Espoo, Finland, 7–9 May 2014; pp. 1667–1674. [Google Scholar] [CrossRef]

- Fan, S.; Zhang, J.; Wang, B.; Chen, J.; Yang, W.; Liu, W.; Li, Y. A deep learning method for fast predicting curing process-induced deformation of aeronautical composite structures. Compos. Sci. Technol. 2023, 232, 109844. [Google Scholar] [CrossRef]

- Xie, X.C.; Wu, Q.; Wang, Y.F.; Fan, B.C.; Liu, Y.; Wang, J.X.; Yan, F.G.; Zhang, Z.W. Virtual Experiment-Driven Neural Network-Based Study of Resin Curing Kinetics. J. Appl. Polym. Sci. 2025, 142, e57339. [Google Scholar] [CrossRef]

- Roy, N.K.; Potter, W.D.; Landau, D.P. Polymer property prediction and optimization using neural networks. IEEE Trans. Neural Netw. 2006, 17, 1001–1014. [Google Scholar] [CrossRef]

- Amouzgar, K.; Bandaru, S.; Ng, A.H.C. Radial basis functions with a priori bias as surrogate models: A comparative study. Eng. Appl. Artif. Intell. 2017, 71, 28–44. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Q.; Jiang, C.; Qiu, H.; Gao, L. Exploring a full latent space for Gaussian process modeling with qualitative and quantitative factors. Mech. Syst. Signal Process. 2025, 239, 113297. [Google Scholar] [CrossRef]

- Malashin, I.; Tynchenko, V.; Gantimurov, A.; Nelyub, V.; Borodulin, A. Support Vector Machines in Polymer Science: A Review. Polymers 2025, 17, 491. [Google Scholar] [CrossRef] [PubMed]

- Qun, L.; Xi-Ping, F.; Kun, Z.; Xue-Mei, H.; Xiao, H.; Jin-Rui, Y. Effect of curing pressure on the curing behavior of an epoxy system: Curing kinetics and simulation verification. Polymer 2022, 256, 125162. [Google Scholar] [CrossRef]

- Rajabi, L.; Motaie, H.; Derakhshan, A.A.; Kurdian, A.R.; Yazdanpanah, R. Dynamic cure kinetics of epoxy/TiO2/MWCNT hybrid nanocomposites. Iran. Polym. J. 2014, 23, 855–867. [Google Scholar] [CrossRef]

- Garschke, C.; Parlevliet, P.P.; Weimer, C.; Fox, B.L. Cure kinetics and viscosity modelling of a high-performance epoxy resin film. Polym. Test. 2013, 32, 150–157. [Google Scholar] [CrossRef]

- Demirelli, K.; Abubakar, A.M.; Tuncer, H.; Salih, B. Preparation, characterization and electrical behaviors of greenish single-chain polymeric molecule-via intramolecular ball type cobalt phthalocyanines/graphite oxide composites. J. Mol. Struct. 2021, 1235, 130132. [Google Scholar] [CrossRef]

- Guo, Z.Y.; Chen, Q.F.; Wang, Z.C.; Gorar, A.A.K.; Pan, Z.C.; Wang, J.; Liu, W.B. A novel bio-based autocatalytic amide-type phthalonitrile monomer: Synthesis, curing kinetics and thermal properties. Eur. Polym. J. 2024, 221, 113550. [Google Scholar] [CrossRef]

- Pagano, R.L.; Calado, V.M.A.; Tavares, F.W.; Biscaia, E.C. Cure kinetic parameter estimation of thermosetting resins with isothermal data by using particle swarm optimization. Eur. Polym. J. 2008, 44, 2678–2686. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, K.; Bao, R. Machine learning models to predict the residual tensile strength of glass fiber reinforced polymer bars in strong alkaline environments: A comparative study. J. Build. Eng. 2023, 73, 106817. [Google Scholar] [CrossRef]

- Zhang, X.; Xia, Y.Y.; Zhang, C.; Wang, C.X.; Liu, B.K.; Fang, H.Y. An Archimedes Optimization Algorithm Based Extreme Gradient Boosting Model for Predicting the Bending Strength of UV Cured Glass Fiber Reinforced Polymer Composites. Polym. Compos. 2025, 1–18. [Google Scholar] [CrossRef]

- Soepangkat, B.O.P.; Pramujati, B.; Effendi, M.K.; Norcahyo, R.; Mufarrih, A.M. Multi-objective Optimization in Drilling Kevlar Fiber Reinforced Polymer Using Grey Fuzzy Analysis and Backpropagation Neural Network-Genetic Algorithm (BPNN-GA) Approaches. Int. J. Precis. Eng. Manuf. 2019, 20, 593–607. [Google Scholar] [CrossRef]

- Yang, Z.; Qiu, H.; Gao, L.; Chen, L.; Liu, J. Surrogate-assisted MOEA/D for expensive constrained multi-objective optimization. Inf. Sci. 2023, 639, 119016. [Google Scholar] [CrossRef]

- Yang, Z.; Chu, S.; Liu, J.; Qiu, H.; Xiao, M.; Gao, L. Incorporating gradient information into dimension perturbation mutation for high-dimensional expensive optimization. Swarm Evol. Comput. 2024, 84, 17. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).