Experimental Study on the Evolution of Mechanical Properties and Their Mechanisms in a HTPB Propellant Under Fatigue Loading

Abstract

1. Introduction

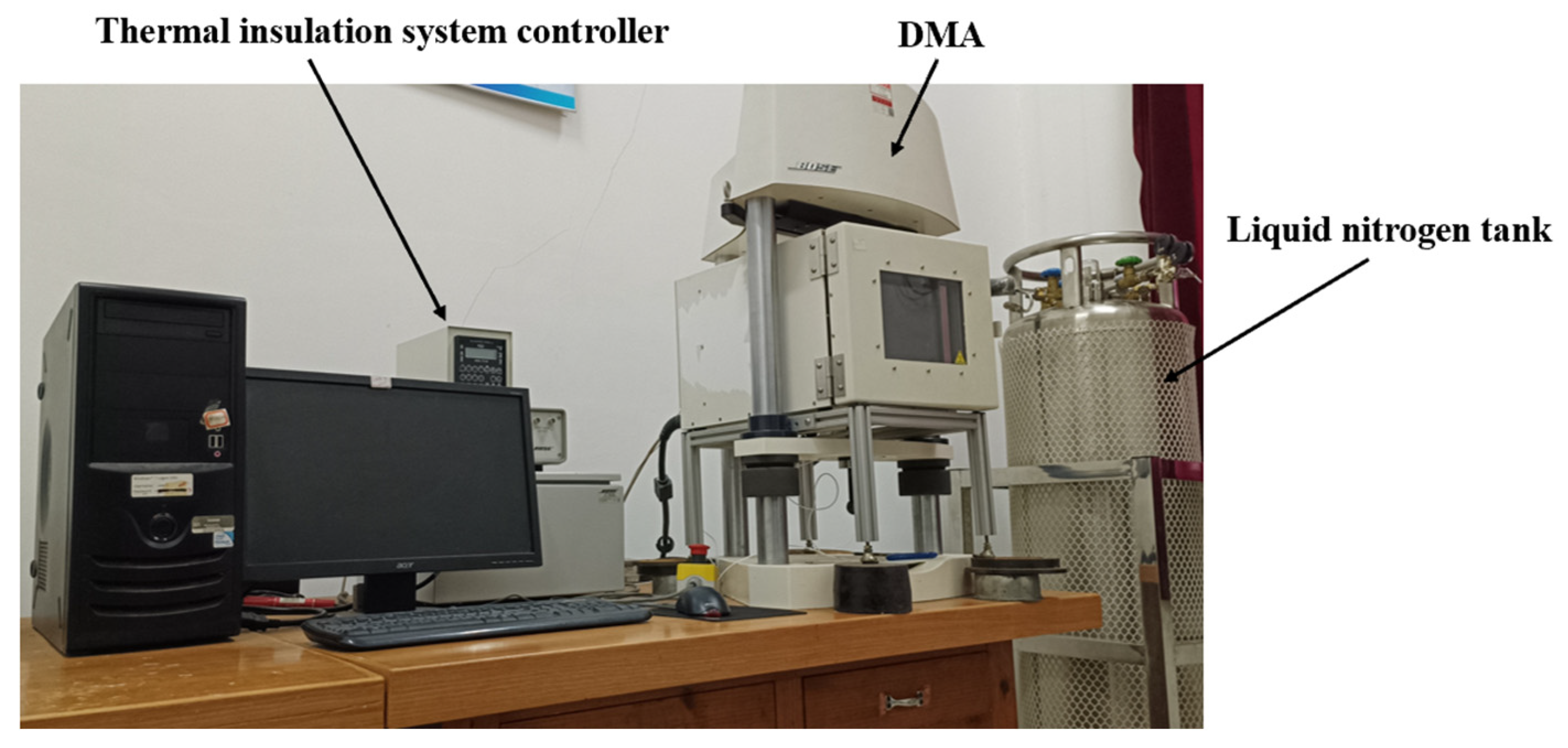

2. Experimental Setup and Method

2.1. Setup and Specimens

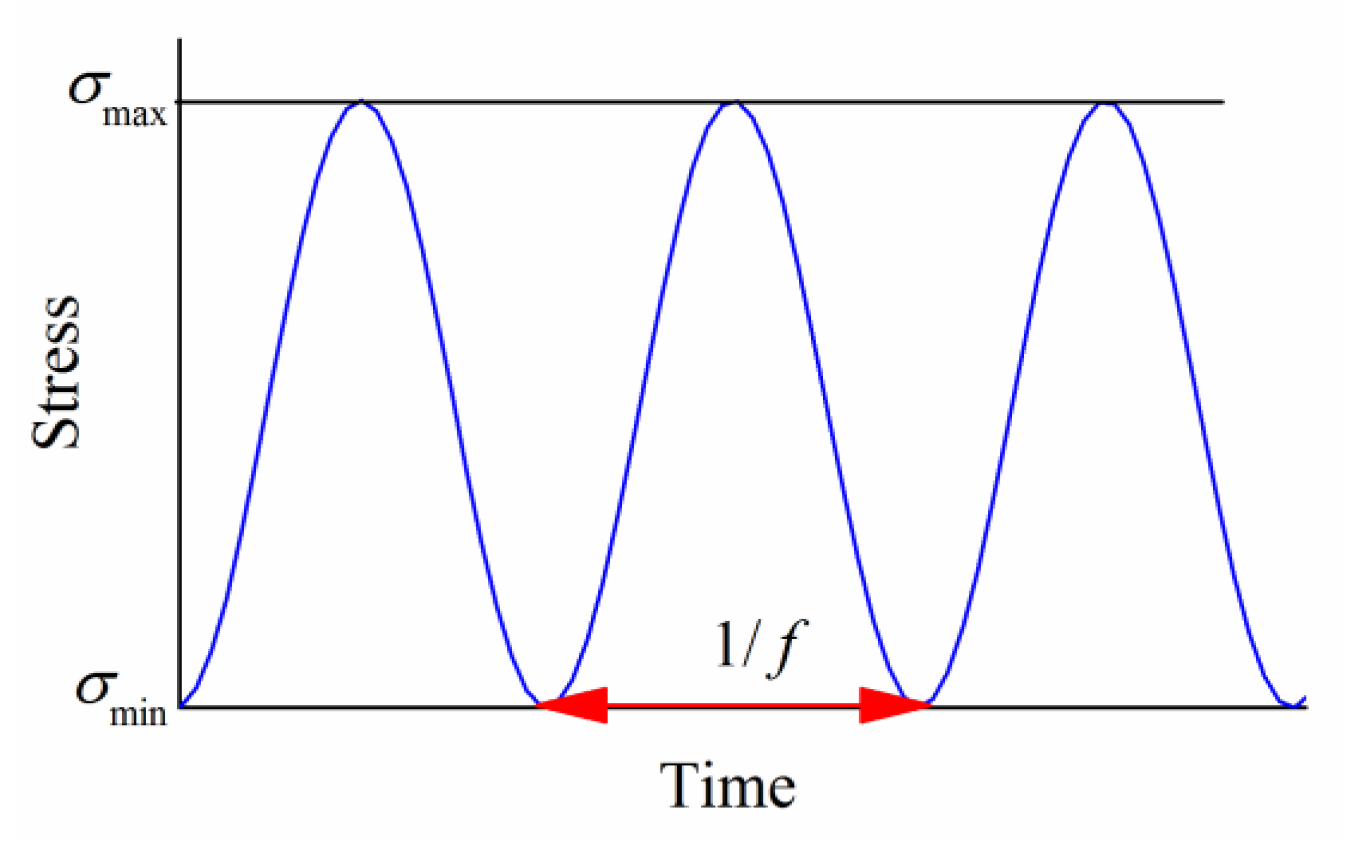

2.2. Experimental Method

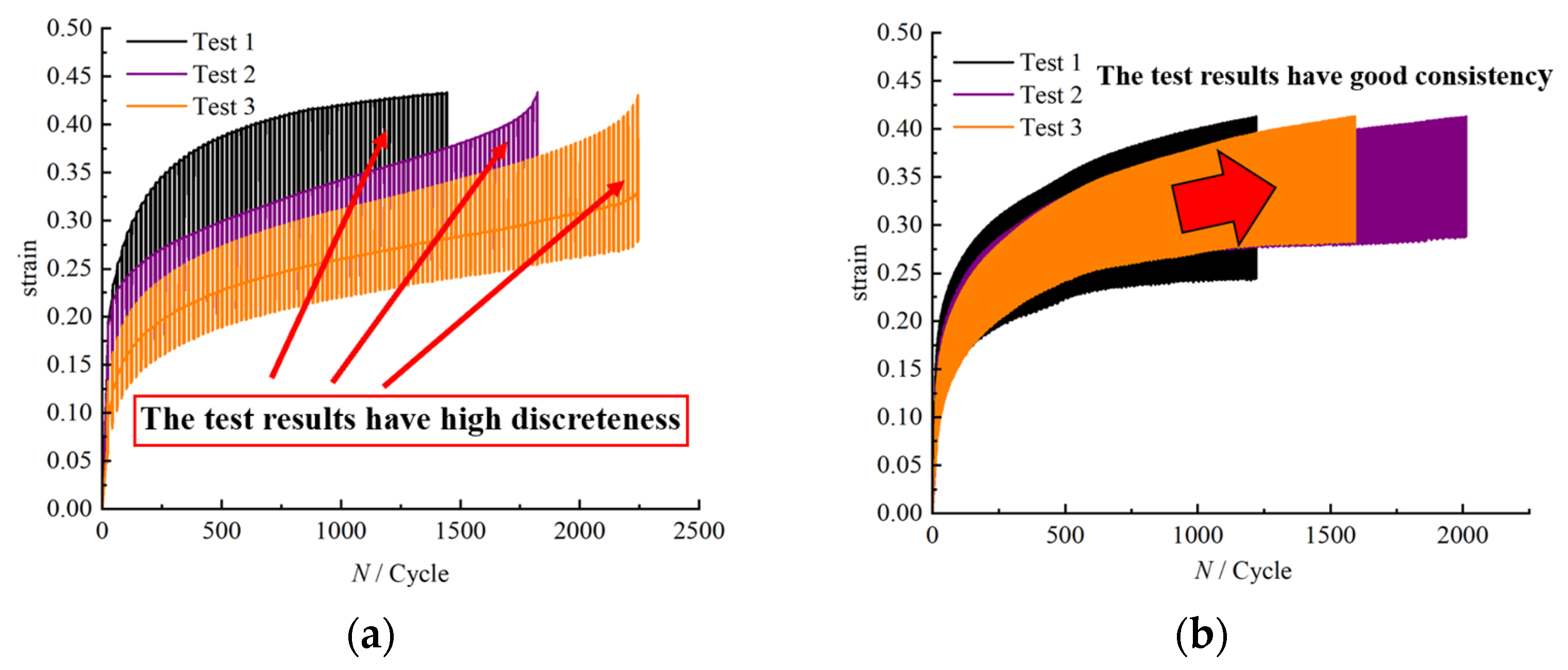

2.3. Quality Control and Statistical Analysis

3. Results and Discussion

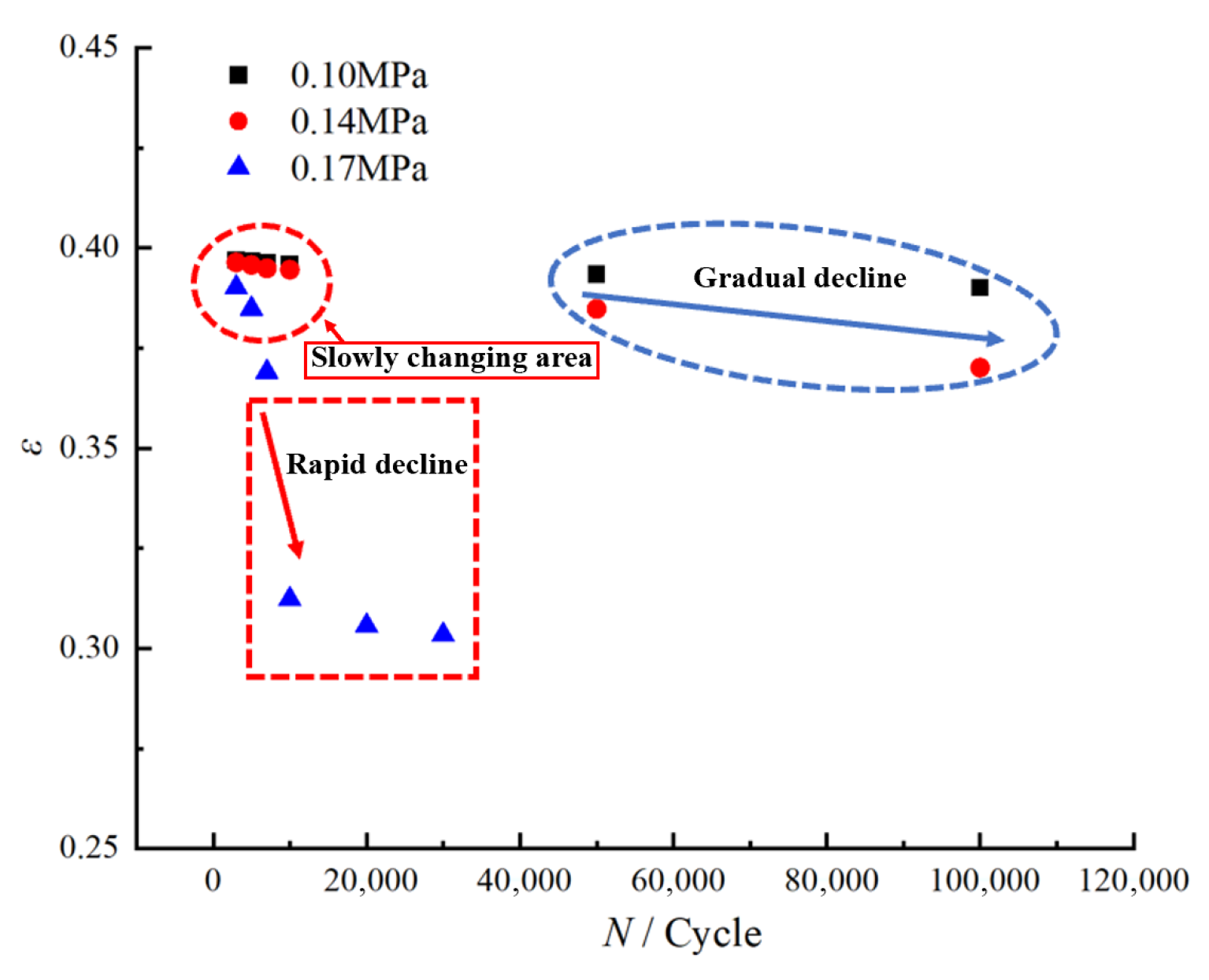

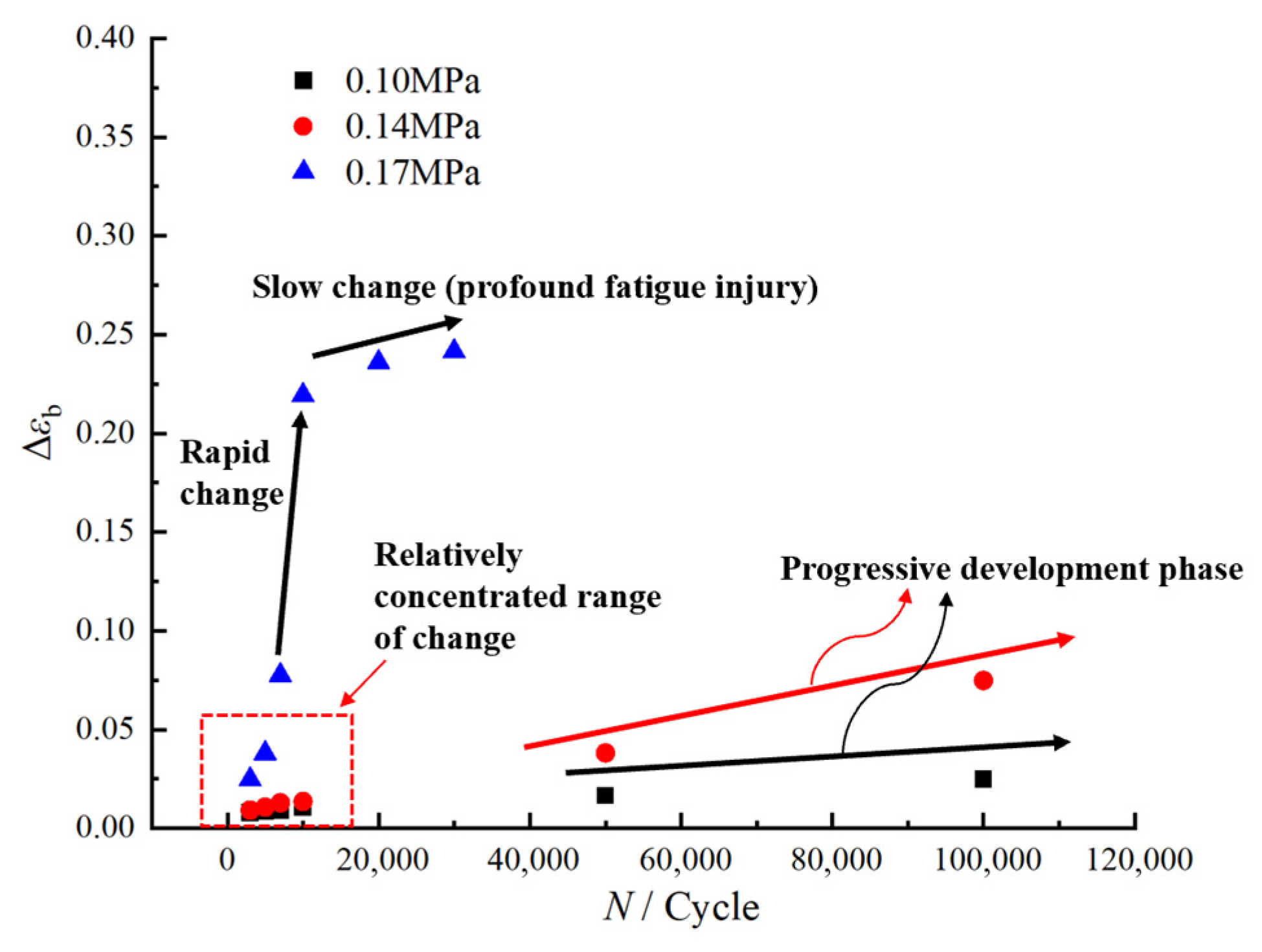

3.1. Analysis of the Evolution Characteristics of Residual Elongation

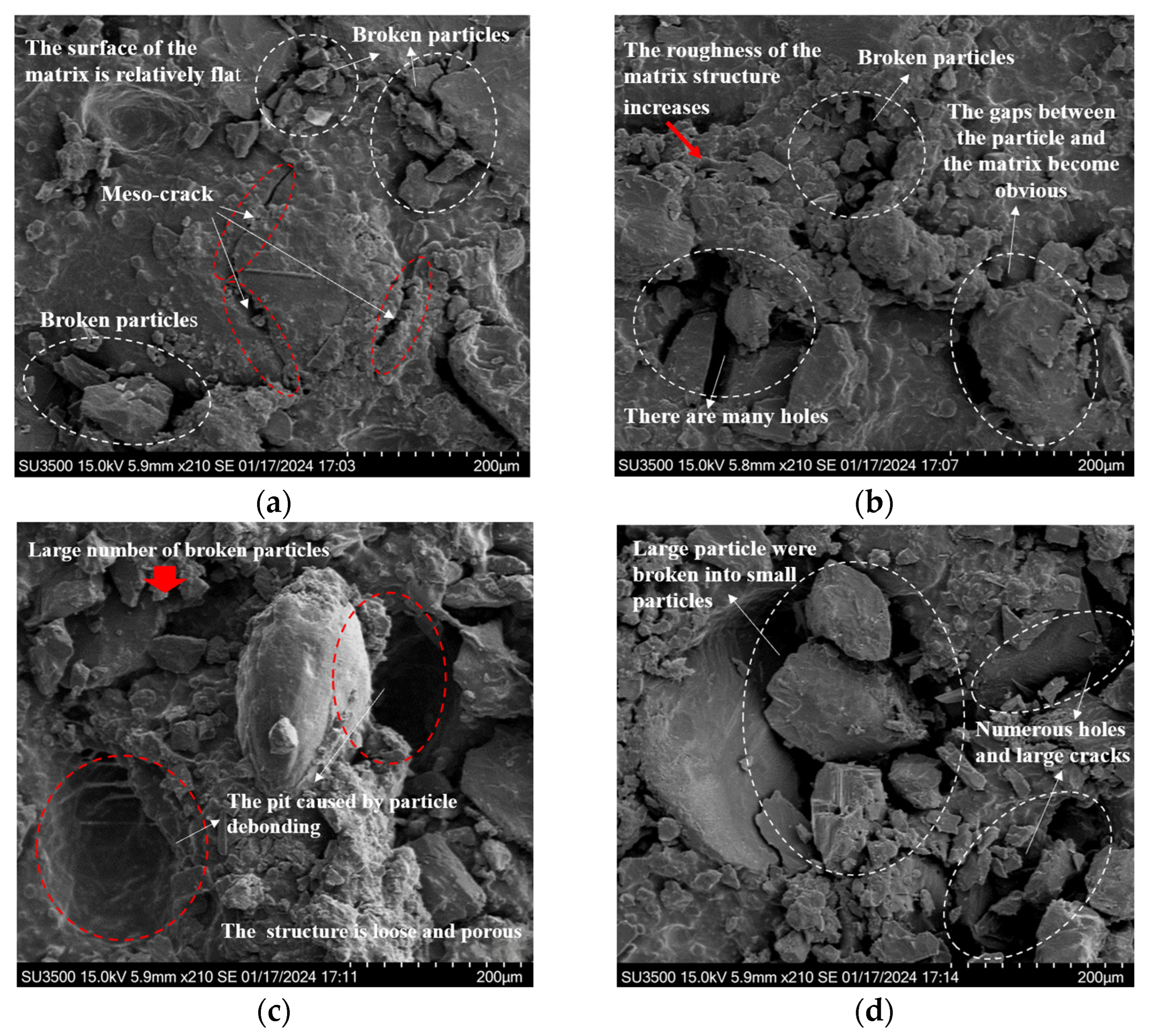

3.2. Analysis of the Influence of Mesostructural Changes on Residual Elongation

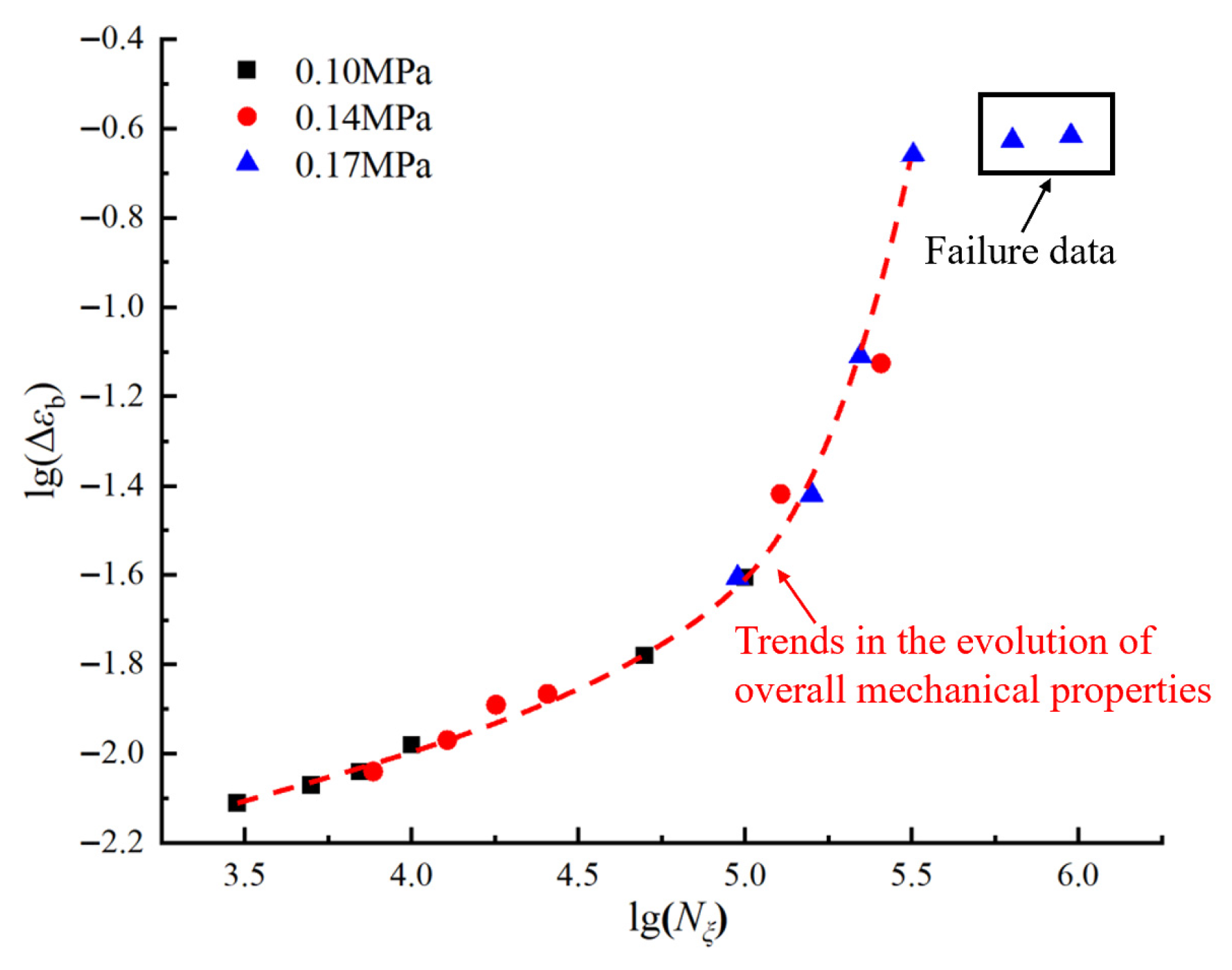

4. Model and Validation

4.1. Model Construction

4.2. Model Validation and Sensitivity Analysis

5. Discussion

5.1. Implications for Rocket Motor Design and Durability

5.2. Relationship Between Laboratory-Scale and Full-Scale Propellant Behavior

5.3. Multi-Scale Fatigue Analysis of Solid Propellants

5.4. Theoretical Parallelism Between WLF Theory and Stress–Cycle Relationships

6. Conclusions

- (1)

- This study proposes a three-region classification method to quantitatively analyze the evolution of residual elongation in HTPB propellants under fatigue loading. By leveraging a rate-of-change threshold approach, the method defines three distinct regions—slow-change, gradual-decline, and rapid-decline—based on the correlation between residual elongation and the number of loading cycles. These regions are delineated by thresholds for the instantaneous rate of change in residual elongation, reflecting the material’s damage evolution at different fatigue stages. The slow-change region, characterized by minimal damage accumulation, indicates relatively stable performance, while the rapid-decline region signifies a significant deterioration in the propellant’s internal structure, leading to a sharp decline in performance. The gradual-decline region reflects the continued, though slower, degradation of the propellant after extensive cycling.This classification provides a systematic framework for understanding fatigue evolution, offering a clearer insight into the material’s behavior under cyclic loading. It also serves as a valuable tool to track the degradation process of different propellant formulations, allowing for the identification of critical stages where performance may significantly decline. While the exact thresholds for classification may vary due to factors such as the material composition, temperature, or loading frequency, the proposed method is effective in capturing the key trends across the fatigue life of solid propellants. Overall, this approach offers new perspectives on long-term performance prediction for solid propellants under fatigue conditions, guiding the optimization of their material properties and performance stability.

- (2)

- At the mesoscopic level, higher maximum loading stresses and increased loading cycles lead to the expansion and interconnection of microcracks within the HTPB propellant. At the same time, there is an increase in the number and size of voids, separation at phase boundaries, and the degree of particle fragmentation. These phenomena progressively degrade the propellant’s continuity and integrity, causing a gradual reduction in its plastic deformation capacity and a continuous decline in residual elongation.

- (3)

- The master curve depicting the decay ratio of the residual elongation was constructed, and, based on this curve, a residual elongation evolution model was established. The mathematical expression of the model is as follows:

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Guery, J.-F.; Chang, I.-S.; Shimada, T.; Glick, M.; Boury, D.; Robert, E.; Napior, J.; Wardle, R.; Pérut, C.; Calabro, M.; et al. Solid propulsion for space applications: An updated roadmap. Acta Astronaut. 2010, 66, 201–219. [Google Scholar] [CrossRef]

- Wang, J.; Wang, N.; Zou, X.; Dong, W.; Wang, C.; Han, L.; Shi, B. Experimental and numerical study on slag deposition in solid rocket motor. Aerosp. Sci. Technol. 2022, 122, 107404. [Google Scholar] [CrossRef]

- Chaturvedi, S.; Dave, P.N. Solid propellants: AP/HTPB composite propellants. Arab. J. Chem. 2019, 12, 2061–2068. [Google Scholar] [CrossRef]

- Zhang, P.; Yuan, J.; Zhang, X.; Deng, J. Synthesis and properties of a multifunctional agent in HTPB propellant. Chin. J. Energetic Mater. 2021, 29, 1031–1038. [Google Scholar] [CrossRef]

- Xing, R.; Wang, L.; Zhang, F.; Hou, C. Mechanical behavior and constitutive model of NEPE solid propellant in finite deformation. Mech. Mater. 2022, 172, 104383. [Google Scholar] [CrossRef]

- Lei, M.; Wang, J.; Cheng, J.; Xiao, J.; Wen, L.; Lu, H.; Hou, X. A constitutive model of the solid propellants considering the interface strength and dewetting. Compos. Sci. Technol. 2020, 185, 107893. [Google Scholar] [CrossRef]

- Yıldırım, H.C.; Özüpek, Ş. Structural assessment of a solid propellant rocket motor: Effects of aging and damage. Aerosp. Sci. Technol. 2011, 15, 635–641. [Google Scholar] [CrossRef]

- Liu, J.; Li, H.; Chen, X.; Li, Y.; Xu, J. A one-dimensional model for the aging and damage effects on the response of composite double-base propellants. Mech. Time-Depend. Mater. 2023, 27, 1007–1023. [Google Scholar] [CrossRef]

- Yılmaz, O.; Kuran, B.; Özgen, G.O. Reliability assessment of solid-propellant rocket motors under storage and transportation loads. J. Spacecr. Rocket. 2017, 54, 1356–1366. [Google Scholar] [CrossRef]

- Gligorijević, N.; Rodić, V.; Pavković, B.; Bogdanov, J.; Živković, S.; Bajić, Z. Effect of cyclic loads on structural damage of rocket propellant grain. Sci. Tech. Rev. 2019, 69, 8–16. [Google Scholar] [CrossRef]

- Secor, G. Dynamic fracture of simulated solid propellant. Int. J. Fract. Mech. 1972, 8, 299–309. [Google Scholar] [CrossRef]

- Drozdov, A.D. Cyclic thermo-viscoplasticity of high density polyethylene. Int. J. Solids Struct. 2010, 47, 1592–1602. [Google Scholar] [CrossRef]

- Starkova, O.; Aniskevich, K.; Sevcenko, J.; Bulderberga, O.; Aniskevich, A. Relationship between the residual and total strain from creep-recovery tests of polypropylene/multiwall carbon nanotube composites. J. Appl. Polym. Sci. 2021, 138, 49957. [Google Scholar] [CrossRef]

- Xu, J.S.; Yang, X.H.; Chen, X.; Du, H.Y.; Li, H. Experimental investigation on fatigue properties of HTPB propellant. Chin. J. Explos. Propellants 2021, 44, 372–378. [Google Scholar]

- Tong, X.; Chen, X.; Xu, J.-S.; Zheng, Y.; Zhi, S.-J. The heat build-up of a polymer matrix composite under cyclic loading: Experimental assessment and numerical simulation. Int. J. Fatigue 2018, 116, 323–333. [Google Scholar] [CrossRef]

- Tong, X.; Chen, X.; Xu, J.; Sun, C.; Liang, W. Excitation of thermal dissipation of solid propellants during the fatigue process. Mater. Des. 2017, 128, 47–55. [Google Scholar] [CrossRef]

- Hu, Q.; Fang, Q.; Sha, B.; Jin, L. Study on the Viscoelastic Damage Properties of NEPE Solid Propellant with Different Cyclic Stress Ratios. Propellants Explos. Pyrotech. 2022, 47, e202100342. [Google Scholar] [CrossRef]

- Li, J.; Huang, W.; Qu, K.; Wang, W.; Yang, M. Experimental Research on Fatigue Damage of Composite Solid Propellant with Constant Constrain. In Proceedings of the 5th International Conference on Electrical Engineering and Automatic Control, Berlin/Berlin, Germany, 16 July 2016; Springer: Berlin/Heidelberg, Germany, 2016; pp. 315–322. [Google Scholar]

- López, R.; Salazar, A.; Rodríguez, J. Fatigue crack propagation behavior of carboxyl-terminated polybutadiene solid rocket propellants. Int. J. Fract. 2020, 223, 3–15. [Google Scholar] [CrossRef]

- Kumar, N.; Patel, B.P.; Rao, V.V.; Subhaschandran, B.S. Hyperviscoelastic constitutive modelling of solid propellants with damage and compressibility. Propellants Explos. Pyrotech. 2018, 43, 461–471. [Google Scholar] [CrossRef]

- Wubuliaisan, M.; Wu, Y.; Hou, X.; Huang, F. A viscoelastic constitutive model considering deformation and environmental-induced damages for solid propellants. Aerosp. Sci. Technol. 2023, 132, 108055. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, R.; Yang, M. Study on constitutive equation of cumulative damage of HTPB propellant. IOP Conf. Ser. Earth Environ. Sci. 2019, 358, 052006. [Google Scholar] [CrossRef]

- Zhang, W.Q.; Zhang, D.P.; Lei, Y.J.; Shen, Z.B.; Wu, F.J. Low-frequency fatigue characteristics of NEPE solid propellant. J. Natl. Univ. Defense Technol. 2025, 47, 31–41. [Google Scholar] [CrossRef]

- Picquart, M.; Poirey, G. A multiscale approach for the development of a nonlinear viscoelastic friction-and-cavitation-based model for solid propellants. Int. J. Solids Struct. 2022, 251, 111749. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, W.; Wang, L.; Xue, Y.; Hou, C.; Wu, S. In situ X-ray tomography study on internal damage evolution of solid propellant for carrier rockets. Mater. Sci. Eng. A 2023, 882, 145451. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, D.; Lei, Y.; Shen, Z. Research on the low-frequency fatigue behavior of NEPE solid composite propellant based on fractional derivative constitutive model. Int. J. Solids Struct. 2024, 300, 112931. [Google Scholar] [CrossRef]

- Hua, J.; Wang, F.; Xue, X.; Ding, Z.; Chen, Z. Residual monotonic mechanical properties of bimetallic steel bar with fatigue damage. J. Build. Eng. 2022, 55, 104703. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, R.; Song, G. Effects of pre-fatigue damage on mechanical properties of Q690 high-strength steel. Constr. Build. Mater. 2020, 252, 118845. [Google Scholar] [CrossRef]

- Han, L.; Chen, X.; Xu, J.-S.; Zhou, C.-S.; Yu, J.-Q. Research on the time–temperature–damage superposition principle of NEPE propellant. Mech. Time-Depend. Mater. 2015, 19, 581–599. [Google Scholar] [CrossRef]

- Zeng, Y.; Huang, W.; Chen, X.; Xu, J.; Song, Q.; Guo, Z.; Yuan, Y. Damage Evolution Mechanism, Accelerated Aging Model Framework, and Failure Lifespan Prediction of HTPB Propellants Under Thermomechanical Coupling. J. Appl. Polym. Sci. 2025, 142, e57370. [Google Scholar] [CrossRef]

- Yang, G.; Li, Q.; Wang, Z.; Wang, H. Evaluation of in-soil creep characteristics of HDPE geogrid using the time-stress superposition method. Int. J. Mater. Prod. Technol. 2022, 65, 224–234. [Google Scholar] [CrossRef]

- Wang, B.; Fancey, K.S. Application of time–stress superposition to viscoelastic behavior of polyamide 6, 6 fiber and its “true” elastic modulus. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Chang, W.; Ju, Y.; Wang, P. Research on correlation between dewetting and mechanical property of HTPB propellant. Acta Armamentarii. 2012, 33, 261. [Google Scholar]

| Component | Role | Mass/% | Density/g·cm−3 | CAS No. |

|---|---|---|---|---|

| HTPB | Adhesive | 12% | 0.95 | 69102-90-5 |

| AP | Oxidant | 69% | 1.95 | 7790-98-9 |

| Al | Fuel | 18% | 2.70 | 7429-90-5 |

| Other | - | 1% | - | - |

| σmax/MPa | 0.10 | 0.14 | 0.17 |

| Nf/cycle | 1.27 × 106 | 1.53 × 105 | 4.76 × 104 |

| σmax/MPa | N | |||||

|---|---|---|---|---|---|---|

| 0.10 | 3000 | 5000 | 7000 | 10,000 | 50,000 | 100,000 |

| 0.14 | 3000 | 5000 | 7000 | 10,000 | 50,000 | 100,000 |

| 0.17 | 3000 | 5000 | 70,000 | 10,000 | 20,000 | 30,000 |

| σmax | N | εi | Δεb | σmax | N | εi | Δεb | σmax | N | εi | Δεb |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.10 MPa | 3000 | 39.689% | 0.778% | 0.14 MPa | 3000 | 39.633% | 0.918% | 0.17 MPa | 3000 | 39.008% | 2.480% |

| 5000 | 39.659% | 0.851% | 5000 | 39.571% | 1.073% | 5000 | 38.479% | 3.802% | |||

| 7000 | 39.635% | 0.913% | 7000 | 39.485% | 1.288% | 7000 | 36.897% | 7.758% | |||

| 10,000 | 39.581% | 1.047% | 10,000 | 39.455% | 1.362% | 10,000 | 31.229% | 21.928% | |||

| 50,000 | 39.337% | 1.658% | 50,000 | 38.474% | 3.815% | 20,000 | 30.562% | 23.595% | |||

| 100,000 | 39.007% | 2.483% | 100,000 | 37.011% | 7.473% | 30,000 | 30.341% | 24.150% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, F.; Chen, X.; Xu, J.; Zeng, Y.; Huang, W.; Dong, J. Experimental Study on the Evolution of Mechanical Properties and Their Mechanisms in a HTPB Propellant Under Fatigue Loading. Polymers 2025, 17, 2756. https://doi.org/10.3390/polym17202756

Feng F, Chen X, Xu J, Zeng Y, Huang W, Dong J. Experimental Study on the Evolution of Mechanical Properties and Their Mechanisms in a HTPB Propellant Under Fatigue Loading. Polymers. 2025; 17(20):2756. https://doi.org/10.3390/polym17202756

Chicago/Turabian StyleFeng, Feiyang, Xiong Chen, Jinsheng Xu, Yi Zeng, Wei Huang, and Junchao Dong. 2025. "Experimental Study on the Evolution of Mechanical Properties and Their Mechanisms in a HTPB Propellant Under Fatigue Loading" Polymers 17, no. 20: 2756. https://doi.org/10.3390/polym17202756

APA StyleFeng, F., Chen, X., Xu, J., Zeng, Y., Huang, W., & Dong, J. (2025). Experimental Study on the Evolution of Mechanical Properties and Their Mechanisms in a HTPB Propellant Under Fatigue Loading. Polymers, 17(20), 2756. https://doi.org/10.3390/polym17202756