From Nature to Function: Green Composites Using Camphoric Acid-Based Unsaturated Polyester Resin and Bamboo/Flax Non-Woven Reinforcements

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Camphoric Acid Preparation

2.3. Synthesis of Camphoric-Based Unsaturated Polyester Resins (Cf-UPRs)

- 40 wt.% of styrene, and the bio-resin was denoted as Cf-UPR/STY;

- 20 wt.% of styrene + 20 wt.% of TMPTA, bio-resin was denoted as Cf-UPR/TMPTA20;

- 10 wt.% of styrene + 30 wt.% of TMPTA, bio-resin was denoted as Cf-UPR/TMPTA30;

- 40 wt.% of TMPTA, and the bio-resin was denoted as Cf-UPR/TMPTA.

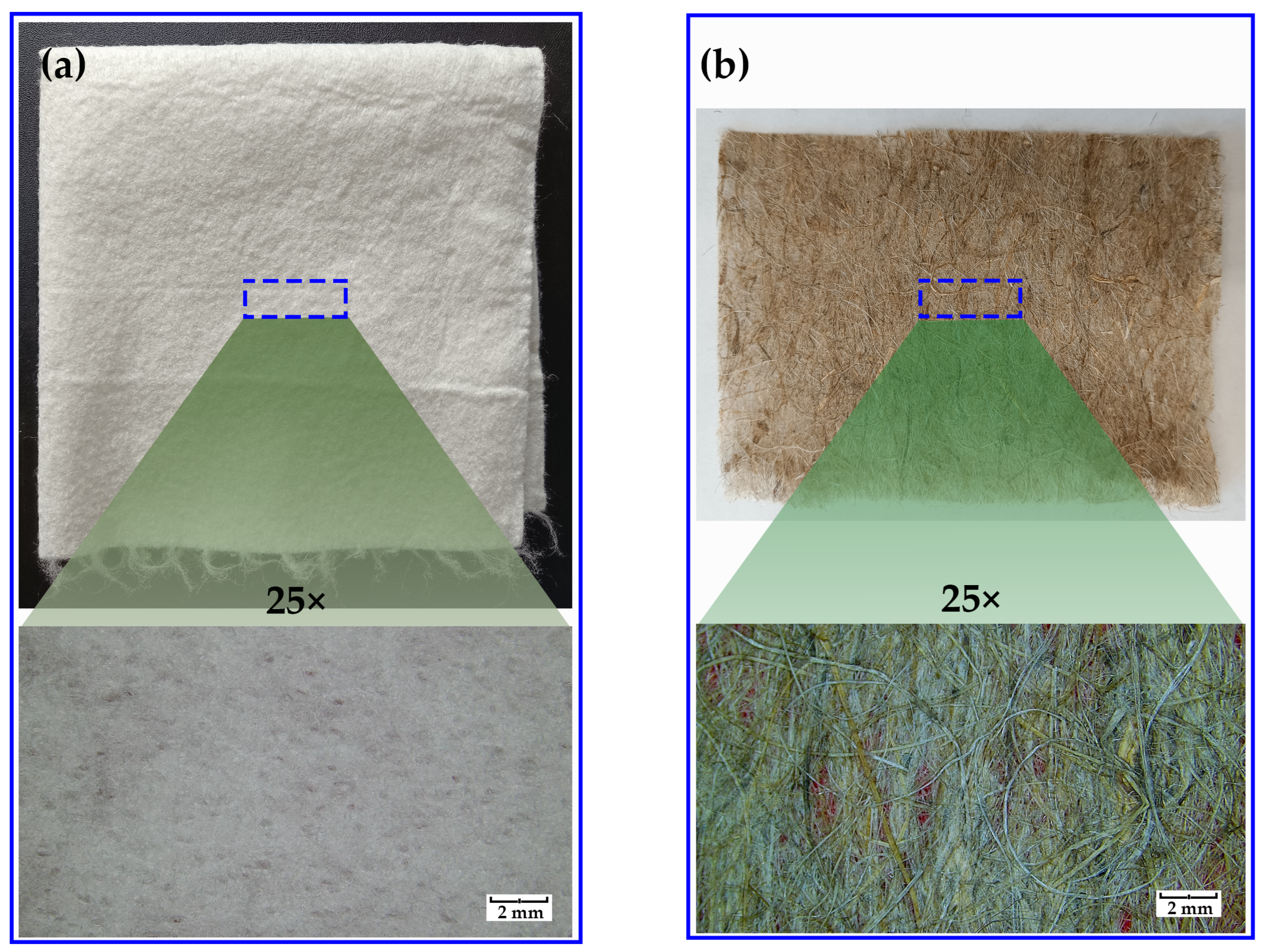

2.4. Composite Material Production

- Bio-composites with polymer matrix Cf-UPR/STY, reinforced with a bamboo mat and flax mat, separately, denoted as Cf-UPR/STY-BAM and Cf-UPR/STY-FLAX, respectively;

- Bio-composites with polymer matrix Cf-UPR/TMPTA30, reinforced with bamboo mat and flax mat, separately, denoted as Cf-UPR/TMPTA30-BAM and Cf-UPR/TMPTA30-FLAX, respectively.

2.5. Characterization Methods

3. Results and Discussion

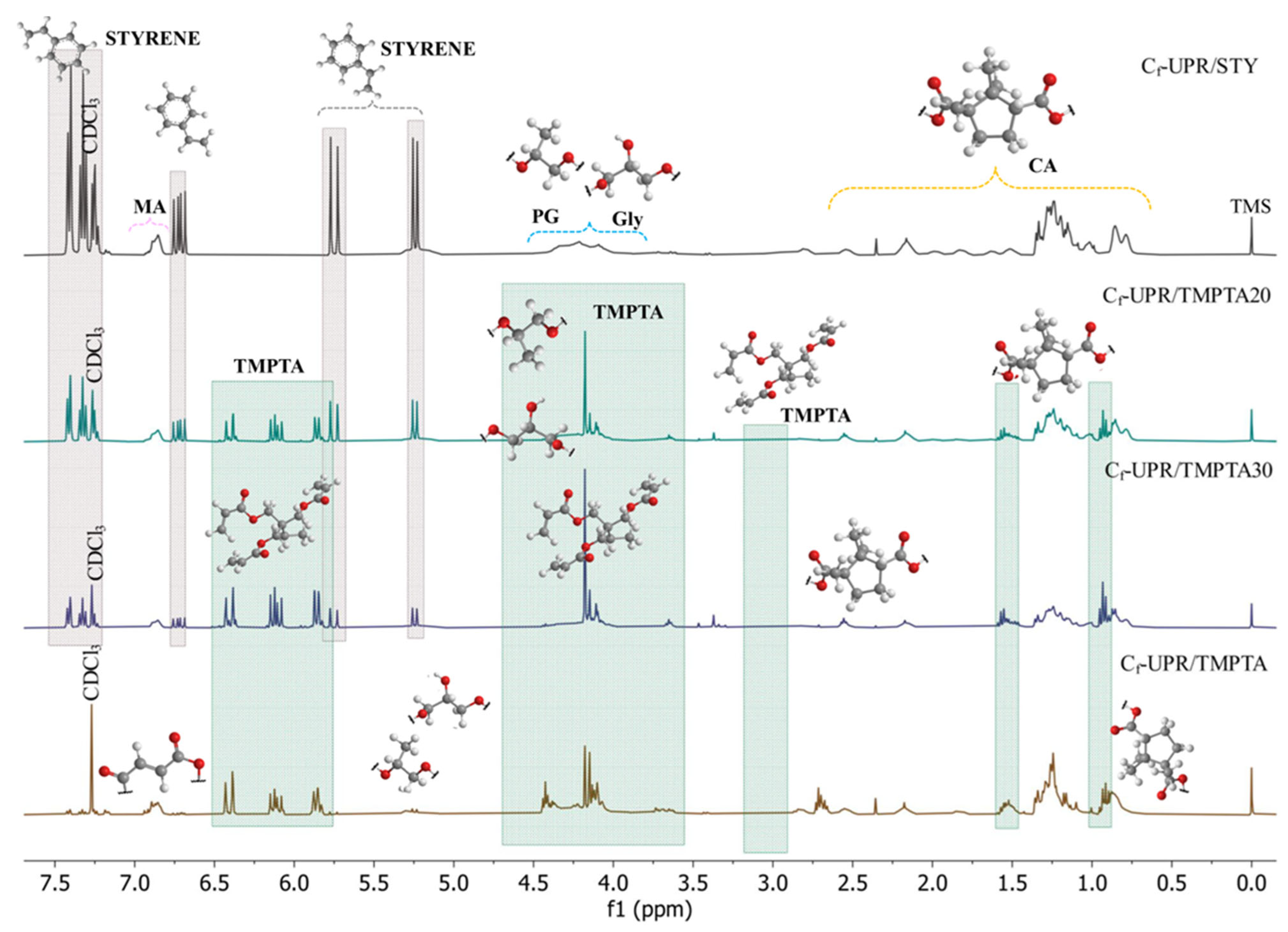

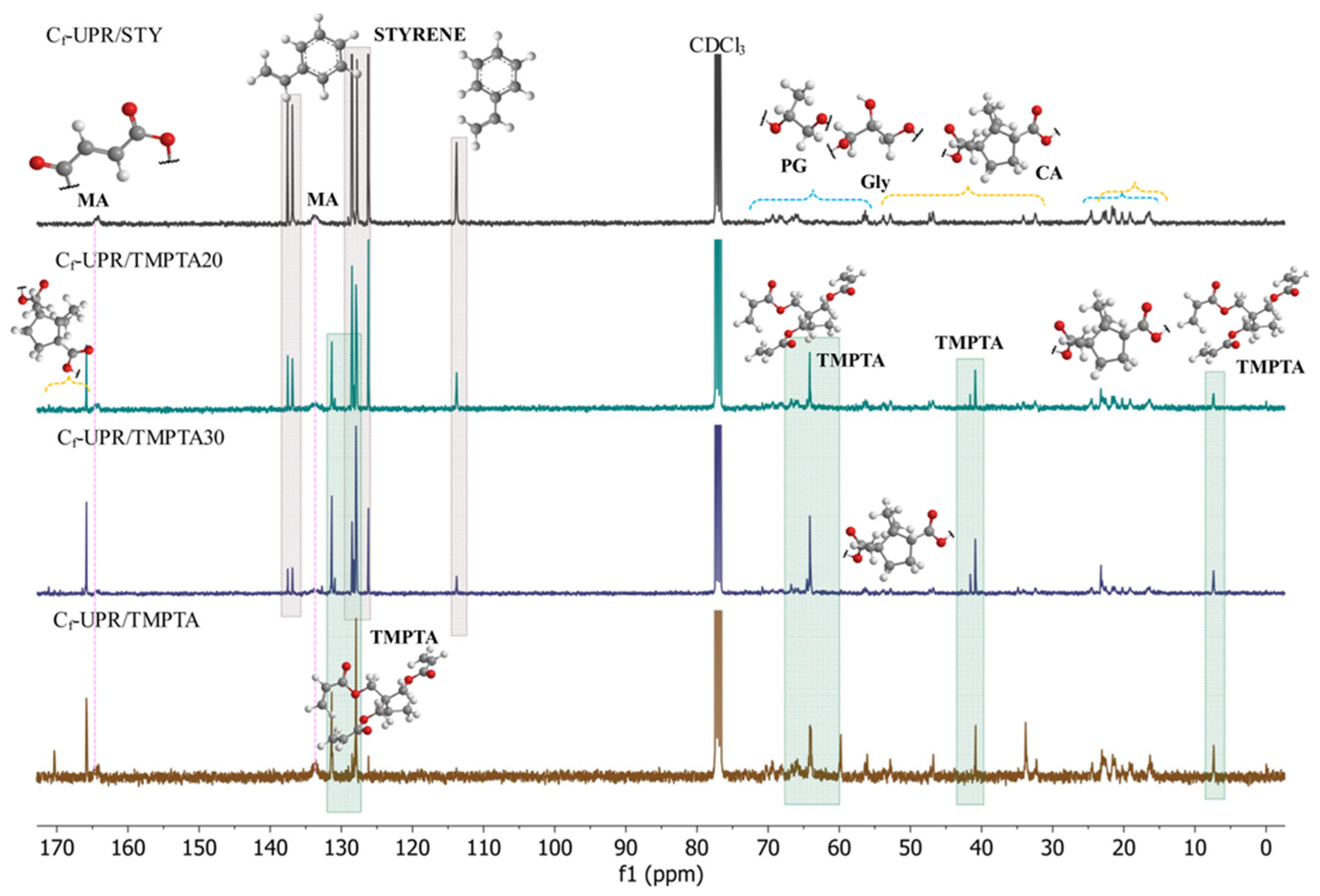

3.1. FTIR and NMR Analysis of Raw Materials, Bio-Resins, and Composites

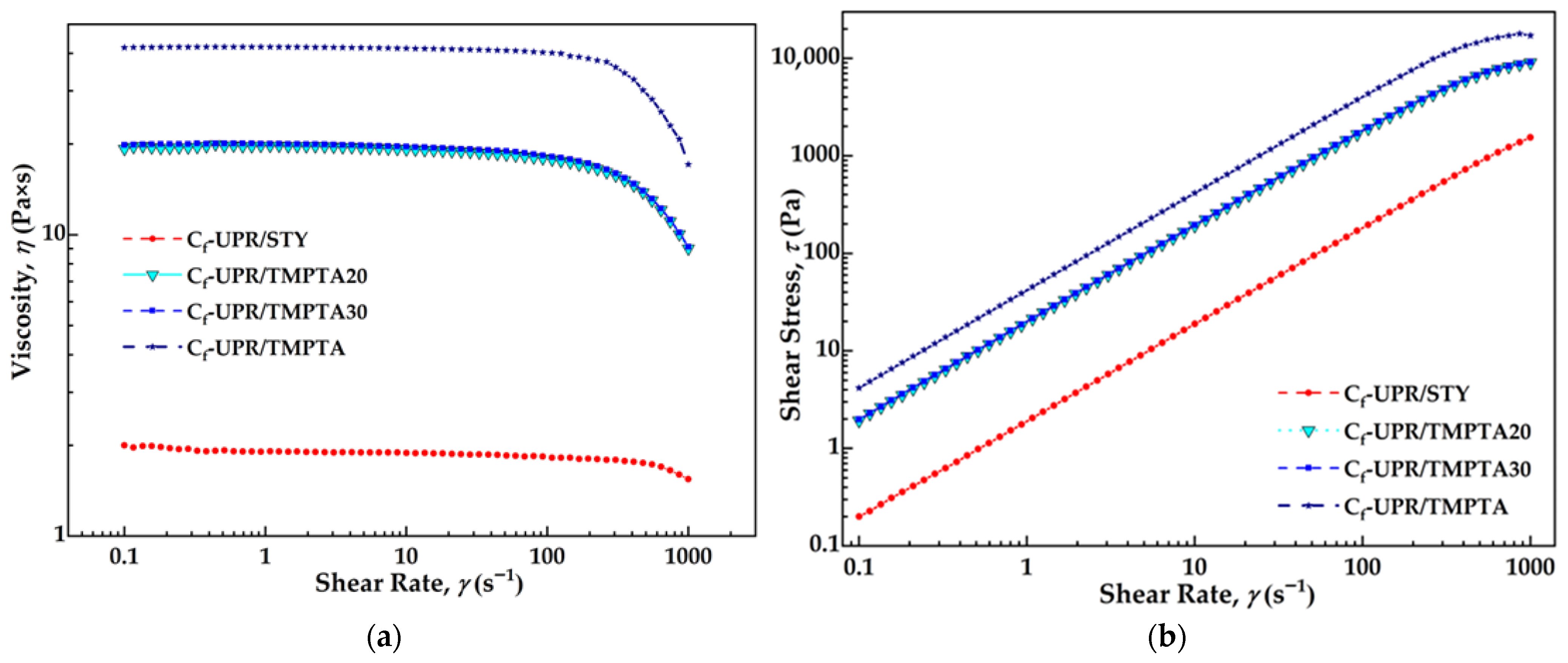

3.2. Rheological Behavior of Uncured Resins

3.3. Water Absorption

3.4. Mechanical and Dynamic-Mechanical Properties of Cured Neat Cf-UPRs and Composites

3.4.1. Tensile and Flexural Properties

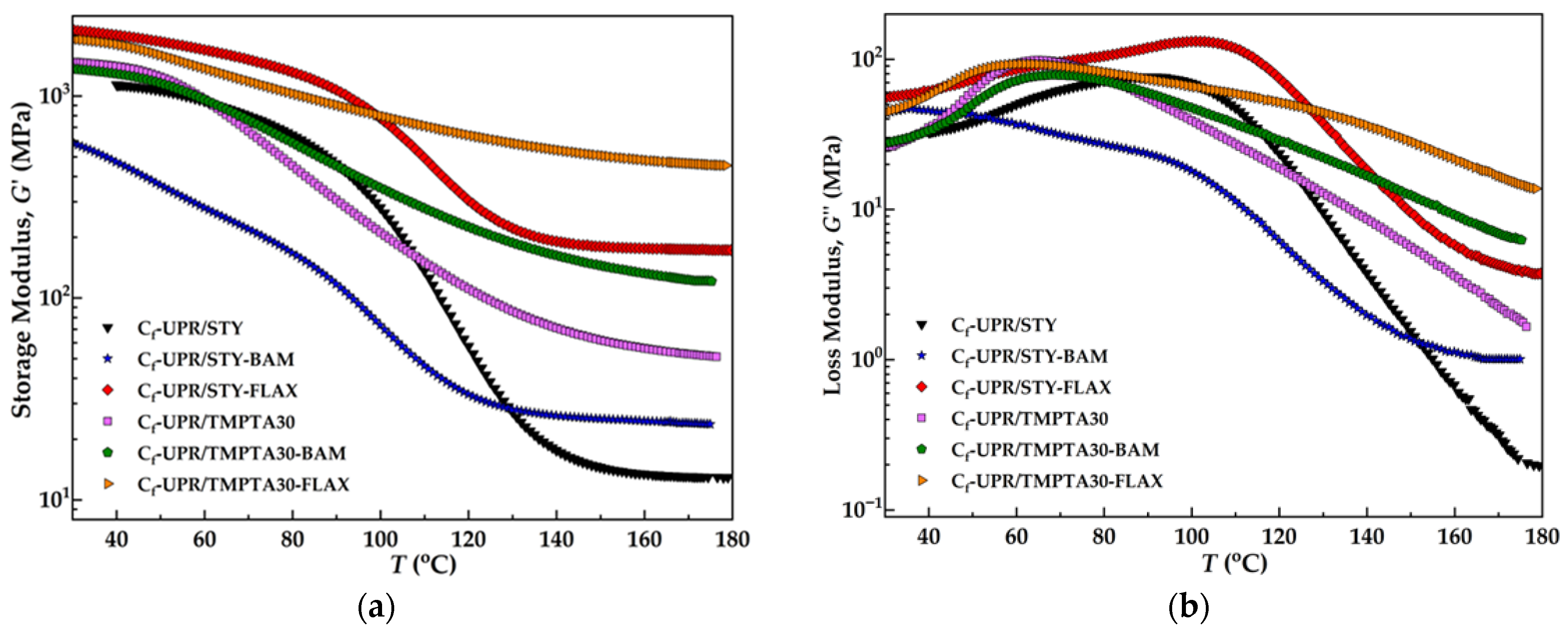

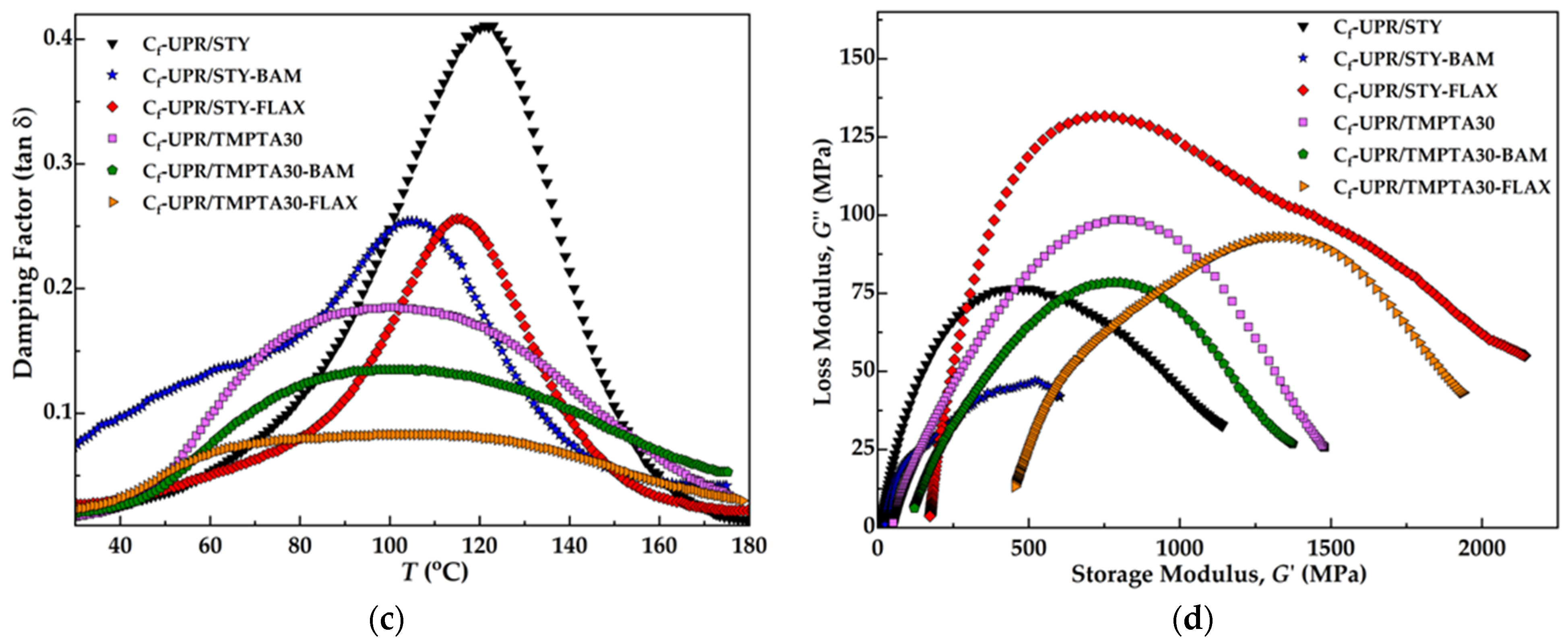

3.4.2. Dynamic-Mechanical Properties

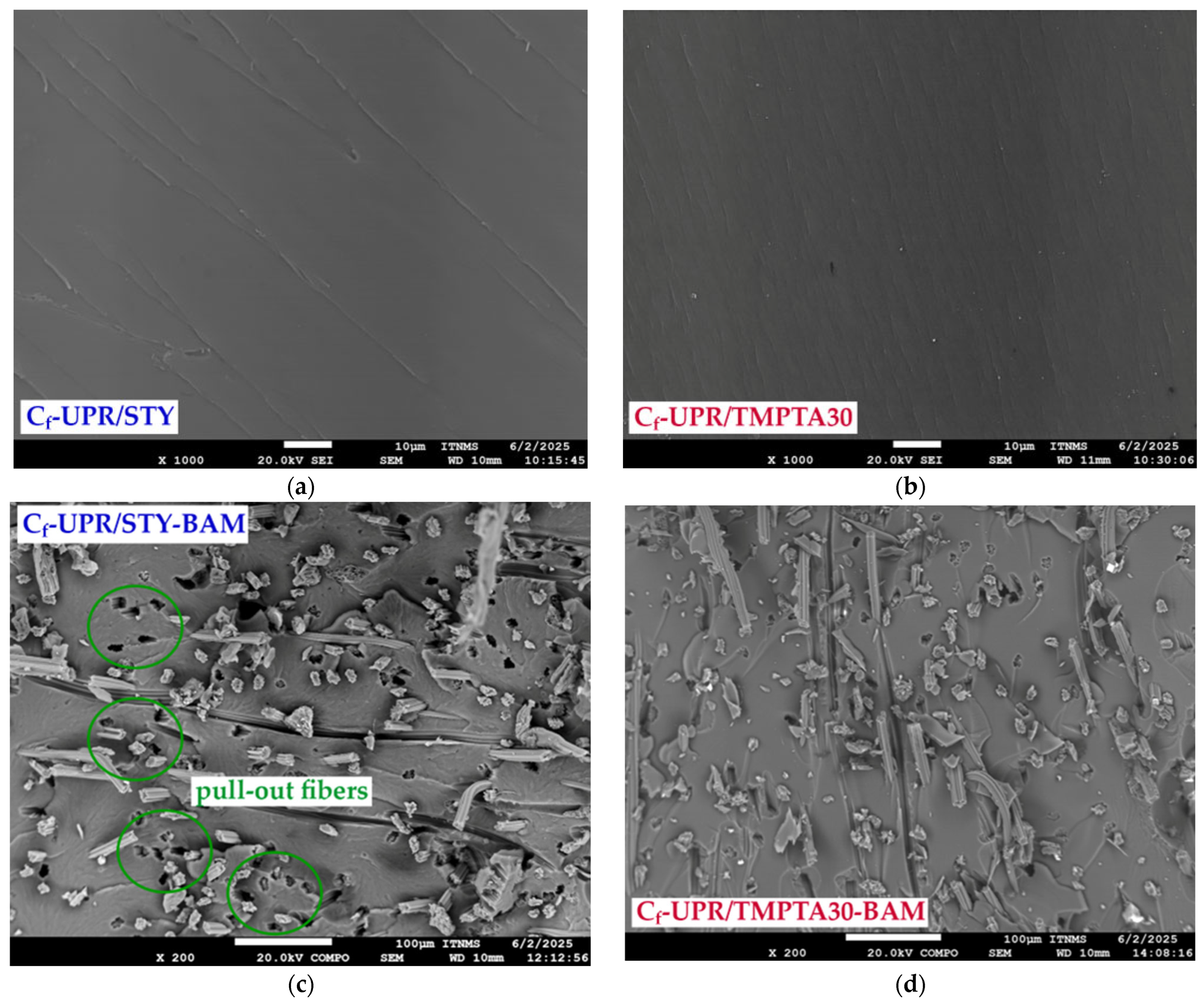

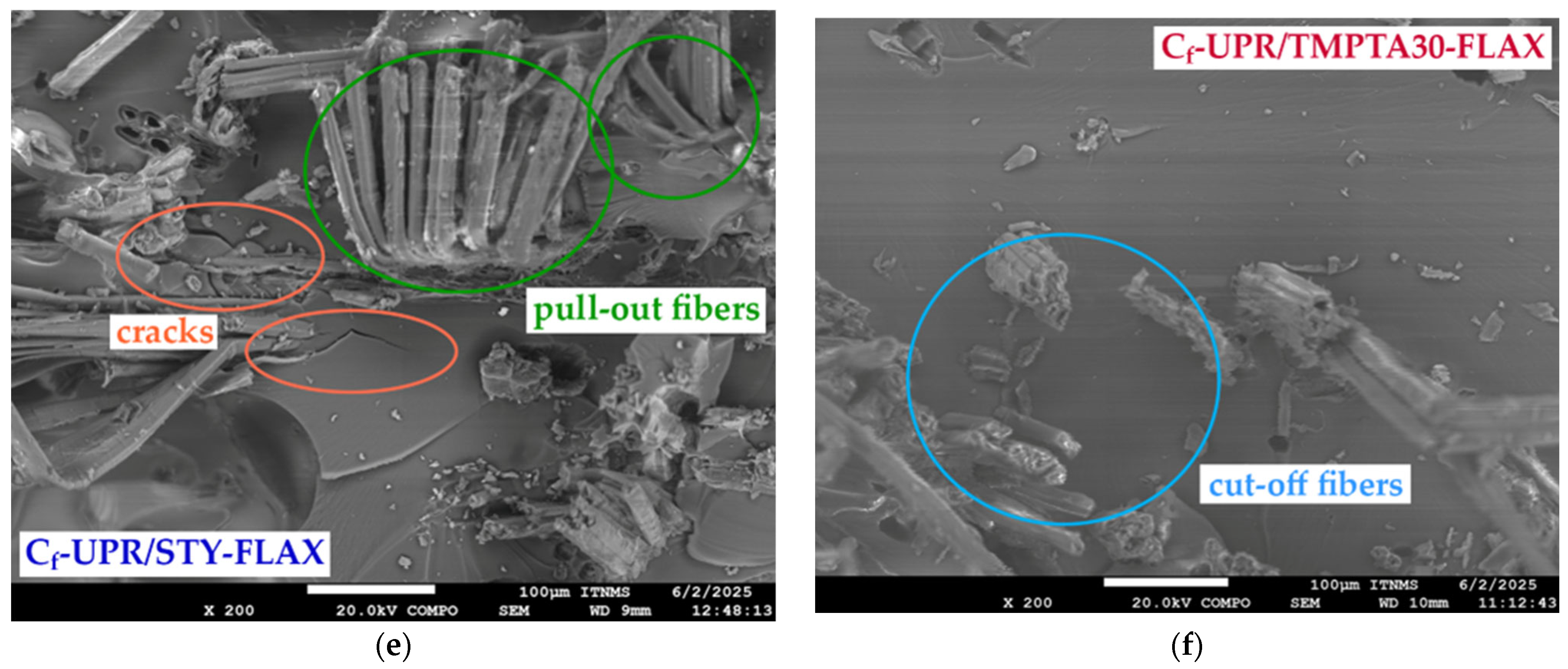

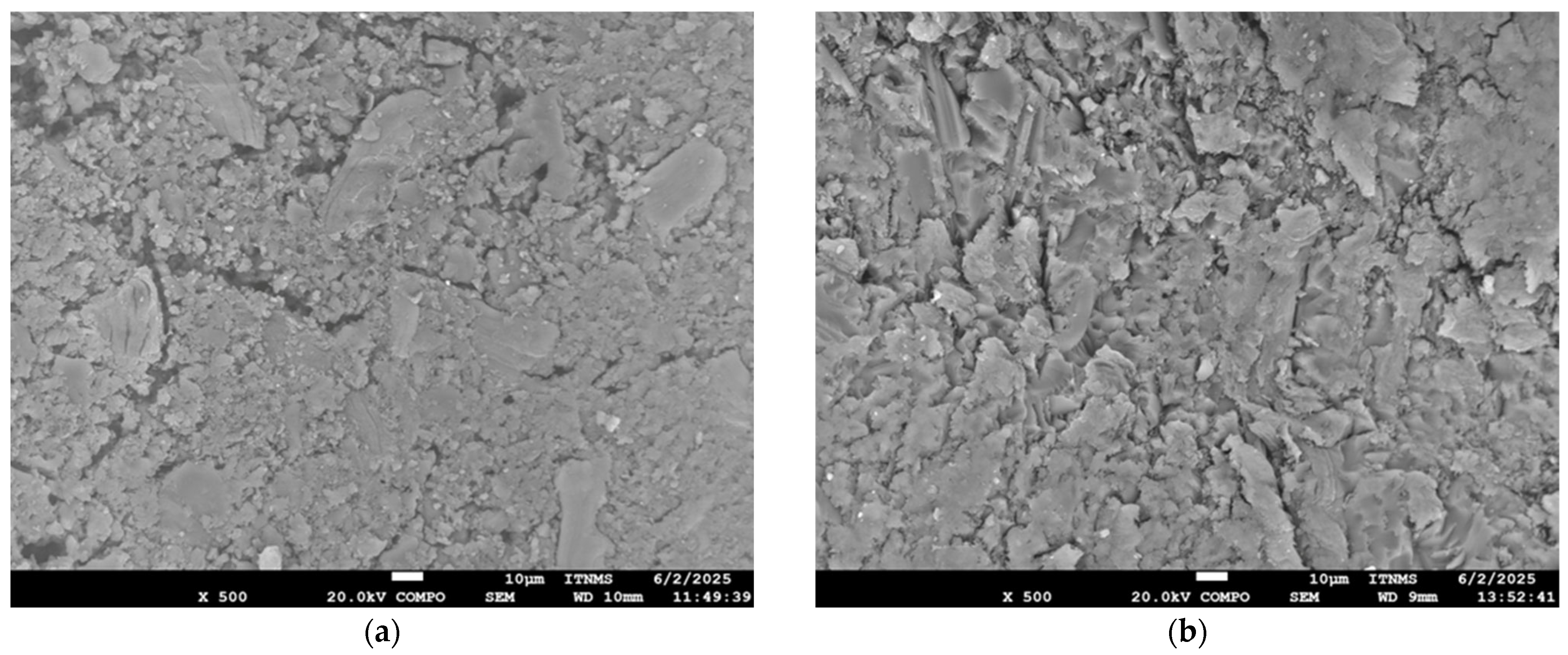

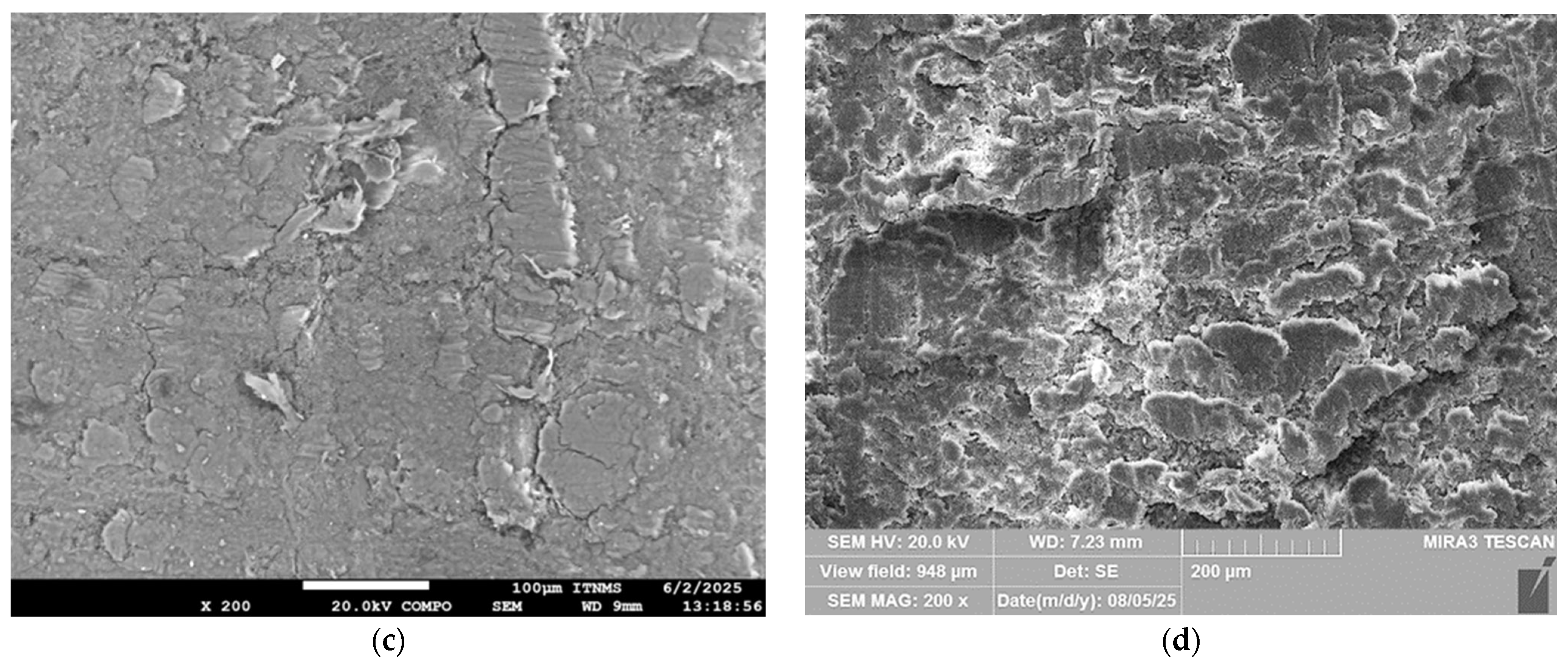

3.5. Microstructure of the Composite Materials

3.6. Thermal Analysis

4. Conclusions

- The rheological behavior of the synthesized resins confirmed their Newtonian character, indicating the absence of significant chain entanglements. The observed increase in viscosity with higher TMPTA content can be attributed to the stronger intermolecular interactions arising from the higher polarity of TMPTA compared to styrene, which reduces the diluent’s ability to separate polyester chains.

- The increased water uptake in nwBf and nwFf composites is primarily governed by the hydrophilic character and porous structure of cellulose-based reinforcements. However, reduced water absorption in Cf-UPR/TMPTA30-based composites indicates that improved interfacial bonding and higher cross-linking density can effectively mitigate moisture sensitivity, enhancing their suitability for applications in humid environments.

- Tensile and flexural testing demonstrated that the incorporation of TMPTA into the polyester matrix enhanced both strength and stiffness due to increased cross-link density, while reinforcement efficiency strongly depended on fiber type and architecture. Non-woven bamboo mats limited load transfer despite good adhesion, whereas flax reinforcements, particularly in combination with Cf-UPR/TMPTA30, provided superior tensile performance through more effective stress transfer and fiber fracture mechanisms.

- Dynamic-mechanical analysis revealed that flax-reinforced composites exhibited higher storage modulus across both glassy and rubbery regions, indicating restricted chain mobility and efficient stress transfer at the fiber-polymer matrix interface. In contrast, bamboo-reinforced composites showed lower initial stiffness, likely due to fabric architecture and porosity, despite adequate interfacial adhesion. The reduction and broadening of damping factor peaks further confirmed improved interfacial bonding and constrained chain dynamics, particularly in Cf-UPR/TMPTA30–FLAX composite, which exhibited the highest reinforcement efficiency.

- SEM analysis revealed that Cf-UPR/STY and its composites exhibited brittle fracture with fiber pullout and voids, indicating weaker fiber–matrix adhesion. In contrast, Cf-UPR/TMPTA30–FLAX composites showed fiber breakage and ripple textures, confirming stronger interfacial bonding, more efficient stress transfer, and superior reinforcement consistent with mechanical performance results.

- TG analysis showed that neat resins degraded in two main stages, with TMPTA-modified systems exhibiting earlier onset of the second stage due to volatilization of residual TMPTA, while fiber-reinforced composites displayed additional degradation related to hemicellulose at ~220 °C. The higher char yield in nwBf- and nwFf-reinforced composites was attributed to lignin decomposition, indicating improved thermal stability compared to neat Cf-UPR/STY and Cf-UPR/TMPTA30.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| UPR | Unsaturated Polyester Resin |

| TMPTA | Trimethylolpropane Triacrylate |

| STY | Styrene |

| DMA | Dynamic-Mechanical Analysis |

| MMA | Methyl Methacrylate |

| CfA | Camphoric Acid |

| nwBf | Non-Woven Bamboo Fabric |

| nwFf | Non-Woven Flax Fabric |

| PG | Propylene Glycol |

| Gly | Glycerol |

| MA | Maleic Anhydride |

| AV | Acidic Value |

| FTIR | Fourier-Transform Infrared Spectroscopy |

| NMR | Nuclear Magnetic Resonance |

| SEM | Scanning Electron Microscope |

| CoAc | Cobalt Octoate |

| MEKP | Methyl Ethyl Ketone Peroxide |

| PTFE | Polytetrafluoroethylene |

| LVR | Linear Viscoelastic Region |

| G′ | Storage Modulus |

| G″ | Loss Modulus |

| tan δ | Loss Factor (Damping Factor) |

| Tg | Glass Transition Temperature |

| υ | Cross-Linking Density |

| C | Coefficient of Reinforcement |

| Cυ | Volume Fraction of Constrained Region |

| Vf | Volume Fraction of the Fibers |

| A | Adhesion Factor |

| TGA | Thermogravimetric Analysis |

| DTG | Derivative Thermogravimetry |

References

- McKay, I.; Vargas, J.; Yang, L.; Felfel, R.M. A Review of Natural Fibres and Biopolymer Composites: Progress, Limitations, and Enhancement Strategies. Materials 2024, 17, 4878. [Google Scholar] [CrossRef]

- Chu, F.; Hu, Y.; Hu, W.; Song, L.; Hu, Y. Advancements in monomers and reinforcements of unsaturated polyester composites: Traditional, bio-based, and flame-retardant types. Compos. Part B Eng. 2025, 294, 112171. [Google Scholar] [CrossRef]

- Cazin, I.; Ocepek, M.; Kecelj, J.; Stražar, A.S.; Schlögl, S. Synthesis of Bio-Based Polyester Resins for Vat Photopolymerization 3D Printing. Materials 2024, 17, 1890. [Google Scholar] [CrossRef] [PubMed]

- Jin, L.; Geng, K.; Arshad, M.; Ahmadi, R.; Ullah, A. Synthesis of Fully Biobased Polyesters from Plant Oil. ACS Sustain. Chem. Eng. 2017, 5, 9793–9801. [Google Scholar] [CrossRef]

- Wang, Z.; Ganewatta, M.S.; Tang, C. Sustainable polymers from biomass: Bridging chemistry with materials and processing. Prog. Polym. Sci. 2020, 101, 101197. [Google Scholar] [CrossRef]

- de Oliveira, É.; Costa, M.; Ramos, L.; Araújo, O. Synthesis and Characterization of Polyester Derived from Glycerol and Its Application as an Adhesive on Different Adherents. J. Braz. Chem. Soc. 2024, 35, 1–12. [Google Scholar] [CrossRef]

- Rubeš, D.; Vinklárek, J.; Prokůpek, L.; Podzimek, Š.; Honzíček, J. Styrene-free unsaturated polyester resins derived from itaconic acid curable by cobalt-free accelerators. J. Mater. Sci. 2023, 58, 6203–6219. [Google Scholar] [CrossRef]

- Grimalt, J.; Frattini, L.; Carreras, P.; Fombuena, V. Optimizing rheological performance of unsaturated polyester resin with bio-based reactive diluents: A comprehensive analysis of viscosity and thermomechanical properties. Polym. Test. 2023, 129, 108264. [Google Scholar] [CrossRef]

- Rubeš, D.; Vinklárek, J.; Podzimek, Š.; Honzíček, J. Bio-based unsaturated polyester resin from post-consumer PET. RSC Adv. 2024, 14, 8536–8547. [Google Scholar] [CrossRef]

- Puttegowda, M.; Rangappa, S.M.; Khan, A.; Al-Zahrani, S.A.; Al Otaibi, A.; Shivanna, P.; Moure, M.M.; Siengchin, S. Preparation and characterization of new hybrid polymer composites from Phoenix pusilla fibers/E-glass/carbon fabrics on potential engineering applications: Effect of stacking sequence. Polym. Compos. 2020, 41, 4572–4582. [Google Scholar] [CrossRef]

- Wielage, B.; Lampke, T.; Utschick, H.; Soergel, F. Processing of natural-fibre reinforced polymers and the resulting dynamic–mechanical properties. J. Mater. Process. Technol. 2003, 139, 140–146. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Makarov, I.S.; Smyslov, A.G.; Palchikova, E.E.; Vinogradov, M.I.; Shandryuk, G.A.; Levin, I.S.; Arkharova, N.A.; Kulichikhin, V.G. Nonwoven materials based on natural and artificial fibers. Cellulose 2024, 31, 1927–1940. [Google Scholar] [CrossRef]

- Belal, S.M.; Anwar, M.S.; Islam, M.S.; Arifuzzaman, M.; Al Bari, M.A. Numerical study on the design of flax/bamboo fiber reinforced hybrid composites under bending load. Hybrid Adv. 2023, 4, 100112. [Google Scholar] [CrossRef]

- Venkatesha, R.A.; Venkatesh, A.M. Exploring the Thermal and Mechanical Properties of Flax/Bamboo Fiber Natural Composite as a Sustainable Alternate for Enhanced Performance in Composite Materials. SSRN Electron. J. 2024. [Google Scholar] [CrossRef]

- Walter, L.; Scherdel, M.; Taha, I. Fabrication and Characterisation of Fully Bio-Based Flax Fibre-Reinforced Polyester Composites. J. Compos. Sci. 2025, 9, 241. [Google Scholar] [CrossRef]

- Möhl, C.; Weimer, T.; Caliskan, M.; Baz, S.; Bauder, H.-J.; Gresser, G.T. Development of Natural Fibre-Reinforced Semi-Finished Products with Bio-Based Matrix for Eco-Friendly Composites. Polymers 2022, 14, 698. [Google Scholar] [CrossRef]

- Di Matteo, P.; Iadarola, A.; Ciardiello, R.; Paolino, D.S.; Gazza, F.; Lambertini, V.G.; Brunella, V. Cross-Linking Reaction of Bio-Based Epoxy Systems: An Investigation into Cure Kinetics. Polymers 2024, 16, 2499. [Google Scholar] [CrossRef]

- Stamboulis, A.; Baillie, C.A.; Garkhail, S.K.; van Melick, H.G.H.; Peijs, T. Environmental Durability of Flax Fibres and their Composites based on Polypropylene Matrix. Appl. Compos. Mater. 2000, 7, 273–294. [Google Scholar] [CrossRef]

- Thomason, J.; Yang, L.; Gentles, F. Characterisation of the Anisotropic Thermoelastic Properties of Natural Fibres for Composite Reinforcement. Fibers 2017, 5, 36. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Aslan, M.; Chinga-Carrasco, G.; Sørensen, B.F.; Madsen, B. Strength variability of single flax fibres. J. Mater. Sci. 2011, 46, 6344–6354. [Google Scholar] [CrossRef]

- Maiti, S.; Islam, M.R.; Uddin, M.A.; Afroj, S.; Eichhorn, S.J.; Karim, N. Sustainable Fiber-Reinforced Composites: A Review. Adv. Sustain. Syst. 2022, 6, 2200258. [Google Scholar] [CrossRef]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Pokharel, A.; Falua, K.J.; Babaei-Ghazvini, A.; Acharya, B. Biobased Polymer Composites: A Review. J. Compos. Sci. 2022, 6, 255. [Google Scholar] [CrossRef]

- Prasad, V.; Alliyankal Vijayakumar, A.; Jose, T.; George, S.C. A Comprehensive Review of Sustainability in Natural-Fiber-Reinforced Polymers. Sustainability 2024, 16, 1223. [Google Scholar] [CrossRef]

- Hofmann, M.A.; Shahid, A.T.; Garrido, M.; Ferreira, M.J.; Correia, J.R.; Bordado, J.C. Biobased Thermosetting Polyester Resin for High-Performance Applications. ACS Sustain. Chem. Eng. 2022, 10, 3442–3454. [Google Scholar] [CrossRef]

- Embirsh, H.S.A.; Stajčić, I.; Gržetić, J.; Mladenović, I.O.; Anđelković, B.; Marinković, A.; Vuksanović, M.M. Synthesis, Characterization and Application of Biobased Unsaturated Polyester Resin Reinforced with Unmodified/Modified Biosilica Nanoparticles. Polymers 2023, 15, 3756. [Google Scholar] [CrossRef]

- Nsengiyumva, O.; Miller, S.A. Synthesis, characterization, and water-degradation of biorenewable polyesters derived from natural camphoric acid. Green Chem. 2019, 21, 973–978. [Google Scholar] [CrossRef]

- Mijatov, S.; Vuksanović, M.M.; Knežević, N.; Anđelković, B.; Cvijetić, I.; Milošević, M.; Mladenović, I.O.; Marinković, A. Mechanical Properties of the Bio-Composites: Effect of Kraft Lignin and Flax Fabric to Camphoric Acid Based Unsaturated Polyester Resin’s Reinforcement. Polym. Compos. 2025. [Google Scholar] [CrossRef]

- Embirsh, H.S.A.; Vuksanović, M.M.; Mladenović, I.O.; Knežević, N.; Milošević, M.; Mijatov, S.; Heinemann, R.J.; Marinković, A. Unsaturated polyester resin based composites: A case study of lignin valorisation. Chemosphere 2024, 362, 142144. [Google Scholar] [CrossRef]

- Rusmirović, J.D.; Rančić, M.P.; Pavlović, V.B.; Rakić, V.M.; Stevanović, S.; Djonlagić, J.; Marinković, A.D. Cross-Linkable Modified Nanocellulose/Polyester Resin-Based Composites: Effect of Unsaturated Fatty Acid Nanocellulose Modification on Material Performances. Macromol. Mater. Eng. 2018, 303, 1700648. [Google Scholar] [CrossRef]

- Rusmirović, J.D.; Kovačević, T.M.; Brzić, S.J.; Marinković, A.D. Cross-Linkable Bio and Mineral Fillers for Reactive Polymer Composites: Processing and Characterization. In Reactive and Functional Polymers Volume Two: Modification Reactions, Compatibility and Blends; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Kovačević, T.; Rusmirović, J.; Tomić, N.; Marinović-Cincović, M.; Kamberović, Ž.; Tomić, M.; Marinković, A. New composites based on waste PET and non-metallic fraction from waste printed circuit boards: Mechanical and thermal properties. Compos. Part B Eng. 2017, 127, 1–14. [Google Scholar] [CrossRef]

- Rusmirovic, J.D.; Trifkovic, K.T.; Bugarski, B.; Pavlovic, V.B.; Dzunuzovic, J.; Tomic, M.; Marinkovic, A.D. High performances unsaturated polyester based nanocomposites: Effect of vinyl modified nanosilica on mechanical properties. Express Polym. Lett. 2016, 10, 139–159. [Google Scholar] [CrossRef]

- Rusmirović, J.D.; Ivanović, J.Z.; Pavlović, V.B.; Rakić, V.M.; Rančić, M.P.; Djokić, V.; Marinković, A.D. Novel modified nanocellulose applicable as reinforcement in high-performance nanocomposites. Carbohydr. Polym. 2017, 164, 64–74. [Google Scholar] [CrossRef]

- Elmas, G.M.; Yilgor, N. Chemical and thermal characterizations of Pinus sylvestris and Pinus pinaster. BioResources 2020, 15, 3604–3620. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D.L.A.P. Determination of Structural Carbohydrates and Lignin in Biomass; Laboratory Analytical Procedure (LAP): Denver West Parkway Golden, CO, USA, 2008. [Google Scholar]

- ASTM D-1166–84; Standard Test Method for Methoxyl Groups in Wood and Related Materials. ASTM: West Conshohocken, PA, USA, 2013.

- T 222 om-02; Standard Specific Interest Group for this Test Method TAPPI. Acid-Insoluble Lignin in Wood and Pulp. TAPPI: Peachtree Corners, GA, USA, 2002.

- Rowell, R.M. Handbook of Wood Chemistry and Wood Composites, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Mudri, N.H.; Abdullah, L.C.; Aung, M.M.; Biak, D.R.A.; Tajau, R. Structural and Rheological Properties of Nonedible Vegetable Oil-Based Resin. Polymers 2021, 13, 2490. [Google Scholar] [CrossRef]

- Kim, T.H.; Kim, M.; Lee, W.; Kim, H.-G.; Lim, C.-S.; Seo, B. Synthesis and Characterization of a Polyurethane Phase Separated to Nano Size in an Epoxy Polymer. Coatings 2019, 9, 319. [Google Scholar] [CrossRef]

- Prabhakar, M.N.; Song, J. Fabrication and characterisation of starch/chitosan/flax fabric green flame-retardant composites. Int. J. Biol. Macromol. 2018, 119, 1335–1343. [Google Scholar] [CrossRef]

- Xu, G.; Wang, L.; Liu, J.; Wu, J. FTIR and XPS analysis of the changes in bamboo chemical structure decayed by white-rot and brown-rot fungi. Appl. Surf. Sci. 2013, 280, 799–805. [Google Scholar] [CrossRef]

- Salih, R.; Veličković, Z.; Milošević, M.; Pavlović, V.P.; Cvijetić, I.; Sofrenić, I.V.; Gržetić, J.D.; Marinković, A. Lignin based microspheres for effective dyes removal: Design, synthesis and adsorption mechanism supported with theoretical study. J. Environ. Manag. 2023, 326, 116838. [Google Scholar] [CrossRef] [PubMed]

- Spasojevic, P.; Seslija, S.; Markovic, M.; Pantic, O.; Antic, K.; Spasojevic, M. Optimization of Reactive Diluent for Bio-Based Unsaturated Polyester Resin: A Rheological and Thermomechanical Study. Polymers 2021, 13, 2667. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.; Sun, H.; Zhang, Z.; Wang, J.; Zhang, X.; Du, P. Effect of modified PE fiber grafted with nano-SiO2 on the tensile properties of high-strength engineering cementitious composites. Constr. Build. Mater. 2024, 420, 135618. [Google Scholar] [CrossRef]

- Hasan, M.H.; Hasan, M.R.; Rahman, M.H.; Islam, M.N.; Sabur, M.A.; Rahman, G.M.S.; Mamun, M.A. Synergistic effect of chemically treated eco-friendly Luffa and glass fiber reinforcement for layered hybrid polymer composites: A novel approach. SPE Polym. 2025, 6, e70007. [Google Scholar] [CrossRef]

- Manalo, A.C.; Wani, E.; Zukarnain, N.A.; Karunasena, W.; Lau, K. Effects of alkali treatment and elevated temperature on the mechanical properties of bamboo fibre–polyester composites. Compos. Part B Eng. 2015, 80, 73–83. [Google Scholar] [CrossRef]

- Martijanti, M.; Sutarno, S.; Juwono, A.L. Polymer Composite Fabrication Reinforced with Bamboo Fiber for Particle Board Product Raw Material Application. Polymers 2021, 13, 4377. [Google Scholar] [CrossRef]

- Nayan, A.; Yusuf, M.; Siska, D. Tensile Strength Comparison of Polymer Composite Materials Reinforced by Three Types of Bamboo Fiber Treated With 5% aq. NaOH Solution. Int. J. Eng. Sci. Inf. Technol. 2023, 3, 37–46. [Google Scholar] [CrossRef]

- Pothan, L.A.; Oommen, Z.; Thomas, S. Dynamic mechanical analysis of banana fiber reinforced polyester composites. Compos. Sci. Technol. 2003, 63, 283–293. [Google Scholar] [CrossRef]

- He, L.; Xia, F.; Wang, Y.; Yuan, J.; Chen, D.; Zheng, J. Mechanical and Dynamic Mechanical Properties of the Amino Silicone Oil Emulsion Modified Ramie Fiber Reinforced Composites. Polymers 2021, 13, 4083. [Google Scholar] [CrossRef]

- Ahmad, M.A.A.; Abdul Majid, M.S.; Ridzuan, M.J.M.; Mazlee, M.N.; Gibson, A.G. Dynamic mechanical analysis and effects of moisture on mechanical properties of interwoven hemp/polyethylene terephthalate (PET) hybrid composites. Constr. Build. Mater. 2018, 179, 265–276. [Google Scholar] [CrossRef]

- Nouigues, A.; Salle, E.L.G.L.; Bailleul, J.-L. Thermo-mechanical characterization of unsaturated polyester/glass fiber composites for recycling. Int. J. Mater. Form. 2021, 14, 153–174. [Google Scholar] [CrossRef]

- Simić, D.M.; Stojanović, D.B.; Brzić, S.J.; Totovski, L.; Uskoković, P.S.; Aleksić, R.R. Aramid hybrid composite laminates reinforced with inorganic fullerene-like tungsten disulfide nanoparticles. Compos. Part B Eng. 2017, 123, 10–18. [Google Scholar] [CrossRef]

- Kaboorani, A.; Blanchet, P. Determining the Linear Viscoelastic Region of Sugar Maple Wood by Dynamic Mechanical Analysis. BioResources 2014, 9, 4392–4409. [Google Scholar] [CrossRef]

- Saba, N.; Safwan, A.; Sanyang, M.L.; Mohammad, F.; Pervaiz, M.; Jawaid, M.; Alothman, O.Y.; Sain, M. Thermal and dynamic mechanical properties of cellulose nanofibers reinforced epoxy composites. Int. J. Biol. Macromol. 2017, 102, 822–828. [Google Scholar] [CrossRef] [PubMed]

- Kovačević, T.; Brzić, S.; Kalagasidis Krušić, M.; Nešić, J.; Radović, L.; Dojčinović, M.; Rusmirović, J. Reuse potential of functionalized thermoplastic waste as reinforcement for thermoset polymers: Mechanical properties and erosion resistance. J. Compos. Mater. 2021, 55, 4207–4220. [Google Scholar] [CrossRef]

- Alothman, O.Y.; Jawaid, M.; Senthilkumar, K.; Chandrasekar, M.; Alshammari, B.A.; Fouad, H.; Hashem, M.; Siengchin, S. Thermal characterization of date palm/epoxy composites with fillers from different parts of the tree. J. Mater. Res. Technol. 2020, 9, 15537–15546. [Google Scholar] [CrossRef]

- Atiqah, A.; Jawaid, M.; Sapuan, S.M.; Ishak, M.R.; Alothman, O.Y. Thermal properties of sugar palm/glass fiber reinforced thermoplastic polyurethane hybrid composites. Compos. Struct. 2018, 202, 954–958. [Google Scholar] [CrossRef]

- Sathyaseelan, P.; Sellamuthu, P.; Palanimuthu, L. Dynamic mechanical analysis of areca/kenaf fiber reinforced epoxy hybrid composites fabricated in different stacking sequences. Mater. Today Proc. 2021, 39, 1202–1205. [Google Scholar] [CrossRef]

- Azadi, F.; Jafari, S.H.; Khonakdar, H.A.; Arjmand, M.; Wagenknecht, U.; Altstädt, V. Influence of Graphene Oxide on Thermally Induced Shape Memory Behavior of PLA/TPU Blends: Correlation with Morphology, Creep Behavior, Crystallinity, and Dynamic Mechanical Properties. Macromol. Mater. Eng. 2021, 306, 2000576. [Google Scholar] [CrossRef]

- Haris, N.I.N.; Ilyas, R.A.; Hassan, M.Z.; Sapuan, S.M.; Afdzaluddin, A.; Jamaludin, K.R.; Zaki, S.A.; Ramlie, F. Dynamic Mechanical Properties and Thermal Properties of Longitudinal Basalt/Woven Glass Fiber Reinforced Unsaturated Polyester Hybrid Composites. Polymers 2021, 13, 3343. [Google Scholar] [CrossRef]

- Ornaghi, H.L.; Neves, R.M.; Monticeli, F.M.; Thomas, S. Modeling of dynamic mechanical curves of kenaf/polyester composites using surface response methodology. J. Appl. Polym. Sci. 2022, 139, 52078. [Google Scholar] [CrossRef]

- Drah, A.; Kovačević, T.; Rusmirović, J.; Tomić, N.; Brzić, S.; Bogosavljavić, M.; Marinković, A. Effect of surface activation of alumina particles on the performances of thermosetting-based composite materials. J. Compos. Mater. 2019, 53, 2727–2742. [Google Scholar] [CrossRef]

- Kovačević, T.; Rusmirović, J.; Tomić, N.; Mladenović, G.; Milošević, M.; Mitrović, N.; Marinković, A. Effects of oxidized/treated non-metallic fillers obtained from waste printed circuit boards on mechanical properties and shrinkage of unsaturated polyester-based composites. Polym. Compos. 2019, 40, 1170–1186. [Google Scholar] [CrossRef]

- Schroeder, M.J.; Roland, C.M. Segmental Relaxation in End-Linked Poly(dimethylsiloxane) Networks. Macromolecules 2002, 35, 2676–2681. [Google Scholar] [CrossRef]

- Mittal, M.; Chaudhary, R. Effect of fiber content on thermal behavior and viscoelastic properties of PALF/Epoxy and COIR/Epoxy composites. Mater. Res. Express 2018, 5, 125305. [Google Scholar] [CrossRef]

- Balakrishnan, P.; Sreekala, M.S.; Kunaver, M.; Huskić, M.; Thomas, S. Morphology, transport characteristics and viscoelastic polymer chain confinement in nanocomposites based on thermoplastic potato starch and cellulose nanofibers from pineapple leaf. Carbohydr. Polym. 2017, 169, 176–188. [Google Scholar] [CrossRef]

- Krishnasamy, P.; Rajamurugan, G.; Thirumurugan, M. Dynamic mechanical characteristics of jute fiber and 304 wire mesh reinforced epoxy composite. J. Ind. Text. 2021, 51, 540–558. [Google Scholar] [CrossRef]

- Ornaghi, H.L.; Bolner, A.S.; Fiorio, R.; Zattera, A.J.; Amico, S.C. Mechanical and dynamic mechanical analysis of hybrid composites molded by resin transfer molding. J. Appl. Polym. Sci. 2010, 118, 887–896. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Khalina, A.; Sapuan, S.M.; Ilyas, R.A.; Rafiqah, S.A.; Hanafee, Z.M. Thermal properties of treated sugar palm yarn/glass fiber reinforced unsaturated polyester hybrid composites. J. Mater. Res. Technol. 2020, 9, 1606–1618. [Google Scholar] [CrossRef]

- Arulmurugan, M.; Prabu, K.; Rajamurugan, G.; Selvakumar, A.S. Impact of BaSO4 filler on woven Aloevera/Hemp hybrid composite: Dynamic mechanical analysis. Mater. Res. Express 2019, 6, 045309. [Google Scholar] [CrossRef]

- Manoharan, S.; Suresha, B.; Ramadoss, G.; Bharath, B. Effect of Short Fiber Reinforcement on Mechanical Properties of Hybrid Phenolic Composites. J. Mater. 2014, 2014, 478549. [Google Scholar] [CrossRef]

- Motta Neves, R.; Zattera, A.J.; Campos Amico, S. Enhancing thermal and dynamic-mechanical properties of epoxy reinforced by amino-functionalized microcrystalline cellulose. J. Appl. Polym. Sci. 2021, 138, 51329. [Google Scholar] [CrossRef]

- Tan, Y.; Wang, X.; Wu, D. Preparation, microstructures, and properties of long-glass-fiber-reinforced thermoplastic composites based on polycarbonate/poly(butylene terephthalate) alloys. J. Reinf. Plast. Compos. 2015, 34, 1804–1820. [Google Scholar] [CrossRef]

- Ji, W.M.; Zhang, L.W. Diamond nanothread reinforced polymer composites: Ultra-high glass transition temperature and low density. Compos. Sci. Technol. 2019, 183, 107789. [Google Scholar] [CrossRef]

- Brzic, S.; Uscumlic, G.; Dimic, M.; Tomic, M.; Rodic, V.; Fidanovski, B. Viscoelastic behavior of carboxyl-terminated (butadiene-co-acrylonitrile)-based composite propellant binder containing polyglycidyl-type bonding agent. Chem. Ind. 2016, 70, 547–556. [Google Scholar] [CrossRef]

- Pothan, L.A.; Thomas, S.; Groeninckx, G. The role of fibre/matrix interactions on the dynamic mechanical properties of chemically modified banana fibre/polyester composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1260–1269. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.P.S.; Hassan, A.; Dungani, R.; Hadiyane, A. Effect of jute fibre loading on tensile and dynamic mechanical properties of oil palm epoxy composites. Compos. Part B Eng. 2013, 45, 619–624. [Google Scholar] [CrossRef]

- Idicula, M.; Malhotra, S.K.; Joseph, K.; Thomas, S. Dynamic mechanical analysis of randomly oriented intimately mixed short banana/sisal hybrid fibre reinforced polyester composites. Compos. Sci. Technol. 2005, 65, 1077–1087. [Google Scholar] [CrossRef]

- Bindu, P.; Thomas, S. Viscoelastic Behavior and Reinforcement Mechanism in Rubber Nanocomposites in the Vicinity of Spherical Nanoparticles. J. Phys. Chem. B 2013, 117, 12632–12648. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Hejna, A. Poly(ε-Caprolactone)/Brewers’ Spent Grain Composites—The Impact of Filler Treatment on the Mechanical Performance. J. Compos. Sci. 2020, 4, 167. [Google Scholar] [CrossRef]

- Hidalgo-Salazar, M.A.; Correa-Aguirre, J.P.; García-Navarro, S.; Roca-Blay, L. Injection Molding of Coir Coconut Fiber Reinforced Polyolefin Blends: Mechanical, Viscoelastic, Thermal Behavior and Three-Dimensional Microscopy Study. Polymers 2020, 12, 1507. [Google Scholar] [CrossRef] [PubMed]

- Chang, B.; Schneider, K.; Vogel, R.; Heinrich, G. Influence of Annealing on Mechanical αc-Relaxation of Isotactic Polypropylene: A Study from the Intermediate Phase Perspective. Macromol. Mater. Eng. 2017, 302, 1700291. [Google Scholar] [CrossRef]

- Mallarino, S.; Chailan, J.F.; Vernet, J.L. Glass fibre sizing effect on dynamic mechanical properties of cyanate ester composites I. Single frequency investigations. Eur. Polym. J. 2005, 41, 1804–1811. [Google Scholar] [CrossRef]

- Rathinasabapathi, G.; Krishnamoorthy, A. Cole-cole plot of graphene nano filler disseminated glass fiber reinforced polymer composites. Mater. Today Proc. 2021, 44, 3816–3822. [Google Scholar] [CrossRef]

- Romanzini, D.; Lavoratti, A.; Ornaghi, H.L.; Amico, S.C.; Zattera, A.J. Influence of fiber content on the mechanical and dynamic mechanical properties of glass/ramie polymer composites. Mater. Des. 2013, 47, 9–15. [Google Scholar] [CrossRef]

- Feng, L.; Li, R.; Yang, H.; Chen, S.; Yang, W. The Hyperbranched Polyester Reinforced Unsaturated Polyester Resin. Polymers 2022, 14, 1127. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, H.; Liu, J.; Wei, T. Characterization of Properties and Kinetic Analysis of Unsaturated Polyester Resin Synthesized from PET Alcoholysis Waste. Polymers 2025, 17, 820. [Google Scholar] [CrossRef]

- Chu, F.; Zhou, X.; Mu, X.; Zhu, Y.; Cai, W.; Zhou, Y.; Xu, Z.; Zou, B.; Mi, Z.; Hu, W. An insight into pyrolysis and flame retardant mechanism of unsaturated polyester resin with different valance states of phosphorus structures. Polym. Degrad. Stab. 2022, 202, 110026. [Google Scholar] [CrossRef]

- de Oliveira, J.M.; Sousa, V.M.Z.; Teixeira, L.A.; Leão, R.M.; Sales-Contini, R.C.M.; Steier, V.F.; da Luz, S.M. The Role of Chemical Treatments on Curaua Fibers on Mechanical and Thermal Behavior of Biodegradable Composites. Appl. Sci. 2024, 14, 10621. [Google Scholar] [CrossRef]

- Nair, S.S.; Kuo, P.-Y.; Chen, H.; Yan, N. Investigating the effect of lignin on the mechanical, thermal, and barrier properties of cellulose nanofibril reinforced epoxy composite. Ind. Crops Prod. 2017, 100, 208–217. [Google Scholar] [CrossRef]

| Time (h) | Cf-UPR/STY | Cf-UPR/ TMPTA-30 | Cf-UPR/ STY-BAM | Cf-UPR/ STY-FLAX | Cf-UPR/ TMPTA30-BAM | Cf-UPR/ TMPTA30-FLAX |

|---|---|---|---|---|---|---|

| 4 | 0.13 | 0.12 | 2.74 | 2.47 | 2.22 | 2.17 |

| 8 | 0.17 | 0.19 | 3.02 | 2.86 | 2.66 | 2.59 |

| 12 | 0.20 | 0.22 | 3.19 | 3.01 | 2.84 | 2.78 |

| 16 | 0.20 | 0.23 | 3.24 | 3.06 | 2.9 | 2.84 |

| 20 | 0.21 | 0.23 | 3.3 | 3.08 | 2.93 | 2.88 |

| 24 | 0.21 | 0.23 | 3.35 | 3.11 | 2.96 | 2.90 |

| Polymer Matrix | Reinforcement | Tensile Strength (MPa) | Young’s Modulus (GPa) | Flexural Strength (MPa) | Flexural Modulus (GPa) | Ref. |

|---|---|---|---|---|---|---|

| UPR with bio-based reactive diluents CINN a, LIM b, MMA c, STY d | - | - | - | 21.4 ± 5.4 a 17.2 ± 2.3 b 18.5 ± 4.8 c 29.3 ± 4.2 d | 3.26 ± 0.3 a 2.99 ± 0.4 b 3.29 ± 0.3 c 3.99 ± 0.4 d | [8] |

| UPR (AROPOL 1472/25P Infusion) | Bamboo fibers (treated with 6% NaOH) | 21.0 | - | 44.2 | 4.0 | [51] |

| UPR (Yukalac 157 BQTN-EX) | - | 9.88 | - | 19.4 | - | [52] |

| Bamboo fiber Gigantochloa atter, 50 mesh, 30% (treated with 6% NaOH) | 21.4 | - | 32.6 | - | ||

| UPR (STRUKTOL® POLYVERTEC® 3831) with 2-hydroxyethyl methacrylate (HEMA) diluent | Non-woven flax mat (EcoTechnilin FibriMat TM F300) | 37.9 ± 2.9 | 4.03 ± 0.3 | 51.16 ± 7.4 | 2.95 ± 0.6 | [16] |

| UPR | Bambusa vulgaris, 60% volume fraction, with random orientation (treated with 5% NaOH solution) | 16.7 | - | - | - | [53] |

| UPR (bio-based, from camphoric acid) and STY reactive diluent (40 wt.%) | - | 18.7 ± 0.7 | 0.74 ± 0.02 | 39.5 ± 2.0 | 3.03 ± 0.03 | This work |

| Bamboo mat, 30 wt.% (recycled from domestic use) | 13.6 ± 0.8 | 1.33 ± 0.04 | 26.3 ± 1.1 | 2.46 ± 0.09 | ||

| Flax mat, 30 wt.% (textile waste flex fibers) | 39.8 ± 3.0 | 2.65 ± 0.08 | 71.2 ± 5.2 | 5.99 ± 0.12 | ||

| UPR (bio-based, from camphoric acid) and STY + TMPTA reactive diluents (10 + 30 wt.%) | - | 25.2 ± 0.7 | 0.96 ± 0.02 | 56.1 ± 2.1 | 3.34 ± 0.03 | |

| Bamboo mat, 30 wt.% (recycled from domestic use) | 13.6 ± 0.7 | 1.19 ± 0.03 | 31.4 ± 1.2 | 2.70 ± 0.06 | ||

| Flax mat, 30 wt.% (textile waste flex fibers) | 42.7 ± 2.9 | 2.76 ± 0.07 | 95.5 ± 5.9 | 9.04 ± 0.20 |

| Material | Storage Modulus, G′, (MPa) at Certain T | Tg(G′), (°C) | υ × 10−3, (mol cm−3) | ||

|---|---|---|---|---|---|

| 40 °C | 100 °C | 160 °C | |||

| Cf-UPR/STY | 1137 | 280 | 13.4 | 93.6 | 3.53 |

| Cf-UPR/STY-BAM | 474 | 74 | 24.6 | 84.6 | 6.65 |

| Cf-UPR/STY-FLAX | 2006 | 776 | 178 | 93.1 | 49.8 |

| Cf-UPR/TMPTA30 | 1408 | 211 | 56.4 | 51.4 | 17.6 |

| Cf-UPR/TMPTA30-BAM | 1294 | 352 | 132 | 50.8 | 40.0 |

| Cf-UPR/TMPTA30-FLAX | 1811 | 802 | 484 | 47.1 | 139 |

| Material | Coefficient of Reinforcement, C | Volume Fraction of Constrained Region, Cυ (%) | Volume Fraction of the Fibers, Vf |

|---|---|---|---|

| Cf-UPR/STY | - | 1.18 | - |

| Cf-UPR/STY-BAM | 0.227 | 32.0 | 0.663 |

| Cf-UPR/STY-FLAX | 0.133 | 29.9 | 0.542 |

| Cf-UPR/TMPTA30 | - | 4.01 | - |

| Cf-UPR/TMPTA30-BAM | 0.393 | 26.2 | 0.678 |

| Cf-UPR/TMPTA30-FLAX | 0.382 | 55.5 | 0.548 |

| Material | Tg(tan δ), (°C) | tan δ Height | Adhesion Factor, A |

|---|---|---|---|

| Cf-UPR/STY | 121.1 | 0.41 | - |

| Cf-UPR/STY-BAM | 104.9 | 0.25 | 0.809 |

| Cf-UPR/STY-FLAX | 115.5 | 0.26 | 0.386 |

| Cf-UPR/TMPTA30 | 100.9 | 0.19 | - |

| Cf-UPR/TMPTA30-BAM | 102.4 | 0.14 | 1.288 |

| Cf-UPR/TMPTA30-FLAX | 105.0 | 0.08 | −0.069 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mijatov, S.; Savić, S.; Brzić, S.; Ivanović, S.; Simić, M.; Milošević, M.; Marinković, A. From Nature to Function: Green Composites Using Camphoric Acid-Based Unsaturated Polyester Resin and Bamboo/Flax Non-Woven Reinforcements. Polymers 2025, 17, 3038. https://doi.org/10.3390/polym17223038

Mijatov S, Savić S, Brzić S, Ivanović S, Simić M, Milošević M, Marinković A. From Nature to Function: Green Composites Using Camphoric Acid-Based Unsaturated Polyester Resin and Bamboo/Flax Non-Woven Reinforcements. Polymers. 2025; 17(22):3038. https://doi.org/10.3390/polym17223038

Chicago/Turabian StyleMijatov, Slavko, Sanja Savić, Saša Brzić, Stefan Ivanović, Milena Simić, Milena Milošević, and Aleksandar Marinković. 2025. "From Nature to Function: Green Composites Using Camphoric Acid-Based Unsaturated Polyester Resin and Bamboo/Flax Non-Woven Reinforcements" Polymers 17, no. 22: 3038. https://doi.org/10.3390/polym17223038

APA StyleMijatov, S., Savić, S., Brzić, S., Ivanović, S., Simić, M., Milošević, M., & Marinković, A. (2025). From Nature to Function: Green Composites Using Camphoric Acid-Based Unsaturated Polyester Resin and Bamboo/Flax Non-Woven Reinforcements. Polymers, 17(22), 3038. https://doi.org/10.3390/polym17223038