Performance Evaluation and Optimization of an Ink/Polyurethane Actuator for Light-Driven Soft Gripper

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

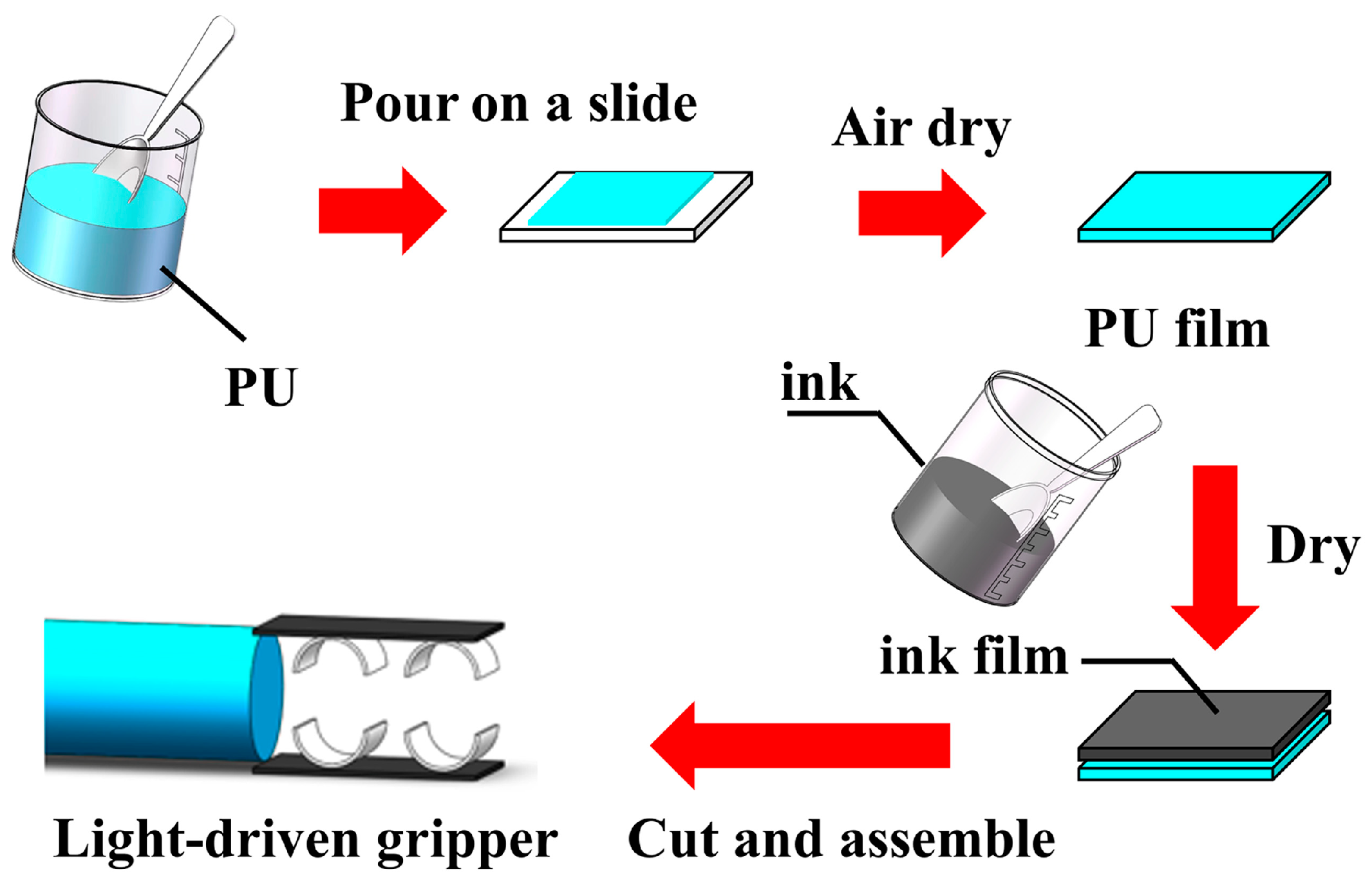

2.2. Design and Fabrication of Actuators

2.3. Characterization

3. Results and Discussion

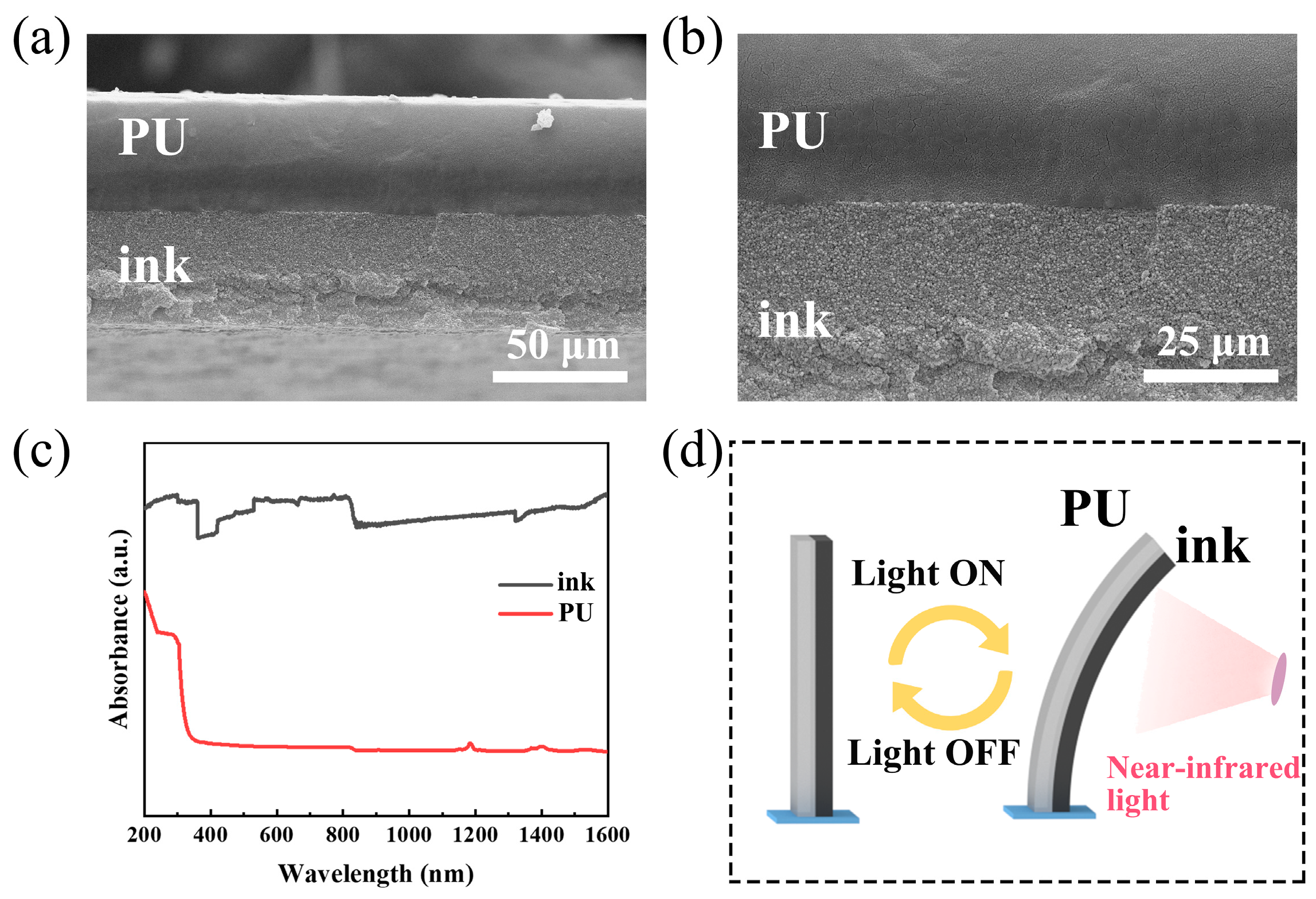

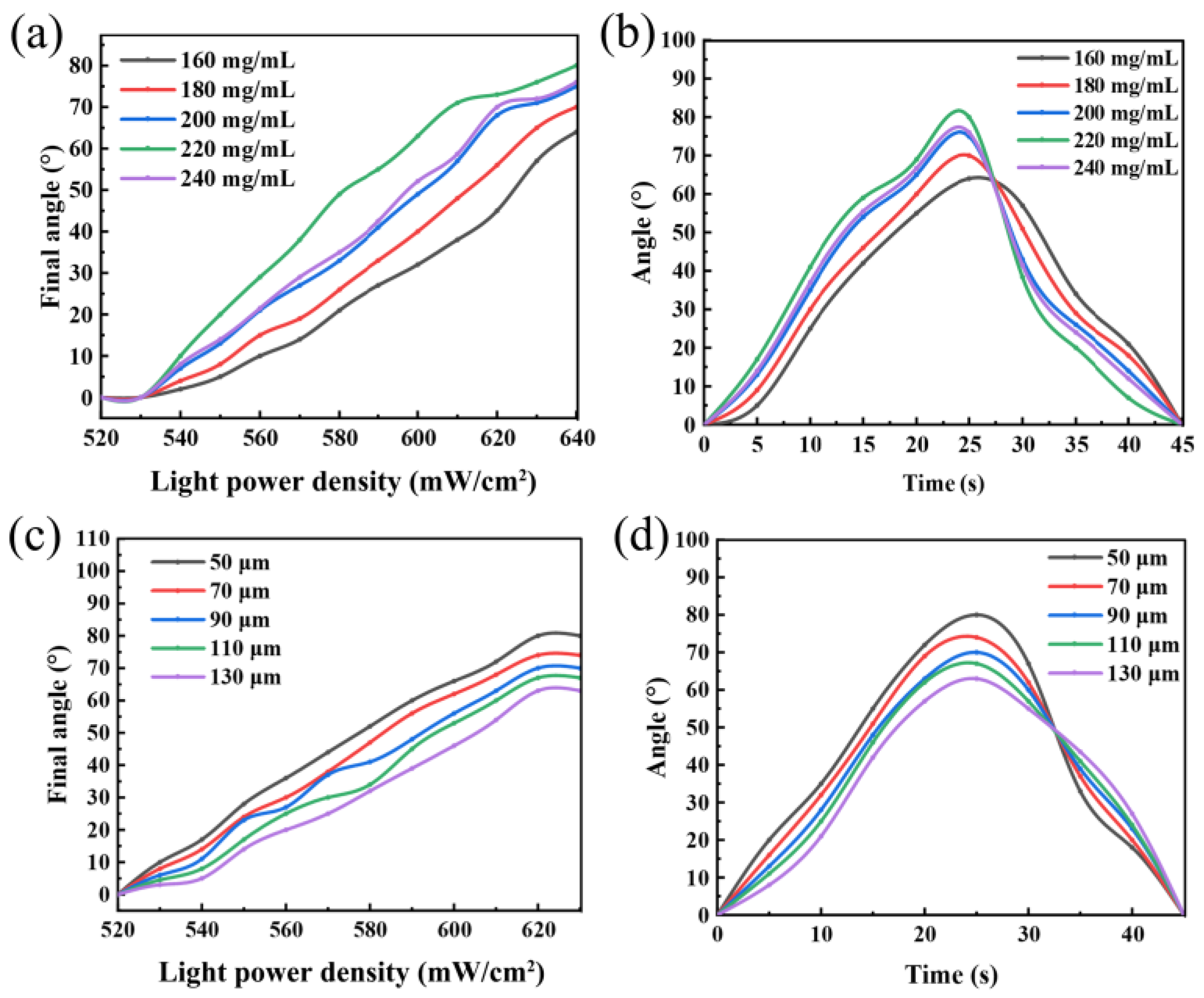

3.1. Photomechanical Bending Characterization

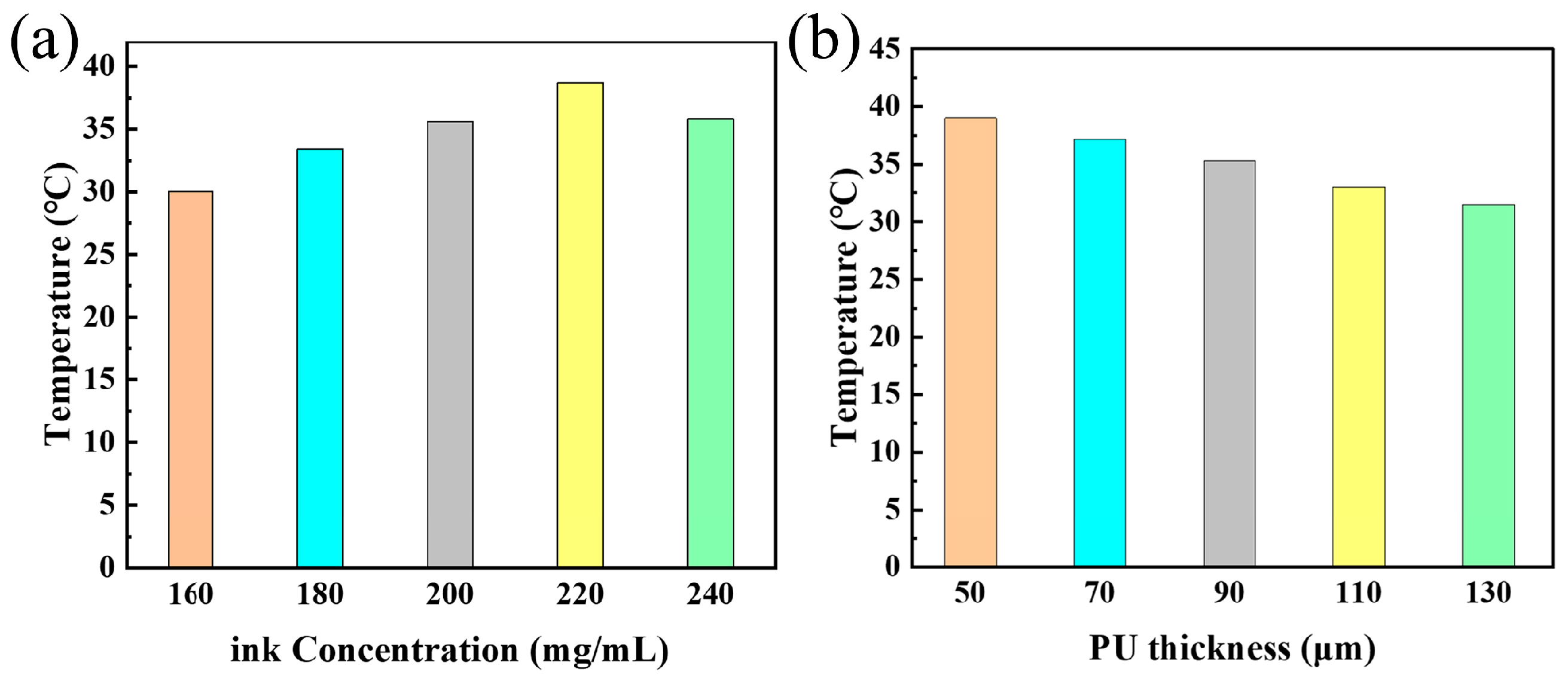

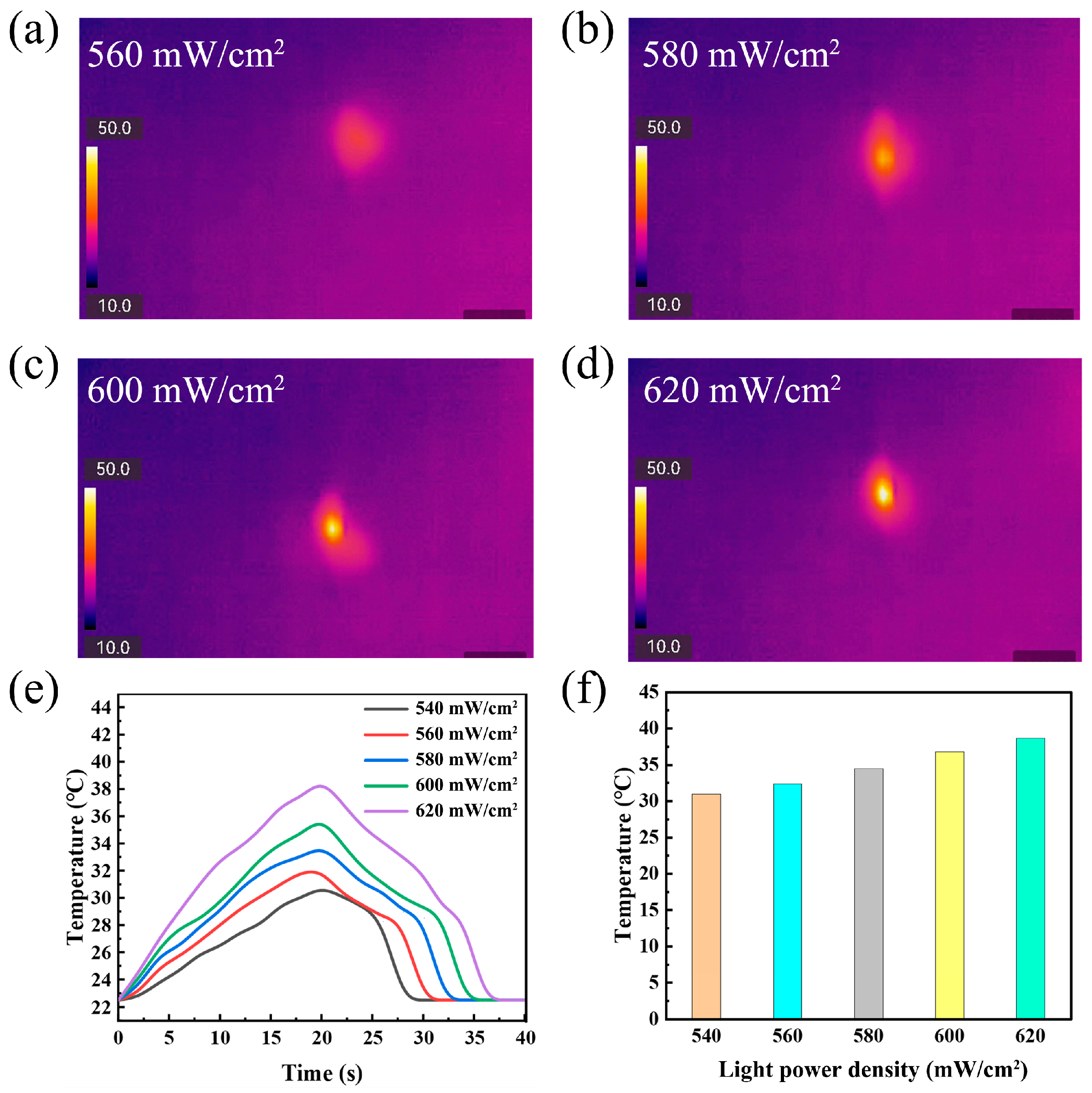

3.2. Photothermal Conversion Analysis

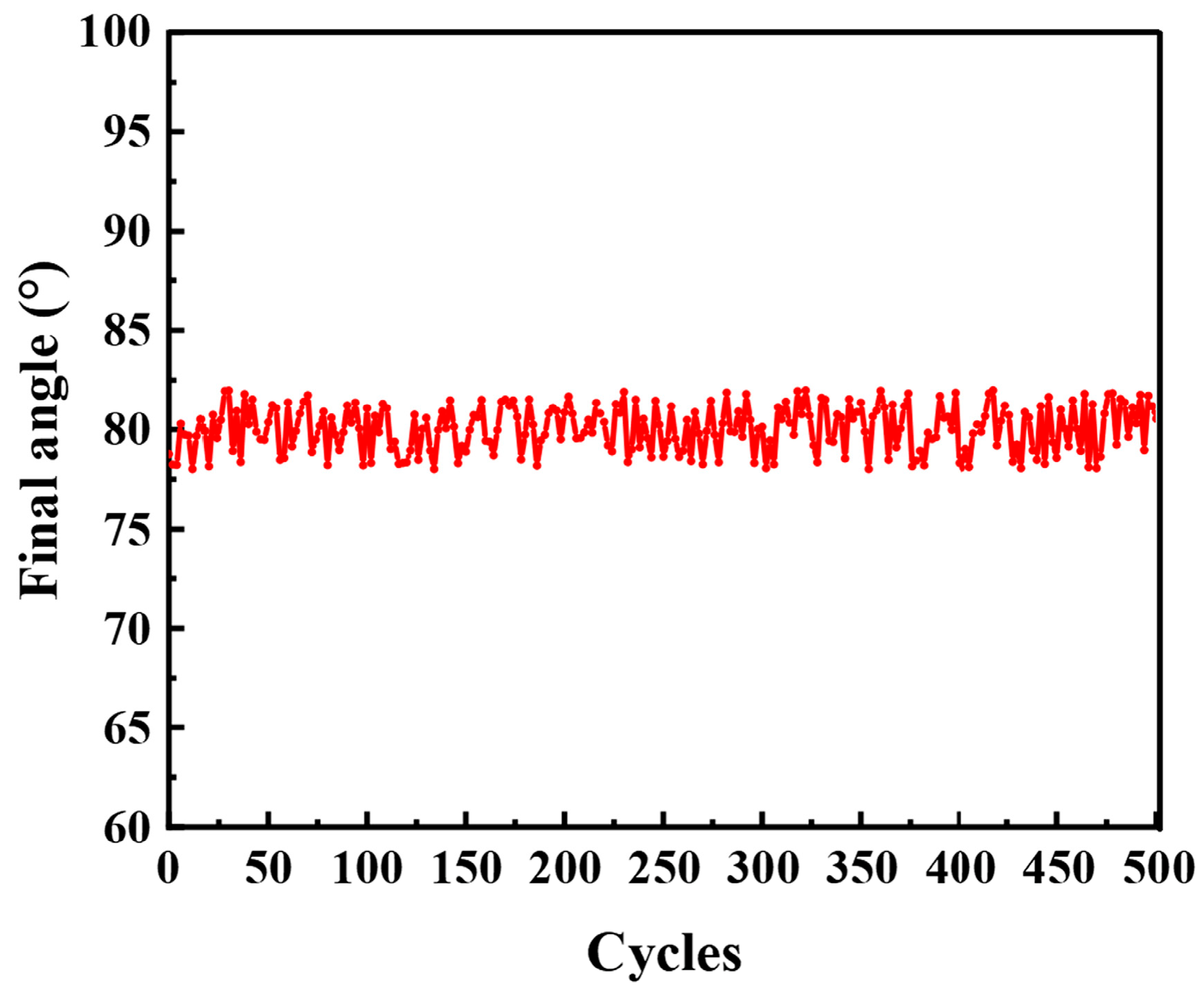

3.3. Durability and Cyclic Stability

3.4. Application as a Light-Driven Soft Gripper

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, K.; Zhang, Q.; Cui, X.; Liu, Y.; Liu, Y.; Yang, Y. Photothermal-Driven Soft Actuator Capable of Alternative Control Based on Coupled-Plasmonic Effect. Chem. Eng. J. 2024, 498, 155057. [Google Scholar] [CrossRef]

- Yu, W.; Zhao, W.; Zhu, X.; Li, M.; Yi, X.; Liu, X. Laser-Printed All-Carbon Responsive Material and Soft Robot. Adv. Mater. 2024, 36, 2401920. [Google Scholar] [CrossRef] [PubMed]

- Chiba, S.; Waki, M.; Takeshita, M.; Ohyama, K. Examination of Factors to Improve the Performance of Dielectric Elastomer Transducers and Their Applications. Smart Mater. Struct. 2024, 33, 065016. [Google Scholar] [CrossRef]

- Kalulu, M.; Chilikwazi, B.; Hu, J.; Fu, G. Soft Actuators and Actuation: Design, Synthesis, and Applications. Macromol. Rapid Commun. 2025, 46, 2400282. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Liu, Y.; Duan, G.; Liang, Z.; Huang, Y.; Zhang, C.; Han, X.; Ma, C.; He, S.; Jiang, S. Recent Advances of Biomass-Based Smart Hydrogel Actuators: A Review. Chem. Eng. J. 2024, 498, 155157. [Google Scholar] [CrossRef]

- Kozuki, H.; Yoshida, K.; Yasuga, H.; Kurashina, Y. Hydrogel-Polymer Hybrid Actuator with Soft Lattice Skeleton for Excellent Connectivity. Sens. Actuators B Chem. 2025, 430, 137377. [Google Scholar] [CrossRef]

- Annapooranan, R.; Wang, Y.; Cai, S. Harnessing Soft Elasticity of Liquid Crystal Elastomers to Achieve Low Voltage Driven Actuation. Adv. Mater. Technol. 2023, 8, 2201969. [Google Scholar] [CrossRef]

- Lugger, S.J.D.; Mulder, D.J.; Debije, M.G.; Schenning, A.P.H.J. Thermoplastic Liquid Crystal Elastomer Soft Actuators. Liq. Cryst. 2024, 51, 2137–2143. [Google Scholar] [CrossRef]

- Qing, H.; Chi, Y.; Hong, Y.; Zhao, Y.; Qi, F.; Li, Y.; Yin, J. Fully 3D-Printed Miniature Soft Hydraulic Actuators with Shape Memory Effect for Morphing and Manipulation. Adv. Mater. 2024, 36, 2402517. [Google Scholar] [CrossRef]

- Xu, L.; Xu, Y.; Li, L.; Qiu, C.; Ling, Y.; Hu, Y.; Chang, L.; Peng, Q.; He, X. MXene-Based Soft Actuators With Phototropic Self-Sustained Oscillation for Versatile Applications in Micro Robotics. Adv. Funct. Mater. 2025, 35, 2414338. [Google Scholar] [CrossRef]

- Zhang, X.; Aziz, S.; Salahuddin, B.; Zhu, Z. Bioinspired Hydro- and Hydrothermally Responsive Tubular Soft Actuators. ACS Appl. Mater. Interfaces 2024, 16, 59202–59215. [Google Scholar] [CrossRef]

- Yue, X.; Dong, C.; Wang, Y.; Cui, Z.; Ren, Z.; Guan, Z.-H. Three Birds with One Stone: Design and Synthesis of Polyurethane Actuator for Executing Heat, Light and Humidity Triggered Deformation. Chem. Eng. J. 2023, 457, 141290. [Google Scholar] [CrossRef]

- Shin, S.R.; Migliori, B.; Miccoli, B.; Li, Y.; Mostafalu, P.; Seo, J.; Mandla, S.; Enrico, A.; Antona, S.; Sabarish, R.; et al. Electrically Driven Microengineered Bioinspired Soft Robots. Adv. Mater. 2018, 30, 1704189. [Google Scholar] [CrossRef]

- Tang, D.; Zhang, C.; Sun, H.; Dai, H.; Xie, J.; Fu, J.; Zhao, P. Origami-Inspired Magnetic-Driven Soft Actuators with Programmable Designs and Multiple Applications. Nano Energy 2021, 89, 106424. [Google Scholar] [CrossRef]

- Xu, J.; Song, W.; Ren, L.; Wu, N.; Zeng, R.; Wang, S.; Wang, Z.; Zhang, Q. Reinforced Hydrogel Building via Formation of Alginate-Chitosan Double Network with pH & Salt-Responsiveness and Electric Conductivity for Soft Actuators. Int. J. Biol. Macromol. 2024, 263, 130282. [Google Scholar] [CrossRef]

- Bai, C.; Kang, J.; Wang, Y.Q. Light-Induced Motion of Three-Dimensional Pendulum with Liquid Crystal Elastomeric Fiber. Int. J. Mech. Sci. 2024, 266, 108911. [Google Scholar] [CrossRef]

- Xiang, S.-L.; Su, Y.-X.; Yin, H.; Li, C.; Zhu, M.-Q. Visible-Light-Driven Isotropic Hydrogels as Anisotropic Underwater Actuators. Nano Energy 2021, 85, 105965. [Google Scholar] [CrossRef]

- Xu, Y.; Qi, H.; Sun, M.; Liu, Z.; Liu, Q.; Li, K.; Guo, W. Unraveling Programmable Motion of MXene/Polyurethane Motor Driven by the near-Infrared Light. Chem. Eng. J. 2024, 499, 155881. [Google Scholar] [CrossRef]

- Zeng, L.; Chen, L.; Lin, J.; Lin, J.; Wu, Y.; Wang, Y.; Luo, Z.; Huang, F.; Chen, D. Glow-Worm-Inspired Fluorescent Self-Healing Actuators for Soft Robot and Reconfigurable Information Encryption. Adv. Mater. 2025, 37, 2501007. [Google Scholar] [CrossRef]

- Liu, B.; Zhou, Y.; Chen, L.; Feng, Y.; Liu, M. High-Performance Sensors Based on Chinese Ink and Water-Based Glue for Detection of Strain, Temperature, and Humidity. ACS Sustain. Chem. Eng. 2022, 10, 1847–1856. [Google Scholar] [CrossRef]

- Duan, Z.; Yuan, Z.; Jiang, Y.; Yuan, L.; Tai, H. Amorphous Carbon Material of Daily Carbon Ink: Emerging Applications in Pressure, Strain, and Humidity Sensors. J. Mater. Chem. C 2023, 11, 5585–5600. [Google Scholar] [CrossRef]

- Wei, R.; Liu, B.; Wu, F.; Zhou, X.; Liu, M. Chinese Ink-Coated Elastic PU/PET Fibers as Multifunctional Flexible Wearable Sensors. Sens. Actuators Phys. 2024, 380, 116011. [Google Scholar] [CrossRef]

- Wang, H.; Yang, W.; Cheng, L.; Guan, C.; Yan, H. Chinese Ink: High Performance Nanofluids for Solar Energy. Sol. Energy Mater. Sol. Cells 2018, 176, 374–380. [Google Scholar] [CrossRef]

- Wu, F.; Lin, X.; Xu, Y.; Zhang, D.; He, Y.; Liu, M. Light-Driven Locomotive Soft Actuator and Multi-Functional Sensors Based on Asymmetric PVA/Carbon/PE Bilayer Film. Sci. China Mater. 2023, 66, 4782–4793. [Google Scholar] [CrossRef]

- Yang, H.-C.; Chen, Z.; Xie, Y.; Wang, J.; Elam, J.W.; Li, W.; Darling, S.B. Chinese Ink: A Powerful Photothermal Material for Solar Steam Generation. Adv. Mater. Interfaces 2019, 6, 1801252. [Google Scholar] [CrossRef]

- Lin, J.; Zhou, P.; Chen, Q.; Zhang, W.; Luo, Z.; Chen, L. Reprogrammable, Light-Driven and Sensing Actuators Based on Chinese Ink Composite: A Synergetic Use of Shape-Memory and Self-Healing Strategies. Sens. Actuators B Chem. 2022, 362, 131776. [Google Scholar] [CrossRef]

- Lin, J.; Zhou, P.; Wen, Z.; Zhang, W.; Luo, Z.; Chen, L. Chinese Ink: A Programmable, Dual-Responsive and Self-Sensing Actuator Using a Healing–Assembling Method. Nanoscale 2021, 13, 20134–20143. [Google Scholar] [CrossRef] [PubMed]

- Chai, Y.; Qin, Y.; Xu, Z.; Zheng, X.; Jia, H. Advances in Fabric-Based Pneumatic Soft Actuators for Flexible Robotics: Design and Applications. Sensors 2025, 25, 3665. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.; Kaarthik, P.; Truby, R.L. A Flexible, Architected Soft Robotic Actuator for Motorized Extensional Motion. Adv. Intell. Syst. 2024, 6, 2300866. [Google Scholar] [CrossRef]

| Performance Index | pH (25 °C) | Viscosity (mPa·s) | Film Forming Temperature Conditions (°C) | Storing Temperature (°C) |

|---|---|---|---|---|

| Index value | 6∼8 | 800∼1200 | 20 | 5∼30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niu, Q.; Gu, X.; Wu, H.; Yu, W.; Yan, X.; Wang, X. Performance Evaluation and Optimization of an Ink/Polyurethane Actuator for Light-Driven Soft Gripper. Polymers 2025, 17, 3004. https://doi.org/10.3390/polym17223004

Niu Q, Gu X, Wu H, Yu W, Yan X, Wang X. Performance Evaluation and Optimization of an Ink/Polyurethane Actuator for Light-Driven Soft Gripper. Polymers. 2025; 17(22):3004. https://doi.org/10.3390/polym17223004

Chicago/Turabian StyleNiu, Quanwang, Xiangyu Gu, Hao Wu, Weiyang Yu, Xiaohong Yan, and Xiangfu Wang. 2025. "Performance Evaluation and Optimization of an Ink/Polyurethane Actuator for Light-Driven Soft Gripper" Polymers 17, no. 22: 3004. https://doi.org/10.3390/polym17223004

APA StyleNiu, Q., Gu, X., Wu, H., Yu, W., Yan, X., & Wang, X. (2025). Performance Evaluation and Optimization of an Ink/Polyurethane Actuator for Light-Driven Soft Gripper. Polymers, 17(22), 3004. https://doi.org/10.3390/polym17223004