Impact of Partial Gelatinization on Structure, Physicochemical and Enzymatic Digestion Properties of Rice Starch Used for Rice Noodle-Making

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Material

2.2. Isolation of Native Starch

2.3. Preparation of Partially Gelatinized Starches

2.4. X-Ray Diffraction Analysis

2.5. Differential Scanning Calorimetry Analysis

2.6. Measurement of Amylose Content and Swelling Power

2.7. In Vitro Digestion Analysis of Starch

2.8. Statistical Analysis

3. Results and Discussion

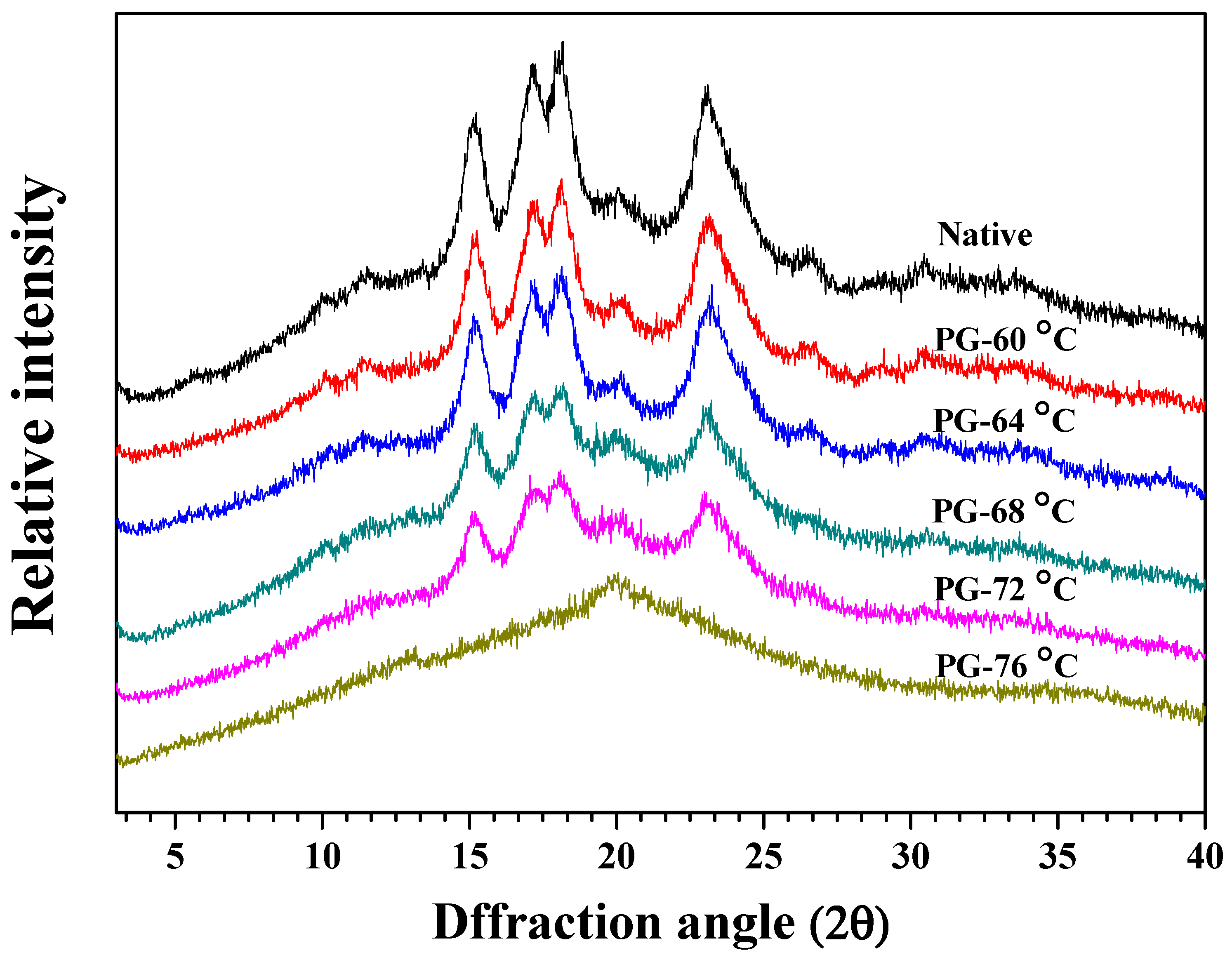

3.1. X-Ray Diffraction Spectrum of Starch

3.2. Amylose Content and Swelling Power

3.3. Gelatinization Properties

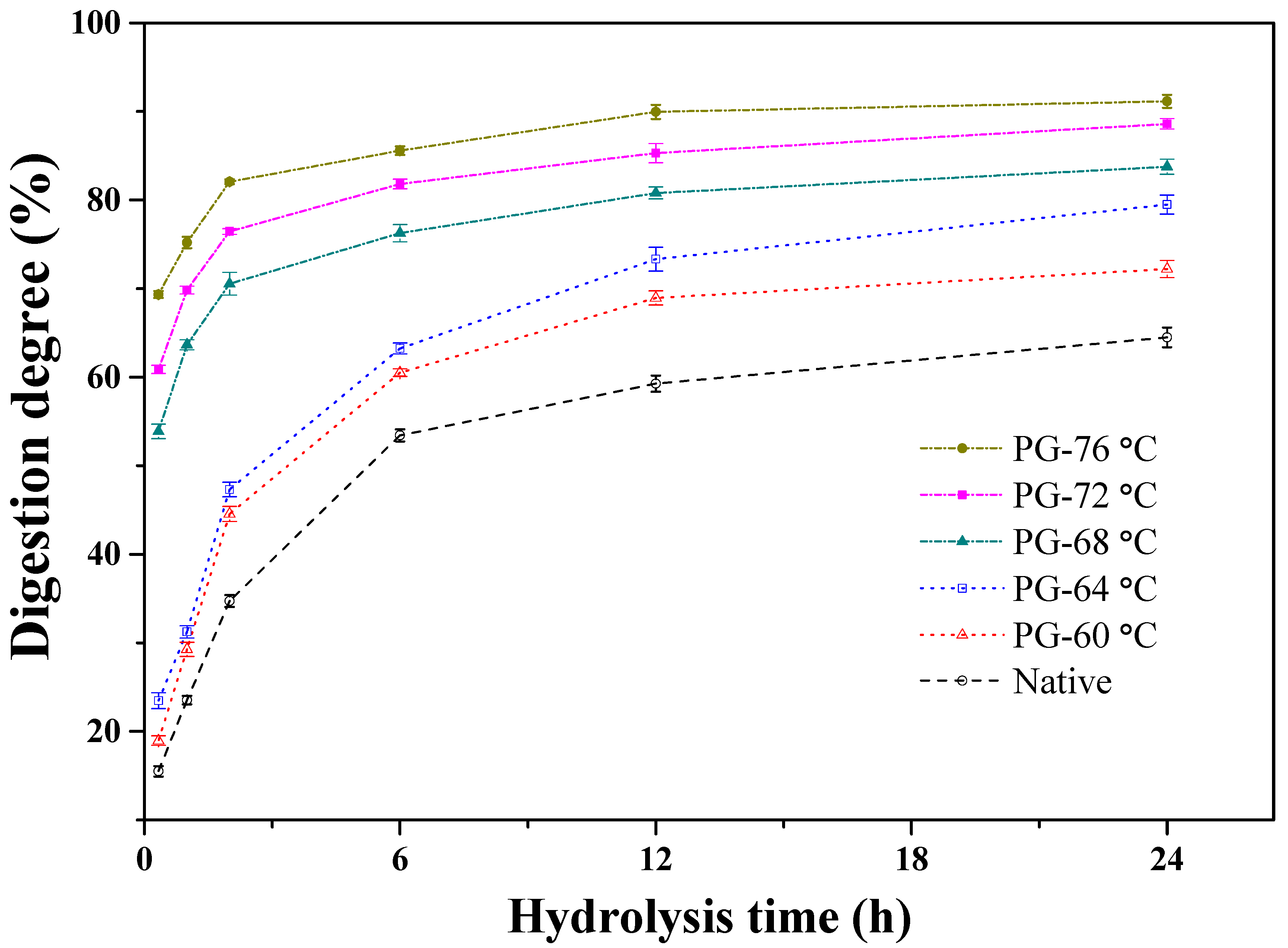

3.4. In Vitro Starch Digestibility

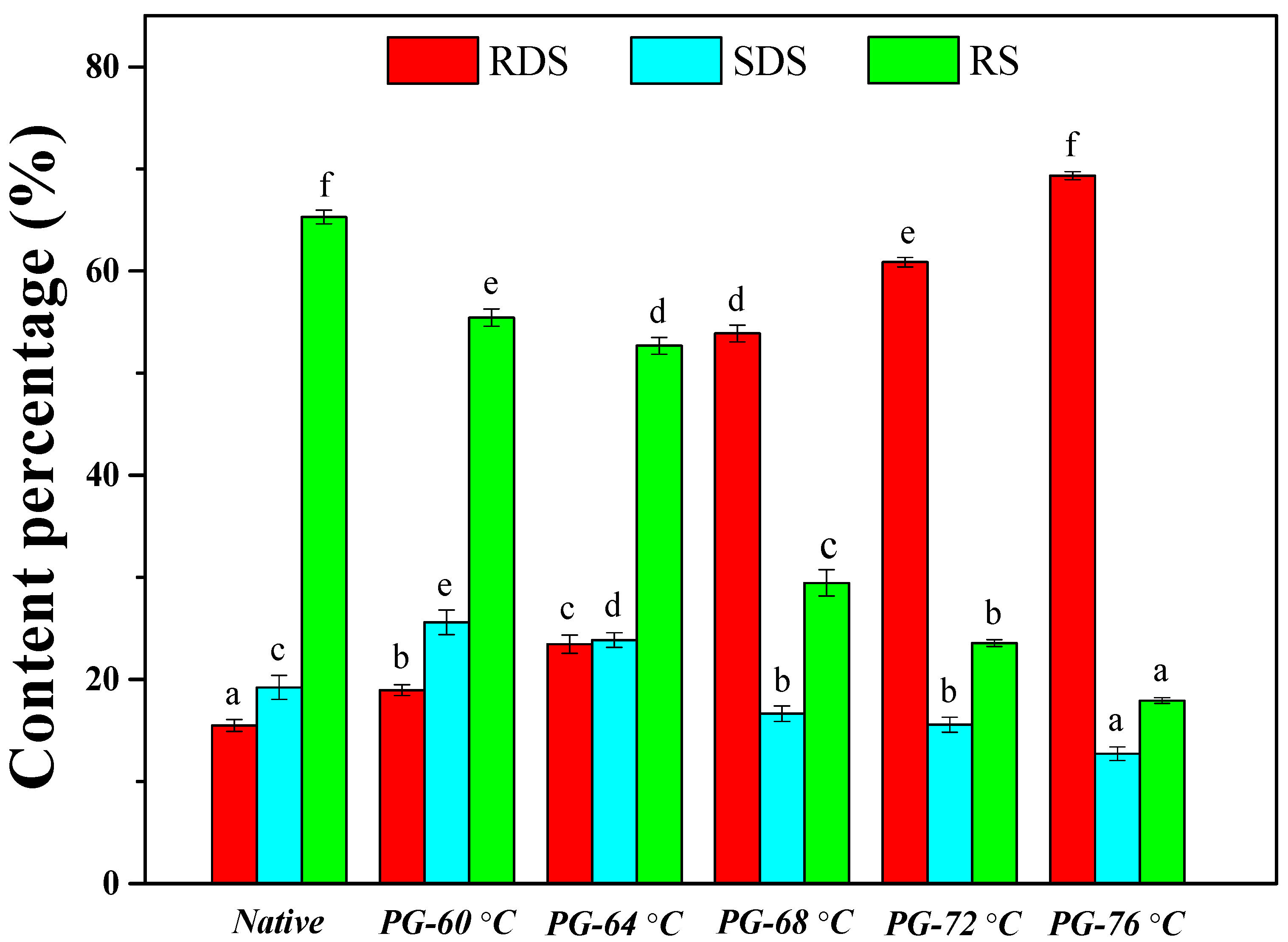

3.5. Starch Nutritional Fractions in Relation to Structural and Physicochemical Properties of Starch

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yoenyongbuddhagal, S.; Noomhorm, A. Effect of physicochemical properties of high-amylose thai rice flours on vermicelli quality. Cereal Chem. 2002, 79, 481–485. [Google Scholar] [CrossRef]

- Teng, B.; Song, F.; Gan, Q.; Lin, C.; Ni, D. Marker-assisted breeding of rice lines special for rice noodle-making by pyramiding the Wxg2 and ALKGC genes. Euphytica 2023, 219, 30. [Google Scholar] [CrossRef]

- Fu, B.X. Asian noodles: History, classification, raw materials, and processing. Food Res. Int. 2008, 41, 888–902. [Google Scholar] [CrossRef]

- Jeong, S.; Kim, Y.; Ko, S.; Yoon, M.R.; Lee, J.S.; Lee, S. Physicochemical characterization and in-vitro digestibility of extruded rice noodles with different amylose contents based on rheological approaches. J. Cereal Sci. 2016, 71, 258–263. [Google Scholar] [CrossRef]

- Gallagher, E.; Gormley, T.R.; Arendt, E.K. Recent advances in the formulation of gluten-free cereal-based products. Trends Food Sci. Tech. 2004, 15, 143–152. [Google Scholar] [CrossRef]

- Zhang, G.; Hamaker, B.R. Cereal carbohydrates and colon health. Cereal Chem. 2010, 87, 331–341. [Google Scholar] [CrossRef]

- Chi, C.; Li, X.; Huang, S.; Chen, L.; Zhang, Y.; Li, L.; Miao, S. Basic principles in starch multi-scale structuration to mitigate digestibility: A review. Trends Food Sci. Tech. 2021, 19, 154–168. [Google Scholar] [CrossRef]

- Sandhu, K.S.; Mukesh, M.K. Studies on noodle quality of potato and ice starches and their blends in relation to their physicochemical, pasting and textural properties. LWT Food Sci. Technol. 2010, 43, 1289–1293. [Google Scholar] [CrossRef]

- Kim, Y.; Kee, J.I.; Lee, S.; Yoo, S.H. Quality improvement of rice noodle restructured with rice protein isolate and transglutaminase. Food Chem. 2014, 145, 409–416. [Google Scholar] [CrossRef]

- Hormdok, R.; Noomhorm, A. Hydrothermal treatments of rice starch for improvement of rice noodle quality. LWT Food Sci. Technol. 2007, 40, 1723–1731. [Google Scholar] [CrossRef]

- Cham, S.; Suwannaporn, P. Effect of hydrothermal treatment of rice flour on various rice noodles quality. J Cereal Sci. 2010, 51, 284–291. [Google Scholar] [CrossRef]

- Seo, H.I.; Ryu, B.M.; Kim, C.S. Effect of heat-moisture treatment of domestic rice flours containing different amylose contents on rice noodle quality. J. Korean Soc. Food Sci. Nutr. 2011, 40, 1597–1603. [Google Scholar] [CrossRef]

- Xing, J.J.; Cheng, L.L.; Feng, S.; Guo, X.N.; Zhu, K.X. Humidity-controlled heat treatment of fresh spinach noodles for color preservation and storage quality improvement. Food Chem. X 2023, 20, 101042. [Google Scholar] [CrossRef] [PubMed]

- Mathobo, V.M.; Silungwe, H.; Ramashia, S.E.; Anyasi, T.A. Effects of heat-moisture treatment on the thermal, functional properties and composition of cereal, legume and tuber starches—A review. J. Food Sci. Tech. 2021, 58, 412–426. [Google Scholar] [CrossRef] [PubMed]

- Jacobs, H.; Delcour, J.A. Hydrothermal modifications of granular starch, with retention of the granular structure: A review. J. Agric. Food Chem. 1998, 46, 2895–2905. [Google Scholar] [CrossRef]

- Gunaratne, A.; Hoover, R. Effect of heat-moisture treatment on the structure and physicochemical properties of tuber and root starches. Carbohydr. Polym. 2002, 49, 425–437. [Google Scholar] [CrossRef]

- Chung, H.J.; Liu, Q.; Hoover, R. The impact of single and dual hydro- thermal modifications on the molecular structure and physicochemical properties of normal corn starch. Int. J. Biol. Macromol. 2009, 44, 203–210. [Google Scholar] [CrossRef]

- Chung, H.J.; Liu, Q.; Hoover, R. Impact of annealing and heat-moisture treatment on rapidly digestible, slowly digestible and resistant starch levels in native and gelatinized corn, pea and lentil starches. Carbohydr. Polym. 2009, 75, 436–447. [Google Scholar] [CrossRef]

- Bae, I.Y.; Lee, H.G. Effect of dry heat treatment on physical property and in vitro starch digestibility of high amylose rice starch. Int. J. Biol. Macromol. 2018, 108, 568–575. [Google Scholar] [CrossRef]

- Tester, R.F.; Debon, S.J.J. Annealing of starch—A review. Int. J. Biol. Macromol. 2000, 27, 1–12. [Google Scholar] [CrossRef]

- Lim, S.T.; Chang, E.H.; Chung, H.J. Thermal transition characteristics of heatemoisture treated corn and potato starches. Carbohydr. Polym. 2001, 46, 107–115. [Google Scholar] [CrossRef]

- Eerlingen, R.C.; Jacobs, H.; Block, K.; Delcour, J.A. Effects of hydrothermal treatments on the rheological properties of potato starch. Carbohydr. Res. 1997, 297, 347–356. [Google Scholar] [CrossRef]

- Parker, R.; Ring, S.G. Aspects of the physical chemistry of starch. J. Cereal Sci. 2001, 34, 1–17. [Google Scholar] [CrossRef]

- Wani, A.A.; Singh, P.; Shah, M.A.; Schweiggert-Weisz, U.; Gul, K.; Wani, I.A. Rice Starch Diversity: Effects on structural, morphological, thermal, and physicochemical properties–A review. Compr. Rev. Food Sci. Saf. 2012, 11, 417–436. [Google Scholar] [CrossRef]

- Chung, H.J.; Lim, H.S.; Lim, S.T. Effect of partial gelatinization and retrogradation on the enzymatic digestion of waxy rice starch. J. Cereal Sci. 2006, 43, 353–359. [Google Scholar] [CrossRef]

- Hickman, B.E.; Janaswamy, S.; Yao, Y. Properties of starch subjected to partial gelatinization and β-amylolysis. J. Agric. Food Chem. 2009, 57, 666–674. [Google Scholar] [CrossRef] [PubMed]

- Fu, Z.; Wang, L.; Li, D.; Adhikari, B. Effects of partial gelatinization on structure and thermal properties of corn starch after spray drying. Carbohydr. Polym. 2012, 88, 1319–1325. [Google Scholar] [CrossRef]

- Fu, Z.; Wang, L.; Li, D.; Zhou, Y.; Adhikari, B. The effect of partial gelatinization of corn starch on its retrogradation. Carbohydr. Polym. 2013, 97, 512–517. [Google Scholar] [CrossRef]

- Miao, M.; Zhang, T.; Mu, W.M.; Jiang, B. Effect of controlled gelatinization in excess water on digestibility of waxy maize starch. Food Chem. 2010, 119, 41–48. [Google Scholar] [CrossRef]

- Englyst, H.N.; Kingman, S.M.; Cummings, J.H. Classification and measurement of nutritionally important starch fractions. Eur. J. Clin. Nutr. 1992, 46, S33–S50. [Google Scholar]

- Ells, L.J.; Seal, C.J.; Kettlitz, B.; Bal, W.; Mathers, J.C. Postprandial glycaemic, lipaemic and haemostatic responses to ingestion of rapidly and slowly digested starches in healthy young women. Brit. J. Nutr. 2005, 94, 948–955. [Google Scholar] [CrossRef]

- Lehmann, U.; Robin, F. Slowly digestible starch-its structure and health implications: A review. Trends Food Sci. Tech. 2007, 18, 346–355. [Google Scholar] [CrossRef]

- Teng, B.; Zhang, Y.; Du, S.; Wu, J.; Li, Z.; Luo, Z.; Yang, J. Crystalline, thermal and swelling properties of starches from single-segment substitution lines with different Wx alleles in rice (Oryza sativa L.). J. Sci. Food Agric. 2007, 97, 108–114. [Google Scholar] [CrossRef] [PubMed]

- Lopez-Rubio, A.; Flanagan, B.M.; Gilbert, E.P.; Gidley, M.J. A Novel approach for calculating starch crystallinity and its correlation with double helix content: A combined XRD and NMR study. Biopolymers 2008, 89, 761–768. [Google Scholar] [CrossRef] [PubMed]

- Konik-Rose, C.; Thistleton, J.; Chanvrier, H.; Tan, I.; Li, Z. Effects of starch synthase IIa gene dosage on grain, protein and starch in endosperm of wheat. Theor. Appl. Genet. 2007, 115, 1053–1065. [Google Scholar] [CrossRef]

- Cai, J.; Man, J.; Huang, J.; Liu, Q.; Wei, W.; Wei, C. Relationship between structure and functional properties of normal rice starches with different amylose contents. Carbohydr. Polym. 2015, 125, 35–44. [Google Scholar] [CrossRef]

- Carciofi, M.; Blennow, A.; Jensen, S.L.; Shaik, S.S.; Henriksen, A.; Buléon, A.; Holm, P.B.; Hebelstrup, K.H. Concerted suppression of all starch branching enzyme genes in barley produces amylose-only starch granules. BMC Plant Biol. 2012, 12, 223. [Google Scholar] [CrossRef]

- Waigh, T.A.; Gidley, M.J.; Komanshek, B.U.; Donald, A.M. The phase of transformation in starch during gelatinization: A liquid crystalline approach. Carbohydr. Polym. 2000, 328, 165–176. [Google Scholar] [CrossRef]

- Lin, L.; Wang, Y.; Xu, X.; Teng, B.; Wei, C. Relationships between starch molecular components and eating and cooking qualities of rice using single-segment substitution lines with different Wx loci. J. Cereal Sci. 2023, 114, 103765. [Google Scholar] [CrossRef]

- Sasaki, T.; Matsuki, J. Effect of wheat structure on swelling power. Cereal Chem. 1998, 75, 525–529. [Google Scholar] [CrossRef]

- Man, J.; Yang, Y.; Zhang, C.; Zhang, F.; Wang, Y.; Gu, M.; Liu, Q.; Wei, C. Morphology and structural characterization of high-amylose rice starch residues hydrolyzed by porcine pancreatic α-amylase. Food Hydrocolloid 2013, 31, 195–203. [Google Scholar] [CrossRef]

- Nakamura, Y.; Sato, A.; Juliano, B.O. Short-chain-length distribution in debranched rice starches differing in gelatinization temperature or cooked rice hardness. Starch Stärke 2006, 58, 155–160. [Google Scholar] [CrossRef]

- Tester, R.F.; Morrison, W.R. Swelling and gelatinization of cereal starches I. Effects of amylopectin, amylose and lipids. Cereal Chem. 1990, 67, 551–557. [Google Scholar]

- Cooke, D.; Gidley, M.J. Loss of crystalline and molecular order during starch gelatinization: Origin of the enthalpic transition. Carbohydr. Res. 1992, 227, 103–112. [Google Scholar] [CrossRef]

- Cameron, R.E.; Donald, A.M. A small-angle X-ray scattering study of starch gelatinization in excess and limiting water. J. Polym. Sci. Part B Polym. Phys. 1992, 31, 1197–1203. [Google Scholar] [CrossRef]

- Miao, M.; Jiang, B.; Zhang, T. Effect of pullulanase debranching and recrystallization on structure and digestibility of waxy maize starch. Carbohydr. Polym. 2009, 76, 214–221. [Google Scholar] [CrossRef]

- Zhang, G.; Ao, Z.; Hamaker, B.R. Slow digestion property of native cereal starches. Biomacromolecules 2006, 7, 3252–3258. [Google Scholar] [CrossRef]

- Benmoussa, M.; Moldenhauer, K.A.K.; Hamaker, B.R. Rice amylopectin fine structure variability affects starch digestion properties. J. Agric. Food Chem. 2007, 55, 1475–1479. [Google Scholar] [CrossRef]

- Bornet, F.R.J.; Fontvieille, A.M.; Rizkalla, S.; Colonna, P.; Blayo, A.; Mercier, C.; Slamma, G. Insulin and glycemic responses in healthy humans to native starches processed in different ways: Correlation with in vitro a-amylase hydrolysis. Am. J. Clin. Nutr. 1989, 50, 315–332. [Google Scholar] [CrossRef] [PubMed]

| Zhenguiai | Relative Crystallinity (%) | Amylose Content (%) | Swelling Power |

|---|---|---|---|

| Native | 29.36 ± 0.51 f | 25.37 ± 0.40 d | 16.28 ± 0.47 d |

| PG-60 | 27.29 ± 0.54 e | 25.15 ± 0.28 d | 10.50 ± 0.33 c |

| PG-64 | 23.99 ± 0.56 d | 24.92 ± 0.23 d | 9.99 ± 0.10 b |

| PG-68 | 15.22 ± 0.77 c | 24.18 ± 0.43 c | 9.61 ± 0.14 b |

| PG-72 | 12.94 ± 0.38 b | 23.42 ± 0.66 b | 9.10 ± 0.04 a |

| PG-76 | 0.05 ± 0.01 a | 21.18 ± 0.35 a | 8.91 ± 0.25 a |

| Zhenguiai | Thermal Parameter | ||||

|---|---|---|---|---|---|

| To (°C) | Tp (°C) | Tc (°C) | ΔT (°C) | ΔH (J/g) | |

| Native | 61.50 ± 0.17 a | 68.83 ± 0.15 a | 75.57 ± 0.15 a | 13.07 ± 0.25 d | 12.42 ± 0.43 c |

| PG-60 | 65.30 ± 0.10 b | 69.07 ± 0.23 b | 76.53 ± 0.25 b | 10.23 ± 0.15 c | 11.91 ± 0.61 c |

| PG-64 | 66.13 ± 0.21 c | 69.00 ± 0.17 ab | 76.80 ± 0.36 b | 9.67 ± 0.21 b | 11.69 ± 0.34 c |

| PG-68 | 69.37 ± 0.15 d | 70.77 ± 0.15 c | 76.57 ± 0.15 b | 6.20 ± 0.20 a | 5.42 ± 0.36 b |

| PG-72 | 72.90 ± 0.20 e | 74.30 ± 0.26 d | 78.93 ± 0.42 c | 5.03 ± 0.42 a | 2.67 ± 0.10 a |

| PG-76 | ND | - | - | - | - |

| Property | RDS | SDS | RS |

|---|---|---|---|

| RCD a | −0.954 ** | 0.838 * | 0.944 ** |

| AC a | −0.888 * | 0.809 | 0.872 * |

| SP a | −0.674 | 0.274 | 0.760 |

| To b | 0.936 * | −0.563 | −0.971 ** |

| Tp b | 0.895 * | −0.738 | −0.878 |

| Tc b | 0.755 | −0.426 | −0.789 |

| ΔT b | −0.957 ** | 0.586 | 0.989 ** |

| ΔH b | −0.992 ** | 0.815 | 0.974 ** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teng, B.; Zhang, C.; Wang, H. Impact of Partial Gelatinization on Structure, Physicochemical and Enzymatic Digestion Properties of Rice Starch Used for Rice Noodle-Making. Polymers 2025, 17, 3003. https://doi.org/10.3390/polym17223003

Teng B, Zhang C, Wang H. Impact of Partial Gelatinization on Structure, Physicochemical and Enzymatic Digestion Properties of Rice Starch Used for Rice Noodle-Making. Polymers. 2025; 17(22):3003. https://doi.org/10.3390/polym17223003

Chicago/Turabian StyleTeng, Bin, Chen Zhang, and Hui Wang. 2025. "Impact of Partial Gelatinization on Structure, Physicochemical and Enzymatic Digestion Properties of Rice Starch Used for Rice Noodle-Making" Polymers 17, no. 22: 3003. https://doi.org/10.3390/polym17223003

APA StyleTeng, B., Zhang, C., & Wang, H. (2025). Impact of Partial Gelatinization on Structure, Physicochemical and Enzymatic Digestion Properties of Rice Starch Used for Rice Noodle-Making. Polymers, 17(22), 3003. https://doi.org/10.3390/polym17223003