Properties of Plastic-Based Composite Panels Manufactured from Municipal Waste Under Accelerated Weathering as Potential Paving Slabs

Abstract

1. Introduction

2. Materials and Methods

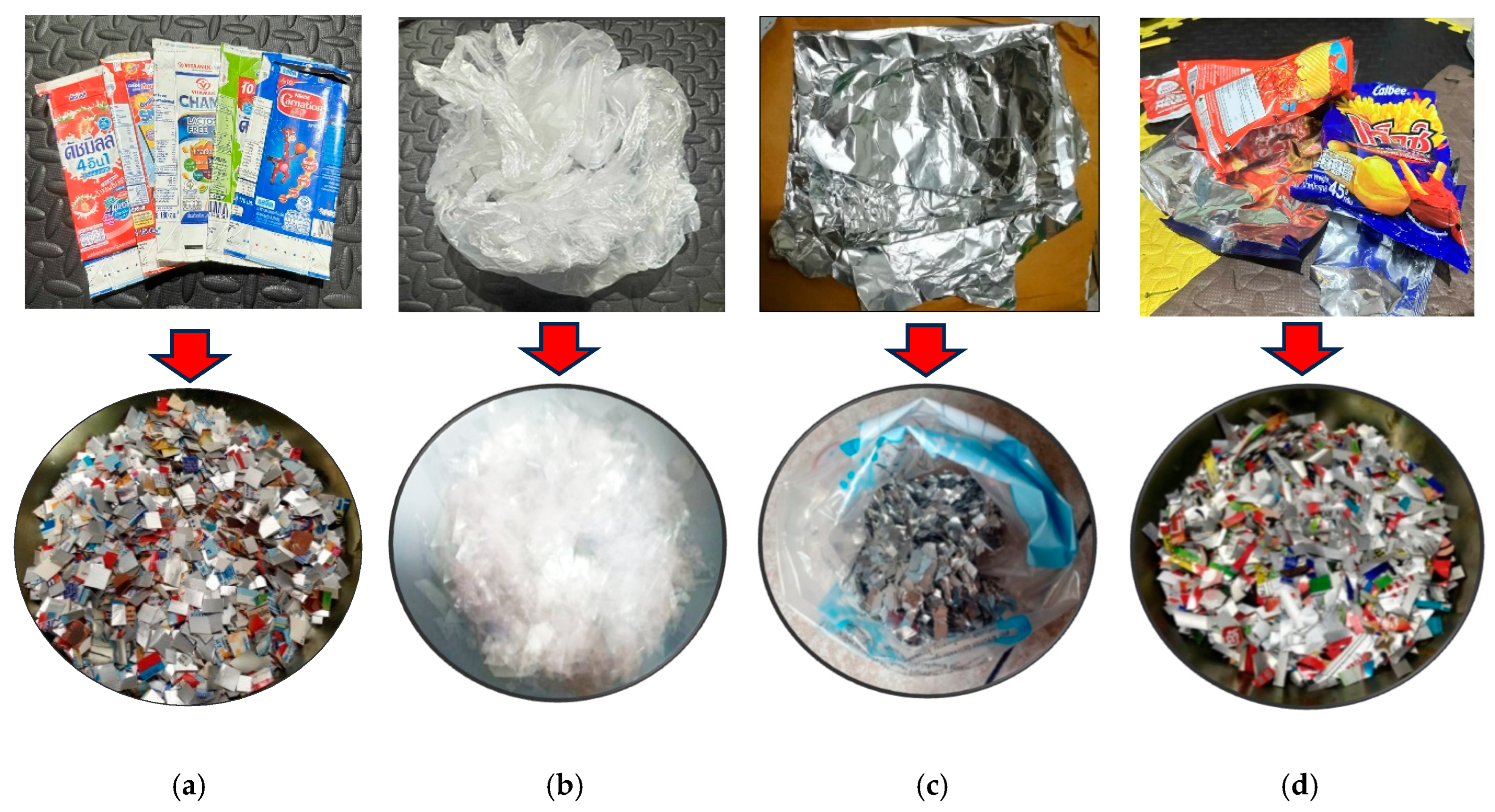

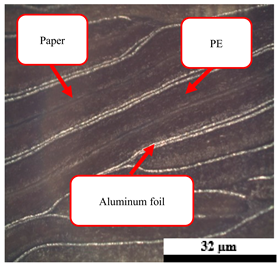

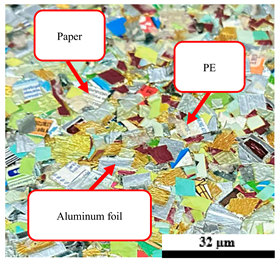

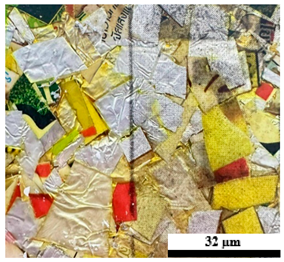

2.1. Materials

2.2. Preparation of the Composite Samples

2.3. Characterizations of Composite Samples

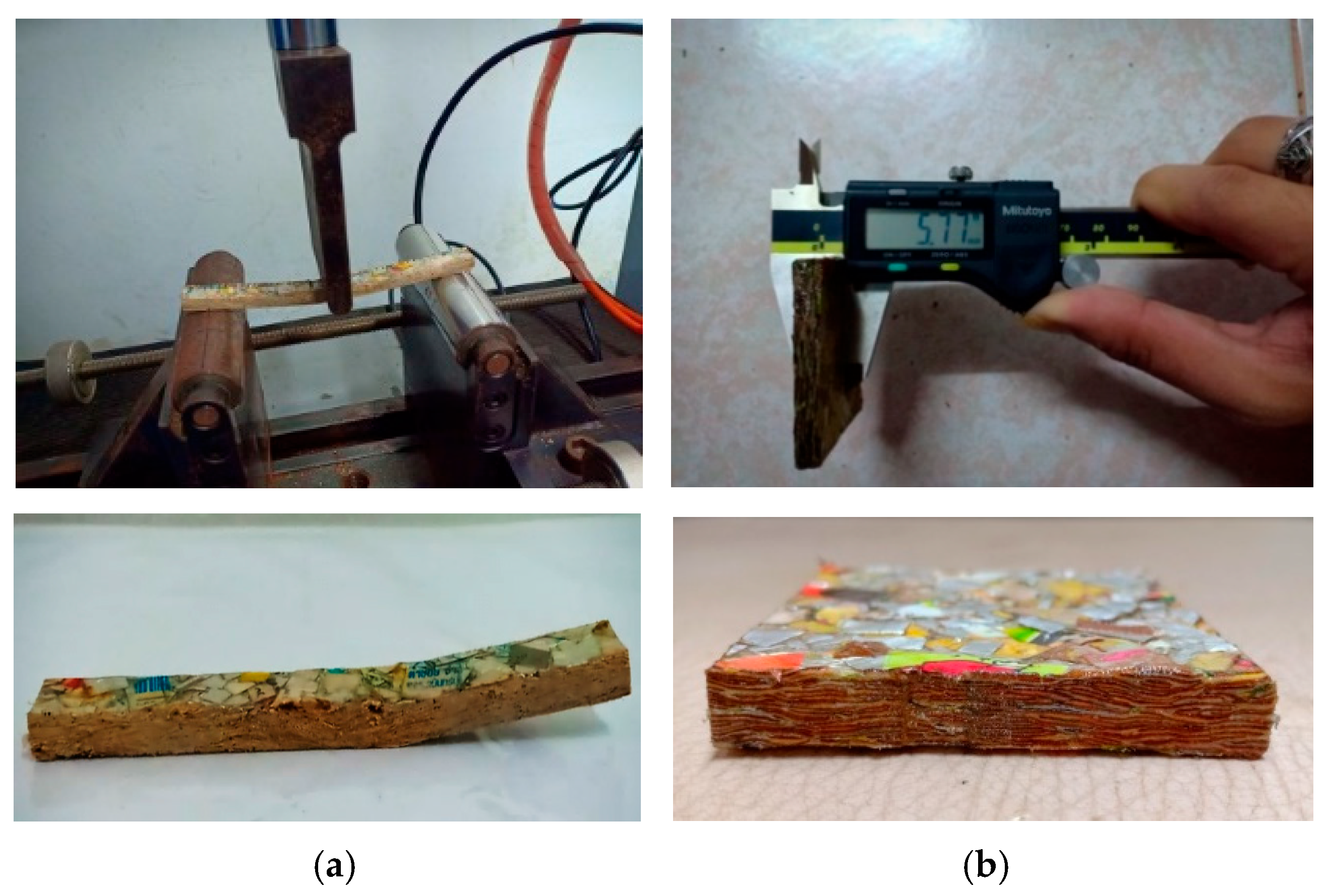

2.3.1. Flexural Test of the Samples

2.3.2. Compressive Test of the Samples

2.3.3. Direct Screw Withdrawal Test of the Samples

2.3.4. Hardness Test of the Samples

2.3.5. Dimensional Stability Test of the Samples

2.3.6. Density Values of the Samples

2.3.7. Abrasion Test of the Samples

2.4. Thermal Conductivity of the Samples

2.5. Accelerated Weathering of the Samples

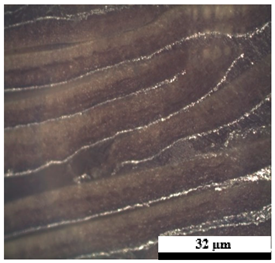

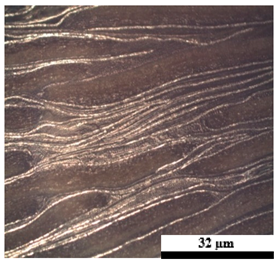

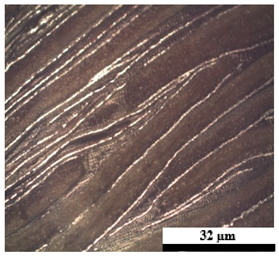

2.6. Visual Surface Analysis of the Samples

2.7. Statistical Analysis

3. Results and Discussion

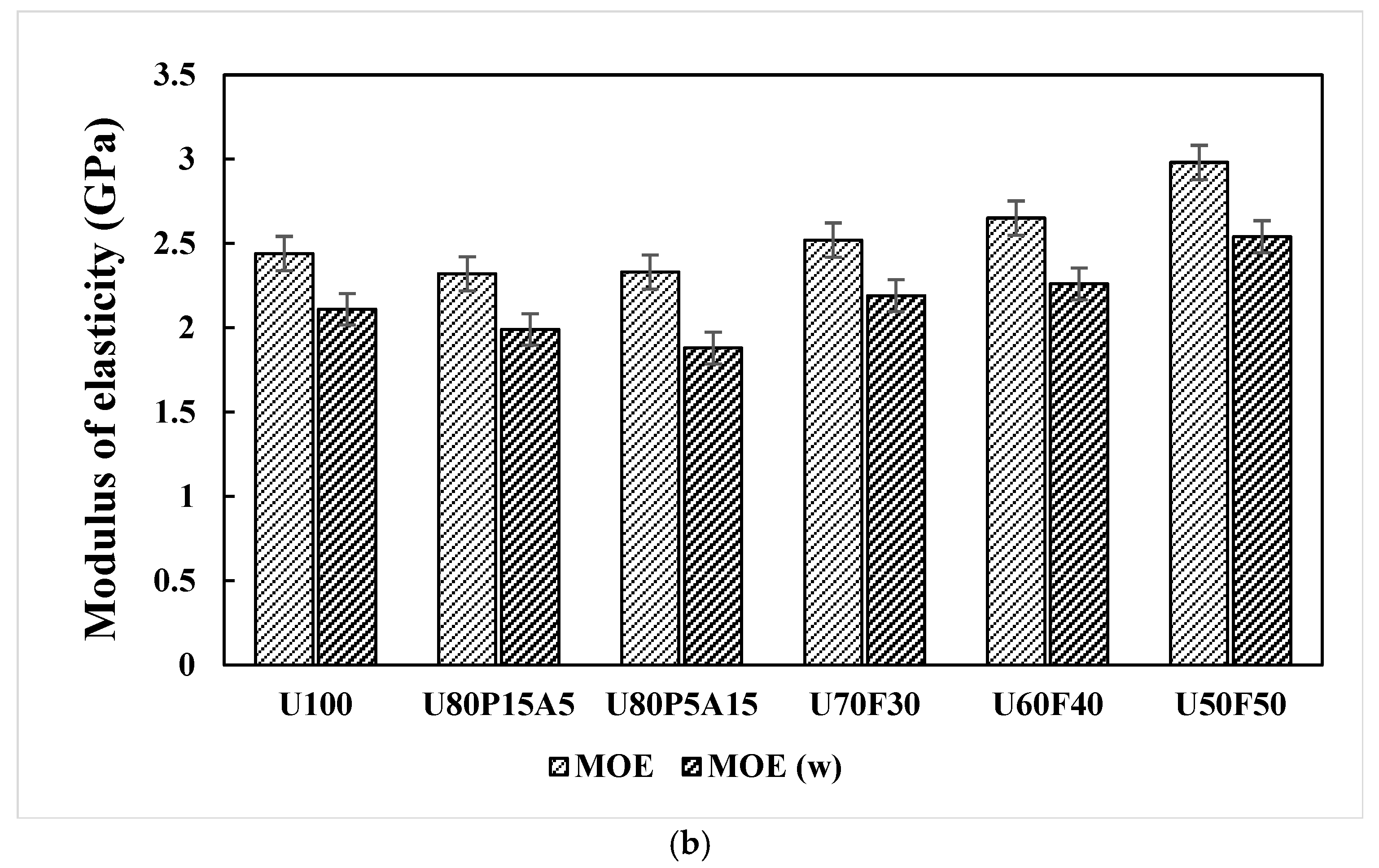

3.1. Flexural Properties of the Samples as a Function of Weathering and Mixing Ratios

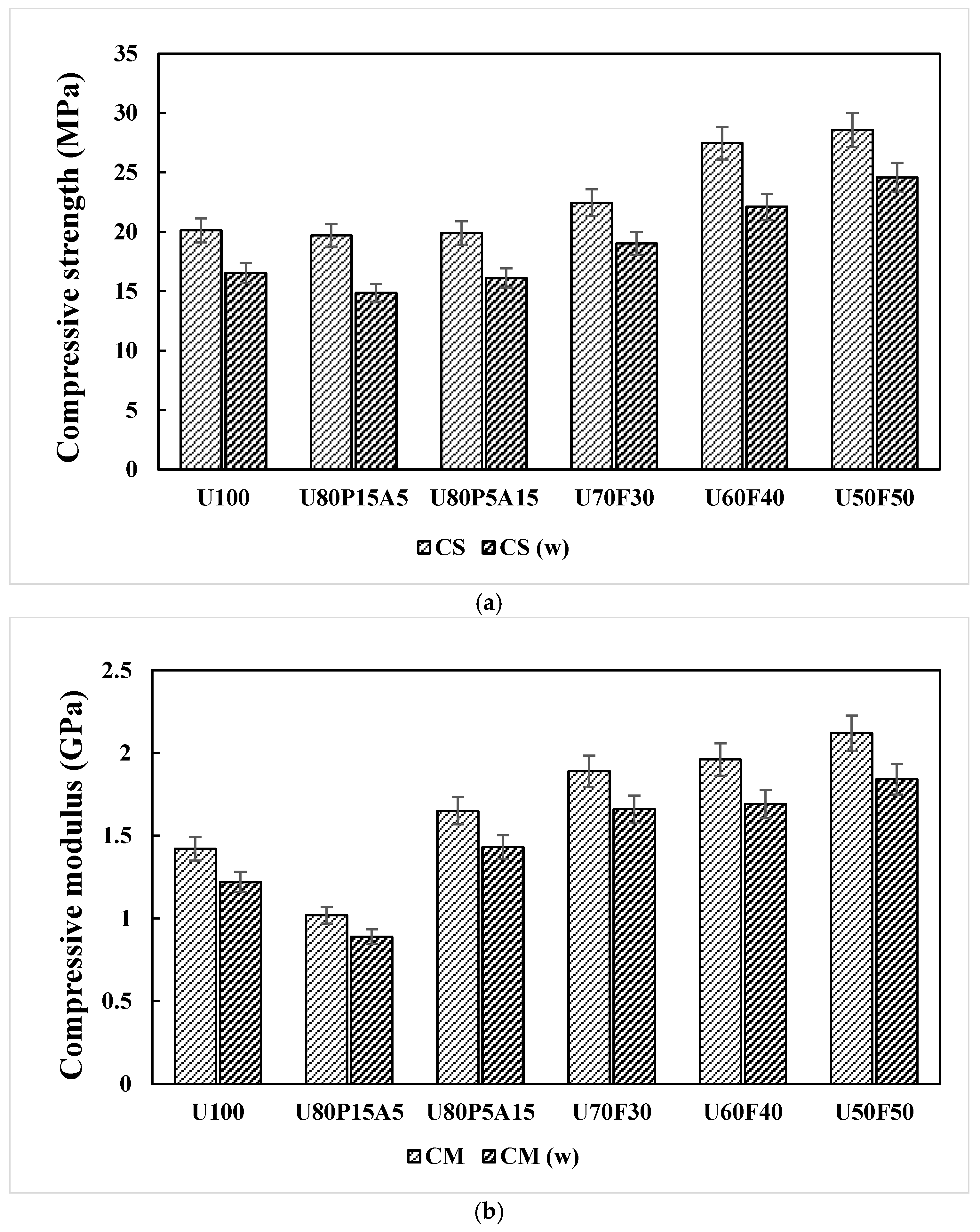

3.2. Effects of Mixing Ratios and Weathering on Compressive Strength of the Samples

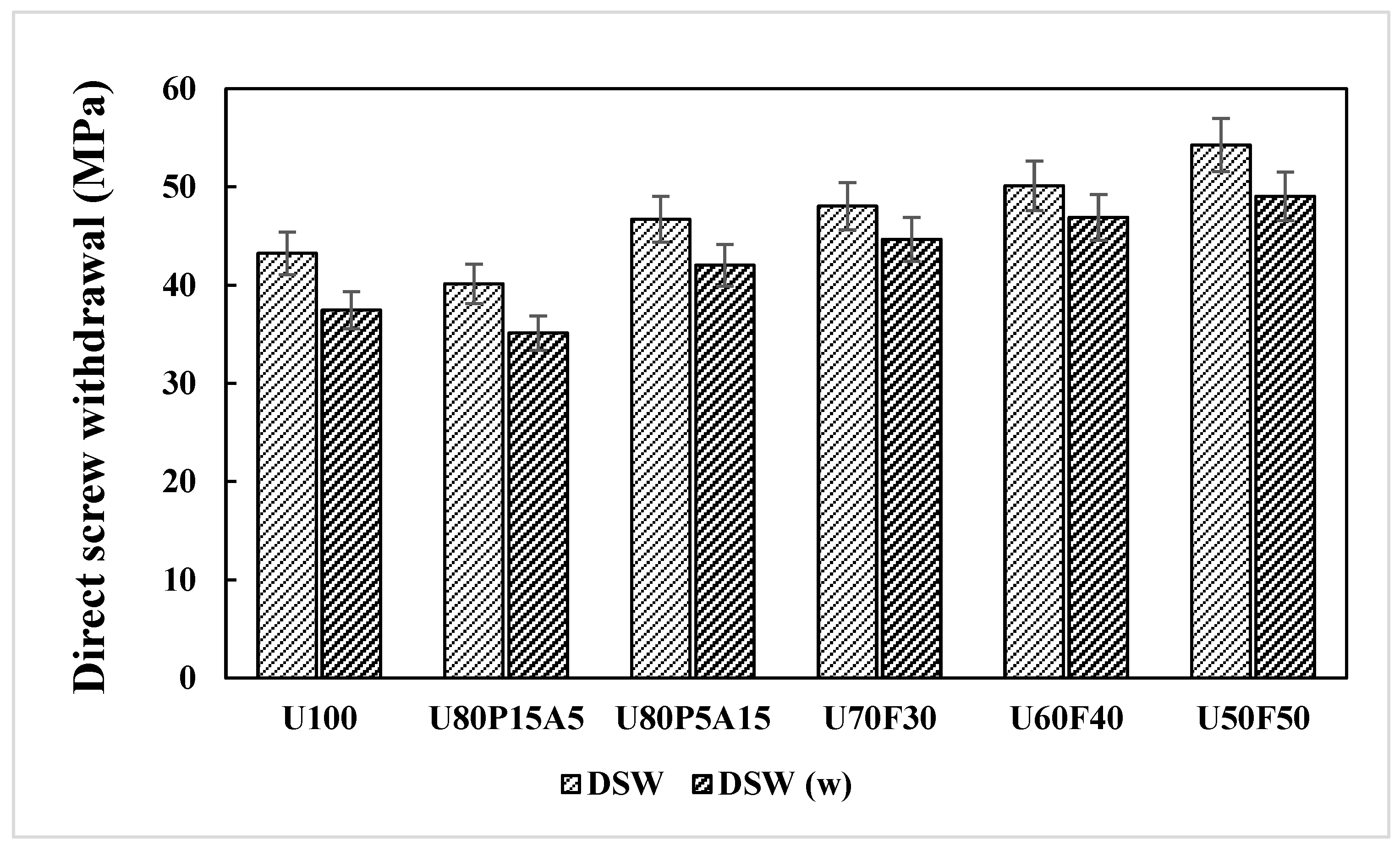

3.3. Effects of Mixing Ratios and Weathering on the Direct Screw Withdrawal Strength of the Samples

3.4. Effects of Mixing Ratios and Weathering on Hardness of the Samples

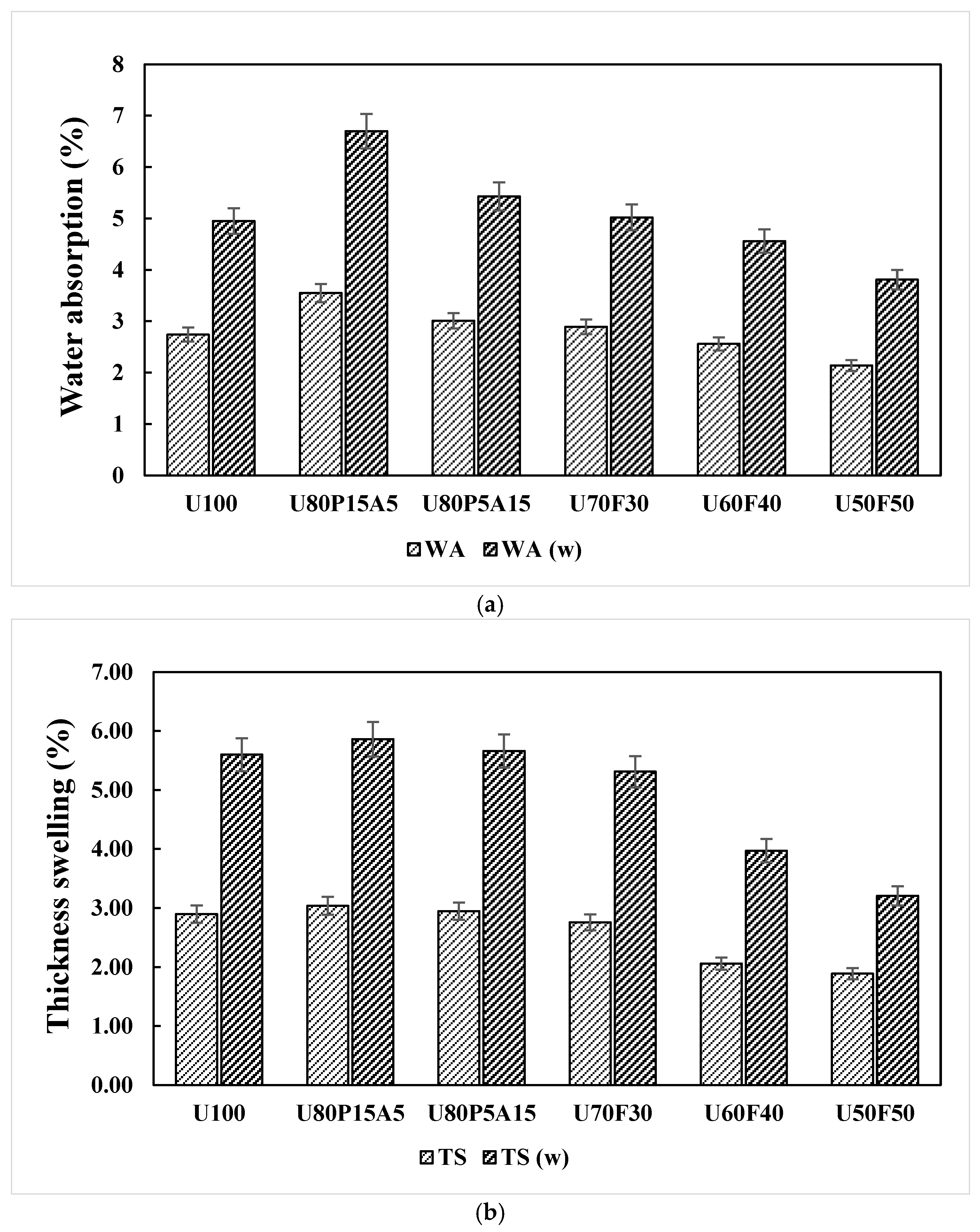

3.5. Effects of Mixing Ratios and Weathering on WA and TS of the Samples

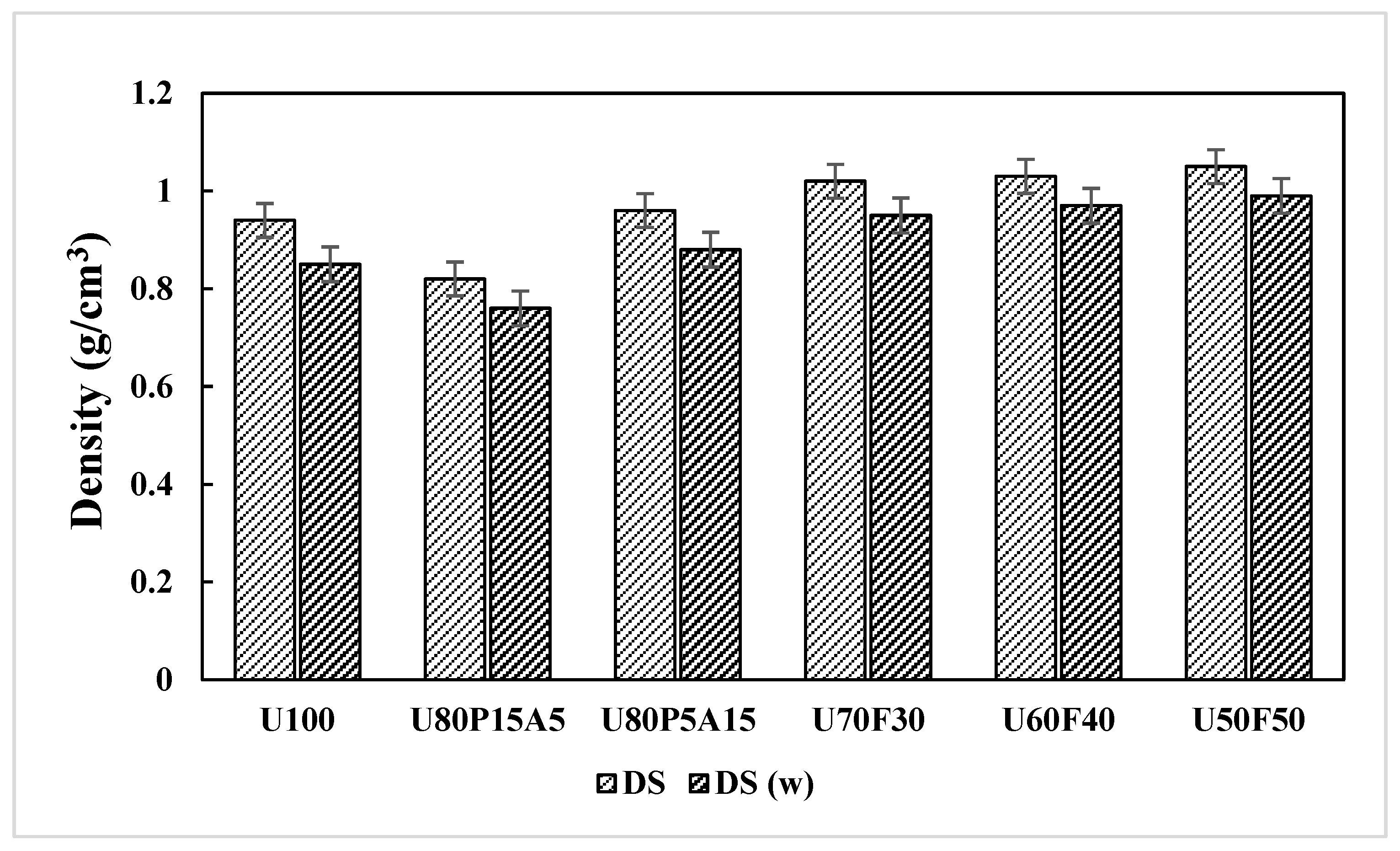

3.6. Effects of Mixing Ratios and Weathering on the Density of the Samples

3.7. Effects of Mixing Ratios and Weathering on Abrasion of the Samples

3.8. Effects of Mixing Ratios and Weathering on Thermal Conductivity of the Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ke, H.; Fei, M.L.; Zhang, C.S.; Zhan, L.T.; Zhang, G.B.; Lan, J.W.; Xuan, Q.Z.; Zheng, S.N.; Chen, Y.M. Heavy metal distribution in MSW-derived soils and migration within the subjacent soil strata of landfills. Waste Manag. 2026, 209, 115181. [Google Scholar] [CrossRef]

- Homkhiew, C.; Srivabut, C.; Boonchouytan, W.; Rawangwong, S. Sandwich composites from recycled plastic reinforced with krajood (Lepironia articulata) fiber for building applications. Iran. Polym. J. 2024, 33, 839–853. [Google Scholar] [CrossRef]

- Khamtree, S.; Homkhiew, C.; Srivabut, C.; Ratanawilai, T.; Rawangwong, S.; Hiziroglu, S. Evaluation of mechanical properties of composites made from recycled plastic and waste rubberwood using multiply-response surface optimization as green building materials. Fibers Polym. 2023, 24, 2819–2834. [Google Scholar] [CrossRef]

- Srivabut, C.; Ratanawilai, T.; Hiziroglu, S. Effect of nanoclay, talcum, and calcium carbonate as filler on properties of composites manufactured from recycled polypropylene and rubberwood fiber. Constr. Build. Mater. 2018, 162, 450–458. [Google Scholar] [CrossRef]

- Yang, F.; Ye, X.; Zhong, J.; Lin, Z.; Wu, S.; Hu, Y.; Zheng, W.; Zhou, W.; Wei, Y.; Dong, X. Recycling of waste crab shells into reinforced poly (lactic acid) biocomposites for 3D printing. Int. J. Biol. Macromol. 2023, 234, 122974. [Google Scholar] [CrossRef]

- Feranc, J.; Repiská, M.; Plavec, R.; Tomanová, K.; Durfina, M.; Vanovcanová, Z.; Vašková, I.; Omaníková, L.; Fogašová, M.; Hlaváciková, S.; et al. Biodegradable PLA/PHB composites with inorganic fillers and modifiers. Polymers 2025, 17, 2721. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Tzounis, L.; Pongwisuthiruchte, A.; Potiyaraj, P. Effect of various surface treatments on the performance of jute fibers filled natural rubber (NR) composites. Polymers 2020, 12, 369. [Google Scholar] [CrossRef]

- Kandola, B.K.; Mistik, S.I.; Pornwannachai, W.; Horrocks, A.R. Effects of water and chemical solutions ageing on the physical, mechanical, thermal and flammability properties of natural fibre-reinforced thermoplastic composites. Molecules 2021, 26, 4581. [Google Scholar] [CrossRef]

- Srivabut, C.; Homkhiew, C.; Rawangwong, S.; Boonchouytan, W. Possibility of using municipal solid waste for manufacturing wood-plastic composites: Effects of natural weathering, wood waste types, and contents. J. Mater. Cycles Waste Manag. 2022, 24, 1407–1422. [Google Scholar] [CrossRef]

- Khamtree, S.; Sookyung, U.; Phetsuwan, W.; Homkhiew, C.; Srivabut, C.; Boonchouytan, W.; Rawangwong, S. Development of paving slab product manufactured from thermoplastic elastomer composites reinforced with crab shell particles for out-door application. J. Thermoplast. Compos. Mater. 2025, 38, 4668–4702. [Google Scholar] [CrossRef]

- Ding, R.; He, K.; Wu, R.; Lou, M.; Liu, Z.; Piao, Y.; Liu, X.; Mu, Z.; Wu, J. Research on the quality deterioration of ultrahigh temperature milk products during shelf life: Core microorganisms and related characteristics. Food Sci. Hum. Wellness 2024, 13, 2866–2875. [Google Scholar] [CrossRef]

- Krishna, T.C.; Najda, A.; Bains, A.; Tosif, M.M.; Papliński, R.; Kapłan, M.; Chawla, P. Influence of ultra-heat treatment on properties of milk proteins. Polymers 2021, 13, 3164. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, R.; Li, Q.; Ma, Y. Influence of storage time on protein composition and simulated digestion of UHT milk and centrifugation presterilized UHT milk in vitro. J. Dairy Sci. 2022, 106, 3109–3122. [Google Scholar] [CrossRef]

- Kılınç, K.; Kanbur, Y.; Tayfun, Ü. Mechanical, thermo-mechanical and water uptake performance of wood flour filled polyurethane elastomer eco-composites: Influence of surface treatment of wood flour. Holzforschung 2019, 73, 401–407. [Google Scholar] [CrossRef]

- Yadav, R.; Singh, M.; Shekhawat, D.; Lee, S.Y.; Park, S.J. The role of fillers to enhance the mechanical, thermal, and wear characteristics of polymer composite materials: A review. Compos. Part A Appl. Sci. Manuf. 2023, 175, 107775. [Google Scholar] [CrossRef]

- Bachchan, A.A.; Das, P.P.; Chaudhary, V. Effect of moisture absorption on the properties of natural fiber reinforced polymer composites: A review. Mater. Today Proc. 2022, 49, 3403–3408. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials. Res. Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Urtekin, G.; Ullah, M.S.; Yildirim, R.; Ozkoc, G.; Kodal, M. A comprehensive review of the recent developments in thermoplastics and rubber blends-based composites and nanocomposites. Polym. Compos. 2023, 44, 8303–8329. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Puttegowda, M.; Rangappa, S.M.; Siengchin, S. A review on extraction, chemical treatment, characterization of natural fibers and its composites for potential applications. Polym. Compos. 2021, 42, 6239–6264. [Google Scholar] [CrossRef]

- Yaghoobi, H.; Fereidoon, A. Preparation and characterization of short kenaf fiber-based biocomposites reinforced with multi-walled carbon nanotubes. Compos. Part B Eng. 2019, 162, 314–322. [Google Scholar] [CrossRef]

- Li, X.; Mou, Q.; Ji, S.; Li, X.; Chen, Z.; Yuan, G. Effect of elevated temperature on physical and mechanical properties of engineered bamboo composites. Ind. Crops Prod. 2022, 189, 115847. [Google Scholar] [CrossRef]

- Sookyung, U.; Homkhiew, C.; Srivabut, C.; Boonchouytan, W.; Rawangwong, S. Utilization of crab shell as waste reinforced in thermoplastic elastomer composites for building applications in high humidity conditions. J. Thermoplast. Compos. Mater. 2025; first published. [Google Scholar] [CrossRef]

- Gumus, N.; Doganci, F.; Aytac, A. Evaluations of the effects of different flame retardants combinations on particleboards produced using urea–formaldehyde resin. Eur. J. Wood Prod. 2024, 82, 747–759. [Google Scholar] [CrossRef]

- Nabergoj, M.; Urevc, J.; Halilovi, M. Modelling of mechanical response of weldlines in injection-moulded short fibre-reinforced polymer components. Polymers 2025, 17, 2712. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, J.; Yuan, X.; Guo, X.; Zhu, Z.; Zhang, F.; Cao, P. Research on the orthogonal cutting performance of polyethylene-based wood-plastic composite based on principal component analysis. Eur. J. Wood. Prod. 2023, 81, 591–603. [Google Scholar] [CrossRef]

- Sahu, P.; Gupta, M.K. Water absorption behavior of cellulosic fibres polymer composites: A review on its effects and remedies. J. Ind. Text. 2020, 51, 7480–7512. [Google Scholar] [CrossRef]

- Memon, A.M.; Sutanto, M.H.; Napiah, M.; Khan, M.I.; Rafiq, W. Modeling and optimization of mixing conditions for petroleum sludge modified bitumen using response surface methodology. Constr. Build. Mater. 2020, 264, 120701. [Google Scholar] [CrossRef]

- Qin, X.; Cheng, J.; Qi, X.; Guan, N.; Chen, Q.; Pei, X.; Jiang, Y.; Yang, X.; Man, C. Effect of thermostable enzymes produced by psychrotrophic bacteria in raw milk on the quality of ultra-high temperature sterilized milk. Foods 2023, 12, 3752. [Google Scholar] [CrossRef]

- Homkhiew, C.; Srivabut, C.; Boonchouytan, W.; Ratanawilai, T.; Rawangwong, S. Optimization of the physical properties of recycled plastic hybrid composites reinforced with rubberwood flour and crab shell flour for underwater use. Compos. Part C Open Access 2023, 12, 100411. [Google Scholar] [CrossRef]

- Alrubaie, M.A.A.; Gardner, D.J.; Lopez-Anido, R.A. Modeling the long-term deformation of a geodesic spherical frame structure made from wood plastic composite lumber. Appl. Sci. 2020, 10, 5017. [Google Scholar] [CrossRef]

- Ratanawilai, T.; Taneerat, K. Alternative polymeric matrices for wood-plastic composites: Effects on mechanical properties and resistance to natural weathering. Constr. Build. Mater. 2018, 172, 349–357. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Panchal, H.; Shanmugan, S.; Muthuramalingam, T.; El-Kassas, A.M.; Ramesh, B. Recent progresses in wood-plastic composites: Pre-processing treatments, manufacturing techniques, recyclability and eco-friendly assessment. Clean. Eng. Technol. 2022, 8, 100450. [Google Scholar] [CrossRef]

- Semwal, A.; Gautam, K.; Bhatt, M.; Yadav, R.; Barthwal, S.; Singh, H. Green synthesis and application of metal nanoparticles (MNPs): A sustainable strategy for protecting wood from fungal and termite decay. Next Mater. 2025, 9, 100962. [Google Scholar] [CrossRef]

- Cherradi, Y.; Rosca, I.C.; Cerbu, C.; Kebir, H.; Guendouz, A.; Benyoucef, M. Acoustic properties for composite materials based on alfa and wood fibers. Appl. Acoust. 2021, 174, 107759. [Google Scholar] [CrossRef]

- Tan, W.H.; Wahab, F.; Mat, F.; Chan, C.K.; Teoh, R.J. Sound absorption coefficient measurement and analysis for multisection perforation microperforated panel. J. Mech. Sci. Technol. 2024, 38, 2797–2803. [Google Scholar] [CrossRef]

- ASTM D0790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. Advancing Standards Transforming Markets: West Conshohocken, PA, USA, 2017.

- ASTM D1084-97; Standard Test Methods for Viscosity of Adhesives. Advancing Standards Transforming Markets: West Conshohocken, PA, USA, 2017.

- ASTM D1037; Standard Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials. Advancing Standards Transforming Markets: West Conshohocken, PA, USA, 2020.

- ASTM D2240; Standard Test Method for Rubber Property—Durometer Hardness. Advancing Standards Transforming Markets: West Conshohocken, PA, USA, 2021.

- ASTM D570; Standard Test Method for Water Absorption of Plastics. Advancing Standards Transforming Markets: West Conshohocken, PA, USA, 2022.

- ASTM D792; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. Advancing Standards Transforming Markets: West Conshohocken, PA, USA, 2020.

- ASTM D1044; Standard Test Method for Resistance of Transparent Plastics to Surface Abrasion by the Taber Abraser. Advancing Standards Transforming Markets: West Conshohocken, PA, USA, 2024.

- ISO 8301:1991; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus. International Organization for Standardization: Geneva, Switzerland, 1991.

- ASTM G 154; Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Materials. Advancing Standards Transforming Markets: West Conshohocken, PA, USA, 2023.

- Xiang, H.F.; Wang, D.; Liua, H.C.; Zhao, N.; Xu, J. Investigation on sound absorption properties of kapok fibers. J. Polym. Sci. 2013, 31, 521–529. [Google Scholar] [CrossRef]

- Bhaskar, K.; Jayabalakrishnan, D.; Kumar, M.V.; Sendilvelan, S.; Prabhahar, M. Analysis on mechanical properties of wood plastic composite. Mater. Today Proc. 2021, 45, 5886–5891. [Google Scholar] [CrossRef]

- Parsons, L.A.; Nwaubani, S.O. Abrasion-wear resistance of precarbonated and water-cured concrete made using ABS plastic derived from waste electrical and electronic equipment. Cem. Concr. Res. 2024, 179, 107470. [Google Scholar] [CrossRef]

- Wachowicz, J.; Fik, J.; Bałaga, Z.; Stradomski, G. Testing for abrasion resistance of WC-Co composites for blades used in wood-based material processing. Materials 2023, 16, 5836. [Google Scholar] [CrossRef]

- Ebe, K.; Sekino, N. Surface deterioration of wood plastic composites under outdoor exposure. J. Wood Sci. 2015, 61, 143–150. [Google Scholar] [CrossRef]

- Matseevich, A.; Matseevich, A.T.; Askadskii, A. Study of the abrasion resistance of wood-polymer composites and mixtures of ABS-plastic with polyvinyl chloride. MATEC Web Conf. 2018, 196, 04069. [Google Scholar] [CrossRef]

- Zha, J.W.; Wang, F.; Wan, B. Polymer composites with high thermal conductivity: Tsheory, simulation, structure and interfacial regulation. Prog. Mater. Sci. 2025, 148, 101362. [Google Scholar] [CrossRef]

- Xu, N.; Li, S.; Chen, Y. Shaohua Chen Enhancing the thermal conductivity of composite materials via surface microstructure design. Compos. Commun. 2025, 53, 102203. [Google Scholar] [CrossRef]

| Compositions | UHT Carton (wt%) | Plastic Bags (wt%) | Aluminum Foil (wt%) | Foil Bags (wt%) |

|---|---|---|---|---|

| U100 | 100 | - | - | - |

| U80P15A5 | 80 | 15 | 5 | - |

| U80P5A15 | 80 | 5 | 15 | - |

| U70F30 | 70 | - | - | 30 |

| U60F40 | 60 | - | - | 40 |

| U50F50 | 50 | - | - | 50 |

| Compositions (wt%) | Mechanical Properties | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MOR | MOR (w) | MOE | MOE (w) | CS | CS (w) | CM | CM (w) | DSW | DSW (w) | HN | HN (w) | |

| (MPa) | (MPa) | (GPa) | (GPa) | (MPa) | (MPa) | (GPa) | (GPa) | (MPa) | (MPa) | (Shore D) | (Shore D) | |

| U100 | 80.06 | 64.05 | 2.44 | 2.11 | 20.12 | 16.55 | 1.42 | 1.22 | 43.23 | 37.45 | 62.08 | 57.07 |

| U80P15A5 | 64.96 | 52.22 | 2.32 | 1.99 | 19.69 | 14.87 | 1.02 | 0.89 | 40.12 | 35.12 | 60.07 | 55.90 |

| U80P5A15 | 93.27 | 74.39 | 2.33 | 1.88 | 19.89 | 16.12 | 1.65 | 1.43 | 46.69 | 42.02 | 62.43 | 58.49 |

| U70F30 | 109.5 | 88.23 | 2.52 | 2.19 | 22.45 | 19.02 | 1.89 | 1.66 | 48.03 | 44.65 | 63.56 | 60.33 |

| U60F40 | 115.61 | 95.67 | 2.65 | 2.26 | 27.47 | 22.11 | 1.96 | 1.69 | 50.12 | 46.89 | 64.53 | 61.45 |

| U50F50 | 121.20 | 100.44 | 2.98 | 2.54 | 28.56 | 24.58 | 2.12 | 1.84 | 54.25 | 49.04 | 66.25 | 63.17 |

| p-value | 0.000 * | 0.000 * | 0.001 * | 0.001 * | 0.000 * | 0.000 * | 0.001 * | 0.001 * | 0.000 * | 0.000 * | 0.000 * | 0.000 * |

| Compositions (wt%) | Physical Properties | |||||

|---|---|---|---|---|---|---|

| WA | WA (w) | TS | TS (w) | DS | DS (w) | |

| (%) | (%) | (%) | (%) | (g/cm3) | (g/cm3) | |

| U100 | 2.74 | 4.95 | 2.90 | 5.60 | 0.94 | 0.85 |

| U80P15A5 | 3.55 | 6.70 | 3.04 | 5.86 | 0.82 | 0.76 |

| U80P5A15 | 3.01 | 5.43 | 2.95 | 5.66 | 0.96 | 0.88 |

| U70F30 | 2.89 | 5.02 | 2.76 | 5.31 | 1.02 | 0.95 |

| U60F40 | 2.56 | 4.56 | 2.06 | 3.97 | 1.03 | 0.97 |

| U50F50 | 2.14 | 3.81 | 1.89 | 3.21 | 1.05 | 0.99 |

| p-value | 0.002 * | 0.002 * | 0.001 * | 0.001 * | 0.002 * | 0.002 * |

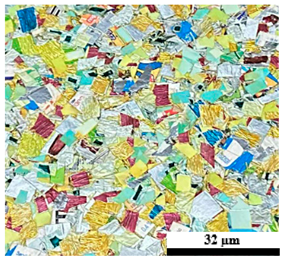

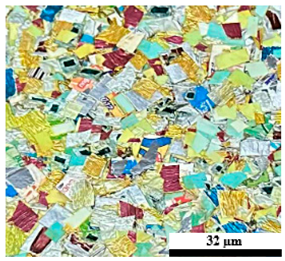

| Components | U100 (100:0:0:0 wt%) | U80P15A5 (80:15:5:0 wt%) | U80P5A15 (80:5:15:0 wt%) |

| UHT carton: Plastic bags: Aluminum foil: Foil bags: |  |  |  |

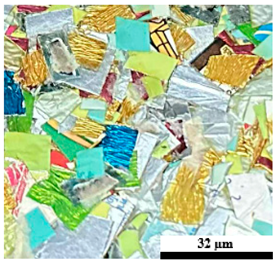

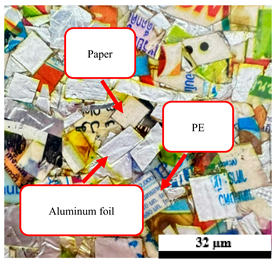

| Components | U70F30 (70:0:0:30 wt%) | U60F40 (60:0:0:40 wt%) | U50F50 (50:0:0:50 wt%) |

| UHT carton: Plastic bags: Aluminum foil: Foil bags: |  |  |  |

| Components | U100 (100:0:0:0 wt%) | U80P15A5 (80:15:5:0 wt%) | U80P5A15 (80:5:15:0 wt%) |

| UHT carton: Plastic bags: Aluminum foil: Foil bags: |  |  |  |

| Components | U70F30 (70:0:0:30 wt%) | U60F40 (60:0:0:40 wt%) | U50F50 (50:0:0:50 wt%) |

| UHT carton: Plastic bags: Aluminum foil: Foil bags: |  |  |  |

| Components | U100 (100:0:0:0 wt%) | U80P15A5 (80:15:5:0 wt%) | U80P5A15 (80:5:15:0 wt%) |

| UHT carton: Plastic bags: Aluminum foil: Foil bags: |  |  |  |

| Components | U70F30 (70:0:0:30 wt%) | U60F40 (60:0:0:40 wt%) | U50F50 (50:0:0:50 wt%) |

| UHT carton: Plastic bags: Aluminum foil: Foil bags: |  |  |  |

| Code | Sample Weight (g) | Weight Loss | |||

|---|---|---|---|---|---|

| Initial Weight | 20 s | 40 s | 60 s | (%) | |

| U100 | 22.657 | 22.567 | 21.345 | 20.356 | 10.156 |

| U80P15A5 | 21.897 | 21.790 | 20.786 | 19.059 | 12.961 |

| U80P5A15 | 21.809 | 21.715 | 20.369 | 19.457 | 10.785 |

| U70F30 | 22.456 | 22.346 | 21.357 | 20.077 | 10.594 |

| U60F40 | 22.344 | 22.266 | 21.055 | 20.112 | 9.989 |

| U50F50 | 22.487 | 22.366 | 21.856 | 20.562 | 8.561 |

| p-value | 0.001 * | 0.000 * | 0.000 * | 0.000 * | 0.000 * |

| Code | Sample Weight (g) | Weight Loss | |||

|---|---|---|---|---|---|

| Initial Weight | 20 s | 40 s | 60 s | (%) | |

| U100 | 22.204 | 21.890 | 20.278 | 19.135 | 16.039 |

| U80P15A5 | 21.459 | 21.136 | 19.747 | 17.915 | 19.782 |

| U80P5A15 | 21.373 | 21.064 | 19.351 | 18.290 | 16.856 |

| U70F30 | 22.007 | 21.676 | 20.289 | 18.872 | 16.612 |

| U60F40 | 21.897 | 21.598 | 20.002 | 18.905 | 15.827 |

| U50F50 | 22.037 | 21.695 | 20.763 | 19.328 | 14.016 |

| p-value | 0.000 * | 0.000 * | 0.000 * | 0.001 * | 0.000 * |

| Code | Thermal Conductivity (λ) (W/m·K) | Thermal Resistance (R) (m2·K/W) | ||

|---|---|---|---|---|

| S.D. | S.D. | |||

| U100 | 0.148 | (±0.003) | 0.151 | (±0.002) |

| U80P15A5 | 0.136 | (±0.002) | 0.142 | (±0.002) |

| U80P5A15 | 0.149 | (±0.001) | 0.156 | (±0.001) |

| U70F30 | 0.165 | (±0.002) | 0.187 | (±0.003) |

| U60F40 | 0.175 | (±0.001) | 0.205 | (±0.001) |

| U50F50 | 0.189 | (±0.002) | 0.213 | (±0.002) |

| p-value | 0.000 * | 0.000 * | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Homkhiew, C.; Pantamanatsopa, P.; Khamtree, S.; Srivabut, C.; Boonchouytan, W.; Rawangwong, S.; Hiziroglu, S. Properties of Plastic-Based Composite Panels Manufactured from Municipal Waste Under Accelerated Weathering as Potential Paving Slabs. Polymers 2025, 17, 2998. https://doi.org/10.3390/polym17222998

Homkhiew C, Pantamanatsopa P, Khamtree S, Srivabut C, Boonchouytan W, Rawangwong S, Hiziroglu S. Properties of Plastic-Based Composite Panels Manufactured from Municipal Waste Under Accelerated Weathering as Potential Paving Slabs. Polymers. 2025; 17(22):2998. https://doi.org/10.3390/polym17222998

Chicago/Turabian StyleHomkhiew, Chatree, Pruttipong Pantamanatsopa, Sriwan Khamtree, Chainarong Srivabut, Worapong Boonchouytan, Surasit Rawangwong, and Salim Hiziroglu. 2025. "Properties of Plastic-Based Composite Panels Manufactured from Municipal Waste Under Accelerated Weathering as Potential Paving Slabs" Polymers 17, no. 22: 2998. https://doi.org/10.3390/polym17222998

APA StyleHomkhiew, C., Pantamanatsopa, P., Khamtree, S., Srivabut, C., Boonchouytan, W., Rawangwong, S., & Hiziroglu, S. (2025). Properties of Plastic-Based Composite Panels Manufactured from Municipal Waste Under Accelerated Weathering as Potential Paving Slabs. Polymers, 17(22), 2998. https://doi.org/10.3390/polym17222998