Effect of Dehydration on the Resilient Modulus of Biopolymer-Treated Sandy Soil for Pavement Construction

Abstract

1. Introduction

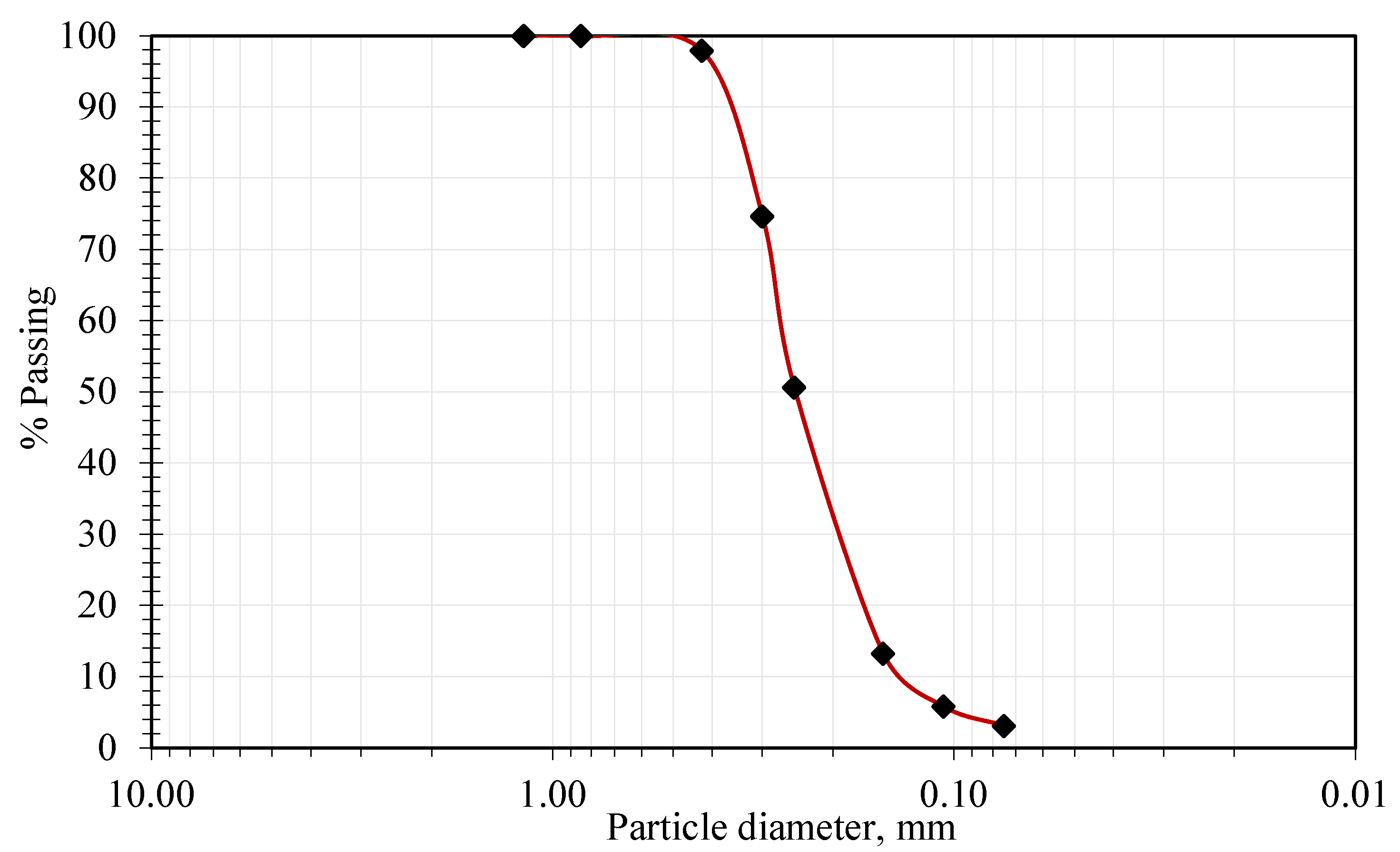

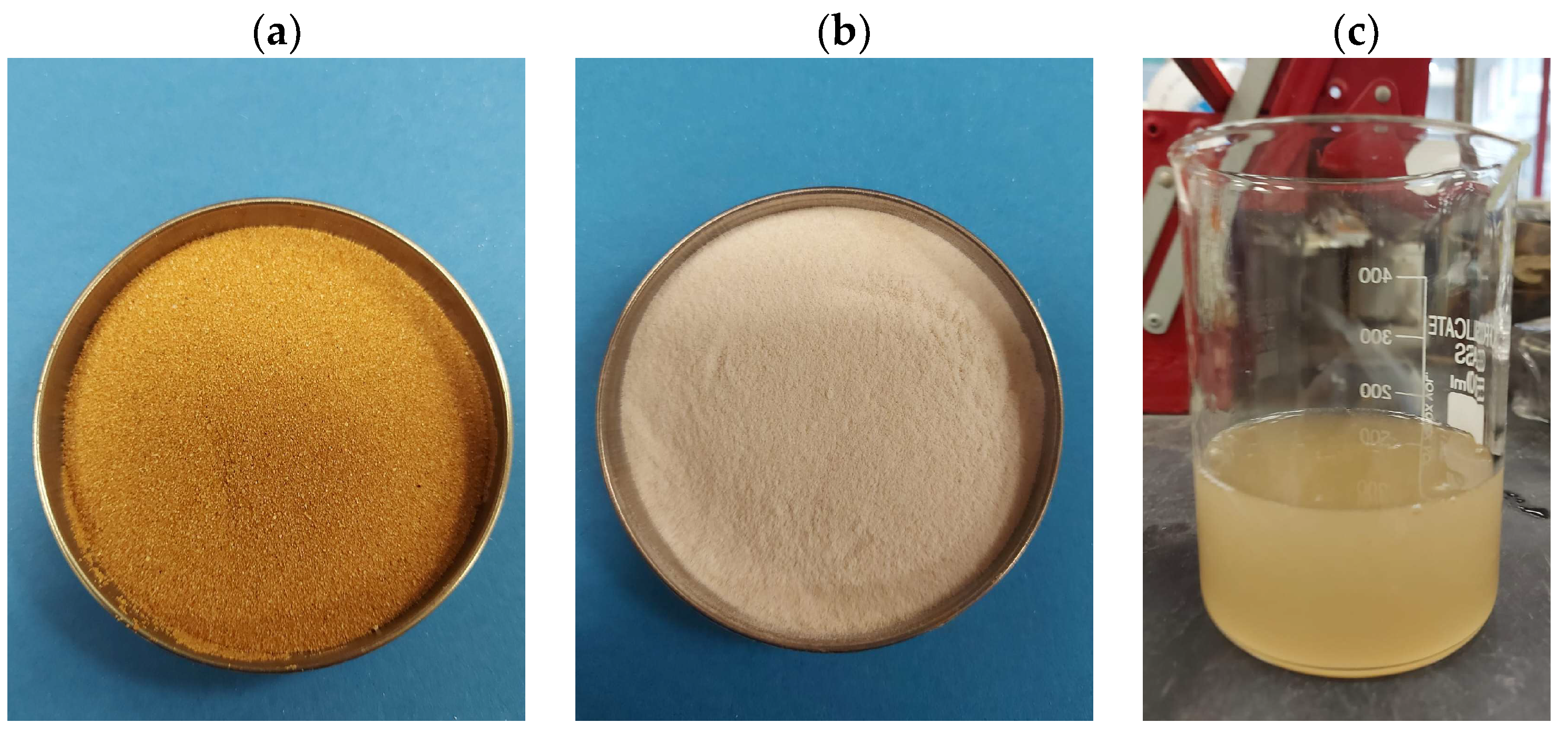

2. Materials and Methods

3. Experimental Program

3.1. Specimen Preparation

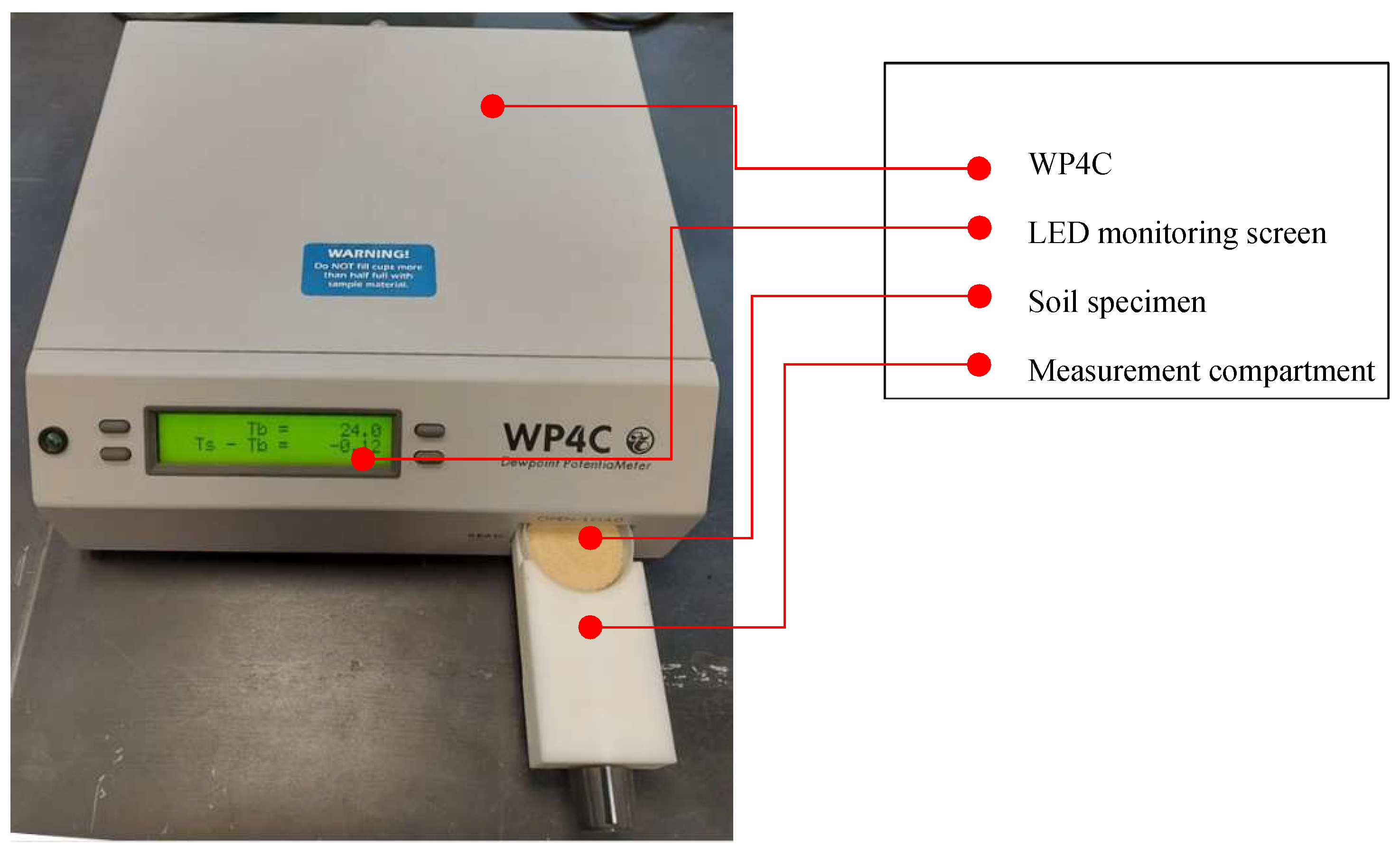

3.2. Determination of SWRC

3.3. Curing Process

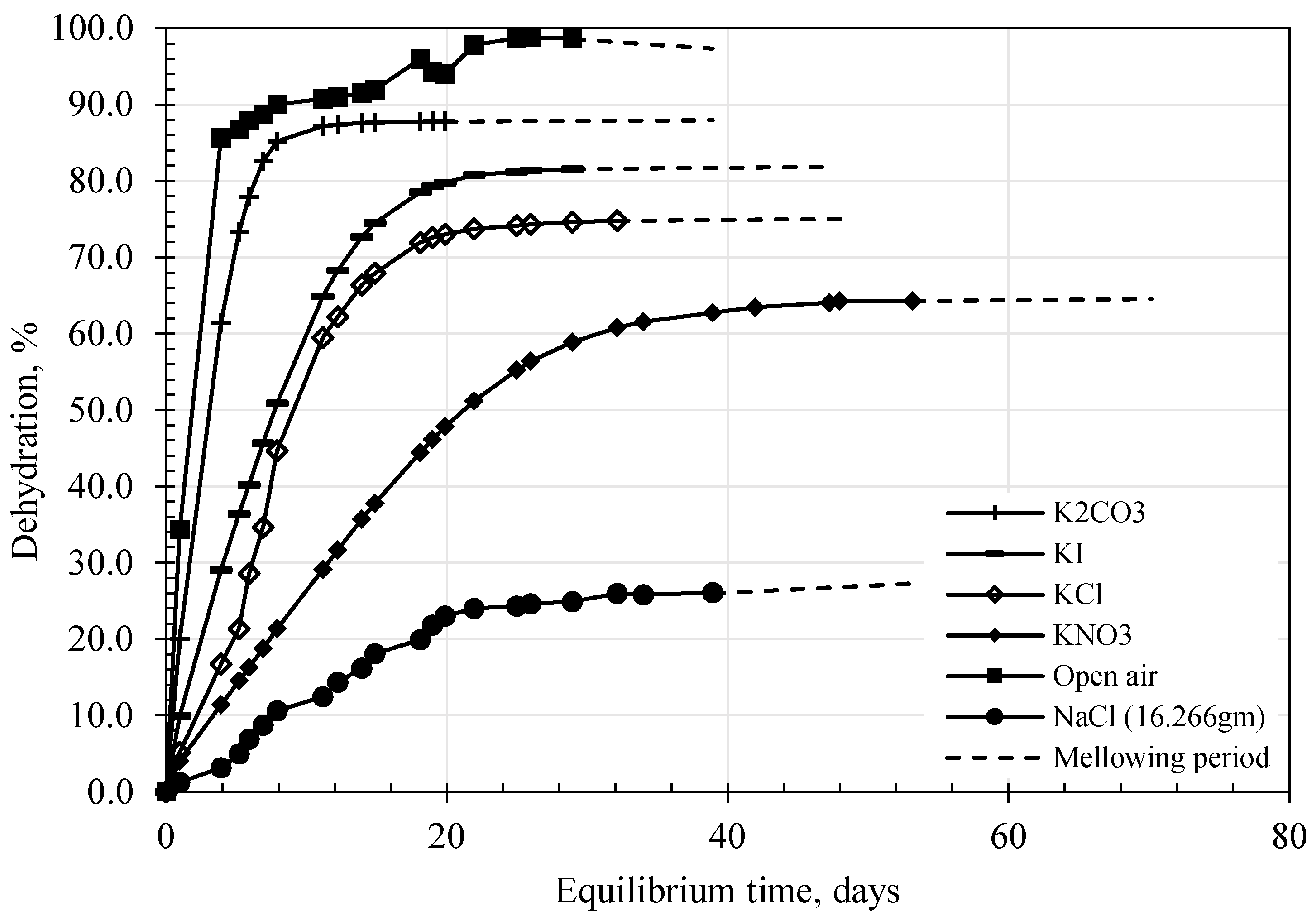

3.3.1. Closed-System Curing

3.3.2. Dehydration Curing

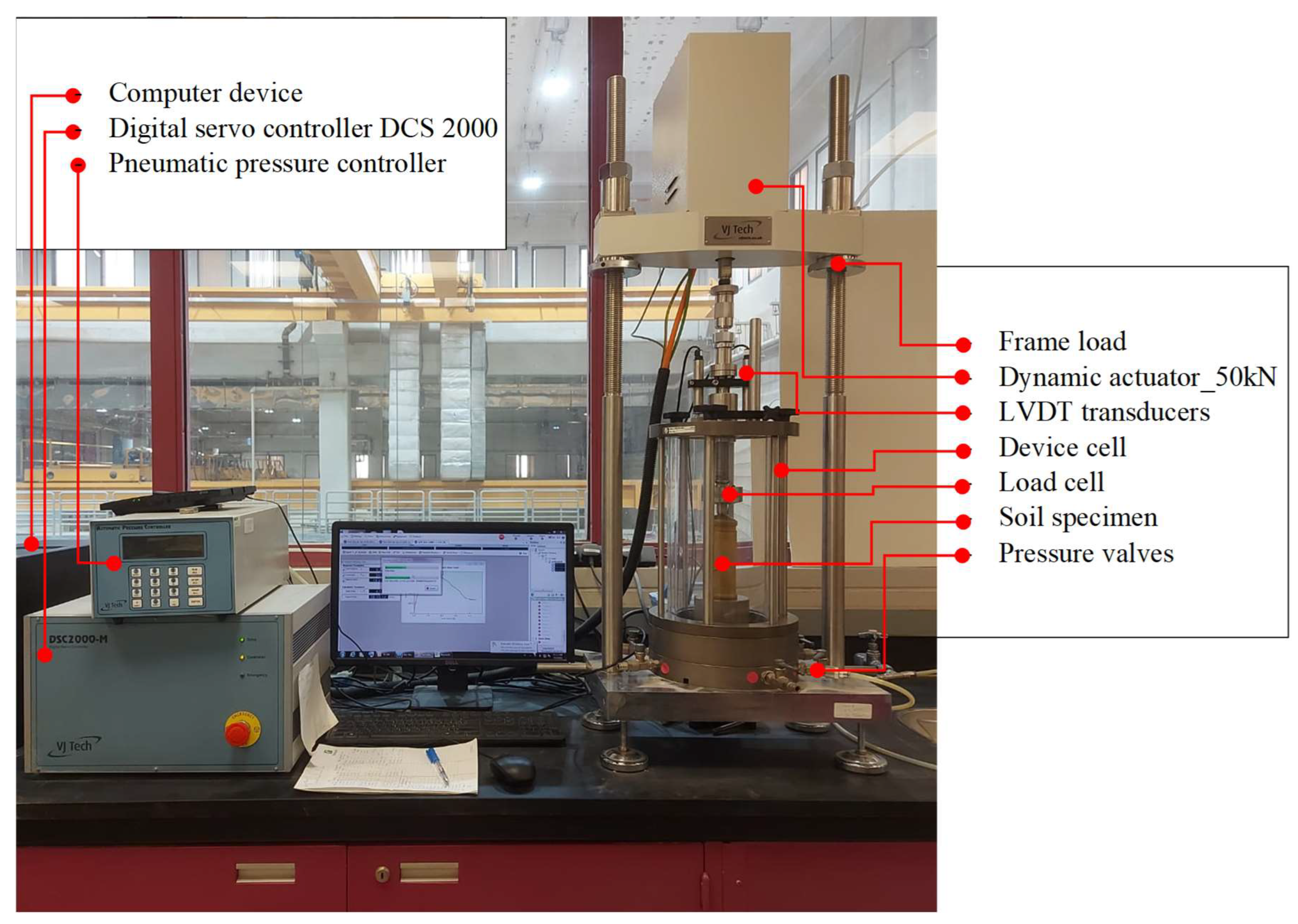

3.4. MR Testing

4. Results and Discussion

4.1. SWRC and Selected Points for DC Treatment

4.2. MR Result Selection and Statistical Variation

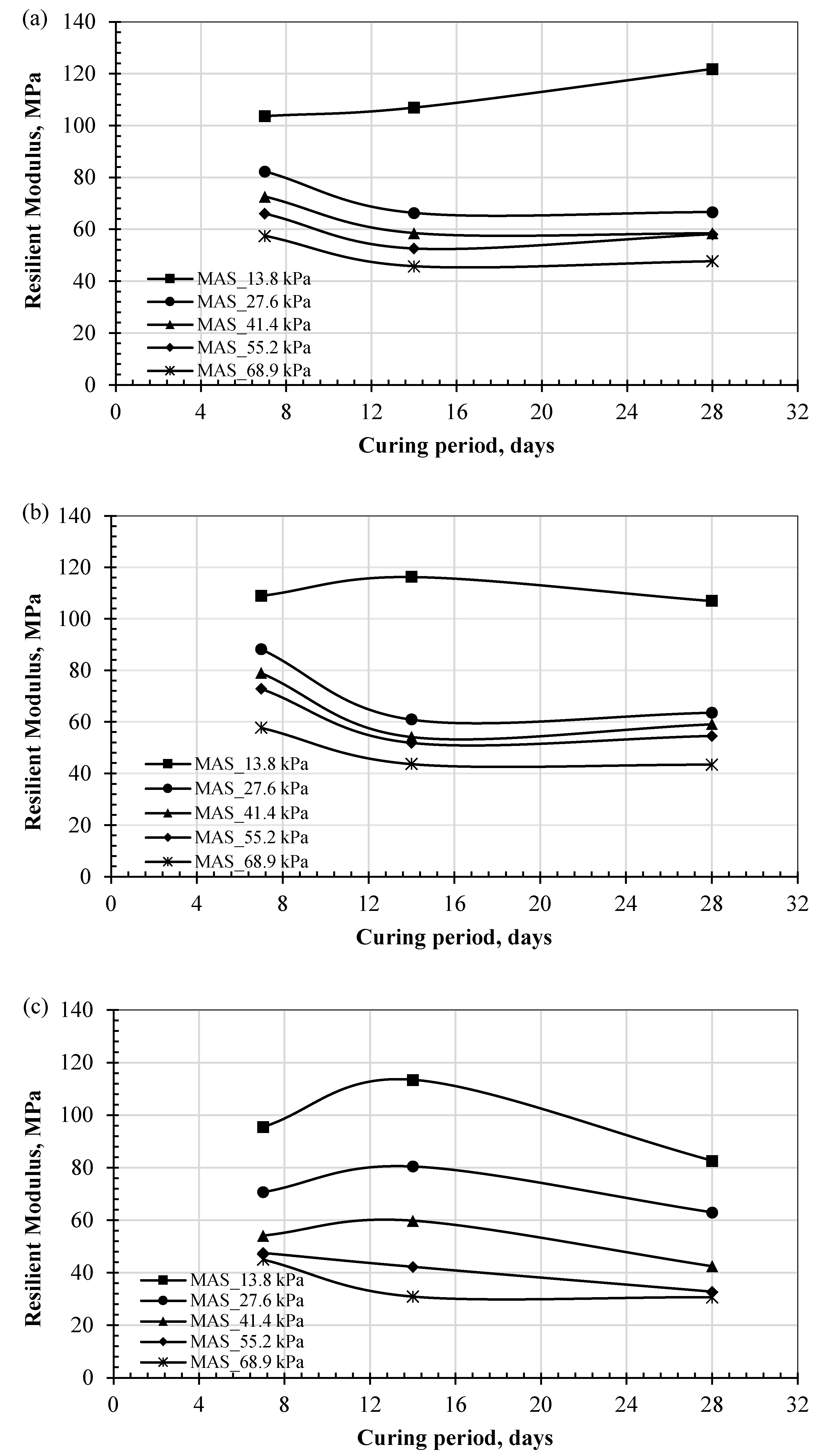

4.3. Effect of Closed-System Curing (CSC) on the MR

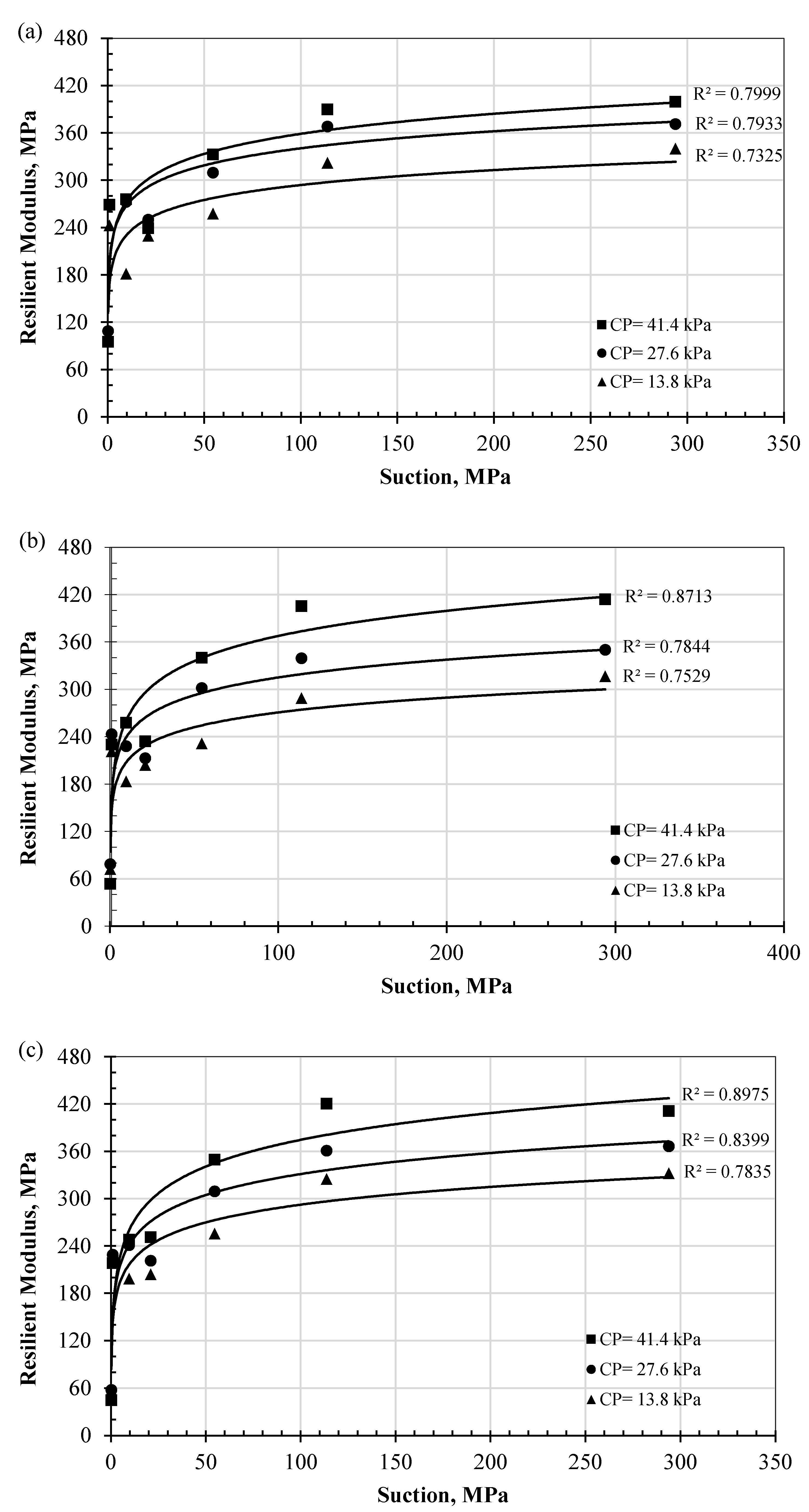

4.4. Effect of Dehydration DC on MR Values

5. Summary and Conclusions

- The response of biopolymer-treated sand and its resilience characteristics under dynamic loads were significantly affected by the dehydration regime.

- The SWRC for treated soil exhibited a bimodal shape and defined the different dehydration regimes along the entire range of suction. The major extent of dehydration occurred in the transition regime.

- CSC curing generally reduced MR by approximately 10% to 30%. In the presence of water, strain-softening behavior developed, weakening the resilience characteristics.

- DC resulted in a substantial increase in MR, which rose nearly eightfold up to the residual regime. The most significant development in MR during DC was attained in the transition zone, where dehydration was most active.

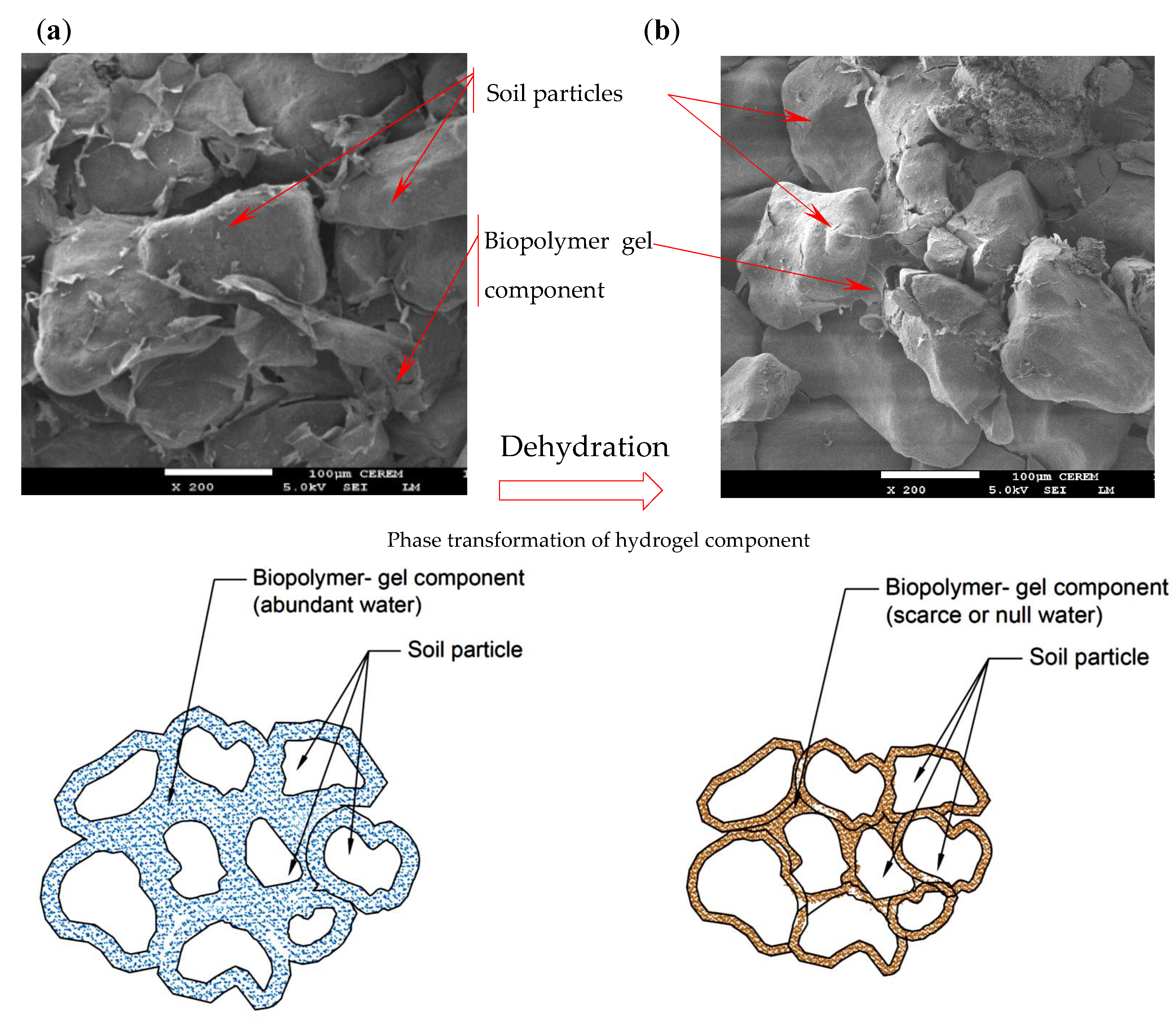

- At the highest level of dehydration (high suction), the biopolymer gel components strengthened interparticle bonding. The phase change from hydrogel to films was supported by SEM images, and the enhancement of the cross-linking phenomenon generated tensile strength and improved resilience characteristics.

- Considering the advantages of linking DC and the results of MR to different dehydration regimes of SWRC, a new model was developed to predict MR values, considering the confinement, dynamic axial stress, and suction level.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Camarena, S. Sustainable road maintenance and construction utilizing new technologies. In Proceedings of the Internmational Public Works Conference, Darwin, Australia, 11–15 August 2013; Institute of Public Works Engineering: Sydney, Australia, 2013. [Google Scholar]

- Ahmed, M.; Bashar, I.; Alam, S.T.; Wasi, A.I.; Jerin, I.; Khatun, S.; Rahman, M. An overview of Asian cement industry: Environmental impacts, research methodologies and mitigation measures. Sustain. Prod. Consum. 2021, 28, 1018–1039. [Google Scholar] [CrossRef]

- Gao, T.; Shen, L.; Shen, M.; Liu, L.; Chen, F.; Gao, L. Evolution and projection of CO2 emissions for China’s cement industry from 1980 to 2020. Renew. Sustain. Energy Rev. 2017, 74, 522–537. [Google Scholar] [CrossRef]

- Feng, D.; Liang, B.; Wan, Y.; Yi, F.; Liu, L.; Zhang, Y.; He, X. Mechanical and water stability properties of biopolymer-treated silty sand. J. Rock Mech. Geotech. Eng. 2025, 17, 3910–3924. [Google Scholar] [CrossRef]

- Aryal, R.; Jung Karki, A.; Sasar, M.; Abdelaziz, S.L. The Durability of Biopolymer Treated Sand. In Proceedings of the IFCEE, Dallas, TX, USA, 7–10 May 2024; pp. 296–305. [Google Scholar]

- Fortuna, B.; Logar, J.; Sorze, A.; Valentini, F.; Smolar, J. Influence of Xanthan Gum-Based Soil Conditioners on the Geotechnical Properties of Soils. Appl. Sci. 2024, 14, 4044. [Google Scholar] [CrossRef]

- Bai, Y.; Liu, J.; Cui, Y.; Shi, X.; Song, Z.; Qi, C. Mechanical behavior of polymer stabilized sand under different temperatures. Constr. Build. Mater. 2011, 290, 123237. [Google Scholar] [CrossRef]

- Lee, M.; Im, J.; Cho, G.C.; Ryu, H.H.; Chang, I. Interfacial shearing behavior along xanthan gum biopolymer-treated sand and solid interfaces and its meaning in geotechnical engineering aspects. Appl. Sci. 2020, 11, 139. [Google Scholar] [CrossRef]

- Lee, S.; Im, J.; Cho, G.C.; Chang, I. Laboratory triaxial test behavior of xanthan gum biopolymer-treated sands. Geomech. Eng. 2019, 17, 445. [Google Scholar]

- Qureshi, M.U.; Chang, I.; Al-Sadarani, K. Strength and durability characteristics of biopolymer-treated desert sand. Geomech. Eng. 2017, 12, 785–801. [Google Scholar] [CrossRef]

- Smitha, S.; Sachan, A. Use of agar biopolymer to improve the shear strength behavior of sabarmati sand. Int. J. Geotech. Eng. 2016, 10, 387–400. [Google Scholar] [CrossRef]

- Bagheri, P.; Gratchev, I.; Rybachuk, M. Effects of Xanthan Gum Biopolymer on Soil Mechanical Properties. Appl. Sci. 2023, 13, 887. [Google Scholar] [CrossRef]

- Bozyigit, I.; Javadi, A.; Altun, S. Strength properties of xanthan gum and guar gum treated kaolin at different water contents. J. Rock Mech. Geotech. Eng. 2021, 13, 1160–1172. [Google Scholar] [CrossRef]

- Fatehi, H.; Ong, D.E.L.; Yu, J.; Chang, I. Biopolymers as green binders for soil improvement in geotechnical applications: A review. Geosciences 2021, 11, 291. [Google Scholar] [CrossRef]

- Chang, I.; Cho, G.C. Shear strength behavior and parameters of microbial gellan gum-treated soils: From sand to clay. Acta Geotech. 2019, 14, 361–375. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Awraheem, M.H.; Khalaf, M.M. Geotechnical properties of a low-plasticity clay with biopolymer. J. Mater. Civ. Eng. 2018, 30, 04018170. [Google Scholar] [CrossRef]

- Joga, J.R.; Varaprasad, B.J.S. Sustainable improvement of expansive clays using xanthan gum as a biopolymer. Civ. Eng. J. 2019, 5, 1893–1903. [Google Scholar] [CrossRef]

- Zhou, C.; So, P.S.; Chen, X.W. A water retention model considering biopolymer-soil interactions. J. Hydrol. 2020, 586, 124874. [Google Scholar] [CrossRef]

- Ni, J.; Li, S.S.; Ma, L.; Geng, X.Y. Performance of soils enhanced with eco-friendly biopolymers in unconfined compression strength tests and fatigue loading tests. Constr. Build. Mater. 2020, 263, 120039. [Google Scholar] [CrossRef]

- Lemboye, K.; Almajed, A. Effect of Varying Curing Conditions on the Strength of Biopolymer Modified Sand. Polymers 2023, 15, 1678. [Google Scholar] [CrossRef]

- Vydehi, K.V.; Moghal, A.A.B. Effect of biopolymeric stabilization on the strength and compressibility characteristics of cohesiv soil. J. Mater. Civ. Eng. 2022, 34, 04021428. [Google Scholar] [CrossRef]

- National Cooperative Highway Research Program (NCHRP). Chapter 2: Material characterization. In Mechanistic Empirical Guide for New and Rehabilitated Pavement Structures: Final Report–Part 2 Design Input; Transportation Research Board, National Research Council: Washington, DC, USA, 2002. [Google Scholar]

- Ghosh, D.; Banerjee, A. Uncovering the Impact of Freeze–Thaw Cycles on Resilient Modulus of Cement-Stabilized Sulfate-Rich Subgrade Soil. In Cold Regions Engineering; American Society of Civil Engineers: Reston, VA, USA, 2024; pp. 484–494. [Google Scholar]

- Kumar, P.; Puppala, A.J.; Congress, S.S.C.; Tingle, J.S. Resilient moduli characterization of cement-treated silt. In E3S Web of Conferences; EDP Sciences: London, UK, 2024; Volume 544, p. 11014. [Google Scholar]

- Al-Mahbashi, A.M.; Al-Shamrani, M. Long-term and immediate effects of freeze–thaw cycles on the resilient modulus of treated expansive subgrades. Road Mater. Pavement Des. 2023, 24, 2411–2424. [Google Scholar] [CrossRef]

- Rabab’ah, S.; Al Hattamleh, O.; Aldeeky, H.; Aljarrah, M.M.; Al_Qablan, H.A. Resilient response and permanent strain of subgrade soil stabilized with byproduct recycled steel and cementitious materials. J. Ofmaterials Civ. Eng. 2020, 32, 04020139. [Google Scholar] [CrossRef]

- Patel, S.; Reddy, L.M.; Chaudhary, P.M. Feasibility of lime stabilized expansive soil as a subbase material for flexible pavements. In Proceedings of the 8th International Conference on Electrical, Electronics and Civil Engineering (ICEECE’2016), Dubai, United Arab Emirates, 12–13 January 2016; pp. 52–56. [Google Scholar]

- Elkady, T.; Al-Mahbashi, A.; Al-Shamrani, M. Resilient modulus lime-treated expansive subgrade. In From Fundamentals to Applications in Geotechnics; Manzanal, D., Sfriso, A.O., Eds.; IOS Press: Amsterdam, The Netherlands, 2015; pp. 1631–1638. [Google Scholar]

- Rahman, M.T.; Tarefder, R.A. Assessment of Molding Moisture and Suction on Resilient Modulus of Lime Stabilized Clayey Subgrade Soils. Geotech. Test. J. 2015, 38, 6. [Google Scholar] [CrossRef]

- Georgees, R.N.; Hassan, R.A.; Evans, R.P.; Jegatheesan, P. Resilient response characterization of pavement foundation materials using a polyacrylamide-based stabilizer. J. Mater. Civ. Eng. 2018, 30, 04017252. [Google Scholar] [CrossRef]

- Kumar, P.; Puppala, A.J.; Tingle, J.S.; Chakraborty, S.; Sarat Chandra Congress, S. Resilient Characteristics of Polymer Emulsion-Treated Sandy Soil. Transp. Res. Rec. 2022, 2676, 526–538. [Google Scholar] [CrossRef]

- Banerjee, A.; Puppala, A.J.; Congress, S.S.; Chakraborty, S.; Likos, W.J.; Hoyos, L.R. Variation of Resilient Modulus of Subgrade Soils over a Wide Range of Suction States. J. Geotech. Geoenvironmental Eng. 2020, 146, 04020096. [Google Scholar] [CrossRef]

- Saloura, F.; Erlingsson, S. Resilient modulus modelling of unsaturated subgrade soils: Laboratory investigation of silty sand subgrade. Road Mater. Pavement Des. 2015, 16, 553–568. [Google Scholar] [CrossRef]

- Howari, F.M. Evaluation of chemical and petrographic characteristics of Silica sand from Tabuk in Saudi Arabia. J. Geol. Geophys. 2015, 4, 2. [Google Scholar] [CrossRef]

- Almajed, A.; Al-Mahbashi, A.M. Contribution of Fine Contents on Retention Characteristics of Biopolymer-Stabilized Sand. Arab. J. Sci. Eng. 2025, 50, 1–17. [Google Scholar] [CrossRef]

- Al-Mahbashi, A.M.; Dafalla, M. Effects of Expansive Clay Content on the Hydromechanical Behavior of Liners Under Freeze-Thaw Conditions. Minerals 2025, 15, 291. [Google Scholar] [CrossRef]

- ASTM D2487-2017; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2017.

- Bakhshizadeh, A.; Khayat, N.; Horpibulsuk, S. Surface stabilization of clay using sodium alginate. Case Stud. Constr. Mater. 2022, 16, e01006. [Google Scholar] [CrossRef]

- Hasnain, M.S.; Jameel, E.; Mohanta, B.; Dhara, A.K.; Alkahtani, S.; Nayak, A.K. Alginates: Sources, structure, and properties. In Alginates in Drug Delivery; Academic Press: Cambridge, MA, USA, 2020; pp. 1–17. [Google Scholar]

- Fatehi, H.; Bahmani, M.; Noorzad, A. Strengthening of dune sand with sodium alginate biopolymer. In Proceedings of the Eighth International Conference on Case Histories in Geotechnical Engineering, Philadelphia, PA, USA, 24–27 March 2019; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 157–166. [Google Scholar]

- Al-Mahbashi, A.M.; Almajed, A. The Role of Biopolymers on the Water Retention Capacity of Stabilized Sand. Sustainability 2024, 16, 8612. [Google Scholar] [CrossRef]

- ASTM D698-12e2; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft3 (600 kN-m/m3)). Annual Book of Standards, Vol. 4.08. ASTM International: West Conshohocken, PA, USA, 2012.

- Theng, B.K.G. Formation and Properties of Clay-Polymer Complexes; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- BS EN 13286-53; Unbound and Hydraulically Bound Mixtures. Methods for the Manufacture of Test Specimens of Hydraulically Bound Mixtures Using Axial Compression. British Standard Institute: London, UK, 2004.

- ASTM D6836; Standard Test Methods for Determination of the Soil Water Characteristic Curve for Desorption Using a Hanging Column, Pressure Extractor, ChilledMirror Hygrometer, and/or Centrifuge (Vol. 15.09). ASTM International: West Conshohocken, PA, USA, 2016.

- Fong, A.; Tuli, A. Determination of Soil Water Characteristic Curve Using 5 Bar Ceramic Pressure Plate Extractor. Standard Operating Procedure Number: METH016. 00. 2018. Available online: https://www.cdpr.ca.gov/wp-content/uploads/2024/12/meth016.pdf (accessed on 1 June 2025).

- Al-Mahbashi, A.M.; Elkady, T.Y.; Al-Shamrani, M.A. Hysteresis soil-water characteristic curves of highly expansive clay. Eur. J. Environ. Civ. Eng. 2018, 22, 1041–1059. [Google Scholar] [CrossRef]

- Dafalla, M.A.; Al-Mahbashi, A.M.; Almajed, A.; Al-Shamrani, M. Predicting Soil-Water Characteristic Curves of Clayey Sand Soils Using Area Computation. Math. Probl. Eng. 2020, 2020, 4548912. [Google Scholar] [CrossRef]

- ASTM E 104; Standard Practice for Maintaining Constant Relative Humidity by Means of Aqueous Solutions. Annual Book of ASTM Standards. ASTM Internaltional: West Conshohocken, PA, USA, 2007.

- Fredlund, D.G.; Rahardjo, H. Soil Mechanics for Unsaturated Soils; Wiley InterScience: New York, NY, USA, 1993. [Google Scholar]

- ASTM D 5298; Standard Test Method for Measurement of Soil Potential (Suction) Using Filter Paper (Vol. 4.08). D-18 Committee on Soils and Rocks: West Conshohocken, PA, USA, 2003.

- AASHTO T 307-99; Standard Method of Test for Determining the Resilient Modulus of Soils and Aggregate Materials. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2007.

- Rahardjo, H.; Aung, K.K.; Leong, E.C.; Rezaur, R.B. Characteristics of residual soils in Singapore as formed by weathering. Eng. Geol. 2024, 73, 157–169. [Google Scholar] [CrossRef]

- Satyanaga, A.; Rahardjo, H.; Leong, E.C.; Wang, J.Y. Water characteristic curve of soil with bimodal grain size distribution. Comput. Geotech. 2013, 48, 51–61. [Google Scholar] [CrossRef]

- Chen, R.P.; Liu, P.; Liu, X.M.; Wang, P.F.; Kang, X. Pore-scale model for estimating the bimodal soil–water characteristic curve and hydraulic conductivity of compacted soils with different initial densities. Eng. Geol. 2019, 260, 105199. [Google Scholar] [CrossRef]

- Zhou, H.; Mooney, S.J.; Peng, X. Bimodal soil pore structure investigated by a combined soil water retention curve and X-Ray computed tomography approach. Soil Sci. Soc. Am. J. 2017, 81, 1270–1278. [Google Scholar] [CrossRef]

- Elkady, T.Y. The effect of curing conditions on the unconfined compression strength of lime-treated expansive soils. Road Mater. Pavement Des. 2016, 17, 52–69. [Google Scholar] [CrossRef]

- Elkady, T.Y.; Al-Mahbashi, A.M.; Al-Shamrani, M.A. Effect of moisture hysteresis on the resilient modulus of lime-treated expansive clay. J. Test. Eval. 2017, 45, 2039–2049. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.C. Effects of xanthan gum biopolymer on soil strengthening, Constr. Build. Mater 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Reddy, N.; Reddy, R.; Jiang, Q. Crosslinking biopolymers for biomedical applications. Trends Biotechnol. 2015, 33, 362–369. [Google Scholar] [CrossRef] [PubMed]

- Munyiri, C.N.; Madivoli, E.S.; Kisato, J.; Gichuki, J.; Kareru, P.G. Biopolymer based hydrogels: Crosslinking strategies and their applications. Int. J. Polym. Mater. Polym. Biomater. 2025, 74, 625–640. [Google Scholar] [CrossRef]

- Cabalar, A.; Wiszniewski, M.; Skutnik, Z. Effects of xanthan gum biopolymer on the permeability, odometer, unconfined compressive and triaxial shear behavior of a sand. Soil Mech. Found. Eng. 2017, 54, 356–361. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Lee, S.-W.; Cho, G.-C. Strength durability of gellan gum biopolymer-treated Korean sand with cyclic wetting and drying. Constr. Build. Mater. 2017, 143, 210–221. [Google Scholar] [CrossRef]

- Lee, M.; Chang, I.; Cho, G.C. Advanced biopolymer–based soil strengthening binder with trivalent chromium–xanthan gum crosslinking for wet strength and durability enhancement. J. Mater. Civ. Eng. 2023, 35, 04023360. [Google Scholar] [CrossRef]

- Soldo, A.; Mileti’c, M.; Auad, M.L. Biopolymers as a sustainable solution for the enhancement of soil mechanical properties. Sci. Rep. 2020, 10, 267. [Google Scholar] [CrossRef] [PubMed]

- Puppala, A.J. Estimating Stiffness of Subgrade and Unbound Materials for Pavement Design; Transportation Research Board: Washington, DC, USA, 2008; Volume 382, pp. 1–132. [Google Scholar] [CrossRef]

| Salt Solution | Nominal Suction Values, kPa | Measured Suction Values (Using WP4C), kPa | Relative Humidity % |

|---|---|---|---|

| Potassium carbonate (K2CO3) | 113,700 | 113,910 | 43.16 ± 0.39 |

| Potassium iodide (KI) | 50,376 | 51,930 | 68.86 ± 0.24 |

| Potassium chloride (KCl) | 21,848 | 23,290 | 85.06 ± 0.38 |

| Potassium nitrate (KNO3) | 8959 | 9660 | 93.58 ± 0.55 |

| Sodium chloride (NaCl) * | |||

| NaCl (16.266 gm)/1000 mL water | 1000 | 1070 | 98.6 ± 0.50 |

| Air-drying | - | 294,300 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Mahbashi, A.M.; Almajed, A. Effect of Dehydration on the Resilient Modulus of Biopolymer-Treated Sandy Soil for Pavement Construction. Polymers 2025, 17, 2738. https://doi.org/10.3390/polym17202738

Al-Mahbashi AM, Almajed A. Effect of Dehydration on the Resilient Modulus of Biopolymer-Treated Sandy Soil for Pavement Construction. Polymers. 2025; 17(20):2738. https://doi.org/10.3390/polym17202738

Chicago/Turabian StyleAl-Mahbashi, Ahmed M., and Abdullah Almajed. 2025. "Effect of Dehydration on the Resilient Modulus of Biopolymer-Treated Sandy Soil for Pavement Construction" Polymers 17, no. 20: 2738. https://doi.org/10.3390/polym17202738

APA StyleAl-Mahbashi, A. M., & Almajed, A. (2025). Effect of Dehydration on the Resilient Modulus of Biopolymer-Treated Sandy Soil for Pavement Construction. Polymers, 17(20), 2738. https://doi.org/10.3390/polym17202738