Effect of Fiber Characteristics on Cracking Resistance Properties of Stone Mastic Asphalt (SMA) Mixture

Abstract

1. Introduction

2. Experimental Program

2.1. Raw Materials

2.1.1. Asphalt

2.1.2. Fiber

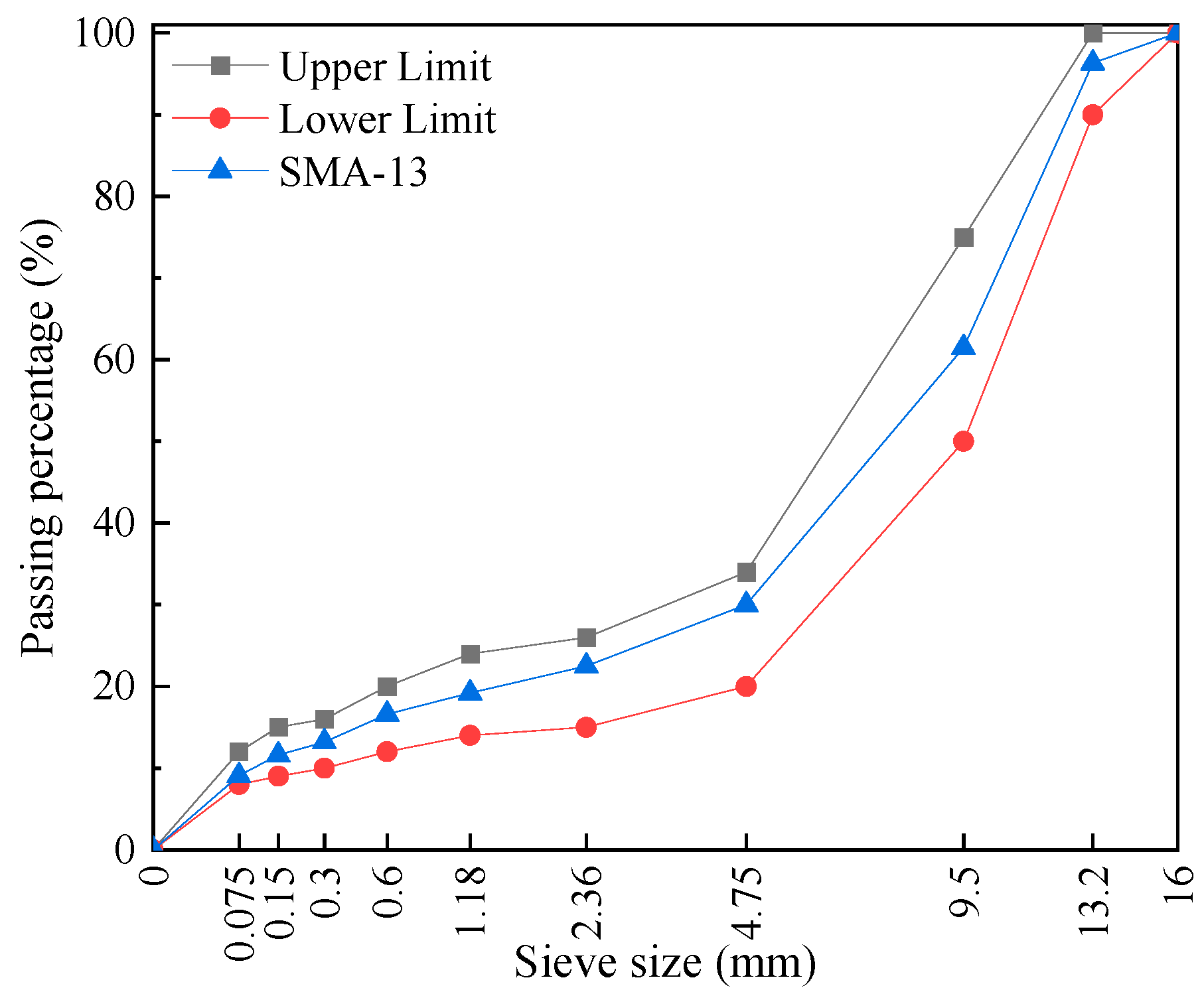

2.2. Mixtures Design

2.3. Experimental Methods

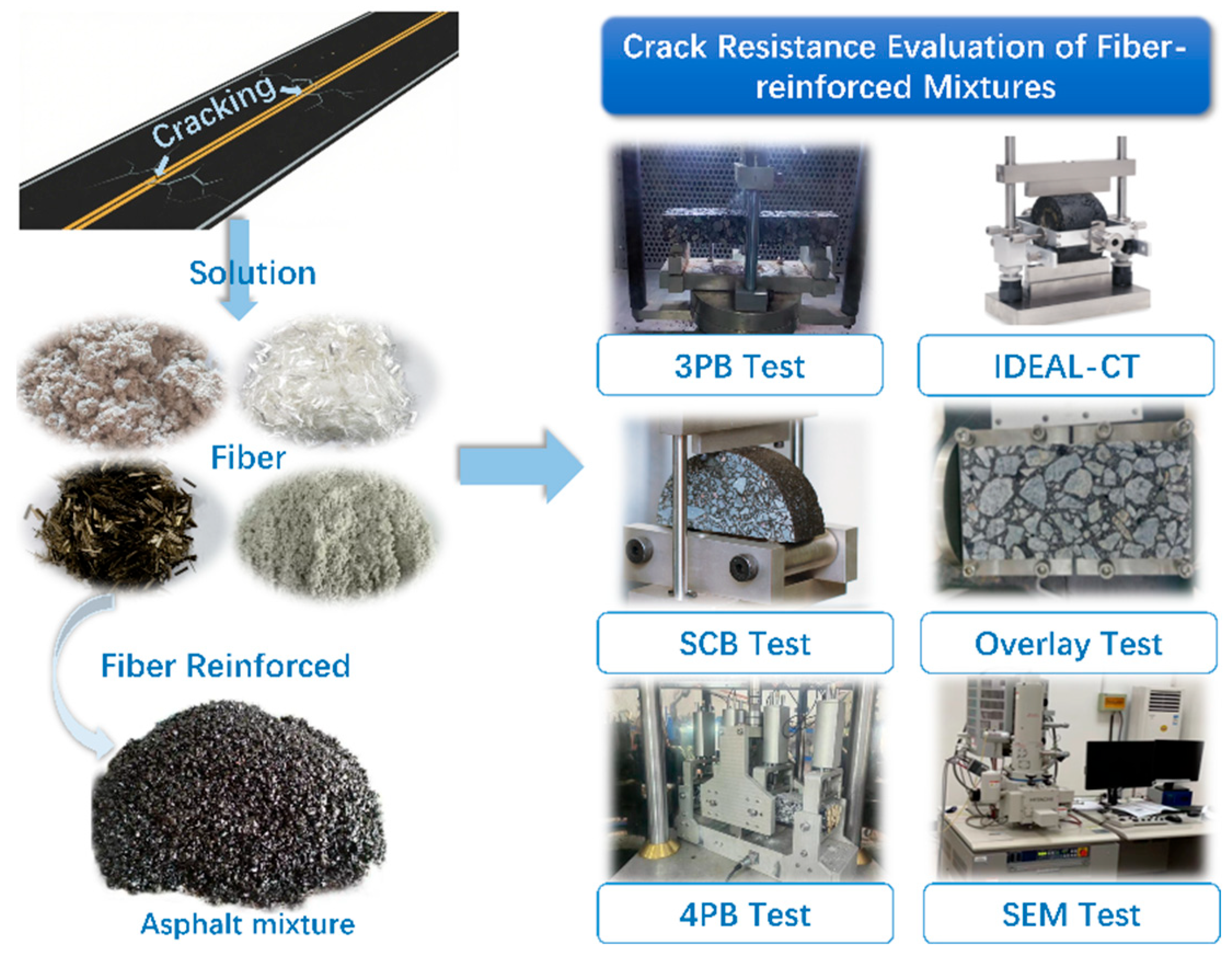

2.3.1. Experimental Framework

2.3.2. Three-Point Bending Beam Test

2.3.3. Indirect Tensile Cracking Test

2.3.4. Semi-Circular Bending Test

2.3.5. Overlay Test

2.3.6. Four-Point Bending Test

2.3.7. Scanning Electron Microscope (SEM) Test

3. Results and Discussion

3.1. Low-Temperature Cracking Resistance

3.2. Tensile Cracking Resistance

3.3. Crack Propagation Resistance

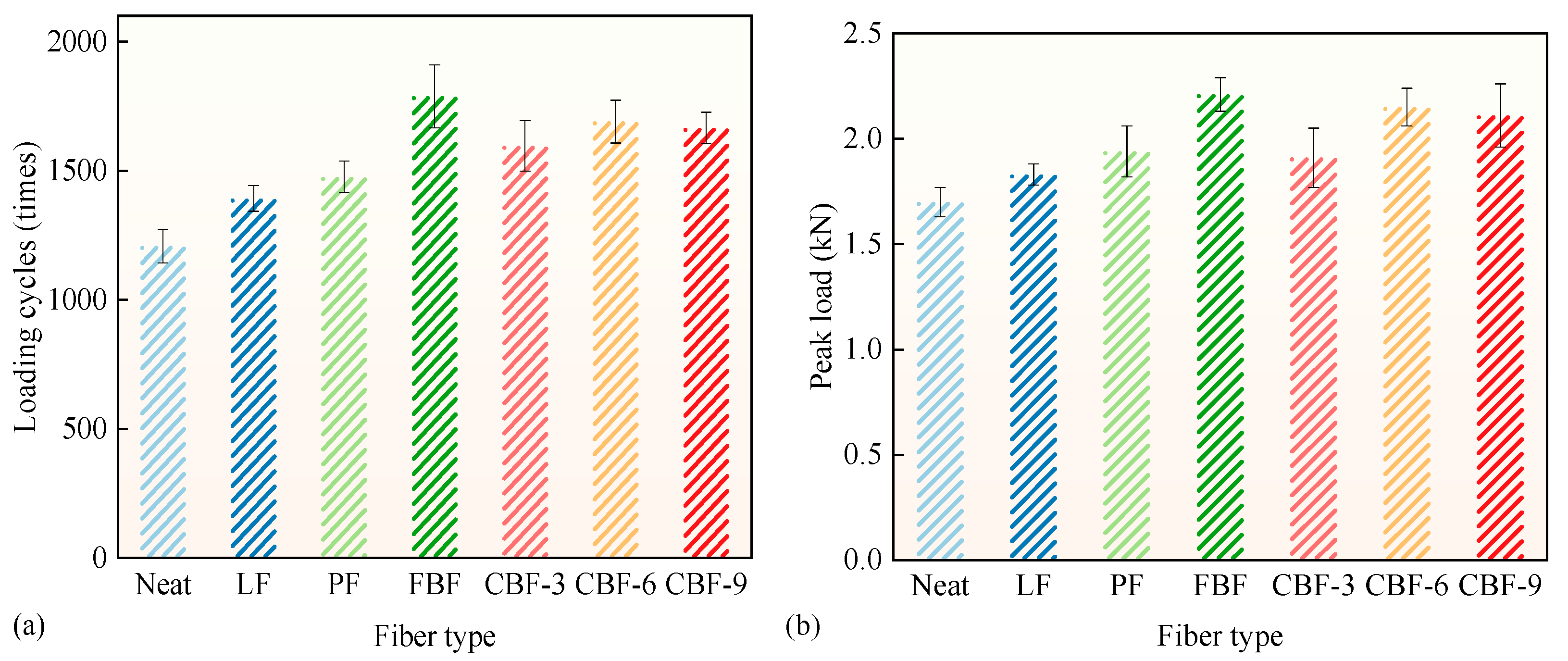

3.4. Reflective Cracking Resistance

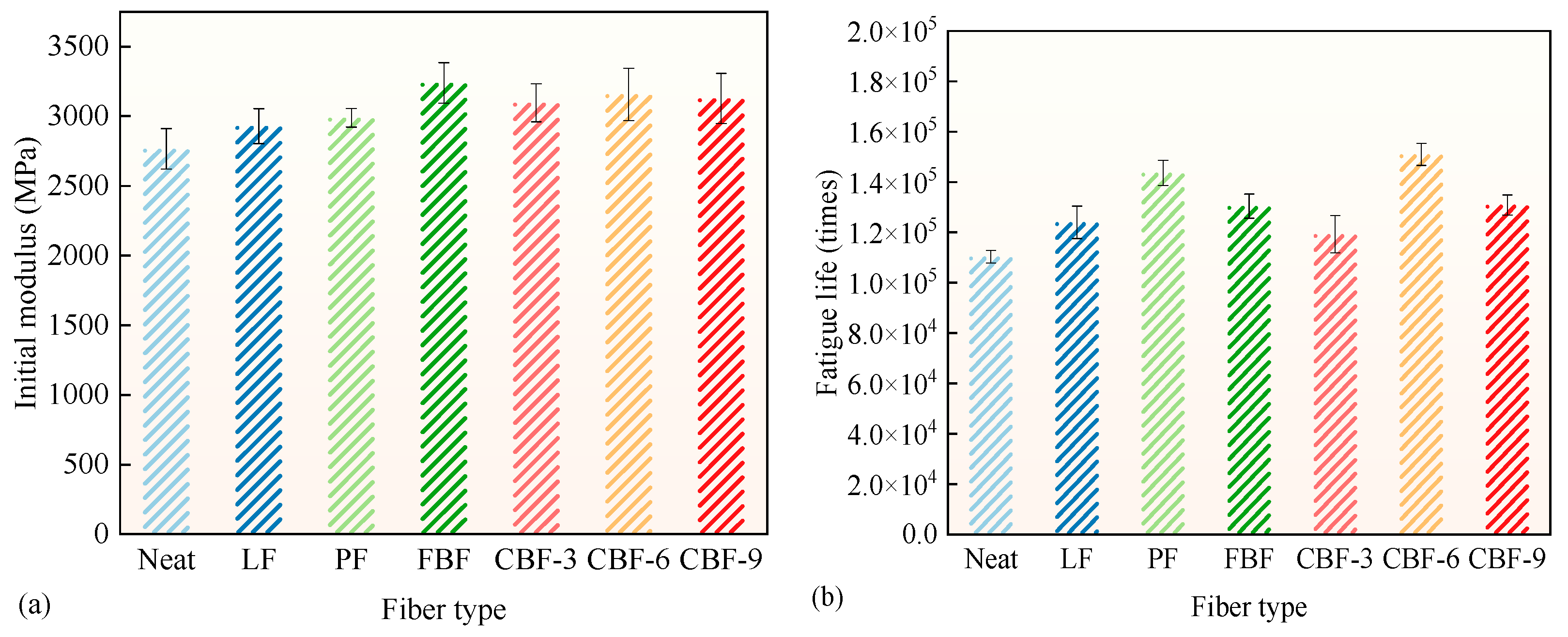

3.5. Fatigue Cracking Resistance

3.6. Fiber–Asphalt Interface Morphology

4. Conclusions

- (1)

- All fibers significantly improved the low-temperature flexural–tensile performance of SMA-13. PF exhibited the best enhancement, with a 26.8% increase in bending strength and a 16.6% improvement in MBS value. Among CBF lengths, the 6 mm CBF outperformed its 3 mm and 9 mm counterparts.

- (2)

- Fibers significantly enhanced the tensile cracking resistance of SMA-13, as indicated by increased fracture energy and CTindex. 6 mm CBF and FBF showed the most prominent effects, with fracture energy increases of 29.8% and 27.9%, respectively.

- (3)

- The SCB test findings indicated that 6 mm CBF and PF optimized crack propagation resistance, with fracture energy increases of 53.2% and 47.6%, respectively. The moderate fiber length (6 mm) performed better, while inadequate dispersion (for FBF) and suboptimal length (3 mm/9 mm CBF) limited enhancement efficacy.

- (4)

- The OT results demonstrated that FBF provided the best resistance to reflective cracking (30.0% higher peak load and 48.0% more loading cycles), followed by 6 mm CBF.

- (5)

- The 4PB fatigue test further highlighted 6 mm CBF as the best-performing fiber (+36.9% improvement), followed by PF (+30.2% improvement), with other fibers showing moderate or limited improvement.

- (6)

- SEM analysis indicated that fiber morphology and interfacial bonding strongly governed mixture performance. PF and 6 mm CBF exhibited favorable structures for coating and dispersion, while LF and FBF faced challenges due to aggregation or non-uniform distribution.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Han, Z.; Pang, Y.; Lin, H. Improvement of Cold Recycled Mixture Performance Based on Improved Density Test Method and RAP Characteristics. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2025, 40, 79–87. [Google Scholar] [CrossRef]

- Du, X.; Lin, H.; Sun, M.; Liu, W.; Zhang, H. Field Compaction Characteristics of Ultra-Thin Porous Friction Course Based on Laboratory Simulation. Appl. Sci. 2024, 14, 5489. [Google Scholar] [CrossRef]

- Kong, L.; Xu, J.; Yang, H.; Wu, P.; Li, X.; Ma, D.; Wang, Z.; Ren, D.; Ai, C. Enhancing crack resistance in basalt fiber asphalt mixtures: A full-field time-domain investigation of stress distribution and pore structure optimisation. Int. J. Pavement Eng. 2025, 26, 2460746. [Google Scholar] [CrossRef]

- Song, Y.; Sun, Y. Low-Temperature Crack Resistance of Basalt Fiber-Reinforced Phase-Change Asphalt Mixture Based on Digital-Image Correlation Technology. J. Mater. Civ. Eng. 2023, 35, 04023141. [Google Scholar] [CrossRef]

- Hajek, J.J.; HAAS, R.C.G. Factor Analysis of Pavement Distresses for Surface Condition Predictions. In Transportation Research Record 1117; Transportation Research Board: Washington, DC, USA, 1987; pp. 125–133. [Google Scholar]

- Wu, B.; Pei, Z.; Luo, C.; Xia, J.; Chen, C.; Kang, A. Effect of different basalt fibers on the rheological behavior of asphalt mastic. Constr. Build. Mater. 2022, 318, 125718. [Google Scholar] [CrossRef]

- Wu, B.; Pei, Z.; Xiao, P.; Lou, K.; Wu, X. Influence of fiber-asphalt interface property on crack resistance of asphalt mixture. Case Stud. Constr. Mater. 2022, 17, e01703. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Y.; Bahia, H.U. The role of binders in mixture cracking resistance measured by ideal-CT test. Int. J. Fatigue 2021, 142, 105947. [Google Scholar] [CrossRef]

- Phan, T.M.; Nguyen, S.N.; Seo, C.-B.; Park, D.-W. Effect of treated fibers on performance of asphalt mixture. Constr. Build. Mater. 2021, 274, 122051. [Google Scholar] [CrossRef]

- Hajiloo, H.R.; Karimi, H.R.; Aliha, M.R.M.; Zanjirani Farahani, H.; Salehi, S.M.; Hajiloo, M.; Jafari Haghighatpour, P. Crack resistance of fiber-reinforced asphalt mixtures: Effect of test specimen and test condition. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 921–937. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Li, B.; Kang, A.; Wang, Y. Evaluation of Cracking Resistance of SMA-13 Hot Recycling Asphalt Mixtures Reinforced by Basalt Fiber. Materials 2024, 17, 1762. [Google Scholar] [CrossRef] [PubMed]

- Kaloush, K.E.; Biligiri, K.P.; Zeiada, W.A.; Rodezno, M.C.; Reed, J.X. Evaluation of Fiber-Reinforced Asphalt Mixtures Using Advanced Material Characterization Tests. J. Test. Eval. 2010, 38, 400–411. [Google Scholar] [CrossRef]

- Jia, H.; Sheng, Y.; Guo, P.; Underwood, S.; Chen, H.; Kim, Y.R.; Li, Y.; Ma, Q. Effect of synthetic fibers on the mechanical performance of asphalt mixture: A review. J. Traffic Transp. Eng. (Engl. Ed.) 2023, 10, 331–348. [Google Scholar] [CrossRef]

- Luo, D.; Khater, A.; Yue, Y.; Abdelsalam, M.; Zhang, Z.; Li, Y.; Li, J.; Iseley, D.T. The performance of asphalt mixtures modified with lignin fiber and glass fiber: A review. Constr. Build. Mater. 2019, 209, 377–387. [Google Scholar] [CrossRef]

- Chen, H.; Xu, Q.; Chen, S.; Zhang, Z. Evaluation and design of fiber-reinforced asphalt mixtures. Mater. Des. 2009, 30, 2595–2603. [Google Scholar] [CrossRef]

- Abtahi, S.M.; Sheikhzadeh, M.; Hejazi, S.M. Fiber-reinforced asphalt-concrete—A review. Constr. Build. Mater. 2010, 24, 871–877. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Ji, G.; Fan, Z.; Guo, Y.; Gao, W.; Xin, L. Mechanical Performance Characterization of Lignin-Modified Asphalt Mixture. Appl. Sci. 2020, 10, 3324. [Google Scholar] [CrossRef]

- Wu, S.; Ye, Q.; Li, N. Investigation of rheological and fatigue properties of asphalt mixtures containing polyester fibers. Constr. Build. Mater. 2008, 22, 2111–2115. [Google Scholar] [CrossRef]

- Ye, Q.; Wu, S.; Li, N. Investigation of the dynamic and fatigue properties of fiber-modified asphalt mixtures. Int. J. Fatigue 2009, 31, 1598–1602. [Google Scholar] [CrossRef]

- Sun, X.; Qin, X.; Chen, Q.; Ma, Q. Investigation of enhancing effect and mechanism of basalt fiber on toughness of asphalt material. Pet. Sci. Technol. 2018, 36, 1710–1717. [Google Scholar] [CrossRef]

- Gu, Q.; Kang, A.; Li, B.; Xiao, P.; Ding, H. Effect of fiber characteristic parameters on the high and low temperature rheological properties of basalt fiber modified asphalt mortar. Case Stud. Constr. Mater. 2022, 17, e01247. [Google Scholar] [CrossRef]

- Guo, F.; Li, R.; Lu, S.; Bi, Y.; He, H. Evaluation of the Effect of Fiber Type, Length, and Content on Asphalt Properties and Asphalt Mixture Performance. Materials 2020, 13, 1556. [Google Scholar] [CrossRef]

- Xie, T.; Wang, L. Optimize the design by evaluating the performance of asphalt mastic reinforced with different basalt fiber lengths and contents. Constr. Build. Mater. 2023, 363, 129698. [Google Scholar] [CrossRef]

- Wu, J.; Hu, Y.; Jin, Q.; Ren, H. Macro-microscopic study on the crack resistance of polyester fiber asphalt mixture under dry-wet cycling and neural network prediction. Case Stud. Constr. Mater. 2024, 20, e03058. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, W.; Zhang, Y.; Lv, Q.; Yan, C. Evaluating four typical fibers used for OGFC mixture modification regarding drainage, raveling, rutting and fatigue resistance. Constr. Build. Mater. 2020, 253, 119131. [Google Scholar] [CrossRef]

- Kou, C.; Chen, Z.; Kang, A.; Zhang, M.; Wang, R. Rheological behaviors of asphalt binders reinforced by various fibers. Constr. Build. Mater. 2022, 323, 126626. [Google Scholar] [CrossRef]

- JTG 3410-2025; Technical Standards of the Chinese Technical Specifications for Construction of Highway Asphalt Pavements. Ministry of Transport of the People’s Republic of China: Beijing, China, 2025.

- TP105; Standard Method of Test for Determining the Fracture Energy of Asphalt Mixtures Using the Semicircular Bend Geometry (SCB). AASHTO: Washington, DC, USA, 2020.

- Zhou, F.; Hu, S.; Chen, D.-H.; Scullion, T. Overlay Tester: Simple Performance Test for Fatigue Cracking. Transp. Res. Rec. 2007, 2001, 1–8. [Google Scholar] [CrossRef]

- Wu, B.; Meng, W.; Xia, J.; Xiao, P. Influence of Basalt Fibers on the Crack Resistance of Asphalt Mixtures and Mechanism Analysis. Materials 2022, 15, 744. [Google Scholar] [CrossRef]

- Pang, Y.; Li, H.; Han, Z.; Wu, P.; Lin, H. Performance evaluation of asphalt mixture reinforced by lignin and ceramic fiber. J. Eng. Res. 2023, 13, 1439–1448. [Google Scholar] [CrossRef]

- Adepu, R.; Venkat Ramayya, V.; Mamatha, A.; Vinayaka Ram, V. Fracture studies on basalt fiber reinforced asphalt mixtures with reclaimed asphalt pavement derived aggregates and warm mix additives. Constr. Build. Mater. 2023, 386, 131548. [Google Scholar] [CrossRef]

- Tang, Q.; Xiao, P.; Lou, K.; Wu, Y. Interfacial characteristics of fiber asphalt mastic and aggregates: Impact on mixture crack resistance performance. Constr. Build. Mater. 2024, 414, 134866. [Google Scholar] [CrossRef]

- JTG F40-2004; Technical Specifications for Construction of Highway Asphalt Pavements. Ministry of Transport of the People’s Republic of China: Beijing, China, 2004.

- Wu, S.; Haji, A.; Adkins, I. State of art review on the incorporation of fibres in asphalt pavements. Road Mater. Pavement Des. 2023, 24, 1559–1594. [Google Scholar] [CrossRef]

- Li, H.; Xing, C.; Zhu, B.; Zhang, X.; Gao, Y.; Tang, S.; Cheng, H. Comparative analysis of four styrene-butadiene-styrene (SBS) structure repair agents in the rejuvenation of aged SBS-modified bitumen. Constr. Build. Mater. 2025, 476, 141232. [Google Scholar] [CrossRef]

- D8225; Standard Test Method for Determination of Cracking Tolerance Index of Asphalt Mixture Using the Indirect Tensile Cracking Test at Intermediate Temperature. ASTM: West Conshohocken, PA, USA, 2019; 6p. [CrossRef]

- Li, M.; Han, Z.; Cheng, H.; Yang, R.; Yuan, J.; Jin, T. Low-temperature performance improvement strategies for high RAP content recycled asphalt mixtures: Focus on RAP gradation variability and mixing process. Fuel 2025, 387, 134362. [Google Scholar] [CrossRef]

- Xing, C.; Tang, S.; Chang, Z.; Han, Z.; Li, H.; Zhu, B. A comprehensive review on the plant-mixed cold recycling technology of emulsified asphalt: Raw materials and factors affecting performances. Constr. Build. Mater. 2024, 439, 137344. [Google Scholar] [CrossRef]

- Seitllari, A. Exploring cracking resistance in modified asphalt mixtures through a comparative assessment of mechanical behavior and performance screening indicators. Constr. Build. Mater. 2025, 464, 140187. [Google Scholar] [CrossRef]

- Wei, J.; Mao, J.; Han, Y.; Li, P.; Wu, W.; Yi, C. Influence of Different Fibers on Performance of Bitumen Binders and Thin-Overlay Bitumen Mixtures. Appl. Sci. 2025, 15, 22. [Google Scholar] [CrossRef]

- Malik, M.I.; Ahmad, A.; Mir, M.S.; ul Haq, S.M.; Bhat, M.M. Performance assessment of polyester fiber modified stone matrix asphalt mixtures with statistical analysis. Innov. Infrastruct. Solut. 2024, 9, 315. [Google Scholar] [CrossRef]

- Yucel, A.O. An Evaluation of the Cracking Resistance of Steel- and Glass-Fiber-Reinforced Asphalt Mixtures Produced at Different Temperatures. Sustainability 2023, 15, 13356. [Google Scholar] [CrossRef]

- Yan, J.; Du, X.; Lin, H. Performance Evaluation of Porous Asphalt Mixture Reinforced with Waste Cellulose Acetate Fibers. Sustainability 2025, 17, 3447. [Google Scholar] [CrossRef]

- Cheng, X.; Zhong, B.; Wu, Z. Material-specific coefficients C1 and C2 in Williams-Landel-Ferry equations and phase transition behaviors of asphalt binder reinforced by various basalt fibers. Case Stud. Constr. Mater. 2024, 21, e03619. [Google Scholar] [CrossRef]

- Chen, C.; Li, C.; Zhang, S.; Liu, W.; Lin, H.; Zhang, H. Performance Evaluation on Open-Graded Friction Course Reinforced by Double-Adding Fibers Technology. Processes 2024, 12, 428. [Google Scholar] [CrossRef]

| References | Fiber Type | Test Method | Key Findings |

|---|---|---|---|

| Lin et al. [3] | BF | SCB test | Play a role in refining pore distribution while slowing down the spread of micro-cracks. |

| Song et al. [4] | BF | SCB test | Lower both the crack growth rate and interfacial damage severity, and strengthen resistance to low-temperature cracking. |

| Wu et al. [7] | BF, PF, and polyacrylonitrile fiber (PAF) | IDEAL-CT/SCB test | The interface adhesion characteristics between fibers and asphalt have a great influence on the crack propagation process. |

| Phan et al. [9] | Aramid fiber | IDEAL-CT | Enhance the cracking tolerance index and prolong fatigue life. |

| Hajiloo et al. [10] | Polyolefin–aramid fiber | SCB test | Increases the fracture toughness. |

| Zhang et al. [11] | BF and LF | IDEAL-CT, 3PB and SCB test | LF and BF can improve the low and intermediate temperature crack resistance of hot recycled mixtures. |

| Zhang et al. [17] | LF and lignin powder | 3PB and 4PB test | Lignin powder-modified asphalt enhances the asphalt mixture’s overall mechanical performance, whereas lignin fiber strengthens thermal cracking resistance but weakens fatigue performance. |

| Wu et al. [18] | PF | Dynamic modulus test | PF can improve the fatigue performance of asphalt mixtures, especially under lower stress conditions. |

| Ye et al. [19] | Cellulose, polyester and mineral fiber | Indirect tension fatigue test (ITFT) | Fiber-modified asphalt mixtures showed better fatigue resistance. |

| Xie et al. [23] | 3/6/9 mm BF | BBR | Enhanced cracking potential of asphalt mastics. |

| Sun et al. [20] | BF | Strip tensile test | BF led to the enhancing effect on toughness capacity of asphalt. |

| Zhang et al. [25] | LF, BF, PF, and PAF | 3PB and 4PB test | Fiber modification enhances the overall performance of the mixture, though the efficacy varies significantly. |

| Wu et al. [30] | LF and BF | 4PB and SCB test | Enhances both the fatigue crack resistance and temperature crack resistance of asphalt mixtures. |

| Guo et al. [22] | LF, PF and 6/9/15 mm BF | 3PB test | 6 mm BF enables a significant improvement in the low-temperature cracking resistance of asphalt mixtures. |

| Pang et al. [31] | Lignin and ceramic fiber (CF) | 3PB and 4PB test | SMA mixtures with both fibers had 11% higher low-temperature bending strain and 8% longer fatigue life than those with CF. |

| Adepu et al. [32] | BF | SCB and ITFT | Mixtures containing 30% RAP and 0.60% basalt fiber exhibited the best fracture and fatigue properties. |

| Tang et al. [33] | BF, PF, and glass fiber | Disk-shaped compact tension tests | Fiber incorporation enhances asphalt mixtures’ crack resistance; among fibers where BF outperforms PF and glass fibers. |

| Indices | 25 °C Penetration (0.1 mm) | 5 °C Ductility (cm) | Softening Point (°C) | 135 °C Viscosity (Pa·s) |

|---|---|---|---|---|

| Value | 53.2 | 35 | 68 | 2.6 |

| Standard [34] | 40–60 | ≥20 | ≥60 | ≤3 |

| Indices | Length (mm) | Density (g·cm−3) | Elongation at Break (%) | Tensile Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|

| LF | <6 | 1.10 | 10–15 | <350 | 3–5 |

| PF | 6 | 1.37 | 10–25 | >800 | 10–15 |

| FBF | <6 | 2.77 | 2–6 | 2500–3500 | 100–120 |

| CBF | 3/6/9 | 2.83 | >3 | >2000 | 95~110 |

| Fiber Type | OAC (%) | VV (%) | VMA (%) | VFA (%) | Theoretical Maximum Specific Gravity | Binder Drainage Loss (%) |

|---|---|---|---|---|---|---|

| Neat | 5.95 | 3.7 | 18.2 | 79.4 | 2.544 | 0.08 |

| LF | 6.37 | 3.5 | 17.9 | 80.6 | 2.568 | 0.01 |

| PF | 6.18 | 3.6 | 18.2 | 79.7 | 2.559 | 0.06 |

| FBF | 6.24 | 3.6 | 17.7 | 81.0 | 2.563 | 0.02 |

| CBF-3 | 6.02 | 3.8 | 18.4 | 80.1 | 2.550 | 0.05 |

| CBF-6 | 6.10 | 3.5 | 18.3 | 79.6 | 2.556 | 0.06 |

| CBF-9 | 6.15 | 3.7 | 18.4 | 79.4 | 2.560 | 0.06 |

| Standard [34] | / | 3–4 | ≥17 | 75–85 | / | ≤0.1% |

| Fiber | Fiber Diameter (μm) | |||||

|---|---|---|---|---|---|---|

| ① | ② | ③ | Average Value | Standard Deviation | Coefficient of Variation (CV) | |

| LF | 14.3 | 19.1 | 13.9 | 15.8 | 2.9 | 18.4% |

| PF | 13.5 | 13.4 | 13.5 | 13.5 | 0.1 | 0.4% |

| FBF | 7.9 | 5.6 | 7.0 | 6.8 | 1.2 | 17.0% |

| CBF | 19.6 | 19.7 | 19.8 | 19.7 | 0.1 | 0.5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, K.; Huang, W.; Sun, M.; Zheng, Z.; Lin, H. Effect of Fiber Characteristics on Cracking Resistance Properties of Stone Mastic Asphalt (SMA) Mixture. Polymers 2025, 17, 2623. https://doi.org/10.3390/polym17192623

Yang K, Huang W, Sun M, Zheng Z, Lin H. Effect of Fiber Characteristics on Cracking Resistance Properties of Stone Mastic Asphalt (SMA) Mixture. Polymers. 2025; 17(19):2623. https://doi.org/10.3390/polym17192623

Chicago/Turabian StyleYang, Kai, Wenyuan Huang, Mutian Sun, Zhixian Zheng, and Hongwei Lin. 2025. "Effect of Fiber Characteristics on Cracking Resistance Properties of Stone Mastic Asphalt (SMA) Mixture" Polymers 17, no. 19: 2623. https://doi.org/10.3390/polym17192623

APA StyleYang, K., Huang, W., Sun, M., Zheng, Z., & Lin, H. (2025). Effect of Fiber Characteristics on Cracking Resistance Properties of Stone Mastic Asphalt (SMA) Mixture. Polymers, 17(19), 2623. https://doi.org/10.3390/polym17192623