Progress in Electromagnetic Wave Absorption of Multifunctional Structured Metamaterials

Abstract

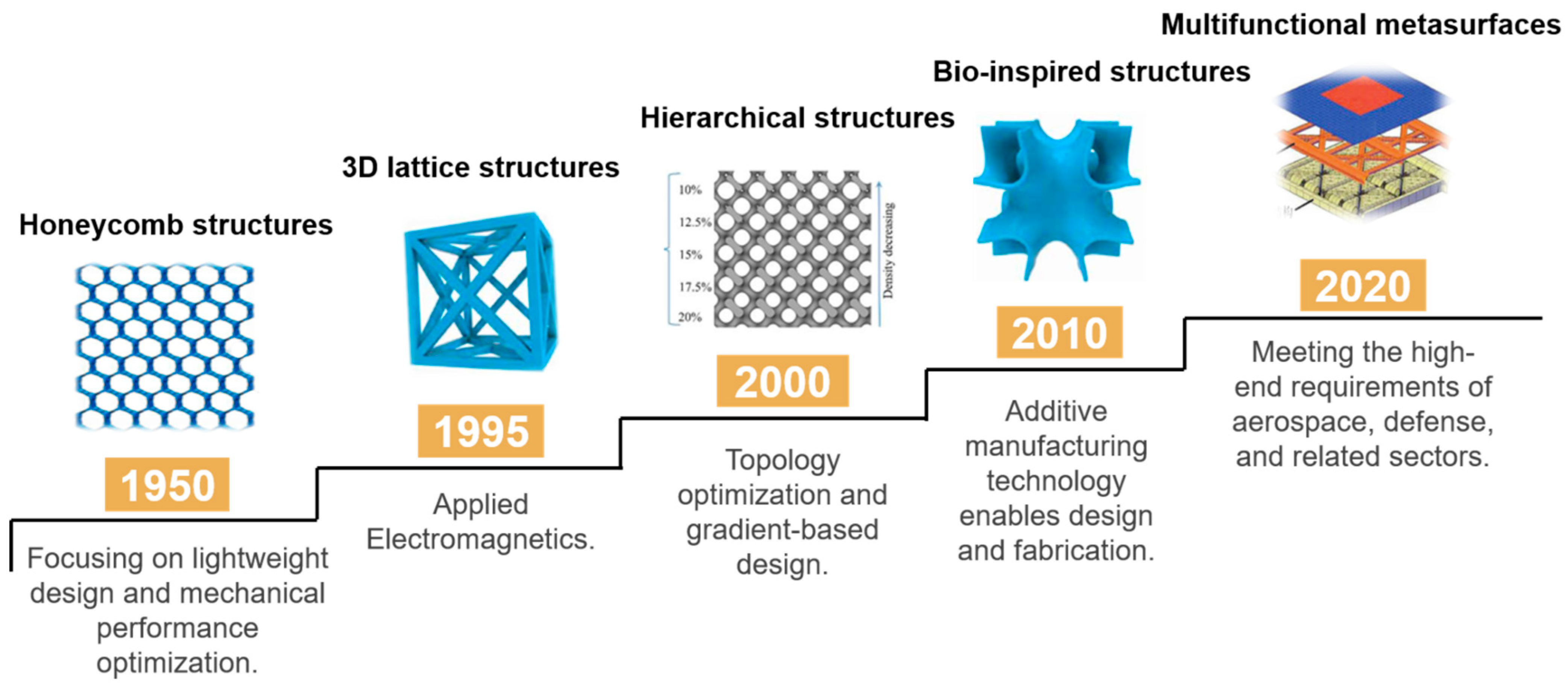

1. Introduction

2. Mechanisms of Electromagnetic Wave Absorption in Multifunctional Metamaterials

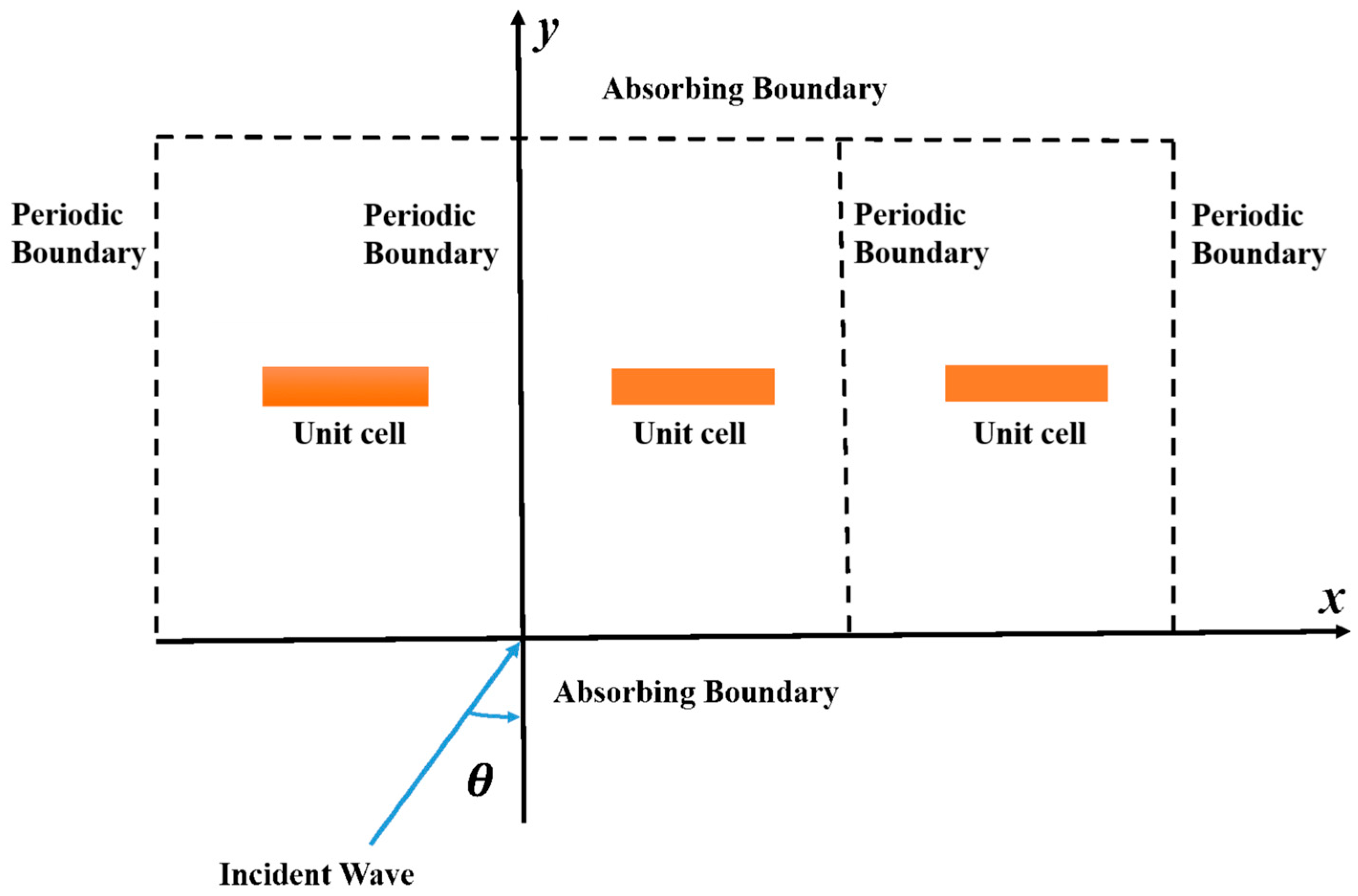

2.1. Electromagnetic Wave Absorption Efficiency

2.2. Electromagnetic Wave Absorption Mechanism

2.3. Electromagnetic Parameters

2.4. Impedance Matching

2.5. Multifunctional

3. Research Progress in Multifunctional Metamaterials for Electromagnetic Wave Absorption

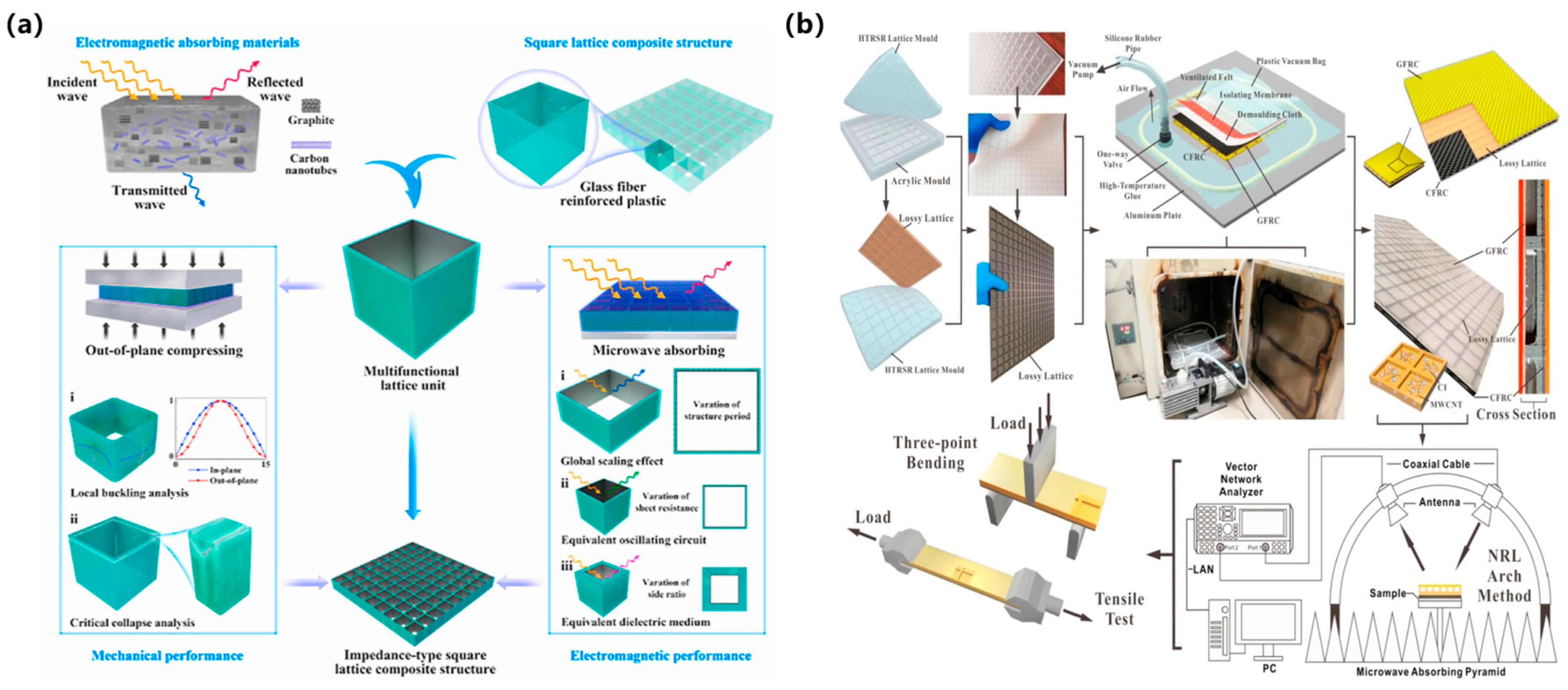

3.1. Three-Dimensional Lattice Structures

3.1.1. Honeycomb Structures

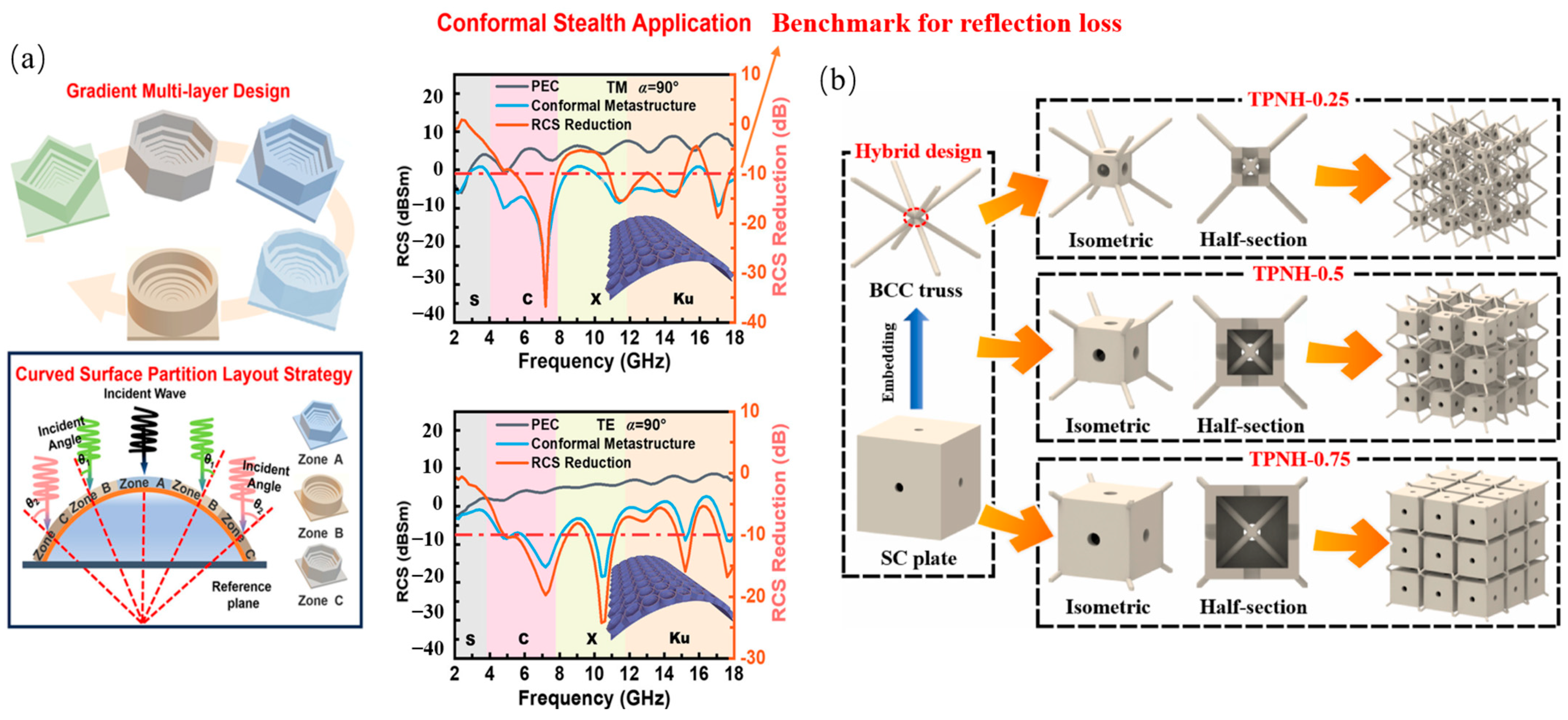

3.1.2. Truss Structures

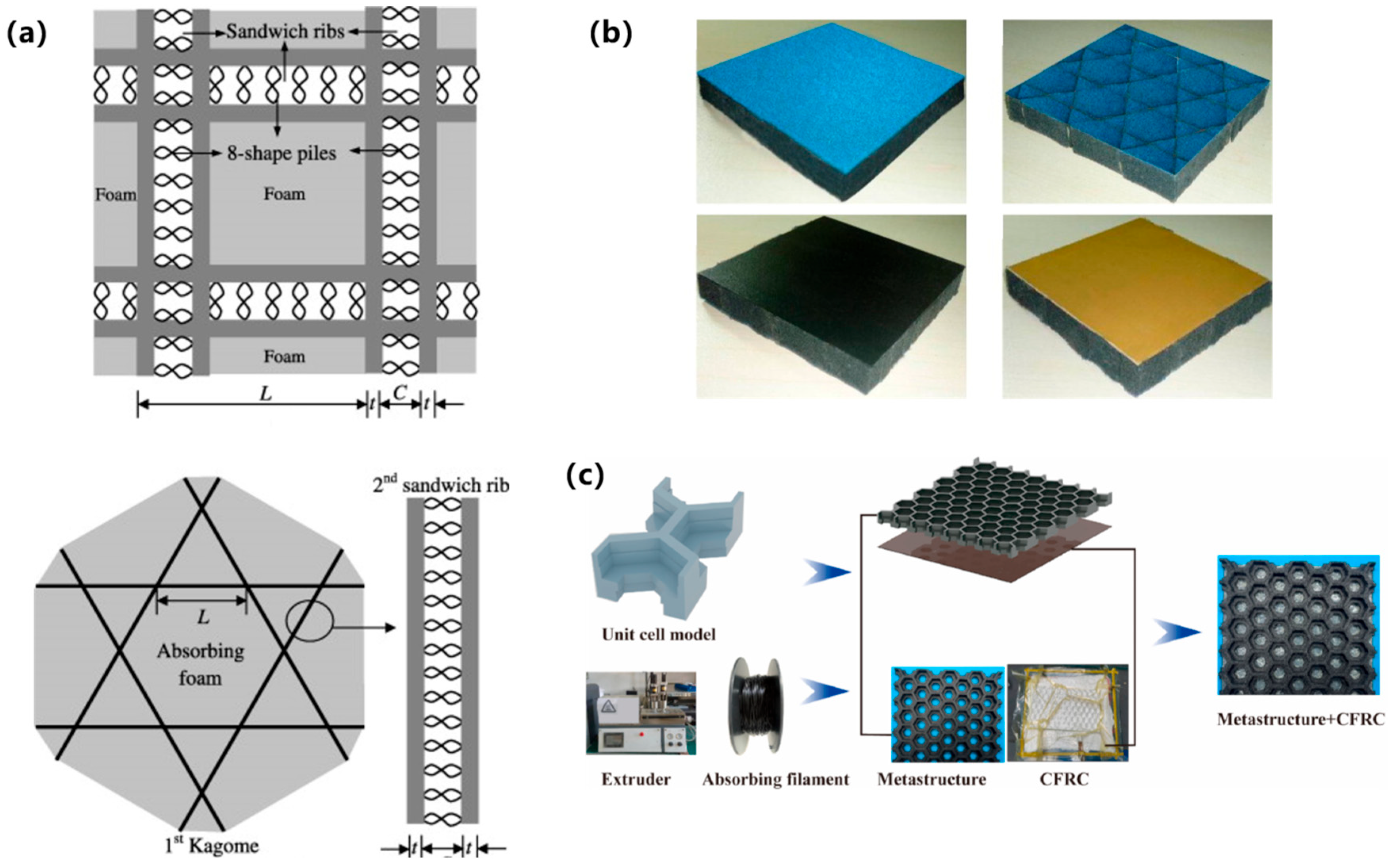

3.1.3. Other Periodic Lattice Structures

3.2. Composite Layered Structures

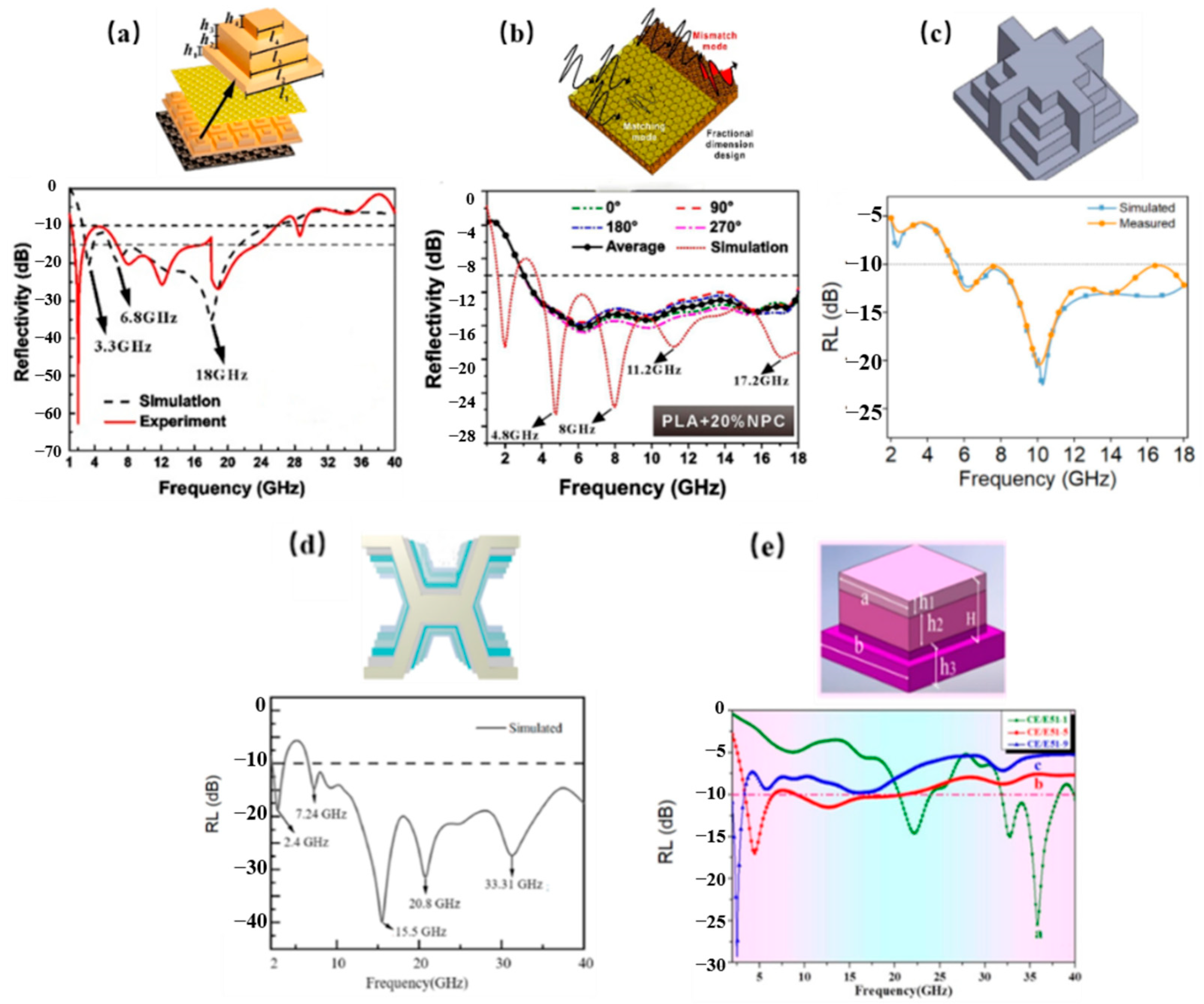

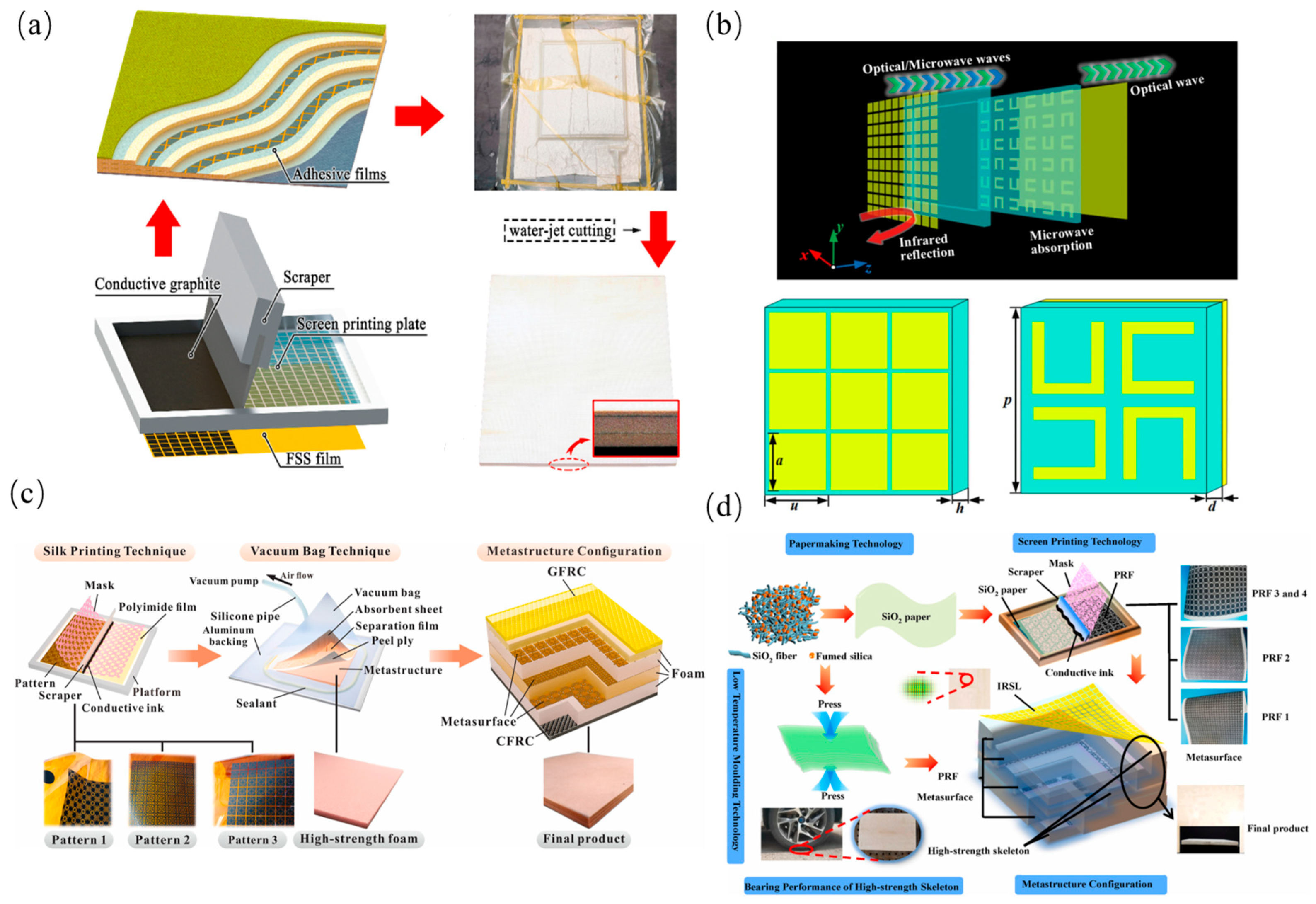

3.2.1. Multilayer Structures

3.2.2. Gradient Structures

3.2.3. Sandwich Structures

3.3. Conformal Structures

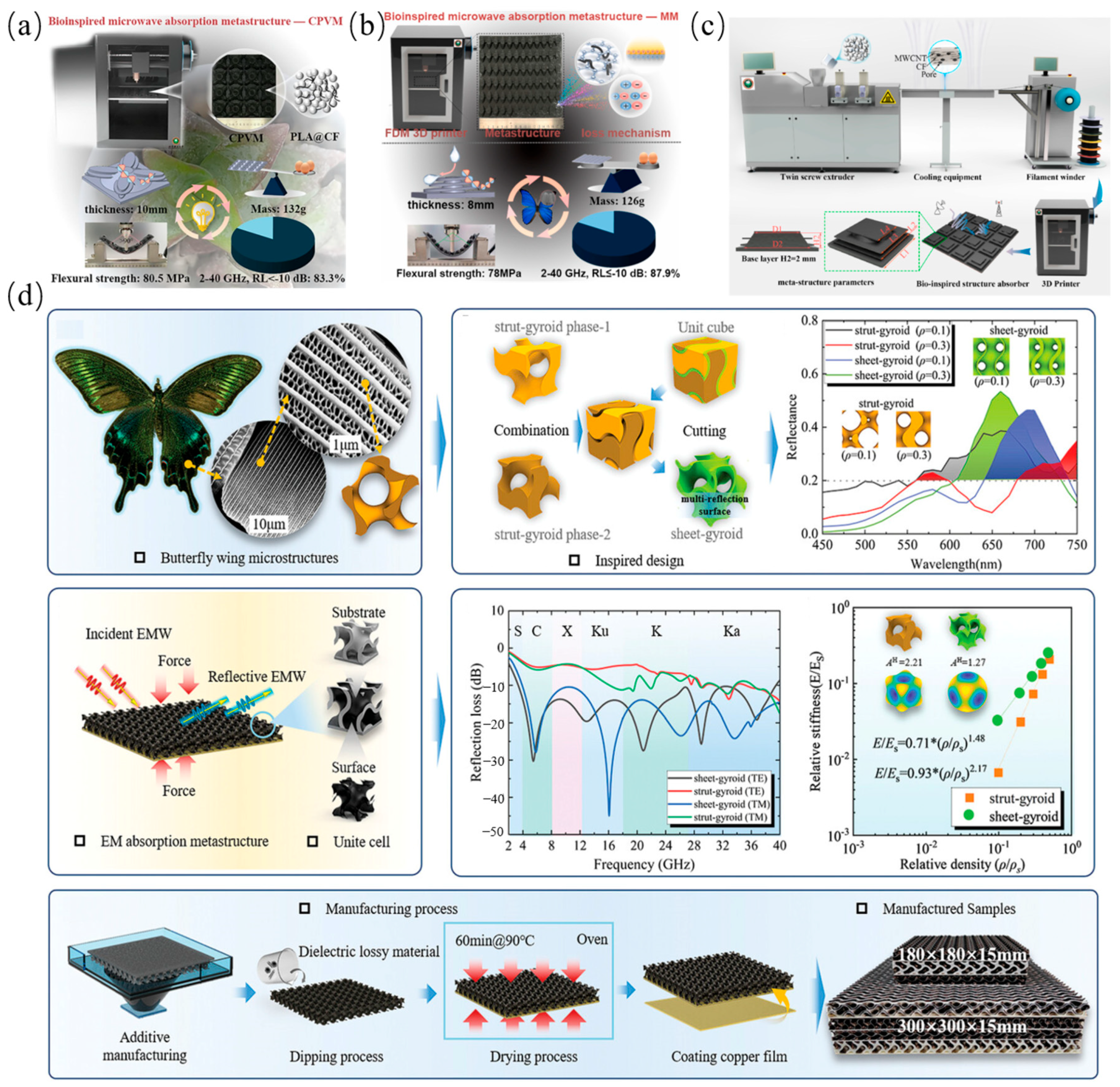

3.4. Bio-Inspired Structure

3.5. Metasurfaces

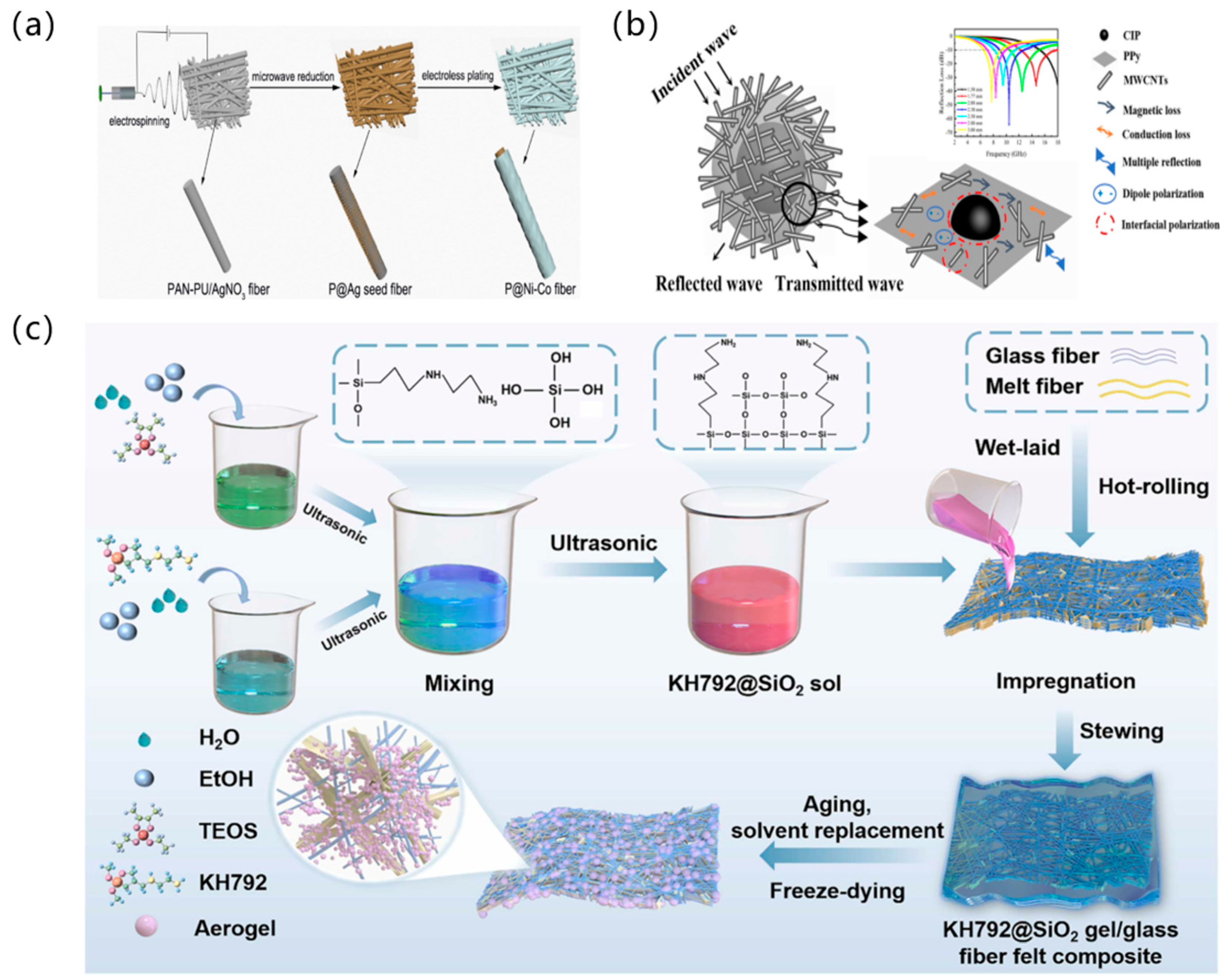

3.6. Composite Metamaterials

4. Conclusions and Outlook

4.1. Conclusions

4.2. Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Smith, D.R.; Padilla, W.J.; Vier, D.C.; Nemat-Nasser, S.C.; Schultz, S. Composite Medium with Simultaneously Negative Permeability and Permittivity. Phys. Rev. Lett. 2000, 84, 4184–4187. [Google Scholar] [CrossRef]

- Qiao, Y.; Meng, Z.; Wang, P.; Yan, D. Research Progress of Bionic Adaptive Camouflage Materials. Front. Mater. 2021, 8, 637664. [Google Scholar] [CrossRef]

- Huang, S.; Fan, Q.; Xu, C.; Wang, B.; Wang, J.; Yang, B.; Tian, C.; Meng, Z. A visible-light-transparent camouflage-compatible flexible metasurface for infrared–radar stealth applications. J. Phys. D Appl. Phys. 2021, 54, 015001. [Google Scholar] [CrossRef]

- Hossain, M.J.; Mubashsara, N.; Khan, R.; Matin, M.A.; Sarigiannidis, P.; Goudos, S.K. Design of an Ultra-thin Metamaterial Absorber with Machine Learning-Assisted Absorption Prediction. IEEE Trans. Artif. Intell. 2025, 1–15. [Google Scholar] [CrossRef]

- Panwar, R.; Puthucheri, S.; Agarwala, V.; Singh, D. Fractal Frequency-Selective Surface Embedded Thin Broadband Microwave Absorber Coatings Using Heterogeneous Composites. IEEE Trans. Microw. Theory Tech. 2015, 63, 2438–2448. [Google Scholar] [CrossRef]

- Sudarsan, H.; Mahendran, K.; Rathika, S. Design of microwave metamaterial absorber for Ku-, X-, and C- band applications. Results Opt. 2024, 15, 100653. [Google Scholar] [CrossRef]

- Qu, N.; Sun, H.; Sun, Y.; He, M.; Xing, R.; Gu, J.; Kong, J. 2D/2D coupled MOF/Fe composite metamaterials enable robust ultra–broadband microwave absorption. Nat. Commun. 2024, 15, 5642. [Google Scholar] [CrossRef]

- Ma, W.; Liu, X.; Yang, T.; Wang, J.; Qiu, Z.; Cai, Z.; Bai, P.; Ji, X.; Huang, Y. Strong Magnetic–Dielectric Synergistic Gradient Metamaterials for Boosting Superior Multispectral Ultra-Broadband Absorption with Low-Frequency Compatibility. Adv. Funct. Mater. 2025, 35, 2314046. [Google Scholar] [CrossRef]

- Wang, D.; Dong, L.; Gu, G. 3D Printed Fractal Metamaterials with Tunable Mechanical Properties and Shape Reconfiguration. Adv. Funct. Mater. 2023, 33, 2208849. [Google Scholar] [CrossRef]

- Zhang, T.; Li, D.; Yang, Z.; Duan, Y.; Zhang, N.; Wang, L.; Liang, Q. A multi-materials 3D-printed continuous conductive fibre-based metamaterial for broadband microwave absorption. Virtual Phys. Prototyp. 2024, 19, e2285417. [Google Scholar] [CrossRef]

- Jiao, P.; Mueller, J.; Raney, J.R.; Zheng, X.R.; Alavi, A.H. Mechanical metamaterials and beyond. Nat. Commun. 2023, 14, 6004. [Google Scholar] [CrossRef] [PubMed]

- Cui, T.J.; Li, L.; Liu, S.; Ma, Q.; Zhang, L.; Wan, X.; Jiang, W.X.; Cheng, Q. Information Metamaterial Systems. iScience 2020, 23, 101403. [Google Scholar] [CrossRef]

- Wu, L.; Xue, J.; Tian, X.; Liu, T.; Li, D. 3D-printed Metamaterials with Versatile Functionalities. Chin. J. Mech. Eng. Addit. Manuf. Front. 2023, 2, 100091. [Google Scholar] [CrossRef]

- Sirote-Katz, C.; Shohat, D.; Merrigan, C.; Lahini, Y.; Nisoli, C.; Shokef, Y. Emergent disorder and mechanical memory in periodic metamaterials. Nat. Commun. 2024, 15, 4008. [Google Scholar] [CrossRef]

- Cui, T. Electromagnetic metamaterials—From effective media to field programmable systems. Sci. Sin. Inform. 2020, 50, 1427. [Google Scholar] [CrossRef]

- Tuong, P.V.; Park, J.W.; Lam, V.D.; Jang, W.H.; Nikitov, S.A.; Lee, Y.P. Dielectric and Ohmic losses in perfectly absorbingmetamaterials. Opt. Commun. 2013, 295, 17–20. [Google Scholar] [CrossRef]

- Jadav, M.; Bhatnagar, S.P. The complex magnetic and dielectric properties of bi-dispersed magnetic fluids. J. Magn. Magn. Mater. 2024, 590, 171614. [Google Scholar] [CrossRef]

- Chen, Y.; Ma, Y.; Yin, Q.; Pan, F.; Cui, C.; Zhang, Z.; Liu, B. Advances in mechanics of hierarchical composite materials. Compos. Sci. Technol. 2021, 214, 108970. [Google Scholar] [CrossRef]

- Tao, R.; Xi, L.; Wu, W.; Li, Y.; Liao, B.; Liu, L.; Leng, J.; Fang, D. 4D printed multi-stable metamaterials with mechanically tunable performance. Compos. Struct. 2020, 252, 112663. [Google Scholar] [CrossRef]

- Ranjan, S.K.; Sahoo, S. A Review of Metamaterial-Based Microwave Absorbers and Sensors. J. Electron. Mater. 2024, 53, 571–595. [Google Scholar] [CrossRef]

- Saeed Zolfaghary pour; Chegini, E.; Mighani, M. Design of wideband metamaterial absorber using circuit theory for X-band applications. IET Microw. Antennas Propag. 2023, 17, 292–300. [Google Scholar] [CrossRef]

- Wu, J.; Yuan, X.; Zhang, Y.; Yan, X.; Zhang, X. Dual-Tunable Broadband Terahertz Absorber Based on a Hybrid Graphene-Dirac Semimetal Structure. Micromachines 2020, 11, 1096. [Google Scholar] [CrossRef] [PubMed]

- Zhong, S.; He, S. Ultrathin and lightweight microwave absorbers made of mu-near-zero metamaterials. Sci. Rep. 2013, 3, 2083. [Google Scholar] [CrossRef]

- Li, C.; Li, D.; Zhang, S.; Ma, L.; Zhang, L.; Zhang, J.; Gong, C. Interface Engineering of Titanium Nitride Nanotube Composites for Excellent Microwave Absorption at Elevated Temperature. Nano-Micro Lett. 2024, 16, 168. [Google Scholar] [CrossRef]

- Maxit, L.; Yang, C.; Cheng, L.; Guyader, J.L. Modeling of micro-perforated panels in a complex vibro-acoustic environment using patch transfer function approach. J. Acoust. Soc. Am. 2012, 131, 2118–2130. [Google Scholar] [CrossRef]

- Hou, Z.-L.; Gao, X.; Zhang, J.; Wang, G. A perspective on impedance matching and resonance absorption mechanism for electromagnetic wave absorbing. Carbon 2024, 222, 118935. [Google Scholar] [CrossRef]

- Wen, B.; Miao, Y.; Zhang, Z.; Li, N.; Xiao, J.; Li, Y.; Feng, J.; Ding, S.; Yang, G. Tuning Electromagnetic Parameters Induced by Synergistic Dual-Polarization Enhancement Mechanisms with Amorphous Cobalt Phosphide with Phosphorus Vacancies for Excellent Electromagnetic Wave Dissipation Performance. Nanomaterials 2023, 13, 3025. [Google Scholar] [CrossRef]

- Pendry, J.B.; Holden, A.J.; Robbins, D.J.; Stewart, W.J. Magnetism from conductors and enhanced nonlinear phenomena. IEEE Trans. Microw. Theory Tech. 1999, 47, 2075–2084. [Google Scholar] [CrossRef]

- Qu, Y.; Chen, Y.; Chen, S.; Wu, Q.; Liu, J.; Yi, Z.; Fu, L. Research on multi-resonance mechanism to achieve ultra-wideband high absorption of a metamaterial absorber in the UV to MIR range. Chin. J. Phys. 2024, 91, 632–643. [Google Scholar] [CrossRef]

- Sharma, S.; Parne, S.R.; Panda, S.S.S.; Gandi, S. Progress in microwave absorbing materials: A critical review. Adv. Colloid Interface Sci. 2024, 327, 103143. [Google Scholar] [CrossRef]

- Jin, Y.; Ping, C.; Wang, R.; Zhu, X.; Ren, S.; Chen, P. Rational design of hierarchical CoNi@SiO2@C multi-shell microspheres for efficient broadband microwave absorption. Compos. Commun. 2025, 57, 102469. [Google Scholar] [CrossRef]

- Luo, H.; Luo, J.; Zhang, Z.; Wu, C.; Li, Q.; Liu, W.; Peng, R.; Wang, M.; Li, H.; Lai, Y. Dielectric metamaterials with effective self-duality and full-polarization omnidirectional brewster effect. Light Sci. Appl. 2024, 13, 262. [Google Scholar] [CrossRef] [PubMed]

- Smith, D.R.; Schultz, S.; Markoš, P.; Soukoulis, C.M. Determination of effective permittivity and permeability of metamaterials from reflection and transmission coefficients. Phys. Rev. B 2002, 65, 195104. [Google Scholar] [CrossRef]

- He, K.; Yu, Q.; Yang, L.; He, Y.; Liu, J.; Chen, W. Graphical impedance-matching method for a superconducting parametric amplifier. Phys. Rev. Appl. 2024, 21, 034055. [Google Scholar] [CrossRef]

- Landy, N.I.; Sajuyigbe, S.; Mock, J.J.; Smith, D.R.; Padilla, W.J. Perfect Metamaterial Absorber. Phys. Rev. Lett. 2008, 100, 207402. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Guan, M.; Cheng, Y.; Li, H.; Ji, G.; Chen, H.; Fu, X.; Awuye, D.E.; Zhu, Y.; Yin, X.; et al. Boehmite-enhanced poly (vinylidene fluoride-co-hexafluoropropylene)/polyacrylonitrile (PVDF-HFP/PAN) coaxial electrospun nanofiber hybrid membrane: A superior separator for lithium-ion batteries. Adv. Compos. Hybrid Mater. 2023, 6, 219. [Google Scholar] [CrossRef]

- Islam, S.S.; Faruque, M.R.I.; Islam, M.T. An Object-Independent ENZ Metamaterial-Based Wideband Electromagnetic Cloak. Sci. Rep. 2016, 6, 33624. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, X.; Han, B.; Ren, B.; Jin, X.; Wu, J.; Wang, Y. The protective mechanism of pyramid lattice on submarine subjected to undex. Sci. Sin. Phys. Mech. Astron. 2021, 51, 124606. [Google Scholar] [CrossRef]

- Wang, D.; Huang, H.; Xu, Y.; Zhao, M. Study on thermal-mechanical coupling performance and failure mechanism of titanium alloy lattice structures in high temperature environment. Xibei Gongye Daxue Xuebao/J. Northwest. Polytech. Univ. 2022, 40, 25–32. [Google Scholar] [CrossRef]

- Zhang, Z.; Ouyang, Y.; Cheng, Y.; Chen, J.; Li, N.; Zhang, G. Size-dependent phononic thermal transport in low-dimensional nanomaterials. Phys. Rep. 2020, 860, 1–26. [Google Scholar] [CrossRef]

- Stinson, V.P.; Shuchi, N.; McLamb, M.; Boreman, G.D.; Hofmann, T. Mechanical Control of the Optical Bandgap in One-Dimensional Photonic Crystals. Micromachines 2022, 13, 2248. [Google Scholar] [CrossRef]

- Wang, D.; Chen, G.; Wang, L. Thermal tunability of photonic bandgaps in liquid crystal filled polymer photonic crystal fiber. Opt. Fiber Technol. 2016, 29, 95–99. [Google Scholar] [CrossRef]

- Xu, C.; Jiang, J.; Yan, M.; Wang, W.; Wang, L.; Wang, J.; Sui, S.; Fan, Q.; Wang, J. Optically transparent infrared stealth metamaterials based on frequency-selective thermal radiator. Infrared Phys. Technol. 2025, 148, 105888. [Google Scholar] [CrossRef]

- Yuan, X.; Chen, M.; Yao, Y.; Guo, X.; Huang, Y.; Peng, Z.; Xu, B.; Lv, B.; Tao, R.; Duan, S.; et al. Recent progress in the design and fabrication of multifunctional structures based on metamaterials. Curr. Opin. Solid State Mater. Sci. 2021, 25, 100883. [Google Scholar] [CrossRef]

- Ma, W.W.S.; Yang, H.; Zhao, Y.; Li, X.; Ding, J.; Qu, S.; Liu, Q.; Hu, Z.; Li, R.; Tao, Q.; et al. Multi-Physical Lattice Metamaterials Enabled by Additive Manufacturing: Design Principles, Interaction Mechanisms, and Multifunctional Applications. Adv. Sci. 2025, 12, 2405835. [Google Scholar] [CrossRef]

- Zhao, Y.; Shan, Y.; Ji, G.; Sun, Y.; Shi, W.; Li, M. Enhanced Microwave-Absorbing Property of Honeycomb Sandwich Structure with a Significant Interface Effect. Materials 2022, 15, 5741. [Google Scholar] [CrossRef] [PubMed]

- Choi, W.-H.; Kim, C.-G. Broadband microwave-absorbing honeycomb structure with novel design concept. Compos. Part B Eng. 2015, 83, 14–20. [Google Scholar] [CrossRef]

- Cha, J.-H.; Jang, W.-H.; Noh, J.-E.; Choi, W.-H.; Kim, C.-G. A space stealth and cosmic radiation shielding composite: Polydopamine-coating and multi-walled carbon nanotube grafting onto an ultra-high-molecular-weight polyethylene/hydrogen-rich benzoxazine composite. Compos. Sci. Technol. 2022, 230, 109711. [Google Scholar] [CrossRef]

- Wang, G.; Li, D.; Liu, T.; Zhang, C.; Xie, Y.M.; Liao, W. Design and manufacturing of lightweight modular broadband microwave absorbing metastructure. Compos. Part B Eng. 2023, 266, 111007. [Google Scholar] [CrossRef]

- Choi, J.-H.; Jang, M.-S.; Jang, W.-H.; Kim, C.-G. Investigation on microwave absorption characteristics of conductive-coated honeycomb absorber. Compos. Struct. 2020, 242, 112129. [Google Scholar] [CrossRef]

- Zhang, Y.; Dong, H.; Yu, C.; Wang, Z.; Huang, Y. Metastructure based broadband structural stealth with material-structure-function integration. Compos. Sci. Technol. 2024, 253, 110661. [Google Scholar] [CrossRef]

- Shaikeea, A.J.D. Exploration of truss metamaterials with graph based generative modeling. Nat. Commun. 2023, 14, 7565. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Q.; Fan, H.; Liu, J.; Ma, Y.; Yang, L. Hierarchical lattice composites for electromagnetic and mechanical energy absorptions. Compos. Part B Eng. 2013, 53, 152–158. [Google Scholar] [CrossRef]

- Yang, L.; Fan, H.; Liu, J.; Ma, Y.; Zheng, Q. Hybrid lattice-core sandwich composites designed for microwave absorption. Mater. Des. 2013, 50, 863–871. [Google Scholar] [CrossRef]

- Lei, H.; Shan, M.; Zhang, Y.; Zhao, P.; Yu, C.; Huang, Y. Design-manufacturing-evaluation integration of microwave absorbing metastructures based on additive manufacturing. Compos. Sci. Technol. 2023, 243, 110270. [Google Scholar] [CrossRef]

- Lim, D.D.; Park, J.; Lee, J.; Noh, D.; Lee, J.; Choi, J.; Choi, W. Broadband mechanical metamaterial absorber enabled by fused filament fabrication 3D printing. Addit. Manuf. 2022, 55, 102856. [Google Scholar] [CrossRef]

- Lim, D.D.; Ibarra, A.; Lee, J.; Jung, J.; Choi, W.; Gu, G.X. A tunable metamaterial microwave absorber inspired by chameleon’s color-changing mechanism. Sci. Adv. 2025, 11, eads3499. [Google Scholar] [CrossRef]

- Zhang, Z.; Lei, H.; Yang, H.; Chen, M.; Wang, C.; Yang, H.; Fang, D. Novel multifunctional lattice composite structures with superior load-bearing capacities and radar absorption characteristics. Compos. Sci. Technol. 2021, 216, 109064. [Google Scholar] [CrossRef]

- Huang, Y.; Yuan, X.; Chen, M.; Song, W.-L.; Chen, J.; Fan, Q.; Tang, L.; Fang, D. Ultrathin multifunctional carbon/glass fiber reinforced lossy lattice metastructure for integrated design of broadband microwave absorption and effective load bearing. Carbon 2019, 144, 449–456. [Google Scholar] [CrossRef]

- Shin, J.-H.; Jang, H.-K.; Choi, W.-H.; Song, T.-H.; Kim, C.-G.; Lee, W.-Y. Design and verification of a single slab RAS through mass production of glass/MWNT added epoxy composite prepreg. J. Appl. Polym. Sci. 2015, 132, 42019. [Google Scholar] [CrossRef]

- Choi, W.-H.; Kwak, B.-S.; Kweon, J.-H.; Nam, Y.-W. Radar-absorbing foam-based sandwich composite with electroless nickel-plated glass fabric. Compos. Struct. 2020, 243, 112252. [Google Scholar] [CrossRef]

- Pang, Y.; Li, Y.; Wang, J.; Yan, M.; Chen, H.; Sun, L.; Xu, Z.; Qu, S. Carbon fiber assisted glass fabric composite materials for broadband radar cross section reduction. Compos. Sci. Technol. 2018, 158, 19–25. [Google Scholar] [CrossRef]

- Choi, W.-H.; Shin, J.-H.; Song, T.-H.; Kim, J.-B.; Lee, W.-Y.; Kim, C.-G. A thin hybrid circuit-analog (CA) microwave absorbing double-slab composite structure. Compos. Struct. 2015, 124, 310–316. [Google Scholar] [CrossRef]

- Choi, J.; Jung, H.-T. A new triple-layered composite for high-performance broadband microwave absorption. Compos. Struct. 2015, 122, 166–171. [Google Scholar] [CrossRef]

- Lee, W.-J.; Lee, J.-W.; Kim, C.-G. Characteristics of an electromagnetic wave absorbing composite structure with a conducting polymer electromagnetic bandgap (EBG) in the X-band. Compos. Sci. Technol. 2008, 68, 2485–2489. [Google Scholar] [CrossRef]

- Nam, Y.-W.; Choi, J.-H.; Lee, W.-J.; Kim, C.-G. Thin and lightweight radar-absorbing structure containing glass fabric coated with silver by sputtering. Compos. Struct. 2017, 160, 1171–1177. [Google Scholar] [CrossRef]

- Shan, M.; Zhang, Y.; Lei, H.; Zhao, P.; Yu, C.; Huang, Y. Vehicle metastructure skin designed by overall-parameter evolutionary optimization for broadband microwave absorption. Compos. Sci. Technol. 2023, 232, 109880. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, P.; Lu, Q.; Zhang, Y.; Lei, H.; Yu, C.; Huang, Y.; Yu, J. Functional additive manufacturing of large-size metastructure with efficient electromagnetic absorption and mechanical adaptation. Compos. Part A Appl. Sci. Manuf. 2023, 173, 107652. [Google Scholar] [CrossRef]

- Dong, H.; Gao, S.; Yu, C.; Wang, Z.; Zhang, H.; Huang, Y.; Zhao, T.; Li, Y. Design and performance of 3D-Printed ABS@rGO/CF/CeO2 composites for microwave absorption and mechanical strength. Chem. Eng. J. 2024, 499, 156696. [Google Scholar] [CrossRef]

- Huang, Y.; Zhao, P.; Sun, Y.; Liao, H.; Dong, H.; Gao, S.; Li, Q.; Zhao, T.; Li, Y. Design-manufacturing-evaluation integrated of microwave absorption metastructure based on large variation genetic-ant colony fusion optimization algorithm and additive manufacturing. Compos. Commun. 2025, 54, 102264. [Google Scholar] [CrossRef]

- Fan, Q.; Yang, X.; Lei, H.; Liu, Y.; Huang, Y.; Chen, M. Gradient nanocomposite with metastructure design for broadband radar absorption. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105698. [Google Scholar] [CrossRef]

- Jiang, W.; Ma, H.; Yan, L.; Wang, J.; Han, Y.; Zheng, L.; Qu, S. A microwave absorption/transmission integrated sandwich structure based on composite corrugation channel: Design, fabrication and experiment. Compos. Struct. 2019, 229, 111425. [Google Scholar] [CrossRef]

- Shen, L.; Pang, Y.; Yan, L.; Shen, Y.; Xu, Z.; Qu, S. Broadband radar absorbing sandwich structures with enhanced mechanical properties. Results Phys. 2018, 11, 253–258. [Google Scholar] [CrossRef]

- Xu, C.; Wang, B.; Yan, M.; Pang, Y.; Meng, Y.; Wang, W.; Wang, J.; Fan, Q.; Qu, S. An optically transparent sandwich structure for radar-infrared bi-stealth. Infrared Phys. Technol. 2020, 105, 103108. [Google Scholar] [CrossRef]

- Álvarez-Trejo, A.; Cuan-Urquizo, E.; Bhate, D.; Roman-Flores, A. Mechanical metamaterials with topologies based on curved elements: An overview of design, additive manufacturing and mechanical properties. Mater. Des. 2023, 233, 112190. [Google Scholar] [CrossRef]

- Chen, M.; Wang, L.; Liu, G.; Ge, C.; Wang, L.; Liu, T.; Li, D.; Liang, Q.; Huang, Y. Achieving broadband RCS reduction on curved surfaces through gradient unit design and partition layout strategy. Thin-Walled Struct. 2025, 208, 112804. [Google Scholar] [CrossRef]

- Li, L.; Wu, J.; Yang, F.; Li, P.; Lu, G.; Fan, H.; Zhao, J.; Zhang, N.; Yang, Q. Mechanisms of low-frequency bandgap formation and energy absorption of three-dimensional nested hybrid lattice structures. Compos. Part B Eng. 2025, 291, 112045. [Google Scholar] [CrossRef]

- Ge, C.; Dong, H.; Li, Z.; Yu, C.; Wang, Z.; Sun, Y.; Huang, Y.; Zhao, T.; Li, Y.; Wang, L. Bioinspired 3D printed metamaterial for wideband microwave absorption and aerodynamic efficiency. Compos. Sci. Technol. 2024, 257, 110846. [Google Scholar] [CrossRef]

- Dong, H.; Gao, S.; Yu, C.; Wang, Z.; Huang, Y.; Zhao, T.; Li, Y. Enhancing microwave absorption of bio-inspired structure through 3D printed concentric infill pattern. Compos. Part B Eng. 2025, 289, 111924. [Google Scholar] [CrossRef]

- Dong, H.; Zhang, Y.; Yu, C.; Wang, Z.; Huang, Y. Eco-friendly microwave absorption metastructure: Design, optimization, and performance of CPVM based on PLA@CF. Chem. Eng. J. 2024, 493, 152477. [Google Scholar] [CrossRef]

- An, Q.; Li, D.; Liao, W.; Liu, T.; Joralmon, D.; Li, X.; Zhao, J. A Novel Ultra-Wideband Electromagnetic-Wave-Absorbing Metastructure Inspired by Bionic Gyroid Structures. Adv. Mater. 2023, 35, 2300659. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, C.; Yang, H.; Wang, P.; Chen, M.; Lei, H.; Fang, D. Broadband radar absorbing composites: Spatial scale effect and environmental adaptability. Compos. Sci. Technol. 2020, 197, 108262. [Google Scholar] [CrossRef]

- Yuan, Q.; Jiang, J.; Li, Y.; Xu, C.; Cheng, Y.; Jiang, L.; Zhu, Z.; Qin, Z.; Wang, H.; Wang, J.; et al. The compatible method of designing the transparent ultra-broadband radar absorber with low infrared emissivity. Infrared Phys. Technol. 2022, 123, 104114. [Google Scholar] [CrossRef]

- Huang, Y.; Wu, D.; Zhang, K.; Yang, H.; Dong, W.; Chen, M.; Fang, D. Topological designs of mechanical-electromagnetic integrated laminate metastructure for broadband microwave absorption based on bi-directional evolutionary optimization. Compos. Sci. Technol. 2021, 213, 108898. [Google Scholar] [CrossRef]

- An, Z.; Huang, Y.; Zhang, R. High-temperature multispectral stealth metastructure from the microwave-infrared compatible design. Compos. Part B Eng. 2023, 259, 110737. [Google Scholar] [CrossRef]

- Fan, R.; Li, D.; Liao, W.; Liu, T.; Li, X.; Tang, T.; Zhao, J.; Jiang, T. A pattern design strategy for microwave-absorbing coding metamaterials with tortuosity and connectivity. Compos. Part B Eng. 2024, 287, 111880. [Google Scholar] [CrossRef]

- Zhang, N.; Zhao, R.; He, D.; Ma, Y.; Qiu, J.; Jin, C.; Wang, C. Lightweight and flexible Ni-Co alloy nanoparticle-coated electrospun polymer nanofiber hybrid membranes for high-performance electromagnetic interference shielding. J. Alloys Compd. 2019, 784, 244–255. [Google Scholar] [CrossRef]

- Li, S.; Tian, X.; Wang, J.; Ma, L.; Li, C.; Qin, Z.; Qu, S. Ternary heterogeneous core-shell structure CIP@PPy/MWCNTs composites for broadband microwave absorption. Diam. Relat. Mater. 2022, 130, 109420. [Google Scholar] [CrossRef]

- Xue, J.; Liu, L.; Meng, Y.; Chen, Z.; Yang, Y. Constructing powerful interface between glass fiber and silica aerogel via an interfacial molecular bridge allows for excellent acoustic-thermal insulation composites. Constr. Build. Mater. 2025, 465, 140260. [Google Scholar] [CrossRef]

- Choi, J.-H.; Nam, Y.-W.; Jang, M.-S.; Kim, C.-G. Characteristics of silicon carbide fiber-reinforced composite for microwave absorbing structures. Compos. Struct. 2018, 202, 290–295. [Google Scholar] [CrossRef]

| Performance Metric | Core Significance |

|---|---|

| Absorption Strength | Characterized by a reflection loss (RL) ≤ −10 dB, corresponding to ≥90% absorption efficiency. |

| Absorption Bandwidth | Defined as the frequency range over which RL ≤ −10 dB is maintained. |

| Thickness & Weight | Thickness: Typically ≤ 50 mm (for practical applications) Areal Density: Typically ≤ 1.5 g/cm3 (for practical applications) |

| Thermal Stability | Variation in RL (ΔRL) ≤ 2 dB over the operational temperature range (−50 °C to 150 °C) |

| Structural Type | Primary Mechanism | Absorption Characteristics | Representative Applications |

|---|---|---|---|

| 3D Lattice Structures | Multi-reflection & Gradient Impedance | Broadband/High-Loss | Aerospace Stealth |

| Composite Stratification | Interference-Dissipation Synergy | Broadband/Multi-Mechanism | High-Temperature EM Absorption |

| Conformal Architectures | Multi-Scale Resonance & Scattering | Broadband | Wideband Absorbing Materials |

| Bioinspired Topologies | Anti-Reflection & Multi-Level Loss | Wide-Angle/Broadband | Infrared-Microwave Compatible Stealth |

| Metasurfaces | Phase Discontinuity & Near-Field Enhancement | Narrowband/Tunable | Flexible Stealth Screens |

| Structural Archetype | Effective Bandwidth (GHz) | Min. RL (dB) | Thickness/Unit Cell Size (mm) | Figure | Reference |

|---|---|---|---|---|---|

| Honeycomb | 3–16 | −35 | 0.2 |  | [47] |

| 2–20.37 | −41.6 | 4.1 |  | [49] | |

| 2.7–25.2 | −17 | 0.1 |  | [50] | |

| 1.92–17.6 | −30 | --- |  | [51] | |

| Truss | 7–17 | −58.2 | 1.2 |  | [53] |

| 5.8–18 | −30.7 | 1.2 |  | [54] | |

| 2–6.8 10.4–40 | --- | 4 |  | [55] | |

| Other Periodic Lattice | 5.4–18 | --- | 0.2 |  | [58] |

| 3.42–19.73 | −34 | 3.5 |  | [59] | |

| 12.87–17.78 | −29.2 | 1.62 |  | [60] | |

| 5.8–18 | −24 | 3.4 |  | [61] | |

| 8.7–19.2 | −30.5 | 2.7 |  | [62] |

| Structural Archetype | Effective Bandwidth (GHz) | Min. RL (dB) | Thickness/Unit Cell Size (mm) | Figure | Reference |

|---|---|---|---|---|---|

| Multilayer | 8.2–12.4 | −35 | 2.37 |  | [63] |

| 4.7–13.7 | −22.3 | 2.5 |  | [64] | |

| 8.2–12.4 | −33.5 | 3.9 |  | [65] | |

| 8.2–12.4 | −32.3 | 1.84 |  | [66] | |

| Gradient | 1.26–25.8 | −25 | 9.1 |  | [67] |

| 3.03–18 | −26 | 21 |  | [68] | |

| 5.3–39.8 | −15 | 2.2 |  | [69] | |

| 2–18 26.6–40 | −15 | 5 |  | [70] | |

| 5.25–39.47 | −39.95 | 2 |  | [71] | |

| Sandwich | 5.74–7.84 | −19 | 0.2 |  | [72] |

| 2.6–21 | −21 | 9.73 |  | [73] | |

| 5.8–8.3 | −18 | 3.5 |  | [74] |

| Structural Archetype | Effective Bandwidth (GHz) | Min. RL (dB) | Thickness/Unit Cell Size (mm) | Figure | Reference |

|---|---|---|---|---|---|

| Conformal | 5.4–18 | −22.3 | 30 |  | [76] |

| 4.5–18 | --- | 20 |  | [77] |

| Structural Archetype | Effective Bandwidth (GHz) | Min. RL (dB) | Thickness/Unit Cell Size (mm) | Figure | Reference |

|---|---|---|---|---|---|

| Bio-inspired | 2.9–18 23–40 | −47.7 | 8 |  | [78] |

| 4–15.5 18–36.2 | −40 | 10.8 |  | [79] | |

| 4.44–40 | −54.4 | 13 |  | [80] | |

| 2.3–40 | --- | 15 |  | [81] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Z.; Liu, L.; Chen, Z.; Wang, C.; Zhu, X.; Lu, X.; Yuan, H.; Huang, H. Progress in Electromagnetic Wave Absorption of Multifunctional Structured Metamaterials. Polymers 2025, 17, 2559. https://doi.org/10.3390/polym17182559

Lu Z, Liu L, Chen Z, Wang C, Zhu X, Lu X, Yuan H, Huang H. Progress in Electromagnetic Wave Absorption of Multifunctional Structured Metamaterials. Polymers. 2025; 17(18):2559. https://doi.org/10.3390/polym17182559

Chicago/Turabian StyleLu, Zhuo, Luwei Liu, Zhou Chen, Changxian Wang, Xiaolei Zhu, Xiaofeng Lu, Hui Yuan, and Hao Huang. 2025. "Progress in Electromagnetic Wave Absorption of Multifunctional Structured Metamaterials" Polymers 17, no. 18: 2559. https://doi.org/10.3390/polym17182559

APA StyleLu, Z., Liu, L., Chen, Z., Wang, C., Zhu, X., Lu, X., Yuan, H., & Huang, H. (2025). Progress in Electromagnetic Wave Absorption of Multifunctional Structured Metamaterials. Polymers, 17(18), 2559. https://doi.org/10.3390/polym17182559