Deflection Control of Concrete Wide Beams Supporting Columns Using CFRP Composites and Honeycomb Plates

Abstract

1. Introduction

2. Experimental Campaign

2.1. Specimen Details

2.2. Properties of Materials

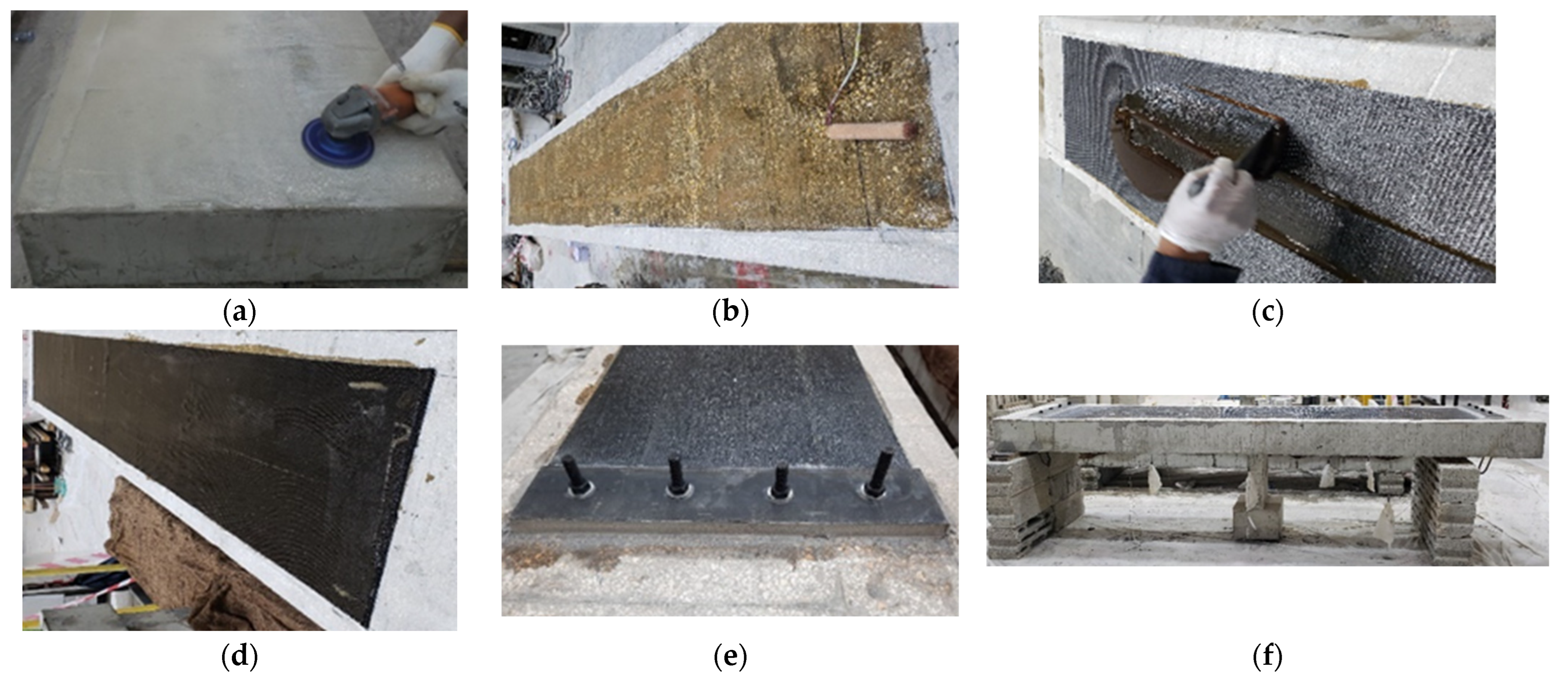

2.3. Preparation of Test Specimens

2.4. Instrumentation and Testing

3. Experimental Results and Discussion

3.1. Failure Modes and Flexural Capacity

3.2. Load–Displacement Response

3.3. Load–Strain Response

3.4. Comparison of Strengthening Schemes

4. Analytical Study

Discussion of Analytical Results

5. Conclusions

- The control beams exhibited the typical flexure failure characteristic of tension-controlled reinforced concrete elements. This included the growth of major flexure cracks near the mid-span, yielding of tension reinforcement, and subsequent concrete crushing at the top (compression zone) surrounding the planted column. In contrast, the failure sequence of the retrofitted beams initiated with the tension rebars’ yielding, then debonding of the CFRP reinforcement, ultimately culminating in the crushing of concrete within the compression region.

- Both strengthening techniques employed in this study proved to be beneficial in upgrading the flexure performance of concrete wide beams, particularly causing enhancement in strength as well as stiffness. Both upgrading schemes significantly reduced the total deflection of beams to a level that satisfied the serviceability requirements of the current codes.

- The inclusion of CFRP reinforcement alone in the specimen WB-CON-S1 resulted in a 65% enhancement in peak load and a 63% enhancement in stiffness in comparison with the control beam WB-CON. The stiffness of WB-CON-S1 was also comparable to that of the ideal control specimen WB-ACI, with only a 6% difference. Additionally, the specimen exhibited a 3% increase in dissipated energy relative to WB-CON; however, this value was 1% lower than that of WB-ACI.

- The adoption of a hybrid strengthening system comprising CFRP sheets and CFRP/honeycomb plates in the specimen WB-CON-S2 led to increases of 71% and 67% in the peak load and stiffness, respectively, relative to the control beam WB-CON. The stiffness of WB-CON-S2 was also closely aligned with that of the ideal control specimen WB-ACI, with only a 4% difference. In addition, the hybrid system significantly improved energy dissipation, showing increases of 80% and 74% in comparison with WB-CON and WB-ACI, respectively.

- Analytical models were presented in this study to estimate the flexural capacity and deflection of both control and strengthened reinforced concrete wide beams. These models demonstrated strong predictive capability, with maximum errors of 7% for peak load and 8% for deflection when compared to the test results.

- A key limitation of the study is the testing of only one specimen per configuration, preventing statistical evaluation of variability. While the responses align with established trends, the restricted sample size limits generality; future studies with multiple replicates and parametric variations are recommended to improve statistical reliability. Additionally, future studies could incorporate full-scale tests or finite element modeling to complement the experiments and enable parametric exploration of RC wide beams upgraded in flexure using FRP and/or honeycomb composites.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-Negheimish, A.I.; El-Sayed, A.K.; Al-Zaid, R.A.; Shuraim, A.B.; Alhozaimy, A.M. Behavior of wide shallow RC beams strengthened with CFRP reinforcement. J. Compos. Constr. 2012, 16, 418–429. [Google Scholar] [CrossRef]

- Conforti, A.; Minelli, F.; Plizzari, G.A. Wide-shallow beams with and without steel fibres: A peculiar behaviour in shear and flexure. Compos. Part B Eng. 2013, 51, 282–290. [Google Scholar] [CrossRef]

- Ibrahim, A.; Askar, H. Dynamic analysis of a multistory frame RC building with and without floating columns. Am. J. Civ. Eng. 2021, 9, 177. [Google Scholar] [CrossRef]

- ur Rehman Khan, A.; Fareed, S. Behaviour of reinforced concrete beams strengthened by CFRP wraps with and without end anchorages. Procedia Eng. 2014, 77, 123–130. [Google Scholar] [CrossRef]

- Kalyani, G.; Pannirselvam, N. Experimental and numerical investigations on RC beams flexurally strengthened utilizing hybrid FRP sheets. Results Eng. 2023, 19, 101337. [Google Scholar] [CrossRef]

- Ali, H.T.; Akrami, R.; Fotouhi, S.; Bodaghi, M.; Saeedifar, M.; Yusuf, M.; Fotouhi, M. Fiber reinforced polymer composites in bridge industry. In Structures; Elsevier: Amsterdam, The Netherlands, 2021; Volume 30, pp. 774–785. [Google Scholar] [CrossRef]

- Vijayan, D.S.; Sivasuriyan, A.; Devarajan, P.; Stefańska, A.; Wodzyński, Ł.; Koda, E. Carbon fibre-reinforced polymer (CFRP) composites in civil engineering application—A comprehensive review. Buildings 2023, 13, 1509. [Google Scholar] [CrossRef]

- Hammad, M.; Bahrami, A.; Khokhar, S.A.; Khushnood, R.A. A State-of-the-Art Review on Structural Strengthening Techniques with FRPs: Effectiveness, Shortcomings, and Future Research Directions. Materials 2024, 17, 1408. [Google Scholar] [CrossRef]

- Pham, N.V.; Ohgaki, K.; Miki, T.; Hidekuma, Y.; Sakurai, S. Seismic retrofitting method using CFRP sheets for H-section steel beam with variable cross section. J. Struct. Eng. 2022, 148, 04022004. [Google Scholar] [CrossRef]

- Phan Viet, N.; Kitano, Y.; Matsumoto, Y. Experimental investigations of the strengthening effects of CFRP for thin-walled storage tanks under dynamic loads. Appl. Sci. 2020, 10, 2521. [Google Scholar] [CrossRef]

- Mallikarjuna, K.; Ravindra, P.M.; Archana, D.P.; Daniyal, M.; Asiri, A.N.M.; Khan, M.A.; Islam, S. Employing carbon fiber reinforced polymer composites toward the flexural strengthening of reinforced concrete T-beams. ACS Omega 2023, 8, 18830. [Google Scholar] [CrossRef]

- Al-Azad, N.; Mojutan, E.C.; Shah, M.K.M. A mini review on natural fiber honeycomb (NFH) sandwiched structure composite: Flexural perfomance perspective. J. Mater. Sci. Chem. Eng. 2021, 9, 1–10. [Google Scholar] [CrossRef]

- Wei, X.; Xiong, J.; Wang, J.; Xu, W. New advances in fiber-reinforced composite honeycomb materials. Sci. China Technol. Sci. 2020, 63, 1348–1370. [Google Scholar] [CrossRef]

- Birman, V.; Kardomateas, G.A. Review of current trends in research and applications of sandwich structures. Compos. Part B Eng. 2018, 142, 221–240. [Google Scholar] [CrossRef]

- Zhao, T.; Yang, J.; Chen, J.; Guan, S. Review of carbon fiber-reinforced sandwich structures. Polym. Polym. Compos. 2022, 30, 09673911221098729. [Google Scholar] [CrossRef]

- Shi, S.; Sun, Z.; Hu, X.; Chen, H. Flexural strength and energy absorption of carbon-fiber–aluminum-honeycomb composite sandwich reinforced by aluminum grid. Thin-Walled Struct. 2014, 84, 416–422. [Google Scholar] [CrossRef]

- Dong, J.; Wang, Q.; Guan, Z. Structural behaviour of RC beams with external flexural and flexural–shear strengthening by FRP sheets. Compos. Part B Eng. 2013, 44, 604–612. [Google Scholar] [CrossRef]

- Zeng, Y.; Li, X.; Ali Ahmed, A.H.; Wu, G. Comparative study on the flexural strengthening of RC beams using EB CFRP sheets, NSM CFRP bars, P-SWRs, and their combinations. Adv. Struct. Eng. 2021, 24, 1009–1023. [Google Scholar] [CrossRef]

- Nguyen, V.N.; Van Cao, V. Experimental and Analytical Study on Postfire Reinforced Concrete Beams Retrofitted with CFRP in Flexure and Shear. Civ. Eng. J. 2023, 9, 1610–1629. [Google Scholar] [CrossRef]

- Askar, M.K.; Hassan, A.F.; Al-Kamaki, Y.S. Flexural and shear strengthening of reinforced concrete beams using FRP composites: A state of the art. Case Stud. Constr. Mater. 2022, 17, e01189. [Google Scholar] [CrossRef]

- Dias, S.J.; Silva, J.R.M.; Barros, J.A. Flexural and shear strengthening of reinforced concrete beams with a hybrid CFRP solution. Compos. Struct. 2021, 256, 113004. [Google Scholar] [CrossRef]

- Turki, A.Y.; Al-Farttoosi, M.H. Flexural Strength of Damaged RC Beams Repaired with Carbon Fiber-Reinforced Polymer (CFRP) Using Different Techniques. Fibers 2023, 11, 61. [Google Scholar] [CrossRef]

- Wang, H.T.; Bian, Z.N.; Xu, G.W.; Chen, M.S.; Xiong, H.; Liu, S.S. Flexural strengthening of large-scale RC beams with nonprestressed and prestressed CFRP using different anchorages. Polymers 2022, 14, 5498. [Google Scholar] [CrossRef]

- Mashrei, M.A.; Makki, J.S.; Sultan, A.A. Flexural strengthening of reinforced concrete beams using carbon fiber reinforced polymer (CFRP) sheets with grooves. Lat. Am. J. Solids Struct. 2019, 16, e176. [Google Scholar] [CrossRef]

- Assad, M.; Hawileh, R.A.; Abdalla, J.A. Flexural strengthening of reinforced concrete beams with CFRP laminates and spike anchors. Compos. Part C Open Access 2024, 13, 100443. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Mohammed, A.; Hawileh, R.A. Flexural strengthening of reinforced concrete beams with externally bonded hybrid systems. Procedia Struct. Integr. 2020, 28, 2312–2319. [Google Scholar] [CrossRef]

- Choobbor, S.S.; Hawileh, R.A.; Abu-Obeidah, A.; Abdalla, J.A. Performance of hybrid carbon and basalt FRP sheets in strengthening concrete beams in flexure. Compos. Struct. 2019, 227, 111337. [Google Scholar] [CrossRef]

- Siddika, A.; Al Mamun, M.A.; Alyousef, R.; Amran, Y.M. Strengthening of reinforced concrete beams by using fiber-reinforced polymer composites: A review. J. Build. Eng. 2019, 25, 100798. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Abbas, H.; Almusallam, T.H.; Al-Salloum, Y.A. Hybrid UHPC/NSM CFRP strips vs. traditional systems for flexural upgrading of RC beams–Experimental and FE study. Compos. Struct. 2021, 261, 113291. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Al-Salloum, Y.A.; Almusallam, T.H.; Alshenawy, A.O.; Abbas, H. Experimental and numerical study on FRP-upgraded RC beams with large rectangular web openings in shear zones. Constr. Build. Mater. 2019, 194, 322–343. [Google Scholar] [CrossRef]

- Almusallam, T.H.; Elsanadedy, H.M.; Al-Salloum, Y.A. Effect of longitudinal steel ratio on behavior of RC beams strengthened with FRP composites: Experimental and FE study. J. Compos. Constr. 2015, 19, 04014028. [Google Scholar] [CrossRef]

- Almusallam, T.; Al-Salloum, Y.; Elsanadedy, H.; Alshenawy, A.; Iqbal, R. Behavior of FRP-strengthened RC beams with large rectangular web openings in flexure zones: Experimental and numerical study. Int. J. Concr. Struct. Mater. 2018, 12, 47. [Google Scholar] [CrossRef]

- Ayaz, Y.; Berktaş, B.; KOÇ, E. Beam Strengthening Using Honeycomb Plates. Int. J. Mech. Prod. Eng. 2017, 5, 100–102. [Google Scholar]

- Essaadaoui, K.; El Fqih, M.A.; Idiri, M.; Boubeker, B. Numerical study on reinforced concrete beams by honeycomb sandwich panel structures. Int. J. Appl. Eng. Res. 2019, 14, 3685–3688. [Google Scholar]

- Kantarci, M.; Maras, M.M.; Ayaz, Y. Experimental performance of RC beams strengthened with aluminum honeycomb sandwich composites and CFRP U-jackets. Exp. Tech. 2023, 47, 767–786. [Google Scholar] [CrossRef]

- Mosallam, A.; Elsanadedy, H.M.; Almusallam, T.H.; Al-Salloum, Y.A.; Alsayed, S.H. Structural evaluation of reinforced concrete beams strengthened with innovative bolted/bonded advanced FRP composites sandwich panels. Compos. Struct. 2015, 124, 421–440. [Google Scholar] [CrossRef]

- El-Sayed, A.K.; Al-Zaid, R.A.; Al-Negheimish, A.I.; Shuraim, A.B.; Alhozaimy, A.M. Long-term behavior of wide shallow RC beams strengthened with externally bonded CFRP plates. Constr. Build. Mater. 2014, 51, 473–483. [Google Scholar] [CrossRef]

- Abass, A.L.; Hassan, Y.R. Flexural Strengthening of Reinforced Concrete Wide Beams with Different Width of CFRP. Diyala J. Eng. Sci. 2017, 10, 14–29. [Google Scholar] [CrossRef]

- Lee, S.J.; Eom, T.S. Shear strength of nonprestressed concrete dapped-end beams with various reinforcement details. Eng. Struct. 2025, 341, 120855. [Google Scholar] [CrossRef]

- Elansary, A.A.; Elnazlawy, Y.Y.; Abdalla, H.A. Shear behaviour of concrete wide beams with spiral lateral reinforcement. Aust. J. Civ. Eng. 2022, 20, 174–194. [Google Scholar] [CrossRef]

- Moubarak, A.M.; Elwardany, H.; El-hassan, K.A.; Taher, S.E.D. Shear strengthening of wide-shallow beams by inserted fasteners. Eng. Struct. 2022, 268, 114554. [Google Scholar] [CrossRef]

- Liu, X.; Lu, Z.D.; Li, L.Z. The use of bolted side plates for shear strengthening of RC beams: A review. Sustainability 2018, 10, 4658. [Google Scholar] [CrossRef]

- Kadhim, M.M.A.; Jaafar, M.S.; Sulaiman, S.A.; Ali, A.S. Experimental Study on RC Beams Strengthened in Flexure with CFRP-Reinforced Systems. Buildings 2023, 13, 2256. [Google Scholar] [CrossRef]

- Abduljabbar, R.A.; Salman, A.; Hasan, H.A. Effects of CFRP Sheets on the Flexural Behavior of High-Strength RC Beams. Materials 2024, 17, 5678. [Google Scholar] [CrossRef]

- ACI Committee, 3.1.8.; 2019 Building Code Requirements for Structural Concrete Commentary, A.C.I.3.1.8.-1.9. American Concrete Institute: Detroit, MI, USA, 2019. [CrossRef]

- Saudi Building Code National Committee (SBCNC). Saudi Building Code 304: Structural Requirements; Edition 200923; Saudi Building Code National Committee: Riyadh, Saudi Arabia, 2018. [Google Scholar]

- ASTM C39/C39M-21; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM E8/E8M-16A; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- ASTM D3039/D3039M-08; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2008. [CrossRef]

- Mander, J.B.; Priestley, M.J.; Park, R. Theoretical stress-strain model for confined concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef]

- ACI Committee 440; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. ACI 440.2R-17; American Concrete Institute: Farmington Hills, MI, USA, 2017.

- ACI Committee 435; Deflections of Reinforced Concrete Flexural Members, ACI 435-95, Reapproved 2000, with Appendix B Added in 2003. American Concrete Institute: Farmington Hills, MI, USA, 2003.

| Specimen ID | Description | No. of Specimens |

|---|---|---|

| WB-CON |

| 1 |

| WB-ACI |

| 1 |

| WB-CON-S1 |

| 1 |

| WB-CON-S2 |

| 1 |

| Total No. of Specimens | 4 | |

| Specimen | Mid-Span Deflection Due to | Total Deflection (δtotal = δL + λδD+SL) (mm) | Allowable Deflection (mm) | Deflection Check | |||

|---|---|---|---|---|---|---|---|

| Dead Load (δD) (mm) | Dead and Live Loads (δD+L) (mm) | Live Load (δL) (mm) | Dead and Sustained Live Loads (δD+SL) (mm) | ||||

| WB-CON | 9.3 | 13.4 | 4.1 | 10.4 | 16.7 | 12.5 | Not good |

| WB-ACI | 5.9 | 8.5 | 2.6 | 6.6 | 11.1 | 12.5 | OK |

| WB-CON-S1 | 6.5 | 9.2 | 2.7 | 7.2 | 11.4 | 12.5 | OK |

| WB-CON-S2 | 6.7 | 9.4 | 2.7 | 7.3 | 11.7 | 12.5 | OK |

| Bar Diameter (mm) | Tensile Strength (MPa) | |

|---|---|---|

| Yield | Ultimate | |

| 8 | 525 | 537 |

| 10 | 547 | 572 |

| 12 | 550 | 657 |

| 18 | 528 | 658 |

| Material | CFRP Sheet * | CFRP Honeycomb Plate * | Epoxy Adhesive Mortar (SIKA-31/41) ** | HM-180C3P Carbon Fiber Impregnated Adhesive ** |

|---|---|---|---|---|

| Elastic modulus (GPa) | 71.46 | 90 | 2.6 | 3.1 |

| Tensile strength (MPa) | 710 | 1100 | 13 | 60 |

| Rupture strain | 0.01 | 0.012 | - | - |

| Thickness per CFRP layer (mm) | 1.0 | 0.65 | - | - |

| Thickness of honeycomb core (mm) | - | 11.7 | - | - |

| Compressive strength (MPa) | - | - | 52 | 95 |

| Bond strength to concrete (MPa) | - | - | >4 | >2.5 |

| Specimen | Cracking Load (kN) | Yield Load (kN) | Peak Load (kN) | Mid-Span Deflection (mm) | Mode of Failure * | |||

|---|---|---|---|---|---|---|---|---|

| At Cracking Load | At Yield Load | At Peak Load | At Ultimate State | |||||

| WB-CON | 21.4 | 140.7 | 185.4 | 1.6 | 18.5 | 49.6 | 119.8 | Y-C |

| WB-ACI | 54.9 | 137.7 | 185.3 | 2.0 | 10.3 | 71.4 | 120.7 | Y-C |

| WB-CON-S1 | 31.9 | 254.7 | 305.1 | 1.7 | 20.6 | 25.7 | 26.9 | Y-IC |

| WB-CON-S2 | 35.2 | 269.8 | 316.6 | 1.7 | 21.2 | 27.3 | 24.2 | Y-IC |

| Specimen | Pre-Cracking Stiffness (kN/mm) | Secant Stiffness (kN/mm) | Post-Cracking Stiffness (kN/mm) | Dissipated Energy (kN·m) | Deflection Ductility |

|---|---|---|---|---|---|

| WB-CON | 13.4 | 7.6 | 7.1 | 19.2 | 6.4 |

| WB-ACI | 27.3 | 13.3 | 10.0 | 19.9 | 11.7 |

| WB-CON-S1 | 18.8 | 12.4 | 11.8 | 19.7 | 5.0 |

| WB-CON-S2 | 20.5 | 12.7 | 12.1 | 34.6 | 7.8 |

| Specimen | Experimental | Analytical | Difference (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Peak Load (kN) | Total Deflection (mm) | Secant Stiffness (kN/mm) | Peak Load (kN) | Total Deflection (mm) | Secant Stiffness (kN/mm) | Peak Load | Total Deflection | Secant Stiffness | |

| WB-CON | 185.4 | 18.1 | 7.6 | 173.3 | 16.7 | 8.1 | 6.5 | 7.6 | 6.6 |

| WB-ACI | 185.3 | 12.1 | 13.3 | 194.5 | 11.1 | 14.6 | 5.0 | 7.6 | 9.7 |

| WB-CON-S1 | 305.1 | 12.1 | 12.4 | 322.2 | 11.4 | 13.6 | 5.6 | 5.8 | 9.6 |

| WB-CON-S2 | 316.6 | 11.1 | 12.7 | 297.8 | 11.7 | 13.2 | 5.9 | 5.4 | 3.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baatiah, A.; Elsanadedy, H.; Abadel, A.; Abbas, H.; Almusallam, T.; Al-Salloum, Y. Deflection Control of Concrete Wide Beams Supporting Columns Using CFRP Composites and Honeycomb Plates. Polymers 2025, 17, 2560. https://doi.org/10.3390/polym17182560

Baatiah A, Elsanadedy H, Abadel A, Abbas H, Almusallam T, Al-Salloum Y. Deflection Control of Concrete Wide Beams Supporting Columns Using CFRP Composites and Honeycomb Plates. Polymers. 2025; 17(18):2560. https://doi.org/10.3390/polym17182560

Chicago/Turabian StyleBaatiah, Abdulaziz, Hussein Elsanadedy, Aref Abadel, Husain Abbas, Tarek Almusallam, and Yousef Al-Salloum. 2025. "Deflection Control of Concrete Wide Beams Supporting Columns Using CFRP Composites and Honeycomb Plates" Polymers 17, no. 18: 2560. https://doi.org/10.3390/polym17182560

APA StyleBaatiah, A., Elsanadedy, H., Abadel, A., Abbas, H., Almusallam, T., & Al-Salloum, Y. (2025). Deflection Control of Concrete Wide Beams Supporting Columns Using CFRP Composites and Honeycomb Plates. Polymers, 17(18), 2560. https://doi.org/10.3390/polym17182560