Processing-Driven Structuring of Polymer-Based Materials: A Brief Overview

Abstract

1. Introduction

1.1. Solvent-Assisted Production of All-Polymer Materials

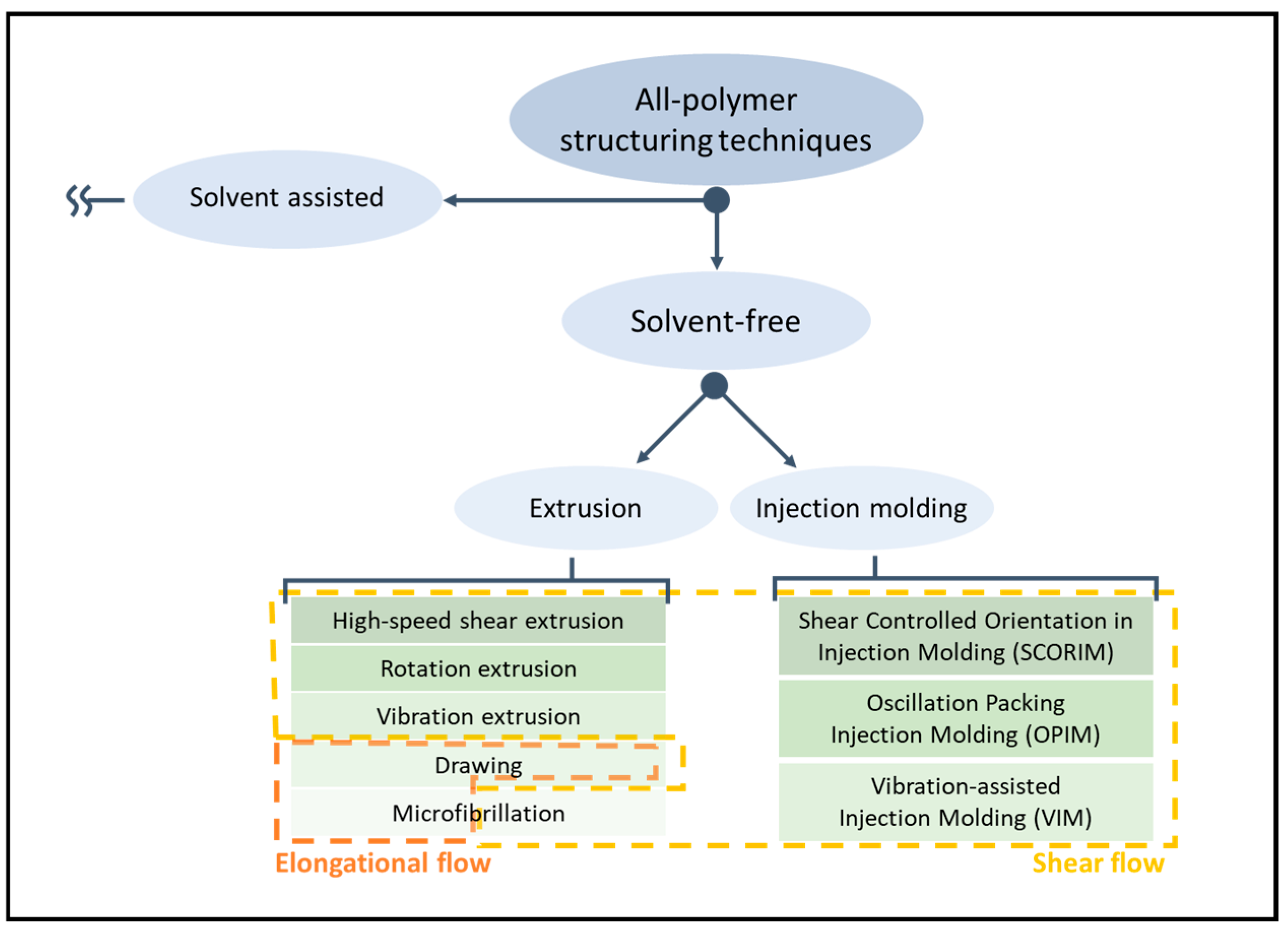

1.2. Solvent-Free Production of All-Polymer Materials

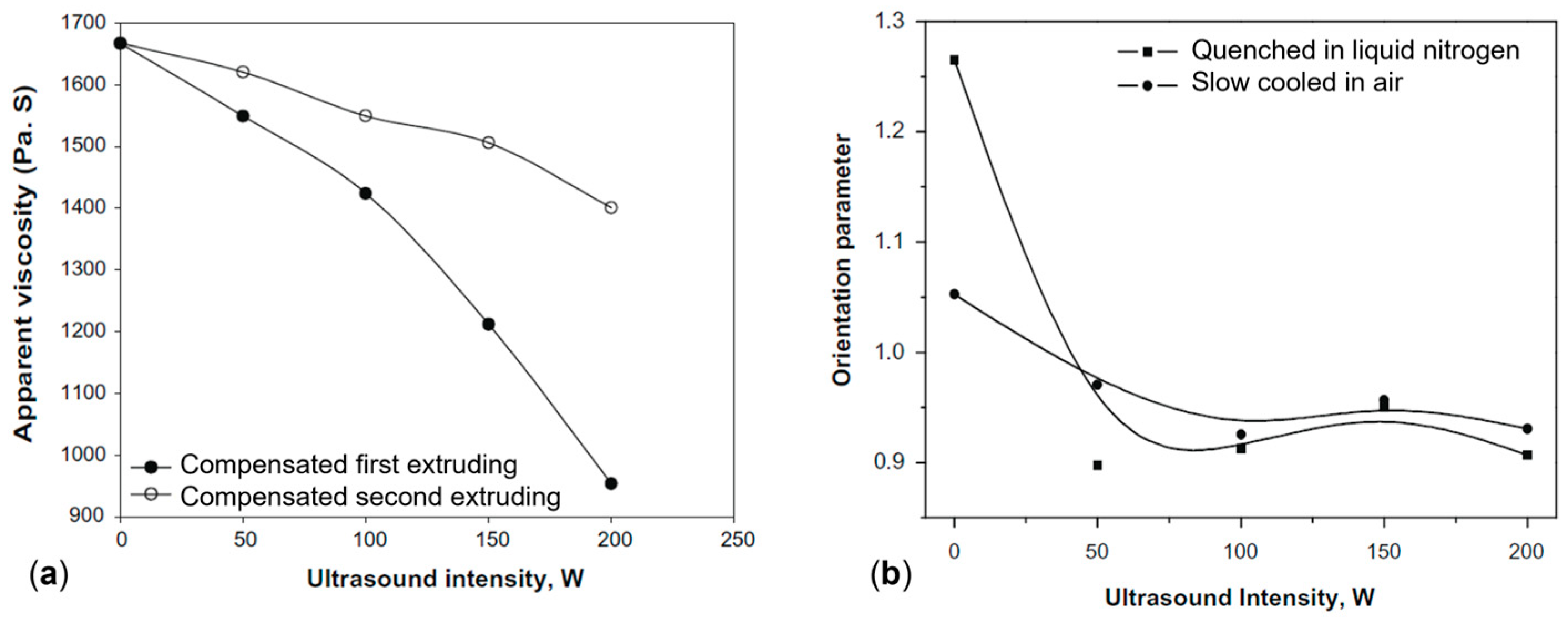

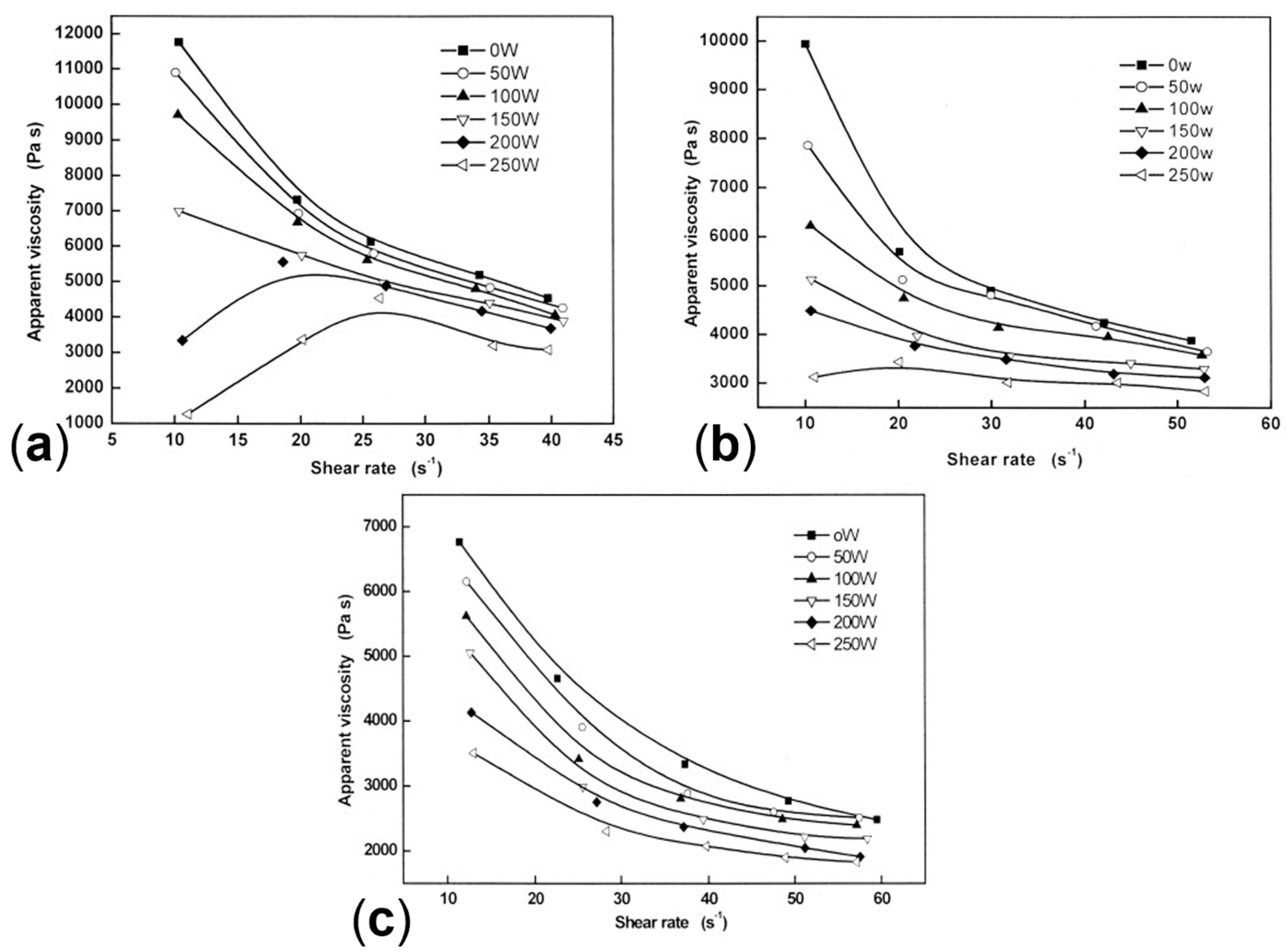

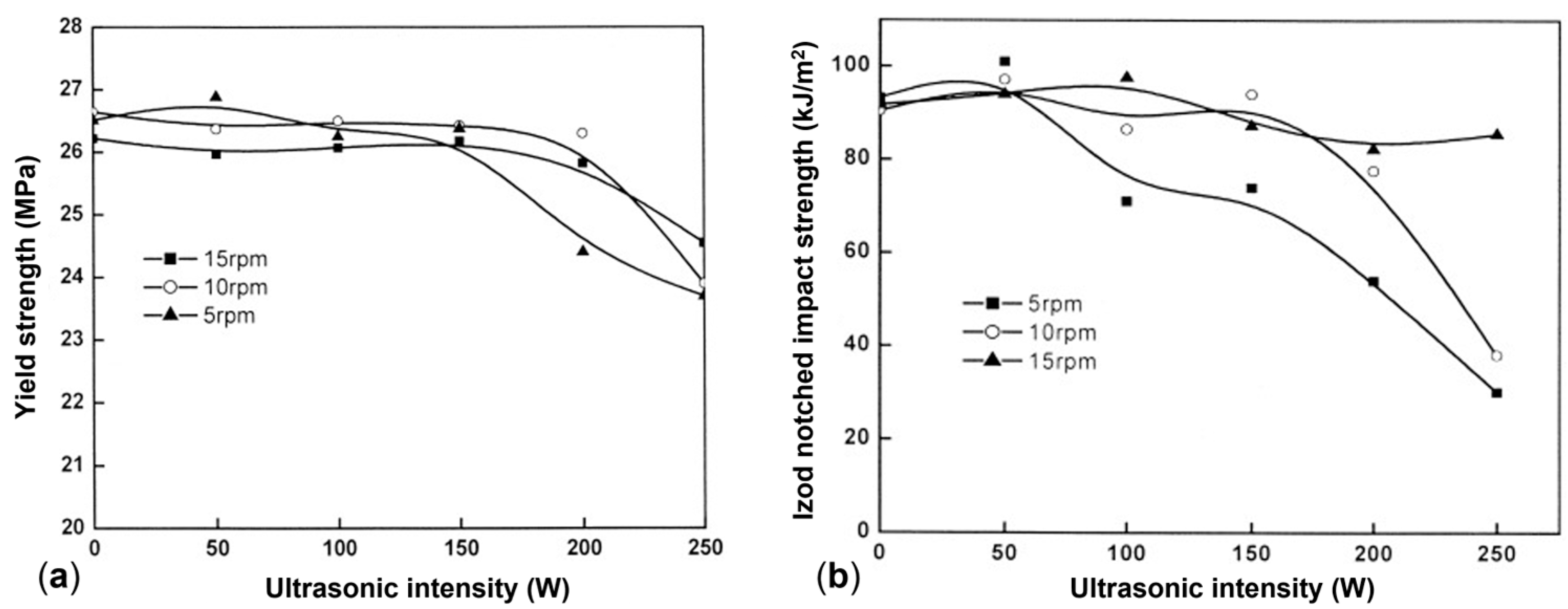

2. Extrusion

2.1. High-Speed Shear Extrusion

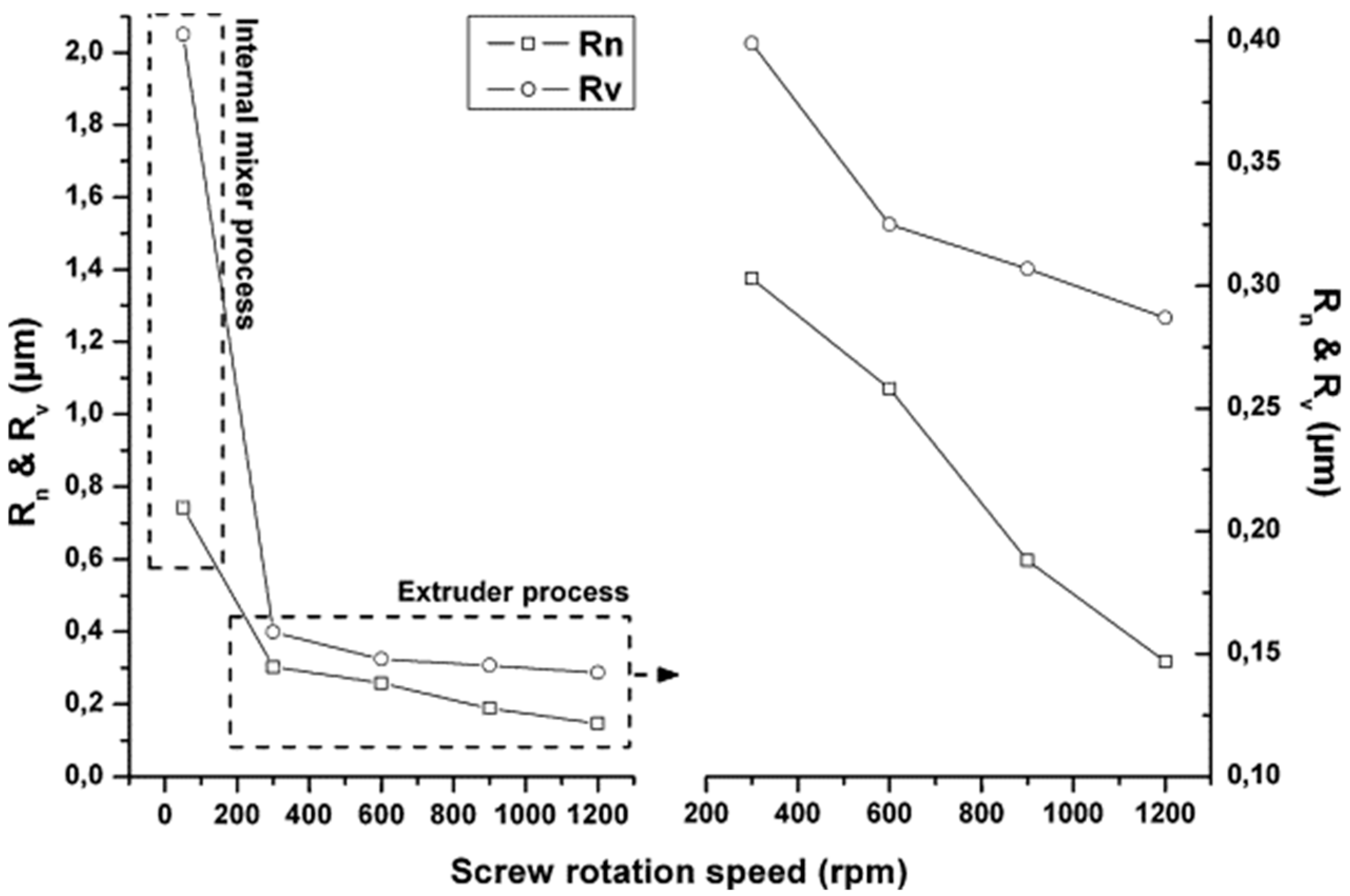

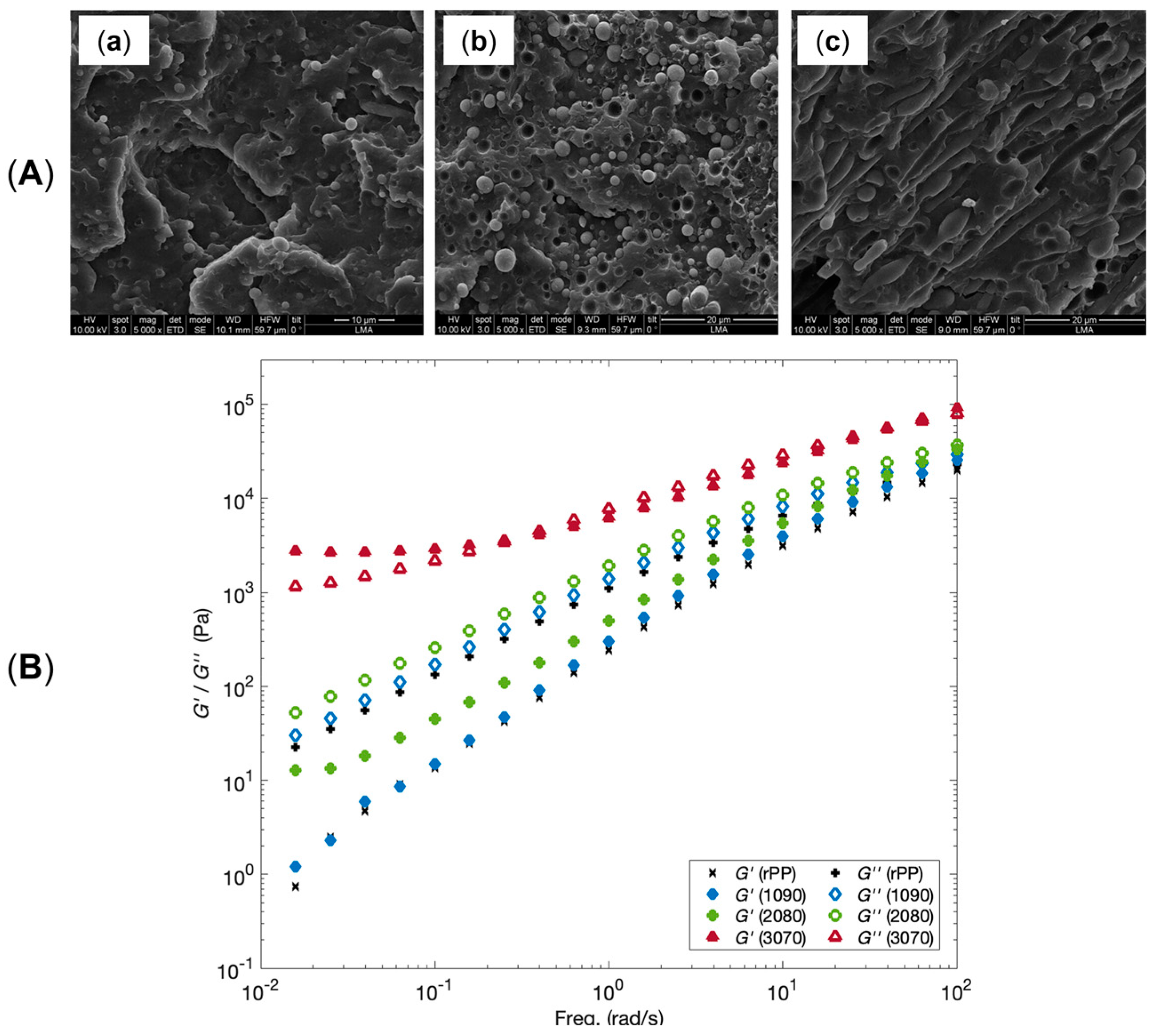

2.1.1. The Role of the Screw Speed

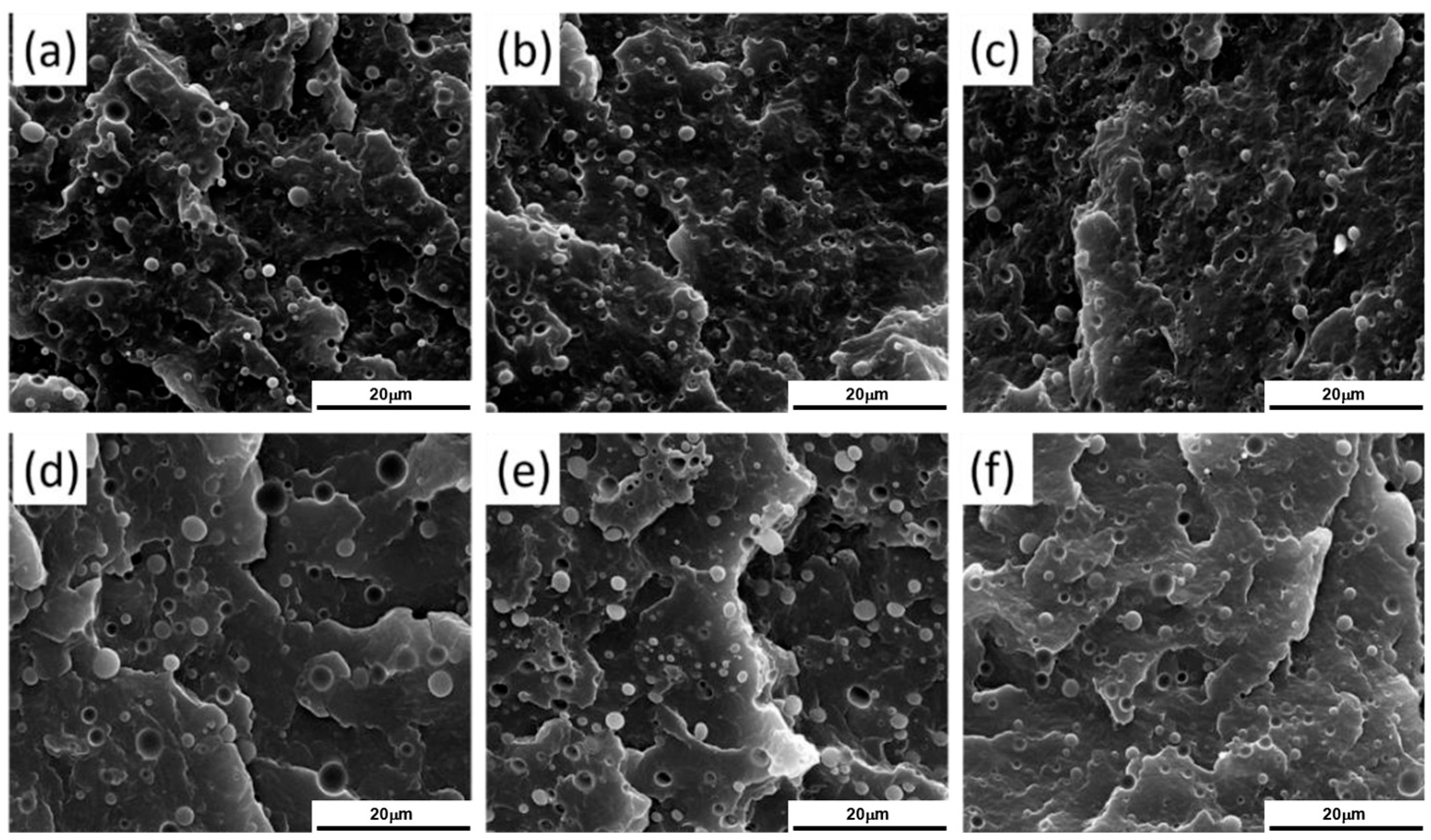

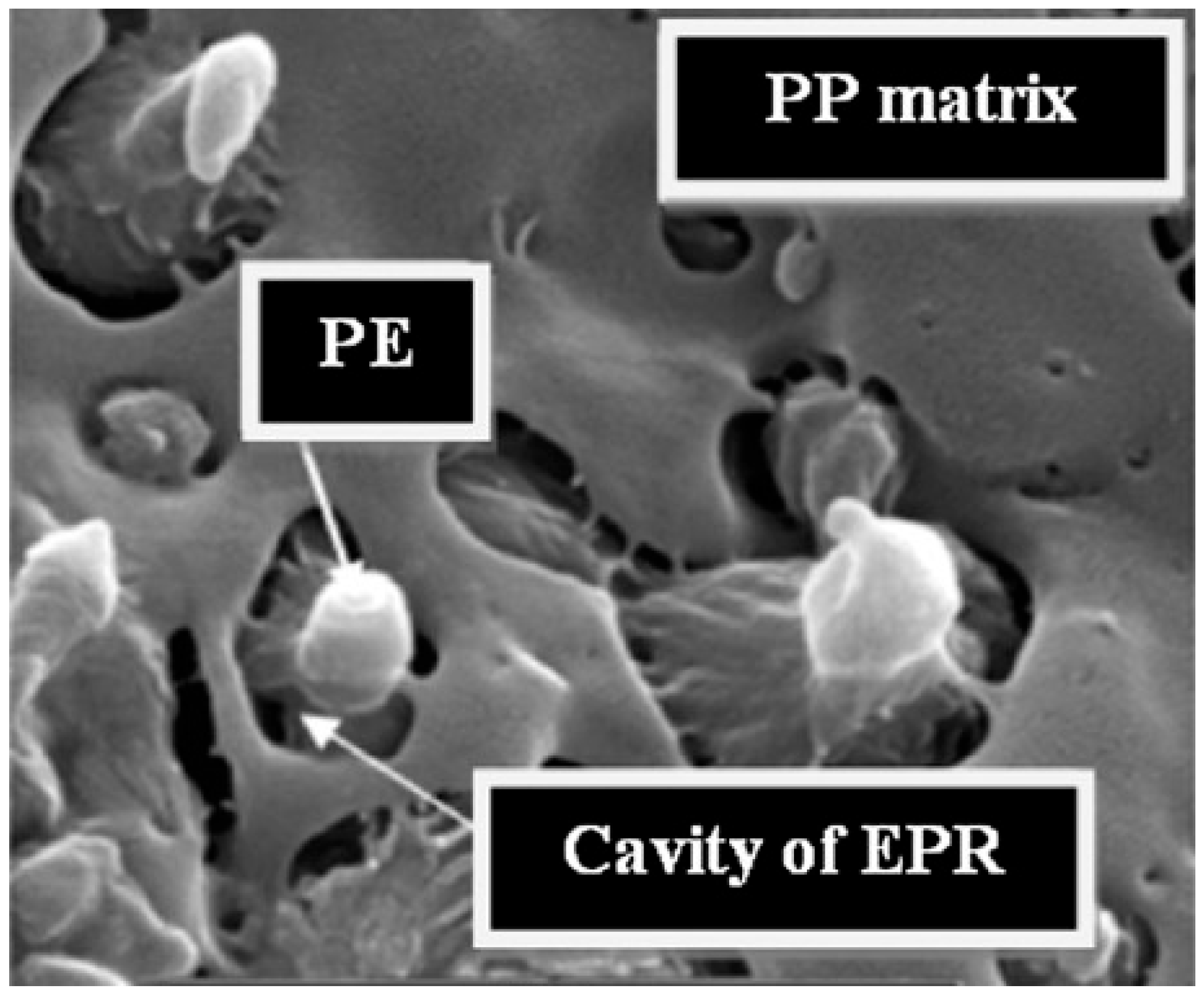

2.1.2. The Role of the Matrix-to-Second-Phase Content

2.2. Rotation Extrusion

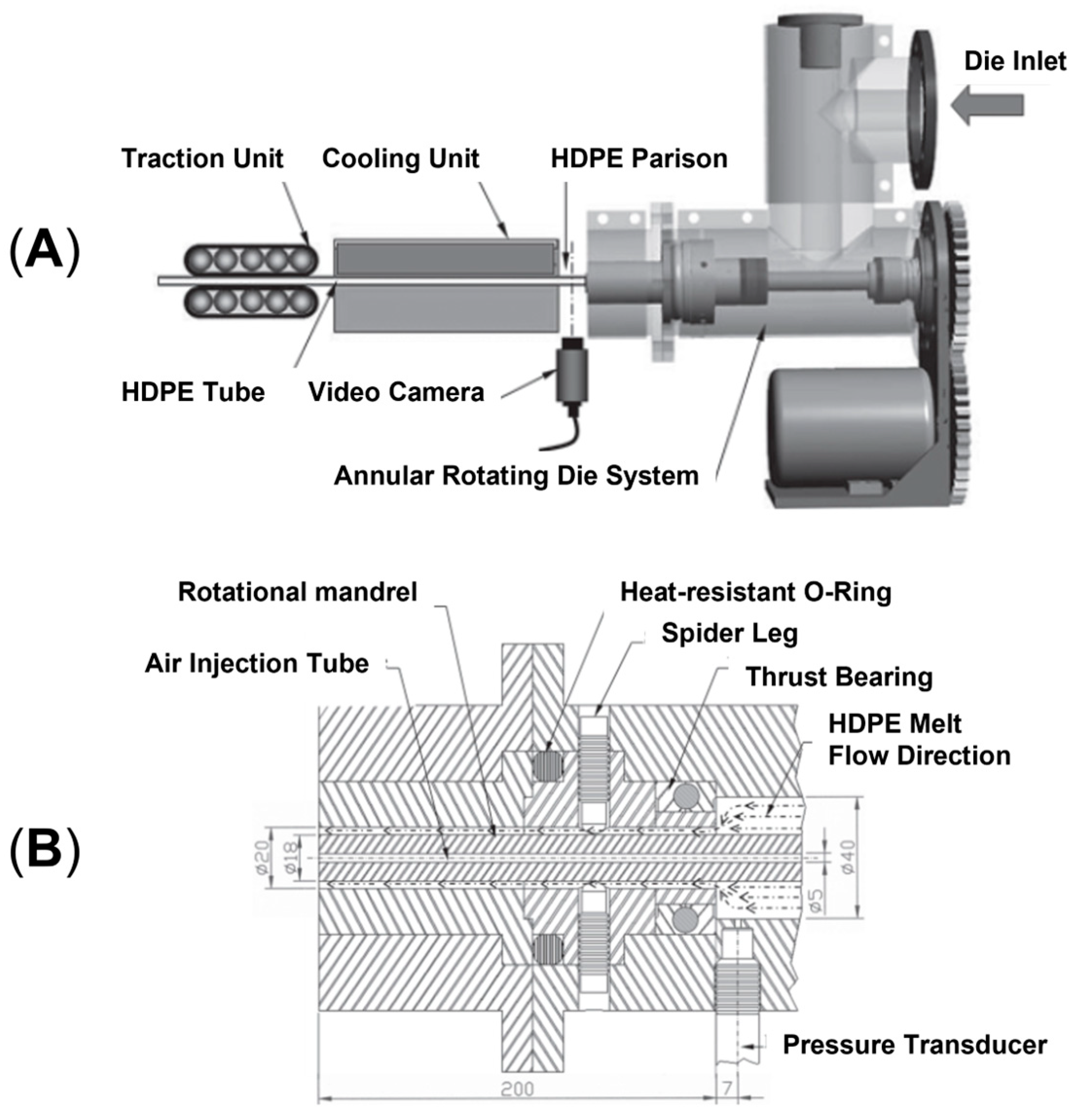

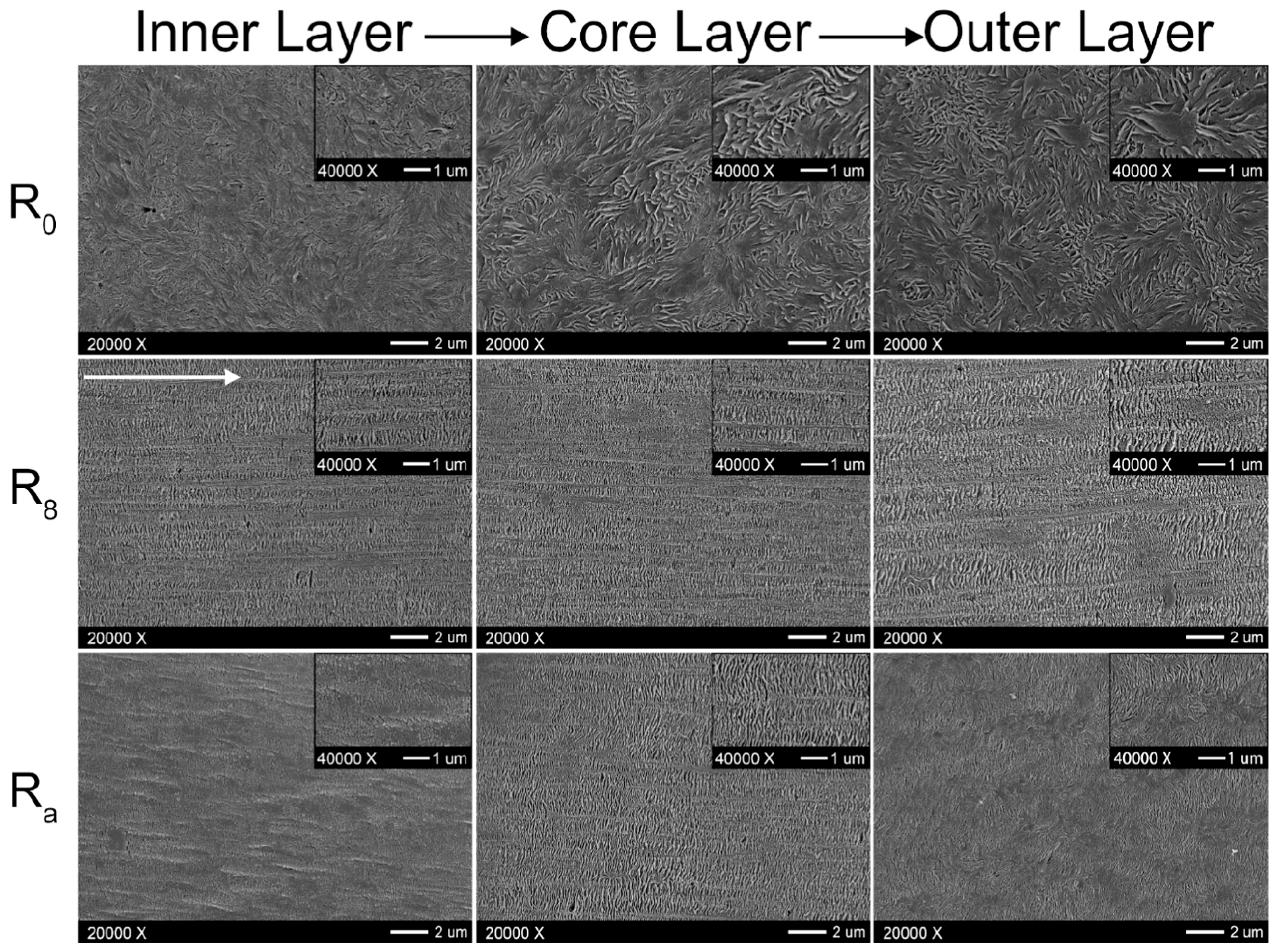

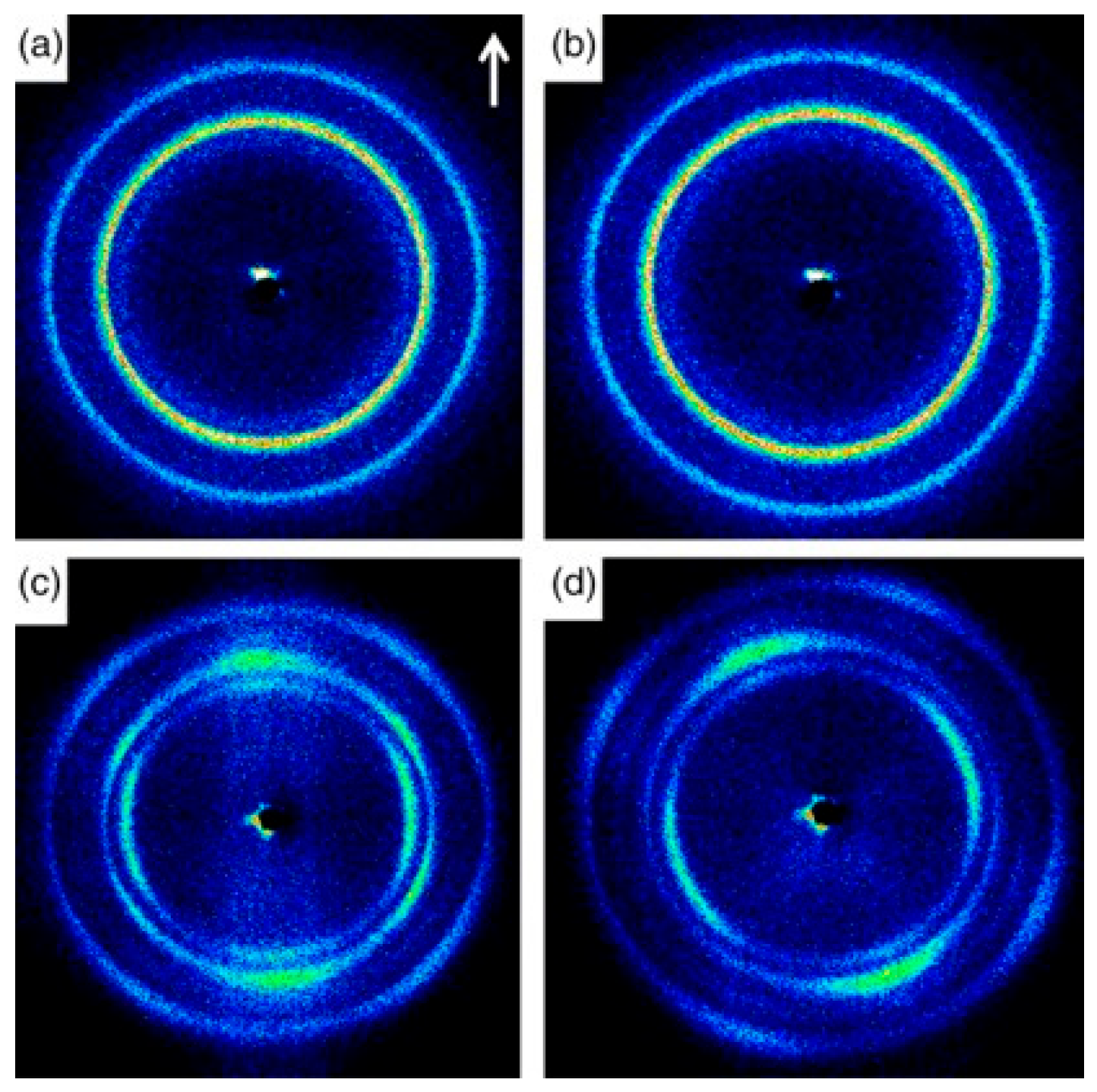

2.2.1. The Role of Screw and Mandrel Rotation Speeds

2.2.2. The Role of the Annealing Treatment

2.2.3. The Role of the Die Temperature

2.2.4. The Role of the Nucleating Agent

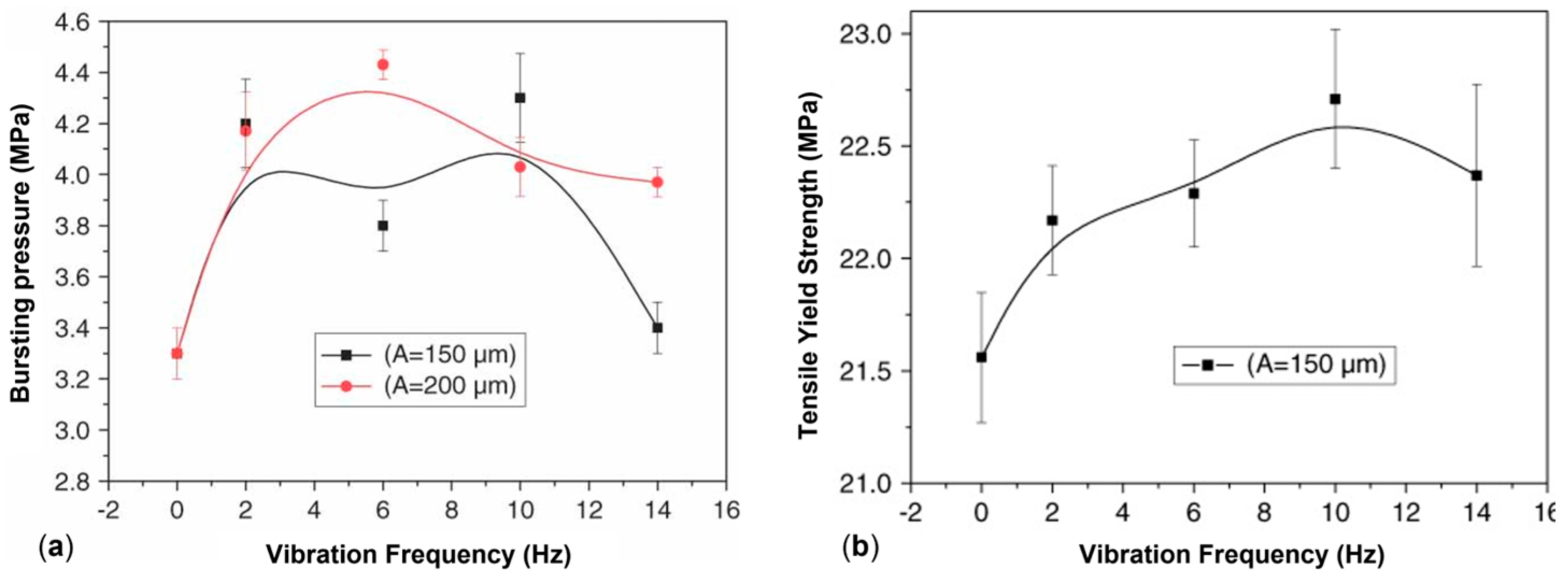

2.3. Vibration Extrusion

2.4. Drawing

2.4.1. Film Casting

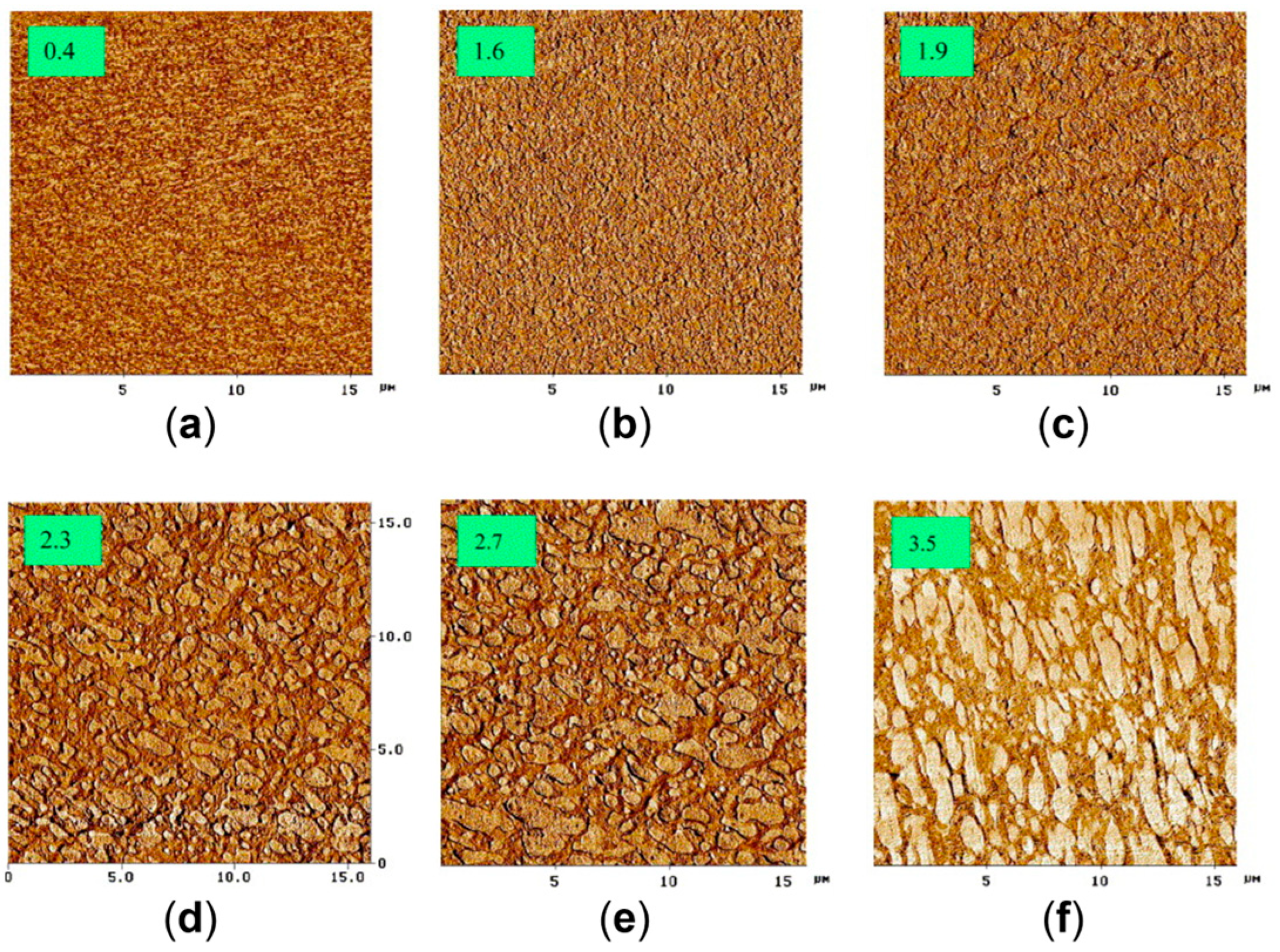

The Role of the Draw Ratio

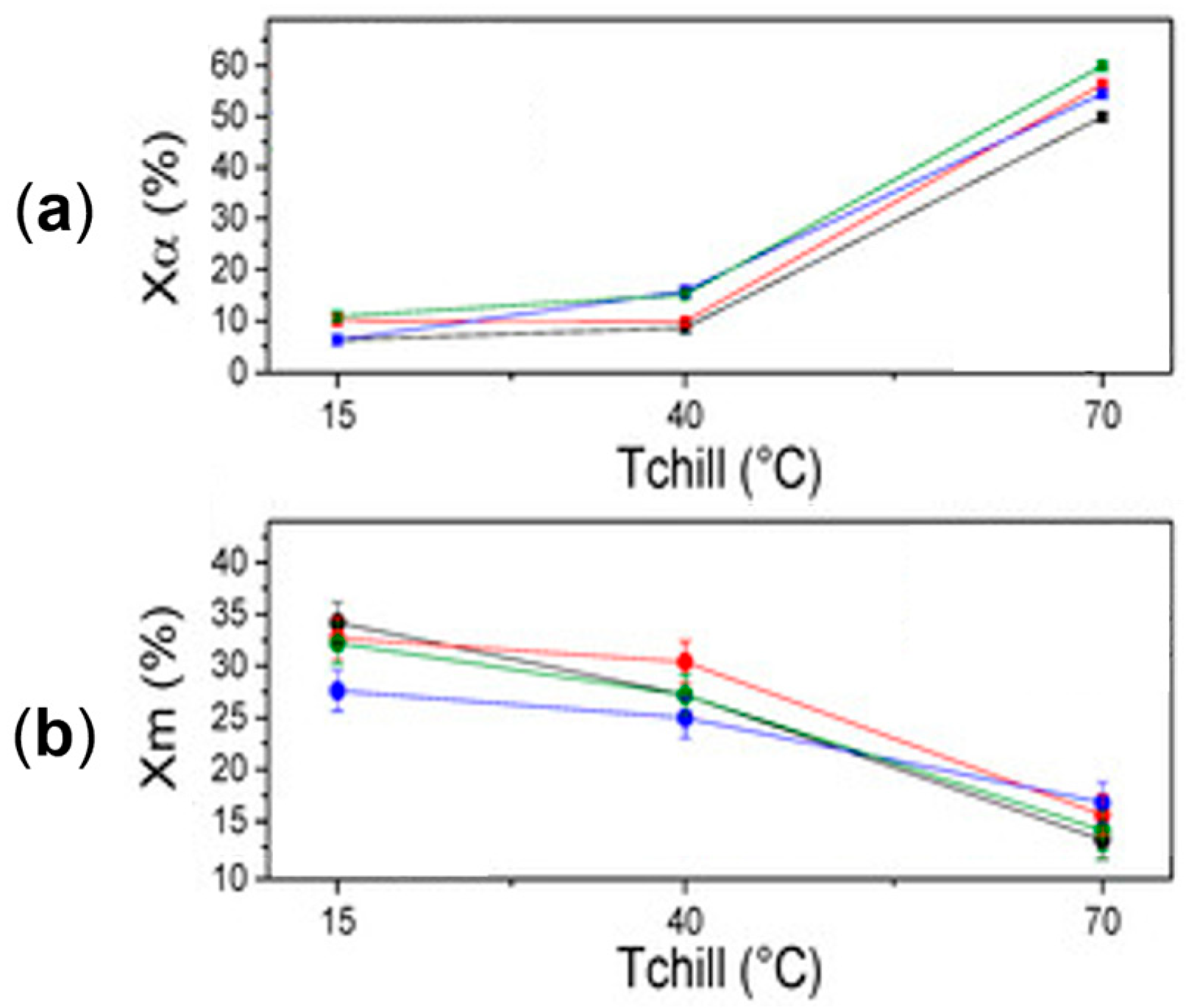

The Role of Chilling-Roll Temperature

The Role of the Annealing Treatment

2.4.2. Melt Spinning

The Role of the Draw Ratio

The Role of the Drawing Temperature

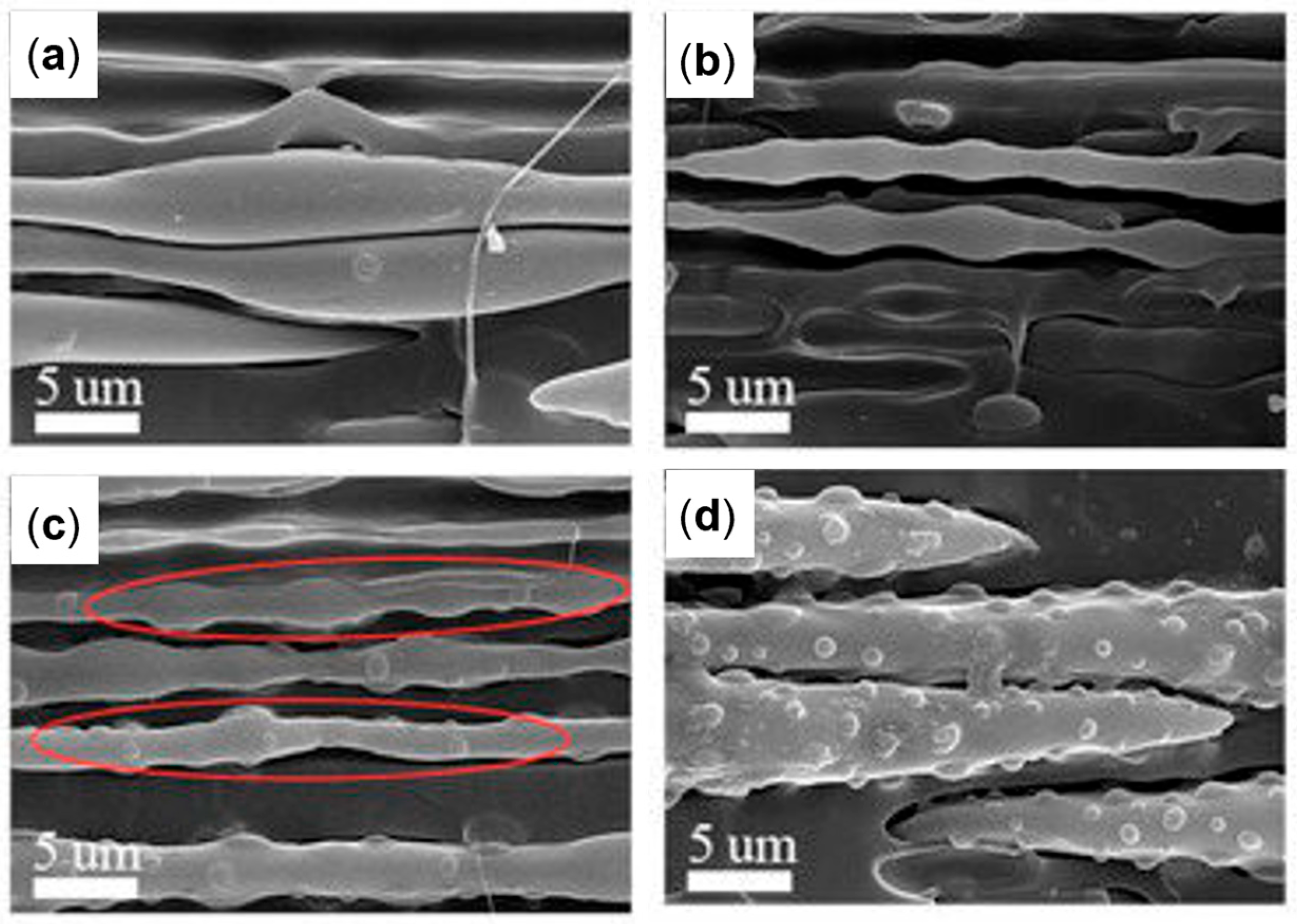

2.5. Microfibrillation

2.5.1. One-Step Fibrillation

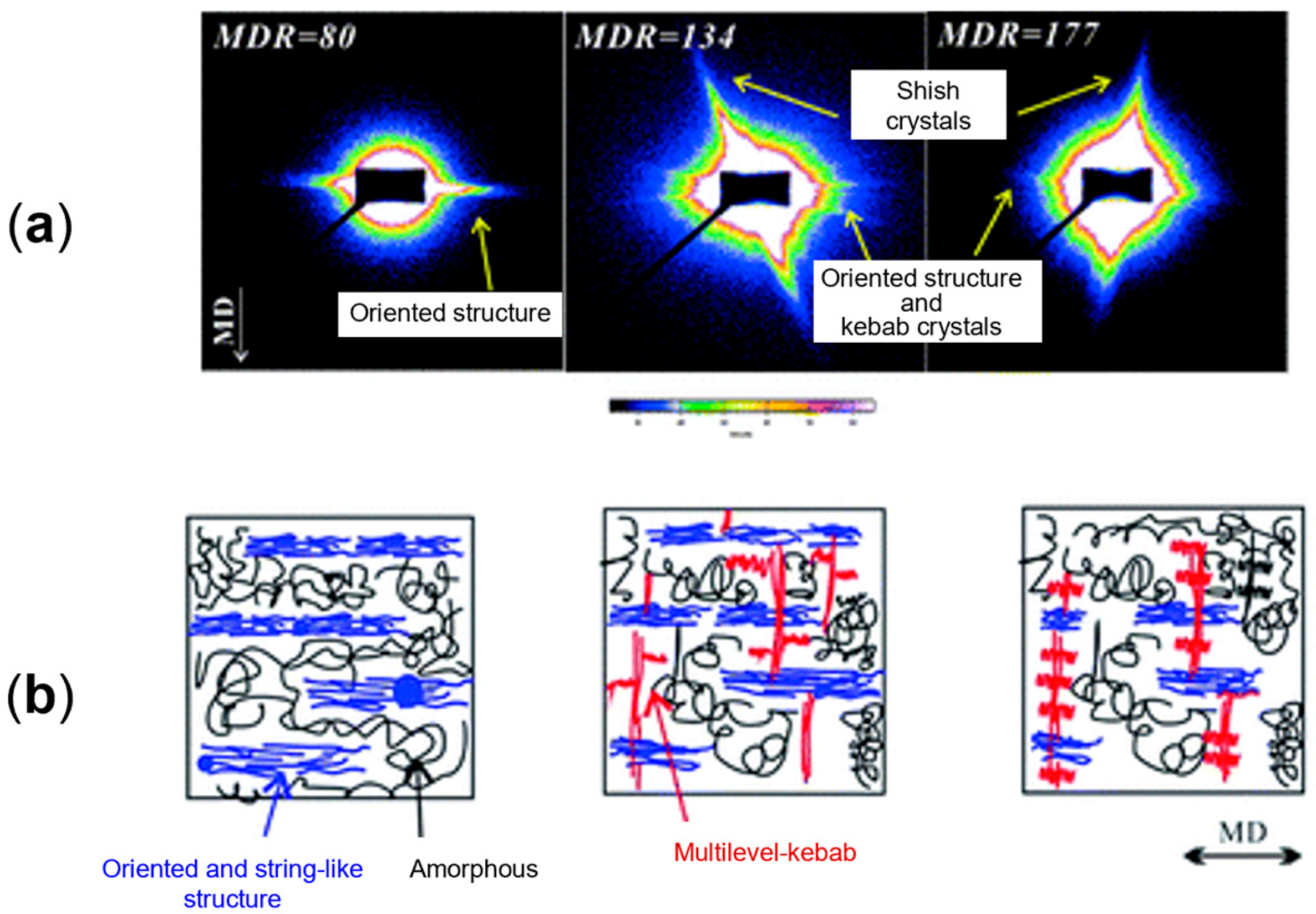

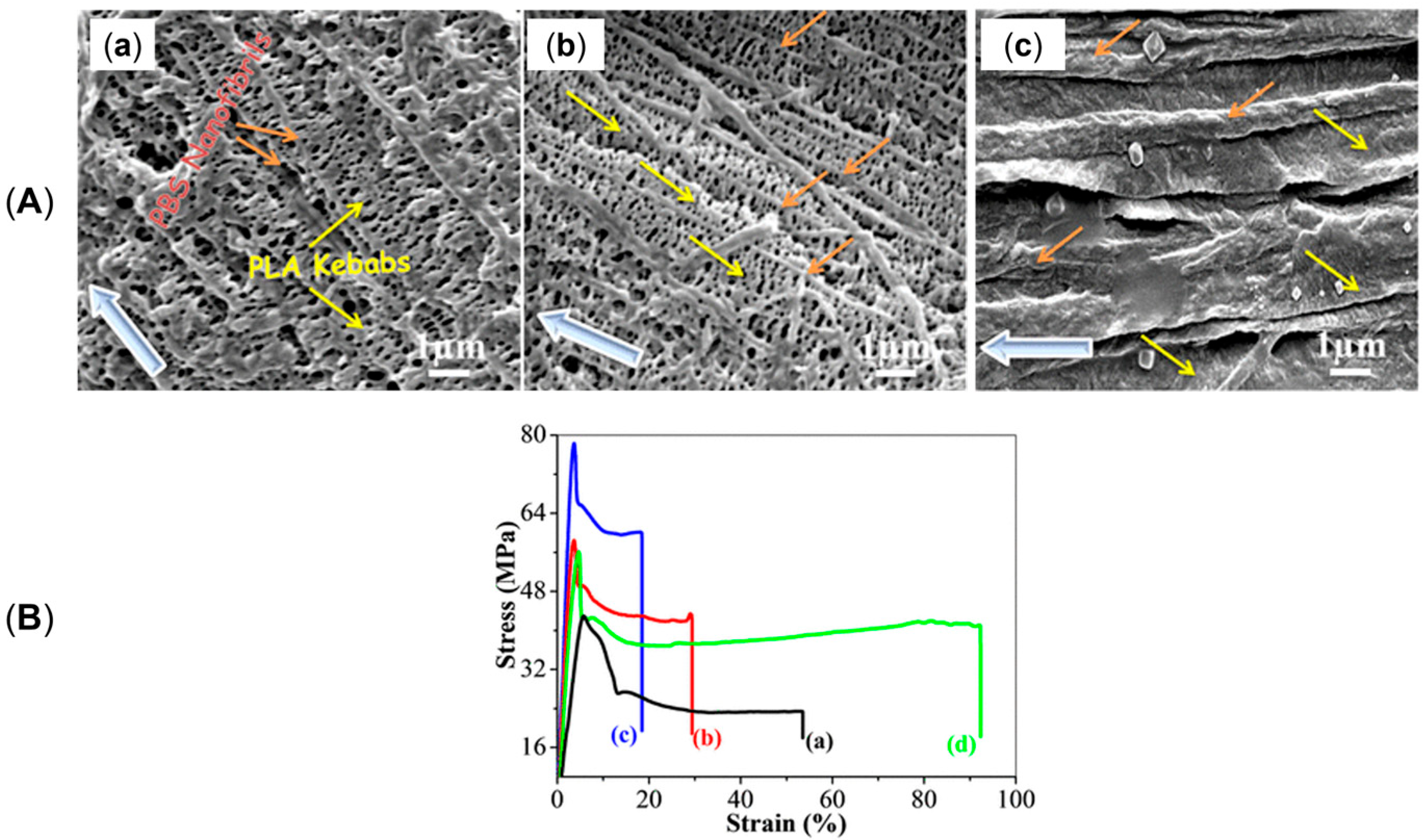

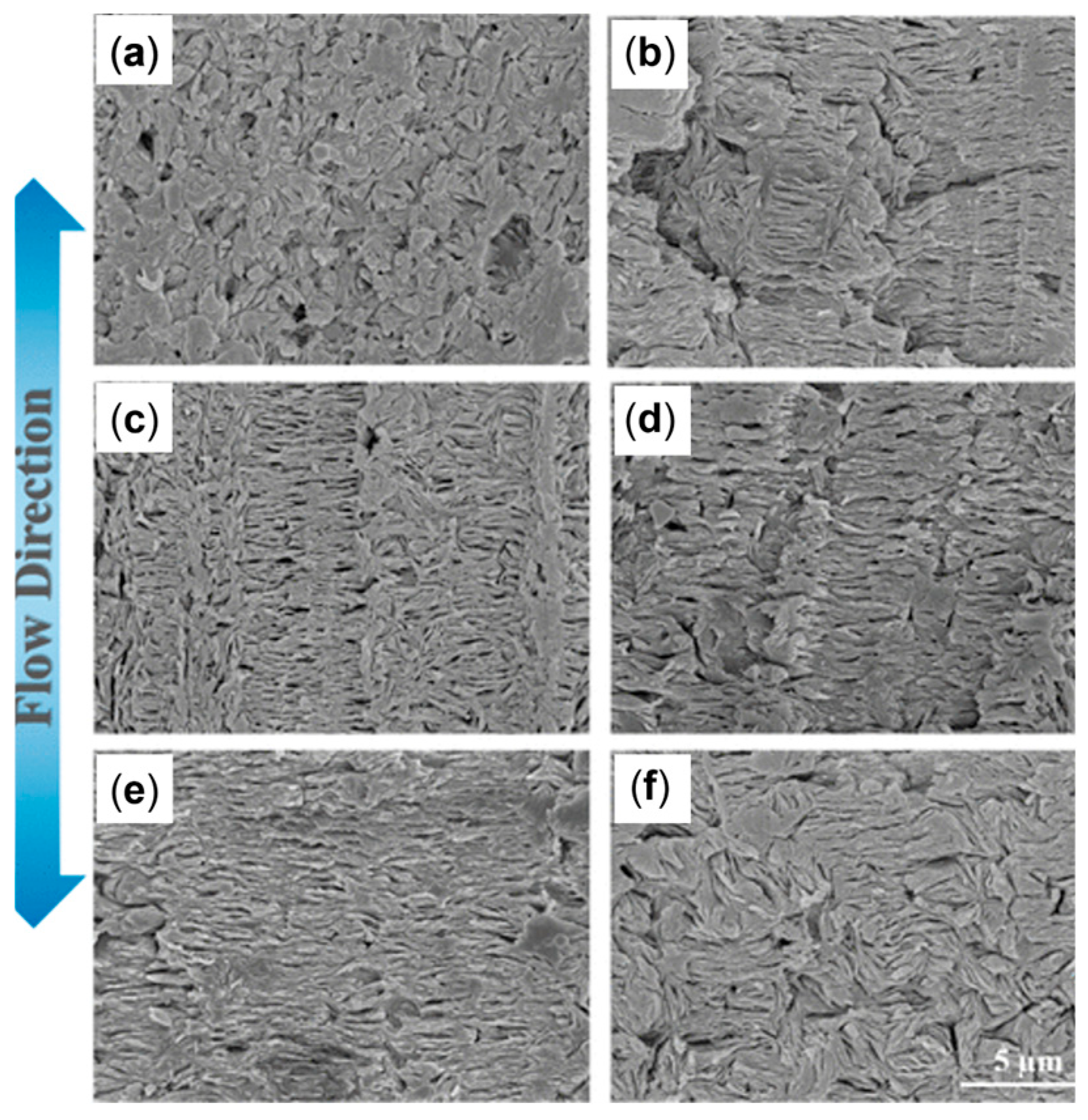

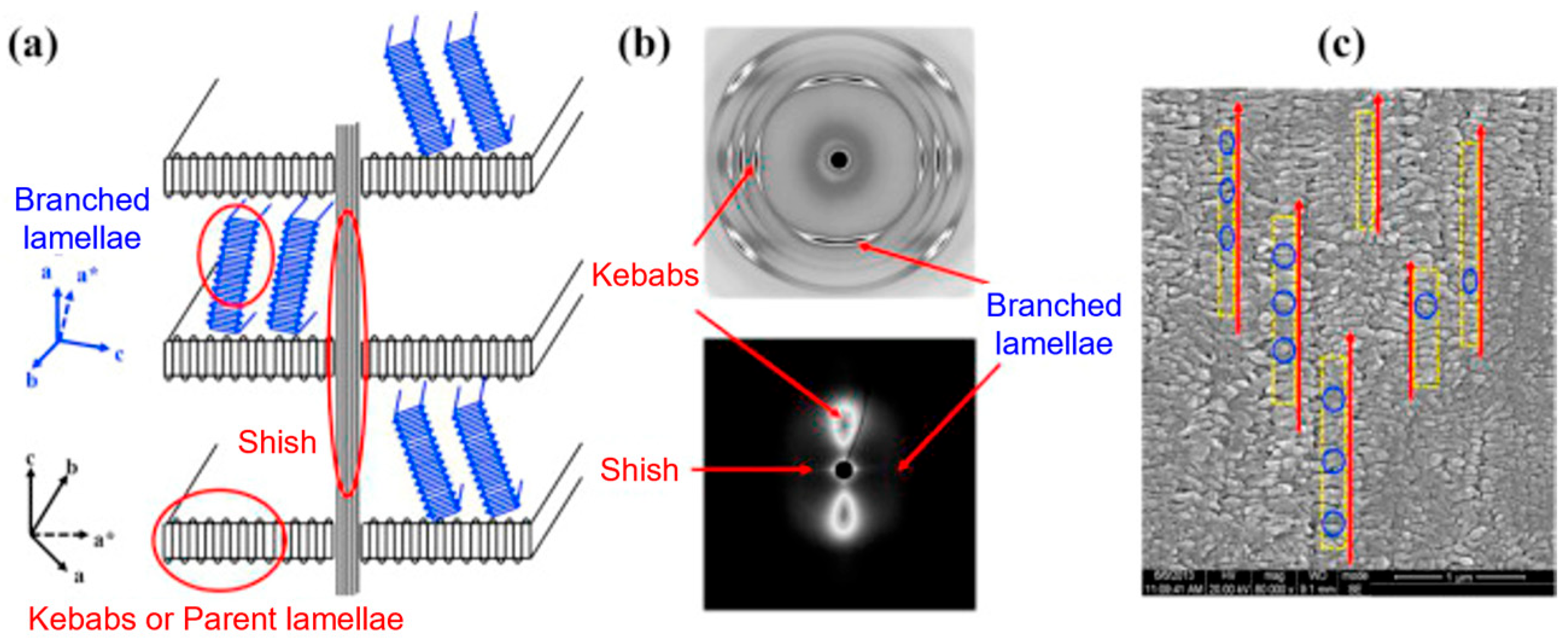

Molten-State Approach Involving FIC

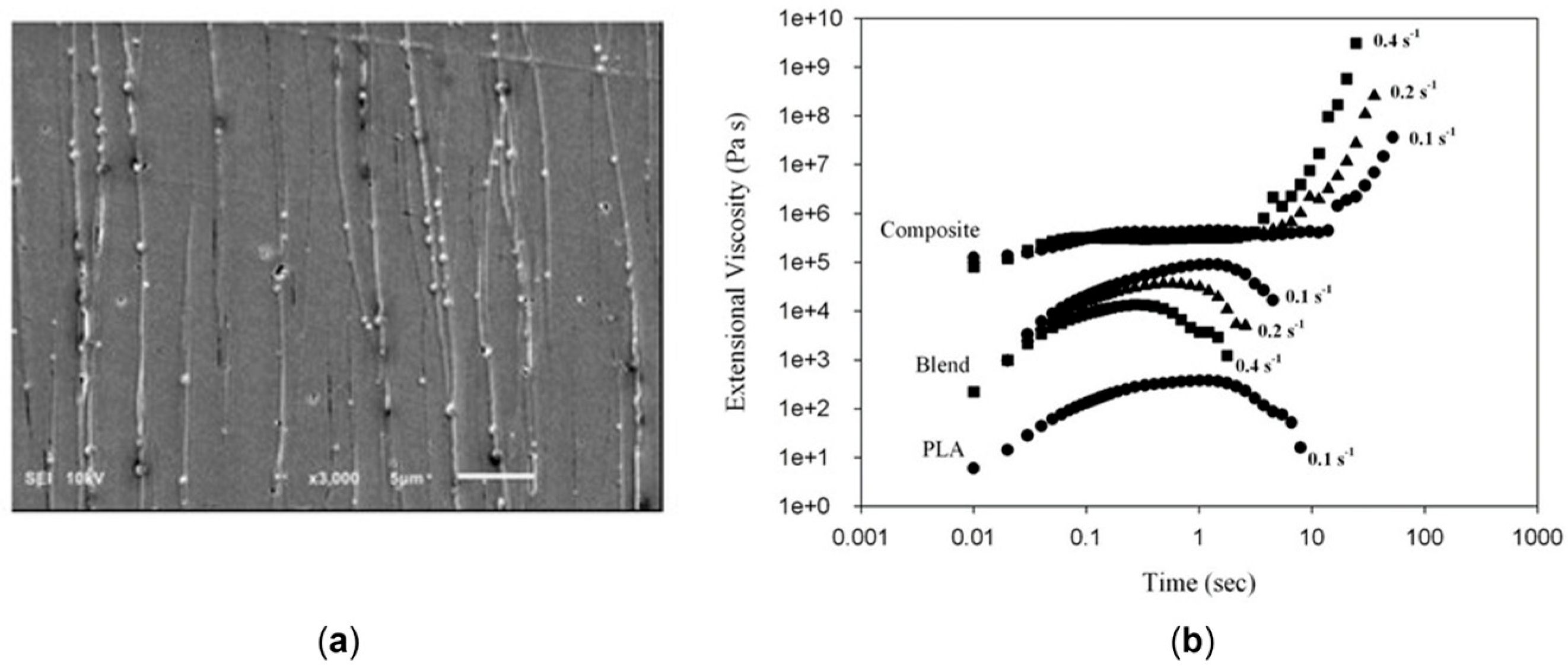

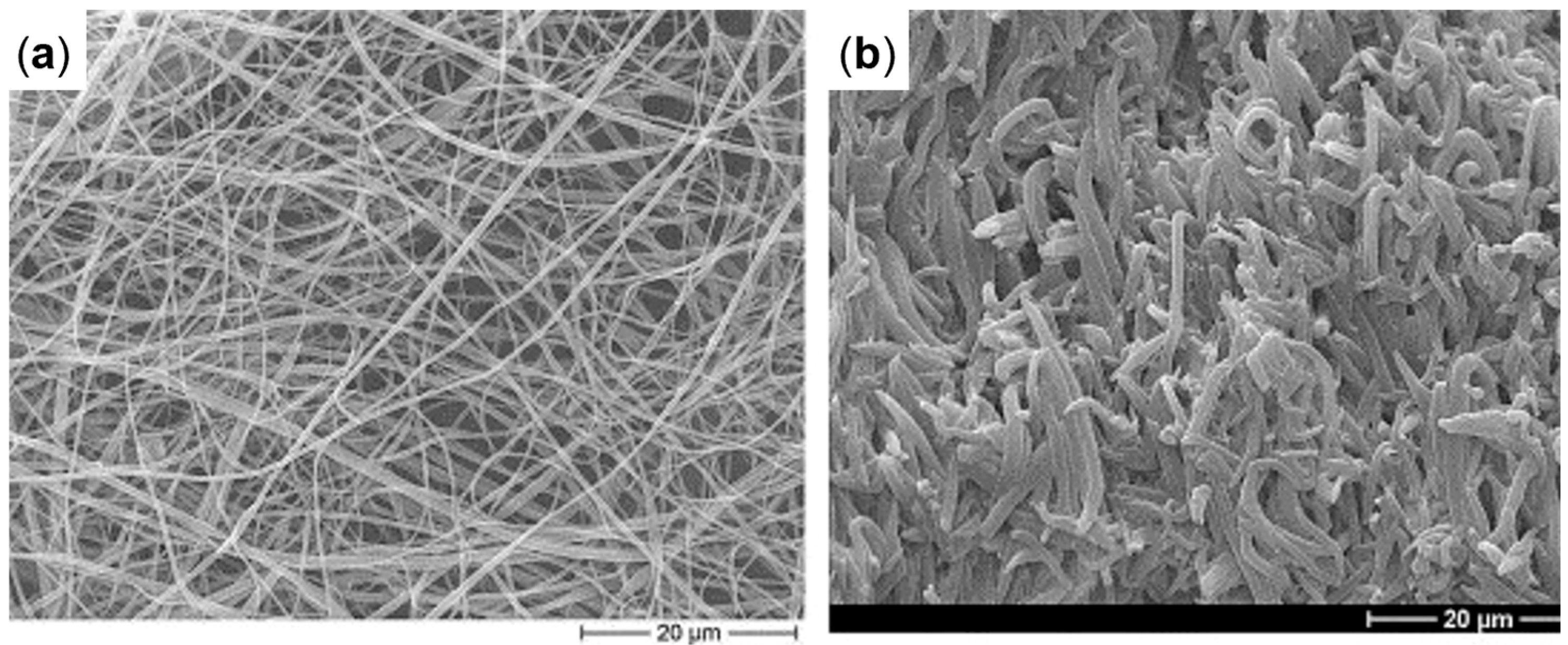

Solid-State Deformation Method

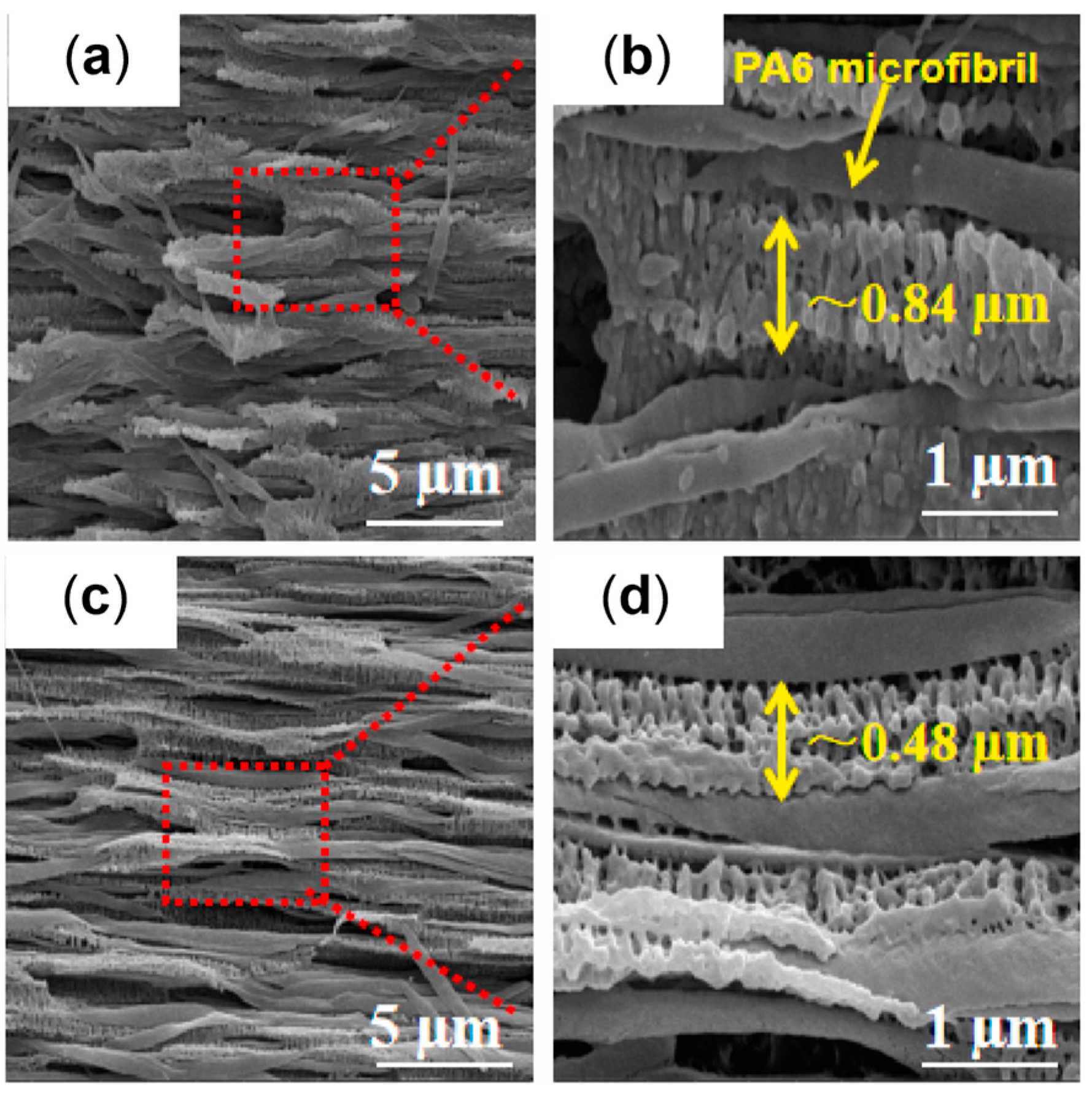

2.5.2. Two-Step Fibrillation

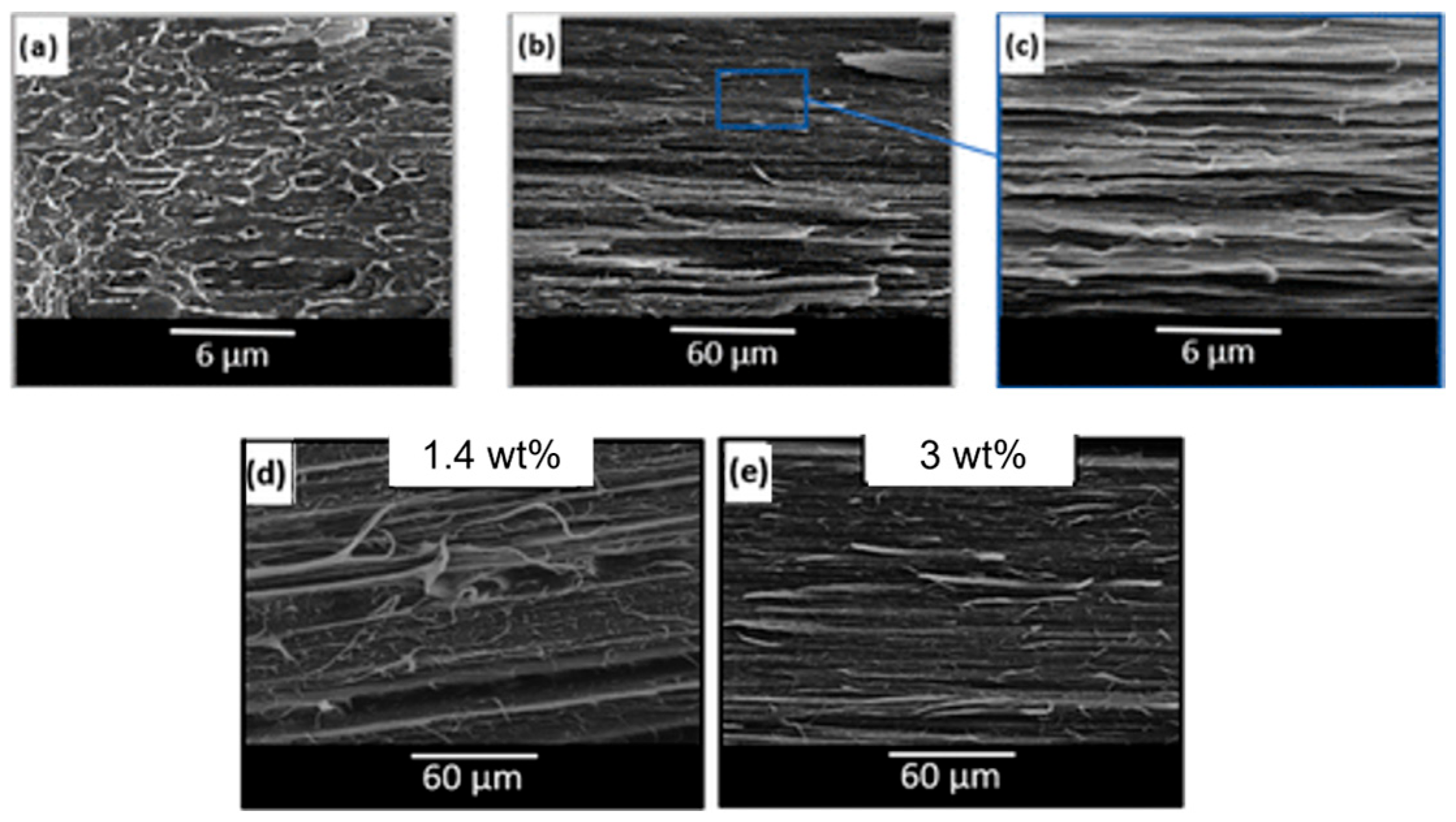

The Role of the Matrix-to-Second-Phase Content

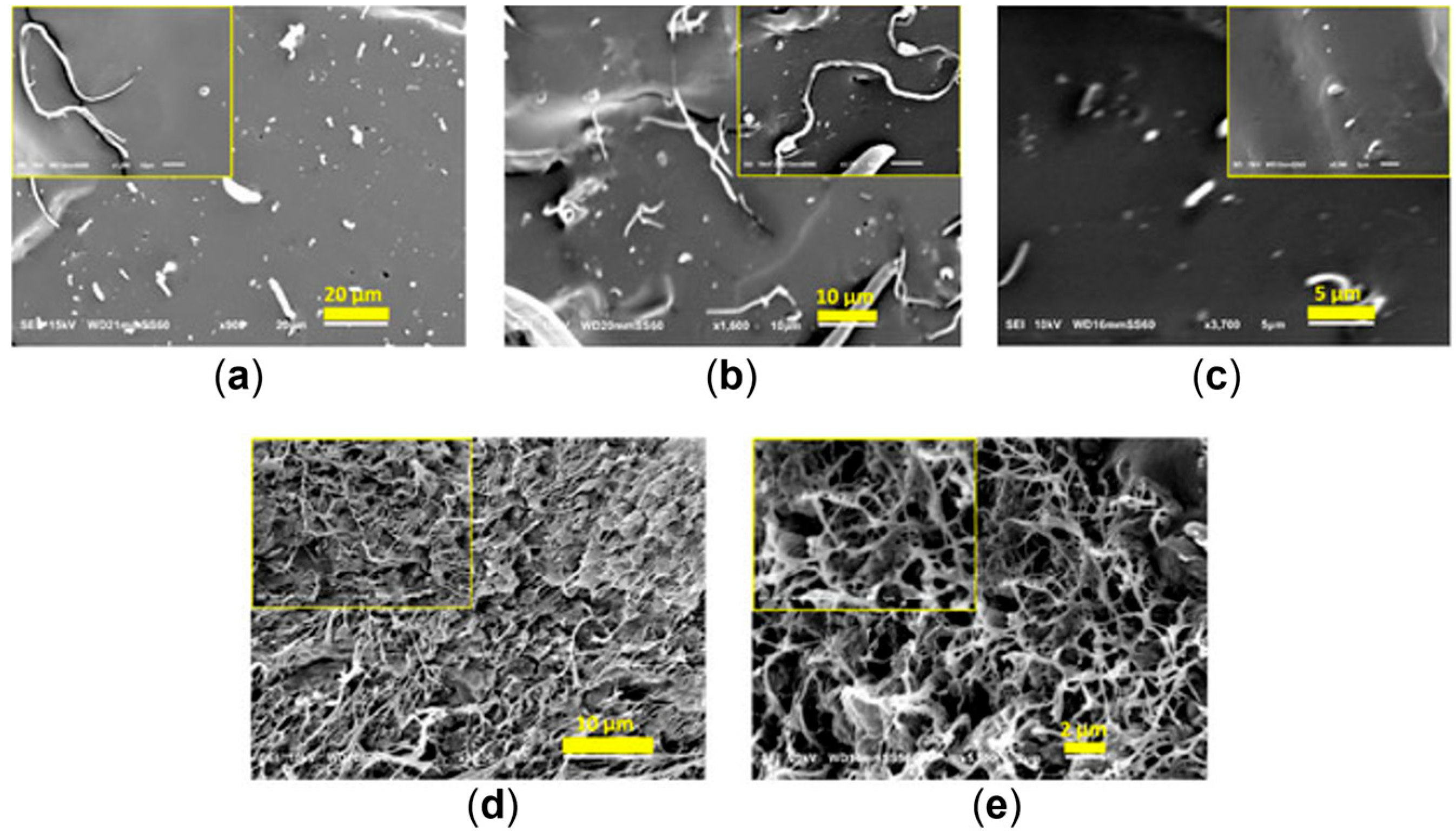

The Role of the Compatibilizer

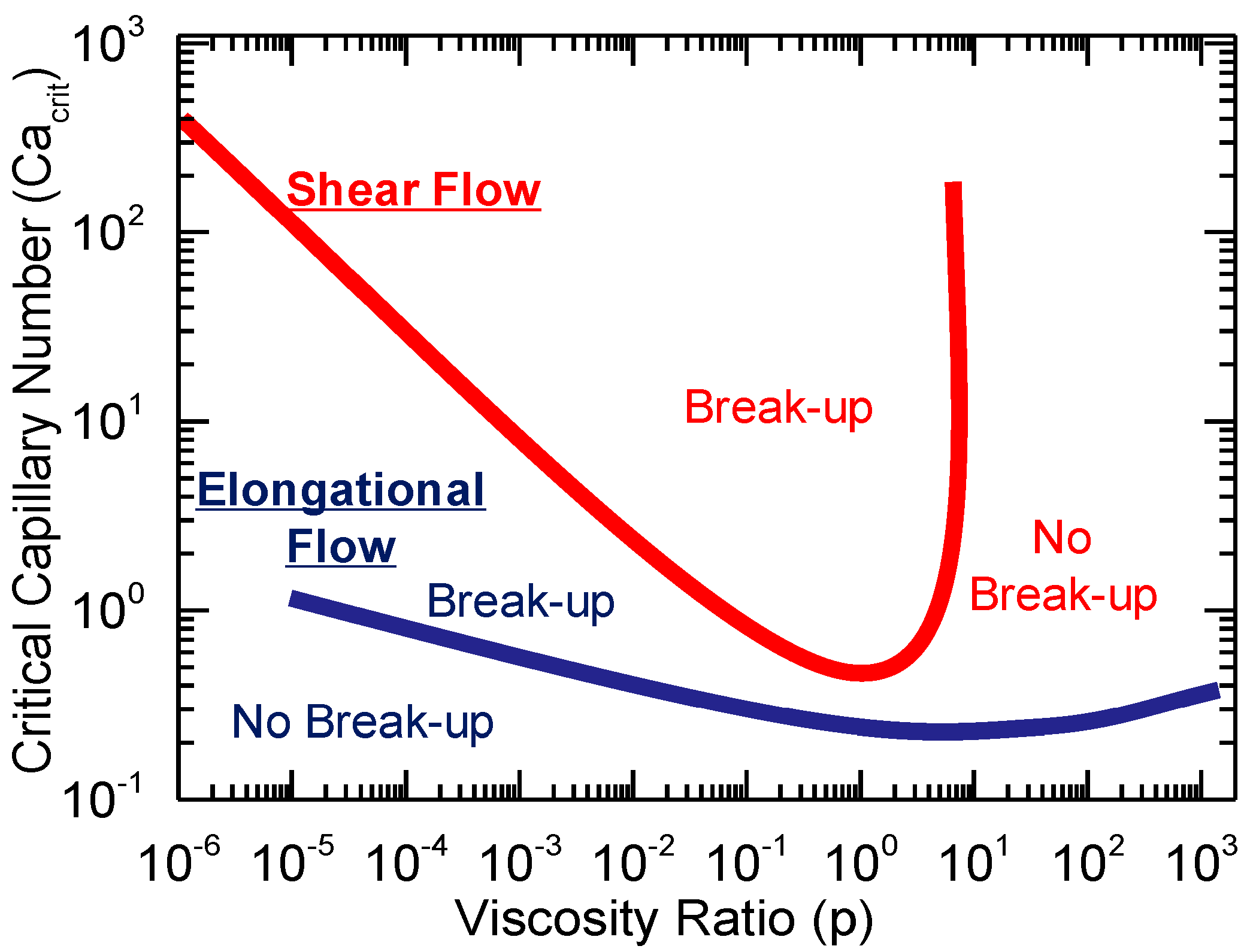

The Role of the Viscosity Ratio

The Role of the Draw Ratio

Fibrils as Heterogeneous Nucleation Sites for the Matrix

3. Injection Molding

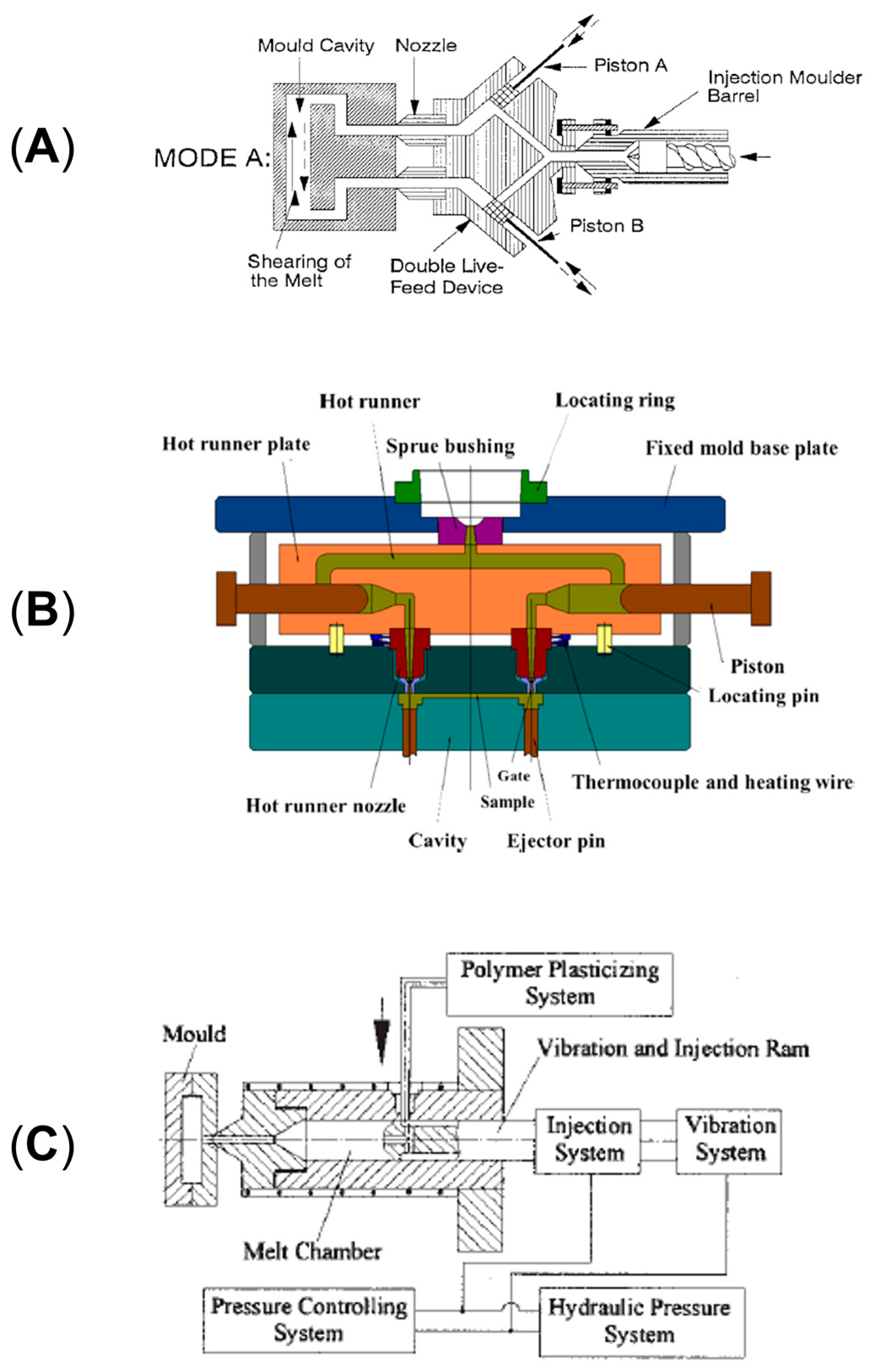

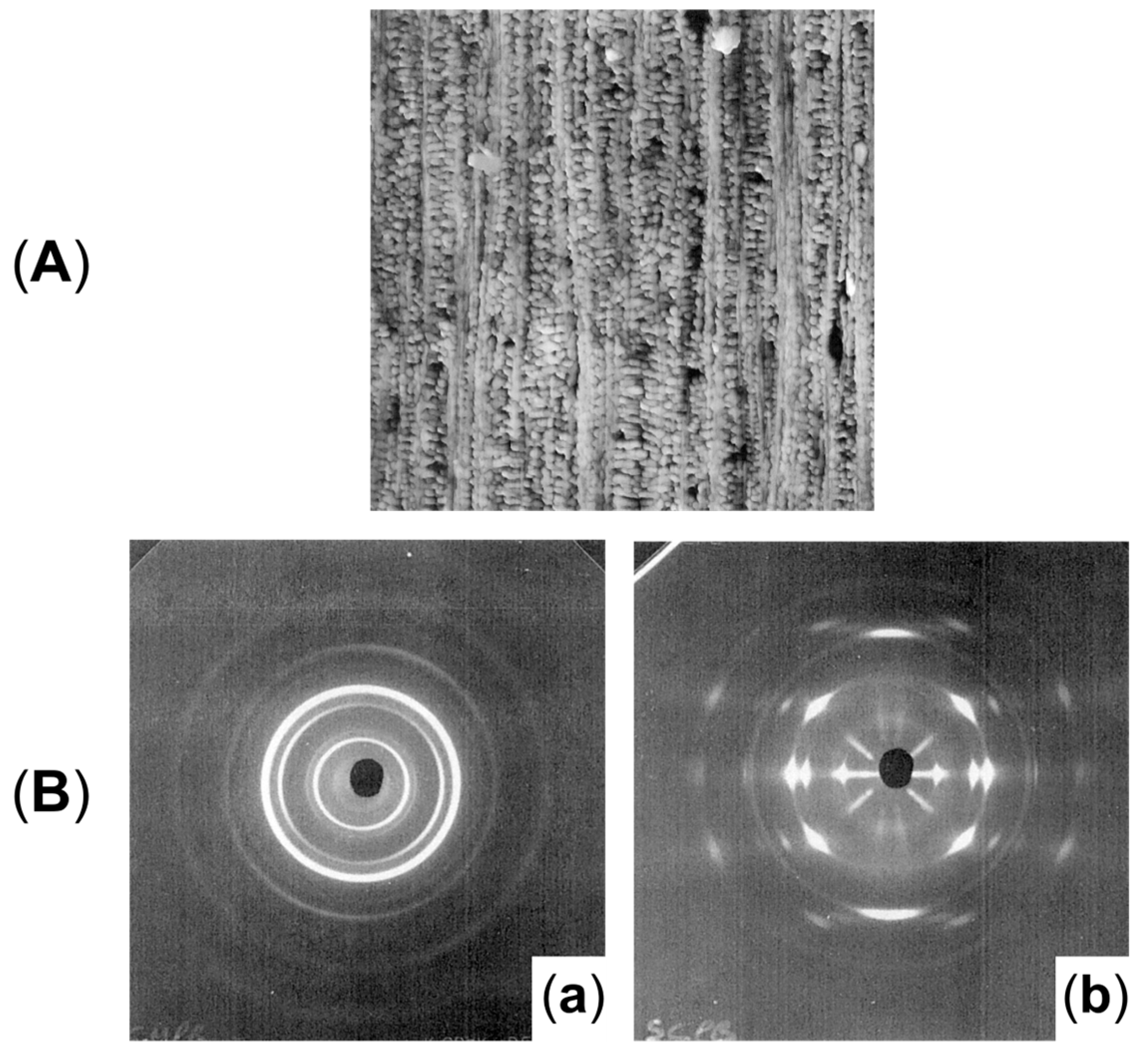

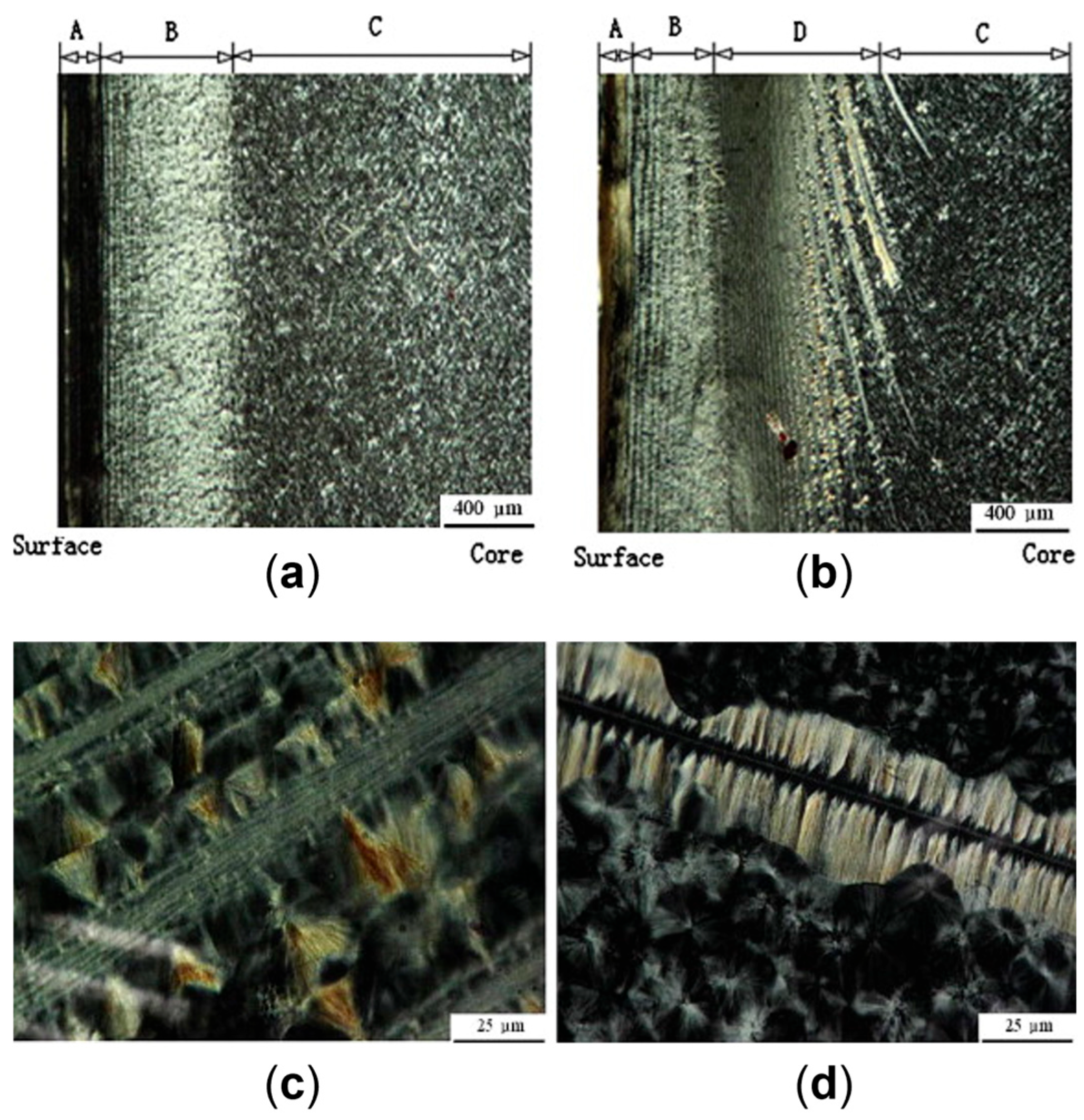

3.1. SCORIM

3.2. OPIM

3.3. VIM

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mishra, R.K.; Maria, H.J.; Joseph, K.; Thomas, S. Basic Structural and Properties Relationship of Recyclable Microfibrillar Composite Materials from Immiscible Plastics Blends: An Introduction. In Micro and Nano Fibrillar Composites (MFCs and NFCs) from Polymer Blends; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 1–25. ISBN 978-0-08-101992-4. [Google Scholar][Green Version]

- Zhong, G.J.; Yang, S.G.; Lei, J.; Li, Z.M. Flow-Induced Polymer Crystallization Under Pressure and Its Engineering Application in “Structuring” Polymer Processing. Macromolecules 2024, 57, 789–809. [Google Scholar] [CrossRef]

- Chen, Y.; Ma, Y.; Yin, Q.; Pan, F.; Cui, C.; Zhang, Z.; Liu, B. Advances in Mechanics of Hierarchical Composite Materials. Compos. Sci. Technol. 2021, 214, 108970. [Google Scholar] [CrossRef]

- Mishnaevsky, L.; Tsapatsis, M. Hierarchical Materials: Background and Perspectives. MRS Bull. 2016, 41, 661–664. [Google Scholar] [CrossRef]

- Wu, T.; Wang, K.; Chen, X.; Yang, X.; Xiang, M.; Fu, Q. Practicing the Concept of “Structuring” Processing in the Manufacture of Polymer Films. Sci. China Chem. 2023, 66, 993–1010. [Google Scholar] [CrossRef]

- Wan, C.; Bowen, C.R. Multiscale-Structuring of Polyvinylidene Fluoride for Energy Harvesting: The Impact of Molecular-, Micro- and Macro-Structure. J. Mater. Chem. A 2017, 5, 3091–3128. [Google Scholar] [CrossRef]

- Serpe, G.; Jarrin, J.; Dawans, F. Morphology-Processing Relationships in Polyethylene-Polyamide Blends. Polym. Eng. Sci. 1990, 30, 553–565. [Google Scholar] [CrossRef]

- Kalay, G.; Kalay, C.R. Structure and Physical Property Relationships in Processed Polybutene-1. J. Appl. Polym. Sci. 2003, 88, 814–824. [Google Scholar] [CrossRef]

- Jancar, J.; Douglas, J.F.; Starr, F.W.; Kumar, S.K.; Cassagnau, P.; Lesser, A.J.; Sternstein, S.S.; Buehler, M.J. Current Issues in Research on Structure-Property Relationships in Polymer Nanocomposites. Polymer 2010, 51, 3321–3343. [Google Scholar] [CrossRef]

- Resch, K.; Wallner, G.M.; Teichert, C.; Gahleitner, M. Highly Transparent Polypropylene Cast Films: Relationships Between Optical Properties, Additives, and Surface Structure. Polym. Eng. Sci. 2007, 47, 1021–1032. [Google Scholar] [CrossRef]

- Di Sacco, F.; Gahleitner, M.; Wang, J.; Portale, G. Systematic Investigation on the Structure-Property Relationship in Isotactic Polypropylene Films Processed via Cast Film Extrusion. Polymers 2020, 12, 1636. [Google Scholar] [CrossRef] [PubMed]

- Fakirov, S. Nano-/Microfibrillar Polymer-Polymer and Single Polymer Composites: The Converting Instead of Adding Concept. Compos. Sci. Technol. 2013, 89, 211–225. [Google Scholar] [CrossRef]

- Wang, K.; Chen, F.; Li, Z.; Fu, Q. Control of the Hierarchical Structure of Polymer Articles via “Structuring” Processing. Prog. Polym. Sci. 2014, 39, 891–920. [Google Scholar] [CrossRef]

- An, F.Z.; Wang, Z.W.; Hu, J.; Gao, X.Q.; Shen, K.Z.; Deng, C. Morphology Control Technologies of Polymeric Materials During Processing. Macromol. Mater. Eng. 2014, 299, 400–423. [Google Scholar] [CrossRef]

- Laird, E.D.; Li, C.Y. Structure and Morphology Control in Crystalline Polymer-Carbon Nanotube Nanocomposites. Macromolecules 2013, 46, 2877–2891. [Google Scholar] [CrossRef]

- Pesneau, I.; At Kadi, A.; Bousmina, M.; Cassagnau, P.; Michel, A. From Polymer Blends to in Situ Polymer/Polymer Composites: Morphology Control and Mechanical Properties. Polym. Eng. Sci. 2002, 42, 1990–2004. [Google Scholar] [CrossRef]

- Banerjee, R.; Ray, S.S. Role of Rheology in Morphology Development and Advanced Processing of Thermoplastic Polymer Materials: A Review. ACS Omega 2023, 8, 27969–28001. [Google Scholar] [CrossRef] [PubMed]

- Tabatabaei, S.H.; Carreau, P.J.; Ajji, A. Effect of Processing on the Crystalline Orientation, Morphology, and Mechanical Properties of Polypropylene Cast Films and Microporous Membrane Formation. Polymer 2009, 50, 4228–4240. [Google Scholar] [CrossRef]

- Chandran, S.; Baschnagel, J.; Cangialosi, D.; Fukao, K.; Glynos, E.; Janssen, L.M.C.; Müller, M.; Muthukumar, M.; Steiner, U.; Xu, J.; et al. Processing Pathways Decide Polymer Properties at the Molecular Level. Macromolecules 2019, 52, 7146–7156. [Google Scholar] [CrossRef]

- Kuzmanović, M.; Delva, L.; Cardon, L.; Ragaert, K. Relationship Between the Processing, Structure, and Properties of Microfibrillar Composites. Adv. Mater. 2020, 32, 2003938. [Google Scholar] [CrossRef]

- Li, Y.; Yi, X.; Yu, T.; Xian, G. An Overview of Structural-Functional-Integrated Composites Based on the Hierarchical Microstructures of Plant Fibers. Adv. Compos. Hybrid Mater. 2018, 1, 231–246. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Bárány, T. Single-Polymer Composites (SPCs): Status and Future Trends. Compos. Sci. Technol. 2014, 92, 77–94. [Google Scholar] [CrossRef]

- Biswas, S.K.; Sano, H.; Shams, M.I.; Yano, H. Three-Dimensional-Moldable Nanofiber-Reinforced Transparent Composites with a Hierarchically Self-Assembled “Reverse” Nacre-like Architecture. ACS Appl. Mater. Interfaces 2017, 9, 30177–30184. [Google Scholar] [CrossRef]

- Baer, E.; Hiltner, A.; Keith, H.D.; Hilmer, A. Hierarchical Structure in Polymeric Materials. Science 1987, 235, 1015–1022. [Google Scholar] [CrossRef]

- Gorbatikh, L.; Liu, Q.; Romanov, V.; Mehdikhani, M.; Matveeva, A.; Shishkina, O.; Aravand, A.; Wardle, B.; Verpoest, I.; Lomov, S.V. Hierarchical Design of Structural Composite Materials down to the Nanoscale via Experimentation and Modelling. IOP Conf. Ser. Mater. Sci. Eng. 2018, 406, 012002. [Google Scholar] [CrossRef]

- Wang, L.; Lin, J.; Zhang, X. Hierarchical Microstructures Self-Assembled from Polymer Systems. Polymer 2013, 54, 3427–3442. [Google Scholar] [CrossRef]

- Lakes, R. Materials with Structural Hierarchy. Nature 1993, 361, 511–515. [Google Scholar] [CrossRef]

- Sang, Z.H.; Xie, X.L.; Zhou, S.Y.; Li, Y.; Yan, Z.; Xu, L.; Zhong, G.J.; Li, Z.M. Gradient Structure of Crystalline Morphology in Injection-Molded Polylactide Parts Tuned by Oscillation Shear Flow and Its Influence on Thermomechanical Performance. Ind. Eng. Chem. Res. 2017, 56, 6295–6306. [Google Scholar] [CrossRef]

- Guan, Q.; Lai, F.S.; Mccarthy, S.P.; Chiu, D.; Zhu, X.; Shen, K. Morphology and Properties of Self-Reinforced High Density Polyethylene in Oscillating Stress Field. Polymer 1997, 38, 5251–5253. [Google Scholar] [CrossRef]

- Lei, J.; Jiang, C.; Shen, K. Biaxially Self-Reinforced High-Density Polyethylene Prepared by Dynamic Packing Injection Molding. II. Microstructure Investigation. J. Appl. Polym. Sci. 2004, 93, 1591–1596. [Google Scholar] [CrossRef]

- Lei, J.; Jiang, C.; Shen, K. Biaxially Self-Reinforced High-Density Polyethylene Prepared by Dynamic Packing Injection Molding. I. Processing Parameters and Mechanical Properties. J. Appl. Polym. Sci. 2004, 93, 1584–1590. [Google Scholar] [CrossRef]

- Mi, D.; Xia, C.; Jin, M.; Wang, F.; Shen, K.; Zhang, J. Quantification of the Effect of Shish-Kebab Structure on the Mechanical Properties of Polypropylene Samples by Controlling Shear Layer Thickness. Macromolecules 2016, 49, 4571–4578. [Google Scholar] [CrossRef]

- Zhong, Y.; Chen, L.; Gao, J.; Guo, J.; Xing, C.; Li, Y.; Wang, Z. Structural Evolution of High-Entanglement Ultrahigh Molecular Weight Polyethylene Films with Reserved Shish Crystals During the Hot Stretching Process. Macromolecules 2024, 57, 2176–2190. [Google Scholar] [CrossRef]

- Yang, S.G.; Li, Y.; Lei, J.; Zhong, G.J.; Li, Z.M. Oriented Polar Crystals in Poly(Vinylidene Fluoride) Produced by Simultaneously Applying Pressure and Flow. Macromol. Chem. Phys. 2018, 219, 1800299. [Google Scholar] [CrossRef]

- Zhou, Q.; Liu, F.; Guo, C.; Fu, Q.; Shen, K.; Zhang, J. Shish-Kebab-like Cylindrulite Structures Resulted from Periodical Shear-Induced Crystallization of Isotactic Polypropylene. Polymer 2011, 52, 2970–2978. [Google Scholar] [CrossRef]

- Chen, Y.; Fang, D.; Hsiao, B.S.; Li, Z. Insight into Unique Deformation Behavior of Oriented Isotactic Polypropylene with Branched Shish-Kebabs. Polymer 2015, 60, 274–283. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, X.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. New Insight into Lamellar Branching of β-Nucleated Isotactic Polypropylene upon Melt-Stretching: WAXD and SAXS Study. J. Mater. Sci. 2014, 50, 599–604. [Google Scholar] [CrossRef]

- Xie, X.L.; Li, Y.; Xu, J.Z.; Yan, Z.; Zhong, G.J.; Li, Z.M. Largely Enhanced Mechanical Performance of Poly(Butylene Succinate) Multiple System via Shear Stress-Induced Orientation of the Hierarchical Structure. J. Mater. Chem. A 2018, 6, 13373–13385. [Google Scholar] [CrossRef]

- Fakirov, S. Nano- and Microfibrillar Single-Polymer Composites: A Review. Macromol. Mater. Eng. 2013, 298, 9–32. [Google Scholar] [CrossRef]

- Liu, D.; Tian, N.; Cui, K.; Zhou, W.; Li, X.; Li, L. Correlation Between Flow-Induced Nucleation Morphologies and Strain in Polyethylene: From Uncorrelated Oriented Point-Nuclei, Scaffold-Network, and Microshish to Shish. Macromolecules 2013, 46, 3435–3443. [Google Scholar] [CrossRef]

- Pan, Y.; Li, N.; Wang, J.; Wang, D.; Pan, X.; Liu, C.; Jian, X. The Role of Expansion Angle and Speed on Shish-Kebab Formation in Expansion Pipe Extruder Head Explored by High Temperature Rapid Stretch. Polym. Test. 2021, 104, 107387. [Google Scholar] [CrossRef]

- Xu, H.; Zhong, G.J.; Fu, Q.; Lei, J.; Jiang, W.; Hsiao, B.S.; Li, Z.M. Formation of Shish-Kebabs in Injection-Molded Poly(L-Lactic Acid) by Application of an Intense Flow Field. ACS Appl. Mater. Interfaces 2012, 4, 6774–6784. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.C.; Deng, L.; Lei, J.; Li, Z.M. Isotactic Polypropylene Reinforced Atactic Polypropylene by Formation of Shish-Kebab Superstructure. Polymer 2015, 78, 120–133. [Google Scholar] [CrossRef]

- Wang, Y.; Na, B.; Fu, Q.; Men, Y. Shear Induced Shish-Kebab Structure in PP and Its Blends with LLDPE. Polymer 2004, 45, 207–215. [Google Scholar] [CrossRef]

- Nie, M.; Han, R.; Wang, Q. Formation and Alignment of Hybrid Shish-Kebab Morphology with Rich Beta Crystals in an Isotactic Polypropylene Pipe. Ind. Eng. Chem. Res. 2014, 53, 4142–4146. [Google Scholar] [CrossRef]

- Liang, S.; Wang, K.; Tang, C.; Zhang, Q.; Du, R.; Fu, Q. Unexpected Molecular Weight Dependence of Shish-Kebab Structure in the Oriented Linear Low Density Polyethylene/High Density Polyethylene Blends. J. Chem. Phys. 2008, 128, 174902. [Google Scholar] [CrossRef]

- Wang, K.; Chen, F.; Zhang, Q.; Fu, Q. Shish-Kebab of Polyolefin by “Melt Manipulation” Strategy in Injection-Molding: A Convenience Pathway from Fundament to Application. Polymer 2008, 49, 4745–4755. [Google Scholar] [CrossRef]

- Liu, T.; Ju, J.; Chen, F.; Wu, B.; Yang, J.; Zhong, M.; Peng, X.; Kuang, T. Superior Mechanical Performance of In-Situ Nanofibrillar HDPE/PTFE Composites with Highly Oriented and Compacted Nanohybrid Shish-Kebab Structure. Compos. Sci. Technol. 2021, 207, 108715. [Google Scholar] [CrossRef]

- Zhou, S.Y.; Niu, B.; Xie, X.L.; Ji, X.; Zhong, G.J.; Hsiao, B.S.; Li, Z.M. Interfacial Shish-Kebabs Lengthened by Coupling Effect of In Situ Flexible Nanofibrils and Intense Shear Flow: Achieving Hierarchy To Conquer the Conflicts Between Strength and Toughness of Polylactide. ACS Appl. Mater. Interfaces 2017, 9, 10148–10159. [Google Scholar] [CrossRef]

- Shahnooshi, M.; Javadi, A.; Nazockdast, H.; Ottermann, K.; Altstädt, V. Rheological Rationalization of in Situ Nanofibrillar Structure Development: Tailoring of Nanohybrid Shish-Kebab Superstructures of Poly (Lactic Acid) Crystalline Phase. Polymer 2020, 211, 123040. [Google Scholar] [CrossRef]

- Han, R.; Nie, M.; Wang, Q. Control over β-Form Hybrid Shish-Kebab Crystals in Polypropylene Pipe via Coupled Effect of Self-Assembly β Nucleating Agent and Rotation Extrusion. J. Taiwan Inst. Chem. Eng. 2015, 52, 158–164. [Google Scholar] [CrossRef]

- Na, B.; Wang, Y.; Zhang, Q.; Fu, Q. Shish and Its Relaxation Dependence of Re-Crystallization of Isotactic Polypropylene from an Oriented Melt in the Blends with High-Density Polyethylene. Polymer 2004, 45, 6245–6260. [Google Scholar] [CrossRef]

- Kmetty, Á.; Bárány, T.; Karger-Kocsis, J. Self-Reinforced Polymeric Materials: A Review. Prog. Polym. Sci. 2010, 35, 1288–1310. [Google Scholar] [CrossRef]

- Fakirov, S. A New Approach to Plastic Recycling via the Concept of Microfibrillar Composites. Adv. Ind. Eng. Polym. Res. 2021, 4, 187–198. [Google Scholar] [CrossRef]

- Liu, W.; Nie, M.; Wang, Q. In-Situ Microfibrillation of Polystyrene(PS)/Polybutene-1 (PB-1) Composites Prepared via Melt Drawing:Morphological Evolution and Properties. J. Polym. Res. 2014, 21, 489. [Google Scholar] [CrossRef]

- Friedrich, K.; Evstatiev, M.; Fakirov, S.; Evstatiev, O.; Ishii, M.; Harrass, M. Microfibrillar Reinforced Composites from PET/PP Blends: Processing, Morphology and Mechanical Properties. Compos. Sci. Technol. 2005, 65, 107–116. [Google Scholar] [CrossRef]

- Lin, X.D.; Cheung, W.L. Study of Poly(Ethylene Terephthalate)/Polypropylene Microfibrillar Composites. I. Morphological Development in Melt Extrusion. J. Appl. Polym. Sci. 2003, 89, 1743–1752. [Google Scholar] [CrossRef]

- Li, X.; Xin, C.; Huang, Y.; Kang, K.; He, Y. Effect of Dispersed Phase on the Morphology of in Situ Microfibrils and the Viscoelastic Properties of Its Composite via Direct Extrusion. J. Appl. Polym. Sci. 2018, 135, 46286. [Google Scholar] [CrossRef]

- Jiang, Y.; Mi, D.; Wang, Y.; Wang, T.; Shen, K.; Zhang, J. Composite Contains Large Content of In Situ Microfibril, Prepared Directly by Injection Molding: Morphology and Property. Macromol. Mater. Eng. 2018, 303, 1800270. [Google Scholar] [CrossRef]

- Xia, X.C.; Yang, W.; Zhang, Q.P.; Wang, L.; He, S.; Yang, M.B. Large Scale Formation of Various Highly Oriented Structures in Polyethylene/Polycarbonate Microfibril Blends Subjected to Secondary Melt Flow. Polymer 2014, 55, 6399–6408. [Google Scholar] [CrossRef]

- Zhao, Z.; Yang, Q.; Xiang, Z.; Kong, M.; Tang, D.; Huang, Y.; Liao, X.; Niu, Y. Effect of in Situ Poly(Ethylene Terephthalate) (PET) Microfibrils on the Morphological Structure and Crystallization Behavior of Isotactic Polypropylene (iPP) Under an Intensive Shear Rate. Polym. Adv. Technol. 2015, 26, 1275–1284. [Google Scholar] [CrossRef]

- Jiang, C.H.; Zhong, G.J.; Li, Z.M. Recyclability of in Situ Microfibrillar Poly(Ethylene Terephthalate)/High-Density Polyethylene Blends. Macromol. Mater. Eng. 2007, 292, 362–372. [Google Scholar] [CrossRef]

- Xu, L.; Zhong, G.J.; Ji, X.; Li, Z.M. Crystallization Behavior and Morphology of One-Step Reaction Compatibilized Microfibrillar Reinforced Isotactic Polypropylene/Poly(Ethylene Terephthalate) (iPP/PET) Blends. Chin. J. Polym. Sci. 2011, 29, 540–551. [Google Scholar] [CrossRef]

- Xia, X.C.; Yang, W.; He, S.; Xie, D.D.; Zhang, R.Y.; Tian, F.; Yang, M.B. Formation of Various Crystalline Structures in a Polypropylene/Polycarbonate: In Situ Microfibrillar Blend During the Melt Second Flow. Phys. Chem. Chem. Phys. 2016, 18, 14030–14039. [Google Scholar] [CrossRef]

- Kuzmanović, M.; Delva, L.; Cardon, L.; Ragaert, K. The Effect of Injection Molding Temperature on the Morphology and Mechanical Properties of PP/PET Blends and Microfibrillar Composites. Polymers 2016, 8, 355. [Google Scholar] [CrossRef]

- Cheng, L.; Wang, J. Crystallization and Morphological and Crystal Structures of PP in an in Situ Microfibrillar Composite of Modified PA66 with PP. Compos. Sci. Technol. 2018, 155, 205–212. [Google Scholar] [CrossRef]

- Shi, M.; Wang, L.; Sun, J.; Yang, W.; Zhang, H. Morphology and Properties of Polyolefin Elastomer/Polyamide 6/Poly(Lactic Acid) In Situ Special-Shaped Microfibrillar Composites: Influence of Viscosity Ratio. Polymers 2022, 14, 4556. [Google Scholar] [CrossRef]

- Li, Z.M.; Li, L.B.; Shen, K.Z.; Yang, W.; Huang, R.; Yang, M.B. Transcrystalline Morphology of an in Situ Microfibrillar Poly(Ethylene Terephthalate)/Poly(Propylene) Blend Fabricated through a Slit Extrusion Hot Stretching-Quenching Process. Macromol. Rapid Commun. 2004, 25, 553–558. [Google Scholar] [CrossRef]

- Li, Z.M.; Li, L.B.; Shen, K.Z.; Yang, M.B.O.; Huang, R. In-Situ Microfibrillar PET/iPP Blend via Slit Die Extrusion, Hot Stretching, and Quenching: Influence of Hot Stretch Ratio on Morphology, Crystallization, and Crystal Structure of iPP at a Fixed PET Concentration. J. Polym. Sci. Part B Polym. Phys. 2004, 42, 4095–4106. [Google Scholar] [CrossRef]

- Jurczuk, K.; Galeski, A.; Piorkowska, E. All-Polymer Nanocomposites with Nanofibrillar Inclusions Generated in Situ During Compounding. Polymer 2013, 54, 4617–4628. [Google Scholar] [CrossRef]

- Wong, W.S.Y.; Stachurski, Z.H.; Nisbet, D.R.; Tricoli, A. Ultra-Durable and Transparent Self-Cleaning Surfaces by Large-Scale Self-Assembly of Hierarchical Interpenetrated Polymer Networks. ACS Appl. Mater. Interfaces 2016, 8, 13615–13623. [Google Scholar] [CrossRef] [PubMed]

- Brodoceanu, D.; Bauer, C.T.; Kroner, E.; Arzt, E.; Kraus, T. Hierarchical Bioinspired Adhesive Surfaces-A Review. Bioinspir. Biomim. 2016, 11, 1001. [Google Scholar] [CrossRef]

- Tritschler, U.; Cölfen, H. Self-Assembled Hierarchically Structured Organic-Inorganic Composite Systems. Bioinspir. Biomim. 2016, 11, 5002. [Google Scholar] [CrossRef]

- Liu, S.; Wang, S.; Sang, M.; Zhou, J.; Zhang, J.; Xuan, S.; Gong, X. Nacre-Mimetic Hierarchical Architecture in Polyborosiloxane Composites for Synergistically Enhanced Impact Resistance and Ultra-Efficient Electromagnetic Interference Shielding. ACS Nano 2022, 16, 19067–19086. [Google Scholar] [CrossRef] [PubMed]

- Lei, C.; Xie, Z.; Wu, K.; Fu, Q. Controlled Vertically Aligned Structures in Polymer Composites: Natural Inspiration, Structural Processing, and Functional Application. Adv. Mater. 2021, 33, 2103495. [Google Scholar] [CrossRef] [PubMed]

- Kastelic, J.; Galeski, A.; Baer, E. The Multicomposite Structure of Tendon. Connect. Tissue Res. 1978, 6, 11–23. [Google Scholar] [CrossRef] [PubMed]

- He, G.; Li, X.; Dai, Y.; Yang, Z.; Zeng, C.; Lin, C.; He, S. Constructing Bioinspired Hierarchical Structure in Polymer Based Energetic Composites with Superior Thermal Conductivity. Compos. B Eng. 2019, 162, 678–684. [Google Scholar] [CrossRef]

- Mu, X.; Fitzpatrick, V.; Kaplan, D.L. From Silk Spinning to 3D Printing: Polymer Manufacturing Using Directed Hierarchical Molecular Assembly. Adv. Healthc. Mater. 2020, 9, 1901552. [Google Scholar] [CrossRef]

- Liu, J.; Huang, W.; Pang, Y.; Zhu, X.; Zhou, Y.; Yan, D. The in Vitro Biocompatibility of Self-Assembled Hyperbranched Copolyphosphate Nanocarriers. Biomaterials 2010, 31, 5643–5651. [Google Scholar] [CrossRef]

- Van Dongen, S.F.M.; De Hoog, H.P.M.; Peters, R.J.R.W.; Nallani, M.; Nolte, R.J.M.; Van Hest, J.C.M. Biohybrid Polymer Capsules. Chem. Rev. 2009, 109, 6212–6274. [Google Scholar] [CrossRef]

- Nofar, M.; Yenigul, B.S.; Ozdemir, B.; Kovanci, C.Y.; Ghanbari, A.; Jalali, A. Mechanical and Viscoelastic Properties of Polyethylene-Based Microfibrillated Composites from 100% Recycled Resources. J. Appl. Polym. Sci. 2021, 138, 50793. [Google Scholar] [CrossRef]

- Gao, C.; Yu, L.; Liu, H.; Chen, L. Development of Self-Reinforced Polymer Composites. Prog. Polym. Sci. 2012, 37, 767–780. [Google Scholar] [CrossRef]

- Hees, T.; Zhong, F.; Stürzel, M.; Mülhaupt, R. Tailoring Hydrocarbon Polymers and All-Hydrocarbon Composites for Circular Economy. Macromol. Rapid Commun. 2019, 40, 1800608. [Google Scholar] [CrossRef]

- Doncom, K.E.B.; Blackman, L.D.; Wright, D.B.; Gibson, M.I.; O’Reilly, R.K. Dispersity Effects in Polymer Self-Assemblies: A Matter of Hierarchical Control. Chem. Soc. Rev. 2017, 46, 4119–4134. [Google Scholar] [CrossRef]

- Frank, A.; Hils, C.; Weber, M.; Kreger, K.; Schmalz, H.; Schmidt, H.W. Hierarchical Superstructures by Combining Crystallization-Driven and Molecular Self-Assembly. Angew. Chem. Int. Ed. 2021, 60, 21767–21771. [Google Scholar] [CrossRef]

- Lu, Y.; Lin, J.; Wang, L.; Zhang, L.; Cai, C. Self-Assembly of Copolymer Micelles: Higher-Level Assembly for Constructing Hierarchical Structure. Chem. Rev. 2020, 120, 4111–4140. [Google Scholar] [CrossRef]

- Liang, R.; Xue, Y.; Fu, X.; Le, A.N.; Song, Q.; Qiang, Y.; Xie, Q.; Dong, R.; Sun, Z.; Osuji, C.O.; et al. Hierarchically Engineered Nanostructures from Compositionally Anisotropic Molecular Building Blocks. Nat. Mater. 2022, 21, 1434–1440. [Google Scholar] [CrossRef]

- Sun, Z.; Liu, R.; Su, T.; Huang, H.; Kawamoto, K.; Liang, R.; Liu, B.; Zhong, M.; Alexander-Katz, A.; Ross, C.A.; et al. Emergence of Layered Nanoscale Mesh Networks through Intrinsic Molecular Confinement Self-Assembly. Nat. Nanotechnol. 2023, 18, 273–280. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Mark, L.H.; Kim, S.; Chang, E.; Park, C.B.; Lee, P.C. Recent Progress in Micro-/Nano-Fibrillar Reinforced Polymeric Composite Foams. Polym. Eng. Sci. 2021, 61, 926–941. [Google Scholar] [CrossRef]

- Dziadowiec, D.; Matykiewicz, D.; Szostak, M.; Andrzejewski, J. Overview of the Cast Polyolefin Film Extrusion Technology for Multi-Layer Packaging Applications. Materials 2023, 16, 1071. [Google Scholar] [CrossRef] [PubMed]

- Naeimirad, M.; Krins, B.; Gruter, G.J.M. A Review on Melt-Spun Biodegradable Fibers. Sustainability 2023, 15, 14474. [Google Scholar] [CrossRef]

- Hofman, A.H.; ten Brinke, G.; Loos, K. Hierarchical Structure Formation in Supramolecular Comb-Shaped Block Copolymers. Polymer 2016, 107, 343–356. [Google Scholar] [CrossRef]

- Matsushita, Y.; Takano, A.; Hayashida, K.; Asari, T.; Noro, A. Hierarchical Nanophase-Separated Structures Created by Precisely-Designed Polymers with Complexity. Polymer 2009, 50, 2191–2203. [Google Scholar] [CrossRef]

- Ma, L.; Huang, H.; Vargo, E.; Huang, J.; Anderson, C.L.; Chen, T.; Kuzmenko, I.; Ilavsky, J.; Wang, C.; Liu, Y.; et al. Diversifying Composition Leads to Hierarchical Composites with Design Flexibility and Structural Fidelity. ACS Nano 2021, 15, 14095–14104. [Google Scholar] [CrossRef]

- Datta, S.; Saha, M.L.; Stang, P.J. Hierarchical Assemblies of Supramolecular Coordination Complexes. Acc. Chem. Res. 2018, 51, 2047–2063. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Jiang, T.; Lin, S.; Lin, J.; Cai, C.; Zhu, X. Hierarchical Nanostructures Self-Assembled from a Mixture System Containing Rod-Coil Block Copolymers and Rigid Homopolymers. Sci. Rep. 2015, 5, 10137. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Hillmyer, M.A.; Lodge, T.P. Morphologies of Multicompartment Micelles Formed by ABC Miktoarm Star Terpolymers. Langmuir 2006, 22, 9409–9417. [Google Scholar] [CrossRef]

- Zhuang, Y.; Wang, L.; Lin, J. Hierarchical Nanostructures Self-Assembled from Diblock Copolymer/Homopolymer Blends with Supramolecular Interactions. J. Phys. Chem. B 2011, 115, 7550–7560. [Google Scholar] [CrossRef] [PubMed]

- Tyler, C.A.; Qin, J.; Bates, F.S.; Morse, D.C. SCFT Study of Nonfrustrated ABC Triblock Copolymer Melts. Macromolecules 2007, 40, 4654–4668. [Google Scholar] [CrossRef]

- Qian, H.J.; Lu, Z.Y.; Chen, L.J.; Li, Z.S.; Sun, C.C. Computer Simulation of Cyclic Block Copolymer Microphase Separation. Macromolecules 2005, 38, 1395–1401. [Google Scholar] [CrossRef]

- Lin, S.; Numasawa, N.; Nose, T.; Lin, J. Brownian Molecular Dynamics Simulation on Self-Assembly Behavior of Rod-Coil Diblock Copolymers. Macromolecules 2007, 40, 1684–1692. [Google Scholar] [CrossRef]

- Qi, S.; Behringer, H.; Schmid, F. Using Field Theory to Construct Hybrid Particle-Continuum Simulation Schemes with Adaptive Resolution for Soft Matter Systems. New J. Phys. 2013, 15, 125009. [Google Scholar] [CrossRef]

- Sides, S.W.; Kim, B.J.; Kramer, E.J.; Fredrickson, G.H. Hybrid Particle-Field Simulations of Polymer Nanocomposites. Phys. Rev. Lett. 2006, 96, 250601. [Google Scholar] [CrossRef]

- Maurits, N.M.; Fraaije, J.G.E.M. Mesoscopic Dynamics of Copolymer Melts: From Density Dynamics to External Potential Dynamics Using Nonlocal Kinetic Coupling. J. Chem. Phys. 1997, 107, 5879–5889. [Google Scholar] [CrossRef]

- Sevink, G.J.A.; Schmid, F.; Kawakatsu, T.; Milano, G. Combining Cell-Based Hydrodynamics with Hybrid Particle-Field Simulations: Efficient and Realistic Simulation of Structuring Dynamics. Soft Matter 2017, 13, 1594–1623. [Google Scholar] [CrossRef]

- Kolli, H.B.; De Nicola, A.; Bore, S.L.; Schäfer, K.; Diezemann, G.; Gauss, J.; Kawakatsu, T.; Lu, Z.Y.; Zhu, Y.L.; Milano, G.; et al. Hybrid Particle-Field Molecular Dynamics Simulations of Charged Amphiphiles in an Aqueous Environment. J. Chem. Theory Comput. 2018, 14, 4928–4937. [Google Scholar] [CrossRef] [PubMed]

- Bore, S.L.; Milano, G.; Cascella, M. Hybrid Particle-Field Model for Conformational Dynamics of Peptide Chains. J. Chem. Theory Comput. 2018, 14, 1120–1130. [Google Scholar] [CrossRef]

- Bore, S.L.; Kolli, H.B.; De Nicola, A.; Byshkin, M.; Kawakatsu, T.; Milano, G.; Cascella, M. Hybrid Particle-Field Molecular Dynamics Under Constant Pressure. J. Chem. Phys. 2020, 152, 184908. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Ma, Z.; Li, L. Flow-Induced Crystallization of Polymers: Molecular and Thermodynamic Considerations. Macromolecules 2016, 49, 1505–1517. [Google Scholar] [CrossRef]

- Hu, W.B. Polymer Features in Crystallization. Chin. J. Polym. Sci. 2022, 40, 545–555. [Google Scholar] [CrossRef]

- Hikosaka, M. Unified Theory of Nucleation of Folded-Chain Crystals (FCCs) and Extended-Chain Crystals (ECCs) of Linear-Chain Polymers: 2. Origin of FCC and ECC*. Polymer 1990, 31, 458–468. [Google Scholar] [CrossRef]

- Hikosaka, M. Unified Theory of Nucleation of Folded-Chain Crystals and Extended-Chain Crystals of Linear-Chain Polymers. Polymer 1987, 28, 1257–1264. [Google Scholar] [CrossRef]

- Yamazaki, S.; Hikosaka, M.; Toda, A.; Wataoka, I.; Gu, F. Role of Entanglement in Nucleation and “melt Relaxation” of Polyethylene. Polymer 2002, 43, 6585–6593. [Google Scholar] [CrossRef]

- Arrigo, R.; Malucelli, G.; Mantia, F.P.L. Effect of the Elongational Flow on the Morphology and Properties of Polymer Systems: A Brief Review. Polymers 2021, 13, 3529. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Tian, N.; Huang, N.; Cui, K.; Wang, Z.; Hu, T.; Yang, H.; Li, X.; Li, L. Extension-Induced Nucleation Under Near-Equilibrium Conditions: The Mechanism on the Transition from Point Nucleus to Shish. Macromolecules 2014, 47, 6813–6823. [Google Scholar] [CrossRef]

- Han, C.C.; Yao, Y.; Zhang, R.; Hobbie, E.K. Effect of Shear Flow on Multi-Component Polymer Mixtures. Polymer 2006, 47, 3271–3286. [Google Scholar] [CrossRef]

- Okamoto, M.; Kubo, H.; Kotaka, T. Elongational Flow-Induced Crystallization and Structure Development in Supercooled Poly(Ethylene Naphthalate). Macromolecules 1998, 31, 4223–4231. [Google Scholar] [CrossRef]

- Watanabe, K.; Suzuki, T.; Masubuchi, Y.; Taniguchi, T.; Takimoto, J.I.; Koyama, K. Crystallization Kinetics of Polypropylene Under High Pressure and Steady Shear Flow. Polymer 2003, 44, 5843–5849. [Google Scholar] [CrossRef]

- Chen, L.B.; Huang, Y.H.; Zhao, X.; Liu, L.; Gu, J.D.; Liu, Z.Y.; Yang, W.; Fu, X.R.; Yang, M.B. Simulation and Experimental Studies on the Formation and Evolution of Hierarchical Crystalline Structures at the Multi-Melt Flow Interface. Compos.-A Appl. Sci. Manuf. 2021, 144, 106269. [Google Scholar] [CrossRef]

- Nie, C.; Peng, F.; Cao, R.; Cui, K.; Sheng, J.; Chen, W.; Li, L. Recent Progress in Flow-induced Polymer Crystallization. J. Polym. Sci. 2022, 60, 3149–3175. [Google Scholar] [CrossRef]

- Yang, S.; Luo, C.; Lin, H.; Xu, P.P.; Xu, L.; Lei, J.; Zhong, G.J.; Li, Z.M. Robust Propylene-Ethylene Copolymer/Polypropylene Films: Extensional Stress-Induced Orientation Realized at Low Temperature Processing. Polymer 2020, 206, 122848. [Google Scholar] [CrossRef]

- Yaoita, T.; Isaki, T.; Masubuchi, Y.; Watanabe, H.; Ianniruberto, G.; Marrucci, G. Primitive Chain Network Simulation of Elongational Flows of Entangled Linear Chains: Stretch/Orientation-Induced Reduction of Monomeric Friction. Macromolecules 2012, 45, 2773–2782. [Google Scholar] [CrossRef]

- White, J.L.; Spruiell, J.E. The Specification of Orientation and Its Development in Polymer Processing. Polym. Eng. Sci. 1983, 23, 247–256. [Google Scholar] [CrossRef]

- Lacroix, C.; Grmela, M.; Carreau, P.J. Morphological Evolution of Immiscible Polymer Blends in Simple Shear and Elongational Flows. J. Non-Newton. Fluid Mech. 1999, 86, 37–59. [Google Scholar] [CrossRef]

- Van Drongelen, M.; Van Erp, T.B.; Peters, G.W.M. Quantification of Non-Isothermal, Multi-Phase Crystallization of Isotactic Polypropylene: The Influence of Cooling Rate and Pressure. Polymer 2012, 53, 4758–4769. [Google Scholar] [CrossRef]

- Schuller, T.; Fanzio, P.; Galindo-Rosales, F.J. Analysis of the Importance of Shear-Induced Elastic Stresses in Material Extrusion. Addit. Manuf. 2022, 57, 102952. [Google Scholar] [CrossRef]

- Tadmor, Z. Molecular Orientation in Injection Molding. J. Appl. Polym. Sci. 1974, 18, 1753–1772. [Google Scholar] [CrossRef]

- Hosseini, H.; Seyev, V.A.; Erdyshev, B.V.B.; Orisov, A.A.B. Rheological Modeling of Polymeric Melts in Extruders upon Two-Dimensional Shear Flow. Int. Polym. Process. 2016, 31, 51–56. [Google Scholar] [CrossRef]

- Ballenger, T.F.; Chen, I.J.; Crowder, J.W.; Hagler, G.E.; Bogue, D.C.; WHITE, J.L. Polymer Melt Flow Instabilities in Extrusion. Investigation of the Mechanism and Material and Geometric Variables. Trans. Soc. Rheol. 1971, 15, 195–215. [Google Scholar] [CrossRef]

- Liang, J.-Z. Characteristics of Melt Shear Viscosity During Extrusion of Polymers. Polym. Test. 2002, 21, 307–311. [Google Scholar] [CrossRef]

- Pandey, V.; Chen, H.; Ma, J.; Maia, J.M. Extension-Dominated Improved Dispersive Mixing in Single-Screw Extrusion. Part 2: Comparative Analysis with Twin-Screw Extruder. J. Appl. Polym. Sci. 2021, 138, 49765. [Google Scholar] [CrossRef]

- Gupta, V.B.; Bhuvanesh, Y.C. Manufactured Fibre Technology—Basic Principles of Flow During Fibre Spinning; Gupta, V.B., Kothari, V.K., Eds.; Chapman & Hall: London, UK, 1997. [Google Scholar]

- Collier, J.; Petrovan, S.; Patil, P.; Collier, B. Elongational Rheology of Fiber Forming Polymers. J. Mater. Sci. 2005, 40, 5133–5137. [Google Scholar] [CrossRef]

- Münstedt, H.; Kurzbeck, S.; Stange, J. Importance of Elongational Properties of Polymer Melts for Film Blowing and Thermoforming. Polym. Eng. Sci. 2006, 46, 1190–1195. [Google Scholar] [CrossRef]

- Revenu, P.; Guillet, J.; Carrot, C. Elongational Flow of Polyethylenes in Isothermal Melt Spinning. J. Rheol. 1993, 37, 1041–1056. [Google Scholar] [CrossRef]

- Yuan, Z.; Chen, X.; Yu, D.; Fernandes, P.; Faroughi, A.; Ferrás, L.L.; Afonso, A.M. Recent Advances in Elongational Flow Dominated Polymer Processing Technologies. Polymers 2021, 13, 1792. [Google Scholar] [CrossRef]

- Haworth, B.; Jumpa, S. Extensional Flow Characterisation and Extrusion Blow Moulding of High Density Polyethylene Modified by Calcium Carbonate. Plast. Rubber Compos. 1999, 28, 363–378. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Scaffaro, R.; Carianni, G.; Mariani, P. Rheological Properties of Different Film Blowing Polyethylene Samples Under Shear and Elongational Flow. Macromol. Mater. Eng. 2005, 290, 159–164. [Google Scholar] [CrossRef]

- Münstedt, H.; Steffl, T.; Malmberg, A. Correlation Between Rheological Behaviour in Uniaxial Elongation and Film Blowing Properties of Various Polyethylenes. Rheol. Acta 2005, 45, 14–22. [Google Scholar] [CrossRef]

- Gupta, R.K.; Meizner, A.B.; Wissbrun, K.F. Modeling of Polymeric Film-Blowing Processes. Polym. Eng. Sci. 1982, 22, 172–181. [Google Scholar] [CrossRef]

- Münstedt, H. Extensional Rheology and Processing of Polymeric Materials. Int. Polym. Process. 2018, 33, 594–618. [Google Scholar] [CrossRef]

- Qin, S.; Jin, T.; Zhang, H.; Zhou, H.; Liu, J.; Xu, X. Optimization of Hot Drawing Process of Ultra-High Molecular Weight Polyethylene Monofilament Prepared by Melt Spinning. J. Appl. Polym. Sci. 2022, 139, 53075. [Google Scholar] [CrossRef]

- Hufenus, R.; Yan, Y.; Dauner, M.; Kikutani, T. Melt-Spun Fibers for Textile Applications. Materials 2020, 13, 4298. [Google Scholar] [CrossRef]

- Yu, W.; Wang, L.; Shi, J. Influence of Drawing and Annealing on the Crystallization, Viscoelasticity, and Mechanical Properties for Middle-Molecular-Weight Polyethylene Fishing Monofilaments. Fibers Polym. 2018, 19, 1050–1056. [Google Scholar] [CrossRef]

- Baimark, Y.; Molloy, R.; Molloy, N.; Siripitayananon, J.; Punyodom, W.; Sriyai, M. Synthesis, Characterization and Melt Spinning of a Block Copolymer of L-Lactide and ε-Caprolactone for Potential Use as an Absorbable Monofilament Surgical Suture. J. Mater. Sci. Mater. Med. 2005, 16, 699–707. [Google Scholar] [CrossRef] [PubMed]

- Charuchinda, A.; Molloy, R.; Siripitayananon, J.; Molloy, N.; Sriyai, M. Factors Influencing the Small-Scale Melt Spinning of Poly(ε-Caprolactone) Monofilament Fibres. Polym. Int. 2003, 52, 1175–1181. [Google Scholar] [CrossRef]

- Siripitayananon, J.; Molloy, R.; Bunkird, S.; Kleawkla, A.; Panjakha, R.; Chooprayoon, P. Effects of Hot-Drawing and Annealing on the Morphology and Mechanical Properties of Biodegradable Polyester Monofilament Fibers. Int. Polym. Process. 2008, 23, 161–167. [Google Scholar] [CrossRef]

- Nazmul Islam, G.M.; Collie, S.; Qasim, M.; Azam Ali, M. Highly Stretchable and Flexible Melt Spun Thermoplastic Conductive Yarns for Smart Textiles. Nanomaterials 2020, 10, 2324. [Google Scholar] [CrossRef]

- Oh, M.O.; Kim, S.H. Conformational Development of Polylactide Films Induced by Uniaxial Drawing. Polym. Int. 2014, 63, 1247–1253. [Google Scholar] [CrossRef]

- Wang, X.; Zheng, H.; Sun, Y. Study on Structures and Properties of Ultra-Hot Drawing UHMWPE Fibers Fabricated via Dry Spinning Method. J. Polym. Eng. 2018, 38, 863–870. [Google Scholar] [CrossRef]

- Taheri, H.; Nóbrega, J.M.; Samyn, P.; Covas, J.A. The Effect of Temperature and Drawing Ratio on the Mechanical Properties of Polypropylene Monofilaments. AIP Conf. Proc. 2014, 1593, 80–85. [Google Scholar] [CrossRef]

- Deroiné, M.; Pillin, I.; Le Maguer, G.; Chauvel, M.; Grohens, Y. Development of New Generation Fishing Gear: A Resistant and Biodegradable Monofilament. Polym. Test. 2019, 74, 163–169. [Google Scholar] [CrossRef]

- Spruiell, J.E. Structure Formation in Polymeric Fibers—Structure Formation During Melt Spinning; Salem, D.R., Ed.; Hanser: Munich, Germany, 2001. [Google Scholar]

- Furuhashi, Y.; Kimura, Y.; Yoshie, N.; Yamane, H. Higher-Order Structures and Mechanical Properties of Stereocomplex-Type Poly(Lactic Acid) Melt Spun Fibers. Polymer 2006, 47, 5965–5972. [Google Scholar] [CrossRef]

- Schimanski, T.; Peijs, T.; Lemstra, P.J.; Loos, J. Influence of Postdrawing Temperature on Mechanical Properties of Melt-Spun Isotactic Polypropylene. Macromolecules 2004, 37, 1810–1815. [Google Scholar] [CrossRef]

- Pötschke, P.; Paul, D.R. Formation of Co-Continuous Structures in Melt-Mixed Immiscible Polymer Blends. J. Macromol. Sci. Polym. Rev. 2003, 43, 87–141. [Google Scholar] [CrossRef]

- Utracki, L.A. On the Viscosity-Concentration Dependence of Immiscible Polymer Blends. J. Rheol. 1991, 35, 1615–1637. [Google Scholar] [CrossRef]

- Pan, D.; Chen, L.; He, H.; Deng, K.; Qin, Z. Deformation of Dispersed Polystyrene Droplets in Immiscible Polypropylene/Polystyrene Blend Fibers Under Uniaxial Elongational Flow. Fibers Polym. 2016, 17, 1343–1351. [Google Scholar] [CrossRef]

- Delaby, I.; Ernst, B.; Germain, Y.; Muller, R. Droplet Deformation in Polymer Blends During Uniaxial Elongational Flow: Influence of Viscosity Ratio for Large Capillary Numbers. J. Rheol. 1994, 38, 1705–1720. [Google Scholar] [CrossRef]

- García-Masabet, V.; Pérez, O.S.; Cailloux, J.; Abt, T.; Sánchez-Soto, M.; Carrasco, F.; Maspoch, M.L. PLA/PA Bio-Blends: Induced Morphology by Extrusion. Polymers 2020, 12, 10. [Google Scholar] [CrossRef]

- Grace, H.P. Dispersion Phenomena in High Viscosity Immiscible Fluid Systems and Application of Static Mixers as Dispersion Devices in Such Systems. Chem. Eng. Commun. 1982, 14, 225–277. [Google Scholar] [CrossRef]

- Cravero, F.; Arrigo, R.; Frache, A. Processing/Microstructure Relationships in Melt Compounded Polyamide 6 with Different Molecular Weights: Effect of Screw Speed and Viscosity Ratio. Polym. Eng. Sci. 2025, 65, 2525–2538. [Google Scholar] [CrossRef]

- Ma, G.Q.; Sun, Z.B.; Ren, J.Y.; Zeng, Y.; Jia, D.Z.; Li, Y.; Guan, B.; Zhong, G.J.; Li, Z.M. Reorganization of Hydrogen Bonding in Biobased Polyamide 5,13 Under the Thermo-Mechanical Field: Hierarchical Microstructure Evolution and Achieving Excellent Mechanical Performance. Biomacromolecules 2022, 23, 3990–4003. [Google Scholar] [CrossRef]

- Wang, L.; Dong, X.; Huang, M.; Wang, D. Transient Microstructure in Long Alkane Segment Polyamide: Deformation Mechanism and Its Temperature Dependence. Polymer 2016, 97, 217–225. [Google Scholar] [CrossRef]

- Cai, Z.; Liu, X.; Zhou, Q.; Wang, Y.; Zhu, C.; Xiao, X.; Fang, D.; Bao, H. The Structure Evolution of Polyamide 1212 after Stretched at Different Temperatures and Its Correlation with Mechanical Properties. Polymer 2017, 117, 249–258. [Google Scholar] [CrossRef]

- Thyashan, N.; Perera, Y.S.; Xiao, R.; Abeykoon, C. Investigation of the Effect of Materials and Processing Conditions in Twin-Screw Extrusion. Int. J. Lightweight Mater. Manuf. 2024, 7, 353–361. [Google Scholar] [CrossRef]

- Bernagozzi, G.; Arrigo, R.; Frache, A. Evolution of the Microstructure of PP-LDHs Nanocomposites During Melt Compounding: A Simulation Approach. Polymers 2024, 16, 70. [Google Scholar] [CrossRef]

- Louizi, M.; Massardier, V.; Cassagnau, P. Contribution of High-Shear Processing to the Compatibilization of (PP/EPR)/PE Ternary Blends. Macromol. Mater. Eng. 2014, 299, 674–688. [Google Scholar] [CrossRef]

- Teyssandier, F.; Cassagnau, P.; Gérard, J.F.; Mignard, N.; Mélis, F. Morphology and Mechanical Properties of PA12/Plasticized Starch Blends Prepared by High-Shear Extrusion. Mater. Chem. Phys. 2012, 133, 913–923. [Google Scholar] [CrossRef]

- Sui, G.; Jing, M.; Zhao, J.; Wang, K.; Zhang, Q.; Fu, Q. A Comparison Study of High Shear Force and Compatibilizer on the Phase Morphologies and Properties of Polypropylene/Polylactide (PP/PLA) Blends. Polymer 2018, 154, 119–127. [Google Scholar] [CrossRef]

- Li, Y.; Shimizu, H. Fabrication of Nanostructured Polycarbonate/Poly(Methyl Methacrylate) Blends with Improved Optical and Mechanical Properties by High-Shear Processing. Polym. Eng. Sci. 2011, 51, 1437–1445. [Google Scholar] [CrossRef]

- Shimizu, H.; Li, Y.; Kaito, A.; Sano, H. Formation of Nanostructured PVDF/PA11 Blends Using High-Shear Processing. Macromolecules 2005, 38, 7880–7883. [Google Scholar] [CrossRef]

- Raj, A.; Samuel, C.; Malladi, N.; Prashantha, K. Enhanced (Thermo)Mechanical Properties in Biobased Poly(l-Lactide)/Poly(Amide-12) Blends Using High Shear Extrusion Processing Without Compatibilizers. Polym. Eng. Sci. 2020, 60, 1902–1916. [Google Scholar] [CrossRef]

- Farahanchi, A.; Boehm, E.; Orbey, N.; Malloy, R. The Effect of Ultra-High Speed Twin Screw Extrusion on ABS/Organoclay Nanocomposite Blend Properties. Polym. Eng. Sci. 2017, 57, 60–68. [Google Scholar] [CrossRef]

- Farahanchi, A.; Malloy, R.A.; Sobkowicz, M.J. Extreme Shear Processing for Exfoliating Organoclay in Nanocomposites with Incompatible Polymers. Polymer 2018, 145, 117–126. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, C.; Dong, P.; Wang, K.; Zhang, Q. Realizing Mechanically Reinforced All-Polyethylene Material by Dispersing UHMWPE via High-Speed Shear Extrusion. Polymer 2019, 180, 121711. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, C.; Dong, P.; Wang, K. Realizing Self-Reinforcement of Polyethylene via High-Speed Shear Processing. J. Polym. Res. 2019, 26, 236. [Google Scholar] [CrossRef]

- Yu, W.J.; Xu, S.M.; Zhang, L.; Fu, Q. Morphology and Mechanical Properties of Immiscible Polyethylene/Polyamide12 Blends Prepared by High Shear Processing. Chin. J. Polym. Sci. 2017, 35, 1132–1142. [Google Scholar] [CrossRef]

- Grizzuti, D.N.; Bifulco, O. Effects of Coalescence and Breakup on the Steady-State Morphology of an Immiscible Polymer Blend in Shear Flow. Rheol. Acta 1997, 36, 406–415. [Google Scholar] [CrossRef]

- Utracki, L.A.; Shi, H. Development of Polymer Blend Morphology During Compounding in a Twin-Screw Extruder. Part I: Droplet Dispersion and Coalescence-A Review. Polym. Eng. Sci. 1992, 32, 1824–1833. [Google Scholar] [CrossRef]

- Ajitha, A.R.; Thomas, S. Introduction: Polymer Blends, Thermodynamics, Miscibility, Phase Separation, and Compatibilization. In Compatibilization of Polymer Blends; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 1–29. ISBN 978-0-12-816006-0. [Google Scholar]

- D’Avino, G.; Maffettone, P.L. Particle Dynamics in Viscoelastic Liquids. J. Non-Newton. Fluid Mech. 2015, 215, 80–104. [Google Scholar] [CrossRef]

- Van Puyvelde, P.; Vananroye, A.; Cardinaels, R.; Moldenaers, P. Review on Morphology Development of Immiscible Blends in Confined Shear Flow. Polymer 2008, 49, 5363–5372. [Google Scholar] [CrossRef]

- Koning, C. Strategies for Compatibilization of Polymer Blends. Prog. Polym. Sci. 1998, 23, 707–757. [Google Scholar] [CrossRef]

- Taylor, G.I. The Formation of Emulsions in Definable Fields of Flow. Proc. R. Soc. Lond. Ser. A 1934, 146, 501–523. [Google Scholar] [CrossRef]

- Taylor, G.I. The Viscosity of a Fluid Containing Small Drops of Another Fluid. Proc. R. Soc. Lond. Ser. A 1932, 138, 41–49. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Tailoring the Toughness of Sustainable Polymer Blends from Biodegradable Plastics via Morphology Transition Observed by Atomic Force Microscopy. Polym. Degrad. Stab. 2020, 173, 109066. [Google Scholar] [CrossRef]

- Graziano, A.; Jaffer, S.; Sain, M. Review on Modification Strategies of Polyethylene/Polypropylene Immiscible Thermoplastic Polymer Blends for Enhancing Their Mechanical Behavior. J. Elastomers Plast. 2019, 51, 291–336. [Google Scholar] [CrossRef]

- Wu, S. Formation of Dispersed Phase in Incompatible Polymer Interfacial and Rheological Effects. Polym. Eng. Sci. 1987, 27, 335–343. [Google Scholar] [CrossRef]

- Pi, L.; Nie, M.; Wang, Q. Crystalline Composition and Morphology in Isotactic Polypropylene Pipe Under Combining Effects of Rotation Extrusion and Fibril β-Nucleating Agent. J. Vinyl Addit. Technol. 2019, 25, 195–202. [Google Scholar] [CrossRef]

- Nie, M.; Bai, S.B.; Wang, Q. High-Density Polyethylene Pipe with High Resistance to Slow Crack Growth Prepared via Rotation Extrusion. Polym. Bull. 2010, 65, 609–621. [Google Scholar] [CrossRef]

- Liu, W.; Wang, Q.; Nie, M. Structure and Performance of Polybutene-1 Pipes Produced via Mandrel Rotation Extrusion. J. Polym. Eng. 2014, 34, 15–22. [Google Scholar] [CrossRef]

- Chen, B.; Yang, H.; Shen, K.; Fu, Q.; Gao, X. The Effect of High-Temperature Annealing on Thermal Properties and Morphology of Polyethylene Pipes Prepared by Rotational Shear. Polymer 2020, 204, 122770. [Google Scholar] [CrossRef]

- Han, R.; Nie, M.; Bai, S.; Wang, Q. Control over Crystalline Form in Polypropylene Pipe via Mandrel Rotation Extrusion. Polym. Bull. 2013, 70, 2083–2096. [Google Scholar] [CrossRef]

- Yang, H.; Luo, X.; Shen, K.; Yuan, Y.; Fu, Q.; Gao, X.; Jiang, L. The Role of Mandrel Rotation Speed on Morphology and Mechanical Properties of Polyethylene Pipes Produced by Rotational Shear. Polymer 2019, 184, 121915. [Google Scholar] [CrossRef]

- Intawong, N.-T.; Arajang, A.D.; Domsom, S.U.; Oochooshai, T.Y.; Antala, C.K. An Annular Rotating-Die Technique in Extrusion Process: Effect of Mandrel Rotating Speed on Extrudate Swell Behavior of HDPE Parison. Int. Polym. Process. 2014, 5, 607–615. [Google Scholar] [CrossRef]

- Lu, X.; Qian, R.; Brown, N.; Buczala, C. The Effect of Pressure and Contaminants on Slow Crack Growth in a Butt Fusion in a Polyethylene Gas Pipe. J. Appl. Polym. Sci. 1992, 46, 1417–1427. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, Q.; Bai, S. The Effect of Rotational Extrusion on the Structure and Properties of HDPE Pipes. Polym.-Plast. Technol. Mater. 2010, 49, 908–915. [Google Scholar] [CrossRef]

- Lu, X.; Zhou, Z.; Brown, N. The Anisotropy of Slow Crack Growth in Polyethylene Pipes. Polym. Eng. Sci. 1994, 34, 109–115. [Google Scholar] [CrossRef]

- Pi, L.; Hu, X.; Nie, M.; Wang, Q. Role of Ultrahigh Molecular Weight Polyethylene During Rotation Extrusion of Polyethylene Pipe. Ind. Eng. Chem. Res. 2014, 53, 13828–13832. [Google Scholar] [CrossRef]

- Nie, M.; Li, X.; Hu, X.; Wang, Q. Effect of Die Temperature on Morphology and Performance of Polyethylene Pipe Prepared via Mandrel Rotation Extrusion. J. Macromol. Sci. Part B Phys. 2014, 53, 1442–1452. [Google Scholar] [CrossRef]

- Li, Y.; Nie, M.; Wang, Q. Synergistic Effect of Self-Assembling Nucleating Agent and Crystallization Promoter on Polypropylene Random Copolymer Pipes via Rotation Extrusion. Polym. Eng. Sci. 2016, 56, 866–873. [Google Scholar] [CrossRef]

- Tang, H.I.; Hiltner, A.; Baer, E. Biaxial Orientation of Polypropylene by Hydrostatic Solid State Extrusion Part III: Mechanical Properties and Deformation Mechanisms. Polym. Eng. Sci. 1987, 27, 876–886. [Google Scholar] [CrossRef]

- Han, R.; Nie, M.; Bai, S.-B.; Wang, Q. Effect of the Mandrel Rotation Speed and Inner Wall Cooling Rate on the Performance and Structure of Polypropylene Block-Copolymer Pipe. Int. Polym. Process. 2013, 5, 496–505. [Google Scholar] [CrossRef]

- Shao, H.; Yao, W.; Huang, B.; Zhao, Y. Effect of Crystallinity and Spherulite Structure on the Mechanical Properties of Poly(I-Butene). J. Polym. Eng. 2009, 29, 341–353. [Google Scholar] [CrossRef]

- Kong, D.C.; Yang, M.H.; Zhang, X.S.; Du, Z.C.; Fu, Q.; Gao, X.Q.; Gong, J.W. Control of Polymer Properties by Entanglement: A Review. Macromol. Mater. Eng. 2021, 306, 2100536. [Google Scholar] [CrossRef]

- Wu, Q.F.; Zhou, N.Q.; Li, B.; Zhang, P. Study on the Effect of Axial Vibration of Screw in Plasticating Process (Extrusion Part). Polym.-Plast. Technol. Mater. 2008, 47, 318–324. [Google Scholar] [CrossRef]

- An, F.Z.; Gao, X.Q.; Lei, J.; Deng, C.; Li, Z.M.; Shen, K.Z. Vibration Assisted Extrusion of Polypropylene. Chin. J. Polym. Sci. 2015, 33, 688–696. [Google Scholar] [CrossRef]

- Ibar, J.P. Processing Polymer Melts Under Rheo-Fluidification Flow Conditions, Part 1: Boosting Shear-Thinning by Adding Low Frequency Nonlinear Vibration to Induce Strain Softening. J. Macromol. Sci. Part B Phys. 2013, 52, 407–441. [Google Scholar] [CrossRef]

- Chen, J.; Chen, Y.; Li, H.; Lai, S.Y.; Jow, J. Physical and Chemical Effects of Ultrasound Vibration on Polymer Melt in Extrusion. Ultrason. Sono. 2010, 17, 66–71. [Google Scholar] [CrossRef] [PubMed]

- Zsayev, A.Z.; Wong, C.M.; Zeng, X. Effect of Oscillations During Extrusion on Rheology and Mechanical Properties of Polymers. Adv. Polym. Technol. 1990, 10, 31–45. [Google Scholar] [CrossRef]

- Casulli, J.; Clermont, J.R.; Ziegler, A.V.; Mena, B. The Oscillating Die: A Useful Concept in Polymer Extrusion. Polym. Eng. Sci. 1990, 30, 1551–1556. [Google Scholar] [CrossRef]

- Fridman, M.L.; Peshkovsky, S.L.; Vinogradov, G.V. The Rheology of Thermoplastics Under Conditions of Spiral Flow and Vibrations on Extrusion. Polym. Eng. Sci. 1981, 21, 755–767. [Google Scholar] [CrossRef]

- Guo, S.; Li, Y.; Chen, G.; Li, H. Ultrasonic Improvement of Rheological and Processing Behaviour of LLDPE During Extrusion. Polym. Int. 2003, 52, 68–73. [Google Scholar] [CrossRef]

- Chen, Y.; Li, H. Mechanism for Effect of Ultrasound on Polymer Melt in Extrusion. J. Polym. Sci. Part B Polym. Phys. 2007, 45, 1226–1233. [Google Scholar] [CrossRef]

- Liu, G.; Li, H. Extrusion of Ultrahigh Molecular Weight Polyethylene Under Ultrasonic Vibration Field. J. Appl. Polym. Sci. 2003, 89, 2628–2632. [Google Scholar] [CrossRef]

- Ibar, J.P. Control of Polymer Properties by Melt Vibration Technology: A Review. Polym. Eng. Sci. 1998, 38, 1–20. [Google Scholar] [CrossRef]

- Cao, Y.; Li, H. Influence of Ultrasound on the Processing and Structure of Polypropylene During Extrusion. Polym. Eng. Sci. 2002, 42, 1534–1540. [Google Scholar] [CrossRef]

- Chen, K.; Zhou, N.Q.; Liu, B.; Wen, S.P. Effect of Vibration Extrusion on the Structure and Properties of High-Density Polyethylene Pipes. Polym. Int. 2009, 58, 117–123. [Google Scholar] [CrossRef]

- Qu, J.; Zeng, G.; Feng, Y.; Jin, G.; He, H.; Cao, X. Effect of Screw Axial Vibration on Polymer Melting Process in Single-Screw Extruders. J. Appl. Polym. Sci. 2006, 100, 3860–3876. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, J.; Chen, C.; Shen, K. Effect of Vibration Extrusion on High-Density Polyethylene. J. Appl. Polym. Sci. 2007, 106, 552–557. [Google Scholar] [CrossRef]

- Chen, K.Y.; Zhou, N.Q.; Liu, B.; Jin, G. Improved Mechanical Properties and Structure of Polypropylene Pipe Prepared Under Vibration Force Field. J. Appl. Polym. Sci. 2009, 114, 3612–3620. [Google Scholar] [CrossRef]

- Peng, B.; Wu, H.; Bao, W.; Guo, S.; Chen, Y.; Huang, H.; Chen, H.; Lai, S.Y.; Jow, J. Effects of Ultrasound on the Morphology and Properties of Propylene-Based Plastomer/Nanosilica Composites. Polym. Int. 2011, 43, 91–96. [Google Scholar] [CrossRef]

- Chen, G.; Guo, S.; Li, Y. Dynamic Rheological Properties of High-Density Polyethylene/Polystyrene Blends Extruded in the Presence of Ultrasonic Oscillations. J. Appl. Polym. Sci. 2004, 92, 3153–3158. [Google Scholar] [CrossRef]

- Isayev, A.I.; Hong, C.K.; Kim, K.J. Continuous Mixing and Compounding of Polymer/Filler and Polymer/Polymer Mixtures with the Aid of Ultrasound. Rubber Chem. Technol. 2003, 76, 923–947. [Google Scholar] [CrossRef]

- Oh, J.S.; Isayev, A.I.; Rogunova, M.A. Continuous Ultrasonic Process for in Situ Compatibilization of Polypropylene/Natural Rubber Blends. Polymer 2003, 44, 2337–2349. [Google Scholar] [CrossRef]

- Bing, L.; Qiao, Z.N.; Hong, Z.Z.; Hua, L.W. Study on Mechanical Properties and Molecular Aggregate of the Dynamic Extrusion Polymer Filling System. Polym. Plast. Technol. Eng. 2007, 46, 293–298. [Google Scholar] [CrossRef]

- Qu, J.; Qin, X.; Cao, X.; Jin, G. Effect of Vibrating Extrusion on the Structure and Mechanical Properties of Isotactic Polypropylene. Polym. Plast. Technol. Eng. 2006, 45, 1065–1071. [Google Scholar] [CrossRef]

- Isayev, A.I.; Wong, C.M.; Zeng, X. Flow of Thermoplastics in an Annular Die Under Orthogonal Oscillations. J. Non-Newton. Fluid Mech. 1990, 34, 375–397. [Google Scholar] [CrossRef]

- Li, Y.; Chen, G.; Guo, S.; Li, H. Effect of Ultrasonic Oscillations on the Rheological Behavior and Morphology of Illite-Filled High-Density Polyethylene Composites. J. Appl. Polym. Sci. 2005, 96, 379–384. [Google Scholar] [CrossRef]

- Wong, C.M.; Chen, C.H.; Isayev, A.I. Flow of Thermoplastics in an Annular Die Under Parallel Oscillations. Polym. Eng. Sci 1990, 30, 1574–1584. [Google Scholar] [CrossRef]

- Wang, Z.W.; Hu, J.; An, F.Z.; Gong, J.W.; Gao, X.Q.; Deng, C.; Shen, K.Z. Vibration-Dependent Morphology and Crystal Structure of Isotactic Polypropylene. J. Mater. Sci. 2013, 48, 6986–6993. [Google Scholar] [CrossRef]

- Palierne, J.F. Linear Rheology of Viscoelastic Emulsions with Interfacial Tension. Rheol. Acta 1990, 29, 204–214. [Google Scholar] [CrossRef]

- Dreval, V.E.; Vinogradov, G.V.; Plotnikova, E.P.; Zabugina, M.P.; Krasnikova, N.P.; Kotova, E.V.; Pelzbauer, Z. Deformation of Melts of Mixtures of Incompatible Polymers in a Uniform Shear Field and the Process of Their Fibrillation. Rheol. Acta 1983, 22, 102–107. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, W.; Wang, X.; Wu, D. Preparation, Mechanical Properties and Microstructure of Polyoxymethylene Fiber through Melt Spinning and Hot Drawing by Using Injection-Molding Grade Resins. Fibers Polym. 2016, 17, 1464–1474. [Google Scholar] [CrossRef]

- Bashirgonbadi, A.; Delva, L.; Caron, E.; Marchesini, F.H.; Van Geem, K.M.; Ragaert, K. The Interplay Between Macromolecular Structure, Rheology, Processing Condition, and Morphology for (Linear) Low Density Polyethylenes in Film Blowing. Polymer 2024, 290, 126566. [Google Scholar] [CrossRef]

- Boone, J.; Loxt, F.; Pottie, S. Deficiencies of Polypropylene in i t s Use as a Food-Packaging Material-a Review. Packag. Technol. Sci. 1993, 6, 277–281. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Challenges and New Opportunities on Barrier Performance of Biodegradable Polymers for Sustainable Packaging. Prog. Polym. Sci. 2021, 117, 101395. [Google Scholar] [CrossRef]

- Chellamani, K.P.; Veerasubramanian, D.; Vignesh Balaji, R.S. Surgical Sutures: An Overview. J. Acad. Indus. Res. 2013, 1, 778–782. [Google Scholar]

- Byrne, M.; Aly, A. The Surgical Suture. Aesthet. Surg. J. 2019, 39, S67–S72. [Google Scholar] [CrossRef]

- Chikhalikar, K.; Banik, S.; Azad, L.B.; Jadhav, K.; Mahajan, S.; Ahmad, Z.; Kulkarni, S.; Gupta, S.; Doshi, P.; Pol, H.; et al. Extrusion Film Casting of Long Chain Branched Polypropylene. Polym. Eng. Sci. 2015, 55, 1977–1987. [Google Scholar] [CrossRef]

- Hu, B.; Cai, Q.; Xu, R.; Mo, H.; Chen, C.; Zhang, F.; Lei, C. Influence of Uniaxial Cold Stretching Followed by Uniaxial Hot Stretching Conditions on Crystal Transformation and Microstructure in Extrusion Cast and Annealed Polyvinylidene Fluoride Porous Membranes. J. Plast. Film Sheeting 2015, 31, 269–285. [Google Scholar] [CrossRef]

- Lin, Y.; Tu, W.; Verpaalen, R.C.P.; Zhang, H.; Bastiaansen, C.W.M.; Peijs, T. Transparent, Lightweight, and High Strength Polyethylene Films by a Scalable Continuous Extrusion and Solid-State Drawing Process. Macrom. Mater. Eng. 2019, 304, 1900138. [Google Scholar] [CrossRef]

- Saffar, A.; Ajji, A.; Carreau, P.J.; Kamal, M.R. The Impact of New Crystalline Lamellae Formation During Annealing on the Properties of Polypropylene Based Films and Membranes. Polymer 2014, 55, 3156–3167. [Google Scholar] [CrossRef]

- Ding, L.; Zhang, D.; Yan, N.; Zhang, S.; Wu, T.; Yang, F.; Lan, F.; Cao, Y.; Xiang, M. The Structure Changes of Polypropylene Precursor Film with Different Die Draw Ratio During Annealing. Polymer 2020, 208, 122958. [Google Scholar] [CrossRef]

- Sabard, M.; Gouanvé, F.; Espuche, E.; Fulchiron, R.; Seytre, G.; Fillot, L.A.; Trouillet-Fonti, L. Influence of Film Processing Conditions on the Morphology of Polyamide 6: Consequences on Water and Ethanol Sorption Properties. J. Membr. Sci. 2012, 415–416, 670–680. [Google Scholar] [CrossRef]

- Xie, J.; Yin, L.; Wu, Y.; Xu, R.; Lei, C. The Effect of the Melt-Drawing Ratio on the Microstructure and Mechanical Properties of Poly(Butylene Succinate) Cast Films with Row-Nucleated Lamellar Structure. Polym. Test. 2021, 104, 107394. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Turng, L.S.; Shen, C.Y. Morphological Evolution and Orientation Development of Stretched iPP Films: Influence of Draw Ratio. J. Polym. Sci. Part B Polym. Phys. 2010, 48, 1223–1234. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Wu, W.B.; Zou, J.; Turng, L.S. Dual-Scale Modeling and Simulation of Film Casting of Isotactic Polypropylene. J. Plast. Film Sheeting 2016, 32, 239–271. [Google Scholar] [CrossRef]

- Liu, J.; Xu, M.; Zhang, S.; Liang, J.; Quan, H.; Liu, J.; Shi, H.; Gao, D. Influences of Processing on the Phase Transition and Crystallization of Polypropylene Cast Films. J. Appl. Polym. Sci. 2014, 131, 41100. [Google Scholar] [CrossRef]

- Mai, F.; Tu, W.; Bilotti, E.; Peijs, T. The Influence of Solid-State Drawing on Mechanical Properties and Hydrolytic Degradation of Melt-Spun Poly(Lactic Acid) (PLA) Tapes. Fibers 2015, 3, 523–538. [Google Scholar] [CrossRef]

- Xu, R.; Zeng, S.; Wang, J.; Kang, J.; Xiang, M.; Yang, F. Impact of Different Die Draw Ratio on Crystalline and Oriented Properties of Polypropylene Cast Films and Annealed Films. J. Polym. Res. 2018, 25, 142. [Google Scholar] [CrossRef]

- Xu, R.; Xie, J.; Lei, C. Influence of Melt-Draw Ratio on the Crystalline Behaviour of a Polylactic Acid Cast Film with a Chi Structure. RSC Adv. 2017, 7, 39914–39921. [Google Scholar] [CrossRef]

- Sadeghi, F.; Ajji, A.; Carreau, P.J. Study of Polypropylene Morphology Obtained from Blown and Cast Film Processes: Initial Morphology Requirements for Making Porous Membrane by Stretching. J. Plast. Film Sheeting 2005, 21, 199–216. [Google Scholar] [CrossRef]

- Agassant, J.F.; Demay, Y.; Sollogoub, C.; Silagy, D. Cast Film Extrusion: An Overview of Experimental and Theoretical Approaches. Int. Polym. Process. 2005, 20, 136–148. [Google Scholar] [CrossRef]

- Xu, R.; Chen, X.; Xie, J.; Cai, Q.; Lei, C. Influence of Melt-Draw Ratio on the Crystalline Structure and Properties of Polypropylene Cast Film and Stretched Microporous Membrane. Ind. Eng. Chem. Res. 2015, 54, 2991–2999. [Google Scholar] [CrossRef]

- Sadeghi, F.; Ajji, A.; Carreau, P.J. Analysis of Row Nucleated Lamellar Morphology of Polypropylene Obtained from the Cast Film Process: Effect of Melt Rheology and Process Conditions. Polym. Eng. Sci. 2007, 47, 1170–1178. [Google Scholar] [CrossRef]

- Hu, B.; Lei, C.; Xu, R.; Shi, W.; Cai, Q.; Mo, H.; Chen, C. Influence of Melt-Draw Ratio on the Structure and Properties of Poly(Vinylidiene Fluoride) Cast Film. J. Plast. Film Sheeting 2014, 30, 300–313. [Google Scholar] [CrossRef]

- Yang, D.C.; Thomas, E.L. An Electron Microscopy and X-Ray Diffraction Study of the Microstructures of Melt-Drawn Polyethylene Films. J. Mater. Sci. 1984, 19, 2098–2110. [Google Scholar] [CrossRef]

- Shanak, H.; Naumann, A.; Lion, J.; Götz, W.; Pelster, R. Orientation of Nano-Crystallites and Anisotropy of Uniaxially Drawn α-Polyamide 6 Films: XRD, FTIR, and Microwave Measurements. J. Mater. Sci. 2014, 49, 8074–8083. [Google Scholar] [CrossRef]

- Houichi, H.; Maazouz, A.; Elleuch, B. Crystallization Behavior and Spherulitic Morphology of Poly(Lactic Acid) Films Induced by Casting Process. Polym. Eng. Sci. 2015, 55, 1881–1888. [Google Scholar] [CrossRef]

- Zeng, B.; Ai, J.; Xia, M.; Pang, Y.; Zheng, Y.; Shen, J.; Guo, S. Deep Insight into the Effect of Microstructure Evolution on Film-Forming Properties of Polylactide During Uniaxial Hot-Stretching Process. Macromolecules 2024, 57, 4937–4946. [Google Scholar] [CrossRef]

- Ma, A.; Xu, L.; Yin, B.; Yang, M.; Xie, B. Influences of Melt-Draw Ratio and Annealing on the Crystalline Structure and Orientation of Poly(4-Methyl-1-Pentene) Casting Films. RSC Adv. 2016, 6, 62038–62044. [Google Scholar] [CrossRef]

- Tabatabaei, S.H.; Carreau, P.J.; Ajji, A. Structure and Properties of MDO Stretched Polypropylene. Polymer 2009, 50, 3981–3989. [Google Scholar] [CrossRef]

- Cui, K.; Ma, Z.; Tian, N.; Su, F.; Liu, D.; Li, L. Multiscale and Multistep Ordering of Flow-Induced Nucleation of Polymers. Chem. Rev. 2018, 118, 1840–1886. [Google Scholar] [CrossRef] [PubMed]

- Wei, Q.-Y.; Huang, J.-Z.; Jia, D.-Z.; Lei, J.; Huang, H.-D.; Lin, H.; Xu, J.-Z.; Zhong, G.-J.; Li, Z.-M. Integration of Stiffness, Ductility, Heat Resistance, and Transparency for Polylactide Films by Manipulation of Amorphous Chain Networks and Oriented Nanocrystals. Macromolecules 2024, 57, 3706–3718. [Google Scholar] [CrossRef]

- Lin, Y.J.; Dias, P.; Chen, H.Y.; Chum, S.; Hiltner, A.; Baer, E. Oxygen Permeability of Biaxially Oriented Polypropylene Films. Polym. Eng. Sci 2008, 48, 642–648. [Google Scholar] [CrossRef]

- Bai, H.; Wang, Y.; Zhang, Z.; Han, L.; Li, Y.; Liu, L.; Zhou, Z.; Men, Y. Influence of Annealing on Microstructure and Mechanical Properties of Isotactic Polypropylene with β-Phase Nucleating Agent. Macromolecules 2009, 42, 6647–6655. [Google Scholar] [CrossRef]

- Zia, Q.; Mileva, D.; Androsch, R. Rigid Amorphous Fraction in Isotactic Polypropylene. Macromolecules 2008, 41, 8095–8102. [Google Scholar] [CrossRef]

- Hedesiu, C.; Demco, D.E.; Kleppinger, R.; Vanden Poel, G.; Gijsbers, W.; Blümich, B.; Remerie, K.; Litvinov, V.M. Effect of Temperature and Annealing on the Phase Composition, Molecular Mobility, and the Thickness of Domains in Isotactic Polypropylene Studied by Proton Solid-State NMR, SAXS, and DSC. Macromolecules 2007, 40, 3977–3989. [Google Scholar] [CrossRef]

- Jiang, Z.; Tang, Y.; Rieger, J.; Enderle, H.F.; Lilge, D.; Roth, S.V.; Gehrke, R.; Wu, Z.; Li, Z.; Li, X.; et al. Structural Evolution of Melt-Drawn Transparent High-Density Polyethylene During Heating and Annealing: Synchrotron Small-Angle X-Ray Scattering Study. Eur. Polym. J. 2010, 46, 1866–1877. [Google Scholar] [CrossRef]

- Xu, R.J.; Lei, C.; Cai, Q.; Hu, B.; Shi, W.; Mo, H.; Chen, C. Micropore Formation Process During Stretching of Polypropylene Casting Precursor Film. Plast. Rubber Compos. 2014, 43, 257–263. [Google Scholar] [CrossRef]

- Rauwendaal, C. Understanding Extrusion; Hanser Publications: Munich, Germany, 2018. [Google Scholar]

- Zhu, M.F.; Yang, H.H. Handbook of Fiber Chemistry—Polypropylene Fibers; Menachem, L., Ed.; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Peacock, A.J.; Calhoun, A. Polymer Chemistry: Properties and Applications; Hanser: Munich, Germany, 2006. [Google Scholar]

- Gnoffo, C.; Arrigo, R.; Frache, A. An Upcycling Strategy for Polyethylene Terephthalate Fibers: All-Polymer Composites with Enhanced Mechanical Properties. J. Compos. Sci. 2024, 8, 527. [Google Scholar] [CrossRef]

- Wang, F.; Liu, L.; Xue, P.; Jia, M.; Wang, S.; Cai, J. The Influence of Formation Temperatures on the Crystal Structure and Mechanical Properties of Ultrahigh-Molecular-Weight Polyethylene/High-Density Polyethylene-Blend Fibers Prepared by Melt Spinning. J. Ind. Text. 2020, 49, 1011–1035. [Google Scholar] [CrossRef]

- Bayramol, D.V. Investigation on the Effect of Draw Ratio on Voltage Outputs of Polarised Isotactic Polypropylene Monofilaments. Tekst. Mühendis 2016, 23, 166–171. [Google Scholar] [CrossRef]

- Rudolf, A.; Smole, M.S. Structure-Properties Relations of the Drawn Poly(Ethylene Terephthalate) Filament Sewing Thread. J. Appl. Polym. Sci. 2008, 110, 2641–2648. [Google Scholar] [CrossRef]

- Zhang, J.M.; Hua, Q.; Reynolds, C.T.; Zhao, Y.; Dai, Z.; Bilotti, E.; Tang, J.; Peijs, T. Preparation of High Modulus Poly(Ethylene Terephthalate): Influence of Molecular Weight, Extrusion, and Drawing Parameters. Int. J. Polym. Sci. 2017, 2017, 2781425. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Y.; Ma, G.; Ren, J.; Wang, G.; Zhang, S.; Zhang, M.; Luan, J. Study of the Microstructure Formation Mechanisms of Poly(Ether-Ether-Ketone) Monofilaments via Melt Spinning. J. Appl. Polym. Sci. 2023, 140, 53365. [Google Scholar] [CrossRef]

- Wang, F.; Liu, L.; Xue, P.; Jia, M.; Sun, H. A Study of the Mechanical Behavior and Crystal Structure of UHMWPE/HDPE Blend Fibers Prepared by Melt Spinning. J. Eng. Fibers Fabr. 2018, 13, 23–36. [Google Scholar] [CrossRef]

- Youn, C.; Gwak, H.J.; Bae, Y.; Kim, D.; Yeang, B.J.; Doh, S.J.; Yeo, S.Y. Improving Mechanical Properties of Melt-Spun Polyetherimide Monofilaments by Thermal Drawing. J. Appl. Polym. Sci. 2022, 139, 53155. [Google Scholar] [CrossRef]

- Fakirov, S.; Bhattacharyya, D.; Lin, R.J.T.; Fuchs, C.; Friedrich, K. Contribution of Coalescence to Microfibril Formation in Polymer Blends During Cold Drawing. J. Macromol. Sci. Part B Phys. 2007, 46, 183–194. [Google Scholar] [CrossRef]

- Yan, X.; Gao, Z.; Zhu, C.; Song, L.; Qi, D.; Mao, N. Microfibrillation and Properties of Poly (Styrene Acrylate) Microspheres Reinforced Polymethyl Methacrylate Composite Fibers. Mater. Lett. 2023, 330, 133319. [Google Scholar] [CrossRef]

- Song, L.; Wang, J.; Yan, X.; Cui, Z.; Li, J.; Qi, D. Microfibrillation Structure Evolution and Mechanical Properties of MS@PMHNTs Reinforced Polymethyl Methacrylate Composite Fiber. Compos. Commun. 2022, 31, 101108. [Google Scholar] [CrossRef]

- Kuzmanović, M.; Delva, L.; Mi, D.; Martins, C.I.; Cardon, L.; Ragaert, K. Development of Crystalline Morphology and Its Relationship with Mechanical Properties of PP/PET Microfibrillar Composites Containing POE and POE-g-MA. Polymers 2018, 10, 291. [Google Scholar] [CrossRef]

- Rosales, C.; Aranburu, N.; Otaegi, I.; Pettarin, V.; Bernal, C.; Müller, A.J.; Guerrica-Echevarriá, G. Improving the Mechanical Performance of LDPE/PP Blends through Microfibrillation. ACS Appl. Polym. Mater. 2022, 4, 3369–3379. [Google Scholar] [CrossRef]

- Jayanarayanan, K.; Ravichandran, A.; Rajendran, D.; Sivathanupillai, M.; Venkatesan, A.; Thomas, S.; Joseph, K. Morphology and Mechanical Properties of Normal Blends and In-Situ Microfibrillar Composites from Low-Density Polyethylene and Poly(Ethylene Terephthalate). Polym. Plast. Technol. Eng. 2010, 49, 442–448. [Google Scholar] [CrossRef]

- Kuzmanović, M.; Delva, L.; Martins, C.I.; Cardon, L.; Ragaert, K. MFC Concept as a Possible Solution for Closed-Loop Recycling of Food Packaging Trays. AIP Conf. Proc. 2020, 2205, 020071. [Google Scholar] [CrossRef]

- Fakirov, S. Polymer Nanocomposites: Why Their Mechanical Performance Does Not Justify the Expectation and a Possible Solution to the Problem? Express Polym. Lett. 2020, 14, 436–466. [Google Scholar] [CrossRef]

- Zhang, A.; Chai, J.; Yang, C.; Zhao, J.; Zhao, G.; Wang, G. Fibrosis Mechanism, Crystallization Behavior and Mechanical Properties of in-Situ Fibrillary PTFE Reinforced PP Composites. Mater. Des. 2021, 211, 110157. [Google Scholar] [CrossRef]

- Jurczuk, K.; Galeski, A. Thermoplastic Elastomers Reinforced with Poly(Tetrafluoroethylene) Nanofibers. Eur. Polym. J. 2016, 80, 58–69. [Google Scholar] [CrossRef]

- Evstatiev, M.; Fakirov, S. Microfibrillar Reinforcement of Polymer Blends. Polymer 1992, 33, 877–880. [Google Scholar] [CrossRef]

- Fakirov, S.; Bhattacharyya, D.; Shields, R.J. Nanofibril Reinforced Composites from Polymer Blends. Colloids Surf. A Physicochem. Eng. Asp. 2008, 313–314, 2–8. [Google Scholar] [CrossRef]

- Anstey, A.; Chang, E.; Kim, E.S.; Rizvi, A.; Kakroodi, A.R.; Park, C.B.; Lee, P.C. Nanofibrillated Polymer Systems: Design, Application, and Current State of the Art. Prog. Polym. Sci. 2021, 113, 101346. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, W.; Liu, S.; Ji, H.; Chen, X.; Zhu, H.; Zhao, H.; Ma, Y.; Xie, L. The Formation of a Highly Oriented Structure and Improvement of Properties in PP/PA6 Polymer Blends During Extrusion-Stretching. Polymers 2020, 12, 878. [Google Scholar] [CrossRef] [PubMed]

- Jayanarayanan, K.; Thomas, S.; Joseph, K. In Situ Microfibrillar Blends and Composites of Polypropylene and Poly (Ethylene Terephthalate): Morphology and Thermal Properties. J. Polym. Res. 2011, 18, 1–11. [Google Scholar] [CrossRef]

- Evstatiev, M.; Fakirov, S.; Krasteva, B.; Friedrich, K.; Covas, J.A.; Cunha, A.M. RecycIing of PoIy(ethyIene terephthaIate) as PoIymer-PoIymer Composites. Polym. Eng. Sci. 2002, 42, 826–835. [Google Scholar] [CrossRef]

- Hosseinnezhad, R.; Vozniak, I.; Romano, D.; Rastogi, S.; Regnier, G.; Piorkowska, E.; Galeski, A. Formation of UHMWPE Nanofibers During Solid-State Deformation. Nanomaterials 2022, 12, 3825. [Google Scholar] [CrossRef] [PubMed]

- Vozniak, I.; Hosseinnezhad, R.; Morawiec, J.; Galeski, A. Nanofibrillar Green Composites of Polylactide/Polyhydroxyalkanoate Produced in Situ Due to Shear Induced Crystallization. Polymers 2019, 11, 1811. [Google Scholar] [CrossRef]

- Voznyak, Y.; Morawiec, J.; Galeski, A. Ductility of Polylactide Composites Reinforced with Poly(Butylene Succinate) Nanofibers. Compos.-A Appl. Sci. Manuf. 2016, 90, 218–224. [Google Scholar] [CrossRef]

- Hosseinnezhad, R.; Vozniak, I.; Morawiec, J.; Galeski, A.; Dutkiewicz, S. In Situ Generation of Sustainable PLA-Based Nanocomposites by Shear Induced Crystallization of Nanofibrillar Inclusions. RSC Adv. 2019, 9, 30370–30380. [Google Scholar] [CrossRef]

- Hosseinnezhad, R.; Vozniak, I.; Morawiec, J.; Galeski, A. Nanofibrillar Green Composites of Polylactide/Polyamide Produced in Situ Due to Shear Induced Crystallization. Compos. Commun. 2020, 22, 100512. [Google Scholar] [CrossRef]

- Hosseinnezhad, R.; Vozniak, I.; Morawiec, J.; Galeski, A. Evolution of Green In-Situ Generated Polyamide Nanofibers Controlled by Viscoelasticity. Express Polym. Lett. 2021, 15, 250–261. [Google Scholar] [CrossRef]

- Vozniak, I.; Hosseinnezhad, R.; Morawiec, J.; Galeski, A. Microstructural Evolution of Poly(ε-Caprolactone), Its Immiscible Blend, and in Situ Generated Nanocomposites. Polymers 2020, 12, 2587. [Google Scholar] [CrossRef]

- Hosseinnezhad, R. Shear-Induced and Nanofiber-Nucleated Crystallization of Novel Aliphatic-Aromatic Copolyesters Delineated for In Situ Generation of Biodegradable Nanocomposites. Polymers 2021, 13, 2315. [Google Scholar] [CrossRef]

- Jurczuk, K.; Galeski, A.; Galeski, A. All-Polymer Fibrillar Nanocomposites and Method for Manufacture Thereof. European Patent EP2428597B1, 4 March 2011. [Google Scholar]

- Bernland, K.; Smith, P. Nucleating Polymer Crystallization with Poly(Tetrafluoroethylene) Nanofibrils. J. Appl. Polym. Sci. 2009, 114, 281–287. [Google Scholar] [CrossRef]

- Krajenta, J.; Pawlak, A.; Galeski, A. Deformation of Disentangled Polypropylene Crystalline Grains into Nanofibers. J. Polym. Sci. B Polym. Phys. 2016, 54, 1983–1994. [Google Scholar] [CrossRef]

- Jurczuk, K.; Galeski, A.; Morawiec, J. Effect of Poly(Tetrafluoroethylene) Nanofibers on Foaming Behavior of Linear and Branched Polypropylenes. Eur. Polym. J. 2017, 88, 171–182. [Google Scholar] [CrossRef]

- Jurczuk, K.; Galeski, A.; Piorkowska, E. Strain Hardening of Molten Thermoplastic Polymers Reinforced with Poly(Tetrafluoroethylene) Nanofibers. J. Rheol. 2014, 58, 589–605. [Google Scholar] [CrossRef]

- Huang, A.; Kharbas, H.; Ellingham, T.; Mi, H.; Turng, L.S.; Peng, X. Mechanical Properties, Crystallization Characteristics, and Foaming Behavior of Polytetrafluoroethylene-Reinforced Poly(Lactic Acid) Composites. Polym. Eng. Sci. 2017, 57, 570–580. [Google Scholar] [CrossRef]

- Huang, A.; Peng, X.; Turng, L.S. In-Situ Fibrillated Polytetrafluoroethylene (PTFE) in Thermoplastic Polyurethane (TPU) via Melt Blending: Effect on Rheological Behavior, Mechanical Properties, and Microcellular Foamability. Polymer 2018, 134, 263–274. [Google Scholar] [CrossRef]

- Wang, K.; Wu, F.; Zhai, W.; Zheng, W. Effect of Polytetrafluoroethylene on the Foaming Behaviors of Linear Polypropylene in Continuous Extrusion. J. Appl. Polym. Sci. 2013, 129, 2253–2260. [Google Scholar] [CrossRef]

- Galeski, S.; Piorkowska, E.; Rozanski, A.; Regnier, G.; Galeski, A.; Jurczuk, K. Crystallization Kinetics of Polymer Fibrous Nanocomposites. Eur. Polym. J. 2016, 83, 181–201. [Google Scholar] [CrossRef]

- Evstatiev, M.; Fakirov, S.; Bechtold, G.; Friedrich, K. Structure-Property Relationships of Injection- and Compression-Molded Microfibrillar-Reinforced PET/PA-6 Composites. Adv. Polym. Technol. 2000, 19, 249–259. [Google Scholar] [CrossRef]

- Fakirov, S.; Evstatiev, M.; Schultz, J.M. Microfibrillar Reinforced Composite from Drawn Poly(Ethylene Terephthalate)/Nylon-6 Blend. Polymer 1993, 34, 4669–4679. [Google Scholar] [CrossRef]

- Evstatiev, M.; Fakirov, S.; Schultz, J.M.; Friedrich, K. In Situ Fibrillar Reinforced PET/PA-6/PA-66 Blend. Polym. Eng. Sci 2001, 41, 192–204. [Google Scholar] [CrossRef]

- Wang, Y.; Li, G.; Wan, Z.; Zhu, H.; Ma, Y.; Xie, L. Establishment of Dynamic Prediction Model on Morphology Development of Polypropylene/Polyamide 6 Blends Under in-Situ Fibrillation Flow. Polymer 2024, 294, 126722. [Google Scholar] [CrossRef]

- Huang, W.-Y.; Shen, J.-W.; Chen, X.-M. Effect of Composition on Phase Morphology and Mechanical Properties of PP/PA66 in Situ Composites via Extrusion-Drawing-Injection Method. J. Mater. Sci. 2003, 38, 541–547. [Google Scholar] [CrossRef]

- Kharghanian, M.; Perchicot, R.; Irusta, S.; Argon, C.Y.; Leonardi, F.; Dagreou, S. Manufacture and Rheological Behavior of All Recycled PET/PP Microfibrillar Blends. Polym. Eng. Sci. 2023, 63, 1702–1715. [Google Scholar] [CrossRef]

- Gonzalez-Nunez, R.; Arellano, M.; Moscoso, F.J.; Gonzalez-Romero, V.M.; Favis, B.D. Polymer Communication Determination of a Limiting Dispersed Phase Concentration for Coalescence in PA6/HDPE Blends Under Extensional Flow. Polymer 2001, 42, 5485–5489. [Google Scholar] [CrossRef]

- Li, Z.-M.; Yang, M.-B.; Feng, J.-M.; Yang, W.; Huang, R. Morphology of in Situ Poly(Ethylene Terephthalate)/Polyethylene Microfiber Reinforced Composite Formed via Slit-Die Extrusion and Hot-Stretching. Mater. Res. Bull. 2002, 37, 2185–2197. [Google Scholar] [CrossRef]

- Li, Z.-M.; Yang, M.-B.; Lu, A.; Feng, J.-M.; Huang, R. Tensile Properties of Poly(Ethylene Terephthalate) and Polyethylene in-Situ Microfiber Reinforced Composite Formed via Slit Die Extrusion and Hot-Stretching. Mater. Lett. 2002, 56, 756–762. [Google Scholar] [CrossRef]

- Qiao, Y.; Li, Q.; Jalali, A.; Yang, J.; Wang, X.; Zhao, N.; Jiang, Y.; Wang, S.; Hou, J.; Jiang, J. In-Situ Microfibrillated Poly(ε-Caprolactone)/Poly(Lactic Acid) Composites with Enhanced Rheological Properties, Crystallization Kinetics and Foaming Ability. Compos. B Eng. 2021, 208, 108594. [Google Scholar] [CrossRef]

- Xie, L.; Xu, H.; Niu, B.; Ji, X.; Chen, J.; Li, Z.M.; Hsiao, B.S.; Zhong, G.J. Unprecedented Access to Strong and Ductile Poly(Lactic Acid) by Introducing in Situ Nanofibrillar Poly(Butylene Succinate) for Green Packaging. Biomacromolecules 2014, 15, 4054–4064. [Google Scholar] [CrossRef]

- Mi, D.; Wang, Y.; Kuzmanovic, M.; Delva, L.; Jiang, Y.; Cardon, L.; Zhang, J.; Ragaert, K. Effects of Phase Morphology on Mechanical Properties: Oriented/Unoriented PP Crystal Combination with Spherical/Microfibrillar PET Phase. Polymers 2019, 11, 248. [Google Scholar] [CrossRef] [PubMed]

- Shahnooshi, M.; Javadi, A.; Nazockdast, H.; Altstädt, V. Development of in Situ Nanofibrillar Poly (Lactic Acid)/Poly (Butylene Terephthalate) Composites: Non-Isothermal Crystallization and Crystal Morphology. Eur. Polym. J. 2020, 125, 109489. [Google Scholar] [CrossRef]

- Gokgoz Erkoc, I.; Guven, T.; Yildirim, F.; Sözer, M.; Güner, F. Effect of Screw Speed, Drawing Ratio and PET Concentration on the Properties of PET/PP Blends. Acta Phys. Pol. A 2018, 134, 442–446. [Google Scholar] [CrossRef]

- Gonzalez-Nunez, R.; Favis, B.D.; Cafweau, P.J.; Lavallee, C. Factors Influencing the Formation of Elongated Morphologies in Immiscible Polymer Blends During Melt Processing. Polym. Eng. Sci. 1993, 33, 851–859. [Google Scholar] [CrossRef]

- Chapleau, N.; Favis, B.D. Droplet/Fibre Transitions in Immiscible Polymer Blends Generated During Melt Processing. J. Mater. Sci. 1995, 30, 142–150. [Google Scholar] [CrossRef]

- Perilla, J.E.; Jana, S.C. A Time-scale Approach for Analysis of Coalescence in Processing Flows. Polym. Eng. Sci 2004, 44, 2254–2265. [Google Scholar] [CrossRef]

- Favis, B.D.; Willis, J.M. Phase Size/Composition Dependence in Immiscible Blends: Experimental and Theoretical Considerations. J. Polym. Sci. B Polym. Phys. 1990, 28, 2259–2269. [Google Scholar] [CrossRef]

- Zanjanijam, A.R.; Hakim, S.; Azizi, H. Morphological, Dynamic Mechanical, Rheological and Impact Strength Properties of the PP/PVB Blends: The Effect of Waste PVB as a Toughener. RSC Adv. 2016, 6, 44673–44686. [Google Scholar] [CrossRef]

- Fuchs, C.; Bhattacharyya, D.; Friedrich, K.; Fakirov, S. Application of Halpin-Tsai Equation to Microfibril Reinforced Polypropylene/Poly(Ethylene Terephthalate) Composites. Compos. Interfaces 2006, 13, 331–344. [Google Scholar] [CrossRef]

- Rybnikar, F.; Kaszonyiova, M. Epitaxial Crystallization of Linear Polyethylene in Blends with Isotactic Polypropylene. J. Macromol. Sci. Part B 2014, 53, 217–232. [Google Scholar] [CrossRef]

- Taepaiboon, P.; Junkasem, J.; Dangtungee, R.; Amornsakchai, T.; Supaphol, P. In Situ Microfibrillar-reinforced Composites of Isotactic Polypropylene/Recycled Poly(Ethylene Terephthalate) System and Effect of Compatibilizer. J. Appl. Polym. Sci. 2006, 102, 1173–1181. [Google Scholar] [CrossRef]

- Yousfi, M.; Soulestin, J.; Marcille, S.; Lacrampe, M.F. In-Situ Nano-Fibrillation of Poly(Butylene Succinate-Co-Adipate) in Isosorbide-Based Polycarbonate Matrix. Relationship Between Rheological Parameters and Induced Morphological and Mechanical Properties. Polymer 2021, 217, 123445. [Google Scholar] [CrossRef]

- Yi, X.; Xu, L.; Wang, Y.L.; Zhong, G.J.; Ji, X.; Li, Z.M. Morphology and Properties of Isotactic Polypropylene/Poly(Ethylene Terephthalate) in Situ Microfibrillar Reinforced Blends: Influence of Viscosity Ratio. Eur. Polym. J. 2010, 46, 719–730. [Google Scholar] [CrossRef]

- Min, K.; White, J.L.; Fellers, J.F. Development of Phase Morphology in Incompatible Polymer Blends During Mixing and Its Variation in Extrusion*. Polym. Eng. Sci. 1984, 24, 1327–1336. [Google Scholar] [CrossRef]