PLA/PBS Biocomposites for 3D FDM Manufacturing: Effect of Hemp Shive Content and Process Parameters on Printing Quality and Performances

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Composites Production

2.2. Filament Production and FDM Printing

2.3. Characterization Techniques

3. Results and Discussion

3.1. Preliminary Characterization of Hemp Shive and Its Composites

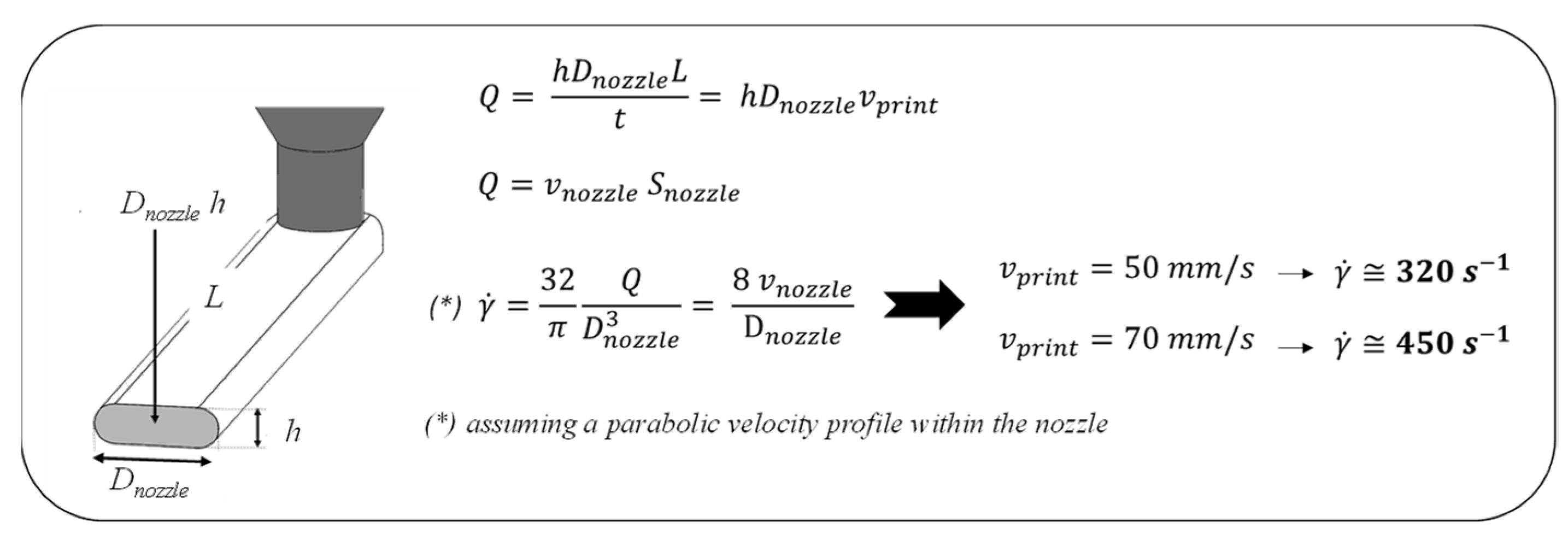

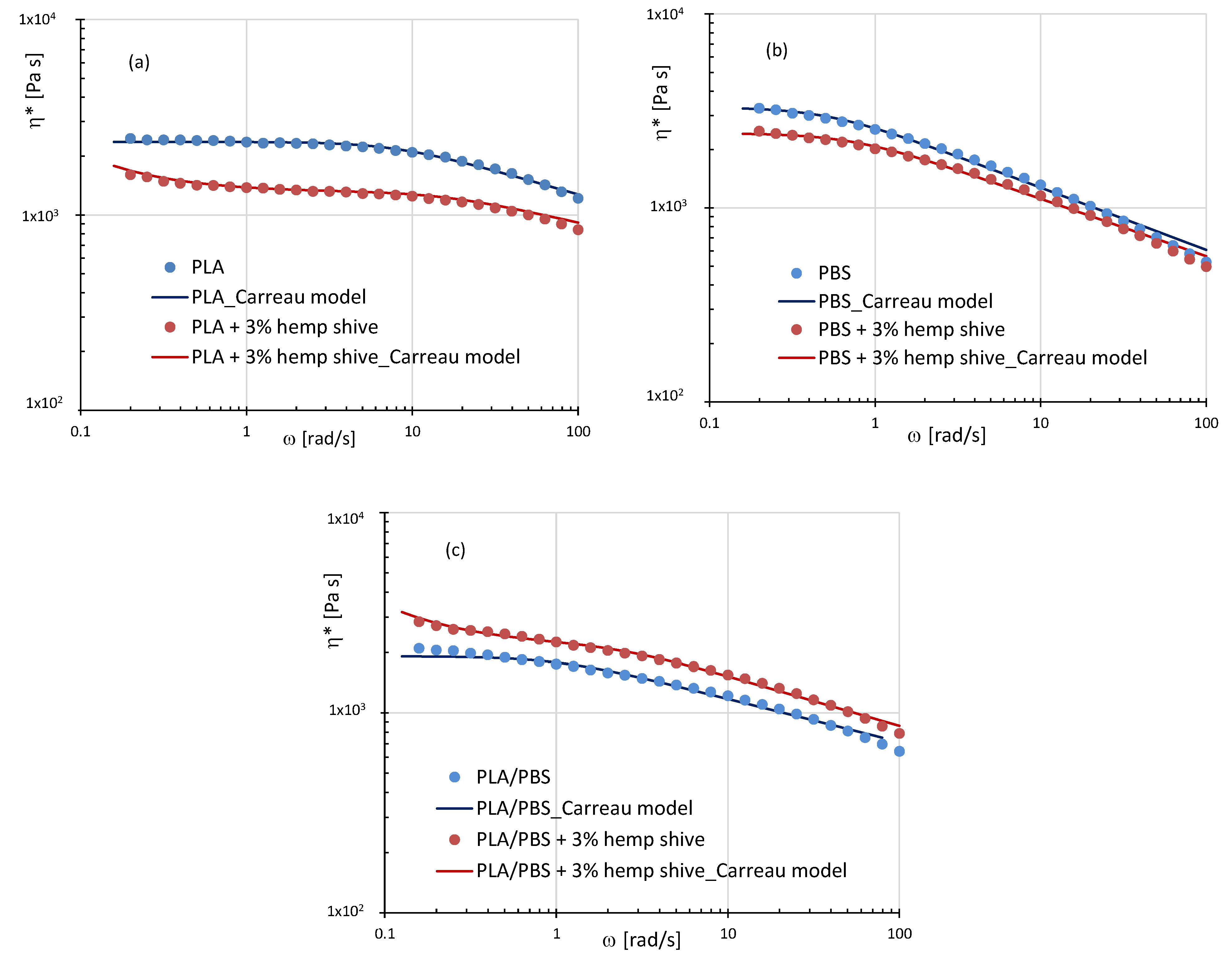

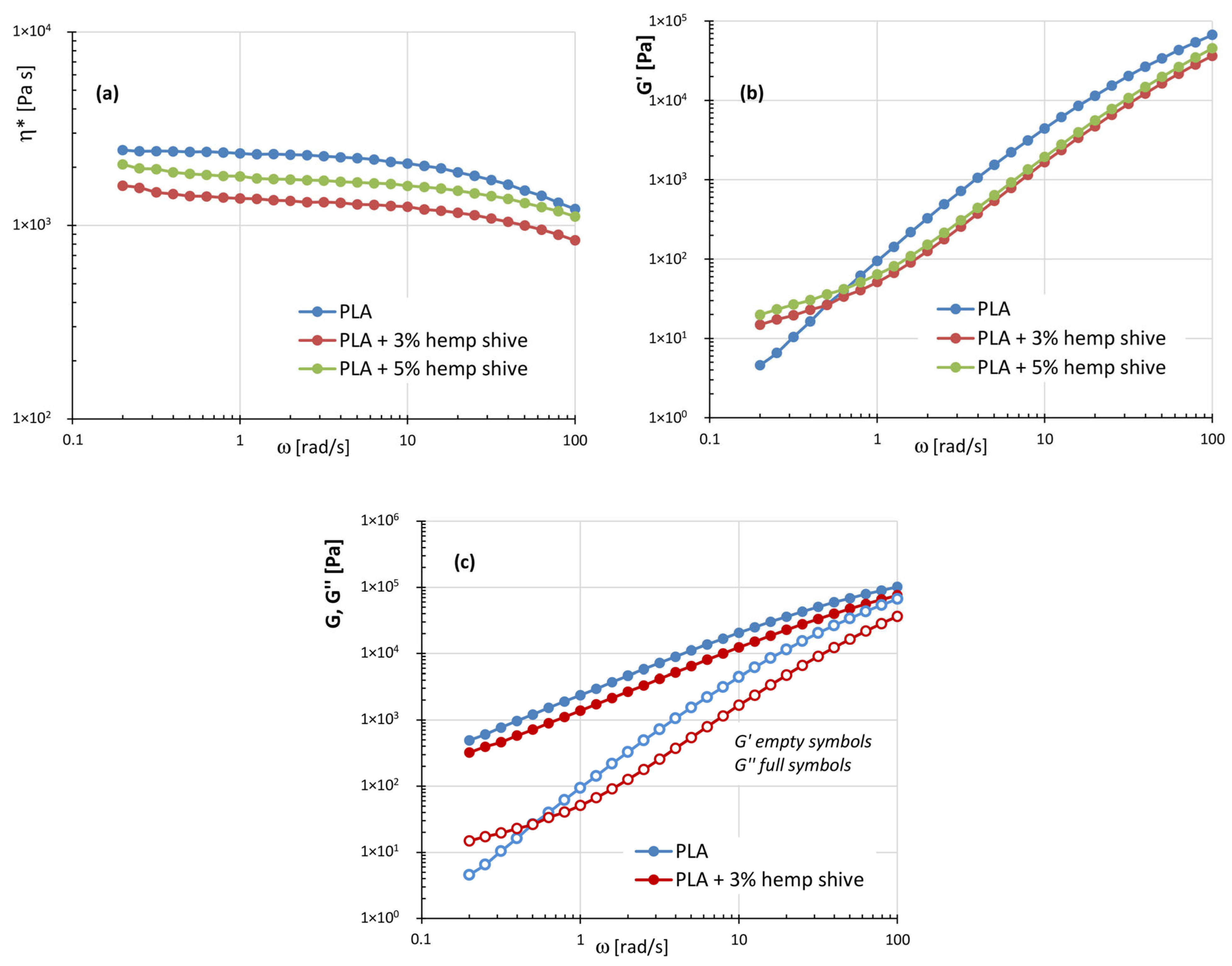

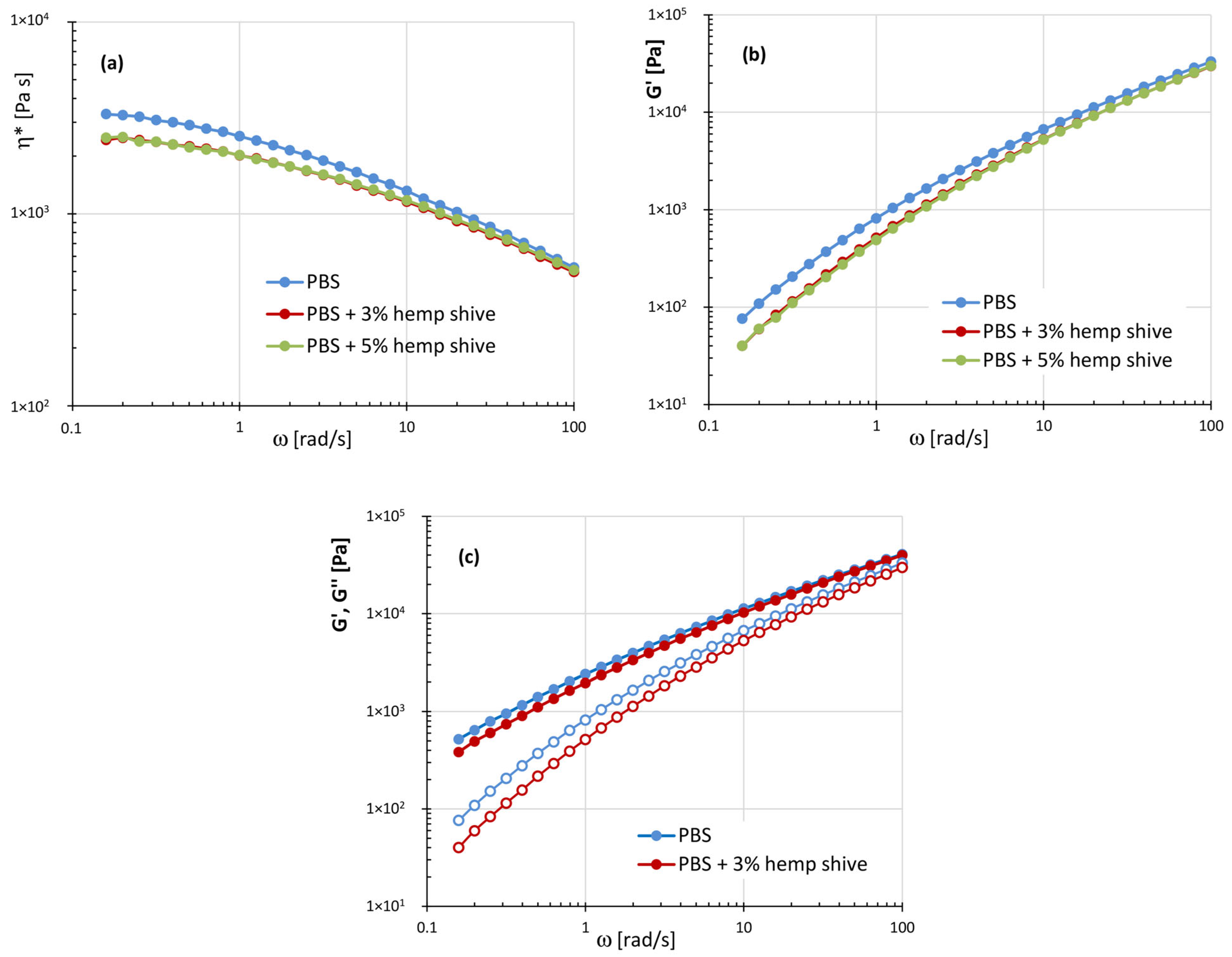

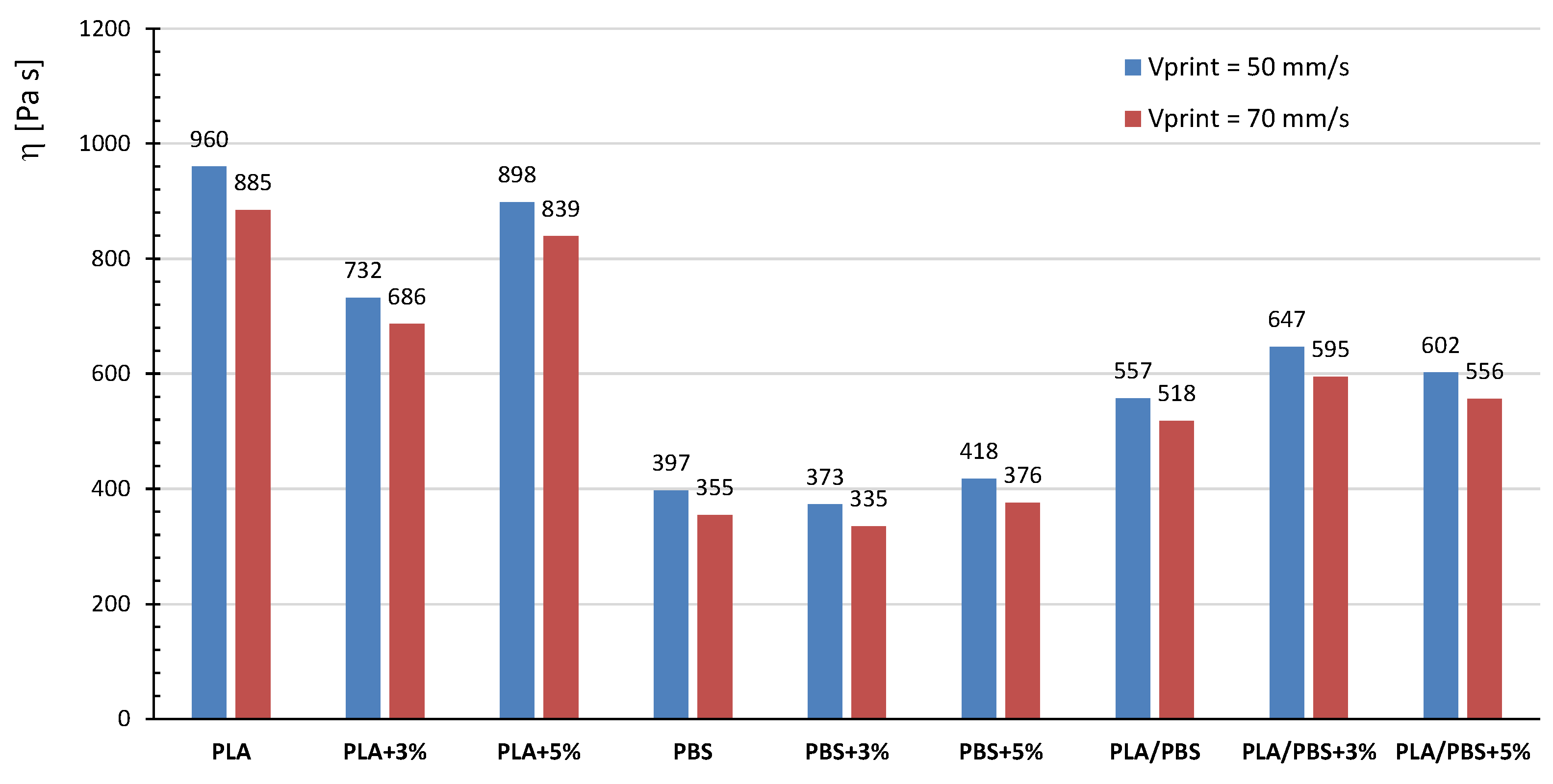

3.2. Rheological Behavior of the Neat Systems and Hemp-Shive-Based Composites

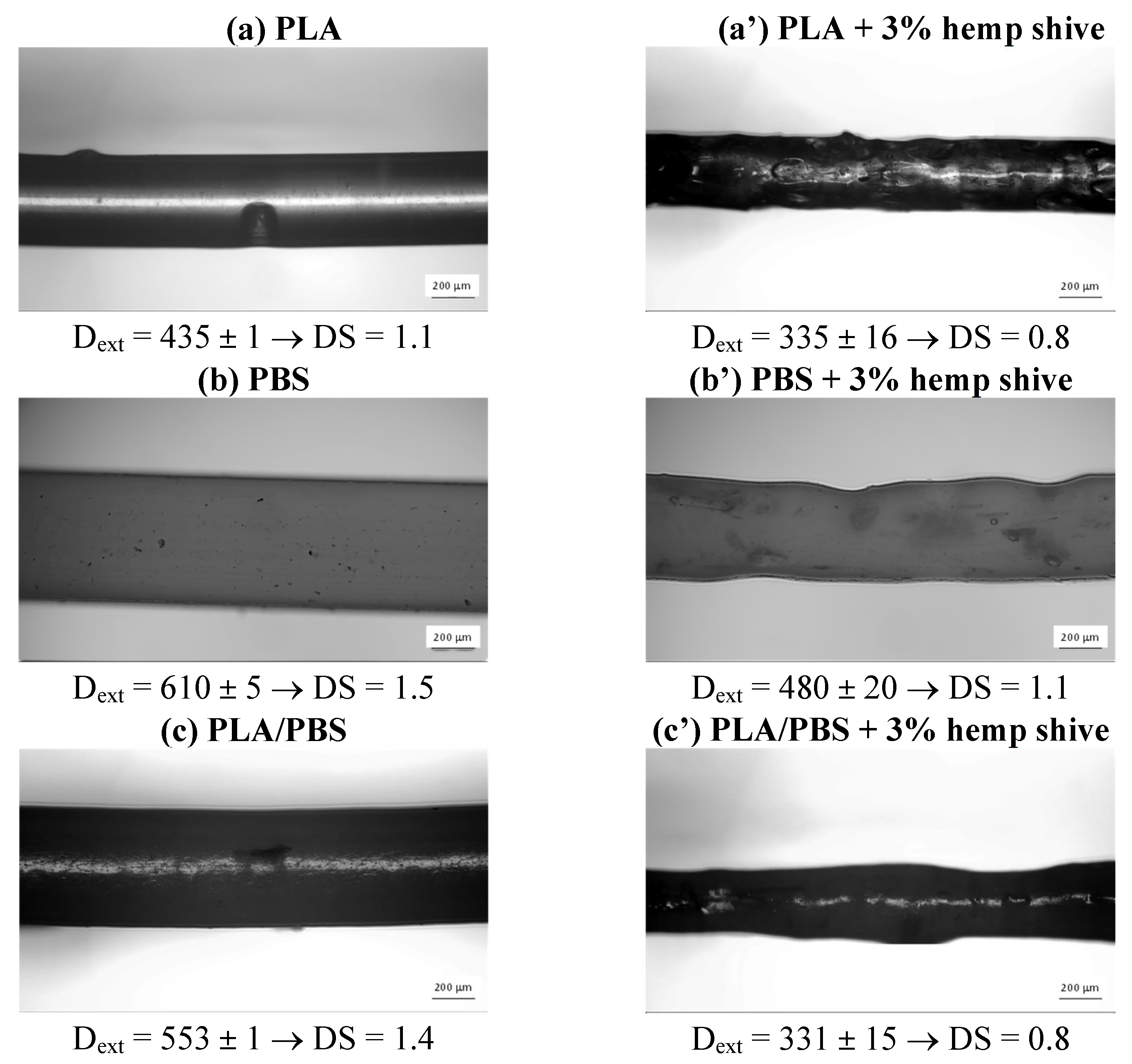

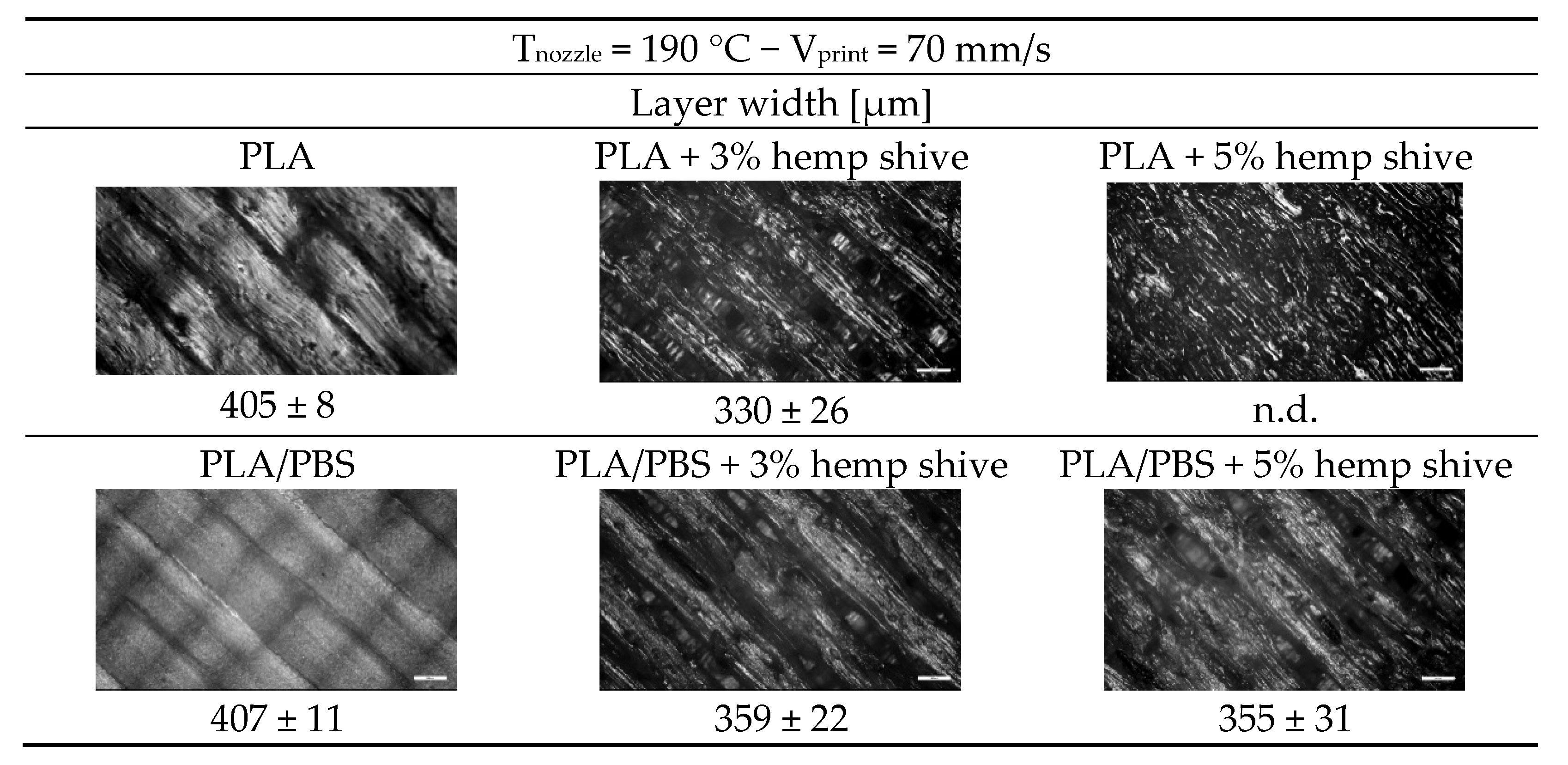

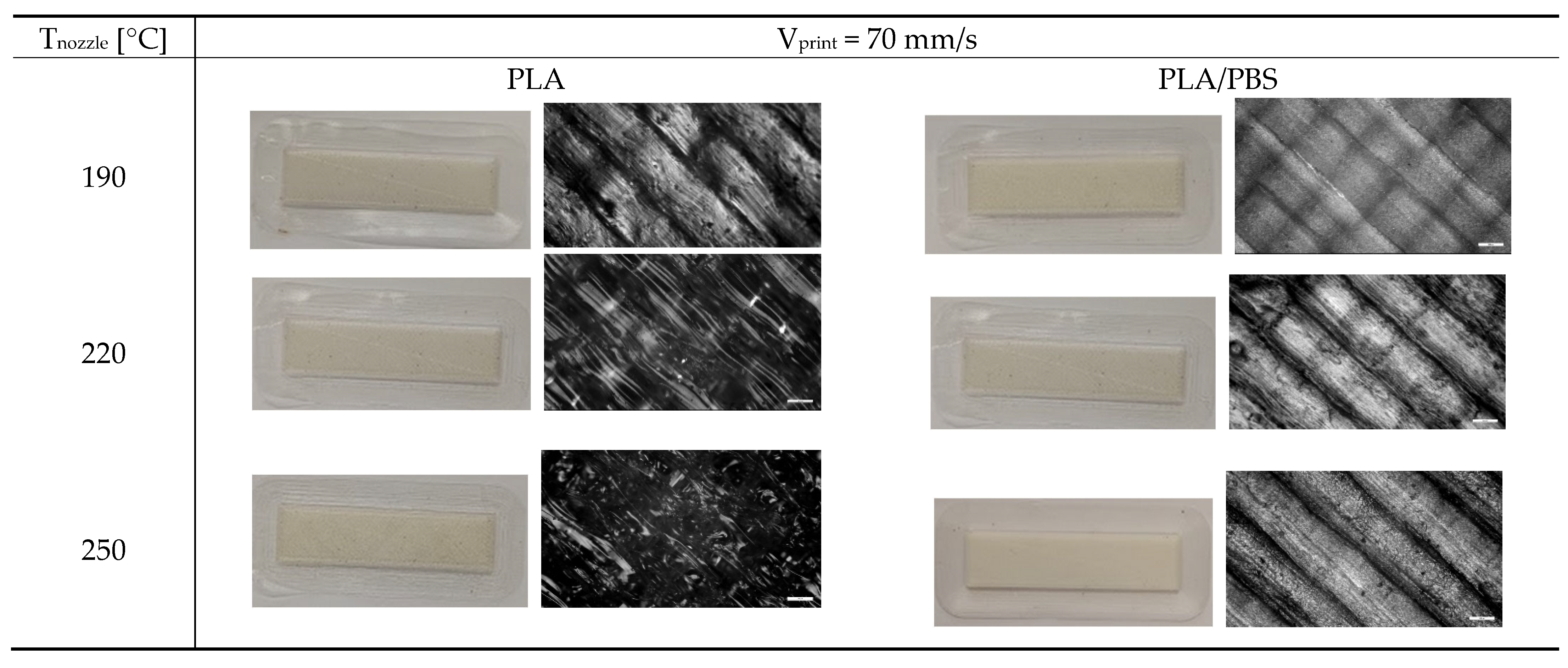

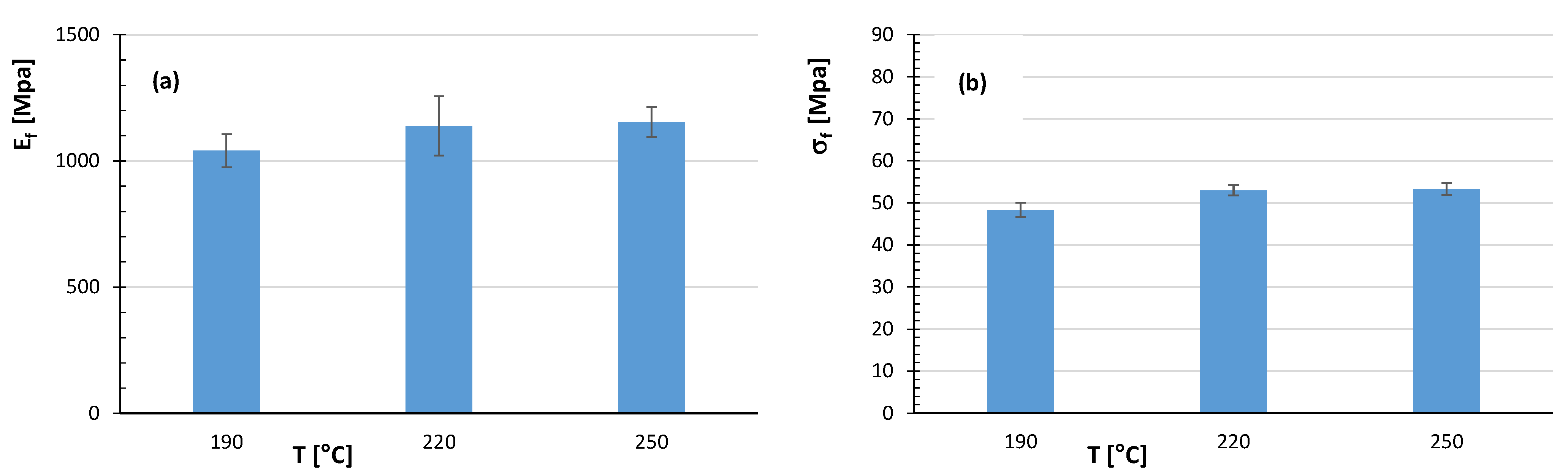

3.3. Effect of Hemp Shive and 3D Printing Parameters on Morphology and Performances of Biocomposites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | Additive Manufacturing |

| FDM | Fused Deposition Modeling |

| CAD | Computer-Aided Design |

Appendix A

References

- Daminabo, S.C.; Goel, S.; Grammatikos, S.A.; Nezhad, H.Y.; Thakur, V.K. Fused Deposition Modeling-Based Additive Manufacturing (3D Printing): Techniques for Polymer Material Systems. Mater. Today Chem. 2020, 16, 100248. [Google Scholar] [CrossRef]

- Hussain, M.; Khan, S.M.; Shafiq, M.; Abbas, N. A Review on PLA-Based Biodegradable Materials for Biomedical Applications. Giant 2024, 18, 100261. [Google Scholar] [CrossRef]

- Chang, F.L.; Hu, B.; Huang, W.T.; Chen, L.; Yin, X.C.; Cao, X.W.; He, G.J. Improvement of Rheology and Mechanical Properties of PLA/PBS Blends by in-Situ UV-Induced Reactive Extrusion. Polymer 2022, 259, 125336. [Google Scholar] [CrossRef]

- Deng, Y.; Thomas, N.L. Blending Poly (Butylene Succinate) with Poly (Lactic Acid): Ductility and Phase Inversion Effects. Eur. Polym. J. 2015, 71, 534–546. [Google Scholar] [CrossRef]

- Holt, A.; Ke, Y.; Bramhall, J.A.; Crane, G.; Grubbs, J.B.; White, E.M.; Horn, J.; Locklin, J. Blends of Poly (Butylene Glutarate) and Poly (Lactic Acid) with Enhanced Ductility and Composting Performance. ACS Appl. Polym. Mater. 2021, 3, 1652–1663. [Google Scholar] [CrossRef]

- Palai, B.; Mohanty, S.; Nayak, S.K. Synergistic Effect of Polylactic Acid (PLA) and Poly (Butylene Succinate-Co-Adipate) (PBSA) Based Sustainable, Reactive, Super Toughened Eco-Composite Blown Films for Flexible Packaging Applications. Polym. Test. 2020, 83, 106130. [Google Scholar] [CrossRef]

- Su, S.; Kopitzky, R.; Tolga, S.; Kabasci, S. Polylactide (PLA) and its blends with poly (butylene succinate) (PBS): A brief review. Polymers 2019, 11, 1193. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Yuan, L.; Laredo, E.; Zhang, M.; Zhou, W. Interfacial Properties, Viscoelasticity, and Thermal Behaviors of Poly (Butylene Succinate)/Polylactide Blend. Ind. Eng. Chem. Res. 2012, 51, 2290–2298. [Google Scholar] [CrossRef]

- Lin, C.; Liu, L.; Liu, Y.; Leng, J. 4D Printing of Shape Memory Polybutylene Succinate/Polylactic Acid (PBS/PLA) and Its Potential Applications. Compos. Struct. 2022, 279, 114729. [Google Scholar] [CrossRef]

- Niang, B.; Schiavone, N.; Askanian, H.; Verney, V.; Ndiaye, D.; Diop, A.B. Development and Characterization of PBSA-Based Green Composites in 3D-Printing by Fused Deposition Modelling. Materials 2022, 15, 7570. [Google Scholar] [CrossRef] [PubMed]

- Ou-Yang, Q.; Guo, B.; Xu, J. Preparation and Characterization of Poly (Butylene Succinate)/Polylactide Blends for Fused Deposition Modeling 3D Printing. ACS Omega 2018, 3, 14309–14317. [Google Scholar] [CrossRef]

- Qahtani, M.; Wu, F.; Misra, M.; Gregori, S.; Mielewski, D.F.; Mohanty, A.K. Experimental Design of Sustainable 3D-Printed Poly(Lactic Acid)/Biobased Poly (Butylene Succinate) Blends via Fused Deposition Modeling. ACS Sustain. Chem. Eng. 2019, 7, 14460–14470. [Google Scholar] [CrossRef]

- Gu, Z.; Zhang, J.; Cao, W.; Liu, X.; Wang, J.; Zhang, X.; Chen, W.; Bao, J. Extraordinary Toughness and Heat Resistance Enhancement of Biodegradable PLA/PBS Blends through the Formation of a Small Amount of Interface-Localized Stereocomplex Crystallites during Melt Blending. Polymer 2022, 262, 125454. [Google Scholar] [CrossRef]

- Ostrowska, J.; Sadurski, W.; Paluch, M.; Tyński, P.; Bogusz, J. The Effect of Poly (Butylene Succinate) Content on the Structure and Thermal and Mechanical Properties of Its Blends with Polylactide. Polym. Int. 2019, 68, 1271–1279. [Google Scholar] [CrossRef]

- Yang, J.; Ching, Y.C.; Chuah, C.H. Applications of Lignocellulosic Fibers and Lignin in Bioplastics: A Review. Polymers 2019, 11, 751. [Google Scholar] [CrossRef] [PubMed]

- Mujtaba, M.; Fernandes Fraceto, L.; Fazeli, M.; Mukherjee, S.; Savassa, S.M.; Araujo de Medeiros, G.; do Espírito Santo Pereira, A.; Mancini, S.D.; Lipponen, J.; Vilaplana, F. Lignocellulosic Biomass from Agricultural Waste to the Circular Economy: A Review with Focus on Biofuels, Biocomposites and Bioplastics. J. Clean. Prod. 2023, 402, 136815. [Google Scholar] [CrossRef]

- Zarna, C.; Opedal, M.T.; Echtermeyer, A.T.; Chinga-Carrasco, G. Reinforcement Ability of Lignocellulosic Components in Biocomposites and Their 3D Printed Applications—A Review. Compos. Part. C Open Access 2021, 6, 100171. [Google Scholar] [CrossRef]

- Marcuello, C.; Chabbert, B.; Berzin, F.; Bercu, N.B.; Molinari, M.; Aguié-Béghin, V. Influence of Surface Chemistry of Fiber and Lignocellulosic Materials on Adhesion Properties with Polybutylene Succinate at Nanoscale. Materials 2023, 16, 2440. [Google Scholar] [CrossRef]

- Frollini, E.; Bartolucci, N.; Sisti, L.; Celli, A. Poly (Butylene Succinate) Reinforced with Different Lignocellulosic Fibers. Ind. Crops Prod. 2013, 45, 160–169. [Google Scholar] [CrossRef]

- Beg, M.D.H.; Pickering, K.L.; Akindoyo, J.O.; Gauss, C. Recyclable Hemp Hurd Fibre-Reinforced PLA Composites for 3D Printing. J. Mater. Res. Technol. 2024, 33, 4439–4447. [Google Scholar] [CrossRef]

- Dönitz, A.; Köllner, A.; Richter, T.; Löschke, O.; Auhl, D.; Völlmecke, C. Additive Manufacturing of Biodegradable Hemp-Reinforced. Polymers 2023, 15, 2271. [Google Scholar] [CrossRef] [PubMed]

- Gallina, L.; Chaji, S.; Manzoli, M.; Cravero, F.; Gnoffo, C.; Gesti, S.; Frache, A.; Cravotto, G. Preparation of Hemp-Based Biocomposites and Their Potential Industrial Application. Polym. Compos. 2025, 46, 3791–3802. [Google Scholar] [CrossRef]

- Jubinville, D.; Sharifi, J.; Fayazfar, H.; Mekonnen, T.H. Hemp Hurd Filled PLA-PBAT Blend Biocomposites Compatible with Additive Manufacturing Processes: Fabrication, Rheology, and Material Property Investigations. Polym. Compos. 2023, 44, 8946–8961. [Google Scholar] [CrossRef]

- Mazzanti, V.; Pariante, R.; Bonanno, A.; Ruiz de Ballesteros, O.; Mollica, F.; Filippone, G. Reinforcing Mechanisms of Natural Fibers in Green Composites: Role of Fibers Morphology in a PLA/Hemp Model System. Compos. Sci. Technol. 2019, 180, 51–59. [Google Scholar] [CrossRef]

- Ucpinar, B.; Sivrikaya, T.; Aytac, A. Sustainable Hemp Fiber Reinforced Polylactic Acid/Poly (Butylene Succinate) Biocomposites: Assessing the Effectiveness of MAH-g-PLA as a Compatibilizer. Polym. Compos. 2025, 46, 9438–9453. [Google Scholar] [CrossRef]

- Xiao, X.; Chevali, V.S.; Song, P.; He, D.; Wang, H. Polylactide/Hemp Hurd Biocomposites as Sustainable 3D Printing Feedstock. Compos. Sci. Technol. 2019, 184, 107887. [Google Scholar] [CrossRef]

- Xiao, X.; Chevali, V.S.; Song, P.; Yu, B.; Feng, J.; Loh, T.W.; Wang, H. Mechanical Properties and Microstructure of Hemp Hurd Reinforced Polylactide Biocomposites for 3D Printing. Polym. Compos. 2025, 46, 4927–4937. [Google Scholar] [CrossRef]

- Mazzanti, V.; Salzano de Luna, M.; Pariante, R.; Mollica, F.; Filippone, G. Natural Fiber-Induced Degradation in PLA-Hemp Biocomposites in the Molten State. Compos. Part. A Appl. Sci. Manuf. 2020, 137, 105990. [Google Scholar] [CrossRef]

- Vitiello, L.; Carroccio, S.C.; Ambrogi, V.; Podda, E.; Filippone, G.; de Salzano Luna, M. Degradation Kinetics of PLA/Hemp Biocomposites: Tradeoff between Nucleating Action and pro-Hydrolytic Effect of Natural Fibers. Compos. Sci. Technol. 2024, 257, 110806. [Google Scholar] [CrossRef]

- Gupta, A.; Chudasama, B.; Chang, B.P.; Mekonnen, T. Robust and Sustainable PBAT—Hemp Residue Biocomposites: Reactive Extrusion Compatibilization and Fabrication. Compos. Sci. Technol. 2021, 215, 109014. [Google Scholar] [CrossRef]

- Apicella, A.; Scarfato, P.; Incarnato, L. Study on 3D Printability of PLA/PBAT/PHBV Biodegradable Blends for Packaging Applications. Polym. Test. 2025, 145, 108748. [Google Scholar] [CrossRef]

- Arrigo, R.; Frache, A. FDM Printability of PLA Based-Materials: The Key Role of the Rheological Behavior. Polymers 2022, 14, 1754. [Google Scholar] [CrossRef] [PubMed]

- Calafel, I.; Aguirresarobe, R.H.; Peñas, M.I.; Santamaría, A.; Boix, M.; Conde, J.I.; Pascual, B. Searching for Rheological Conditions for FFF 3D Printing with Flexible Polymers. In Iberian Meeting on Rheology; Springer: Cham, Switzerland, 2020; pp. 144–147. [Google Scholar] [CrossRef]

- Das, A.; Gilmer, E.L.; Biria, S.; Bortner, M.J. Importance of Polymer Rheology on Material Extrusion Additive Manufacturing: Correlating Process Physics to Print Properties. ACS Appl. Polym. Mater. 2021, 3, 1218–1249. [Google Scholar] [CrossRef]

- Lima, A.L.; Pires, F.Q.; Hilgert, L.A.; Sa-Barreto, L.L.; Gratieri, T.; Gelfuso, G.M.; Cunha-Filho, M. Oscillatory Shear Rheology as an In-Process Control Tool for 3D Printing Medicines Production by Fused Deposition Modeling. J. Manuf. Process. 2022, 76, 850–862. [Google Scholar] [CrossRef]

- Mackay, M.E. The Importance of Rheological Behavior in the Additive Manufacturing Technique Material Extrusion. J. Rheol. 2018, 62, 1549–1561. [Google Scholar] [CrossRef]

- Stevulova, N.; Estokova, A.; Cigasova, J.; Schwarzova, I.; Kacik, F.; Geffert, A. Thermal Degradation of Natural and Treated Hemp Hurds under Air and Nitrogen Atmosphere. J. Therm. Anal. Calorim. 2017, 128, 1649–1660. [Google Scholar] [CrossRef]

- Hussain, A.; Calabria-Holley, J.; Jiang, Y.; Lawrence, M. Modification of Hemp Shiv Properties Using Water-Repellent Sol–Gel Coatings. J. Sol Gel Sci. Technol. 2018, 86, 187–197. [Google Scholar] [CrossRef]

- Sawadogo, M.; Benmahiddine, F.; Hamami, A.E.A.; Belarbi, R.; Godin, A.; Duquesne, M. Investigation of a Novel Bio-Based Phase Change Material Hemp Concrete for Passive Energy Storage in Buildings. Appl. Therm. Eng. 2022, 212, 118620. [Google Scholar] [CrossRef]

- Terpáková, E.; Kidalová, L.; Eštoková, A.; Čigášová, J.; Števulová, N. Chemical Modification of Hemp Shives and Their Characterization. Procedia Eng. 2012, 42, 931–941. [Google Scholar] [CrossRef]

- Garofalo, E.; Galdi, M.R.; D’Arienzo, L.; Di Maio, L.; Incarnato, L. Effect of Polymer/Clay Composition on Processability of Polylactide Nanocomposites by Film Blowing. In Proceedings of the AIP Conference Proceedings, Salerno, Italy, 15–17 October 2015; Volume 1695. [Google Scholar]

- Garofalo, E.; Di Maio, L.; Scarfato, P.; Russo, P.; Incarnato, L. Selective Localization of Nanoparticles to Enhance the Properties of PBS/PLA Nanocomposite Blown Films. J. Polym. Environ. 2023, 31, 4546–4558. [Google Scholar] [CrossRef]

- Garofalo, E.; Di Maio, L.; Scarfato, P.; Vitiello, L.; Incarnato, L. Mechanical Recycling of Poly(Butylene Succinate)/Poly(Lactide) Blends: Assessment of Film Blowing Processability and Film Performances after Multiple Extrusions. Chem. Eng. J. 2025, 505, 159823. [Google Scholar] [CrossRef]

- Hallstein, J.; Gomoll, A.; Lieske, A.; Büsse, T.; Balko, J.; Brüll, R.; Malz, F.; Metzsch-Zilligen, E.; Pfaendner, R.; Zehm, D. Unraveling the Cause for the Unusual Processing Behavior of Commercial Partially Bio-Based Poly (Butylene Succinates) and Their Stabilization. J. Appl. Polym. Sci. 2021, 138, 50669. [Google Scholar] [CrossRef]

- Candal, M.V.; Calafel, I.; Aranburu, N.; Fernández, M.; Gerrica-Echevarria, G.; Santamaría, A.; Müller, A.J. Thermo-Rheological Effects on Successful 3D Printing of Biodegradable Polyesters. Addit. Manuf. 2020, 36, 101408. [Google Scholar] [CrossRef]

- McIlroy, C.; Olmsted, P.D. Disentanglement Effects on Welding Behaviour of Polymer Melts during the Fused-Filament-Fabrication Method for Additive Manufacturing. Polymer 2017, 123, 376–391. [Google Scholar] [CrossRef]

- Coppola, B.; Garofalo, E.; Di Maio, L.; Scarfato, P.; Incarnato, L. Investigation on the Use of PLA/Hemp Composites for the Fused Deposition Modelling (FDM) 3D Printing. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2018; p. 1981. [Google Scholar] [CrossRef]

- Dealy, J.M.; Wissbrun, K.F. Melt Rheology and Its Role in Plastics Processing; Springer: Berlin/Heidelberg, Germany, 1990; ISBN 9780792358862. [Google Scholar]

- Bánhegyi, G. Polymer Compatibility and Interfaces in Extrusion-Based Multicomponent Additive Manufacturing—A Mini-Review. Adv. Ind. Eng. Polym. Res. 2024, 7, 428–453. [Google Scholar] [CrossRef]

- Srinivas, V.; van Hooy-Corstjens, C.S.J.; Rastogi, S.; Harings, J.A.W. Promotion of Molecular Diffusion and/or Crystallization in Fused Deposition Modeled Poly(Lactide) Welds. Polymer 2020, 202, 122637. [Google Scholar] [CrossRef]

| Property | Test Method | Unit | PBS FZ91PM | PLA 4032D |

|---|---|---|---|---|

| Density | ISO 1183 | g/cm3 | 1.26 | 1.24 |

| Melting temperature | DSC | °C | 115 | 170 |

| Glass transition temperature | DSC | °C | −32 | 60 |

| Sample | T1 (°C) | T2 = T7 (°C) | T8 = Tdie (°C) |

|---|---|---|---|

| PBS-based composites | 150 | 165 | 165 |

| PLA-based composites PLA/PBS-based composites | 170 | 190 | 180 |

| Sample | T1 (°C) | T2 = T4 (°C) | Fan Speed [%] |

|---|---|---|---|

| PBS | 150 | 165 | 100 |

| PBS-based composites | 170 | 170 | 75 |

| PLA PLA-based composites | 200 | 200 | 65 |

| PLA/PBS PLA/PBS-based composites | 180 | 180 | 75 |

| PLA | |

|---|---|

| Wavenumber [cm−1] | Assignment |

| 1746 | Stretching CO |

| 1452 | Asymmetric bending CH3 |

| 1358–1382 | Symmetric bending CH3 |

| 1266 | Bending Chand stretching COC |

| 1180 | Asymmetric rocking CH3 |

| 1127 | Asymmetric rocking CH3 |

| 1080 | Symmetric stretching COC |

| 1042 | Symmetric stretching C-CH3 |

| PBS | |

| Wavenumber [cm−1] | Assignment |

| 1712 | Stretching CO |

| 1469–1308 | Deformation C–H in CH2 |

| 1149 | Asymmetric stretching CO in COC |

| 1044 | Symmetric stretching C–O in COC |

| Hemp shive | |

| Wavenumber [cm−1] | Assignment |

| 2915 | Stretching CH (cellulose, hemicellulose) |

| 2896 | Symmetric stretching (polysaccharides) |

| 1732 | Stretching CO (hemicellulose) |

| 1502 | Aromatic symmetrical stretching (lignin) |

| 1421 | Bending CH2 (cellulose) |

| 1370 | Bending CH2 (cellulose) |

| 1318 | In plane bending OH (cellulose) |

| 1157 | Asymmetric oxygen stretching COC (cellulose) |

| 1032 | Ring and side group vibration C–C, C–OH, C–H (hemicellulose, pectin) |

| η0 [Pa·s] | λ [s] | n | σ0 [Pa] | R | |

|---|---|---|---|---|---|

| PLA | 2362 | 0.125 | 0.76 | - | 0.991 |

| PLA + 3% hemp shive | 1307 | 0.065 | 0.81 | 75 | 0.987 |

| PLA + 5% hemp shive | 1679 | 0.069 | 0.80 | 88 | 0.997 |

| PBS | 2961 | 1.247 | 0.66 | - | 0.997 |

| PBS + 3% hemp shive | 2091 | 0.716 | 0.68 | - | 0.999 |

| PBS + 5% hemp shive | 2051 | 0.532 | 0.69 | - | 0.998 |

| PLA/PBS | 1916 | 0.960 | 0.78 | - | 0.992 |

| PLA/PBS + 3% hemp shive | 2175 | 0.431 | 0.75 | - | 0.995 |

| PLA/PBS + 5% hemp shive | 2062 | 0.437 | 0.77 | - | 0.996 |

| Tnozzle = 190 °C − Vprint = 70 mm/s | ||

|---|---|---|

| Flexural Modulus Ef [MPa] | Flexural Strength σf [MPa] | |

| PLA | 1680 ± 60 | 71 ± 4 |

| PLA + 3% hemp shive | 2210 ± 230 | 62 ± 13 |

| PLA + 5% hemp shive | 2000 ± 300 | 58 ± 12 |

| PLA/PBS | 1050 ± 60 | 48 ± 2 |

| PLA/PBS + 3% hemp shive | 1070 ± 70 | 47 ± 3 |

| PLA/PBS + 5% hemp shive | 1150 ± 70 | 38 ± 5 |

| Sample | εY [%] | σY [MPa] | εb [%] | σb [MPa] |

|---|---|---|---|---|

| PLA | 11.3 ± 0.3 | 44.5 ± 1.5 | 14.7 ± 1.6 | 40.0 ± 2.3 |

| PLA + 3% hemp shive | 9.6 ± 0.7 | 38.3 ± 3.3 | 9.6 ± 0.7 | 38.3 ± 3.3 |

| PLA/PBS | 15.3 ± 1.2 | 42.3 ± 0.2 | 126.9 ± 24.4 | 24.6 ± 1.4 |

| PLA/PBS + 3% hemp shive | 16.2 ± 1.2 | 34.3 ± 2.3 | 27.4 ± 5.1 | 24.5 ± 4.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garofalo, E.; Di Maio, L.; Incarnato, L. PLA/PBS Biocomposites for 3D FDM Manufacturing: Effect of Hemp Shive Content and Process Parameters on Printing Quality and Performances. Polymers 2025, 17, 2280. https://doi.org/10.3390/polym17172280

Garofalo E, Di Maio L, Incarnato L. PLA/PBS Biocomposites for 3D FDM Manufacturing: Effect of Hemp Shive Content and Process Parameters on Printing Quality and Performances. Polymers. 2025; 17(17):2280. https://doi.org/10.3390/polym17172280

Chicago/Turabian StyleGarofalo, Emilia, Luciano Di Maio, and Loredana Incarnato. 2025. "PLA/PBS Biocomposites for 3D FDM Manufacturing: Effect of Hemp Shive Content and Process Parameters on Printing Quality and Performances" Polymers 17, no. 17: 2280. https://doi.org/10.3390/polym17172280

APA StyleGarofalo, E., Di Maio, L., & Incarnato, L. (2025). PLA/PBS Biocomposites for 3D FDM Manufacturing: Effect of Hemp Shive Content and Process Parameters on Printing Quality and Performances. Polymers, 17(17), 2280. https://doi.org/10.3390/polym17172280