The Influence of Print Orientation and Discontinuous Carbon Fiber Content on the Tensile Properties of Selective Laser-Sintered Polyamide 12

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Preparation

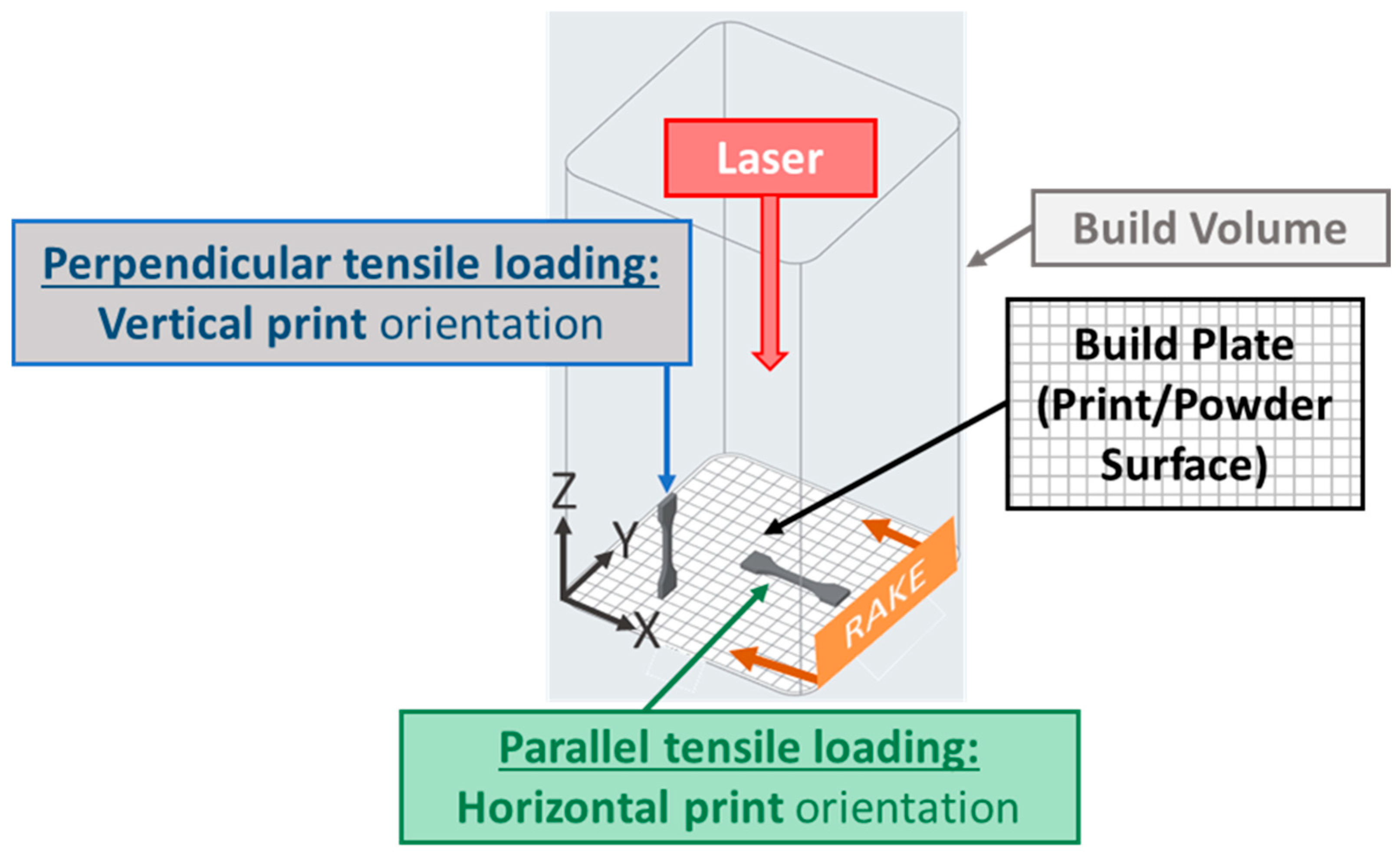

2.2. Additive Manufacturing

2.3. Material Characterization

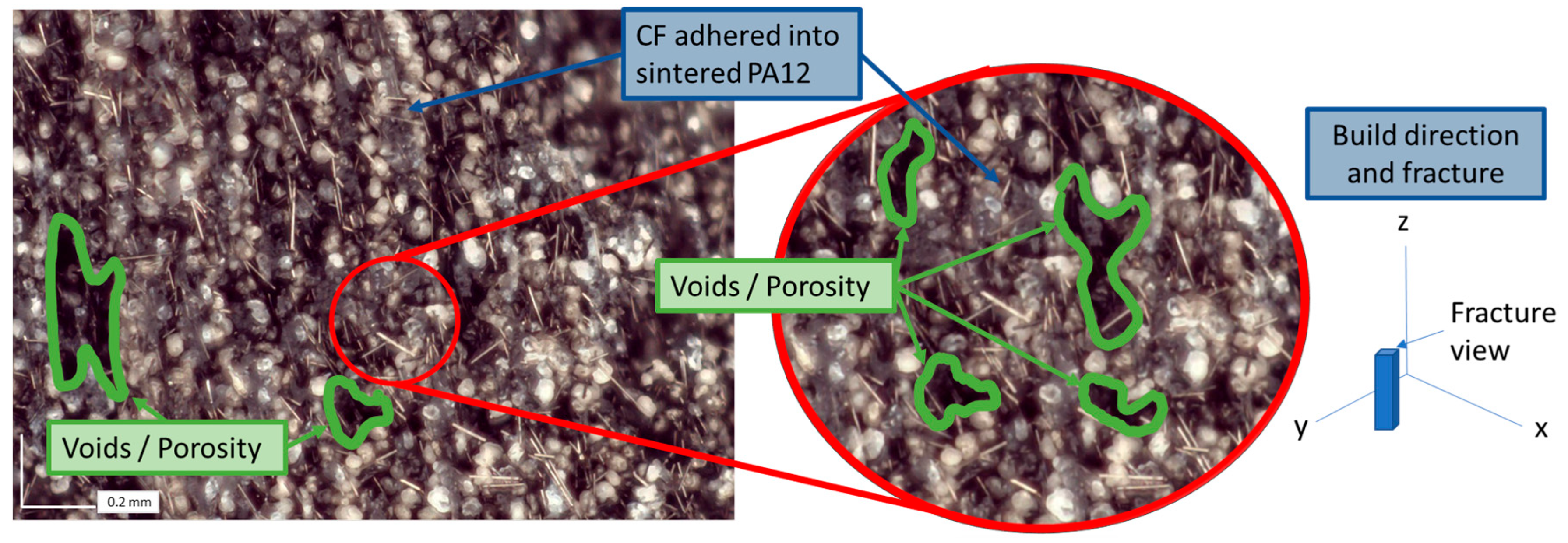

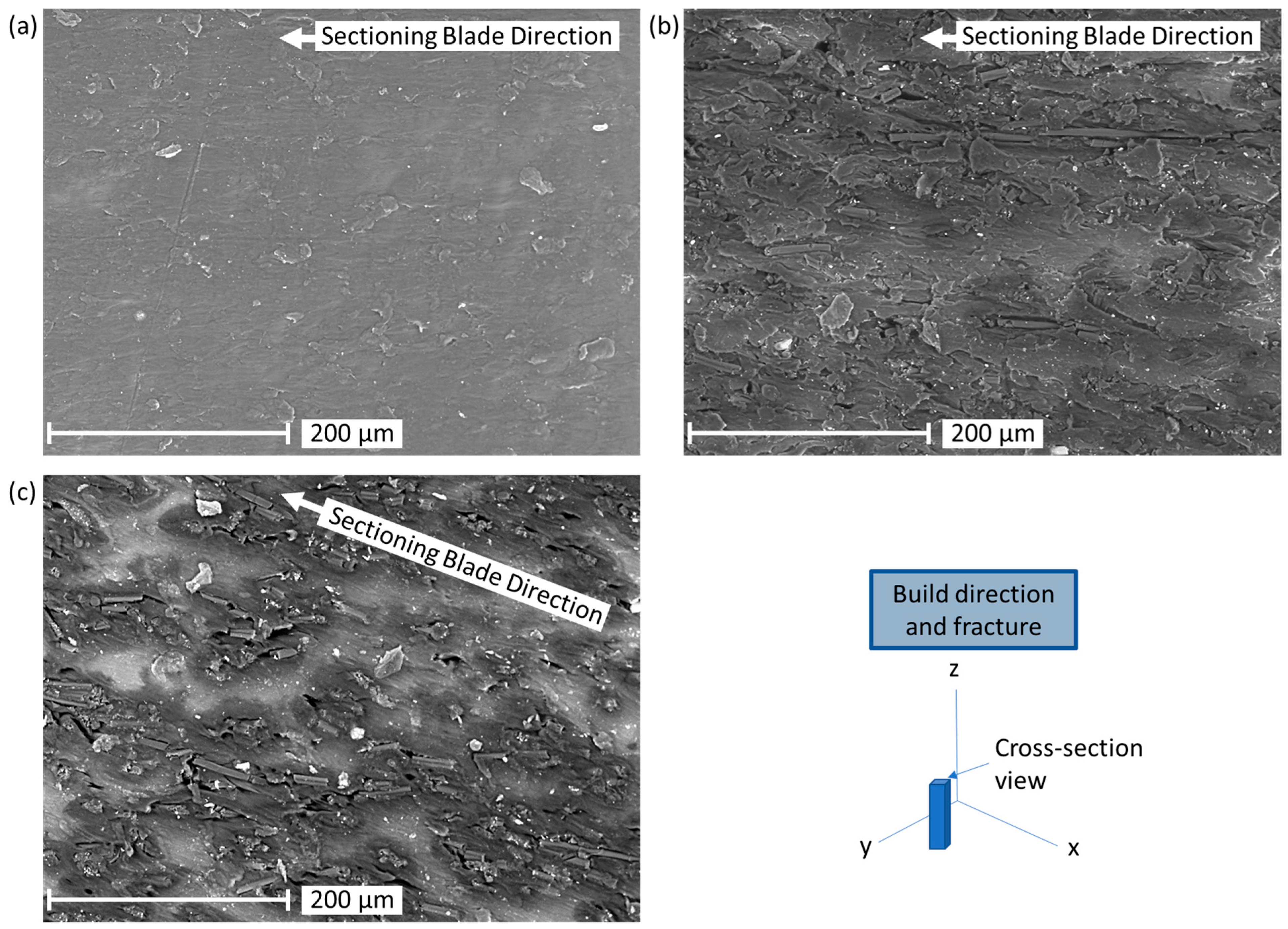

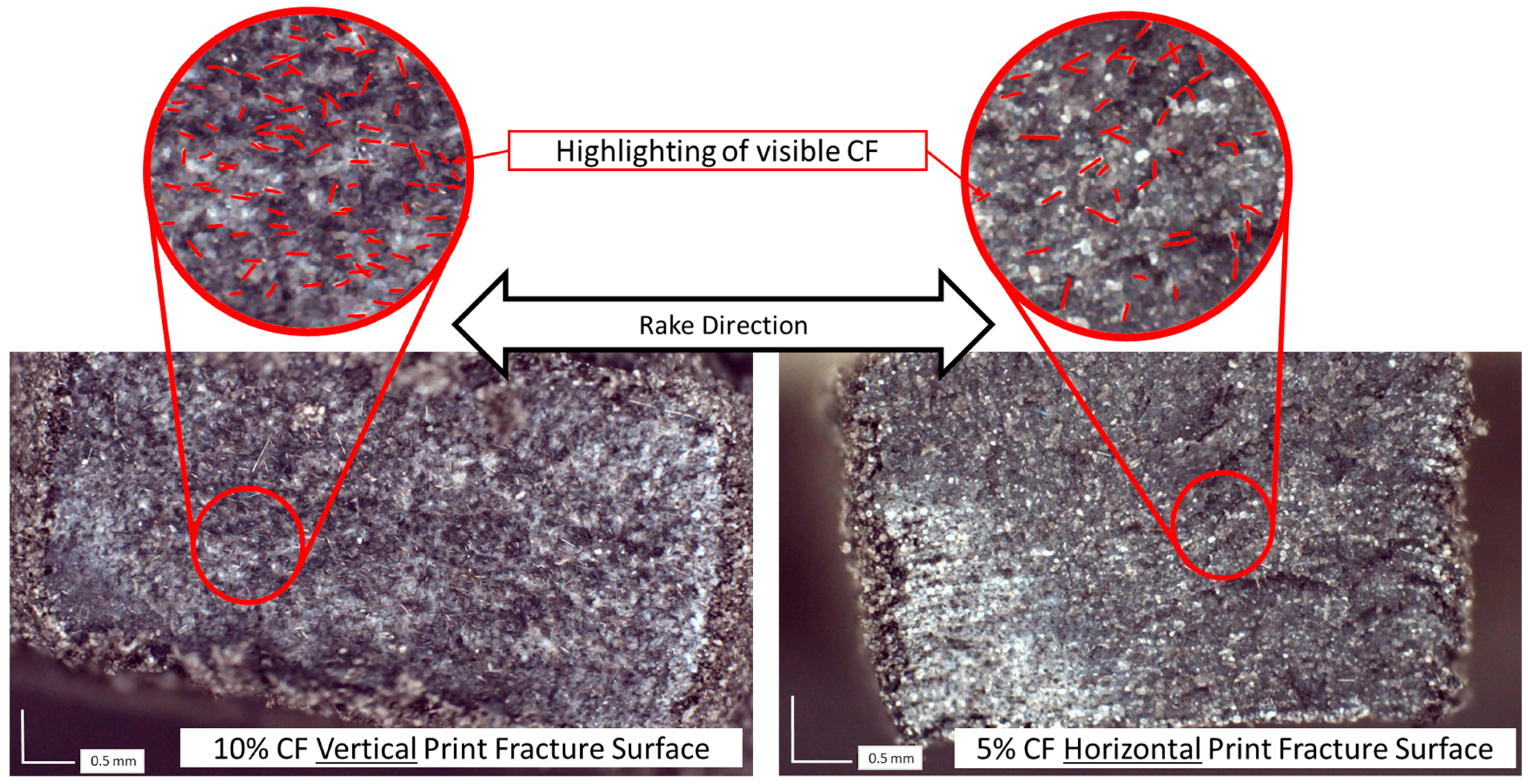

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | Additive Manufacturing |

| CF | Carbon Fiber |

| CFRP | Carbon Fiber-Reinforced Polymer Composites |

| HA | Hydroxyapatite |

| Ef | Fiber Modulus of Elasticity |

| Em | Matrix Modulus of Elasticity |

| FGM | Functionally Graded Material |

| MPa | Megapascal |

| MEX | Material Extrusion |

| MROM | Krenchel and Cox Modified Rule of Mixtures Equation |

| Nm | Nanometer |

| PA11 | Polyamide 11 |

| PA12 | Polyamide 12 |

| PEEK | Polyetheretherketone |

| PBF | Powder Bed Fusion |

| RSME | Root Mean Square Error |

| SD | Standard Deviation |

| SLS | Selective Laser Sintering |

| TRB/F | Thermal Reaction Bonding with Spooled Filament-Based Stock Material |

| Tg | Glass Transition Temperature |

| Tm | Melting Temperature |

| Tr | Re-crystallization Temperature |

| Vf | Fiber Volume Fraction |

| Vm | Matrix Volume Fraction |

| %vol | Percent Volume |

References

- Bhatia, A.; Sehgal, A.K. Additive manufacturing materials, methods and applications: A review. Mater. Today Proc. 2021, 81, 1060–1067. [Google Scholar] [CrossRef]

- Vanaei, S.; Elahinia, M. Applicable Materials and Techniques in 3D Printing, Industrial Strategies and Solutions for 3D Printing: Applications and Optimization; Wiley: New York, NY, USA, 2024; pp. 43–57. [Google Scholar] [CrossRef]

- Vanaei, H.R.; Khelladi, S.; Tcharkhtchi, A. Polymers and Their Application in 3D Printing; MDPI: Basel, Switzerland, 2023. [Google Scholar] [CrossRef]

- Schmid, M.; Wegener, K. Additive Manufacturing: Polymers Applicable for Laser Sintering (LS). Procedia Eng. 2016, 149, 457–464. [Google Scholar] [CrossRef]

- Razaviye, M.K.; Tafti, R.A.; Khajehmohammadi, M. An investigation on mechanical properties of PA12 parts produced by a SLS 3D printer: An experimental approach. CIRP J. Manuf. Sci. Technol. 2022, 38, 760–768. [Google Scholar] [CrossRef]

- Gomes, P.C.; Piñeiro, O.G.; Alves, A.C.; Carneiro, O.S. On the Reuse of SLS Polyamide 12 Powder. Materials 2022, 15, 5486. [Google Scholar] [CrossRef]

- Tomanik, M.; Żmudzińska, M.; Wojtków, M. Mechanical and Structural Evaluation of the PA12 Desktop Selective Laser Sintering Printed Parts Regarding Printing Strategy. 3D Print. Addit. Manuf. 2021, 8, 271–279. [Google Scholar] [CrossRef] [PubMed]

- Gavcar, B.; Sumer, E.H.; Sagbas, B.; Katiyar, J.K. Effect of build orientation on the green tribological properties of multi-jet fusion manufactured PA12 parts. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2023, 237, 2213–2223. [Google Scholar] [CrossRef]

- Cai, C.; Tey, W.S.; Chen, J.; Zhu, W.; Liu, X.; Liu, T.; Zhao, L.; Zhou, K. Comparative study on 3D printing of polyamide 12 by selective laser sintering and multi jet fusion. J. Mech. Work. Technol. 2020, 288, 116882. [Google Scholar] [CrossRef]

- Zárybnická, L.; Petrů, J.; Krpec, P.; Pagáč, M. Effect of Additives and Print Orientation on the Properties of Laser Sintering-Printed Polyamide 12 Components. Polymers 2022, 14, 1172. [Google Scholar] [CrossRef] [PubMed]

- Calignano, F.; Giuffrida, F.; Galati, M. Effect of the build orientation on the mechanical performance of polymeric parts produced by multi jet fusion and selective laser sintering. J. Manuf. Process. 2021, 65, 271–282. [Google Scholar] [CrossRef]

- Zohdi, N.; Yang, R. Material anisotropy in additively manufactured polymers and polymer composites: A review. Polymers 2021, 13, 3368. [Google Scholar] [CrossRef] [PubMed]

- El Magri, A.; Bencaid, S.E.; Vanaei, H.R.; Vaudreuil, S. Effects of Laser Power and Hatch Orientation on Final Properties of PA12 Parts Produced by Selective Laser Sintering. Polymers 2022, 14, 3674. [Google Scholar] [CrossRef] [PubMed]

- Arai, S.; Tsunoda, S.; Yamaguchi, A.; Ougizawa, T. Effect of anisotropy in the build direction and laser-scanning conditions on characterization of short-glass-fiber-reinforced PBT for laser sintering. Opt. Laser Technol. 2019, 113, 345–356. [Google Scholar] [CrossRef]

- Chen, H.; Zhu, W.; Tang, H.; Yan, W. Oriented structure of short fiber reinforced polymer composites processed by selective laser sintering: The role of powder-spreading process. Int. J. Mach. Tools Manuf. 2021, 163, 103703. [Google Scholar] [CrossRef]

- Chung, H.; Das, S. Processing and properties of glass bead particulate-filled functionally graded Nylon-11 composites produced by selective laser sintering. Mater. Sci. Eng. A 2006, 437, 226–234. [Google Scholar] [CrossRef]

- Chung, H.; Das, S. Functionally graded Nylon-11/silica nanocomposites produced by selective laser sintering. Mater. Sci. Eng. A 2008, 487, 251–257. [Google Scholar] [CrossRef]

- Jepson, L.R.; Beaman, J.J.; Bourell, D.L.; Wood, K.L. Multi-Material Selective Laser Sintering: Empirical Studies and Hardware Development. In Proceedings of the NSF Design and Manufacturing Grantees Conference, Vancouver, BC, Canada, 3–6 January 2000; pp. 2–5. [Google Scholar]

- Wei, C.; Sun, Z.; Chen, Q.; Liu, Z.; Li, L. Additive Manufacturing of Horizontal and 3D Functionally Graded 316L/Cu10Sn Components via Multiple Material Selective Laser Melting. J. Manuf. Sci. Eng. 2019, 141, 1–14. [Google Scholar] [CrossRef]

- Tan, K.; Chua, C.; Leong, K.; Cheah, C.; Cheang, P.; Abu Bakar, M.; Cha, S. Scaffold development using selective laser sintering of polyetheretherketone–hydroxyapatite biocomposite blends. Biomaterials 2003, 24, 3115–3123. [Google Scholar] [CrossRef] [PubMed]

- Green, J.T.; Rybak, I.A.; Slager, J.J.; Lopez, M.; Chanoi, Z.; Stewart, C.M.; Gonzalez, R.V. Local composition control using an active-mixing hotend in fused filament fabrication. Addit. Manuf. Lett. 2023, 7, 100177. [Google Scholar] [CrossRef]

- Quero, R.F.; Costa, B.M.d.C.; da Silva, J.A.F.; de Jesus, D.P. Using multi-material fused deposition modeling (FDM) for one-step 3D printing of microfluidic capillary electrophoresis with integrated electrodes for capacitively coupled contactless conductivity detection. Sens. Actuators B Chem. 2022, 365, 131959. [Google Scholar] [CrossRef]

- Baca, D.; Ahmad, R. The impact on the mechanical properties of multi-material polymers fabricated with a single mixing nozzle and multi-nozzle systems via fused deposition modeling. Int. J. Adv. Manuf. Technol. 2020, 106, 4509–4520. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, L.; Tang, F.; Chen, J. Multi-material additive manufacturing via fused deposition modeling 3D printing: A systematic review on the material feeding mechanism. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2024, 09544089231223316. [Google Scholar] [CrossRef]

- Patpatiya, P.; Chaudhary, K.; Shastri, A.; Sharma, S. A review on polyjet 3D printing of polymers and multi-material structures. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 7899–7926. [Google Scholar] [CrossRef]

- Chadha, C.; Olaivar, G.; Patterson, A.E.; Jasiuk, I.M. Design for Multi-Material Manufacturing Using Polyjet Printing Process: A Review. In Proceedings of the ASME Design Engineering Technical Conference, St. Louis, MI, USA, 14–17 August 2022. [Google Scholar] [CrossRef]

- Tee, Y.L.; Peng, C.; Pille, P.; Leary, M.; Tran, P. PolyJet 3D Printing of Composite Materials: Experimental and Modelling Approach. JOM 2020, 72, 1105–1117. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Xu, L.; Shi, Y. Preparation, characterisation and processing of carbon fibre/polyamide-12 composites for selective laser sintering. Compos. Sci. Technol. 2011, 71, 1834–1841. [Google Scholar] [CrossRef]

- Yuan, S.; Shen, F.; Chua, C.K.; Zhou, K. Polymeric composites for powder-based additive manufacturing: Materials and applications. Prog. Polym. Sci. 2019, 91, 141–168. [Google Scholar] [CrossRef]

- Tobolsky, A.; Callinan, T. Properties and structure of polymers. J. Electrochem. Soc. 1960, 107, 243C. Available online: https://archive.org/details/sim_journal-of-the-electrochemical-society_1960-03_107_3/page/232/mode/2up (accessed on 2 July 2025). [CrossRef]

- AZOM. Thermoplastics-An Introduction, AZO Materials. 2001. Available online: https://www.azom.com/article.aspx?ArticleID=83 (accessed on 2 July 2025).

- Weber, R.; Hafner, M.; Michalowksi, A.; Graf, T.; Emmelmann, C. Influence of laser cutting parameters on CFRP part quality. J. Mach. Tools Manuf. 2012, 39, 253–258. [Google Scholar] [CrossRef]

- Rodríguez, A.G.; Mora, E.E.; Velasco, M.A.; Tovar, C.A.N. Mechanical properties of polyamide 12 manufactured by means of SLS: Influence of wall thickness and build direction. Mater. Res. Express 2023, 10, 105304. [Google Scholar] [CrossRef]

- Cano, A.; Salazar, A.; Rodríguez, J. Effect of temperature on the fracture behavior of polyamide 12 and glass-filled polyamide 12 processed by selective laser sintering. Eng. Fract. Mech. 2018, 203, 66–80. [Google Scholar] [CrossRef]

- Slager, J.J.; Earp, B.C.; Ibrahim, A.M. Influence of Build Orientation and Part Thickness on Tensile Properties of Polyamide 12 Parts Manufactured by Selective Laser Sintering. Polymers 2024, 16, 2241. [Google Scholar] [CrossRef] [PubMed]

- Slager, J.J. Multi-Material/Fiber/Particulate Selective Laser Sintering System Capable of Local Composition Control and Material Gradients. Ph.D. Thesis, The University of Texas at El Paso, El Paso, TX, USA, 2022. [Google Scholar]

- Dadbakhsh, S.; Verbelen, L.; Verkinderen, O.; Strobbe, D.; Van Puyvelde, P.; Kruth, J.-P. Effect of PA12 powder reuse on coalescence behaviour and microstructure of SLS parts Special Issue “Trends and Prospects of Biomedical Alloys in Additive Manufacturing” in applied sciences with impact factor of 2.474 View project Dimensional Me-trology CMM View project Effect of PA12 powder reuse on coalescence behaviour and microstructure of SLS parts. Eur. Polym. J. 2017, 92, 250–262. [Google Scholar] [CrossRef]

- Pavan, M.; Faes, M.; Strobbe, D.; Van Hooreweder, B.; Craeghs, T.; Moens, D.; Dewulf, W. On the influence of inter-layer time and energy density on selected critical-to-quality properties of PA12 parts produced via laser sintering. Polym. Test. 2017, 61, 386–395. [Google Scholar] [CrossRef]

- Slager, J.; Green, J. Multi-Material Powder Bed Fusion. U.S. Patent 12157167 B2, 3 December 2024. Available online: https://patents.google.com/patent/US12157167B2/en?inventor=Jonathan+Slager (accessed on 23 August 2024).

- Lumpe, T.S.; Mueller, J.; Shea, K. Tensile properties of multi-material interfaces in 3D printed parts. Mater. Des. 2019, 162, 1–9. [Google Scholar] [CrossRef]

- Tang, H.; Chen, H.; Sun, Q.; Chen, Z.; Yan, W. Experimental and computational analysis of structure-property relationship in carbon fiber reinforced polymer composites fabricated by selective laser sintering. Compos. Part B Eng. 2021, 204, 108499. [Google Scholar] [CrossRef]

- Chatham, C.A.; Long, T.E.; Williams, C.B. A review of the process physics and material screening methods for polymer powder bed fusion additive manufacturing. Prog. Polym. Sci. 2019, 93, 68–95. [Google Scholar] [CrossRef]

- Dino-Lite Digital Microscope. Available online: https://www.dino-lite.com/faq_detail.php?index_id=34 (accessed on 7 June 2021).

- SINTRATEC PA12, Sintratec Material Data Sheet. 2022. Available online: https://www.solidpro.de/wp-content/uploads/3D-Druck/Sintratec/Datenblatt/Sintratec-Datenblatt-PA12-EN.pdf (accessed on 22 June 2024).

- CARBISOTM MF Milled Fiber—ELG CARBON FIBRE LTD.-PDF Catalogs|Technical Documentation|Brochure. Available online: https://pdf.aeroexpo.online/pdf/elg-carbon-fibre-ltd/carbiso-mf-milled-fiber/182993-7284.html (accessed on 2 July 2025).

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly oriented carbon fiber–polymer composites via additive manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef]

- Lu, S.; Zhang, B.; Niu, J.; Yang, C.; Sun, C.; Wang, L.; Li, D. Effect of fiber content on mechanical properties of carbon fiber-reinforced polyether-ether-ketone composites prepared using screw extrusion-based online mixing 3D printing. Addit. Manuf. 2024, 80, 103976. [Google Scholar] [CrossRef]

- Parker, M.; Inthavong, A.; Law, E.; Waddell, S.; Ezeokeke, N.; Matsuzaki, R.; Arola, D. 3D printing of continuous carbon fiber reinforced polyphenylene sulfide: Exploring printability and importance of fiber volume fraction. Addit. Manuf. 2022, 54, 102763. [Google Scholar] [CrossRef]

- Feng, J.; Gao, C.; Safaei, B.; Qin, Z.; Wu, H.; Chu, F.; Scarpa, F. Exceptional damping of CFRPs: Unveiling the impact of carbon fiber surface treatments. Compos. Part B Eng. 2024, 290, 111973. [Google Scholar] [CrossRef]

- Joo, J.H.; Kim, S.H.; Yim, Y.J.; Bae, J.S.; Seo, M.K. Interfacial Interlocking of Carbon Fiber-Reinforced Polymer Composites: A Short Review. Polymers 2025, 17, 267. [Google Scholar] [CrossRef] [PubMed]

- Sommacal, S.; Matschinski, A.; Holmes, J.; Drechsler, K.; Compston, P. Detailed void characterisation by X-ray computed to-mography of material extrusion 3D printed carbon fibre/PEEK. Compos. Struct. 2023, 308, 116635. [Google Scholar] [CrossRef]

- Callister, W.D.; Rethwisch, D.G. Fundamentals of Materials Science and Engineering: An Integrated Approach; John Wiley & Sons: Hoboken, NJ, USA, 2022. [Google Scholar]

- Krenchel, H. Fibre Reinforcement: Theoretical and Practical Investigations of the Elasticity and Strength of Fibre-Reinforced Materials; Akademisk Forlag: Copenhagen, Denmark, 1964. [Google Scholar]

- Cox, H.L. The elasticity and strength of paper and other fibrous materials. Br. J. Appl. Phys. 1952, 3, 72–79. [Google Scholar] [CrossRef]

- Hine, P.; Parveen, B.; Brands, D.; Caton-Rose, F. Validation of the modified rule of mixtures using a combination of fibre orien-tation and fibre length measurements. Compos. Part A Appl. Sci. Manuf. 2014, 64, 70–78. [Google Scholar] [CrossRef]

- Alshabib, A.; Jurado, C.A.; Tsujimoto, A. Short fiber-reinforced resin-based composites (SFRCs); Current status and future perspectives. Dent. Mater. J. 2022, 41, 647–654. [Google Scholar] [CrossRef] [PubMed]

- Norman, D.A.; Robertson, R.E. The effect of fiber orientation on the toughening of short fiber-reinforced polymers. J. Appl. Polym. Sci. 2003, 90, 2740–2751. [Google Scholar] [CrossRef]

- Adil, S.; Lazoglu, I. A review on additive manufacturing of carbon fiber-reinforced polymers: Current methods, materials, mechanical properties, applications and challenges. J. Appl. Polym. Sci. 2023, 140, e53476. [Google Scholar] [CrossRef]

- Mussatto, A. Research progress in multi-material laser-powder bed fusion additive manufacturing: A review of the state-of-the-art techniques for depositing multiple powders with spatial selectivity in a single layer. Results Eng. 2022, 16, 100769. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Tuma, D.; Vaneker, T.; Afrasiabi, M.; Bambach, M.; Gibson, I. Multimaterial powder bed fusion techniques. Rapid Prototyp. J. 2022, 28, 1–19. [Google Scholar] [CrossRef]

- Bareth, T.; Binder, M.; Kindermann, P.; Stapff, V.; Rieser, A.; Seidel, C. Implementation of a multi-material mechanism in a laser-based powder bed fusion (PBF-LB) machine. Procedia CIRP 2022, 107, 558–563. [Google Scholar] [CrossRef]

- Cortis, D.; Pilone, D.; Grazzi, F.; Broggiato, G.; Campana, F.; Orlandi, D.; Shinohara, T.; Planell, O.S. Functionally graded material via L-PBF: Characterisation of multi-material junction between steels (AISI 316L/16MnCr5), copper (CuCrZr) and aluminium alloys (Al-Sc/AlSi10Mg). Prog. Addit. Manuf. 2024, 10, 2455–2472. [Google Scholar] [CrossRef]

| Blend | Print Orientation | Laser Speeds |

|---|---|---|

| (%vol CF) | Preheat-Sinter-Bake (mm/s) | |

| 0 | Horizontal Vertical | 2000-500-3000 1500-800-2000 |

| 2.5 | Horizontal Vertical | *-500-2000 *-400-1200 |

| 5 | Horizontal Vertical | 1000-400-1500 1000-400-1500 |

| 10 | Horizontal Vertical | 2000-400-3000 1000-400-1500 |

| Blend | Measured Density | Calculated Density | |

|---|---|---|---|

| (%vol CF) | (g/cm3) ± SD | (g/cm3) | % Difference |

| 0 | 1.024 ± 0.0009 | 1.024 | NA |

| 5 | 1.076 ± 0.0047 | 1.063 | 1% |

| 10 | 1.100 ± 0.0007 | 1.102 | 0% |

| Blend | Measured Hardness |

|---|---|

| (%vol CF) | (Shore D Rating) ± SD |

| 0 | 74.67 ± 1.48 |

| 5 | 77.89 ± 0.86 |

| 10 | 81.17 ± 0.66 |

| Blend | Modulus | Yield Stress | Yield Strain | UTS | Failure Strain | |

|---|---|---|---|---|---|---|

| (%vol CF) | Orientation | (MPa) ± SD | (MPa) ± SD | (%) ± SD | (MPa) ± SD | (%) ± SD |

| 0 | Horizontal | 1832 ± 171 | 36.41 ± 2.04 | 2.20 ± 0.08 | 51.24 ± 0.75 | 52.85 ± 2.23 |

| Vertical | 1666 ± 286 | 33.17 ± 0.69 | 2.24 ± 0.39 | 46.07 ± 1.65 | 4.94 ± 2.46 | |

| 2.5 | Horizontal | 2203 ± 65 | 37.04 ± 1.12 | 1.88 ± 0.10 | 54.29 ± 0.49 | 13.18 ± 1.06 |

| Vertical | 1809 ± 165 | 24.69 ± 1.24 | 1.57 ± 0.10 | 33.13 ± 1.03 | 2.68 ± 0.38 | |

| 5 | Horizontal | 3217 ± 104 | 41.26 ± 1.50 | 1.48 ± 0.07 | 65.05 ± 0.80 | 10.49 ± 1.79 |

| Vertical | 2412 ± 81 | 29.46 ± 1.94 | 1.42 ± 0.11 | 41.33 ± 1.36 | 2.58 ± 0.08 | |

| 10 | Horizontal | 7589 ± * | 42.09 ± * | 0.75 ± * | 80.46 ± * | 5.23 ± * |

| Vertical | 854 ± 490 | 3.35 ± 2.33 | 0.44 ± 0.10 | 3.35 ± 2.33 | 0.44 ± 0.10 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Slager, J.J.; Green, J.T.; Levine, S.D.; Gonzalez, R.V. The Influence of Print Orientation and Discontinuous Carbon Fiber Content on the Tensile Properties of Selective Laser-Sintered Polyamide 12. Polymers 2025, 17, 2028. https://doi.org/10.3390/polym17152028

Slager JJ, Green JT, Levine SD, Gonzalez RV. The Influence of Print Orientation and Discontinuous Carbon Fiber Content on the Tensile Properties of Selective Laser-Sintered Polyamide 12. Polymers. 2025; 17(15):2028. https://doi.org/10.3390/polym17152028

Chicago/Turabian StyleSlager, Jonathan J., Joshua T. Green, Samuel D. Levine, and Roger V. Gonzalez. 2025. "The Influence of Print Orientation and Discontinuous Carbon Fiber Content on the Tensile Properties of Selective Laser-Sintered Polyamide 12" Polymers 17, no. 15: 2028. https://doi.org/10.3390/polym17152028

APA StyleSlager, J. J., Green, J. T., Levine, S. D., & Gonzalez, R. V. (2025). The Influence of Print Orientation and Discontinuous Carbon Fiber Content on the Tensile Properties of Selective Laser-Sintered Polyamide 12. Polymers, 17(15), 2028. https://doi.org/10.3390/polym17152028