Abstract

Natural-fiber-reinforced polypropylene (PP) composites are gaining increasing interest as lightweight, sustainable alternatives for various packaging and applications. This study investigates the effect of filler addition sequence on the mechanical, morphological, thermal, and dynamic mechanical properties of PP-based composites reinforced with graphite nanoplatelets (GnP) and kenaf fiber (KF). Two filler incorporation sequences were evaluated: GnP/KF/PP (GnP initially mixed with KF before PP addition) and GnP/PP/KF (KF added after mixing GnP with PP). The GnP/KF/PP composite exhibited superior mechanical properties, with tensile strength and flexural strength increasing by up to 25% compared to the control, while GnP/PP/KF showed a 13% improvement. SEM analyses revealed that initial mixing of GnP with KF significantly improved filler dispersion and interfacial bonding, enhancing stress transfer within the composite. XRD and DSC analyses showed reduced crystallinity and lower crystallization temperatures in the addition of KF due to restricted polymer chain mobility. Thermal stability assessed by TGA indicated minimal differences between the composites regardless of filler sequence. DMA results demonstrated a significantly higher storage modulus and enhanced elastic response in the addition of KF, alongside a slight decrease in glass transition temperature (Tg). The results emphasize the importance of optimizing filler addition sequences to enhance mechanical performance, confirming the potential of these composites in sustainable packaging and structural automotive applications.

1. Introduction

Pallet packaging plays a fundamental role in modern logistics and supply chains, providing a stable platform for transporting and storing a wide range of products [1]. Despite their extensive use, traditional wooden pallets face challenges such as susceptibility to moisture, fungal growth, and pest infestation, which often require additional treatments like fumigation or heat treatment [2]. Plastic pallets can be more cost-effective but often face durability issues under repeated loading and impact [3]. Consequently, there is growing demand for pallet materials that can offer improved mechanical performance, lighter weight, and enhanced environmental sustainability without excessively increasing production costs.

One emerging solution involves advanced composites that incorporate both natural fibers and carbon-based nano-reinforcements [4,5]. Among natural fibers, kenaf (Hibiscus cannabinus) fiber (KF) stands out due to its rapid growth rate, excellent tensile properties, and low production cost, making it highly suitable for large-scale manufacturing [6,7]. KF, when blended with polypropylene (PP), can significantly enhance tensile and flexural properties, contributing to greater structural rigidity at a moderate weight increase [8]. However, the inherently hydrophilic nature of KF can lead to weak interfacial bonding with non-polar thermoplastic matrices, thus requiring compatibilizers such as maleic anhydride grafted polypropylene (MAPP) [9,10].

To further boost the mechanical and thermal performance of PP composites, graphite nanoplatelets (GnP) have been proposed as a cost-effective alternative to more expensive carbon nanofillers like multi-walled carbon nanotubes or graphene [11]. GnP, with its two-dimensional platelet structure, provides high stiffness, good thermal conductivity, and potential improvement in wear resistance [12,13,14]. Critically, GnP is available at a market price of about $10–20 per kilogram, making it feasible for large applications such as pallets, where economics and scalability are paramount [15]. Recent studies have already shown that GnP can be dispersed successfully in a wide range of thermoplastic matrices, including polyamide-12, polyethylene and PEEK, using both melt compounding and additive-manufacturing routes. For example, 3D-printed polyamide-12 parts containing up to 10 wt% GnP exhibited an eight-order-of-magnitude jump in electrical conductivity (10−11 → 10−4 S/cm), a 34% reduction in heating time to 90 °C, and a 25% drop in friction coefficient without dimensional distortion [16]. Moreover, Kalaitzidou et al. [17] demonstrated that chemical pretreatment prior to compounding enhances the dispersion of exfoliated graphite nanoplatelets (xGnP), leading to superior mechanical performance. These results confirm the versatility of GnP as a multifunctional reinforcement for thermoplastics and motivate its combined use with natural fibers in pallet-grade composites.

Combining KF and GnP in PP-based composites has the potential to achieve synergistic reinforcement effects, where KF primarily contributes to enhanced tensile properties and impact absorption, and GnP provides improved stiffness, thermal stability, and wear resistance. Such composite systems, having cost efficiency, are particularly relevant for plastic pallets, which are routinely exposed to heavy loads, sudden impacts, and fluctuating temperature/humidity conditions [18]. Despite this promise, the dispersion quality and the sequence in which KF and GnP are incorporated into the PP matrix can significantly affect the final composite properties. Poor dispersion or unfavorable filler-matrix interactions may lead to localized stress concentrations and reduced overall performance [19,20].

Hamma et al. (2014) [21] focused solely on KF in a starch-grafted PP matrix, confirming that fiber length governs the stiffness/creep balance, while Lee et al. (2023) [22] addressed only GnP, showing that high-shear dispersion of 3 wt % GnP in PP boosts dielectric and EMI-shielding properties without considering natural fibers. These studies examined single-filler PP composites; none isolated the sequence of KF and GnP addition as an independent variable.

Because GnP readily re-aggregates once shear forces cease, and rough KF surfaces can act as physical carriers for nanosheets, we hypothesized that pre-coating KF with GnP would maximize nanosheet dispersion and fiber/matrix interfacial contact. This has not been investigated completely. The present work is therefore the first to systematically compare two compounding routes, (i) GnP → KF → PP and (ii) GnP → PP → KF, under identical formulation and processing conditions, and to link the resulting microstructure to mechanical and thermal performance metrics relevant to pallet-grade applications. This aspect is critical as the filler-adding sequence can significantly influence filler dispersion, interfacial adhesion, mechanical performance, and, ultimately, industrial processability and costs.

Therefore, this study evaluates the impact of filler addition sequences, specifically the sequence of KF and GnP incorporation, on the mechanical, morphological, thermal, and dynamic mechanical properties of PP-based composites. The findings aim to inform cost-effective manufacturing strategies, promoting the practical development of high-performance, environmentally sustainable composites for pallet packaging applications.

2. Materials and Methods

2.1. Materials

PP (Mw = 340,000; Mn = 97,000; density = 0.9 g/mL; MFI = 4 g/10 min) and MAPP were purchased from Sigma Aldrich (St. Louis, MO, USA) to serve as polymer matrix and compatibilizer, respectively, thereby enhancing interfacial adhesion between the fillers and the PP. GnP, with an average length of 10–500 nm and a thickness of 5–100 nm, was supplied by Asbury Carbons Inc. (Asbury, NJ, USA), and used as a reinforcing filler. KF (average length ≈ 2 mm; diameter 20–25 µm) was obtained from Carriage House Paper (Brooklyn, NY, USA) and used as a natural fiber reinforcement. Isopropyl alcohol (IPA) was obtained from Spectrum Chemical Mfg. Corp. (New Brunswick, NJ, USA) and used as a dispersing medium during the material preparation process.

2.2. Preparation of PP-Based Composites

PP, KF, and MAPP were first ground with a Thomas Wiley Laboratory Mill (Model 4, Thomas Co., Philadelphia, PA, USA) and sieved through a 2 mm mesh to achieve a uniform particle size. Two mixing sequences were designed to examine how the timing of KF addition influences final composite properties. The physical forms of the individual components used and their respective compositions are presented in Figure 1 and Table 1. KF was fixed at 30 wt%, which lies within the 20–30 wt% window reported to maximize tensile and flexural performance without inducing excessive brittleness or processing viscosity [8]. A lower fiber fraction (<20 wt%) provided insufficient stiffening, whereas higher levels (>35 wt%) caused mold-filling defects in our pilot trials. GnP was fixed at 0.3 wt%, the highest loading that improved stiffness without platelet agglomeration in our preliminary screening. MAPP was held at 3 wt%, the mid-point of the 2–5 wt% range reported to maximize fiber–matrix compatibilization while avoiding surplus additive. This combination provided the optimal balance between mechanical gains, dispersion quality, and material cost.

Figure 1.

Images of polypropylene (PP), graphite nanoplatelets (G), kenaf fiber (K), and maleic anhydride polypropylene (MAPP).

Table 1.

Composition of the PP-based composites.

For GnP/PP/KF, GnP was dispersed in IPA and ultrasonicated for 1 h in pulse mode (on: 45 s, off: 15 s) at 40% amplitude under an ice bath to prevent overheating. PP powder was then gradually introduced under continuous ultrasonication to facilitate uniform interaction between the polymer and nanoparticles. Next, KF was added, followed by an additional ultrasonication step, and finally, MAPP was incorporated.

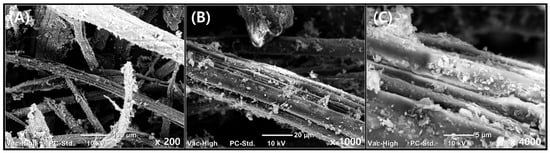

For GnP/KF/PP, GnP was dispersed in IPA and ultrasonicated under the same conditions, after which KF was gradually introduced under continuous ultrasonication. Representative images of the pre-mixed GnP and kenaf fiber prior to compounding are shown in Figure 2.

Figure 2.

Representative microscopic images of pre-mixed GnP and kenaf at different magnifications: (A) ×200; (B) ×1000; (C) ×4000.

PP was then added, and MAPP was introduced last. Each suspension underwent an extra 30 min of ultrasonication to ensure thorough mixing. The mixtures were filtered, dried at 100 °C for 24 h to remove residual IPA, and compounded in a co-rotating twin-screw extruder (HAAKE MiniLab II Micro Compounder, Thermo Scientific Inc., Waltham, MA, USA) at 220 °C and 150 rpm. The extrudates were pelletized using a pelletizer (Benchtop 25 Lab Series, Bay Plastic Machinery, Bay City, MI, USA) and then molded into standard specimens using an injection molding machine (Model 150A, LNS Tech, Yucaipa, CA, USA) at a cylinder temperature (Tcylinder) of 200 °C and a mold temperature (Tmold) of 80 °C. A control sample (GnP/PP) without KF was prepared following the same procedure for comparison.

2.3. Characterization of PP-Based Composites

2.3.1. Mechanical Properties

The unnotched Izod impact strength (IS) was measured using an Izod Impact Tester (CEAST 9050, Instron, Norwood, MA, USA) in accordance with ASTM D256. Tensile strength (TS) and Young’s modulus (YM) were determined using a Universal Testing Machine (MTS Systems Corporation, Eden Prairie, MN, USA) following ASTM D638, and flexural strength (FS) and flexural modulus (FM) were measured according to ASTM D790, all at room temperature.

2.3.2. Dynamic Mechanical Analysis (DMA)

Dynamic mechanical analysis (DMA) was conducted using a DMA Q800 (TA Instruments, New Castle, DE, USA) to evaluate storage modulus, loss modulus, and tan delta. The dual cantilever mode was employed over a temperature range of −60 to 160 °C, at a heating rate of 5 °C/min, an oscillation frequency of 1 Hz, and a strain amplitude of 0.1%. Specimens were injection-molded into dimensions of 62 mm × 13 mm × 3 mm.

2.3.3. Thermal Properties

Thermogravimetric analysis (TGA) was carried out using a TGA Q500 (TA Instruments, New Castle, DE, USA) under a nitrogen atmosphere. Samples (6–8 mg) were heated from room temperature to 600 °C at a rate of 10 °C/min. Differential scanning calorimetry (DSC) was performed using a DSC250 (TA Instruments, New Castle, DE, USA) under a nitrogen atmosphere to investigate the crystallization and melting behaviors of the composites. Each specimen was subjected to a heat–cool–heat cycle: (i) heating from −40 °C to 180 °C at 10 °C/min to erase previous thermal history, (ii) cooling back to −40 °C at the same rate, and (iii) reheating to 180 °C at 10 °C/min. The degree of crystallinity (D) was determined using the following Equation (1):

where D is the degree of crystallinity, ∆Hm is the melting enthalpy, ∆H0 is the melting enthalpy of 100% crystalline PP (209 J/g) [23], and fPP is the weight fraction of PP in the composite

2.3.4. Morphological Analysis

Fracture surfaces of impact-tested specimens were examined using scanning electron microscopy (SEM, NeoScope JCM-5000, JEOL, Tokyo, Japan) to evaluate the morphology and interfacial adhesion between the polymer matrix and fillers. Prior to observation, all samples were sputter-coated with palladium (DESK II Coater, Denton Vacuum Inc., Moorestown, NJ, USA) to mitigate charging effects. SEM micrographs were acquired at an accelerating voltage of 15 kV.

2.3.5. X-Ray Diffraction (XRD) Analysis

X-ray diffraction (XRD) analysis was performed to investigate the crystalline structure and phase composition of the samples. Measurements were conducted using a D8 Advance X-ray diffractometer (Bruker Corporation, Billerica, MA, USA) with Cu Kα radiation (λ = 1.5406 Å) operated at 40 kV and 40 mA. Diffraction patterns were collected in continuous scan mode over a 2θ range of 10–60° with a step size of 0.025° and a counting time of 0.5 s/step. The instrument was equipped with “twin/twin” optics, including a motorized primary slit (0.6 mm) and a secondary slit (5 mm), and was maintained at a cooling temperature of 15–20 °C. The resulting data in brml format were processed using PowDLL or Profex to generate spectra plotting XRD angle (2θ) versus intensity. The crystallinity index (CrI) of PP-based composites was calculated using the following Equation (2):

where Iam represents the peak intensity of the amorphous region, and I200 corresponds to the total intensity under the diffraction curve

2.4. Statistical Analysis

A nested experimental design was implemented with three independent batches, each containing five replicate samples (n = 15 total). Statistical comparisons were performed using one-way analysis of variance (ANOVA) with batch-to-batch variability as the random effect, followed by post hoc Tukey’s honestly significant difference (HSD) test for pairwise comparisons. All analyses were conducted at a 95% confidence interval (α = 0.05) using JMP Pro (v16.0.0, SAS Institute Inc., Cary, NC, USA).

3. Results and Discussion

3.1. Mechanical and Morphological Properties of PP-Based Composites

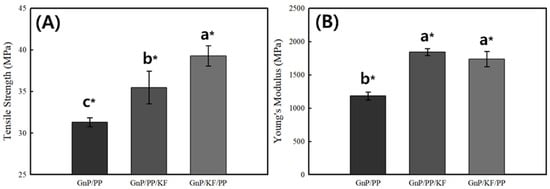

The TS and YM of the PP-based composites are shown in Figure 3. The control composite (GnP/PP) exhibited a TS of 31.30 ± 0.54 MPa and a YM of 1181.89 ± 48.80 MPa. Both composites reinforced with KF and GnP demonstrated significant enhancement in TS and YM. The GnP/KF/PP composite, where GnP was first mixed with KF before blending with PP, displayed the highest TS (39.27 ± 0.89 MPa), representing approximately a 25% increase over the GnP/PP. In contrast, the GnP/PP/KF composite, in which KF was added after mixing GnP with PP, showed a smaller TS improvement of about 13% (35.48 ± 1.96 MPa) than that of GnP/KF/PP. These enhancements are attributed to the optimized filler addition sequence, which promotes better dispersion of GnP and stronger KF-matrix interactions, resulting in improved load transfer and stress distribution within the matrix. SEM observations (Figure 2) further confirm that mixing GnP and KF prior to PP incorporation facilitates more uniform embedding of GnP onto the KF surface without aggregation. This result clearly shows that GnP is effectively anchored onto the KF surfaces, minimizing fiber pull-out and enhancing the interfacial bonding between fillers and the PP matrix. This structural integration enables more efficient stress transfer and significantly contributes to the observed improvements in mechanical performance. Similar observations were reported by Feng et al. [24] in kenaf/PALF fiber-reinforced PP composites, noting fiber-matrix debonding, fiber pull-out, and fiber breakage during tensile testing. Furthermore, the YM similarly reflected the influence of filler addition sequence, increasing to 1842.69 ± 43.89 MPa in GnP/PP/KF and 1736.55 ± 91.99 MPa in GnP/KF/PP. These improvements in YM are likely due to enhanced composite stiffness resulting from improved interfacial adhesion and the reinforcing effects of rigid filler interactions [25].

Figure 3.

Tensile strength (A) and Young’s modulus (B) of PP-based composites as a function of GnP and KF mixing sequence. * indicates statistically significant differences between groups (p < 0.05), determined by Tukey’s HSD test. Data are presented as means ± standard deviations.

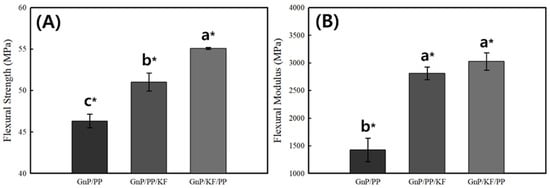

The FS and FM results of the PP-based composites are presented in Figure 4. The GnP/PP composite exhibited the lowest FS (46.32 ± 0.81 MPa) and FM (1427.23 ± 211.40 MPa). Flexural properties were significantly affected by the addition of fillers and the filler-adding sequence, leading to increased values similar to those observed in the tensile properties. The GnP/KF/PP composite showed the most pronounced improvements, achieving the highest FS (55.07 ± 0.11 MPa) and FM (3025.28 ± 156.88 MPa), while the GnP/PP/KF composite demonstrated improved flexural strength (51.01 ± 1.10 MPa) and modulus (2809.70 ± 111.71 MPa). The increase in flexural modulus of the hybrid composites can be attributed to the presence of rigid crystalline phases as well as a higher fraction of KF [26]. This indicates that the filler incorporation sequence markedly influences composite stiffness and load-bearing capacity, likely due to optimized dispersion and enhanced interfacial adhesion between the KF, GnP, and PP matrix. Particularly in plastic pallet packaging applications, increased flexural properties are highly advantageous as they directly contribute to improved load-bearing capacity and rigidity under static and dynamic loads. Higher FM translates to reduced deformation under applied loads, enhancing dimensional stability and durability of plastic pallet structures.

Figure 4.

Flexural Strength (A) and Modulus (B) of PP-based composites as a function of GnP and KF mixing sequence. * indicates statistically significant differences between groups (p < 0.05), determined by Tukey’s HSD test. Data are presented as means ± standard deviations.

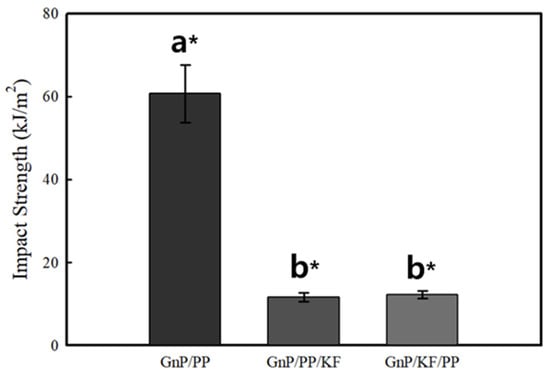

The impact test was conducted to evaluate the resistance of the composites to suddenly applied forces by measuring the impact energy absorbed prior to fracture. The IS results are presented in Figure 5. The GnP/PP composite exhibited an IS of 60.69 ± 6.92 kJ/m2, while the GnP/KF/PP and GnP/PP/KF composites showed IS values of 12.30 ± 0.91 kJ/m2 and 11.59 ± 1.07 kJ/m2, respectively. Although these values indicate a significant reduction compared to GnP/PP alone, both GnP/KF/PP and GnP/PP/KF composites demonstrated significantly enhanced impact resistance relative to neat PP (3.92 kJ/m2) reported in a previous study [27]. This substantial improvement in IS is primarily attributed to the synergistic reinforcement effects provided by GnP and KF, along with enhanced interfacial adhesion facilitated by the incorporation of MAPP. The combined action of GnP and KF effectively improved energy dissipation during impact loading, thus significantly enhancing the composite’s overall toughness and resistance to fracture compared to neat PP. According to previous studies, the fiber length is crucial in the physical and mechanical properties of the fiber-based composites. The fiber length, which was used in this study (2 mm), is relatively very short compared to the literature values. The relatively short fiber length may have further contributed to the reduced impact resistance, as long fibers are generally more effective in dissipating impact energy through fiber pull-out and crack bridging mechanisms. Similar trends have been reported in previous studies, where the incorporation of short natural fibers into thermoplastics led to a decrease in IS [28,29], whereas composites reinforced with long fibers demonstrated improved impact resistance [30]. Based on these findings, fiber length within the thermoplastic matrix plays a crucial role in determining energy absorption capability and overall mechanical performance.

Figure 5.

Impact Strength of PP-based composites as a function of GnP and KF mixing sequence. * indicates statistically significant differences between groups (p < 0.05), determined by Tukey’s HSD test. Data are presented as means ± standard deviations.

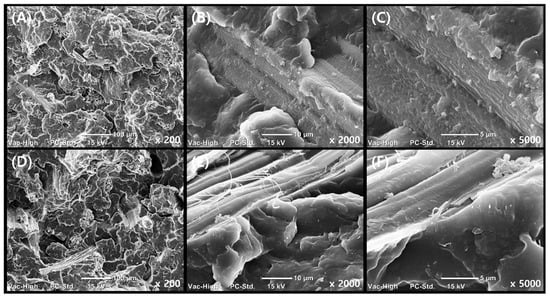

SEM analysis of the tensile fracture surfaces was conducted to examine the effect of filler addition sequence on composite morphology (Figure 6).

Figure 6.

SEM images of tensile fracture surfaces of PP composites: (A–C) GnP/KF/PP; (D–F) GnP/PP/KF at ×200, ×2000, and ×5000, respectively.

In GnP/KF/PP composites, GnP was initially mixed with KF, resulting in uniform dispersion and effective embedding of GnP onto the KF surfaces. SEM images clearly showed minimal fiber pull-out and well-anchored GnP particles [31], indicating strong interfacial bonding and efficient stress transfer within the polymer matrix [26]. In contrast, GnP/PP/KF composites exhibited pronounced fiber pull-out and less effective embedding of GnP onto the KF surfaces, suggesting weaker fiber-matrix adhesion. These morphological findings correlate closely with mechanical test results, providing clear evidence that mixing GnP with KF prior to incorporating it into PP significantly enhances composite performance by optimizing filler dispersion and interfacial interactions.

Consequently, optimizing filler addition sequences, as demonstrated by the GnP/KF/PP composite, may yield composite materials better suited for demanding packaging applications, potentially improving plastic pallet lifespan and reliability.

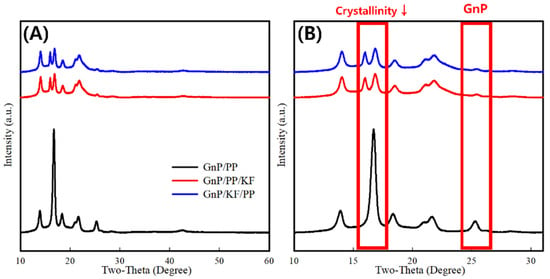

3.2. Crystallinity of PP-Based Composites

XRD patterns of the PP-based composites are presented in Figure 7. A characteristic peak corresponding to GnP was observed at 2θ = 26.07° (200) across all samples [32]. PP exhibited characteristic diffraction peaks at 2θ = 14.2°, 17.0°, and 18.8°, corresponding to the (110), (040), and (130) crystal planes of the α-phase, respectively [33]. Additionally, peaks appearing between 21.1° and 22.1° represent a combination of α-phase (131 and 041) and β-phase (301) of PP [17]. Notably, the GnP/KF/PP and GnP/PP/KF composites exhibited an additional distinct peak at 2θ = 16° corresponding to the (300) plane of the β-phase, indicating that kenaf fibers act as nucleating agents promoting β-phase crystallization. Previous studies have similarly reported KF’s nucleating capability in PP composites, highlighting their role in crystallinity enhancement and secondary reinforcement mechanisms [34,35]. However, crystallinity analysis (Figure 7) showed there is no significant difference in crystallinity between GnP/KF/PP (50%) and GnP/PP/KF (51%), while showing slightly lower than that of GnP/PP (58%). This reduction suggests that, despite the nucleating effects of GnP and KF, KF may restrict polymer segmental chain mobility during crystallization, leading to decreased overall crystallinity [4,36].

Figure 7.

XRD patterns of PP-based composites with different filler addition sequences: (A) full scan (2θ = 10–60°); (B) magnified view of the main region (2θ = 10–30°).

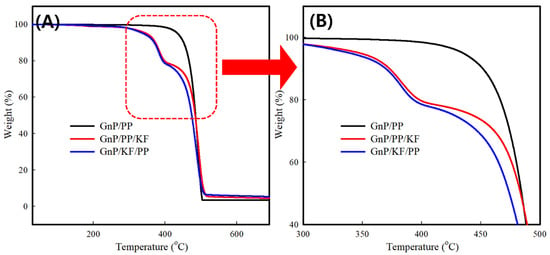

3.3. Thermal Properties of PP-Based Composites

TGA results for PP-based composites are shown in Figure 8 and summarized in Table 2, including onset, 5%, 10% and 20% weight loss temperatures. The control GnP/PP composite displayed thermal decomposition in a single-stage process from approximately 286 °C to 498 °C. In contrast, GnP/KF/PP and GnP/PP/KF composites exhibited two distinct degradation stages: the first stage, ranging from 195 °C to 360 °C, is attributed to the scission of C–O and C–C bonds and thermal degradation of glycosidic linkages via trans-glycosylation at lower temperatures, associated primarily with cellulose and hemicellulose components of KF [37]. The second stage, occurring from approximately 395 °C to 510 °C, is primarily due to aromatization processes involving dehydration, responsible for high-temperature decomposition, and associated with PP degradation [38]. No significant differences were observed between the GnP/KF/PP and GnP/PP/KF composites during the first decomposition stage, while a slight improvement was noted in the GnP/PP/KF composite during the second stage. This may indicate that the decomposition of kenaf fiber accelerates the thermal degradation of polypropylene.

Figure 8.

TGA curves of PP-based composites with different filler addition sequences: GnP/PP, GnP/PP/KF, and GnP/KF/PP. (A) Full-range TGA curves up to complete decomposition. (B) Magnified view of the degradation region (300–500 °C).

Table 2.

Thermal Degradation Temperatures (Td) of PP-based composites with different filler addition sequences, based on TGA.

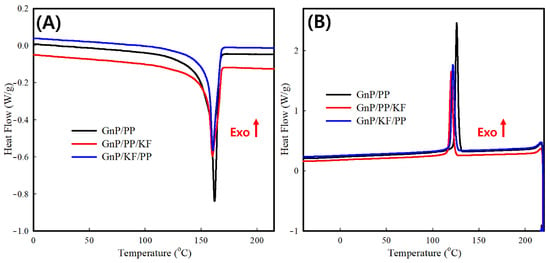

DSC was performed to investigate the crystallization and melting behaviors of composites (Figure 9 and Table 3). Consistent with the XRD findings, DSC analysis indicated a reduction in crystallinity for GnP/KF/PP and GnP/PP/KF composites compared to the GnP/PP composite. Previous studies have reported increased crystallinity upon kenaf fiber addition [17,25,39]; however, the current results suggest that KF limited polymer chain mobility, thereby reducing crystallinity. This decrease is attributed to the hindered segmental alignment of polymer chains during crystallization due to the presence of KF.

Figure 9.

DSC thermograms of PP-based composites with different filler addition sequences: (A) second heating and (B) cooling scans. Exothermic heat flow is plotted in the upward direction.

Table 3.

DSC data of PP-based composites with different filler addition sequences, based on TGA.

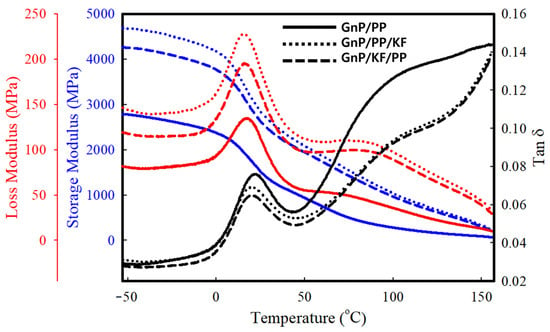

3.4. Viscoelastic Properties of PP-Based Composites

Figure 10 presents the storage modulus and tan delta curves of PP-based composites as a function of temperature ranging from −60 °C to 160 °C. The glass transition temperature (Tg), determined from the tan delta peak, did not differ between GnP/PP/KF (20.1 °C) and GnP/KF/PP (20.4 °C); both were slightly lower than that of GnP/PP (22.3 °C). This reduction aligns with the observed decrease in crystallinity, as lower crystallinity typically correlates with a reduced Tg in semi-crystalline polymers, reflecting transitions occurring over a broader temperature range [17]. The storage modulus, indicative of a material’s ability to store elastic energy, significantly increased with the incorporation of KF, indicating enhanced elastic behavior under loading. This improvement can be attributed to kenaf fibers restricting the mobility of polypropylene chains, thereby increasing overall composite stiffness [40]. Similar trends of increased storage modulus upon natural fiber addition have been reported previously, suggesting effective matrix reinforcement by natural fibers [41,42]. Furthermore, the storage modulus of GnP/KF/PP was slightly higher than that of GnP/PP/KF, indicating that the filler addition sequence also affects viscoelastic behavior. This difference may be attributed to enhanced interfacial bonding and more homogeneous filler dispersion when GnP is pre-mixed with KF, as evidenced by SEM observations. For all composites, a continuous decline in storage modulus was observed above Tg, reflecting the elastic-dominated behavior of PP composites in the extended rubbery regime (Tm—Tg) at higher temperatures. Additionally, the difference in modulus behavior above 80 °C between KF-reinforced and control suggests that fiber-matrix interactions and crystalline structure changes become more prominent at elevated temperatures. The control sample, GnP/PP, exhibited a significantly lower loss modulus (E′′) compared to both GnP/PP/KF and GnP/KF/PP, as shown in Figure 10. This increase is attributed to the addition of kenaf fiber, which enhances the material’s ability to dissipate energy as heat during deformation, resulting from increased internal friction within the composite due to the presence of the kenaf fibers. A similar phenomenon has been well reported in the literature reviewed by Haris et al. [43]. This temperature-dependent divergence is consistent with previous reports that associate DMA thermograms with crystalline phase evolution at higher temperatures [44].

Figure 10.

Storage modulus, loss modulus, and tan δ of PP-based composites with different filler addition sequences (GnP/PP, GnP/PP/KF, and GnP/KF/PP) as a function of temperature.

4. Conclusions

In this study, the effects of incorporating GnP and KF into PP composites, along with varying the filler addition sequence, were comprehensively evaluated. The composite prepared by first mixing GnP with KF (GnP/KF/PP) exhibited superior mechanical performance, including higher TS, FS, and FM compared to the composite with KF added after GnP and PP mixing (GnP/PP/KF). SEM analyses confirmed that initial mixing of GnP with KF enhanced filler dispersion and significantly improved interfacial interactions between fillers and the PP matrix, resulting in more effective stress transfer. XRD results consistently indicated reduced crystallinity in composites containing KF, attributed to restricted polymer chain mobility caused by KF’s presence. TGA revealed no significant differences in thermal stability between the two filler addition sequences, with KF influencing thermal degradation stages primarily due to its inherent characteristics. DMA analyses further confirmed increased stiffness and improved elastic response of the addition of KF. These results indicate that optimizing the filler-adding sequence is crucial for enhancing mechanical properties in PP-based composite fabrication. The findings have significant implications for developing sustainable and environmentally friendly composite materials for structural applications, such as pallet packaging and automotive components, by leveraging the renewable and biodegradable advantages of natural fibers. Looking forward, two practical issues remain. First, the long-term durability of the GnP-pre-coated fiber network under cyclic humidity and UV exposure has yet to be verified, as does modulus retention after multiple recycling passes. Second, the scalability of the GnP pre-coating step must be demonstrated at the pilot-plant level to confirm economic viability. Future work will, therefore, quantify property retention after UV-B exposure, hygrothermal cycling, and repeated mechanical reprocessing, establishing the durability and recyclability required for pallet-grade applications.

Author Contributions

S.L.: Conceptualization, Methodology, Validation, Visualization, Writing—original draft; K.A.: Methodology, Validation, Visualization; S.J.H.: Methodology, Validation, Writing—review and editing; Y.-T.K.: Conceptualization, Funding acquisition, Project administration, Supervision, Writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This study was sponsored by the Korea Pallet Pool Co., Ltd. (Grant # 459486, Virginia Tech).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Elia, V.; Gnoni, M.G. Designing an effective closed loop system for pallet management. Int. J. Prod. Econ. 2015, 170, 730–740. [Google Scholar] [CrossRef]

- Vendl, T.; Stejskal, V.; Kadlec, J.; Aulicky, R. New approach for evaluating the repellent activity of essential oils against storage pests using a miniaturized model of stored-commodity packaging and a wooden transport pallet. Ind. Crops Prod. 2021, 172, 114024. [Google Scholar] [CrossRef]

- Al Suwaiei, F.; Al Husayni, M.; Al Ghamdi, S.; Kanwi, M. The transformation of shipping & transport material to polymer-based products. A case study of wooden-to-plastic pallets. In Proceedings of the MECC 2023, Lake Tahoe, NV, USA, 2–5 October 2023; pp. 1–10. [Google Scholar]

- Idumah, C.I.; Hassan, A. Hibiscus cannabinus fiber/PP based nano-biocomposites reinforced with graphene nanoplatelets. J. Nat. Fibers 2017, 14, 691–706. [Google Scholar] [CrossRef]

- Yaghoobi, H.; Fereidoon, A. Preparation and characterization of short kenaf fiber-based biocomposites reinforced with multi-walled carbon nanotubes. Compos. Part B Eng. 2019, 162, 314–322. [Google Scholar] [CrossRef]

- Vayabari, D.A.; Ilham, Z.; Md Saad, N.; Usuldin, S.R.A.; Norhisham, D.A.; Abd Rahim, M.H.; Wan-Mohtar, W.A.A.Q.I. Cultivation strategies of kenaf (Hibiscus cannabinus L.) as a future approach in Malaysian agriculture industry. Horticulturae 2023, 9, 925. [Google Scholar] [CrossRef]

- Al-Mamun, M.; Rafii, M.Y.; Misran, A.B.; Berahim, Z.; Ahmad, Z.; Khan, M.M.H.; Oladosu, Y.; Arolu, F. Kenaf (Hibiscus cannabinus L.): A promising fiber crop with potential for genetic improvement utilizing both conventional and molecular approaches. J. Nat. Fibers 2023, 20, 2145410. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Sulong, A.B.; Radzi, M.F.; Ismail, N.; Raza, M.; Muhamad, N.; Khan, M.A. Influence of alkaline treatment and fiber loading on the physical and mechanical properties of kenaf/polypropylene composites for variety of applications. Prog. Nat. Sci. Mater. Int. 2016, 26, 657–664. [Google Scholar] [CrossRef]

- Feng, D.; Caulfield, D.; Sanadi, A. Effect of compatibilizer on the structure-property relationships of kenaf-fiber/polypropylene composites. Polym. Compos. 2001, 22, 506–517. [Google Scholar] [CrossRef]

- Mahjoub, R.; Yatim, J.M.; Sam, A.R.M.; Hashemi, S.H. Tensile properties of kenaf fiber due to various conditions of chemical fiber surface modifications. Constr. Build. Mater. 2014, 55, 103–113. [Google Scholar] [CrossRef]

- Su, X.; Wang, R.; Li, X.; Araby, S.; Kuan, H.-C.; Naeem, M.; Ma, J. A comparative study of polymer nanocomposites containing multi-walled carbon nanotubes and graphene nanoplatelets. Nano Mater. Sci. 2022, 4, 185–204. [Google Scholar] [CrossRef]

- Young, R.J.; Liu, M.; Kinloch, I.A.; Li, S.; Zhao, X.; Vallés, C.; Papageorgiou, D.G. The mechanics of reinforcement of polymers by graphene nanoplatelets. Compos. Sci. Technol. 2018, 154, 110–116. [Google Scholar] [CrossRef]

- Raza, M.A.; Westwood, A.; Brown, A.; Hondow, N.; Stirling, C. Characterisation of graphite nanoplatelets and the physical properties of graphite nanoplatelet/silicone composites for thermal interface applications. Carbon 2011, 49, 4269–4279. [Google Scholar] [CrossRef]

- Gu, J.; Yang, X.; Lv, Z.; Li, N.; Liang, C.; Zhang, Q. Functionalized graphite nanoplatelets/epoxy resin nanocomposites with high thermal conductivity. Int. J. Heat Mass Transf. 2016, 92, 15–22. [Google Scholar] [CrossRef]

- Siddiqui, V.U.; Sapuan, S.; Hassan, M.R. Innovative dispersion techniques of graphene nanoplatelets (GNPs) through mechanical stirring and ultrasonication: Impact on morphological, mechanical, and thermal properties of epoxy nanocomposites. Def. Technol. 2025, 43, 13–25. [Google Scholar] [CrossRef]

- Mingione, E.; Salvi, D.; Almonti, D.; Ponticelli, G.S. Improvement of thermal, electrical, and tribological performances of GnPs composites produced by selective laser sintering. Polym. Compos. 2025, 46, 7924–7938. [Google Scholar] [CrossRef]

- Kalaitzidou, K.; Fukushima, H.; Drzal, L.T. A new compounding method for exfoliated graphite–polypropylene nanocomposites with enhanced flexural properties and lower percolation threshold. Compos. Sci. Technol. 2007, 67, 2045–2051. [Google Scholar] [CrossRef]

- Almasarwah, N.; Abdelall, E.; Suer, G.; Egilmez, G.; Singh, M.; Ramadan, S. Pallet loading optimization considering storage time and relative humidity. J. Ind. Eng. Manag. 2023, 16, 453–471. [Google Scholar] [CrossRef]

- Ali, I.; Kim, N.K.; Bhattacharyya, D. Effects of graphene nanoplatelets on mechanical and fire performance of flax polypropylene composites with intumescent flame retardant. Molecules 2021, 26, 4094. [Google Scholar] [CrossRef]

- Mirzaei, J.; Fereidoon, A.; Ghasemi-Ghalebahman, A. Experimental study on mechanical properties of polypropylene nanocomposites reinforced with a hybrid graphene/PP-g-MA/kenaf fiber by response surface methodology. J. Elastomers Plast. 2021, 53, 1063–1089. [Google Scholar] [CrossRef]

- Hamma, A.; Kaci, M.; Ishak, Z.M.; Pegoretti, A. Starch-grafted-polypropylene/kenaf fibres composites. Part 1: Mechanical performances and viscoelastic behaviour. Compos. Part A Appl. Sci. Manuf. 2014, 56, 328–335. [Google Scholar] [CrossRef]

- Lee, B.; Hwang, U.; Kim, J.; Kim, S.-H.; Choi, K.; Park, I.-K.; Choi, C.; Suhr, J.; Nam, J.-D. Highly dispersed graphene nanoplatelets in polypropylene composites by employing high-shear stress for enhanced dielectric properties and frequency-selective electromagnetic interference shielding capability. Compos. Commun. 2023, 37, 101409. [Google Scholar] [CrossRef]

- Forsström, D.; Hamskog, M.; Eriksson, P.; Terselius, B. Oxidation of unstabilised polypropylene particles as studied by microcalorimetry and chemiluminescence techniques. Polym. Degrad. Stab. 2003, 81, 81–88. [Google Scholar] [CrossRef]

- Feng, N.L.; Malingam, S.D.; Ping, C.W.; Razali, N. Mechanical properties and water absorption of kenaf/pineapple leaf fiber-reinforced polypropylene hybrid composites. Polym. Compos. 2020, 41, 1255–1264. [Google Scholar] [CrossRef]

- Nematollahi, M.; Karevan, M.; Fallah, M.; Farzin, M. Experimental and numerical study of the critical length of short kenaf fiber reinforced polypropylene composites. Fibers Polym. 2020, 21, 821–828. [Google Scholar] [CrossRef]

- Nematollahi, M.; Karevan, M.; Mosaddegh, P.; Farzin, M. Morphology, thermal and mechanical properties of extruded injection molded kenaf fiber reinforced polypropylene composites. Mater. Res. Express 2019, 6, 095409. [Google Scholar] [CrossRef]

- Zhou, X.; Feng, J.; Yi, J.; Wang, L. Synergistic improvement of toughness of isotactic polypropylene: The introduction of high density polyethylene and annealing treatment. Mater. Des. 2013, 49, 502–510. [Google Scholar] [CrossRef]

- El-Shekeil, Y.; Sapuan, S.; Abdan, K.; Zainudin, E. Influence of fiber content on the mechanical and thermal properties of Kenaf fiber reinforced thermoplastic polyurethane composites. Mater. Des. 2012, 40, 299–303. [Google Scholar] [CrossRef]

- Joffe, R.; Andersons, J. Mechanical performance of thermoplastic matrix natural-fibre composites. In Properties and Performance of Natural-Fibre Composites; Elsevier: Amsterdam, The Netherlands, 2008; pp. 402–459. [Google Scholar]

- Vardai, R.; Lummerstorfer, T.; Pretschuh, C.; Jerabek, M.; Gahleitner, M.; Bartos, A.; Móczó, J.; Anggono, J.; Pukanszky, B. Improvement of the impact resistance of natural fiber–reinforced polypropylene composites through hybridization. Polym. Adv. Technol. 2021, 32, 2499–2507. [Google Scholar] [CrossRef]

- Kim, J.; Cho, D. Effects of waste expanded polypropylene as recycled matrix on the flexural, impact, and heat deflection temperature properties of kenaf fiber/polypropylene composites. Polymers 2020, 12, 2578. [Google Scholar] [CrossRef]

- Naveen, J.; Jawaid, M.; Zainudin, E.S.; Thariq Hameed Sultan, M.; Yahaya, R. Improved mechanical and moisture-resistant properties of woven hybrid epoxy composites by graphene nanoplatelets (GNP). Materials 2019, 12, 1249. [Google Scholar] [CrossRef]

- Ellis, T.S.; D’Angelo, J.S. Thermal and mechanical properties of a polypropylene nanocomposite. J. Appl. Polym. Sci. 2003, 90, 1639–1647. [Google Scholar] [CrossRef]

- Han, S.O.; Karevan, M.; Sim, I.N.; Bhuiyan, M.A.; Jang, Y.H.; Ghaffar, J.; Kalaitzidou, K. Understanding the reinforcing mechanisms in kenaf fiber/PLA and kenaf fiber/PP composites: A comparative study. Int. J. Polym. Sci. 2012, 2012, 679252. [Google Scholar] [CrossRef]

- Huang, L.; Wu, Q.; Li, S.; Ou, R.; Wang, Q. Toughness and crystallization enhancement in wood fiber-reinforced polypropylene composite through controlling matrix nucleation. J. Mater. Sci. 2018, 53, 6542–6551. [Google Scholar] [CrossRef]

- Joonobi, M.; Harun, J.; Tahir, P.M.; Zaini, L.H.; SaifulAzry, S.; Makinejad, M.D. Characteristic of nanofibers extracted from kenaf core. BioResources 2010, 5, 2556–2566. [Google Scholar] [CrossRef]

- Asim, M.; Paridah, M.T.; Chandrasekar, M.; Shahroze, R.M.; Jawaid, M.; Nasir, M.; Siakeng, R. Thermal stability of natural fibers and their polymer composites. Iran. Polym. J. 2020, 29, 625–648. [Google Scholar] [CrossRef]

- Mohanty, S.; Verma, S.K.; Nayak, S.K. Dynamic mechanical and thermal properties of MAPE treated jute/HDPE composites. Compos. Sci. Technol. 2006, 66, 538–547. [Google Scholar] [CrossRef]

- Pan, P.; Zhu, B.; Kai, W.; Serizawa, S.; Iji, M.; Inoue, Y. Crystallization behavior and mechanical properties of bio-based green composites based on poly (L-lactide) and kenaf fiber. J. Appl. Polym. Sci. 2007, 105, 1511–1520. [Google Scholar] [CrossRef]

- Kumar, S.S.; Duraibabu, D.; Subramanian, K. Studies on mechanical, thermal and dynamic mechanical properties of untreated (raw) and treated coconut sheath fiber reinforced epoxy composites. Mater. Des. 2014, 59, 63–69. [Google Scholar] [CrossRef]

- Zin, M.H.; Abdan, K.; Norizan, M.N. The effect of different fiber loading on flexural and thermal properties of banana/pineapple leaf (PALF)/glass hybrid composite. In Structural Health Monitoring of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–17. [Google Scholar]

- Farsi, M. Thermoplastic matrix reinforced with natural fibers: A study on interfacial behavior. Some Crit. Issues Inject. Molding 2012, 1, 225–250. [Google Scholar]

- Haris, N.N.; Hassan, M.Z.; Ilyas, R.A.; Suhot, M.A.; Sapuan, S.M.; Dolah, R.; Mohammad, R.; Asyraf, M.R.M. Dynamic mechanical properties of natural fiber reinforced hybrid polymer composites: A review. J. Mater. Res. Technol. 2022, 19, 167–182. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).