Polyamide 6 as a Liner Material for Type IV Hydrogen Storage Cylinders: Performance Challenges and Modification Strategies

Abstract

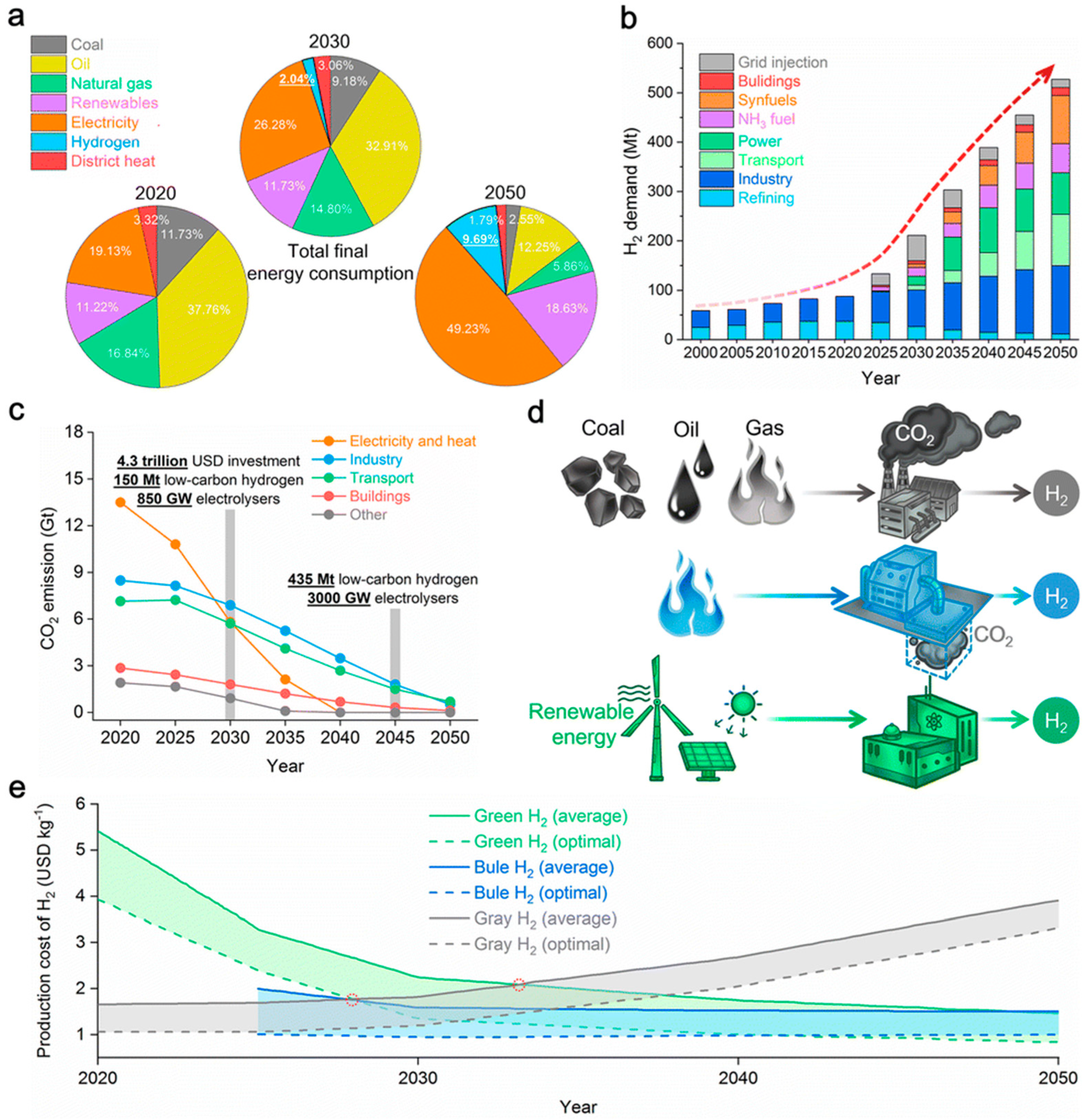

1. Introduction

2. The Liner in Type IV Hydrogen Storage Cylinders

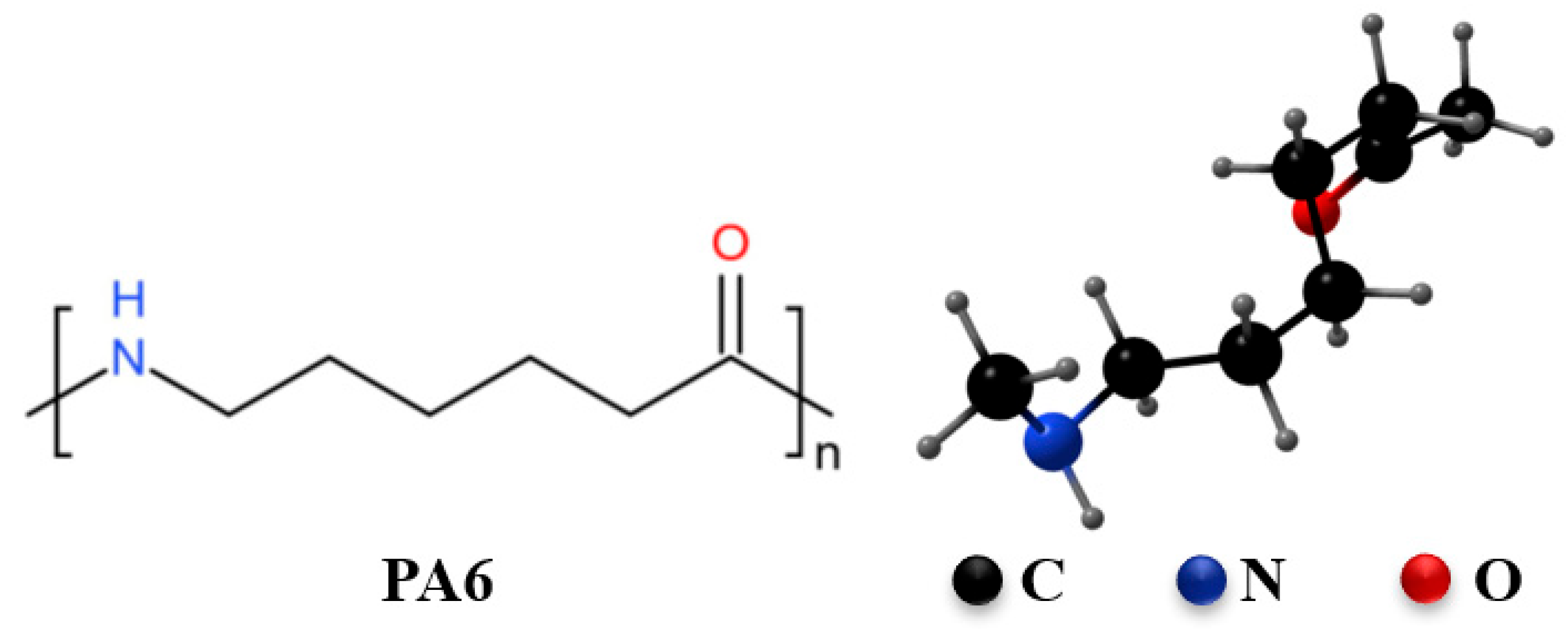

3. Analysis of the Intrinsic Properties of PA6

4. Hydrogen Barrier Properties of PA6

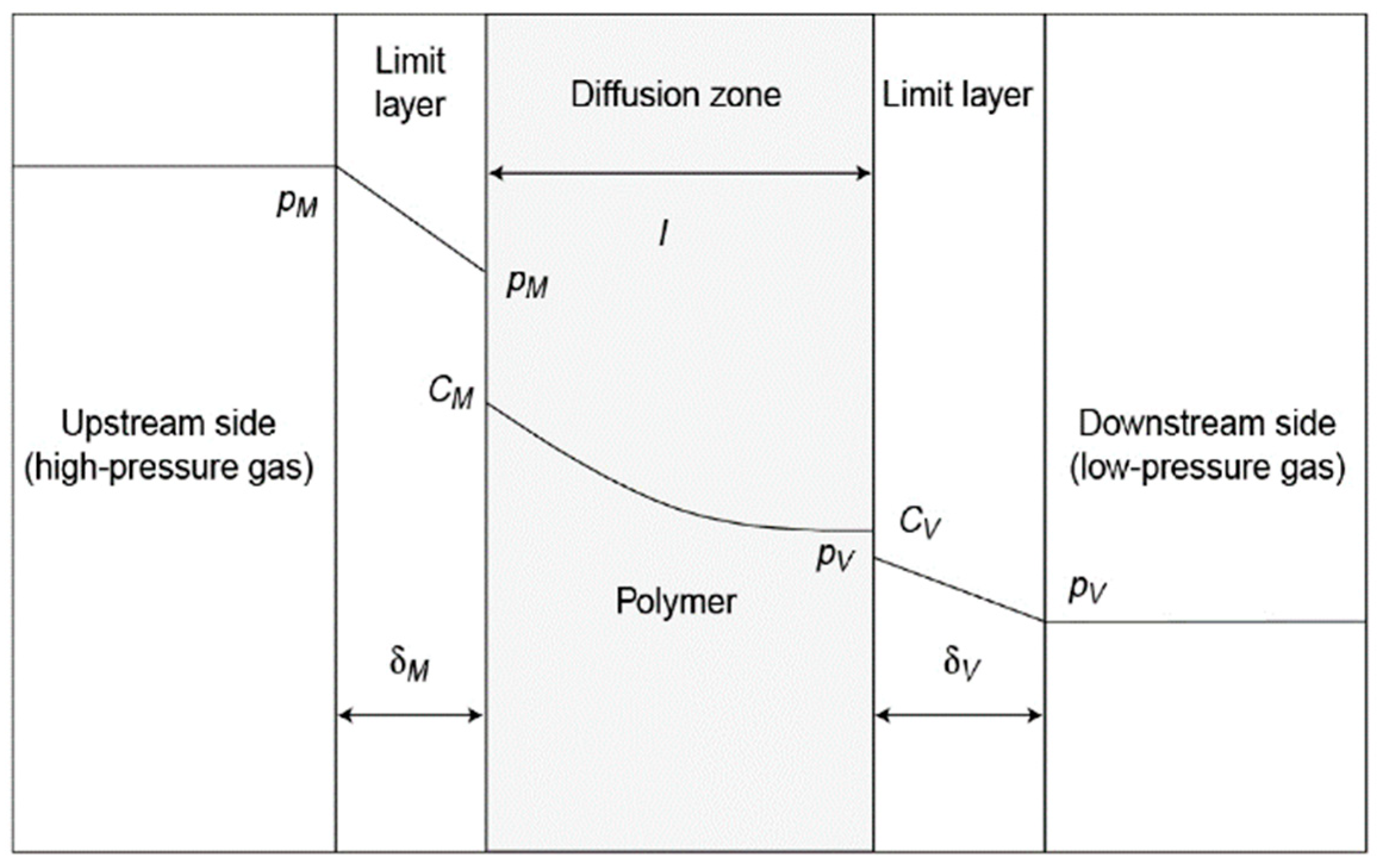

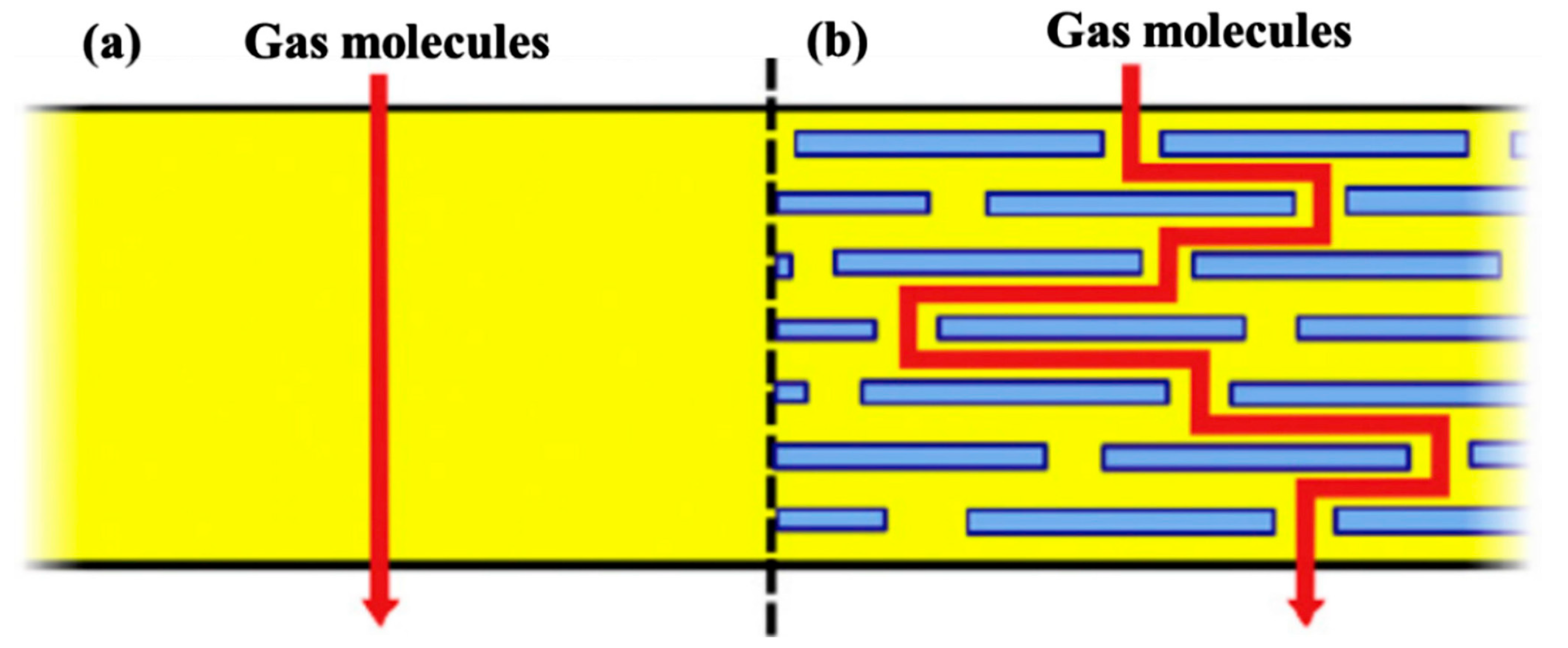

4.1. Gas Permeation Mechanism

4.2. Gas Barrier Enhancement Technologies

4.2.1. Graphene and Its Derivatives

4.2.2. Inorganic Nanocomposites

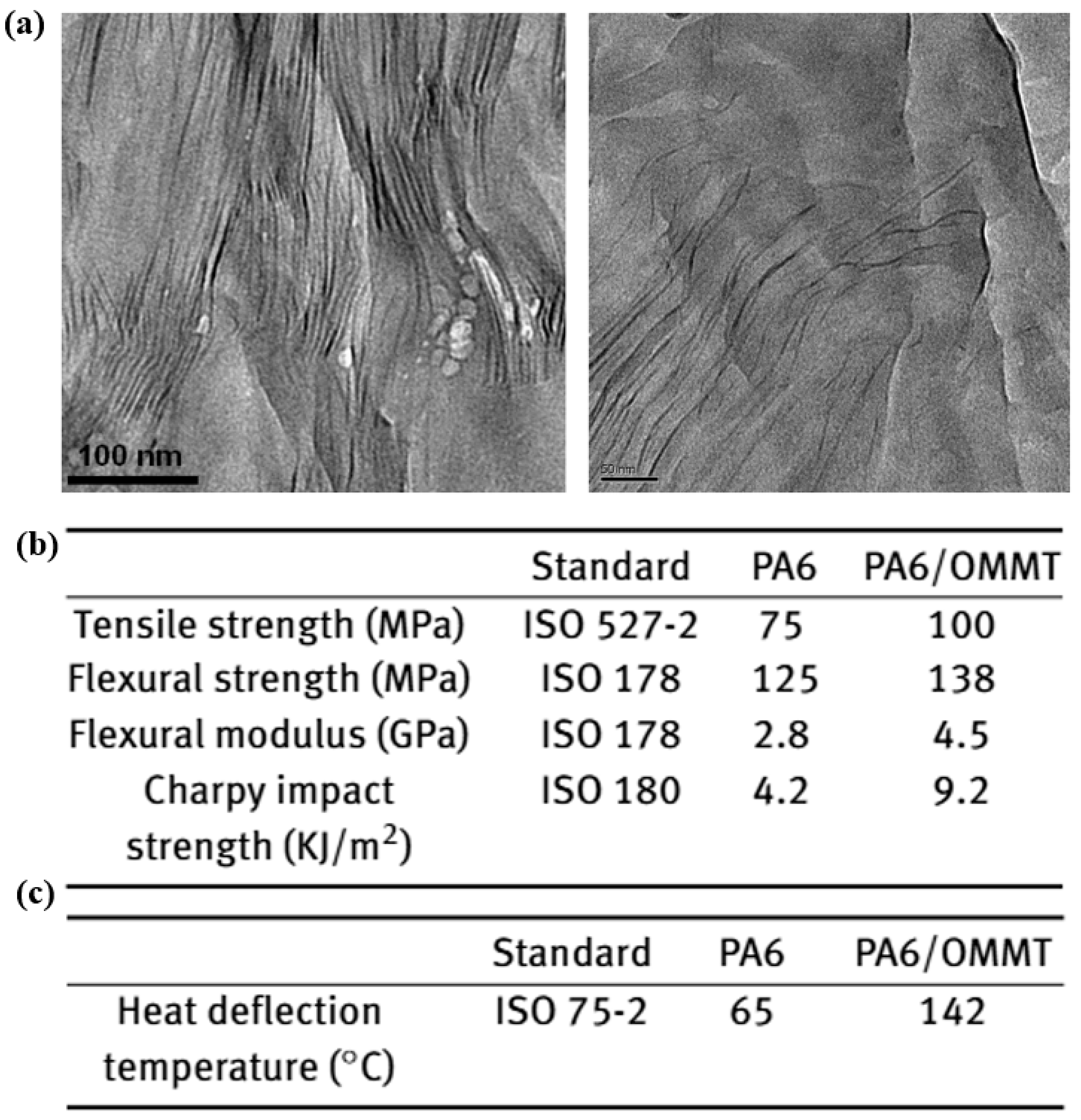

5. Research on the Mechanical Properties of Polyamide 6

5.1. Mechanical Failure of PA 6

5.2. Strategies for Enhancing Mechanical Properties of PA6

5.2.1. In Situ Polymerization of PA6

5.2.2. Filler-Reinforced Composite

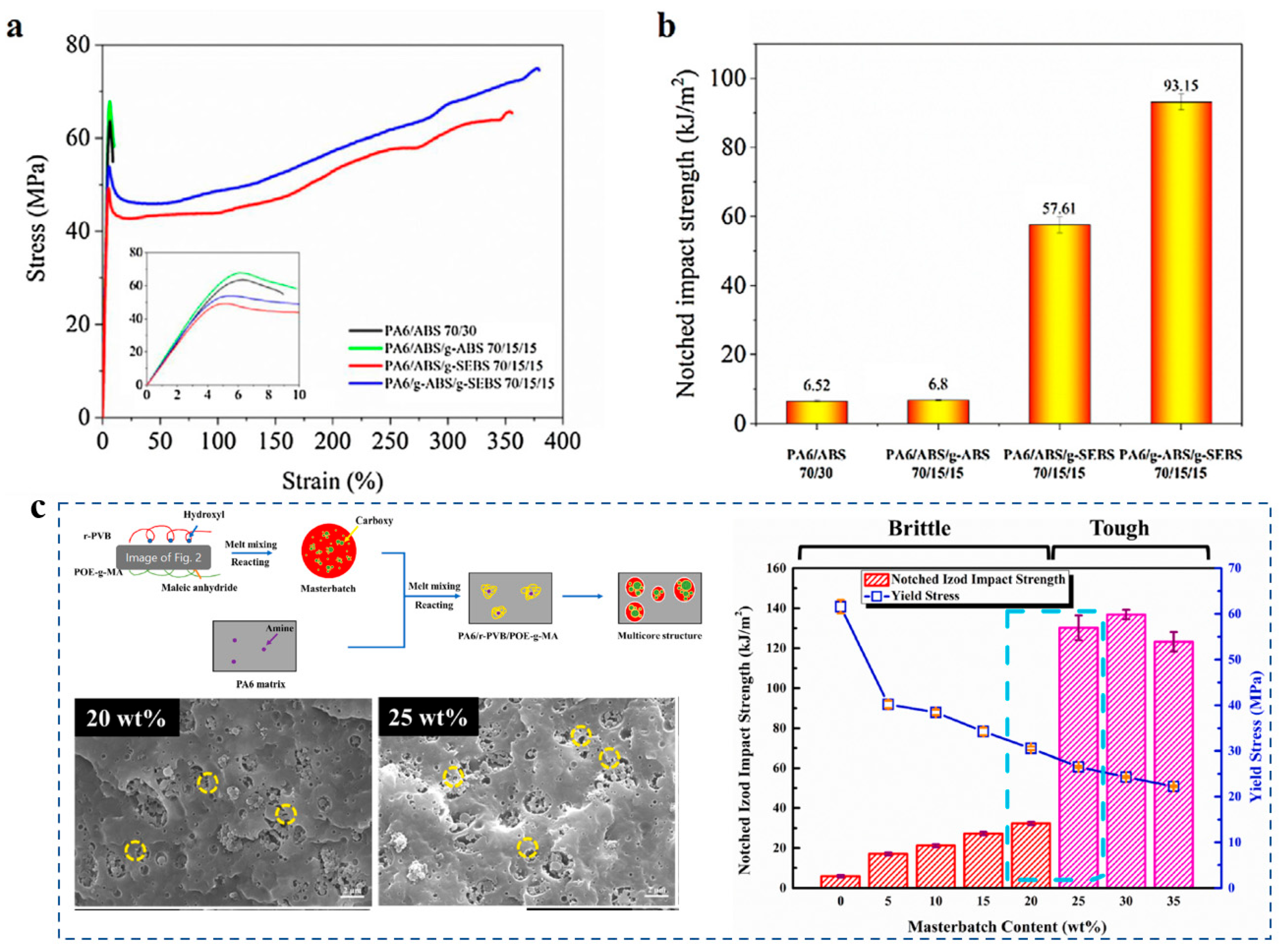

5.2.3. Blending Modification

6. Conclusions

Funding

Conflicts of Interest

References

- Guan, X.; Sun, Y.; Zhao, S.; Li, H.; Zeng, S.; Yao, Q.; Li, R.; Chen, H.; Qu, K. Selectively nucleotide-derived RuP on N, P-codoped carbon with engineered mesopores for energy-efficient hydrogen production assisted by hydrazine oxidation. SusMat 2024, 4, 166–177. [Google Scholar] [CrossRef]

- Mirshokraee, S.A.; Muhyuddin, M.; Lorenzi, R.; Tseberlidis, G.; Lo Vecchio, C.; Baglio, V.; Berretti, E.; Lavacchi, A.; Santoro, C. Litchi-derived platinum group metal-free electrocatalysts for oxygen reduction reaction and hydrogen evolution reaction in alkaline media. SusMat 2023, 3, 248–262. [Google Scholar] [CrossRef]

- Evro, S.; Oni, B.A.; Tomomewo, O.S. Carbon Neutrality and Hydrogen Energy Systems. Int. J. Hydrogen Energy 2024, 78, 1449–1467. [Google Scholar] [CrossRef]

- Serpell, O.; Hsain, Z.; Chu, A. Ammonia’s Role in a Net-Zero Hydrogen Economy. Kleinman Cent. Energy Policy 2023, 17, 1–11. [Google Scholar]

- Asiegbu, A.D.; Kahn, M.T.E.; Almaktoof, A.M. Green Hydrogen: A Clean Energy Solution for Germany’s Transportation Sector. SAIEE Afr. Res. J. 2024, 115, 16–23. [Google Scholar] [CrossRef]

- Martin, P.; Ocko, I.B.; Esquivel-Elizondo, S.; Kupers, R.; Cebon, D.; Baxter, T.; Hamburg, S.P. A Review of Challenges With Using the Natural Gas System for Hydrogen. Energy Sci. Eng. 2024, 12, 3995–4009. [Google Scholar] [CrossRef]

- Guan, D.; Wang, B.; Zhang, J.; Shi, R.; Jiao, K.; Li, L.; Wang, Y.; Xie, B.; Zhang, Q.; Yu, J.; et al. Hydrogen Society: From Present to Future. Energy Environ. Sci. 2023, 16, 4926–4943. [Google Scholar] [CrossRef]

- Xu, Y.; Zhou, Y.; Li, Y.; Ding, Z. Research Progress and Application Prospects of Solid-State Hydrogen Storage Technology. Molecules 2024, 29, 1767. [Google Scholar] [CrossRef]

- Meduri, S.; Nandanavanam, J. Materials for Hydrogen Storage at Room Temperature—An Overview. Mater. Today Proc. 2023, 72, 1–8. [Google Scholar] [CrossRef]

- Züttel, A. Materials for Hydrogen Storage. Mater. Today 2003, 6, 24–33. [Google Scholar] [CrossRef]

- Wang, X.; Li, B.; Jin, X.; Han, B.; Shu, C.M. Ultimate Pressure-Bearing Capacity of Type III Onboard High-Pressure Hydrogen Storage Cylinderss Under Typical Accident Scenarios. J. Energy Storage 2023, 63, 107135. [Google Scholar] [CrossRef]

- Zhang, M.; Lv, H.; Kang, H.; Zhou, W.; Zhang, C. A Literature Review of Failure Prediction and Analysis Methods for Composite High-Pressure Hydrogen Storage Cylinderss. Int. J. Hydrogen Energy 2019, 44, 25777–25799. [Google Scholar] [CrossRef]

- Rohit, G.; Santosh, M.S.; Kumar, M.N.; Raghavendra, K. Numerical Investigation on Structural Stability and Explicit Performance of High-Pressure Hydrogen Storage Cylinderss. Int. J. Hydrogen Energy 2023, 48, 5565–5575. [Google Scholar] [CrossRef]

- Barthélémy, H. Hydrogen Storage–Industrial Prospectives. Int. J. Hydrogen Energy 2012, 37, 17364–17372. [Google Scholar] [CrossRef]

- Khan, S.; Kumar, A. Failure Analysis in Advance Cylindrical Composite Pressure Vessel Under Pressure & Temperature for Hydrogen Storage: A Comprehensive Review. Polym. Compos. 2025, 46, 2933–2973. [Google Scholar]

- Wu, J.; Wang, R.; Liu, R.; Zhang, Z. The Development Status of Composite Materials and Winding Process of Type IV Hydrogen Storage Cylinder. Int. J. Automot. Manuf. Mater. 2025, 4, 4. [Google Scholar] [CrossRef]

- Wang, X.; Tian, M.; Chen, X.; Xie, P.; Yang, J.; Chen, J.; Yang, W. Advances on Materials Design and Manufacture Technology of Plastic Liner of Type IV Hydrogen Storage Vessel. Int. J. Hydrogen Energy 2022, 47, 8382–8408. [Google Scholar] [CrossRef]

- Hu, D.; Shao, W.; Lu, D.; Xu, Y.; Wang, J. Design and Material Optimization of Carbon Fiber Composite Winding Reinforcement Layer for Vehicle Type-IV Hydrogen Storage Vessels. J. Energy Storage 2024, 100, 113459. [Google Scholar] [CrossRef]

- Yersak, T.A.; Baker, D.R.; Yanagisawa, Y. Predictive model for depressurization-induced blistering of type IV tank liners for hydrogen storage. Int. J. Hydrogen Energy 2017, 42, 28910–28917. [Google Scholar] [CrossRef]

- Jin, Z.; Su, Y.; Lv, H.; Liu, M.; Li, W.; Zhang, C. Review of Decompression Damage of the Polymer Liner of the Type IV Hydrogen Storage Cylinderss. Polymers 2023, 15, 2258. [Google Scholar] [CrossRef]

- Su, Y.; Lv, H.; Zhou, W.; Zhang, C. Review of the Hydrogen Permeability of the Liner Material of Type IV On-Board Hydrogen Storage Cylinderss. World Electr. Veh. J. 2021, 12, 130. [Google Scholar] [CrossRef]

- Smith, B. Lifecycle Verification of Tank Liner Polymers; Oak Ridge National Lab (ORNL): Oak Ridge, TN, USA, 2014. [Google Scholar]

- Simaafrookhteh, S.; Van Thillo, T.; Lomov, S.V.; Ivens, J. Crystallinity of Neat and Carbon Fiber-Reinforced Polyamide-6 Processed at Different Cooling Rates. Compos. Part A Appl. Sci. Manuf. 2025, 188, 108520. [Google Scholar] [CrossRef]

- Wang, T.; Li, X.; Luo, R.; He, Y.; Maeda, S.; Shen, Q.; Hu, W. Effects of Amide Comonomers on Polyamide 6 Crystallization Kinetics. Thermochim. Acta 2020, 690, 178667. [Google Scholar] [CrossRef]

- Uematsu, H.; Nishimura, S.; Yamaguchi, A.; Nishimura, F.; Sugihara, S.; Sugiura, N.; Ishikawa, T.; Hayashi, T.; Yamane, M.; Kawabe, K. Crystal Structures of Polyamide 6 at the Interphase and Around Carbon Fiber and Mechanical Properties of Their Composites. Polymer 2023, 275, 125907. [Google Scholar] [CrossRef]

- Shan, G.F.; Yang, W.; Yang, M.; Xie, B.; Li, Z.; Feng, J. Effect of Crystallinity Level on the Double Yielding Behavior of Polyamide 6. Polym. Test. 2006, 25, 452–459. [Google Scholar] [CrossRef]

- Kohutiar, M.; Kakošová, L.; Krbata, M.; Janík, R.; Fekiač, J.J.; Breznická, A.; Eckert, M.; Mikuš, P.; Timárová, Ľ. Comprehensive Review: Technological Approaches, Properties, and Applications of Pure and Reinforced Polyamide 6 (PA6) and Polyamide 12 (PA12) Composite Materials. Polymers 2025, 17, 442. [Google Scholar] [CrossRef]

- Merlonghi, L.; Atiq, O.; Rea, R.; Mangano, E.; Stroeks, A.; Baschetti, M.G.; De Angelis, M.G. An Experimental Study of Hydrogen Sorption and Permeation in High-Performance Polyamides. Int. J. Hydrogen Energy 2024, 88, 1463–1473. [Google Scholar] [CrossRef]

- Dong, C.; Liu, Y.; Li, J.; Bin, G.; Zhou, C.; Han, W.; Li, X. Hydrogen Permeability of Polyamide 6 Used as Liner Material for Type IV On-Board Hydrogen Storage Cylinders. Polymers 2023, 15, 3715. [Google Scholar] [CrossRef]

- Feng, H.; Lu, H.; Geng, Z.; Li, D.; Yang, R. Microporous-Micronucleus Composite Structure Endowing Heterogenous Polyamide 6 With Low-Temperature Toughness, Low Dielectric Constant, Fire Retardancy and Antibacterial Activity. Compos. Part B Eng. 2023, 261, 110808. [Google Scholar] [CrossRef]

- Li, L.; Zhao, J.; Wang, X.; Yang, Q.; Wang, X.; Yin, H. Studies on Modification of Polyamide 6 Plastics for Hydrogen Storage. Polymers 2025, 17, 523. [Google Scholar] [CrossRef]

- Klopffer, M.H.; Flaconneche, B. Transport Properties of Gases in Polymers: Bibliographic Review. Oil Gas Sci. Technol. 2001, 56, 223–244. [Google Scholar] [CrossRef]

- Mozaffari, F.; Eslami, H.; Moghadasi, J. Molecular Dynamics Simulation of Diffusion and Permeation of Gases in Polystyrene. Polymer 2010, 51, 300–307. [Google Scholar] [CrossRef]

- Balasooriya, W.; Clute, C.; Schrittesser, B.; Pinter, G. A Review on Applicability, Limitations, and Improvements of Polymeric Materials in High-Pressure Hydrogen Gas Atmospheres. Polym. Rev. 2022, 62, 175–209. [Google Scholar] [CrossRef]

- McCall, D.W.; Slichter, W.P. Diffusion in Ethylene Polymers. III. Effects of Temperature and Pressure. J. Am. Chem. Soc. 1958, 80, 1861–1868. [Google Scholar] [CrossRef]

- Kanai, T.; Okuyama, Y.; Takashige, M. Dynamics and Structure Development for Biaxial Stretching Polyamide 6 Films. Adv. Polym. Technol. 2018, 37, 2894–2904. [Google Scholar] [CrossRef]

- Li, J.; Zhao, X.; Liang, J.; Zhao, C.; Feng, N.; Guo, G.; Zhou, Z. Molecular Dynamics Simulation of Hydrogen Barrier Performance of Modified Polyamide 6 Lining of IV Hydrogen Storage Cylinders With Graphene. Polymers 2024, 16, 2185. [Google Scholar] [CrossRef]

- Kanesugi, H.; Ohyama, K.; Fujiwara, H.; Nishimura, S. High-Pressure Hydrogen Permeability Model for Crystalline Polymers. Int. J. Hydrogen Energy 2023, 48, 723–739. [Google Scholar] [CrossRef]

- Kong, J.; Li, Z.; Cao, Z.; Han, C.; Dong, L. The Excellent Gas Barrier Properties and Unique Mechanical Properties of Poly (Propylene Carbonate)/Organo-Montmorillonite Nanocomposites. Polym. Bull. 2017, 74, 5065–5082. [Google Scholar] [CrossRef]

- Cui, Y.; Kundalwal, S.I.; Kumar, S. Gas Barrier Performance of Graphene/Polymer Nanocomposites. Carbon 2016, 98, 313–333. [Google Scholar] [CrossRef]

- Allen, M.J.; Tung, V.C.; Kaner, R.B. Honeycomb Carbon: A Review of Graphene. Chem. Rev. 2010, 110, 132–145. [Google Scholar] [CrossRef]

- Kinloch, I.A.; Suhr, J.; Lou, J.; Young, R.J.; Ajayan, P.M. Composites With Carbon Nanotubes and Graphene: An Outlook. Science 2018, 362, 547–553. [Google Scholar] [CrossRef]

- Lin, F.; Liu, Y.; Song, L.; Hao, X.; Liu, X.; Fan, S.; Wu, Y.; Mao, L. Preparation of Biaxially Oriented Polyamide 6/Polyketone/Graphene Oxide Films With Enhanced Barrier and Mechanical Behaviors. J. Appl. Polym. Sci. 2021, 138, 50501. [Google Scholar] [CrossRef]

- Raine, T.P.; Istrate, O.M.; King, B.E.; Craster, B.; Kinloch, I.A.; Budd, P.M. Graphene/Polyamide Laminates for Supercritical CO2 and H2S Barrier Applications: An Approach Toward Permeation Shutdown. Adv. Mater. Interfaces 2018, 5, 1800304. [Google Scholar] [CrossRef]

- Kausar, A. Composite Coatings of Polyamide/Graphene: Microstructure, Mechanical, Thermal, and Barrier Properties. Compos. Interfaces 2018, 25, 109–125. [Google Scholar] [CrossRef]

- Liang, J.; Wu, Y.; Chen, Z.; Wu, T.; Li, Y.; Zhao, C.; Zhao, R.; Li, W. Comprehensive Research on Mechanical and Gas Barrier Properties of Nylon6 Liner Strengthened by Multi-Walled Carbon Nanotubes. Mater. Today Commun. 2024, 41, 111052. [Google Scholar] [CrossRef]

- Ray, S.S.; Okamoto, M. Polymer/Layered Silicate Nanocomposites: A Review From Preparation to Processing. Prog. Polym. Sci. 2003, 28, 1539–1641. [Google Scholar]

- Shiferraw, B.T.; Mengesha, D.N.; Kim, H. Enhanced Adsorption Capacity of Phosphoric Acid-Modified Montmorillonite Clay and Ground Coffee Waste-Derived Carbon-Based Functional Composite Beads for the Effective Removal of Methylene Blue. Colloids Surf. A Physicochem. Eng. Asp. 2024, 695, 134243. [Google Scholar] [CrossRef]

- Wan, H.; Yan, A.; Xiong, H.; Chen, G.; Zhang, N.; Cao, Y.; Liu, X. Montmorillonite: A Structural Evolution From Bulk Through Unilaminar Nanolayers to Nanotubes. Appl. Clay Sci. 2020, 194, 105695. [Google Scholar] [CrossRef]

- Ito, M.; Nagai, K. Thermal Aging and Oxygen Permeation of Nylon-6 and Nylon-6/Montmorillonite Composites. J. Appl. Polym. Sci. 2010, 118, 928–935. [Google Scholar] [CrossRef]

- Sun, Y.; Lv, H.; Zhou, W.; Zhang, C. Research on Hydrogen Permeability of Polyamide 6 as the Liner Material for Type IV Hydrogen Storage Cylinders. Int. J. Hydrogen Energy 2020, 45, 24980–24990. [Google Scholar] [CrossRef]

- Eslami, H.; Muller-Plathe, F. How thick is the interphase in an ultrathin polymer film? Coarse-grained molecular dynamics simulations of polyamide-6, 6 on graphene. J. Phys. Chem. C 2013, 117, 5249–5257. [Google Scholar] [CrossRef]

- Sharma, R.; Morgen, P.; Larsen, M.J.; Roda-Serrat, M.C.; Lund, P.B.; Grahl-Madsen, L.; Andersen, S.M. Recovery, Regeneration, and Reapplication of PFSA Polymer from End-of-Life PEMFC MEAs. ACS Appl. Mater. Interfaces 2023, 15, 48705–48715. [Google Scholar] [CrossRef]

- Eslami, H.; Muller-Plathe, F. Molecular dynamics simulation of water influence on local structure of nanoconfined polyamide-6,6. J. Phys. Chem. B 2011, 115, 9720–9731. [Google Scholar] [CrossRef]

- Lee, S.; Han, H.S.; Seong, D.G. Improving Gas Barrier Property of Polymer Based Nanocomposites Using Layer by Layer Deposition Method for Hydrogen Tank Liner. Compos. Res. 2022, 35, 121–126. [Google Scholar]

- Li, X.; Xiao, Z.; Wu, J.; Zeng, L.; Li, J.; Liu, Y.; Shi, J. Study on the Rapid Decompression Rate of PA6 Liner Material of Type IV On-Board Hydrogen Storage Cylinders. Int. J. Hydrogen Energy 2024, 88, 209–227. [Google Scholar] [CrossRef]

- Kis, D.I.; Bata, A.; Takács, J.; Kókai, E. Mechanical Properties of Clay-Reinforced Polyamide 6 Nanocomposite Liner Materials of Type IV Hydrogen Storage Vessels. Nanomaterials 2024, 14, 1385. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Kalali, E.N.; Wang, D.Y. An In-Situ Polymerization Approach for Functionalized MoS2/Nylon-6 Nanocomposites With Enhanced Mechanical Properties and Thermal Stability. J. Mater. Chem. A 2015, 3, 24112–24120. [Google Scholar] [CrossRef]

- Sun, Y.; Mei, J.; Hu, H.; Ying, J.; Zhou, W.; Zhao, X.; Peng, S. In-Situ Polymerization of Exfoliated Structure PA6/Organo-Clay Nanocomposites. Rev. Adv. Mater. Sci. 2020, 59, 434–440. [Google Scholar] [CrossRef]

- Huang, H.; Yan, L.; Guo, Y.; Lin, H.L.; Chen, L.; Yang, L.F.; Xie, Y.J.; Bian, J. Morphological, Mechanical and Thermal Properties of PA6 Nanocomposites Co-Incorporated With Nano-Al2O3 and Graphene Oxide Fillers. Polymer 2020, 188, 122119. [Google Scholar] [CrossRef]

- Gong, Y.; Chen, J.; Zhang, J.; Ding, Y.; Liu, P.; Fan, H.; Yang, M. Strongly Reinforced Mechanical and Thermal Properties of Polyamide 66 by High Loading Titanium Dioxide Whiskers. Compos. Sci. Technol. 2024, 257, 110811. [Google Scholar] [CrossRef]

- Liu, I.; Phang, L.; Shen, Y.; Chow, S.Y.; Zhang, W.D. Morphology and Mechanical Properties of Multiwalled Carbon Nanotubes Reinforced Nylon-6 Composites. Macromolecules 2004, 37, 7214–7222. [Google Scholar] [CrossRef]

- Li, H.; Xie, X.M. Morphology Development and Superior Mechanical Properties of PP/PA6/SEBS Ternary Blends Compatibilized by Using a Highly Efficient Multi-Phase Compatibilizer. Polymer 2017, 108, 1–10. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Ashenai Ghasemi, F.; Fasihi, M.; Rajaee, P. Fracture Toughness of PA6/POE-g-MA/TiO2 Ternary Nanocomposites According to the Essential Work Fracture Method. Polym. Compos. 2023, 44, 3895–3912. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, Z.; Li, Y.; Zhang, Q.; Zhang, S.; Zhang, L. Enhanced Compatibility, Morphology, and Low-Temperature Toughness of Polyamide 6/Poly(Dimethylsiloxane)/Epoxidized Silicone Rubber Composites. Ind. Eng. Chem. Res. 2023, 62, 9694–9702. [Google Scholar] [CrossRef]

- Kherroub, D.E.; Belbachir, M.; Lamouri, S.; Bouhadjar, L.; Chikh, K. Synthesis of Polyamide-6/Montmorillonite Nanocomposites by Direct In-Situ Polymerization Catalysed by Exchanged Clay. Orient. J. Chem. 2013, 29, 1429–1436. [Google Scholar] [CrossRef]

- Baniasadi, H.; Trifol, J.; Ranta, A.; Seppälä, J. Exfoliated Clay Nanocomposites of Renewable Long-Chain Aliphatic Polyamide Through In-Situ Polymerization. Compos. Part B Eng. 2021, 211, 108655. [Google Scholar] [CrossRef]

- Mekhzoum, M.E.M.; Raji, M.; Rodrigue, D.; el kacem Qaiss, A.; Bouhfid, R. The Effect of Benzothiazolium Surfactant Modified Montmorillonite Content on the Properties of Polyamide 6 Nanocomposites. Appl. Clay Sci. 2020, 185, 105417. [Google Scholar] [CrossRef]

- Xiang, D.; Tian, H.; Ma, J.; Harkin-Jones, E.; Li, Y.; Wang, M.; Liu, L.; Wu, Y.; Cheng, J.; Li, D. 3D Printing and Properties of Carbon Nanotube Modified Basalt Fiber/Nylon 6 Composites. Compos. Commun. 2025, 55, 102313. [Google Scholar] [CrossRef]

- Chen, X.; Xu, H.; Zhu, Y.; Yan, C.; Liu, D.; Zhang, Y. Polyphosphazene Nanotubes/Carbon Fibers Hierarchical Hybrid Reinforcement for Improving Interfacial Adhesion of Polyamide 6 Composites. Iran. Polym. J. 2023, 32, 1033–1044. [Google Scholar] [CrossRef]

- Wang, F.; Wang, J.; Fang, D.; Zhou, S.; Huang, J.; Zhao, G.; Liu, Y. Surface Sizing Introducing Carbon Nanotubes for Interfacial Bond Strengthening of Basalt Fiber–Reinforced Polymer Composites. Adv. Compos. Hybrid Mater. 2023, 6, 117. [Google Scholar] [CrossRef]

- He, L.; Lou, J.; Nie, X.; He, M.; Fan, Q.; Yang, J.; Liu, Y.; Qin, S.; Yu, J. Highly Enhanced Toughness and Thermal Oxygen Aging Resistance of PA6 via Novel Designed Macromolecular Antioxidants. Polymer 2024, 312, 127614. [Google Scholar] [CrossRef]

- Sui, X.; Xie, X.M. Creating Super-Tough and Strong PA6/ABS Blends Using Multi-Phase Compatibilizers. Chin. Chem. Lett. 2019, 30, 149–152. [Google Scholar] [CrossRef]

- Mirzaee, R.; Aref-Azar, A. Modeling and Optimizing Toughness and Rigidity of PA6/SBR: Using Compatibilizer and Response Surface Methodology. Polym. Test. 2020, 83, 106346. [Google Scholar] [CrossRef]

- Wang, W.Y.; Ma, X.; Sun, D.X.; Qi, X.D.; Yang, J.H.; Wang, Y. Achieving Electrical Insulation, High Thermal Conductivity and High Fracture Toughness in Polyamide 6/Carbon Nanofiber Composites Through the Interfacial Welding Effect of Elastomer. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105671. [Google Scholar] [CrossRef]

- Wei, Z.; Wang, R.; Zhang, C.; Wang, J.; Yang, Y.; Wang, W.; Cao, Y. Preparation and Characterization of Super-Toughened PA6/r-PVB Blends With “Transplanted” Multicore Morphology by Reactive Compatibilization. Eur. Polym. J. 2021, 143, 110173. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Zhao, G.; Ma, X.; Ren, D.; Nie, M.; Han, R. Polyamide 6 as a Liner Material for Type IV Hydrogen Storage Cylinders: Performance Challenges and Modification Strategies. Polymers 2025, 17, 1848. https://doi.org/10.3390/polym17131848

Wang W, Zhao G, Ma X, Ren D, Nie M, Han R. Polyamide 6 as a Liner Material for Type IV Hydrogen Storage Cylinders: Performance Challenges and Modification Strategies. Polymers. 2025; 17(13):1848. https://doi.org/10.3390/polym17131848

Chicago/Turabian StyleWang, Wenyan, Guanxi Zhao, Xiao Ma, Dengxun Ren, Min Nie, and Rui Han. 2025. "Polyamide 6 as a Liner Material for Type IV Hydrogen Storage Cylinders: Performance Challenges and Modification Strategies" Polymers 17, no. 13: 1848. https://doi.org/10.3390/polym17131848

APA StyleWang, W., Zhao, G., Ma, X., Ren, D., Nie, M., & Han, R. (2025). Polyamide 6 as a Liner Material for Type IV Hydrogen Storage Cylinders: Performance Challenges and Modification Strategies. Polymers, 17(13), 1848. https://doi.org/10.3390/polym17131848