Green Composite Based on a Polymer Mixture Containing Biopolymer and Waste Coffee Husks

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Methods

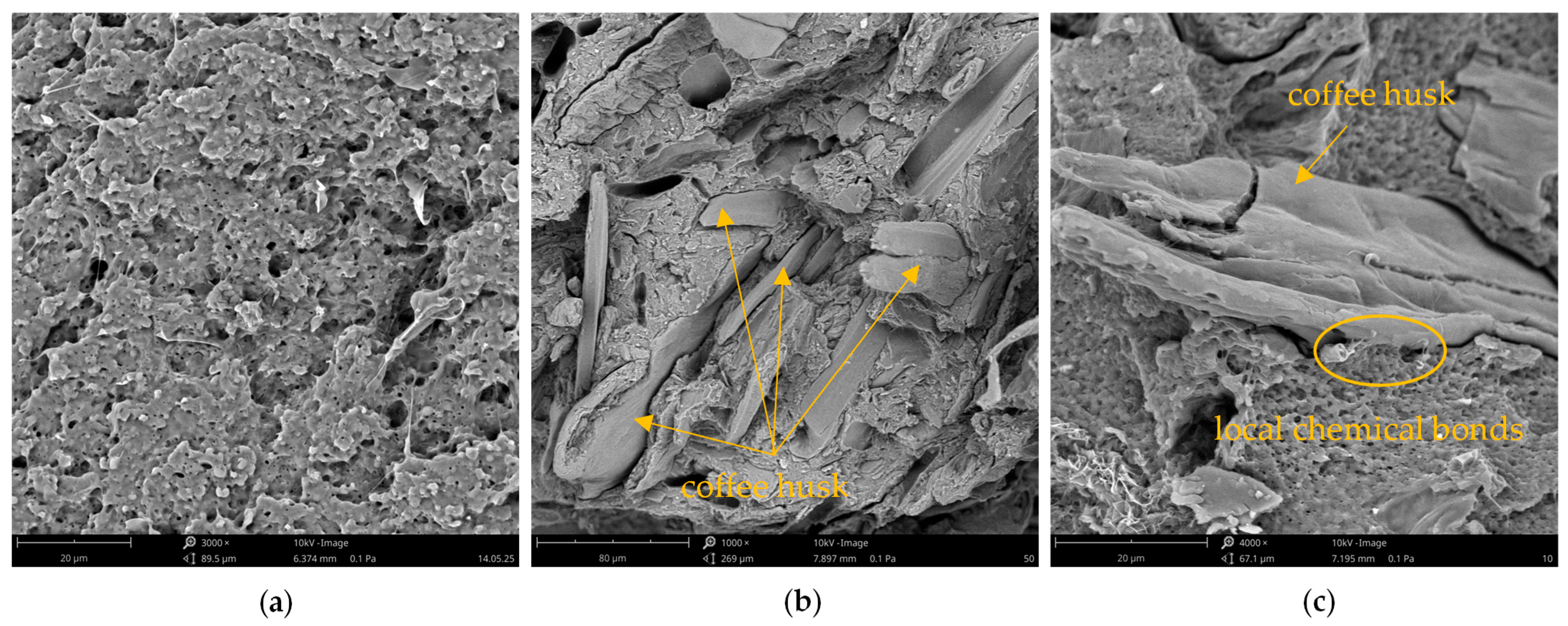

2.2.1. SEM Analysis of Material Structure

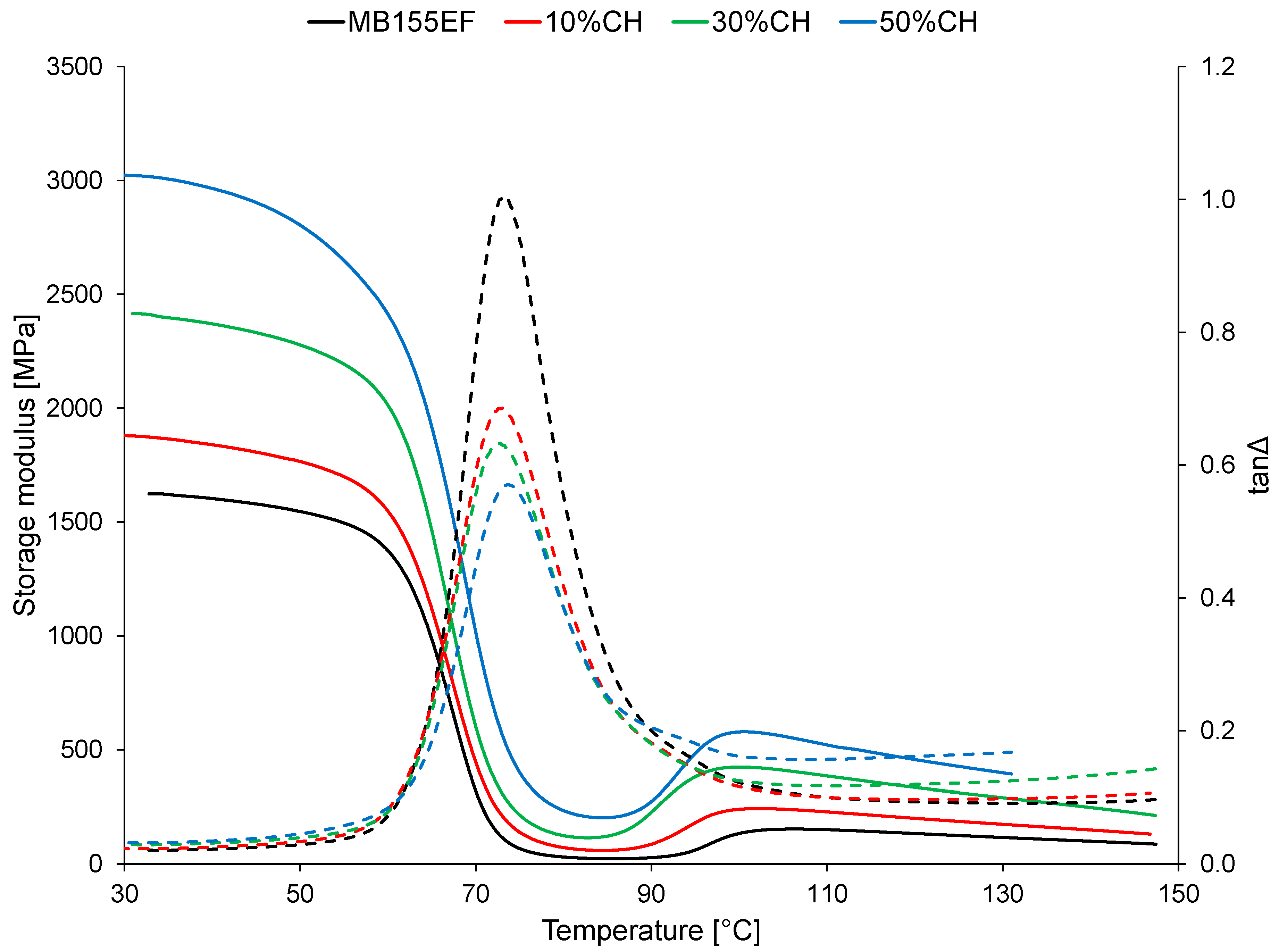

2.2.2. Dynamic Mechanical Analysis (DMA)

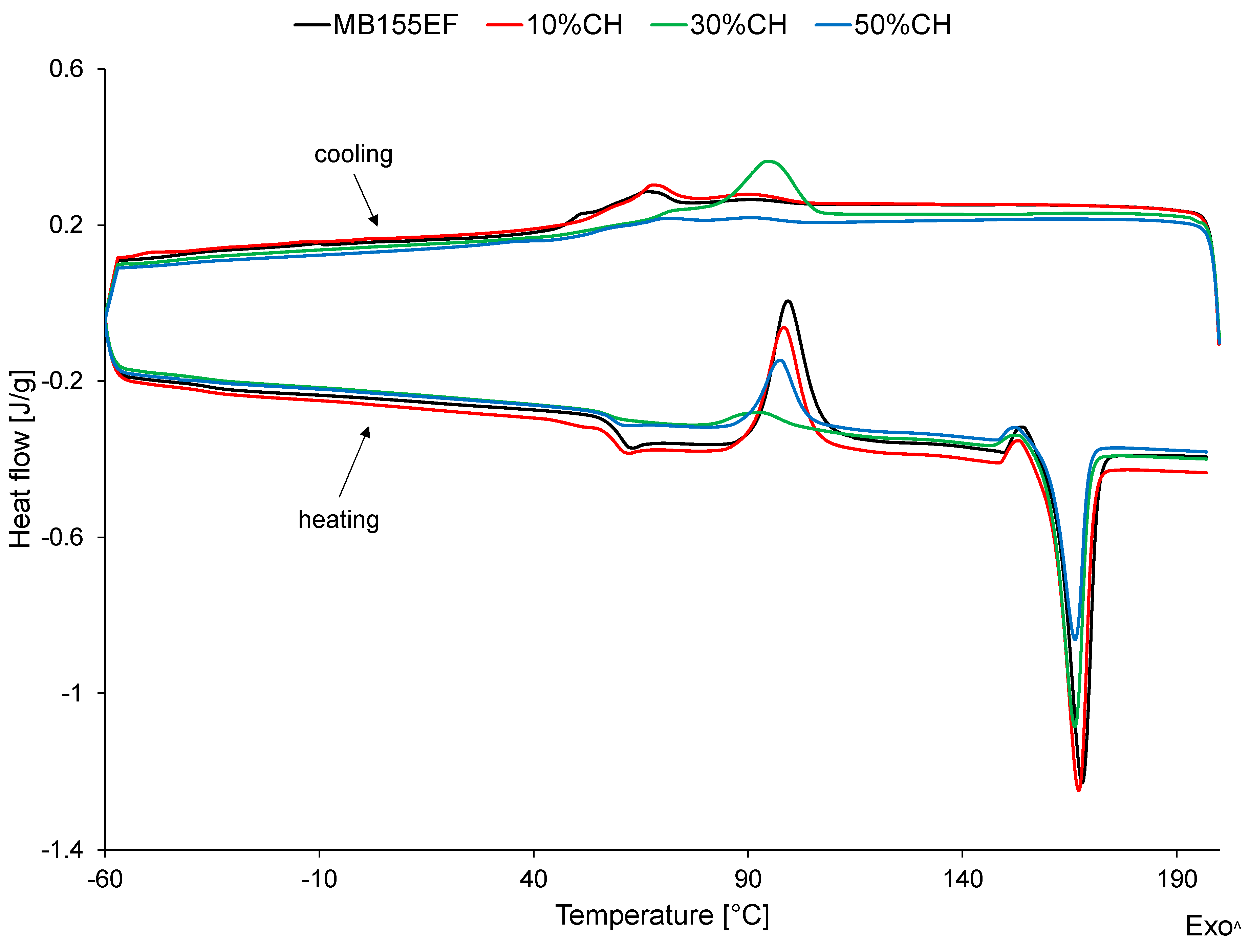

2.2.3. Differential Scanning Calorimetry (DSC)

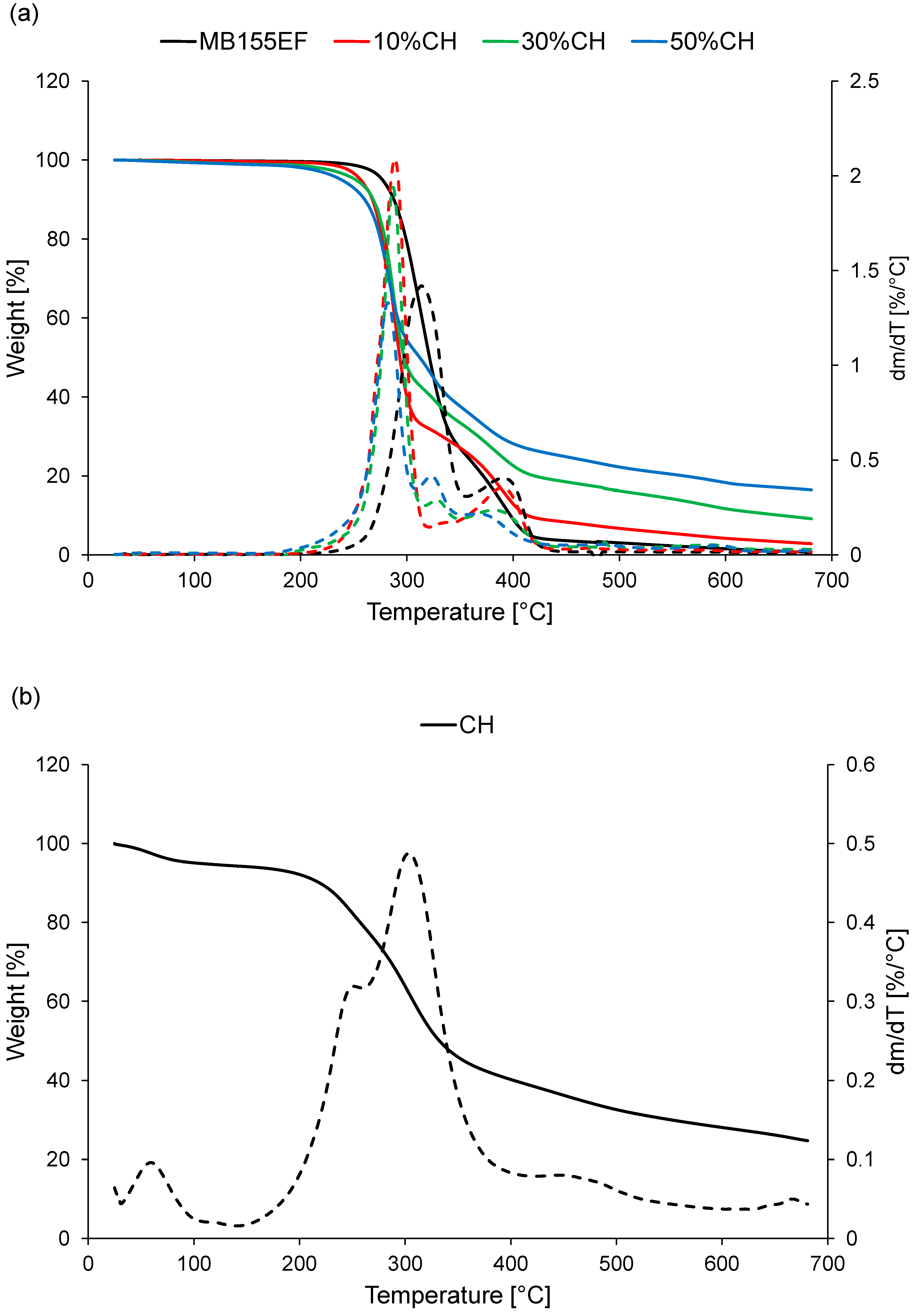

2.2.4. Thermogravimetric Analysis (TGA)

2.2.5. Water Absorption and Thickness Swelling

2.2.6. Mechanical Testing

2.2.7. Statistical Analysis

3. Results and Discussion

3.1. SEM Analysis of Material Structure

3.2. Thermomechanical Properties

3.3. Thermal Properties

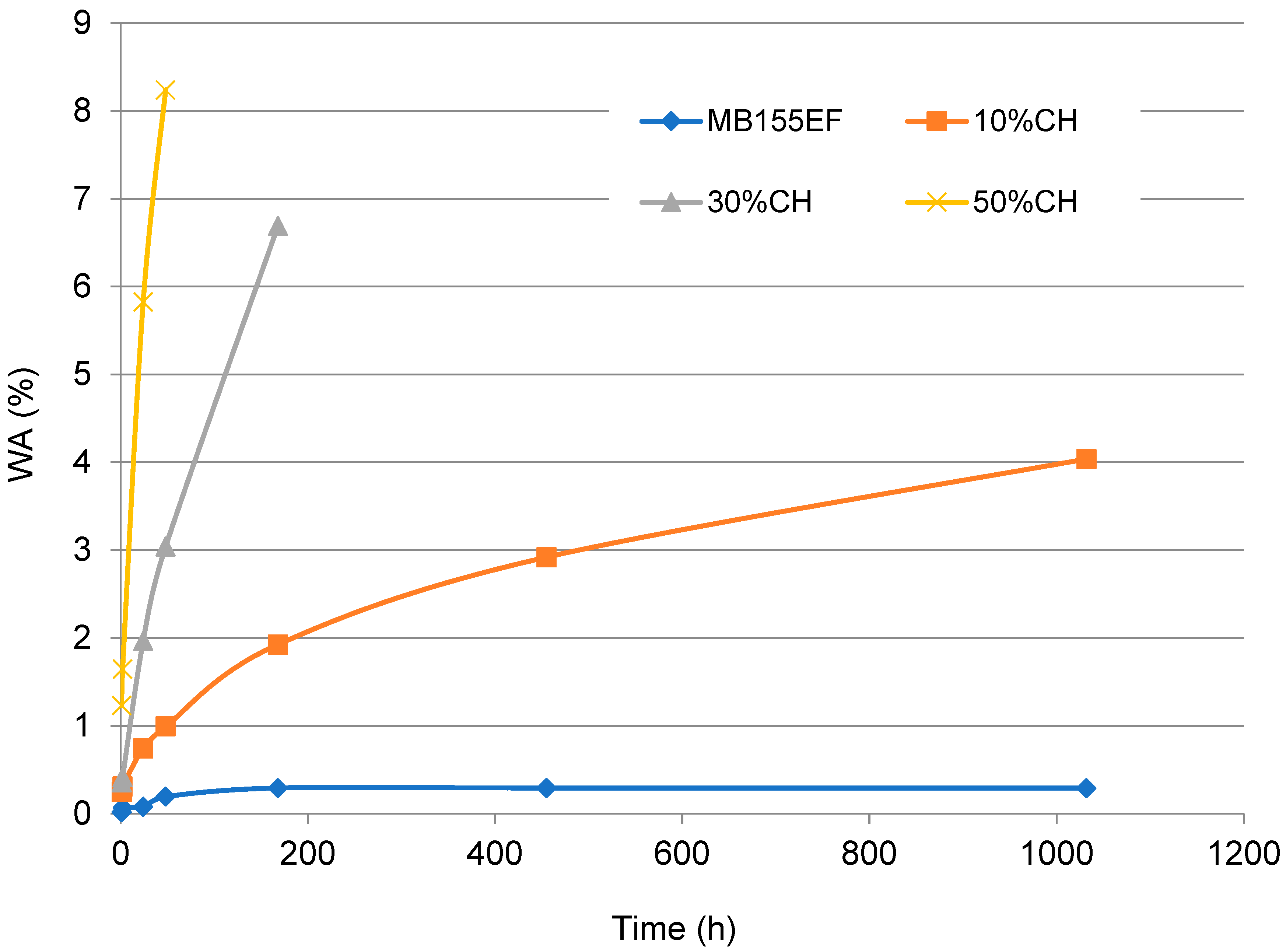

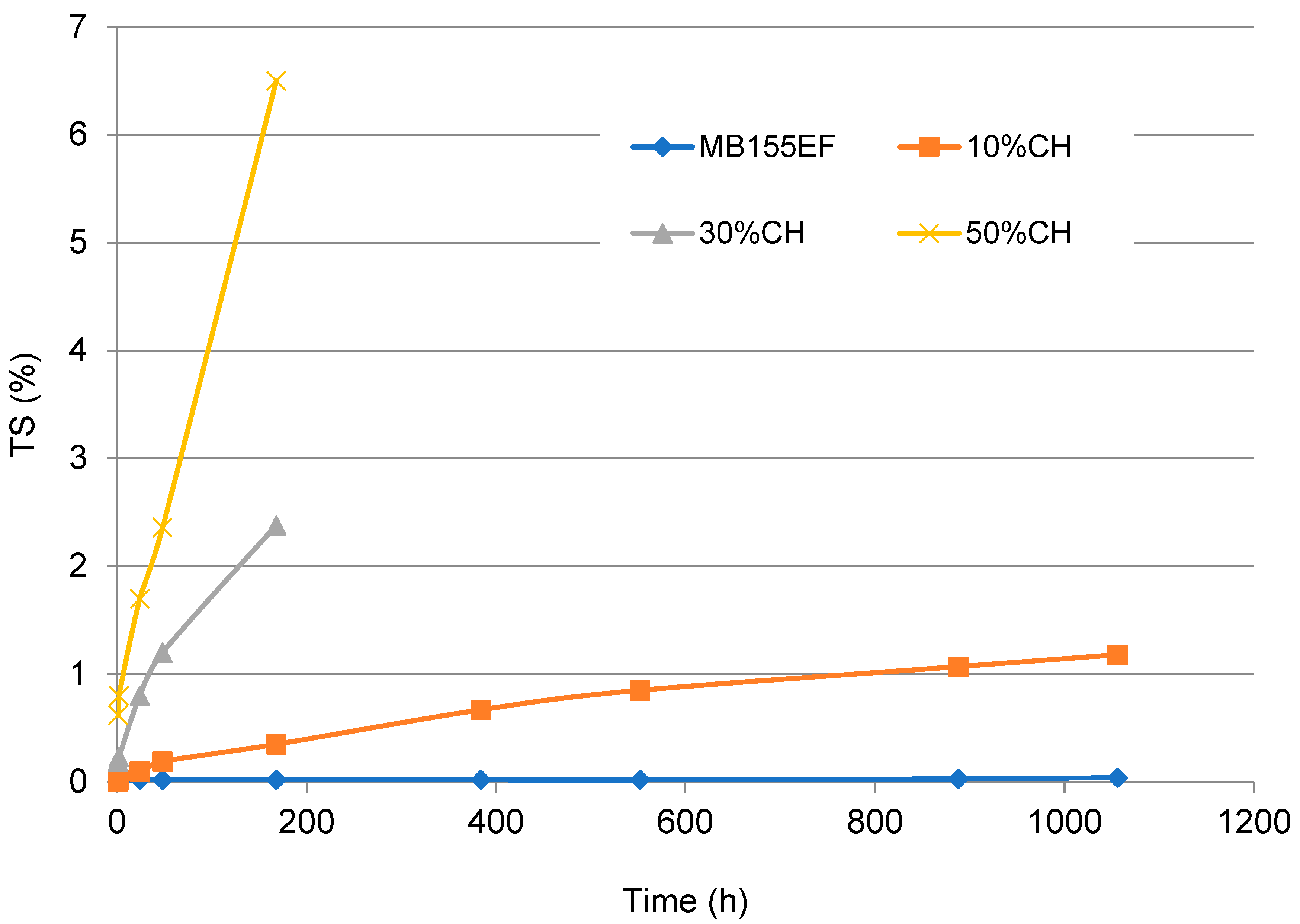

3.4. WA and TS

3.5. Mechanical Properties

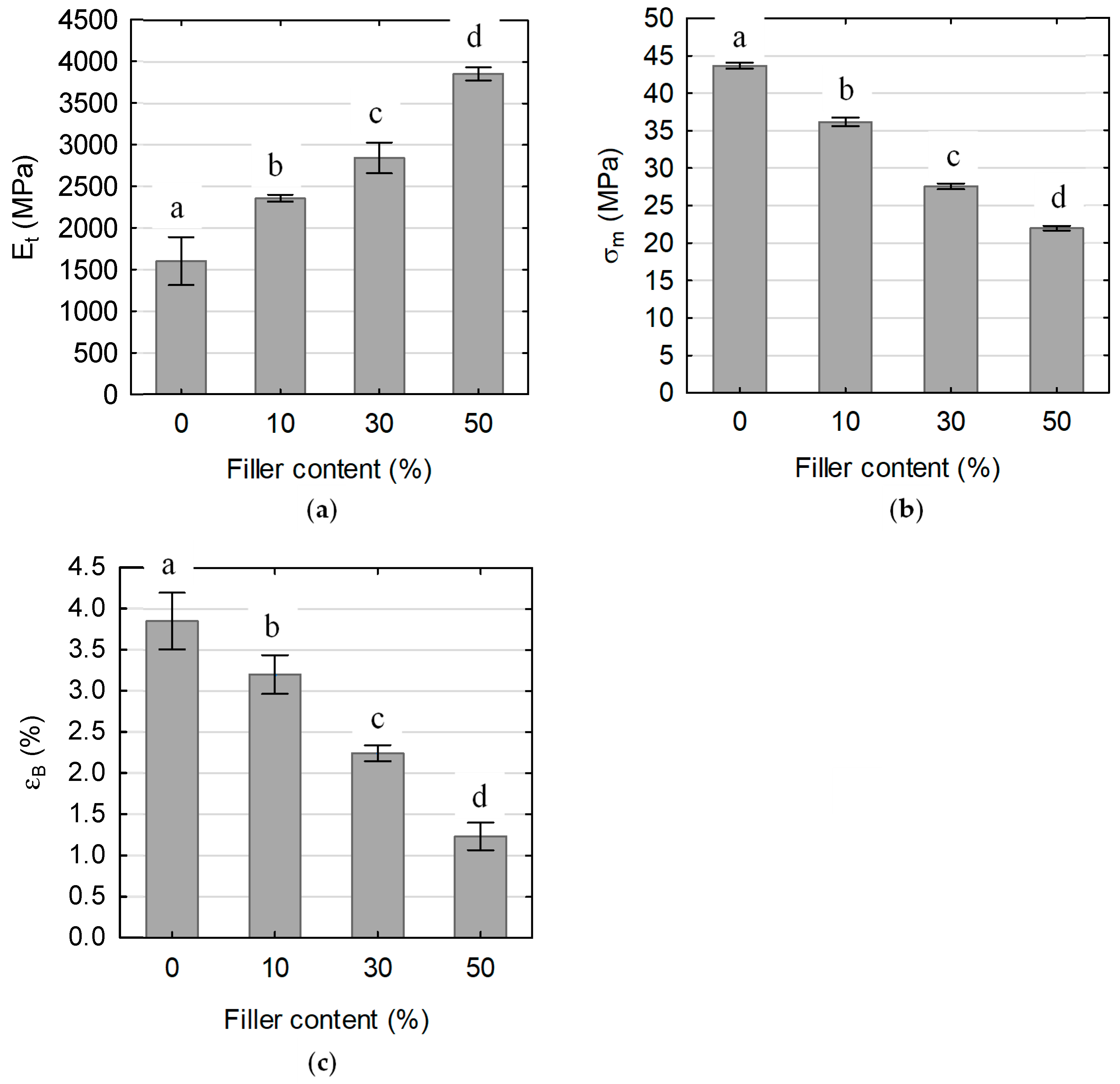

3.5.1. Tensile Properties

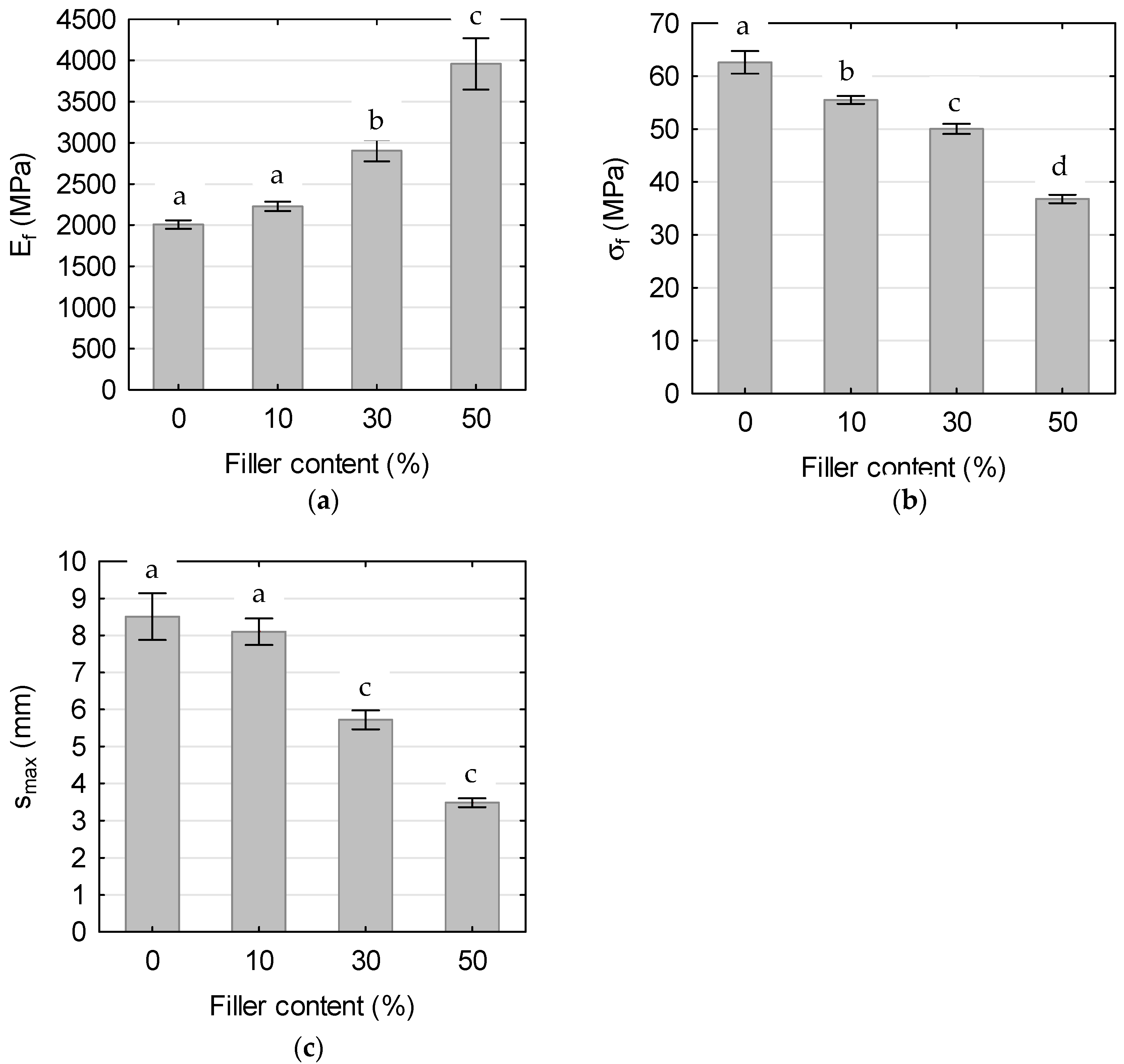

3.5.2. Bending Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Gozdecki, C.; Moraczewski, K.; Kociszewski, M. Thermal and mechanical properties of biocomposites based on polylactide and tall wheatgrass. Materials 2023, 16, 6923. [Google Scholar] [CrossRef] [PubMed]

- Bakas, I.; Fernández, R.; Reichel, A.; Trier, X.; Zeiger, B.; European Environment Agency. Plastics, the Circular Economy and Europe’s Environment: A Priority for Action; European Environment Agency: Copenhagen, Denmark, 2021. [Google Scholar]

- Landrigan, P.J.; Raps, H.; Symeonides, C.; Chiles, T.; Cropper, M.; Enck, J.; Hahn, M.E.; Hixson, R.; Kumar, P.; Mustapha, A.; et al. Announcing the Minderoo–Monaco Commission on plastics and human health. Ann. Glob. Health 2022, 88, 73–74. [Google Scholar] [CrossRef]

- Borghesi, D.C.; Molina, M.F.; Guerra, M.A.; Campos, M.G.N. Biodegradation study of a novel poly-caprolactone–coffee husk composite film. Mater. Res. 2016, 19, 752–758. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Challenges and new opportunities on barrier performance of biodegradable polymers for sustainable packaging. Prog. Polym. Sci. 2021, 117, 101395. [Google Scholar] [CrossRef]

- Kolybaba, M.; Tabil, L.G.; Panigrahi, S.; Crerar, W.J.; Powell, T.; Wang, B. Biodegradable Polymers: Past, Present, and Future; ASABE: St. Joseph, MI, USA, 2006; pp. 1–15. [Google Scholar]

- Tokiwa, Y.; Calabia, B.P.; Ugwu, C.U.; Aiba, S. Biodegradability of plastics. Int. J. Mol. Sci. 2021, 22, 1215. [Google Scholar] [CrossRef]

- RameshKumar, S.; Shaiju, P.; O’Connor, K.E. Bio-based and biodegradable polymers -State-of-the-art, challenges, and emerging trends. Curr. Opin. Green Sustain. Chem. 2020, 21, 75–81. [Google Scholar] [CrossRef]

- Kelaniyagama, S.H.; Gannoruwa, A.; Nilmini, A.H.L. Synthesize and applications of biodegradable plastics as a solution for environmental pollution due to non-biodegradable plastics—A review. Sustain. Polym. Energy 2024, 2, 10011. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Reihmane, S.; Gassan, J. Properties and modification methods for vegetable fibers for natural fiber composites. J. Appl. Polym. Sci. 1996, 59, 1329–1336. [Google Scholar] [CrossRef]

- Zimniewska, M.; Wladyka-Przybylak, M. Natural fibers for composite applications. In Fibrous and Textile Materials for Composite Applications; Woodhead Publishing: Cambridge, UK, 2016; pp. 171–204. [Google Scholar]

- Fenklie, E.G.; Singh, B.; Beri, H.; Gelaw, M. Performance analysis of coffee husk with nano-SiO₂ particles reinforced unsaturated polyester composites. AIP Conf. Proc. 2022, 2393, 1–6. [Google Scholar]

- Jurgilevich, A.; Birge, T.; Kentala-Lehtonen, J.; Korhonen-Kurki, K.; Pietikäinen, J.; Saikku, L.; Schösler, H. Transition towards circular economy in the food system. Sustainability 2016, 8, 69. [Google Scholar] [CrossRef]

- Guillard, V.; Gaucel, S.; Fornaciari, C.; Angellier-Coussy, H.; Buche, P.; Gontard, N. The next generation of sustainable food packaging to preserve our environment in a circular economy context. Front. Nutr. 2018, 5, 121. [Google Scholar] [CrossRef] [PubMed]

- Noyon, M.A.R.; Uddin, M.E.; Dey, T.K.; Jamal, M.; Sivanantham, G.; Islam, R. Biodegradable composite from discarded hair keratin and graphene oxide with improved mechanical, thermal and barrier properties: An eco-friendly solution to waste materials. Polym. Int. 2024, 73, 230–237. [Google Scholar] [CrossRef]

- Tabassum, Z.; Girdhar, M.; Anand, A.; Kumari, N.; Sood, B.; Malik, T.; Kumar, A.; Mohan, A. Trash to treasure: Advancing resource efficiency using waste-derived fillers as sustainable reinforcing agents in bioplastics. Mater. Adv. 2025, 6, 527–546. [Google Scholar] [CrossRef]

- Rizg, W.Y.; Alahmadi, A.A.; Baradwan, M.; Bairwan, R.D.; Mohamed, A.K.; El Saadany, S.; Abdullah, C.; Khalil, H.A. Lignin and biodegradable polymer blends with chemically treated biofiller for green thermoplastic composites. Express Polym. Lett. 2025, 19, 254–267. [Google Scholar] [CrossRef]

- Ramesh, M.J.P.I.M.S. Flax (Linum usitatissimum L.) fibre reinforced polymer composite materials: A review on preparation, properties and prospects. Prog. Mater. Sci. 2019, 102, 109–166. [Google Scholar] [CrossRef]

- Agüero, Á.; Lascano, D.; Garcia-Sanoguera, D.; Fenollar, O.; Torres-Giner, S. Valorization of linen processing by-products for the development of injection-molded green composite pieces of polylactide with improved performance. Sustainability 2020, 12, 652. [Google Scholar] [CrossRef]

- Melendez-Rodriguez, B.; Torres-Giner, S.; Aldureid, A.; Cabedo, L.; Lagaron, J.M. Reactive melt mixing of poly(3-hydroxybutyrate)/rice husk flour composites with purified biosustainably produced poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Materials 2019, 12, 2152. [Google Scholar] [CrossRef]

- Jothibasu, S.; Mohanamurugan, S.; Vijay, R.; Lenin Singaravelu, D.; Vinod, A.; Sanjay, M.R. Investigation on the mechanical behavior of areca sheath fibers/jute fibers/glass fabrics reinforced hybrid composite for lightweight applications. J. Ind. Text. 2020, 49, 1036–1060. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Garcia-Garcia, D.; Carbonell-Verdu, A.; Balart, R.; Torres-Giner, S. Effect of different compatibilizers on injection-molded green composite pieces based on polylactide filled with almond shell flour. Compos. Part B Eng. 2018, 147, 76–85. [Google Scholar] [CrossRef]

- Kumaran, P.; Mohanamurugan, S.; Madhu, S.; Vijay, R.; Lenin Singaravelu, D.; Vinod, A.; Sanjay; Siengchin, S. Investigation on thermo-mechanical characteristics of treated/untreated Portunus sanguinolentus shell powder-based jute fabrics reinforced epoxy composites. J. Ind. Text. 2020, 50, 427–459. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Lagaron, J.M.; Balart, R.; Torres-Giner, S. On the use of acrylated epoxidized soybean oil as a reactive compatibilizer in injection-molded compostable pieces consisting of polylactide filled with orange peel flour. Polym. Int. 2018, 67, 1341–1351. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Hilliou, L.; Melendez-Rodriguez, B.; Figueroa-Lopez, K.J.; Madalena, D.; Cabedo, L.; Covas, J.A.; Vicente, A.A.; Lagaron, J.M. Melt processability, characterization, and antibacterial activity of compression-molded green composite sheets made of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) reinforced with coconut fibers impregnated with oregano essential oil. Food Packag. Shelf Life 2018, 17, 39–49. [Google Scholar] [CrossRef]

- Chaitanya, S.; Singh, I. Processing of PLA/sisal fiber biocomposites using direct- and extrusion-injection molding. Mater. Manuf. Process. 2017, 32, 468–474. [Google Scholar] [CrossRef]

- Ortiz-Barajas, D.L.; Arévalo-Prada, J.A.; Fenollar, O.; Rueda-Ordóñez, Y.J.; Torres-Giner, S. Torrefaction of coffee husk flour for the development of injection-molded green composite pieces of polylactide with high sustainability. Appl. Sci. 2020, 10, 6468. [Google Scholar] [CrossRef]

- Reshmy, R.; Philip, E.; Vaisakh, P.H.; Sindhu, R.; Binod, P.; Madhavan, A.; Pandey, A.; Sirohi, R.; Tarafdar, A. Biodegradable polymer composites. In Biomass, Biofuels, Biochemicals; Elsevier: Amsterdam, The Netherlands, 2021; pp. 393–412. [Google Scholar]

- Ramesh, M.; Deepa, C.; Kumar, L.R.; Sanjay, M.R.; Siengchin, S. Life-cycle and environmental impact assessments on processing of plant fibres and its bio-composites: A critical review. J. Ind. Text. 2022, 51 (Suppl. 4), 5518S–5542S. [Google Scholar] [CrossRef]

- Panhuysen, S.; De Vries, F. Coffee Barometer 2023. Available online: https://www.coffeebarometer.org/ (accessed on 18 February 2025).

- Pandey, A.; Soccol, C.R.; Nigam, P.; Brand, D.; Mohan, R.; Roussos, S. Biotechnological potential of coffee pulp and coffee husk for bioprocesses. Biochem. Eng. J. 2000, 6, 153–162. [Google Scholar] [CrossRef]

- Gonçalves, M.; Guerreiro, M.C.; Oliveira, L.C.; Solar, C.; Nazarro, M.; Sapag, K. Micro mesoporous activated carbon from coffee husk as biomass waste for environmental applications. Waste Biomass Valorization 2013, 4, 395–400. [Google Scholar] [CrossRef]

- Acchar, W.; Dultra, E.J.V.; Segadães, A.M. Untreated coffee husk ashes used as flux in ceramic tiles. Appl. Clay Sci. 2013, 75, 141. [Google Scholar] [CrossRef]

- Getachew, T.; Hussen, A.; Rao, V.M. Defluoridation of water by activated carbon prepared from banana (Musa paradisiaca) peel and coffee (Coffea arabica) husk. Int. J. Environ. Sci. Technol. 2015, 12, 1857–1866. [Google Scholar] [CrossRef]

- Hejna, A. Potential applications of by-products from the coffee industry in polymer technology—Current state and perspectives. Waste Manag. 2021, 121, 296–330. [Google Scholar] [CrossRef]

- Oliveira, G.; Passos, C.P.; Ferreira, P.; Coimbra, M.A.; Gonçalves, I. Coffee by-products and their suitability for developing active food packaging materials. Foods 2021, 10, 683. [Google Scholar] [CrossRef]

- Ilangovan, M.; Guna, V.; Hu, C.; Takemura, A.; Leman, Z.; Reddy, N. Dehulled coffee husk-based biocomposites for green building materials. J. Thermoplast. Compos. Mater. 2021, 34, 1623–1638. [Google Scholar] [CrossRef]

- Melyna, E.; Afridana, A.P. The effect of coffee husk waste addition with alkalisation treatment on the mechanical properties of polypropylene composites. Equilib. J. Chem. Eng. 2023, 7, 14–22. [Google Scholar] [CrossRef]

- Essabir, H.; Raji, M.; Laaziz, S.A.; Rodrique, D.; Bouhfid, R. Thermo-mechanical performances of polypropylene biocomposites based on untreated, treated, and compatibilized spent coffee grounds. Compos. Part B Eng. 2018, 149, 1–11. [Google Scholar] [CrossRef]

- Huang, L.; Mu, B.; Yi, X.; Li, S.; Wang, Q. Sustainable use of coffee husks for reinforcing polyethylene composites. J. Polym. Environ. 2018, 26, 48–58. [Google Scholar] [CrossRef]

- Jaramillo, L.Y.; Vásquez-Rendón, M.; Upegui, S.; Posada, J.C.; Romero-Sáez, M. Polyethylene–coffee husk eco-composites for production of value-added consumer products. Sustain. Environ. Res. 2021, 31, 34. [Google Scholar] [CrossRef]

- Wang, Z.; Dadi Bekele, L.; Qiu, Y.; Dai, Y.; Zhu, S.; Sarsaiya, S.; Chen, J. Preparation and characterization of coffee hull fiber for reinforcing application in thermoplastic composites. Bioengineered 2019, 10, 397–408. [Google Scholar] [CrossRef]

- Hidalgo-Salazar, M.Á.; Correa-Aguirre, J.P.; Montalvo-Navarrete, J.M.; Lopez-Rodriguez, D.F.; Rojas-González, A.F. Recycled polypropylene–coffee husk and coir coconut biocomposites: Morphological, mechanical, thermal and environmental studies. In Thermosoftening Plastics; IntechOpen: Rijeka, Croatia, 2018. [Google Scholar]

- Pattanayak, A.K. Coffee fibres from coffee waste. In Sustainable Fibres for Fashion and Textile Manufacturing; Woodhead Publishing: Cambridge, UK, 2023; pp. 287–307. [Google Scholar]

- Schutz, G.F.; Alves, R.M.V.; Vieira, R.P. Development of starch-based films reinforced with coffee husks for packaging applications. J. Polym. Environ. 2023, 31, 1955–1966. [Google Scholar] [CrossRef]

- Collazo-Bigliardi, S.; Ortega-Toro, R.; Chiralt, A. Using lignocellulosic fractions of coffee husk to improve properties of compatibilised starch–PLA blend films. Food Packag. Shelf Life 2019, 22, 100423. [Google Scholar] [CrossRef]

- Masssijaya, S.Y.; Lubis, M.A.R.; Nissa, R.C.; Nurhamiyah, Y.; Nugroho, P.; Antov, P.; Lee, S.-H.; Papadopoulos, A.N.; Kusumah, S.S.; Karlinasari, L. Utilization of spent coffee grounds as a sustainable resource for the synthesis of bioplastic composites with polylactic acid, starch, and sucrose. J. Compos. Sci. 2023, 7, 512. [Google Scholar] [CrossRef]

- Ibrahim, M.I.J.; Sapuan, S.M.; Zainudin, E.S.; Zuhri, M.Y.M. Potential of using multiscale corn husk fiber as reinforcing filler in cornstarch-based biocomposites. Int. J. Biol. Macromol. 2019, 139, 596–604. [Google Scholar] [CrossRef]

- Rusdianto, A.S.; Usman, M.; Lindriati, T.; Ruriani, E.; Mahardika, N.S. The characterization of biodegradable plastics from cassava starch with varied addition of robusta coffee skin (Coffea canephora) and glycerol. Int. J. Food Agric. Nat. Resour. 2022, 3, 34–38. [Google Scholar]

- Schutz, G.F.; Alves, R.M.V.; Delarmelina, C.; Duarte, M.C.T.; Vieira, R.P. Limonene and its derived oligomer as bioactive additives in starch/coffee husks biocomposites for food packaging applications. Int. J. Biol. Macromol. 2024, 260, 129482. [Google Scholar] [CrossRef]

- Diaz, C.A.; Shah, R.K.; Evans, T.; Trabold, T.A.; Draper, K. Thermoformed containers based on starch and starch/coffee waste biochar composites. Energies 2020, 13, 6034. [Google Scholar] [CrossRef]

- Reis, K.C.; Pereira, L.; Melo, I.C.N.A.; Marconcini, J.M.; Trugilho, P.F.; Tonoli, G.H.D. Particles of coffee wastes as reinforcement in polyhydroxybutyrate (PHB) based composites. Mater. Res. 2015, 18, 546–552. [Google Scholar] [CrossRef]

- Lule, Z.C.; Kim, J. Properties of economical and eco-friendly polybutylene adipate terephthalate composites loaded with surface treated coffee husk. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106154. [Google Scholar] [CrossRef]

- Martinez Villadiego, K.; Arias Tapia, M.J.; Useche, J.; Escobar Macías, D. Thermoplastic starch (TPS)/polylactic acid (PLA) blending methodologies: A review. J. Polym. Environ. 2022, 30, 75–91. [Google Scholar] [CrossRef]

- Rosa, D.; Bardi, M.; Machado, L.; Dias, D.; Silva, L.; Kodama, Y. Starch plasticized with glycerol from biodiesel and polypropylene blends: Mechanical and thermal properties. J. Therm. Anal. Calorim. 2010, 102, 181–186. [Google Scholar] [CrossRef]

- PN EN ISO 527-2; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. International Organization for Standardization: Geneva, Switzerland, 1994.

- ISO 62; Plastics—Determination of Water Absorption. International Organization for Standardization: Geneva, Switzerland, 2008.

- ISO 527-1; Plastics—Determination of Tensile Properties—Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 178; Plastics—Determination of Flexural Properties. International Organization for Standardization: Geneva, Switzerland, 2003.

- Ridho, M.R.; Agustiany, E.A.; Rahmi, M.D. Lignin as green filler in polymer composites: Development methods, characteristics, and potential applications. Adv. Mater. Sci. Eng. 2022, 2022, 1363481. [Google Scholar] [CrossRef]

- Alharbi, M.; Bairwan, R.D.; Rizg, W.Y.; Khalil, H.A.; Murshid, S.S.; Sindi, A.M.; Alissa, M.; Saharudin, N.I.; Abdullah, C.K. Enhancement of spent coffee grounds as biofiller in biodegradable polymer composite for sustainable packaging. Polym. Compos. 2024, 45, 9317–9334. [Google Scholar] [CrossRef]

- Bairwan, R.D.; Khalil, H.P.S.A.; Nuryawan, A.; Ahmad, M.I.; Kassim, M.H.M.; Ahmad, A. Enhancing biopolymer materials with coffee waste-derived reinforcements. Polym. Eng. Sci. 2025, 65, 455–477. [Google Scholar] [CrossRef]

- Manusamy, Y.; Bashir, A.S.M. Recent developments in biocomposites reinforced with natural biofillers from food waste. Polym.-Plast. Technol. Eng. 2015, 54, 1223–1235. [Google Scholar]

| Sample | E′30 [MPa] | E′50 [MPa] | E′90 [MPa] | E′120 [MPa] | tanΔ | TgDMA [°C] |

|---|---|---|---|---|---|---|

| MB155EF | 1624 | 1546 | 27 | 133 | 1.005 | 73.2 |

| 10%CH | 1879 | 1765 | 86 | 200 | 0.6849 | 73.1 |

| 30%CH | 2415 | 2278 | 226 | 335 | 0.6318 | 72.8 |

| 50%CH | 3023 | 2805 | 273 | 457 | 0.5700 | 73.7 |

| Sample | Tg [°C] | Tcc [°C] | ΔHcc [J/g] | Tα’→α [°C] | ΔH α’→α [J/g] | Tm [°C] | ΔHm [J/g] |

|---|---|---|---|---|---|---|---|

| MB155EF | 60.1 | 99.3 | 24.0 | 154.0 | 1.3 | 167.2 | 32.6 |

| 10%CH | 59.3 | 98.4 | 19.9 | 153,2 | 1.5 | 167.1 | 31.5 |

| 30%CH | 58.2 | 93.2 | 4.5 | 153.0 | 1.3 | 166.2 | 25.2 |

| 50%CH | 58.5 | 97.6 | 11.2 | 152.6 | 1.1 | 166.3 | 17.3 |

| Sample | Td [°C] | Tmax1 [°C] | Tmax2 [°C] | Tmax3 [°C] | R [%] |

|---|---|---|---|---|---|

| MB155EF | 277.0 | 313.4 | - | 395.9 | 0.7 |

| 10%CH | 256.5 | 288.6 | 333.8 | 390.8 | 2.9 |

| 30%CH | 251.8 | 287.0 | 329.8 | 387.7 | 9.2 |

| 50%CH | 238.4 | 282.1 | 323.0 | 367.5 | 16.5 |

| CH | 195.4 | 250.5 | 303.2 | 469.8 | 24.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gozdecki, C.; Kociszewski, M.; Moraczewski, K.; Karasiewicz, T.; Łazarska, M.; Stepczyńska, M. Green Composite Based on a Polymer Mixture Containing Biopolymer and Waste Coffee Husks. Polymers 2025, 17, 1748. https://doi.org/10.3390/polym17131748

Gozdecki C, Kociszewski M, Moraczewski K, Karasiewicz T, Łazarska M, Stepczyńska M. Green Composite Based on a Polymer Mixture Containing Biopolymer and Waste Coffee Husks. Polymers. 2025; 17(13):1748. https://doi.org/10.3390/polym17131748

Chicago/Turabian StyleGozdecki, Cezary, Marek Kociszewski, Krzysztof Moraczewski, Tomasz Karasiewicz, Małgorzata Łazarska, and Magdalena Stepczyńska. 2025. "Green Composite Based on a Polymer Mixture Containing Biopolymer and Waste Coffee Husks" Polymers 17, no. 13: 1748. https://doi.org/10.3390/polym17131748

APA StyleGozdecki, C., Kociszewski, M., Moraczewski, K., Karasiewicz, T., Łazarska, M., & Stepczyńska, M. (2025). Green Composite Based on a Polymer Mixture Containing Biopolymer and Waste Coffee Husks. Polymers, 17(13), 1748. https://doi.org/10.3390/polym17131748